1. Introduction

Sustainable manufacturing concept and practice are becoming increasingly a topic of significant interest globally. The need for sustainable manufacturing has become crucial due to the fact that manufacturing activities consume a large amount of energy and natural resources [

1,

2], produce considerable emissions to air and land and deteriorate the earth’s carrying capacity [

3], while having significant implications for the society and economy. More specifically, the expanding food manufacturing industry due to the rapid growth in world population and changing lifestyles, results in the consumption of global resources at a faster pace [

4]. The food sector contributes more than 25% of greenhouse gas (GHG) emissions alone [

5,

6] and is responsible for a large share of water withdrawal [

7,

8]. Moreover, food manufacturing also produces a significant amount of solid waste, wastewater, etc., [

9]. In addition, the food manufacturing industry normally provides high-calorie and unfavorable nutritions in processed food which have potential harmful effects on eating and drinking behaviors [

10]. In short, food manufacturing (processing and packaging) is critical from a sustainability viewpoint, especially in recent times when the world is facing global issues of environmental degradation, fragile and volatile economy and food security and safety.

To respond to this situation, sustainable food manufacturing has become a major concern and priority. In order to improve sustainability performance and green perception, assessment is an essential process [

11,

12,

13,

14]. An assessment and reassessment of how food manufacturing activities are undertaken is necessary to take on the challenges of sustainability while mitigating water usage, energy consumption and negative social and economic impacts. However, although food manufacturing contributes significantly to sustainability related burdens, it has not been given due attention by previous research from sustainability assessment and improvement viewpoints, especially in developing countries [

15]. The major focus of sustainability related research has been on metal manufacturing, building and construction, chemical processing, etc.

The focus of previous sustainability assessment methods and studies in manufacturing remained mainly on environmental concerns alone [

16,

17,

18,

19]. However, the triple-bottom line (TBL) concept of sustainability [

20,

21] requires manufacturing industries to consider all three aspects (environment, economy and society) of sustainability comprehensively. Most of the time, sustainability assessment efforts in food manufacturing were limited to life cycle assessment or energy analysis [

8,

22,

23,

24]. Very few studies were based on the TBL concept. Recently, Ali et al. [

25] tried to include other dimensions of sustainability for food manufacturing; however, their research was limited to environmental and economic impacts only, while the social aspect was overlooked.

Currently available sustainability assessment methods face various challenges, which resultantly hinder their practical application. For example, most of the sustainability assessment methods are based on quantitative indicators only, whereas qualitative indicators are overlooked because of various reasons [

26,

27]. Moreover, the unavailability of applicable and measurable indicators dissuades practitioners to assess sustainability performance. Instead of having generic and overall indicators, applicable and weighted sustainability indicators need to be used for specific industries [

15,

28,

29,

30]. This would give more standardized, precise and comparable sustainability evaluation [

31,

32,

33,

34,

35].

Optimal sustainability related decisions can only be made when both types of fuzzy and stochastic uncertainties are included in one assessment method. Fuzziness (imprecise information) and randomness (stochastic variability) are the two main sources of uncertainties in the real world, which are also associated with sustainability assessment problems. However, overall, many sustainability assessment methods have simply overlooked both fuzzy and stochastic uncertainties. Even in a recent study [

36], uncertainties associated with the data for sustainability assessment were ignored. Among other relevant methods, life cycle sustainability assessment (LCSA) by United Nations Environment Programme (UNEP)/Society of Environmental Toxicology and Chemistry (SETAC) [

37] is an important method for TBL based assessment. However, LCSA is an impact assessment method, just like life cycle assessment (LCA) [

38]. LCSA is based on general guidelines and there is a need to develop a comprehensive and weighted set of indicators. Additionally, from economic and social viewpoints, the impact categories and how to measure them have yet to be agreed upon [

38]. Moreover, the concept of stochastic and fuzzy uncertainties is also missing in LCSA.

The above mentioned research gaps and discussion highlight the need for the development of a TBL-based comprehensive and integrated sustainability performance assessment method that integrates both stochastic and fuzzy uncertainties, while considering weighted and applicable sustainability indicators. Thus, this novel study provides contributions in various aspects. Theoretically, it would answer the research question of how to integrate stochastic and fuzzy uncertainties in a sustainability assessment method. It would also demonstrate how to include and analyze qualitative and quantitative indicators concurrently. This would help to further improve the capabilities of sustainability assessment methods. Practically, by demonstrating the application of this method in the Malaysian food manufacturing industry, it is expected to increase sustainability assessment efforts in a developing country like Malaysia, and may eventually improve its sustainability performance. Currently, the Malaysian food manufacturing industry lags behind in applying sustainability practices in its operations [

39,

40].

To achieve the objective of developing an integrated sustainability assessment method, the Monte Carlo simulation and fuzzy logic approaches were used simultaneously. Fuzzy logic was used for qualitative indicators because it is suitable to address linguistic variables when evaluating sustainability. However, fuzzy logic is unable to address the dynamic and probabilistic nature of quantitative variables. Thus, Monte Carlo simulation was utilized for quantitative indicators to solve this problem. The Crystal Ball software for Monte Carlo simulation and the Fuzzy Logic toolbox of Matlab (R2015b) were used. In order to show the applicability of the developed method, a case study was done in the Malaysian food manufacturing industry. Real data were collected from a case company and the developed method was applied to assess its sustainability performance. After this, the method was validated for its robustness and the results obtained were analyzed and discussed.

The rest of this article is arranged as follows.

Section 2 presents the background and some general concepts, and the developed method is described in

Section 3. The application of the method in a case study along with the results are presented in

Section 4.

Section 5 provides an analysis and discussion. Validation of the method is presented in

Section 6.

Section 7 outlines various implications for practitioners and researchers, and important conclusions are provided in

Section 8.

3. The Proposed Method

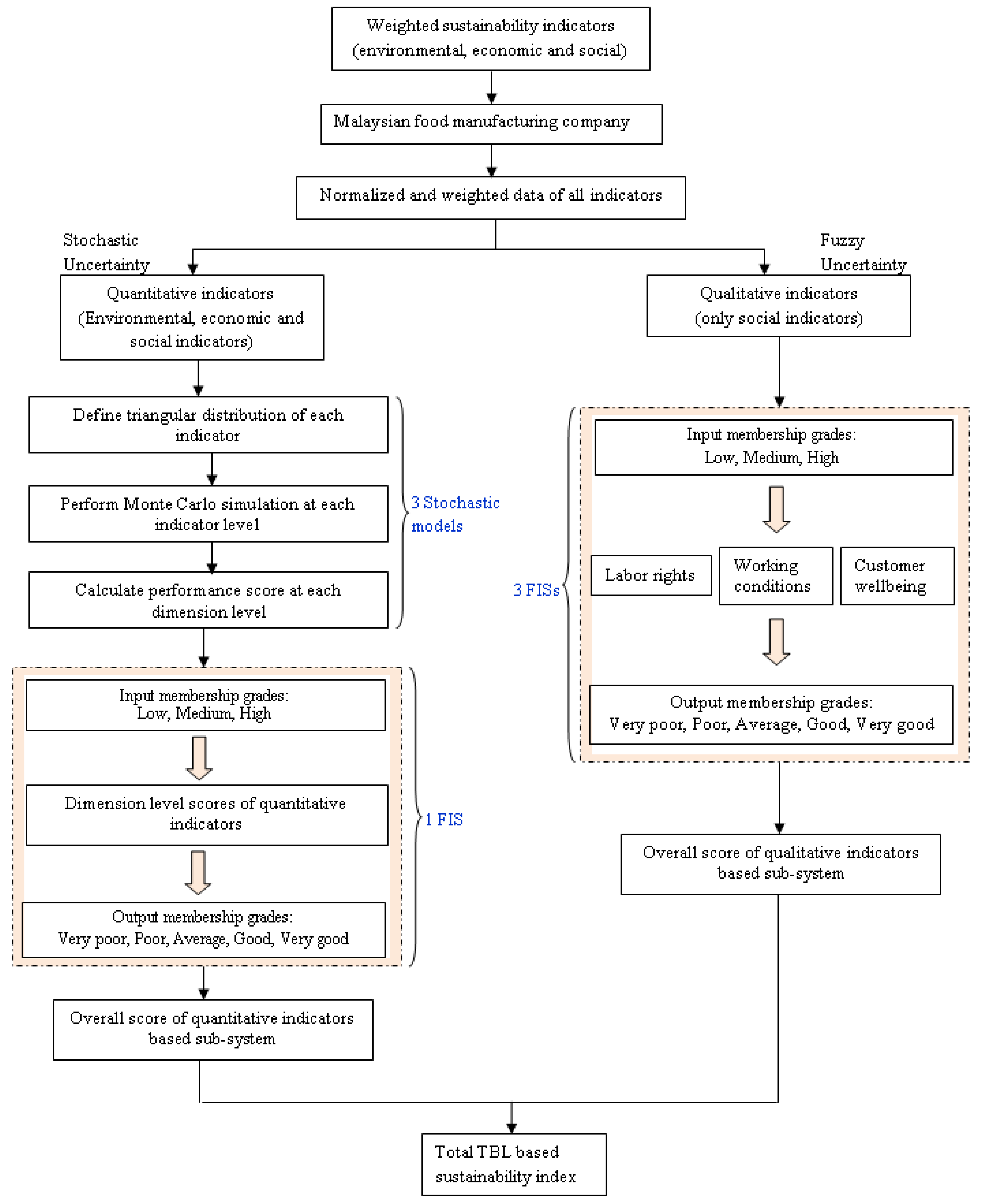

The basic modeling components of the proposed method are shown in

Figure 1. Overall, in order to capture stochastic and fuzzy uncertainties, the method was based on both types of quantitative and qualitative indicators. The quantitative indicators (environmental, economic and social indicators) were treated as stochastic variables, whereas the qualitative indicators (social indicators) were analyzed as fuzzy variables. For simplicity purposes, the method was divided into two sub-systems (quantitative indicators based sub-system and qualitative indicators based sub-system). The method used the fuzzy logic approach for the qualitative indicators based sub-system. The quantitative indicators based sub-system was analyzed based on Monte Carlo simulation first, and then followed by fuzzy logic. The TBL based total sustainability index was grounded on the weighted contribution of each sub-system.

At the outset, using Monte Carlo simulation requires input information to be specified; however, in many real-world applications, the available information is imprecise and scarcely accessible. In such situations, when there are very limited sample data for an uncertain parameter, the triangular distribution is used, where it is based on knowledge of the minimum, maximum and most likely modal values [

68,

69,

70]. Since in this study, the possible ranges of industry data were used for the indicators, it seemed reasonable to use the triangular distribution. The minimum, most likely and maximum values were used to infer the lower bounds, modes and upper bounds of the triangular distributions.

The quantitative indicators were directly measured based on their measuring units, whereas the qualitative indicators were recorded based on linguistic measures, using a Likert scale from 1 to 5 [

71]. The qualitative indicators were processed by using fuzzy models or Fuzzy Inference Systems (FISs). The triangular membership function was used in the fuzzy models because it is the simplest and most commonly used membership function owing to its ability to be adapted into various assessments [

65,

72,

73]. The Mamdani method was used as the fuzzy model and the centroid method was utilized as the defuzzification approach. The Mamdani-type FIS was used because it is widely accepted and provides more consistent results [

74,

75]. Moreover, the selection of the centroid defuzzification method was based on its superior results and steady-state performance [

76,

77]. Briefly, the proposed sustainability assessment method is presented below as a set of steps:

Step 1: As the first step, the goal and scope of the study were defined and the system boundary was specified. The goal and scope were identified at the earliest stage of the evaluation process. In this research, the goal was to develop a method for assessing the sustainability performance of a plant/factory in the Malaysian food manufacturing industry. The scope included the system boundary (either cradle-to-gate, cradle-to-grave, gate-to-grave or gate-to-gate). The extent of the system boundary depended on the goal of the study.

Step 2: This stage was related to the identification and selection of applicable sustainability indicators and their relative weights from the viewpoint of the Malaysian food manufacturing industry. Normally, previous sustainability-related research used a limited number of indicators for ease and simplicity purposes. In contrast, this research was based on a comprehensive set of 57 sustainability indicators. The weighted and applicable indicators that were specifically developed for the Malaysian food manufacturing industry were used. These indicators were first extracted from the literature and then refined and finalized for this specific industry using the Delphi method while engaging various experts from academia, research center and industry. These indicators were reported in [

78]. The weights of the indicators were calculated based on the applicability scores recommended by the experts [

78]. In addition, a positive or negative sign (+ or −) was assigned to each indicator based on its direction of impact on sustainability performance. In other words, if the objective is to increase an indicator’s value, its sign is positive (+); otherwise, its sign is negative (−).

Step 3: The selection of the food manufacturing company was primarily based on the size of the company, and its willingness to participate and share the related data for analysis purposes. As the aim was to develop an applicable and practicable method, Small and Medium Enterprises (SMEs) were chosen for initial demonstration. This was done because SMEs generally find it difficult to cope with emerging challenges due to their financial, technical and other constraints. Thus, in a sense, it could help food manufacturing SMEs in Malaysia.

Step 4: The data were collected from the case study company and they were normalized and weighted for each indicator. Due to different measuring units of different indicators, they could not be processed directly. The data were normalized from 0 to 1 to solve this problem. Two formulas were used; one for indicators with a positive sign (+) and another for indicators with a negative sign (−) [

79]. Equation (1) shows the calculation to normalize scores for positive indicators, and Equation (2) is for negative indicators. The normalized score

was calculated using

as the maximum score and

as the minimum score among the three-point data (

,

,

). As depicted in Equation (3), the normalized score was simply multiplied by the weight (

) of the respective indicator to get the normalized weighted score (

) of that indicator:

For qualitative indicators, in order to get a single real value (

based on three fuzzy estimates, the graded mean integration representation method [

80] was used. The formula is given in Equation (4):

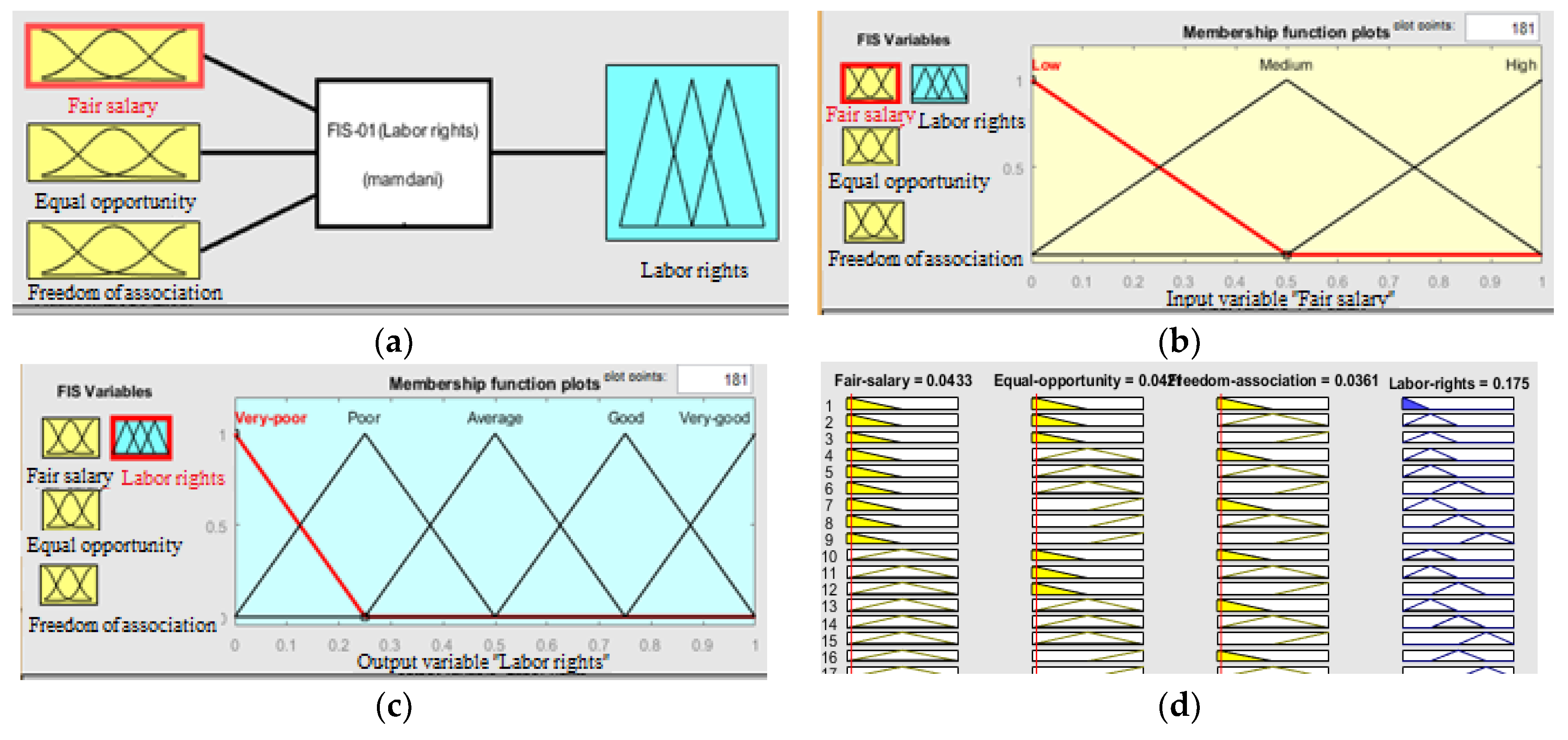

Step 5: This step was about the assessment of the qualitative indicators based sub-system. There were nine social indicators in the qualitative indicators based sub-system under three aspect categories (labor rights, working conditions and customer wellbeing). The fuzzy logic approach was used, and thus, three FISs (one for each aspect category) were designed for the qualitative indicators. In order to develop the FISs, three degrees of triangular membership functions were used for the input variables; low (L), medium (M) and high (H). Three degrees were employed, because they were simple and also commonly used in engineering and management problems. As for the output, five degrees of triangular membership functions were used; very poor (VP), poor (P), average (A), good (G) and very good (VG). Five degrees were proposed to obtain a more accurate result with lower complexity. The fuzzy membership grades (degrees) for the input and output variables are presented in

Table 1 and

Table 2, respectively. Equation (5) was used to calculate the number of rules required in each FIS:

where

n represents the number of fuzzy membership grades for input variables,

v is the number of input variables (indicators) for each aspect category and

R stands for the number of rules needed. The labor rights category was based on three indicators, thus, the rule base comprised 27 rules. The second aspect category (working conditions) consisted of only two indicators, thus, nine rules were used. There were four indicators in the customer wellbeing category, and thus, it required 81 rules. All the rules were connected by using the ‘AND’ operator. The defuzzified value generated by each FIS was used as the score of each aspect category. These scores were summed up to obtain the overall score for the qualitative indicators based sub-system.

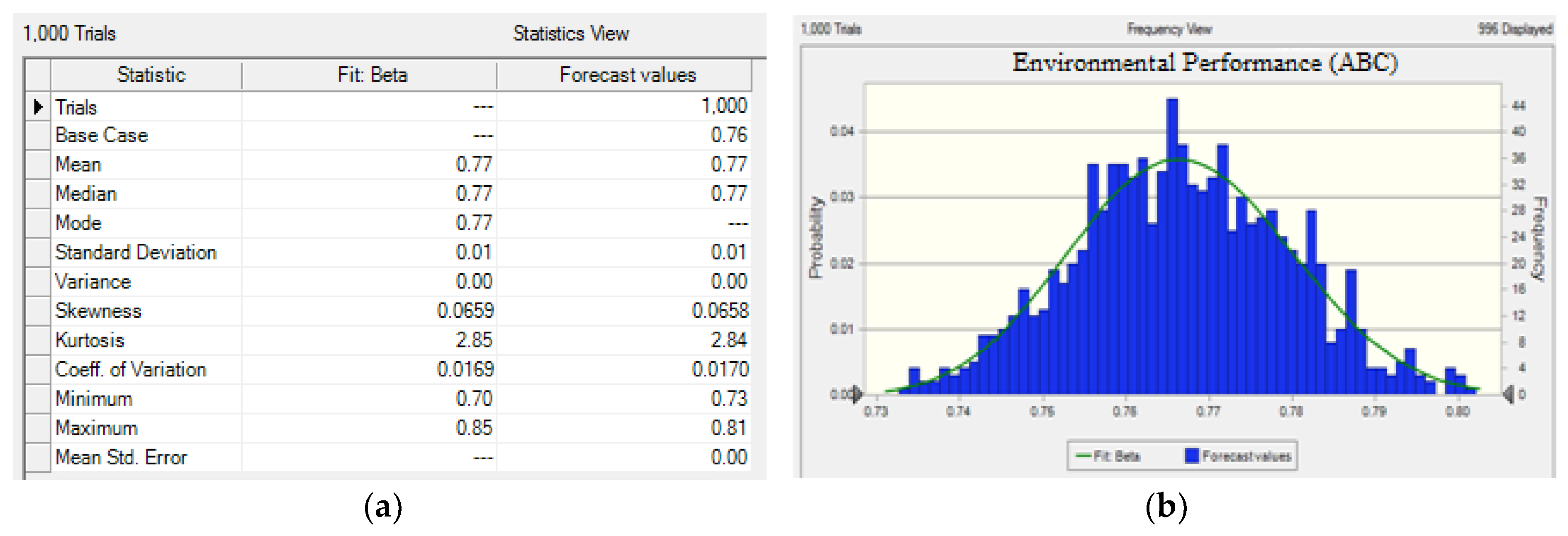

Step 6: The quantitative indicators based sub-system was analyzed using two approaches: firstly, the Monte Carlo simulation was used to address the stochastic uncertainties and then fuzzy logic to cope with the directions of impact of sustainability dimensions. The values of the quantitative indicators were stochastic, and therefore, it was important to simulate their performance. The three-point data were used to represent the triangular distributions. Simulation was performed 1000 times at each indicator level (19 environmental, 14 economic and 15 social indicators) [

54,

55,

56]. The dimension level performance was calculated by adding/subtracting (based on the impact direction of an indicator) the average simulated scores of all quantitative indicators in each dimension. In this way, the environmental, economic and social (with stochastic indicators) dimensions were assigned a score based on the stochastic analysis.

The dimension level scores obtained through stochastic simulation were used to develop another FIS in order to get the overall score for the quantitative indicators based sub-system. Actually, the dimension level scores based on Monte Carlo simulation were not having the same direction of impact on sustainability performance. Since there are more indicators with a negative sign in the environmental and economic dimensions, a lower score means better performance for these two dimensions of sustainability. However, in the case of the social dimension, a higher score is better. Thus, in order to solve this problem, another FIS was designed. The same number of triangular membership functions with the same range, as mentioned in Step 5 were defined for the variables. There were three variables (three sustainability dimensions), which required 27 rules to describe the problem fully. However, because of the direction of impact of the environmental and economic dimensions, different membership grades (

Table 3) were designed for these two dimensions.

Step 7: The overall TBL-based sustainability index was calculated based on the scores received in the previous two steps. The weighted scores of both the sub-systems (qualitative indicators based and quantitative indicators based sub-systems) were summed up to get the total TBL sustainability index of the overall system. Based on this final sustainability index, the food manufacturing company’s sustainability performance could be categorized into one of the five levels given in

Table 4.

5. Discussion and Analysis

This section presents a useful analysis and discussion of the results. These results were discussed with respect to the outputs of the fuzzy and stochastic models, total sustainability index and contribution to uncertainty.

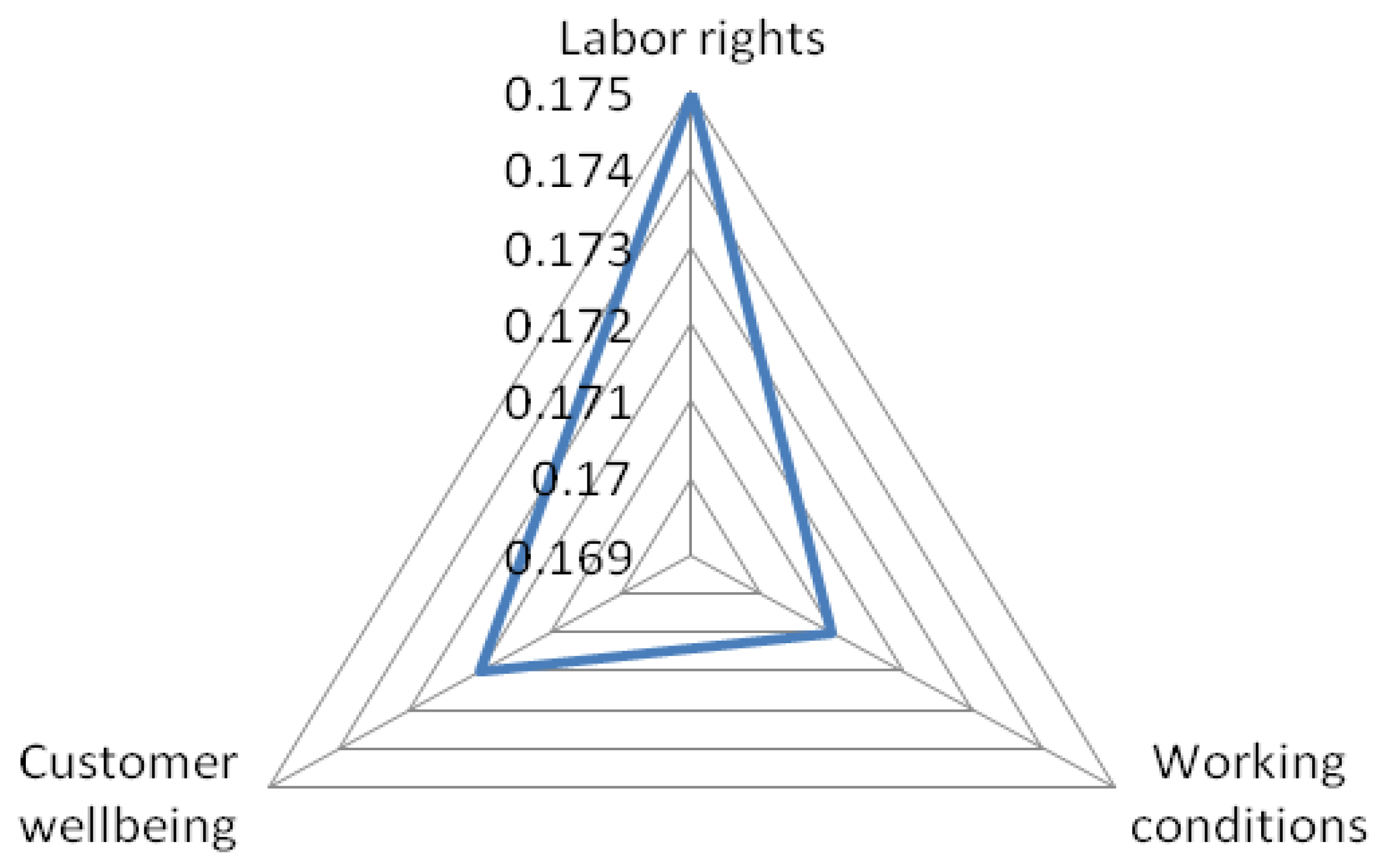

For the qualitative indicators, as depicted in

Figure 4, the aspect category of labor rights was comparatively performing better with a score of 0.175. It was followed by customer wellbeing (0.172) and working conditions (0.171). Based on the direction of impact, higher scores of these aspect categories mean better performance. Comparatively, the better score of the labor rights aspect category could be attributed mainly to the better performance of the case company with respect to fair salary, equal opportunity and freedom of association. In comparison, the working conditions aspect category showed lower performance which was based on decent working hours and decent workload. Grounded on these findings, the case company might increase its sustainability performance by putting more efforts and resources to improve the situations of decent working hours and decent workload. Overall, no aspect category scored 0.2 or higher and this showed that various opportunities exist for improvement. In the same way, the results of the stochastic models could also be analyzed.

For dimension level analysis, both scores pertaining to the social dimension (quantitative indicators with 0.16 and qualitative indicators with 0.518) were added, just for comparison purposes. At the dimension level, as discussed earlier, a lower score of the environmental and economic dimensions, and a higher score of the social dimension represent better performance. From the results, comparatively, the social dimension with a score of 0.678 (by adding 0.16 and 0.518) was performing better. Between the economic and environmental dimensions, the former showed relatively better performance (0.43) than the latter (0.77). The poorer score of the environmental dimension might be attributed to the considerable amount of air emissions and polluted wastewater coming out from the case company. With respect to the economic dimension, the profit based indicators have better scores than the cost related indicators.

The total TBL sustainability index (0.42) marked the case company’s performance as average. Nevertheless, the company’s performance was still far from the ideal sustainability level. In other words, there were various challenges to cope with and different opportunities to improve its sustainability performance. For example, the performance could be improved by focusing more on the low performing sustainability areas.

In addition, reducing uncertainties in the input variables is desirable for effective sustainability assessment. Theoretically, less uncertainties lead to more reliable probabilistic estimates. However, generally reducing uncertainty in any input variable will not necessarily result in the same magnitude of refinement in the output [

81]. An analysis was presented to show how much each sustainability dimension contributed to the uncertainty or variability of the output using the Crystal Ball software.

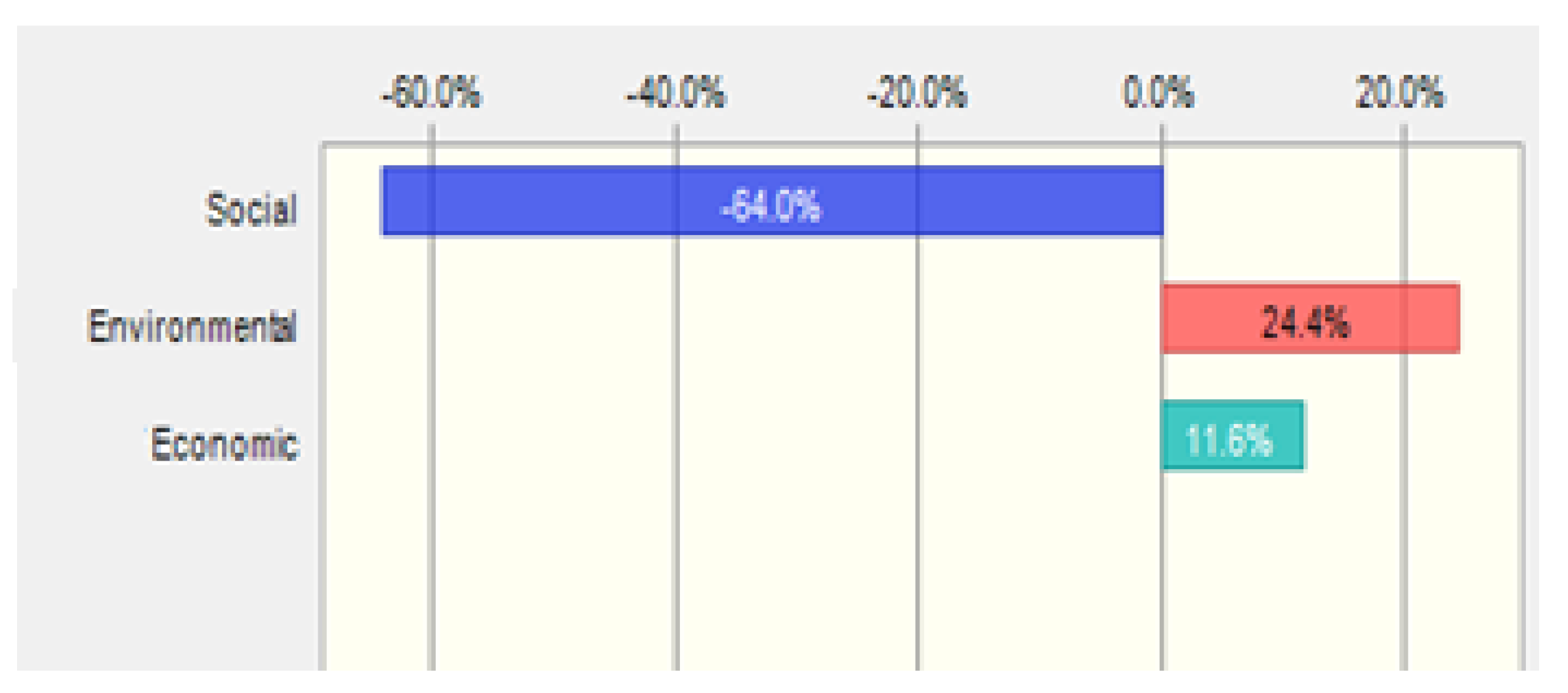

The results of the analysis (

Figure 5) showed that the social dimension contributed more to the output variance for the case company. It was followed by the environmental and economic dimensions of sustainability. In this way, the overall variability can be better and effectively reduced by focusing more efforts on the social dimension of sustainability.

7. Implications

This novel research has various important implications. Firstly, it discussed the development and demonstration of a comprehensive and integrated sustainability assessment method. This new method integrates stochastic and fuzzy approaches in order to deal with uncertainties in a comprehensive way. This integration, which was overlooked in previous methods, has made sustainability assessment more precise and realistic. The proposed method is equally useful for practitioners as well as researchers. Practically, the method has been demonstrated and tested via a case study in the Malaysian food manufacturing industry. Practitioners could employ this method to evaluate and track their company’s sustainability level and performance over time. Researchers could also use it to assess and compare the sustainability performance of food manufacturing activities.

In addition, keeping in view the constraints of resources, some companies are involved in the assessment of only one dimension of sustainability (for example, environmental). This method could also be used individually if separate assessment of one dimension is required. However, at a later stage, such companies might apply all the dimensions in order to have a comprehensive performance evaluation.

Last but not least, this study has shown the important utilization of Monte Carlo simulation and fuzzy logic for sustainability assessment purposes. It could guide researchers on how these two approaches are utilized and integrated to produce useful and reliable assessment results.

8. Conclusions

Current sustainability assessment studies face various challenges. The problems are related to the usage of an applicable, weighted and comprehensive set of sustainability indicators, analysis and quantification of stochastic and fuzzy uncertainties simultaneously, inclusion of the TBL concept of sustainability, assessment of sustainability in developing countries where limited databases and resources are available, etc. There is a need for the development of a new sustainability assessment method that can overcome the deficiencies of previous approaches. Thus, the main objective of this article was to develop and test a comprehensive and integrated stochastic-fuzzy sustainability assessment method. In this regard, Monte Carlo simulation and fuzzy logic were used in an integrated way to address the stochastic and fuzzy uncertainties. The proposed method combined the benefits of Monte Carlo simulation with the advantages of fuzzy inference.

Based on the weighted and comprehensive nature of its indicators, this method helps to provide more reliable and precise results. A real-world case study dealing with sustainability assessment of a Malaysian food manufacturing company was conducted to test the applicability and functionality of the proposed method. The case company showed an average sustainability performance with a total TBL based sustainability index of 0.42. The results revealed that, along with other measures, the sustainability performance of the case company might be improved more effectively by decreasing the amount of air emissions, polluted wastewater, etc., and improving the working conditions. In essence, the results showed that the developed method is useful for evaluating sustainability performance in terms of a total sustainability index within a system containing complicated uncertainties.

Apart from its advantages, this research had its own limitations. Firstly, only one case study was reported in this research. More studies in the future will confirm the usability of the developed method. Secondly, the case study was based on a gate-to-gate system boundary for assessment purposes. Future work could assess the sustainability level of food manufacturing activities by covering the supply chain stages or increasing the assessment boundary.