Repair of Fire-Damaged Reinforced Concrete Members with Axial Load: A Review

Abstract

:1. Introduction

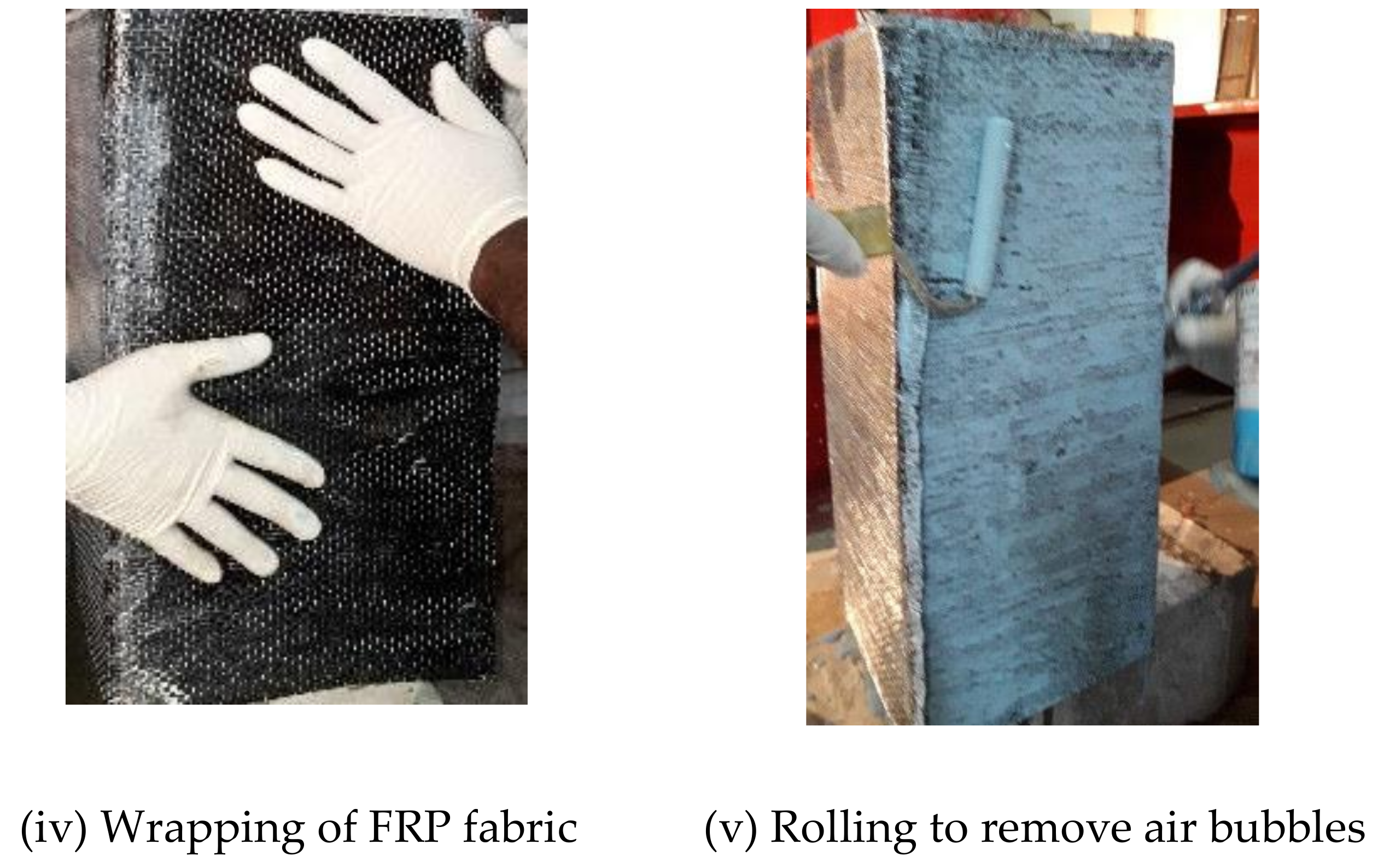

2. Behavior of Reinforced Concrete Compression Members at Elevated Temperature

2.1. Effects of Additional Eccentricity

2.2. Physical Dimension

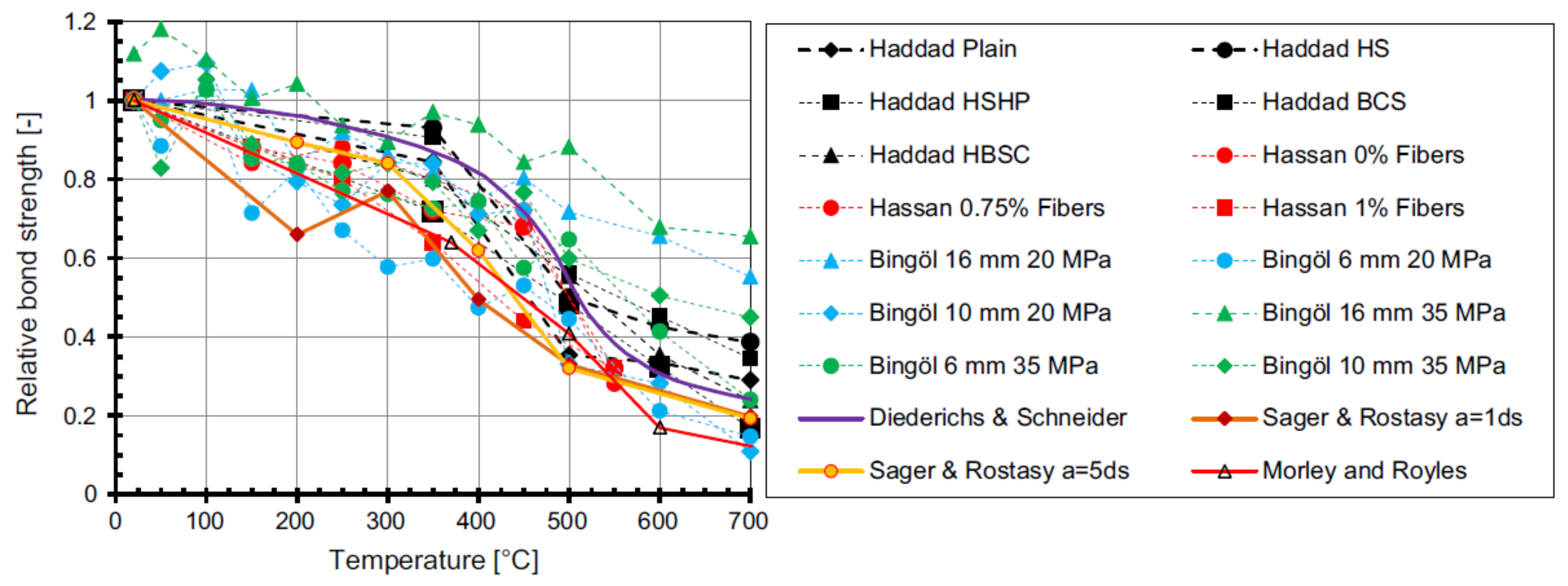

2.3. Bonding Behaviour

3. Repair Methods for Compressed Structural Elements

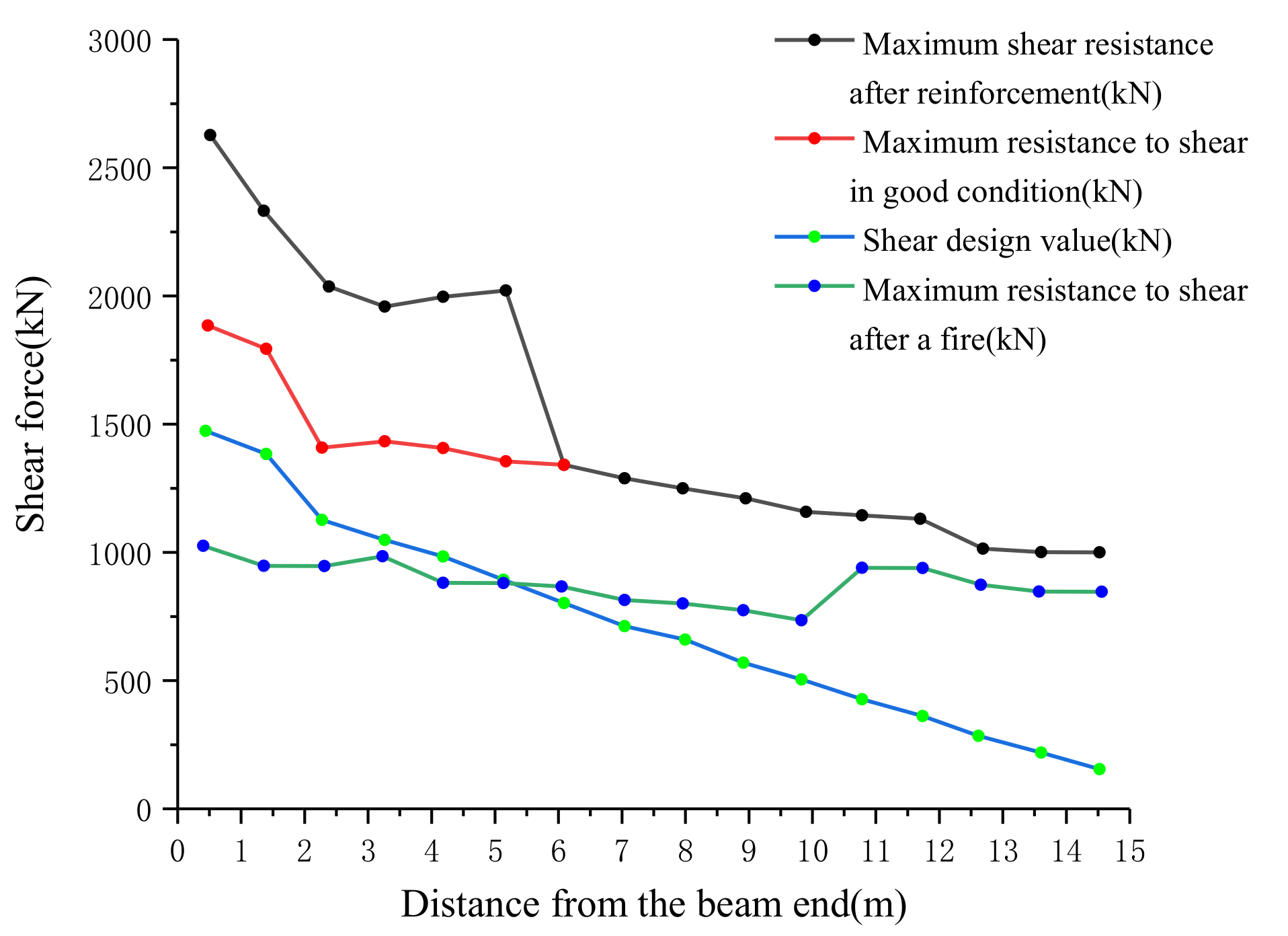

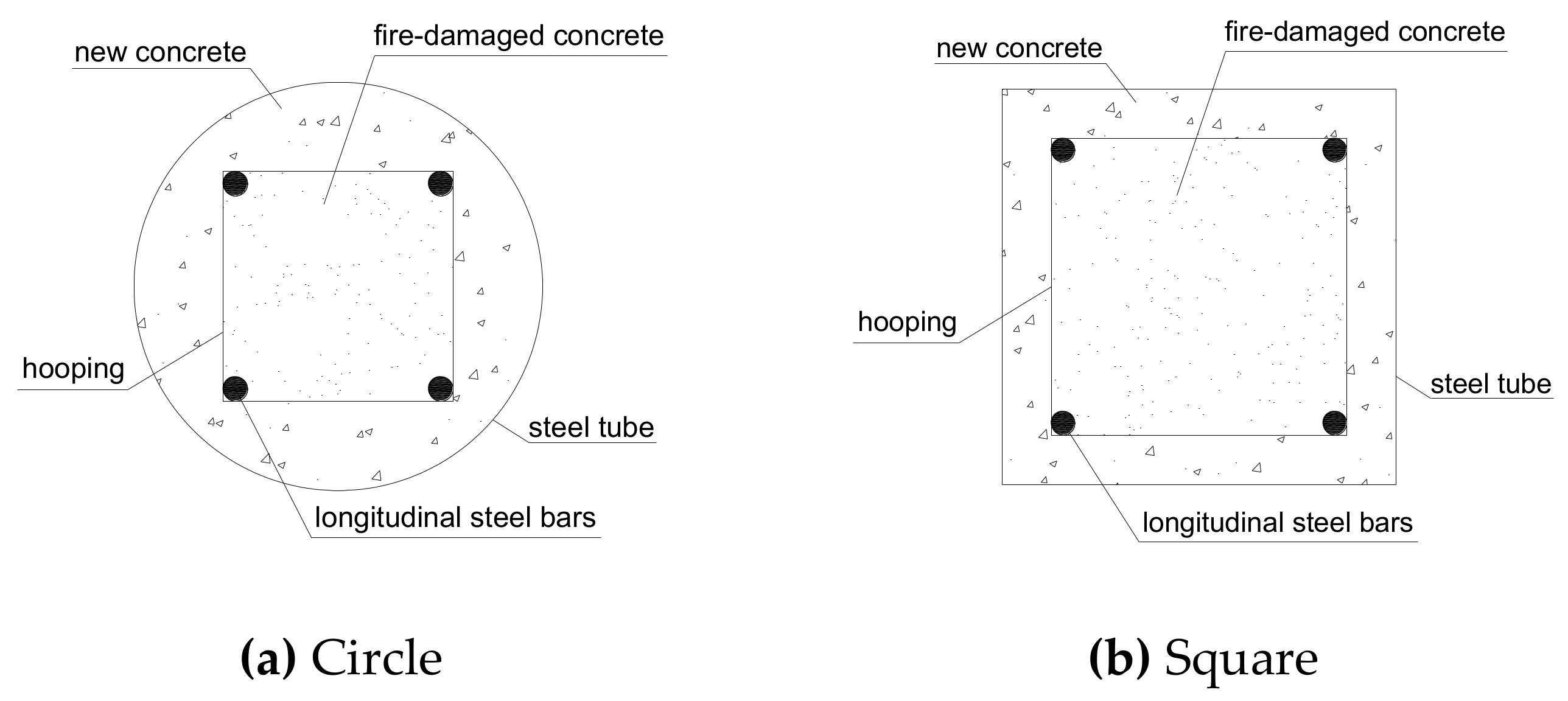

3.1. Section Enlargement Strengthening

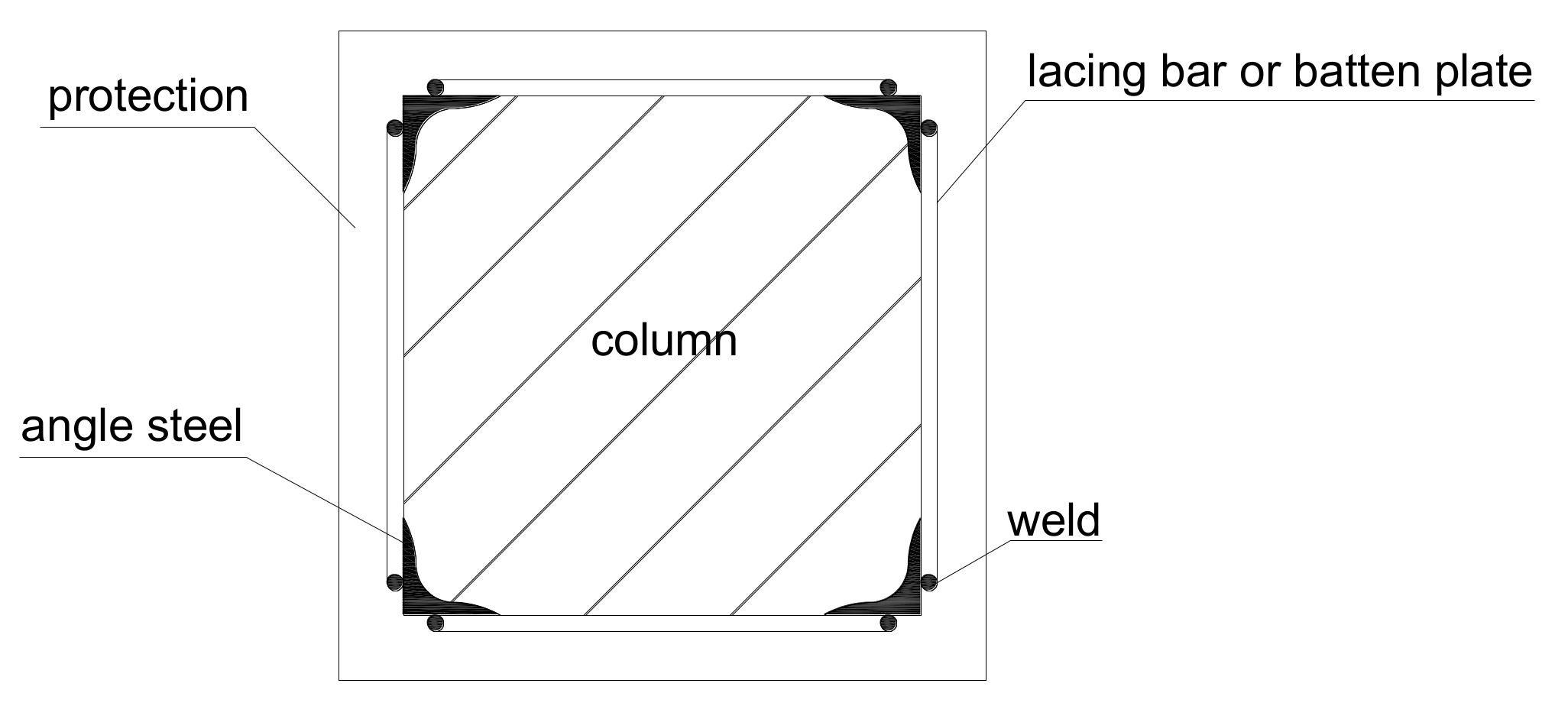

3.2. Steel Wrapping Method

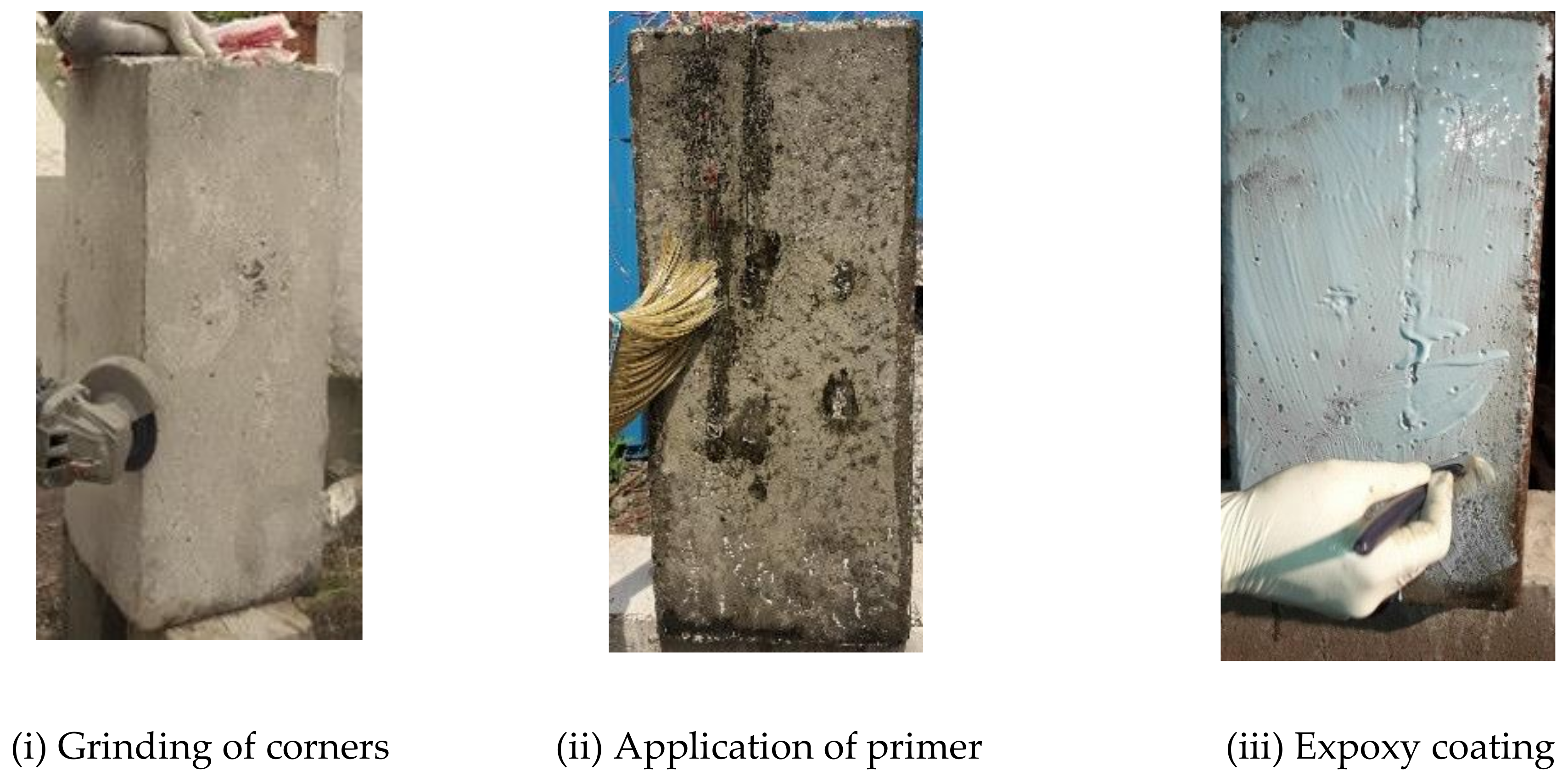

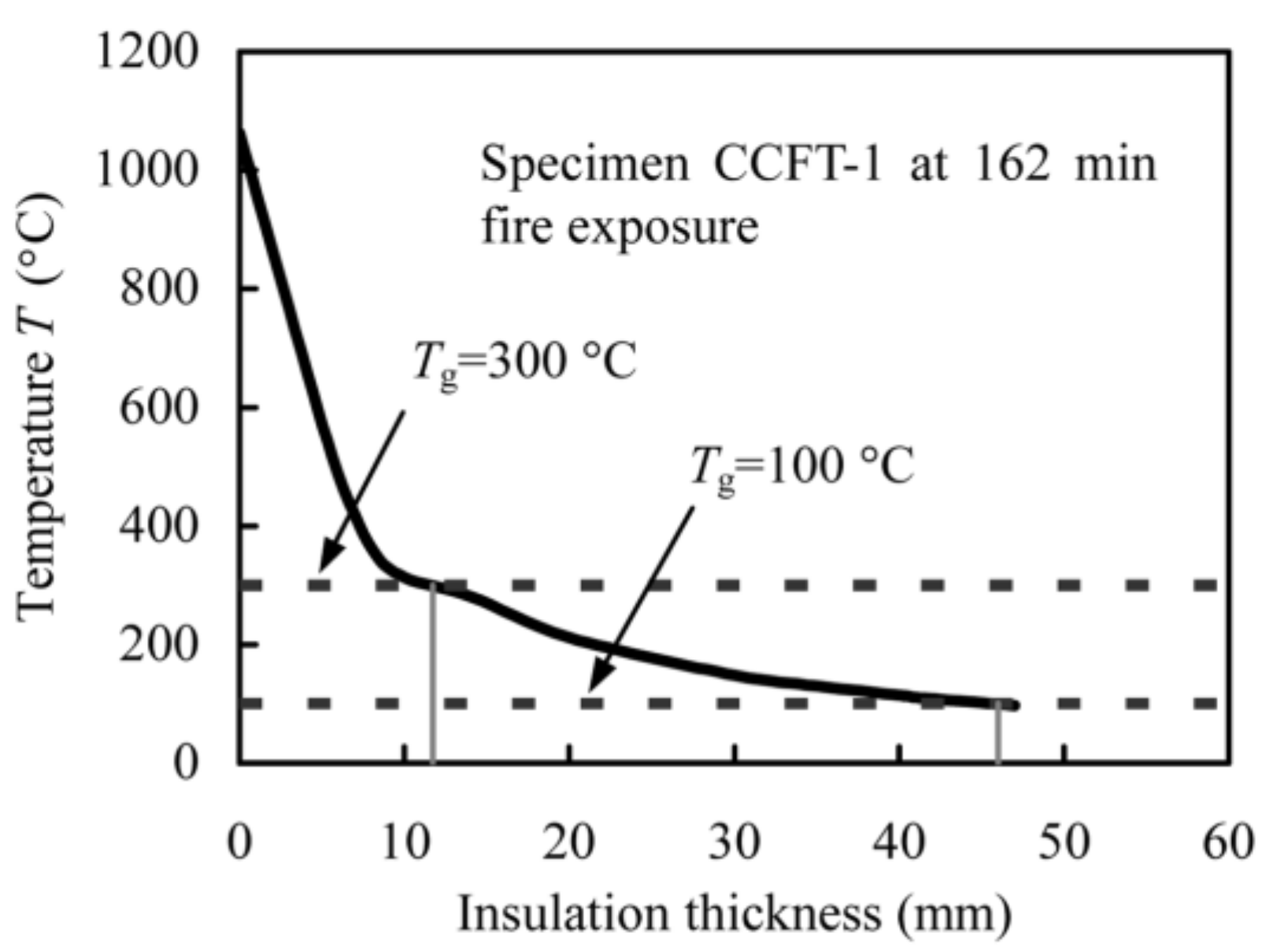

3.3. Externally Bonded Reinforcement Strengthening (EBR)

4. Analytical Modelling of Compressed Members

4.1. Residual Bearing Capacity of Compression Elements

4.2. Steel Wrapping Strengthening

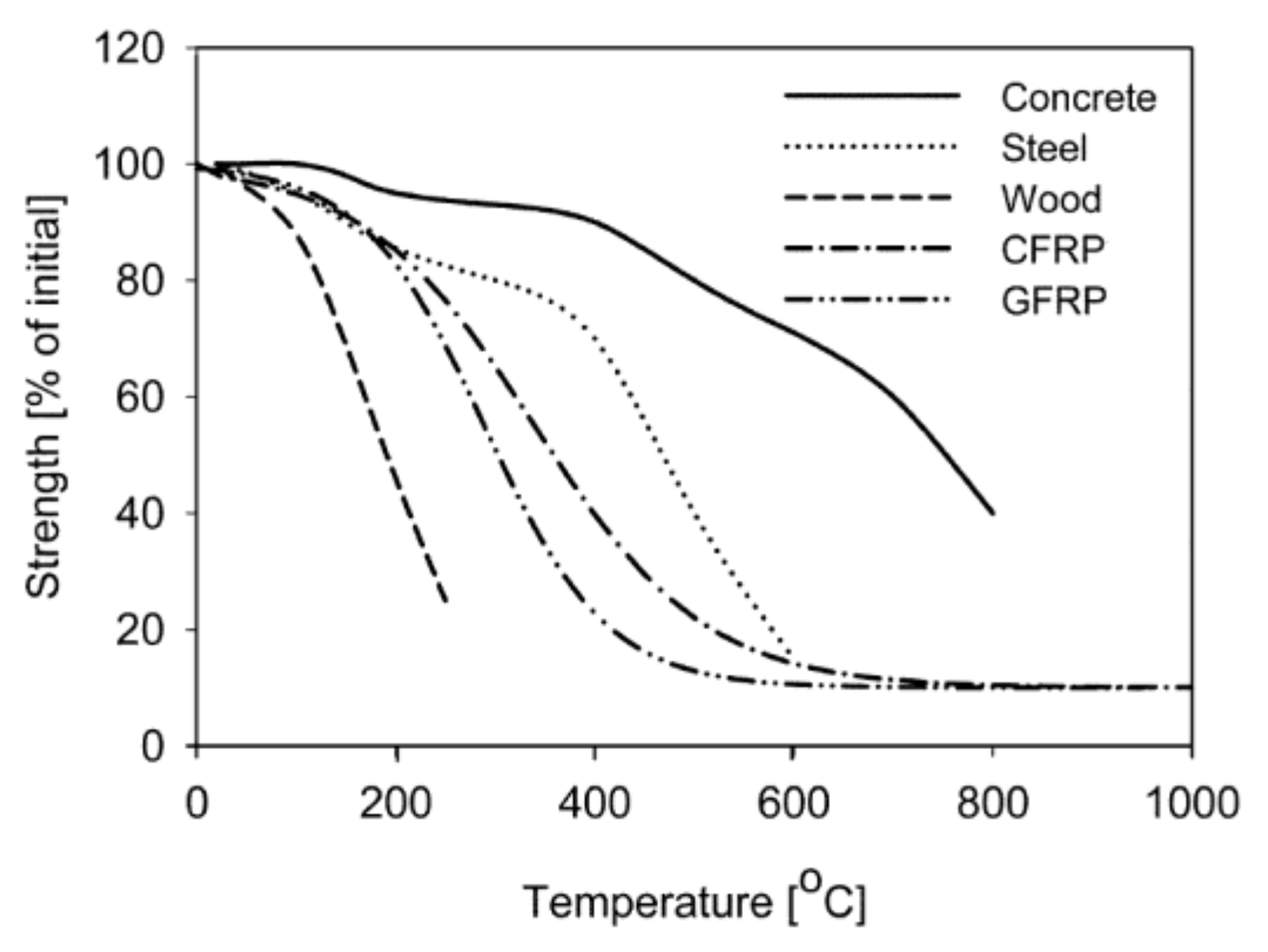

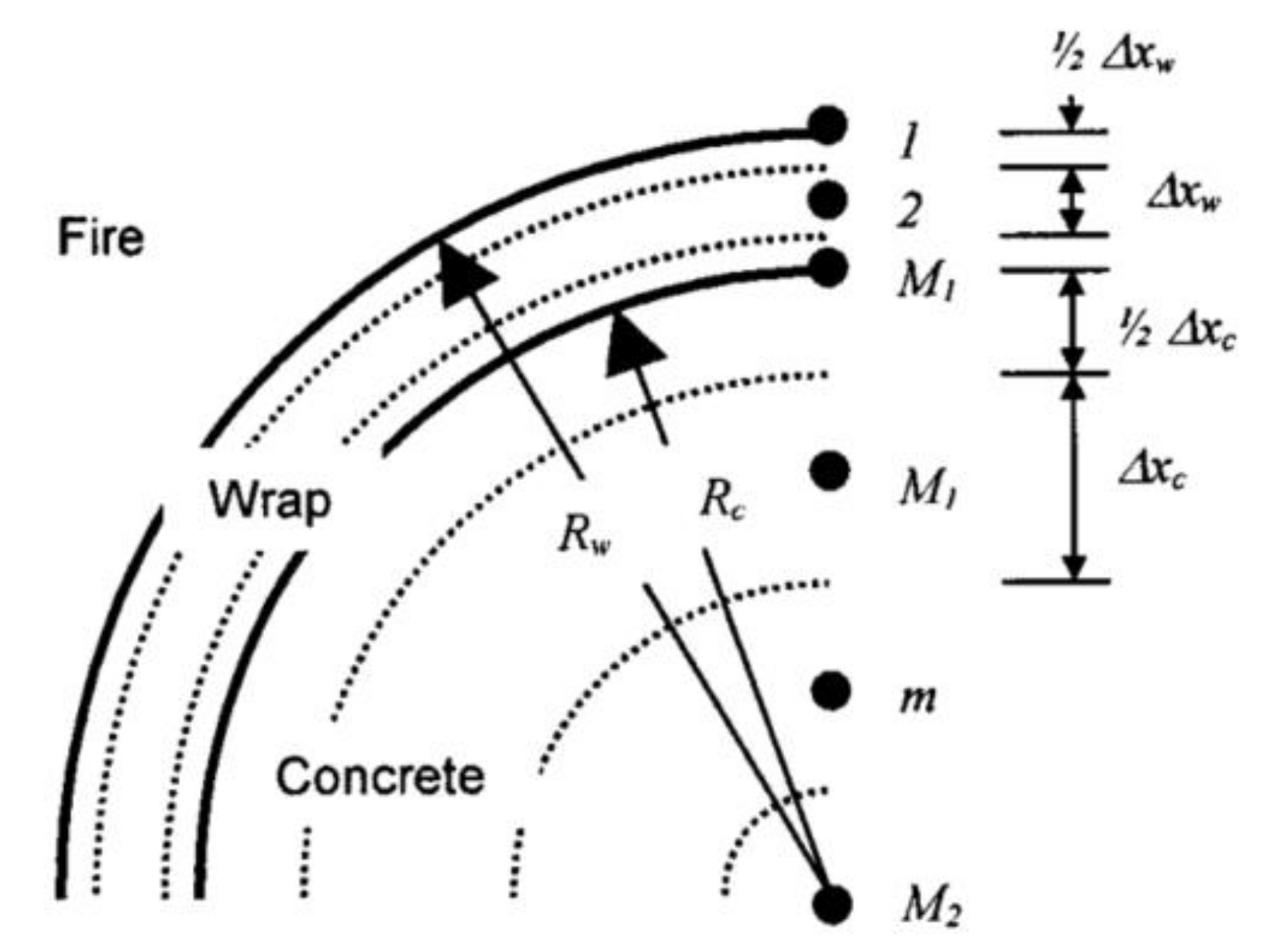

4.3. Fiber Reinforced Polymer (FRP) Strengthening

- is the element temperature at i-1 step;

- is the temperature of the adjacent element at i-1 step;

- is the time internal;

- is the heat capacity of the FRP;

- is the thermal conductivities of the current elements at i-1 step;

- is the thermal conductivities of the adjacent elements at i-1 step.

- is the FRP sheet thickness;

- is the modules of the FRP at the current average wrap temperature;

- is the average diameter of the wrap.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xiao, Y.; Tomii, M.; Sakino, K. Experimental study on design method to prevent shear failure of reinforced concrete short circular columns by confining in steel tube. Trans. Jpn. Concr. Inst. 1986, 8, 535–542. [Google Scholar]

- Priestly, M.J.N.; Seible, F.; Xiao, Y.; Verma, R. Steel jacket retrofitting of reinforced concrete bridge columns for enhanced shear strength-part 1: Theoretical considerations and test design. Aci Struct. J. 1994, 91, 394–405. [Google Scholar]

- Priestley, M.J.N.; Seible, F.; Xiao, Y. Steel jacket retrofitting of reinforced concrete bridge columns for enhanced shear strength-Part 2: Test results and comparison with theory. Aci Struct. J. 1994, 91, 537–551. [Google Scholar]

- Xiao, Y.; Wu, H. Retrofit of reinforced concrete columns using partially stiffened steel jackets. J. Struct. Eng. 2003, 129, 725–732. [Google Scholar] [CrossRef]

- Cirtek, L. RC columns strengthened with bandage-experimental programme and design recommendations. Constr. Build. Mater. 2001, 15, 341–349. [Google Scholar] [CrossRef]

- Cirtek, L. Mathematical model of RC banded column behaviour. Constr. Build. Mater. 2001, 15, 351–359. [Google Scholar] [CrossRef]

- Adam, J.M.; Ivorra, S.; Giménez, E.; Moragues, J.J.; Miguel, P.; Miragall, C.; Calderon, P.A. Behaviour of axially loaded RC columns strengthened by steel angles and strips. Steel Compos. Struct. 2007, 7, 405. [Google Scholar] [CrossRef]

- Adam, J.M.; Giménez, E.; Calderón, P.A.; Pallarés, F.J.; Ivorra, S. Experimental study of beam–column joints in axially loaded RC columns strengthened by steel angles and strips. Steel Compos. Struct. 2008, 8, 329–342. [Google Scholar] [CrossRef]

- Adam, J.M.; Ivorra, S.; Pallarés, F.J.; Jimenez, E.; Calderón, P.A. Column–joint assembly in RC columns strengthened by steel caging. Available online: https://www.icevirtuallibrary.com/doi/10.1680/stbu.2008.161.6.337 (accessed on 1 February 2019).

- Adam, J.M.; Ivorra, S.; Pallarés, F.J.; Giménez, E.; Calderón, P.A. Axially loaded RC columns strengthened by steel caging. Finite element modelling. Constr. Build. Mater. 2009, 23, 2265–2276. [Google Scholar] [CrossRef]

- Adam, J.M.; Ivorra, S.; Pallarés, F.J.; Giménez, E.; Calderón, P.A. Axially loaded RC columns strengthened by steel cages. Proc. ICE-Struct. Build. 2009, 162, 199–208. [Google Scholar] [CrossRef]

- Giménez, E.; Adam, J.M.; Ivorra, S.; Calderón, P.A. Influence of strips configuration on the behaviour of axially loaded RC columns strengthened by steel angles and strips. Mater. Des. 2009, 30, 4103–4111. [Google Scholar] [CrossRef]

- Giménez, E.; Adam, J.M.; Ivorra, S.; Moragues, J.J.; Calderón, P.A. Full-scale testing of axially loaded RC columns strengthened by steel angles and strips. Adv. Struct. Eng. 2009, 12, 169–181. [Google Scholar] [CrossRef]

- Garzón-Roca, J.; Adam, J.M.; Calderón, P.A. Behaviour of RC columns strengthened by steel caging under combined bending and axial loads. Constr. Build. Mater. 2011, 25, 2402–2412. [Google Scholar] [CrossRef]

- Garzón-Roca, J.; Ruiz-Pinilla, J.; Adam, J.M.; Calderón, P.A. An experimental study on steel-caged RC columns subjected to axial force and bending moment. Eng. Struct. 2011, 33, 580–590. [Google Scholar] [CrossRef]

- Yang, K.H.; Ashour, A.F. Tests of reinforced concrete short columns laterally strengthened with wire rope units and steel elements. Mag. Concr. Res. 2007, 59, 547–557. [Google Scholar] [CrossRef]

- Yang, K.H.; Ashour, A.F.; Lee, E.T. Axial behavior of reinforced concrete short columns strengthened with wire rope and T-shaped steel plate units. Mag. Concr. Res. 2009, 61, 143–154. [Google Scholar] [CrossRef]

- Li, J.; Gong, J.; Wang, L. Seismic behavior of corrosion-damaged reinforced concrete columns strengthened using combined carbon fiber-reinforced polymer and steel jacket. Constr. Build. Mater. 2009, 23, 2653–2663. [Google Scholar] [CrossRef]

- Montuori, R.; Piluso, V. Reinforced concrete columns strengthened with angles and battens subjected to eccentric load. Eng. Struct. 2009, 31, 539–550. [Google Scholar] [CrossRef]

- Smith, S.T.; Teng, J.G. FRP-strengthened RC beams. I: Review of debonding strength models. Eng. Struct. 2002, 24, 385–395. [Google Scholar] [CrossRef]

- Tao, Z.; Yu, Q. New Types of Composite Columns Experiments, Theory and Methodology; China Science Press: Beijing, China, 2006; ISBN 7-03-016824-0. [Google Scholar]

- Zhao, X.L.; Zhang, L. State-of-the-art review on FRP strengthened steel structures. Eng. Struct. 2007, 29, 1808–1823. [Google Scholar] [CrossRef]

- Teng, J.G.; Chen, J.F.; Smith, S.T.; Lam, L. Behaviour and strength of FRP-strengthened RC structures: A state-of-the-art review. Available online: https://www.icevirtuallibrary.com/doi/10.1680/stbu.2003.156.1.51 (accessed on 1 February 2019).

- Burke, P.J.; Bisby, L.A.; Green, M.F. Effects of elevated temperature on near surface mounted and externally bonded FRP strengthening systems for concrete. Cem. Concr. Comp. 2013, 35, 190–199. [Google Scholar] [CrossRef]

- Palmieri, A.; Matthys, S.; Taerwe, L. Experimental investigation on fire endurance of insulated concrete beams strengthened with near surface mounted FRP bar reinforcement. Compos. Part B Eng. 2012, 43, 885–895. [Google Scholar] [CrossRef]

- Palmieri, A.; Matthys, S.; Taerwe, L. Fire Endurance and Residual Strength of Insulated Concrete Beams Strengthened with Near-Surface Mounted Reinforcement. J. Compos. Constr. 2013, 17, 454–462. [Google Scholar] [CrossRef]

- Thi, C.N.; Pansuk, W.; Torres, L. Flexural behavior of fire-damaged reinforced concrete slabs repaired with near-surface mounted (NSM) carbon fiber reinforced polymer (CFRP) rods. J. Adv. Concr. Technol. 2015, 13, 15–29. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Baolin, Y. Evaluating the Fire Response of Concrete Beams Strengthened with Near-Surface-Mounted FRP Reinforcement. J. Compos. Constr. 2013, 17, 517–529. [Google Scholar] [CrossRef]

- Rein, G.; Abecassis, E.C.; Carvel, R. (Eds.) The Dalmarnock Fire Tests: Experiments and Modeling; School of Engineering and Electronics, University of Edinburgh: Edinburgh, UK, 2007. [Google Scholar]

- Al-Mahmoud, F.; Castel, A.; Francois, R.; Tourneur, C. RC beams strengthened with NSM CFRP rods and modeling of peeling-off failure. Compos. Struct. 2010, 92, 1920–1930. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Teng, J.G. Near-surface mounted FRP reinforcement: An emerging technique for strengthening structures. Compos Part B Eng. 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Chen, M.T.; Young, B. Material properties and structural behavior of cold-formed steel elliptical hollow section stub columns. Thin-Walled Struct. 2019, 134, 111–126. [Google Scholar] [CrossRef]

- Li, L.Z.; Liu, X.; Yu, J.T.; Lu, Z.D.; Su, M.N.; Liao, J.H.; Xia, M. Experimental study on seismic performance of post-fire reinforced concrete frames. Eng. Struct. 2019, 179, 161–173. [Google Scholar] [CrossRef]

- Lai, M.H.; Hanzic, L.; Ho, J.C.M. Fillers to improve passing ability of concrete. Struct. Concrete 2018. [CrossRef]

- Lai, M.H.; Ho, J.C.M. A theoretical axial stress-strain model for circular concrete-filled-steel-tube columns. Eng. Struct. 2016, 125, 124–43. [Google Scholar] [CrossRef]

- Tan, K.H.; Yao, Y. Fire Resistance of Four-Face Heated Reinforced Concrete Columns. J. Struct. Eng. Asce. 2003, 129, 1220–1229. [Google Scholar] [CrossRef]

- Tan, K.H.; Yao, Y. Fire Resistance of Reinforced Concrete Columns Subjected to 1-, 2-, and 3-Face Heating. J. Struct. Eng. Asce. 2004, 130, 1820–1828. [Google Scholar] [CrossRef]

- Jau, W.C.; Huang, K.L. A study of reinforced concrete corner columns after fire. Cement Concrete Comp. 2008, 30, 622–638. [Google Scholar] [CrossRef]

- Lie, T.T. Fire Resistance of Circular Steel Columns Filled with Bar-reinforced Concrete. J. Struct. Eng. Asce. 1994; 120, 1489–1509. [Google Scholar]

- Lie, T.T.; Irwin, R.J. Fire Resistance of Rectangular Steel Columns Filled with Bar-reinforced Concrete. J. Struct. Eng. Asce. 1995, 121, 797–805. [Google Scholar] [CrossRef]

- Lie, T.T.; Kodur, V.K.R. Fire Resistance of Steel Columns Filled with Bar-reinforced Concrete. J. Struct. Eng. Asce. 1996, 122, 30–36. [Google Scholar] [CrossRef]

- Wu, B.; Hong, Z.; Tang, G.H.; Wang, C. Fire Resistance of Reinforced Concrete Columns with Square Cross Section. Fire Saf. J. 2009, 44, 869–880. [Google Scholar] [CrossRef]

- Rilem, T.C. RILEM Technical Recommendations for the Testing and Use of Constructions Materials, 1st. ed.; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Rehm, G.; Eligehausen, R. Bond of ribbed bars under high cycle repeated loads. J. Am. Concr. Inst. 1979, 76, 297–309. [Google Scholar]

- Vos, E.; Reinhardt, H. Influence of loading rate on bond behaviour of reinforcing steel and prestressing strands. Mater Constr. 1982, 15, 3–10. [Google Scholar] [CrossRef]

- Bosnjak, J.; Sharma, A.; Ottl, C. Modified beam-end test setup to study the bond behavior of reinforcement in concrete after fire. Mart Mater Struct. 2018, 51, 13. [Google Scholar] [CrossRef]

- Bett, B.J.; Klingner, R.E.; Jirsa, J.O. Lateral Load Response of Strengthened and Repaired Reinforced Concrete Columns. Aci. Struct. J. 1988, 499–508. [Google Scholar]

- Deng, X.D.; Wang, L. Application of section enlargement method in fire-damaged bridge reinforcement. J. Mt. 2016, 13, 66–71, In Chinese. [Google Scholar]

- Liu, L.X.; Shi, X.D.; Guo, Z.H. Experimental Investigation of Strengthened Reinforced Concrete Columns After Exposure to High Temperature. Eng. Mech. 2003, 5, 18–23. (In Chinese) [Google Scholar]

- Gholampour, A.; Hassanli, R.; Mills, J.E.; Vincent, T.; Kunieda, M. Experimental investigation of the performance of concrete columns strengthened with fiber reinforced concrete jacket. Constr. Build. Mater. 2019, 194, 51–61. [Google Scholar] [CrossRef]

- Fu, W. Assessment and Reinforcement of Fire-damaged Concrete Structures Based on Fire Temperature and Material Properties. Master’s Thesis, Nanchang University, Nanchang, China, 2015. (In Chinese). [Google Scholar]

- Wang, L.; Su, R.K.L. Repair of Fire-Exposed Preloaded Rectangular Concrete Columns by Postcompressed Steel Plates. J. Struct. Eng. Asce. 2014, 140, 04013083. [Google Scholar] [CrossRef]

- Wang, L.; Su, R.K.L. Theoretical and experimental study of plate-strengthened concrete columns under eccentric compression loading. J. Struct. Eng. 2012, 139, 350–359. [Google Scholar] [CrossRef]

- Su, R.K.L.; Wang, L. Axial strengthening of preloaded rectangular concrete columns by precambered steel plates. Eng. Struct. 2012, 38, 42–52. [Google Scholar] [CrossRef]

- Wang, L.; Su, R.K.L. Experimental investigation of preloaded RC columns strengthened with precambered steel plates under eccentric compression loading. Adv. Struct. Eng. 2012, 15, 1253–1264. [Google Scholar] [CrossRef]

- Su, R.K.L.; Wang, L. Flexural and axial strengthening of preloaded concrete columns under large eccentric loads by flat and precambered steel plates. Struct. Infrastruct. Eng. 2015, 11, 1083–1101. [Google Scholar] [CrossRef]

- Wang, L.; Su, R.K.L. Strengthening of preloaded RC columns by post compressed plates-a review. Struct. Eng. Mech. 2018, 65, 477–490. [Google Scholar]

- Wang, L.; Su, R.K.L.; Cheng, B.; Li, L.Z.; Wan, L.; Shan, Z.W. Seismic behavior of preloaded rectangular RC columns strengthened with precambered steel plates under high axial load ratios. Eng. Struct. 2017, 152, 683–697. [Google Scholar] [CrossRef]

- Sun, J.F. Comparative Experiments of the Behavior of Reinforced Concrete Members Exposed to Different Elevated Temperature Modes. Master’s Thesis, Tsinghua University, Beijing, China, 2001. (In Chinese). [Google Scholar]

- Wu, Q.; Yang, F.Y.; Sun, G.Q.; Liu, W.Q.; Wang, L. Analytical method for determination of temperature-induced interfacial shear stress in foam-core composite sandwich materials. Plast. Rubber Compos. 2018, 47, 232–239. [Google Scholar] [CrossRef]

- Wang, L.; Wu, Z.M.; Liu, W.Q.; Wan, L. Structural behavior of load-bearing sandwich wall panels with GFRP skins and a foam-web core. Sci. Eng. Compos. Mater. 2016, 25, 173–188. [Google Scholar] [CrossRef]

- Zhang, L.F.; Liu, W.Q.; Sun, G.Q.; Wang, L.; Li, L.Z. Two-dimensional Modeling of Thermo-mechanical Responses of Rectangular GFRP Profiles Exposed to Fire. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef]

- Xia, Y.W.; Li, X.P.; Peng, Y.; Lai, M.H.; Wang, L. Impact and Post-Impact Performance of Sandwich Wall Boards with GFRP Face Sheets and a Web-Foam Core: The Effects of Impact Location. Materials 2018, 11. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.K.; Ma, Y.L.; Liu, W.Q.; Liang, R.F.; Wang, L. Mode I interfacial fracture characterization of foam core sandwich materials at elevated temperatures. J. Reinf. Plast. Compos. 2018, 36, 1009–1018. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, K.; Hui, D.; Xu, F.J.; Liu, W.Q.; Yang, S.L.; Wang, L. Monitoring of seawater immersion degradation in glass fibre reinforced polymer composites using quantum dots. Compos. Part B 2017, 112, 93–102. [Google Scholar] [CrossRef]

- Wang, L.; Fan, X.M.; Chen, H.; Liu, W.Q. Axial crush behavior and energy absorption capability of foam-filled GFRP tubes under elevated and high temperature. Compos. Struct. 2016, 149, 339–350. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Moshiri, N. Compressive strength of CFRP composites used for strengthening for RC columns: Comparative evaluation of EBR and grooving method. ASCE J. Compos. Constr. 2015, 19, 04014079. [Google Scholar] [CrossRef]

- Maaddawy, T.; Sayed, M.; Magid, B.A. Effect of cross sectional shape and loading condition on performance of reinforced concrete members confined with carbon fiber reinforced polymers. Mater Des. 2013, 31, 2330–2341. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Zhao, H. Experimental study of high strength concrete columns confined with different types of mesh under eccentric and concentric loading. ASCE J. Mater. 2013, 23. [Google Scholar]

- Herwig, A.; Motavalli, M. Axial behavior of square Reinforced Concrete columns strengthened with lightweight concrete elements and unbonded GFRP wrapping. Asce, J. Compos. Constr. 2016, 16, 747–752. [Google Scholar] [CrossRef]

- Song, X.; Gu, X.; Li, Y.; Chen, T.; Zhang, W. Mechanical behavior of FRP strengthened concrete columns subjected to concentric and eccentric compression. ASCE J. Compos. Constr. 2013, 17, 336–346. [Google Scholar] [CrossRef]

- Hamdy, M.; Afifi, M.M.Z.; Benmokrane, B. Performance evaluation of concrete columns reinforced longitudinally with FRP bars and confined with FRP hoops and spirals under axial load. ASCE J. Bridge Eng. 2014, 19, 04014020. [Google Scholar]

- Lam, L.; Teng, J.G. Design oriented stress strain model for FRP confined concrete. Constr. Build Mater 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. A new stress strain Model for FRP confined concrete. Proc. Frp. Compos. 2001, 1, 283–292. [Google Scholar]

- Rocca, S.; Galati, N.; Nanni, A. Review of design guidelines for FRP confinement of Reinforced Concrete columns of noncircular cross sections. ASCE J. Compos. Constr. 2008, 12, 80–92. [Google Scholar] [CrossRef]

- Chellapandian, M.; Prakash, S.S.; Sharma, A. Strength and ductility of innovative hybrid NSM reinforced and FRP confined short RC columns under axial compression. Compos. Struct. 2017, 176, 205–216. [Google Scholar] [CrossRef]

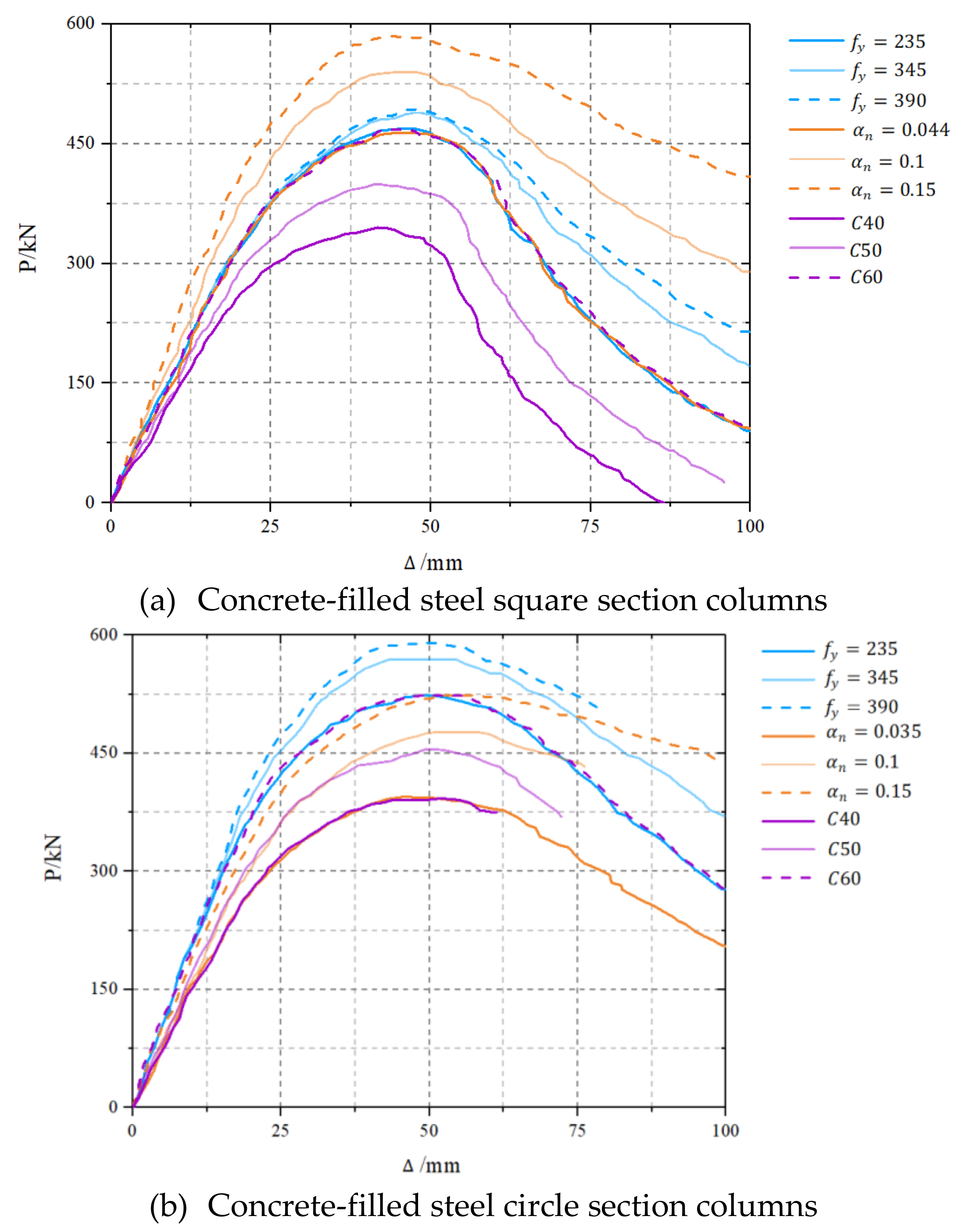

- Tao, Z.; Han, L.H.; Wang, L.L. Compressive and flexural behavior of CFRP-repaired concrete-filled steel tubes after exposure to fire. J. Constr. Steel Res. 2007, 63, 1116–1126. [Google Scholar] [CrossRef]

- Tao, Z.; Wang, Z.B.; Han, L.H.; Uy, B. Fire performance of concrete-filled steel tubular columns strengthened by FRP. Steel Compos. Struct. 2011, 11, 307–324. [Google Scholar] [CrossRef]

- Janwaena, W.; Barrosa, J.A.; Costa, I.G. A new strengthening technique for increasing the load carrying capacity of rectangular reinforced concrete columns subjected to axial compressive loading. Compos. Part B 2019, 158, 67–81. [Google Scholar] [CrossRef]

- Haji, M.; Naderpour, H.; Kheyroddin, A. Experimental study on influence of proposed FRP-strengthening techniques on RC circular short columns considering different types of damage index. Compos. Struct. 2019, 209, 112–128. [Google Scholar] [CrossRef]

- Yaqub, M.; Bailey, C.G. Repair of fire damaged circular reinforced concrete columns with FRP composites. Constr. Build. Mater. 2011, 25, 359–370. [Google Scholar] [CrossRef]

- Roudsaria, S.S.; Hamoushb, S.A.; Soleimanic, S.M.; Madandoust, R. Evaluation of large-size reinforced concrete columns strengthened for axial load using fiber reinforced polymers. Eng. Struct. 2019, 178, 680–693. [Google Scholar] [CrossRef]

- Bisby, L.A.; Kodur, V.K.R.; Green, M.F. Fire endurance of fiber-reinforced polymer-confined concrete columns. Aci. Struct. J. 2005, 102, 883–891. [Google Scholar]

- Chowdhury, E.U.; Bisby, L.A.; Green, M.F.; Kodur, V.K.R. Investigation of insulated FRP-wrapped reinforced concrete columns in fire. Fire Saf. J. 2007, 42, 452–460. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Bisby, L.A.; Green, M.F. Experimental evaluation of the fire behavior of insulated fibre-reinforced-polymer-strengthened reinforced concrete columns. Fire Saf. J. 2006, 41, 547–557. [Google Scholar] [CrossRef]

- Benichou, N.; Cree, D.; Chowdhury, E.U.; Green, M. Fire testing of FRP strengthened reinforced concrete columns. In Proceedings of the 4th International Conference on Durability and Sustainability of FRP Composites for Construction and Rehabilitation, Québec, QC, Canada, 20–22 July 2011. [Google Scholar]

- Wang, L. Application of the section-enlargement method in reinforcing the fire-damaged bridge. Master’s Thesis, Southeast University, Nanjing, China, 2015. (In Chinese). [Google Scholar]

- Wang, W.D.; Guo, Z.F.; Zhang, P.P. Numerical simulation on strengthening behavior of reinforced concrete columns after fire with wrapped steel tube. J. Nat. Disaster. 2012, 21, 204–210. (In Chinese) [Google Scholar]

- Han, L.H.; Yang, Y.F.; Xu, L. An experimental study and calculation on the fire resistance of concrete-filled SHS and RHS columns. J. Constr Steel Res. 2003, 59, 427–452. [Google Scholar] [CrossRef]

- Bisby, L.A.; Green, M.F.; Kodur, V.K.R. Modeling the behavior of fiber reinforced polymer-confined concrete columns exposed to fire. J. Compos. Constr. 2005, 9, 15–24. [Google Scholar] [CrossRef]

- Bisby, L.A.; Kodur, V.K.R.; Green, M.F. Numerical parametric studies on the fire endurance of fibre-reinforced-polymer-confined concrete columns. Can. J. Civ. Eng. 2004, 31, 1090–1100. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Lie, T.T. Evaluation of the fire resistance of rectangular steel columns filled with fibre-reinforced concrete. Can. J. Civ. Eng. 1997, 24, 339–349. [Google Scholar] [CrossRef]

- Spoelstra, M.R.; Monti, G. FRP-confined concrete model. J. Compos. Constr. 1999, 3, 143–150. [Google Scholar] [CrossRef]

- Manfredi, G.; Realfonzo, R. Models for concrete confined by fiber composites. Available online: https://www.researchgate.net/publication/262259777_Models_of_concrete_confined_by_fiber_composites (accessed on 1 February 2019).

| Reference | Reinforced State | Column Size (mm) | Load Type | Destructive Feature | |

|---|---|---|---|---|---|

| Liu et al. [49] | Before | Eccentric | 20 to 800 | , full section compression damage; , partly tensile damage | |

| After | |||||

| Bett et al [47] | Before | axial compression and cyclic lateral loads | Normal | The brittle and shear-dominated failure | |

| Before | |||||

| After | |||||

| Sun [59] | Before | Eccentric | 20 to 800 | , concrete cracking in the tension zone; , compression damage |

| Damage Level | Level One | Level Two | Level Three | Level Four |

|---|---|---|---|---|

| Degree of damage | Mild | Moderate | Serious | Dangerous |

| Concrete temperature () | 400 to 500 | 600 to 700 | ||

| longitudinal reinforcement Temperature () | 350 to 400 | 400 to 500 | ||

| Damaged situation | No significant changes | Deflection meeting the limit | Deflection exceeding the limit by 1 to 3 times | Out-of-plane deformation |

| Section Type | L (min) | Layer(s) of CFRP | Fire Duration Time (min) | (kN) | Esce (N/mm2) | SEI % | DI | |||

|---|---|---|---|---|---|---|---|---|---|---|

| (N/mm2) | (N/mm2) | |||||||||

| circular | 150 × 3.0 | 450 | 0 | 356 | 75 | 0 | 1915 | 46,285 | — | 5.51 |

| 150 × 3.0 | 450 | 0 | 356 | 75 | 180 | 913 | 15,592 | — | 3.95 | |

| 150 × 3.0 | 450 | 1 | 356 | 75 | 180 | 1020 | 16,584 | 11.7 | 1.71 | |

| 150 × 3.0 | 450 | 2 | 356 | 75 | 180 | 1560 | 19,695 | 70.9 | 1.22 | |

| square | 140 × 3.8 | 420 | 0 | 318.5 | 75 | 0 | 1890 | 54,069 | — | 2.88 |

| 140 × 3.8 | 420 | 0 | 318.5 | 75 | 180 | 787 | 19,615 | — | 9.88 | |

| 140 × 3.8 | 420 | 1 | 318.5 | 75 | 180 | 890 | 22,230 | 13.1 | 6.51 | |

| 140 × 3.8 | 420 | 2 | 318.5 | 75 | 180 | 1000 | 25,009 | 27.1 | 2.59 |

| Reference | Column Size (mm) | Technique | FRP Material | Thermal Insulation and Thickness (mm) | Strength Increase (%) | Ultimate Capacity (%) |

|---|---|---|---|---|---|---|

| Bisby et al. [83] | EBR | CFRP | Vermiculite/gypsum mortar, intumescent coating () | 26 | 73 | |

| Chowdhury et al. [84] | EBR | CFRP | Cement-based mortar (53) | 63 | 56 | |

| Kodur et al. [85] | EBR | GFRP | Vermiculite/gypsum mortar (38) | 10 | 75 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Wang, L. Repair of Fire-Damaged Reinforced Concrete Members with Axial Load: A Review. Sustainability 2019, 11, 963. https://doi.org/10.3390/su11040963

Zhou J, Wang L. Repair of Fire-Damaged Reinforced Concrete Members with Axial Load: A Review. Sustainability. 2019; 11(4):963. https://doi.org/10.3390/su11040963

Chicago/Turabian StyleZhou, Jun, and Lu Wang. 2019. "Repair of Fire-Damaged Reinforced Concrete Members with Axial Load: A Review" Sustainability 11, no. 4: 963. https://doi.org/10.3390/su11040963

APA StyleZhou, J., & Wang, L. (2019). Repair of Fire-Damaged Reinforced Concrete Members with Axial Load: A Review. Sustainability, 11(4), 963. https://doi.org/10.3390/su11040963