Feasibility of Using Modified Silty Clay and Extruded Polystyrene (XPS) Board as the Subgrade Thermal Insulation Layer in a Seasonally Frozen Region, Northeast China

Abstract

1. Introduction

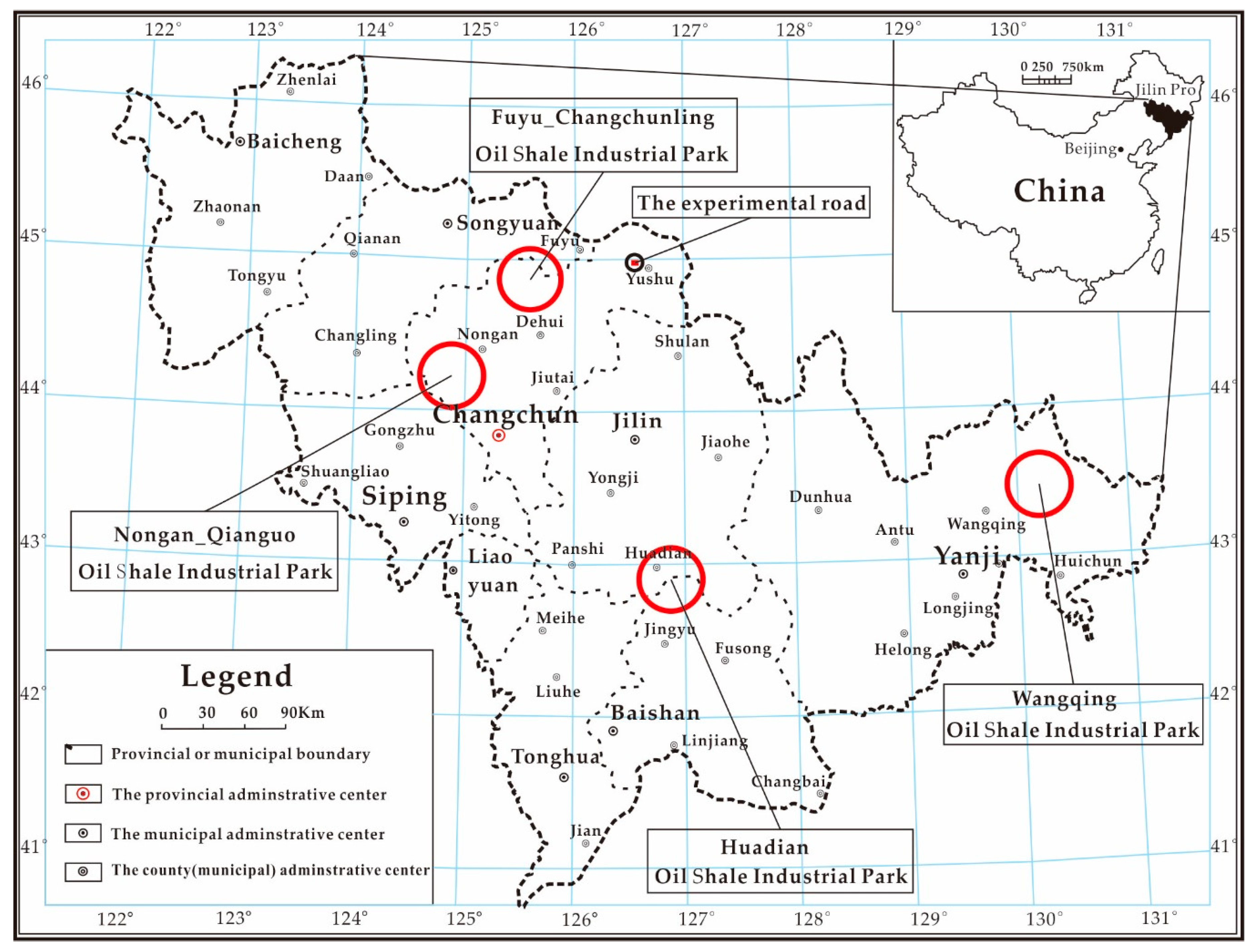

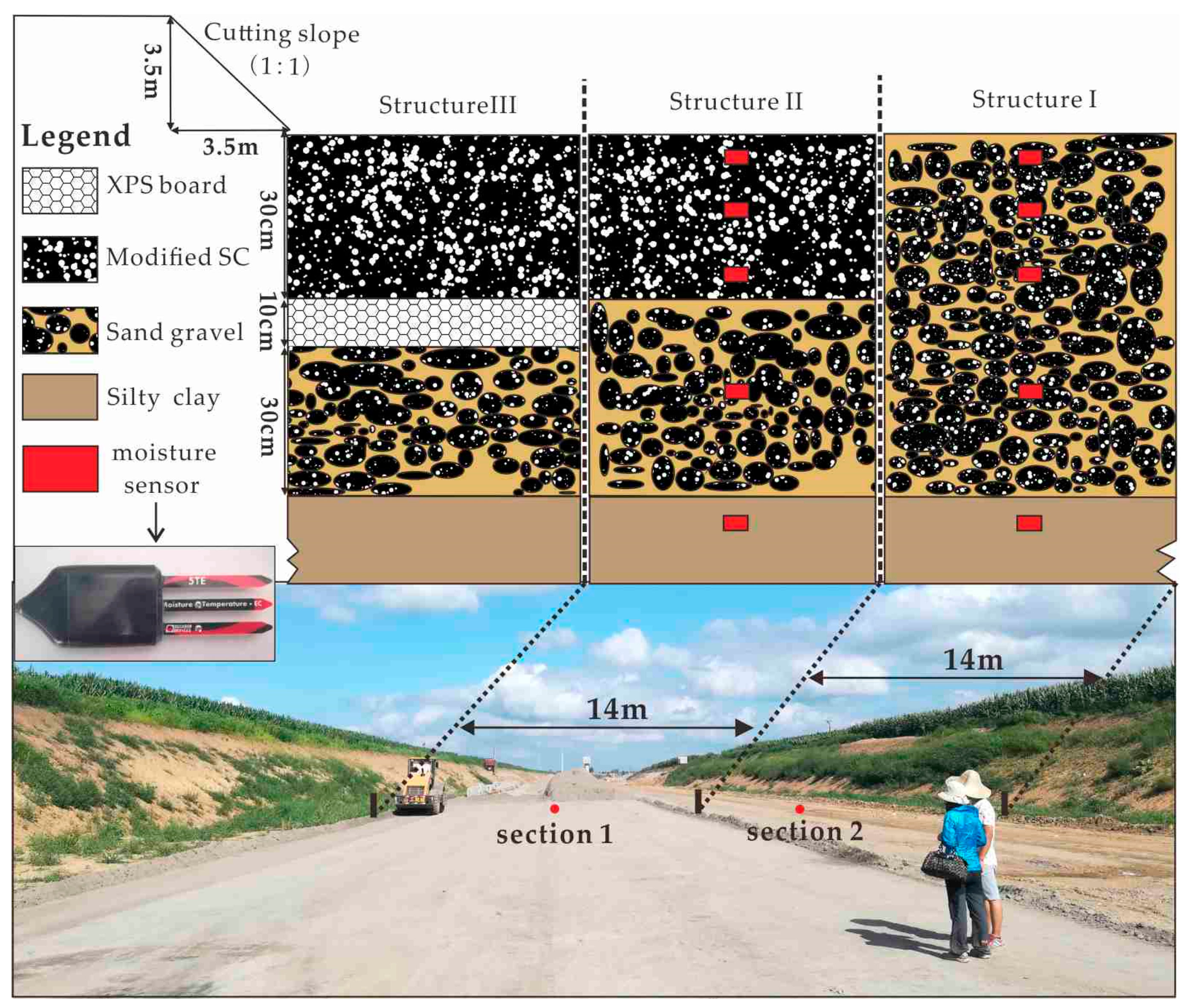

2. Materials and Methods

2.1. Materials

2.2. Samples and Test Methods

2.3. Research Methods

2.3.1. Environmental Pollution Assessment Methods of the NSTIL

2.3.2. Numerical Simulation of Coupling Moisture and Temperature in Subgrade under Freeze-Thaw Cycles

Heat Transport Equation

Water Flow Equation

Dynamic Equilibrium Equation of Phase Transition

Model Setup

3. Results and Discussion

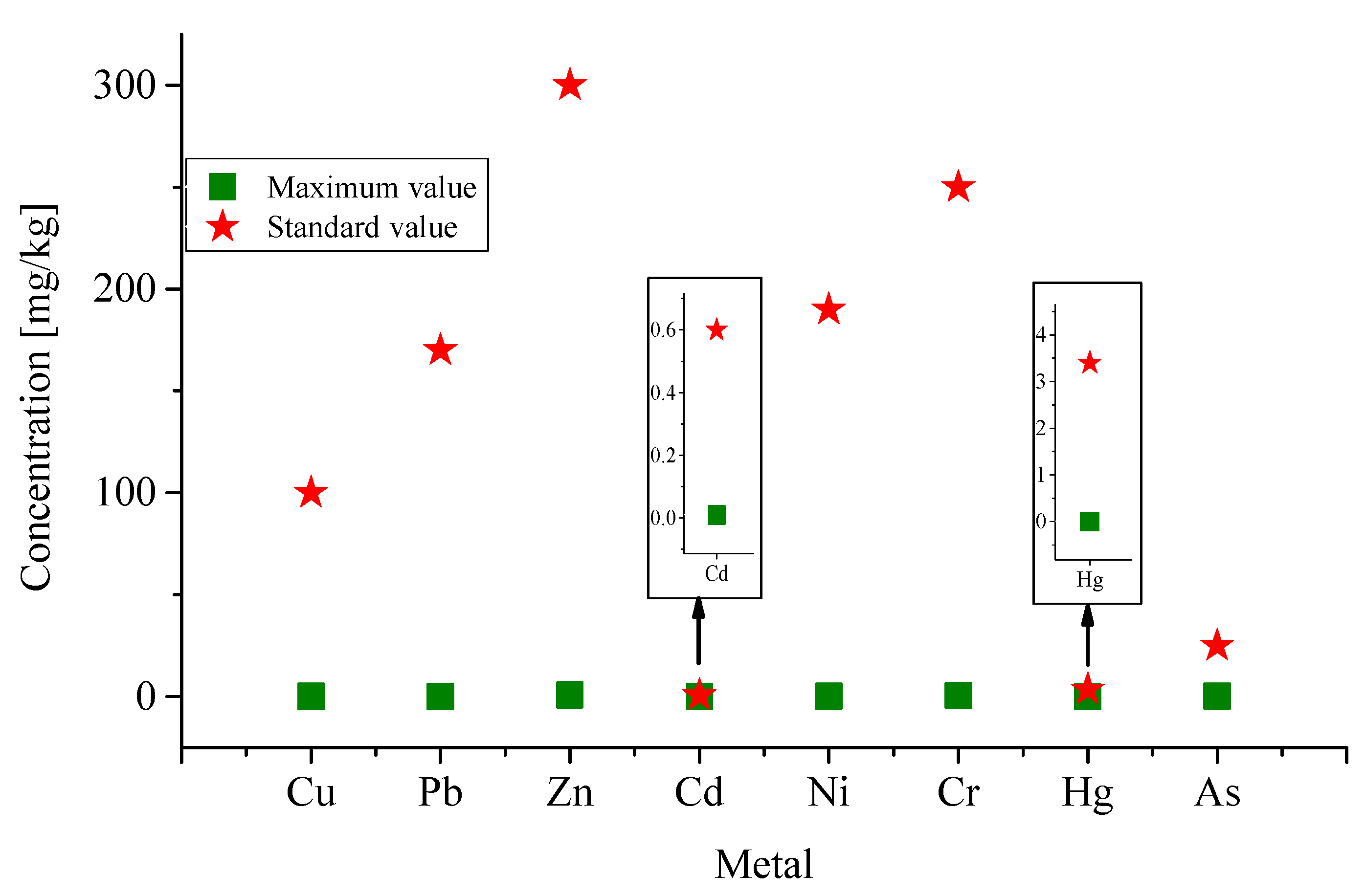

3.1. Environmental Pollution Assessment of the NSTIL

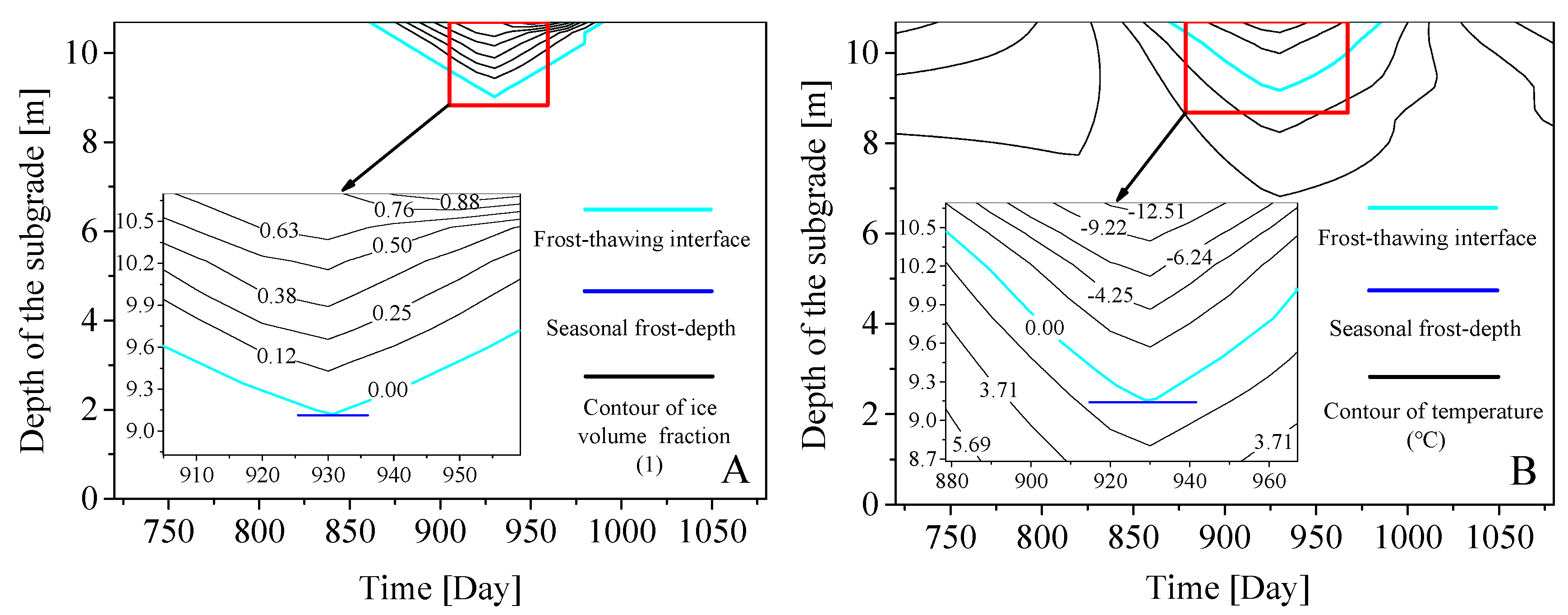

3.2. Numerical Results on Freezing-Thawing Zones of the Structure I

3.3. Numerical Results on Freezing-Thawing Zones of the Structure II

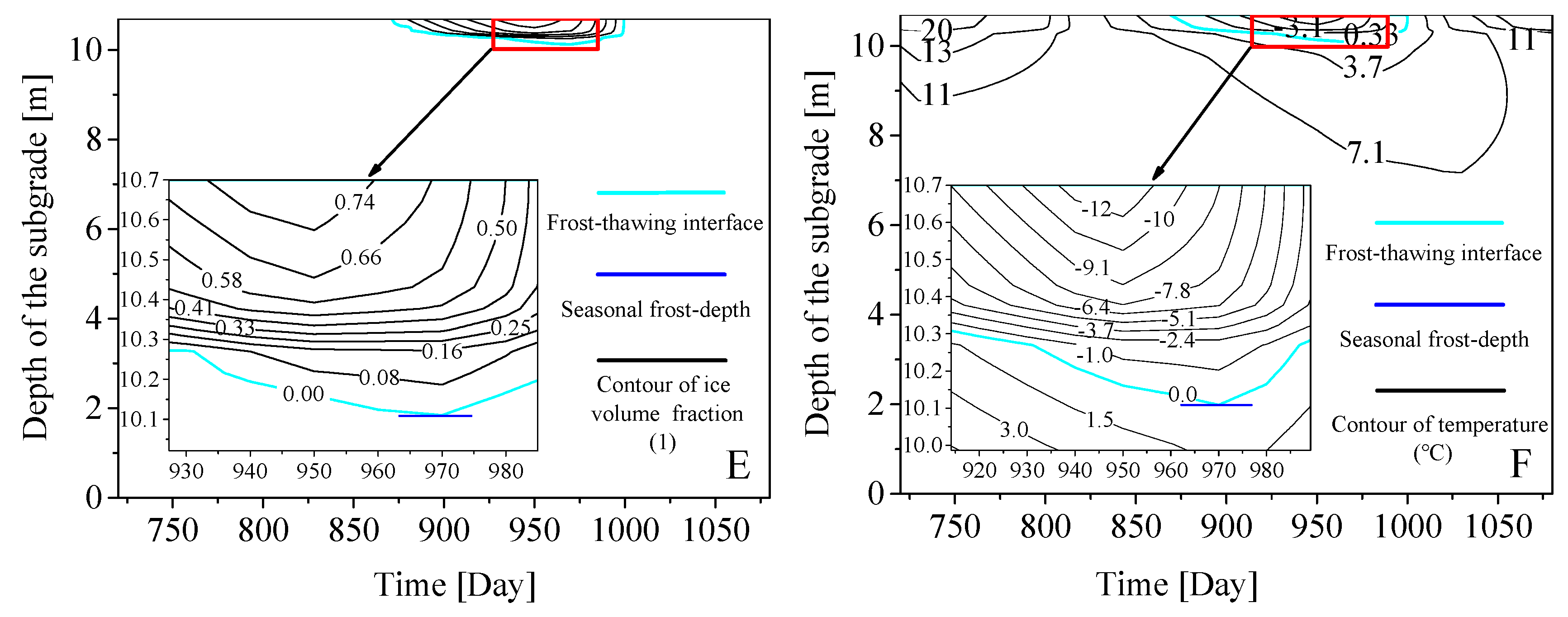

3.4. Numerical Results on Freezing-Thawing Zones of the Structure III

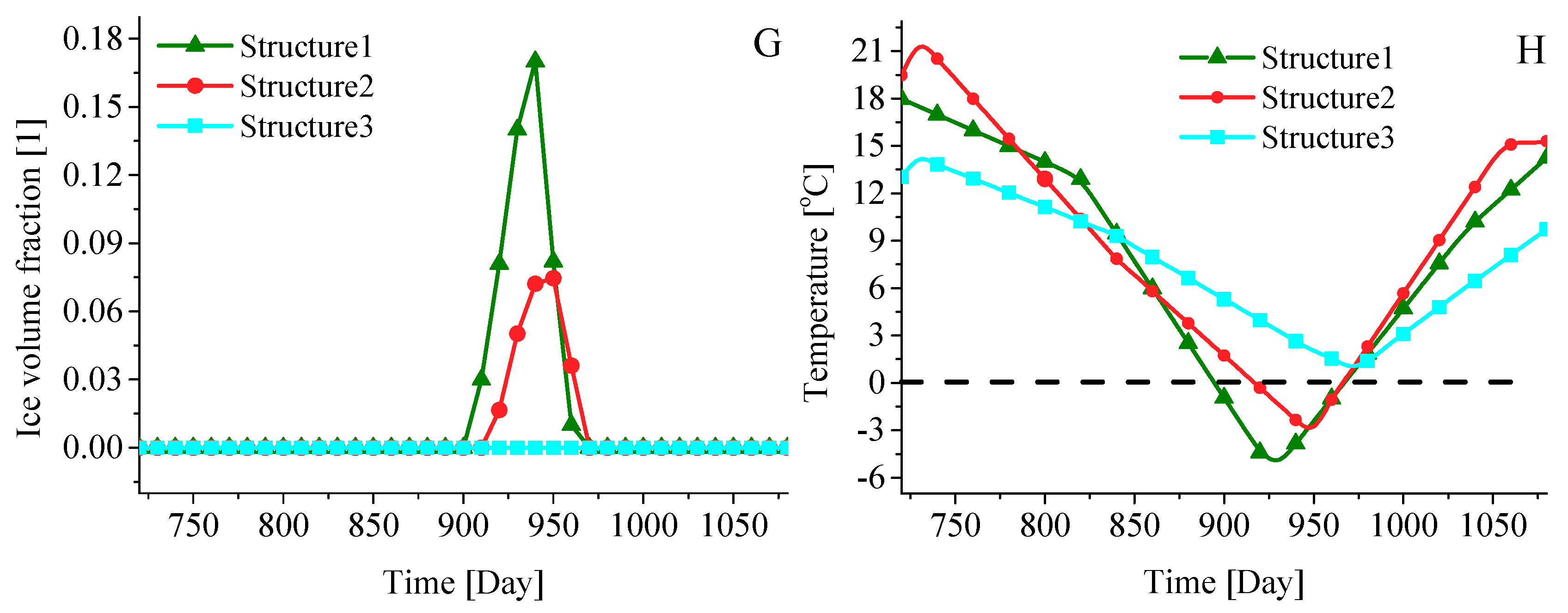

3.5. The Changes of Ice Volume Fraction and Temperature at the Interface between Sand Gravel and Silty Clay for Structures I, II and III

4. Conclusions

- (1)

- According to the average single pollution index () and Nemerow integrated pollution index (), the modified SC, which is used as the thermal insulation layer of the experimental subgrade, will produce pollution to the environmental background of the experimental road.

- (2)

- Compared with the national standards, the concentration of each hydrochemical constituent of the modified SC is all lower than the national tertiary standard for the Standard for Groundwater Quality in China, and its concentrations of Cu, Pb, Zn, Cd, Ni, Cr, Hg and As are lower than the national primary standard of agricultural soil for the Environmental Quality Standard for Soils in China, indicating that the modified SC can be used as the soil-replacing layer of subgrade. Furthermore, in the NSTIL, the Extruded Polystyrene (XPS) board is placed at the bottom of the modified SC. This structure enables XPS board to prevent the SC layer from the pollution of the modified SC layer.

- (3)

- The numerical results of the Structure I are approximated to the official website information of Jilin province, indicating that the coupled moisture-temperature differential equations are effective for coupling moisture and temperature of frozen soil. The seasonal frost depths of Structures II and III are 0.3 m and 0.9 m lower than that of the Structure I, respectively, and the time when their frost-depth reach the seasonal frost-depth is delayed for 30 days and 50 days, correspondingly. Moreover, the Structure III can protect the silty clay of the experimental road from the damage of frost heave, and the effect of frost heave on the silty clay of the Structure I is greater than on that of the Structure II.

- (4)

- Both of the modified SC and NSTIL have the advantage of good thermal insulation property, but the thermal insulation property of the NSTIL is greater. The research results are of great significance for reducing environmental pollution caused by OSW and FA, increasing the utilization rate of industrial waste and enhancing the subgrade stability in the seasonally frozen regions, and show the good feasibility and application prospect using modified SC and XPS board as the subgrade thermal insulation layer in seasonally frozen regions.

Author Contributions

Funding

Conflicts of Interest

References

- Ran, Y.; Li, X.; Cheng, G.; Zhang, T.; Wu, Q.; Jin, H.; Jin, R. Distribution of Permafrost in China: An Overview of Existing Permafrost Maps. Permafr. Periglac. Process. 2012, 23, 322–333. [Google Scholar] [CrossRef]

- Vaitkus, A.; Gražulytė, J.; Skrodenis, E.; Kravcovas, I. Design of frost resistant pavement structure based on road weather stations (RWSs) data. Sustainability 2016, 8, 1328. [Google Scholar] [CrossRef]

- Liu, S.; Yang, J.; Chen, X.; Yang, G.; Cai, D. Application of Mastic Asphalt Waterproofing Layer in High-Speed Railway Track in Cold Regions. Appl. Sci. 2018, 8, 667. [Google Scholar] [CrossRef]

- Özgan, E.; Serin, S.; Ertürk, S.; Vural, I. Effects of Freezing and Thawing Cycles on the Engineering Properties of Soils. Soil Mech. Found. Eng. 2015, 52, 95–99. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, M.; Zhang, X.; Pei, W.; Bi, J. Experimental study on the freezing–thawing deformation of a silty clay. Cold Reg. Sci. Technol. 2018, 151, 19–27. [Google Scholar] [CrossRef]

- Kraszewski, C.; Rafalski, L. Laboratory Examination of Frost-heaving Properties of Road Unbound Mixtures Based on Fines Content and Plasticity Index. Procedia Eng. 2016, 143, 836–843. [Google Scholar] [CrossRef]

- Haghi, N.; Nassiri, S.; Shafiee, M.; Bayat, A. Using Field Data to Evaluate Bottom Ash as Pavement Insulation Layer. Transp. Res. Rec. J. Transp. Res. Board 2014, 2433, 39–47. [Google Scholar] [CrossRef]

- Nurmikolu, A.; Kolisoja, P. Extruded polystyrene (XPS) foam frost insulation boards in railway structures. In Proceedings of the International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–15 September 2005; Aa Balkema Publishers: Rotterdam, The Netherlands, 2005; p. 1761. [Google Scholar]

- Liping, Z. Study of Application of XPS Board in Frozen Subgrade Works. Master’s Thesis, University of Changan, Xi’an, China, 2009. [Google Scholar]

- Wei, H.; Zhang, Y.; Wang, F.; Che, G.; Li, Q. Experimental Research on Resilient Modulus of Silty Clay Modified by Oil Shale Ash and Fly Ash after Freeze-Thaw Cycles. Appl. Sci. 2018, 8, 1298. [Google Scholar] [CrossRef]

- US EPA. Using Coal Ash in Highway Construction: A Guide to Benefits and Impacts; US EPA: Washington, DC, USA, 2005.

- Gobinath, V.; Student, P.G.; Stalin, V.K. Performance of Geogrid Reinforced Rubber Waste as Subgrade Material. In Proceedings of the Geo-Frontiers Congress, Dallas, TX, USA, 13–16 March 2011; pp. 4498–4504. [Google Scholar]

- Kua, T.A.; Arulrajah, A.; Horpibulsuk, S.; Du, Y.J.; Suksiripattanapong, C. Engineering and environmental evaluation of spent coffee grounds stabilized with industrial by-products as a road subgrade material. Clean Technol. Environ. Policy 2016, 19, 1–13. [Google Scholar] [CrossRef]

- Energy Administration of Jilin Province. The 13th Five-Year Plan for Energy Development of Jilin Province; Energy Administration of Jilin Province: Changchun, China, 2017.

- Zhang, F.-Q.; Li, W.-Q.; Guan, X.; Xu, X.-D. Application Research of Oil Shale Ash in Construction of Road. J. Jilin Inst. Archit. Civ. Eng. 2012, 2, 009. [Google Scholar]

- Vallner, L.; Gavrilova, O.; Vilu, R. Environmental risks and problems of the optimal management of an oil shale semi-coke and ash landfill in Kohtla-Järve, Estonia. Sci. Total Environ. 2015, 524–525, 400–415. [Google Scholar] [CrossRef] [PubMed]

- Fulekar, M.H.; Dave, J.M. Disposal of fly ash—An environmental problem. Int. J. Environ. Stud. 1986, 26, 191–215. [Google Scholar] [CrossRef]

- Dahale, P.P.; Nagarnaik, P.B.; Gajbhiye, A.R. Utilization of Solid Waste for Soil Stabilization: A Review. Electron. J. Geotech. Eng. 2012, 17, 2443–2461. [Google Scholar]

- Turner, J.P. Soil Stabilization Using Oil-Shale Solid Waste. J. Geotech. Eng. 1994, 120, 646–660. [Google Scholar] [CrossRef]

- Saravanan, R.; Thomas, R.S.; Joseph, M. A study on soil stabilization of clay soil using fly ash. Int. J. Res. Civ. Eng. Archit. Des. 2013, 1, 33–37. [Google Scholar]

- Brooks, R.M. Soil stabilization with fly ash and rice husk ash. Int. J. Res. Rev. Appl. Sci. 2009, 1, 209–217. [Google Scholar]

- Yilmaz, F.; Kamiloğlu, H.A.; Şadoğlu, E. Soil Stabilization with Using Waste Materials against Freezing Thawing Effect. Acta Phys. Pol. 2015, 128, B–392–B–395. [Google Scholar] [CrossRef]

- Mymrin, V.A.; Ponte, H.A. Oil-shale fly ash utilization as independent binder of natural clayey soils for road and airfield base construction. Part. Sci. Technol. 2005, 23, 99–107. [Google Scholar] [CrossRef]

- MOT China. Specifications for Design of Highway Subgrades (JTG D30-2015); China Communications Press: Beijing, China, 2015; p. 7.

- Taciuk, W. Does oil shale have a significant future? Oil Shale 2013, 30, 1–5. [Google Scholar] [CrossRef]

- Ministry of Housing Urban-Rural Development of Republic of China. Technical Code for Application of Fly Ash Concrete; China Planning Press: Beijing, China, 2014; Volume GB/T 50146-2014.

- Cui, J.H. Research on Stability of Subgrade Soil Modified by Oil Shale Waste Residue and Fly Ash; Jilin University: Chang Chun, China, 2018. [Google Scholar]

- Zhang, Y.P.; Wei, H.B.; Jia, J.K.; Chen, Z. Numerical evaluation on application of roadbed with composite cold resistance layer inseasonal frozen area. J. Jilin Univ. (Eng. Ed.) 2018, 48, 121–128. [Google Scholar]

- Ministry of Ecology and Environment of the People’s Republic of China. Solid Waste-Extraction Procedure for Leaching Toxicity; Horizontal Vibration Method; China Environmental Science Press: Beijing, China, 2010; Volume HJ 557-2009.

- Galson, D.A.; Wilson, N.P.; Schärli, U.; Rybach, L. A comparison of the divided-bar and QTM methods of measuring thermal conductivity. Geothermics 1987, 16, 215–226. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, P.; Yu, Z.; Fang, J.; Li, C. Characteristics of ground thermal properties in Harbin, China. Energy Build. 2014, 69, 9. [Google Scholar] [CrossRef]

- Jiang, X.; Lu, W.X.; Yang, Q.C.; Yang, Z.P. Potential ecological risk assessment and prediction of soil heavy metal pollution around coal gangue dump. Nat. Hazards Earth Syst. Sci. 2014, 14, 1977–2010. [Google Scholar] [CrossRef]

- Yang, Z.P.; Wen-Xi, L.U.; Long, Y.Q.; Liu, X.R. Prediction and Precaution of Heavy Metal Pollution Trend in Urban Soils of Changchun City. Urban Environ. Urban Ecol. 2010, 23, 1–4. [Google Scholar]

- Wei, C.; Zhu, W.; Chen, S.; Ranjith, P. A Coupled Thermal–Hydrological–Mechanical Damage Model and Its Numerical Simulations of Damage Evolution in APSE. Materials 2016, 9, 841. [Google Scholar] [CrossRef] [PubMed]

- Nassar, I.N.; Horton, R. Simultaneous Transfer of Heat, Water, and Solute in Porous Media: I. Theoretical Development. Soil Sci. Soc. Am. J. 1992, 56, 1350–1356. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Zhu, M. Frost heave modelling using porosity rate function. Int. J. Numer. Anal. Methods Geomech. 2006, 30, 703–722. [Google Scholar] [CrossRef]

- Lu, N.; Likos, W.J. Unsaturated Soil Mechanics; John Wiley & Sons: New York, NY, USA, 2004. [Google Scholar]

- Taylor, G.S.; Luthin, J.N. A model for coupled heat and moisture transfer during soil freezing. Rev. Can. De Géotechn. 1978, 15, 548–555. [Google Scholar] [CrossRef]

- Xu, X.; Wang, J.; Zhang, L. Frozen Soil Physics; Science Press: Beijing, China, 2010; pp. 105–107. [Google Scholar]

- Xu, X.Z.; Oliphant, J.L.; Tice, A.R. Prediction of unfrozen water content in frozen soils by a two-point or one-point method. In Proceedings of the 4th International Symposium on Ground Freezing, Sapporo, Japan, 5–7 August 1985; Volume 2, pp. 83–87. [Google Scholar]

- Bai, Q.B.; Xu, L.I.; Tian, Y.H.; Fang, J.H. Equations and numerical simulation for coupled water and heat transfer in frozen soil. Chin. J. Geotech. Eng. 2015, 37, 131–136. [Google Scholar]

- Tan, Y.Q.; Hui-Ning, X.U.; Zhou, C.X.; Zhang, K.; Chen, F.C. Temperature distribution characteristic of subgrade in seasonally frozen regions. J. Harbin Inst. Technol. 2011, 43, 98–102. [Google Scholar]

- Cao, Y.; Sheng, Y.; Jichun, W.U.; Jing, L.I.; Ning, Z.; Xiaoying, H.U.; Feng, Z.; Wang, S. Influence of upper boundary conditions on simulated ground temperature field in permafrost regions. J. Glaciol. Geocryol. 2014, 36, 802–810. [Google Scholar]

- General Administration of Quality Supervision Inspection and Quarantine of the People’s Republic of China. Standard for Groundwater Quality; China Environmental Science Press: Beijing, China, 2017; Volume GB/T 14848-2017.

- Ministry of Ecology and Environment of the People’s Republic of China. Soil Environmental Quality in Risk Control Standard for Soil Contamination of Agricultural Land; China Environmental Science Press: Beijing, China, 2018; Volume GB15618-2018.

- Meteorological Bureau of Jilin Province. Agricultural Meteorological Report of Jilin Province from 2010 to 2018. Available online: http://www.jlqx.gov.cn/ydqhbh/kjcx/ (accessed on 6 September 2018).

| Physical Properties | OSW: FA: SC | SC | ||||

|---|---|---|---|---|---|---|

| 4:3:3 | 3:4:3 | 7:5:8 | 2:1:2 | 9:3:8 | ||

| Plastic Limit [%] | 27.96 | 26.94 | 27.54 | 20.20 | 25.77 | 22.40 |

| Liquid Limit [%] | 40.51 | 40.17 | 42.70 | 32.6 | 42.60 | 34.00 |

| Plasticity [%] | 12.55 | 13.23 | 15.16 | 12.4 | 16.83 | 11.60 |

| Optimum Moisture [%] | 13.50 | 18.00 | 13.00 | 15.00 | 13.20 | 12.20 |

| Maximum Density [kg·m−3] | 1550 | 1460 | 1620 | 1520 | 1690 | 1930 |

| CBR Value soaking for 96h [%] | 17.00 | 13.00 | 31.00 | 40.00 | 33.00 | 1.00 |

| Samples | The Chemical Composition [%] | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| OSW | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | TiO2 | Loss on Ignition |

| 6.42 | 56.28 | 13.44 | 7.22 | 2.49 | 2.31 | 1.84 | 0.59 | 8.56 | |

| FA | 0.92 | SiO3 | SiO2+Al2O3+Fe2O3 | Mg Ti Na and K compounds | 3.19 | ||||

| 0.24 | 88.64 | 6.01% | |||||||

| Water Content w [%] | Permeability k [m2] | Thermal Conductivity [W·m−1K−1] | Density [kg·m−3] | Specific Heat [J·kg−1K−1] | |

|---|---|---|---|---|---|

| Modified SC | 15.6 | 6.5 × 10−14 | 0.65 | 1520 | 1647 |

| XPS board | 0.3 | 1.0 × 10−19 | 0.03 | 45 | 5346 |

| Sand Gravel | 16.0 | 5.5 × 10−12 | 1.06 | 1800 | 840 |

| SC | 23.6 | 5.5 × 10−14 | 0.93 | 1640 | 940 |

| Water | / | / | 0.58 | 980 | 4180 |

| Ice | / | / | 2.22 | 917 | 1874 |

| Constituent | S1 | S2 | S3 | Aver-value | Maxi-value | Back-value | Stan-value A | Pi | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Cu | 0.0044 | 0.0026 | 0.0052 | 0.0041 | 0.0052 | 0.0469 | 1.0000 | 0.0867 | 0.0995 |

| Pb | 0.0011 | 0.0008 | 0.0010 | 0.0010 | 0.0011 | 0.0088 | 0.0100 | 0.1099 | 0.1177 |

| Co | 0.0003 | 0.0004 | 0.0006 | 0.0004 | 0.0006 | 0.0023 | 0.0500 | 0.1884 | 0.2275 |

| Zn | 0.0409 | 0.0311 | 0.0035 | 0.0252 | 0.0409 | 0.1317 | 1.0000 | 0.1912 | 0.2579 |

| Cd | 0.0003 | 0.0001 | 0.0005 | 0.0003 | 0.0005 | 0.0008 | 0.0050 | 0.375 | 0.5154 |

| Ni | 0.0030 | 0.0028 | 0.0033 | 0.003 | 0.0033 | 0.0069 | 0.0200 | 0.4396 | 0.4593 |

| Al | 0.1030 | 0.0616 | 0.0818 | 0.0821 | 0.103 | 0.1026 | 0.2000 | 0.8005 | 0.9079 |

| Cr | 0.0134 | 0.0259 | 0.0164 | 0.0186 | 0.0259 | 0.0226 | 0.0500 | 0.8215 | 0.9971 |

| NH4+ | 0.0800 | 0.0400 | 0.1000 | 0.0733 | 0.1000 | 0.0800 | 0.5000 | 0.917 | 1.096 |

| Hg | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.001 | 1.0000 | 1.0000 |

| PH | 8.2600 | 8.2800 | 8.2800 | 8.2733 | 8.2800 | 7.4600 | 8.5000 | 1.1090 | 1.1100 |

| Ag | 0.0003 | 0.0002 | 0.0003 | 0.0003 | 0.0003 | 0.0002 | 0.0500 | 1.2500 | 1.3807 |

| TFe | 0.0030 | 0.0570 | 0.0610 | 0.0403 | 0.0610 | 0.0270 | 0.3000 | 1.494 | 1.915 |

| Cl− | 6.9700 | 5.2200 | 7.3700 | 6.5200 | 7.3700 | 3.4830 | 250.000 | 1.872 | 1.998 |

| Sb | 0.0003 | 0.0005 | 0.0004 | 0.0004 | 0.0005 | 0.0002 | 0.0050 | 2.0000 | 2.2639 |

| As | 0.0071 | 0.0077 | 0.0066 | 0.0071 | 0.0077 | 0.0028 | 0.0100 | 2.5476 | 2.6507 |

| Na+ | 24.7100 | 26.8600 | 28.2600 | 26.6100 | 28.2600 | 7.0500 | 200.000 | 3.7750 | 3.8930 |

| Ba | 0.0750 | 0.0967 | 0.0859 | 0.0859 | 0.0967 | 0.0125 | 0.7000 | 6.8693 | 7.3155 |

| NO3− | 3.4430 | 3.5440 | 2.6620 | 3.2160 | 3.5440 | 0.4430 | 20.000 | 7.2600 | 7.6390 |

| TDS | 570.503 | 609.471 | 590.911 | 590.295 | 609.4710 | 72.8640 | 1000.00 | 8.1010 | 8.2300 |

| WH | 389.446 | 422.194 | 408.863 | 406.834 | 422.194 | 47.4200 | 450.000 | 8.5790 | 8.7430 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Wei, H.; Han, L.; Wang, F.; Zhang, Y.; Han, S. Feasibility of Using Modified Silty Clay and Extruded Polystyrene (XPS) Board as the Subgrade Thermal Insulation Layer in a Seasonally Frozen Region, Northeast China. Sustainability 2019, 11, 804. https://doi.org/10.3390/su11030804

Li Q, Wei H, Han L, Wang F, Zhang Y, Han S. Feasibility of Using Modified Silty Clay and Extruded Polystyrene (XPS) Board as the Subgrade Thermal Insulation Layer in a Seasonally Frozen Region, Northeast China. Sustainability. 2019; 11(3):804. https://doi.org/10.3390/su11030804

Chicago/Turabian StyleLi, Qinglin, Haibin Wei, Leilei Han, Fuyu Wang, Yangpeng Zhang, and Shuanye Han. 2019. "Feasibility of Using Modified Silty Clay and Extruded Polystyrene (XPS) Board as the Subgrade Thermal Insulation Layer in a Seasonally Frozen Region, Northeast China" Sustainability 11, no. 3: 804. https://doi.org/10.3390/su11030804

APA StyleLi, Q., Wei, H., Han, L., Wang, F., Zhang, Y., & Han, S. (2019). Feasibility of Using Modified Silty Clay and Extruded Polystyrene (XPS) Board as the Subgrade Thermal Insulation Layer in a Seasonally Frozen Region, Northeast China. Sustainability, 11(3), 804. https://doi.org/10.3390/su11030804