4.1. Midpoint and Endpoint Environmental Impact Category Indicators and Identification of Hotspots

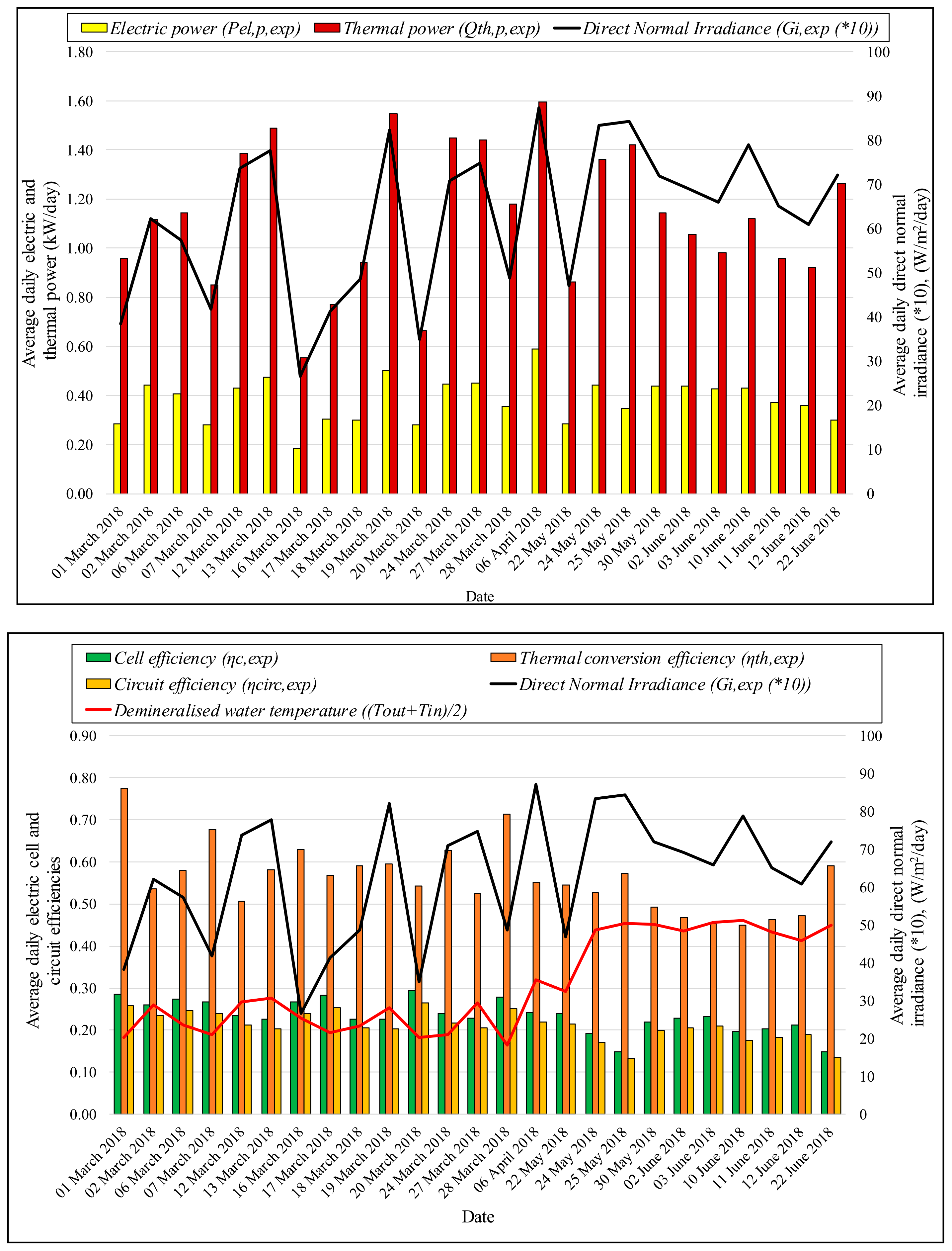

The results of midpoint and endpoint environmental impacts are presented in

Table 5 (presented numerically in the first two columns) and

Figure 7 respectively.

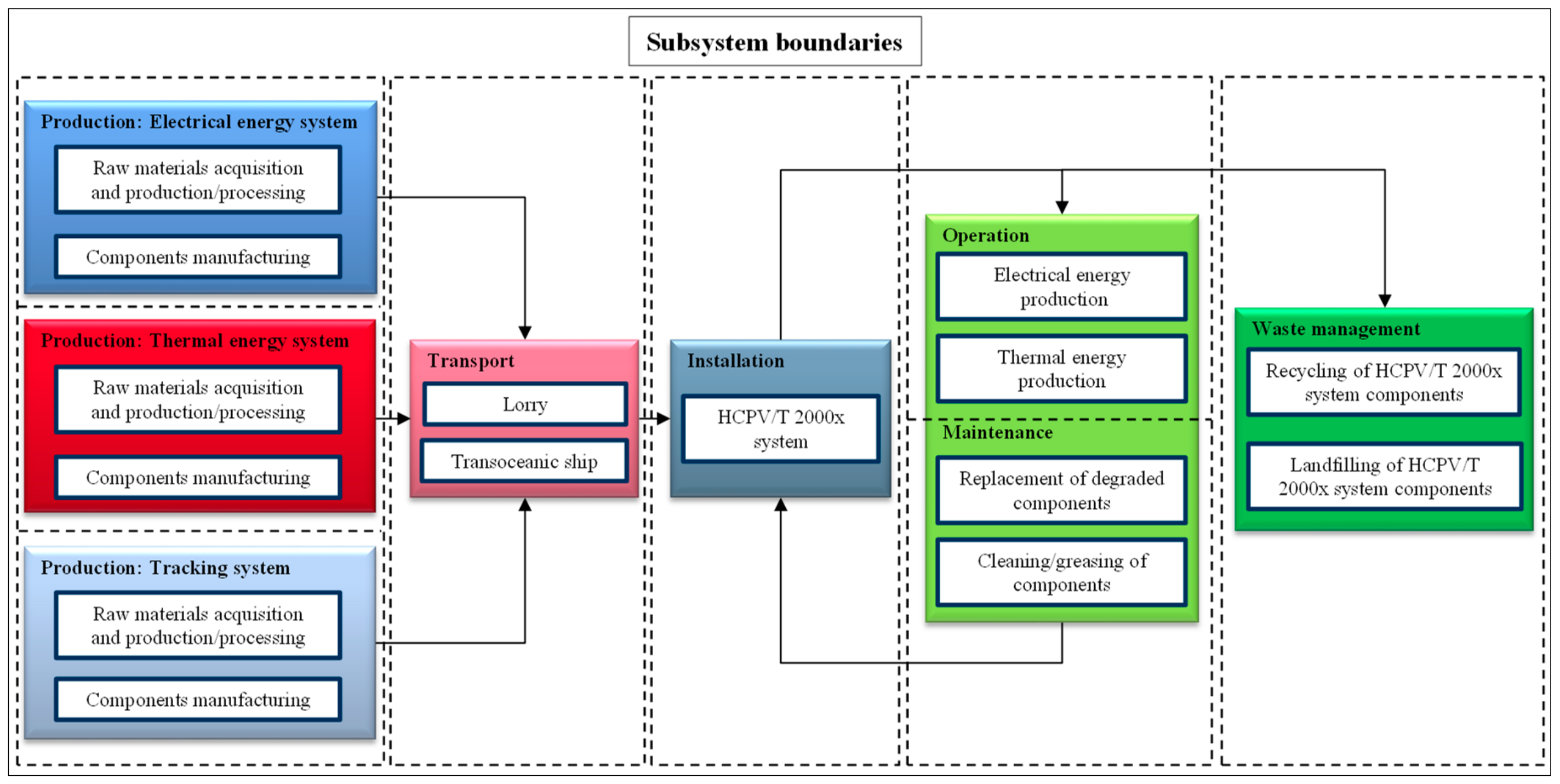

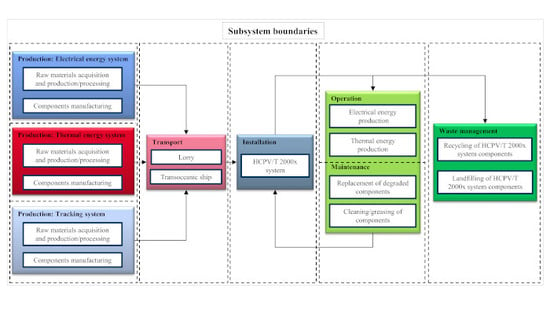

Figure 8 presents the percentage contribution by the subsystem boundaries presented in

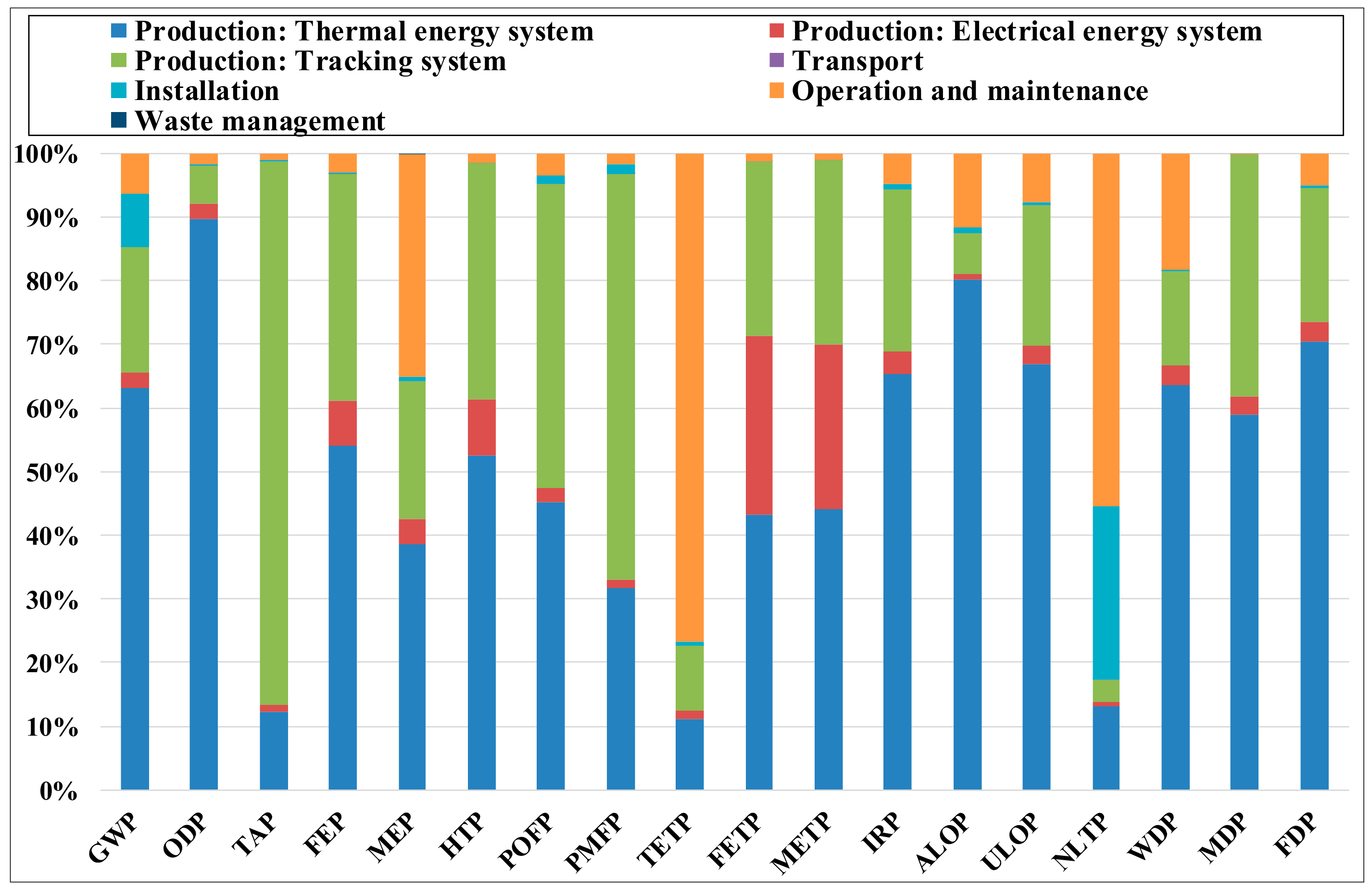

Figure 6. The results are presented separately for the Electrical Energy Impact Allocation (EEIA) and Thermal Energy Impact Allocation (TEIA) for the defined functional units of 1 kWh for the electrical energy and 1 kWh for the thermal energy. At the midpoint level as shown in

Figure 8, the

production: thermal energy and

tracking systems are the main contributors to the following 13 impact category indicators: GWP, ODP, TAP, FEP, MEP, HTP, POFP, PMFP, FETP, IRP and FDP. The main contributors to TETP, WDP and ALOP are the

operation and maintenance and

production: thermal energy system. The main contributors to METP are

production: thermal and electrical energy and

tracking systems. Finally, the main contributors to NLTP are

operation and maintenance and

installation.

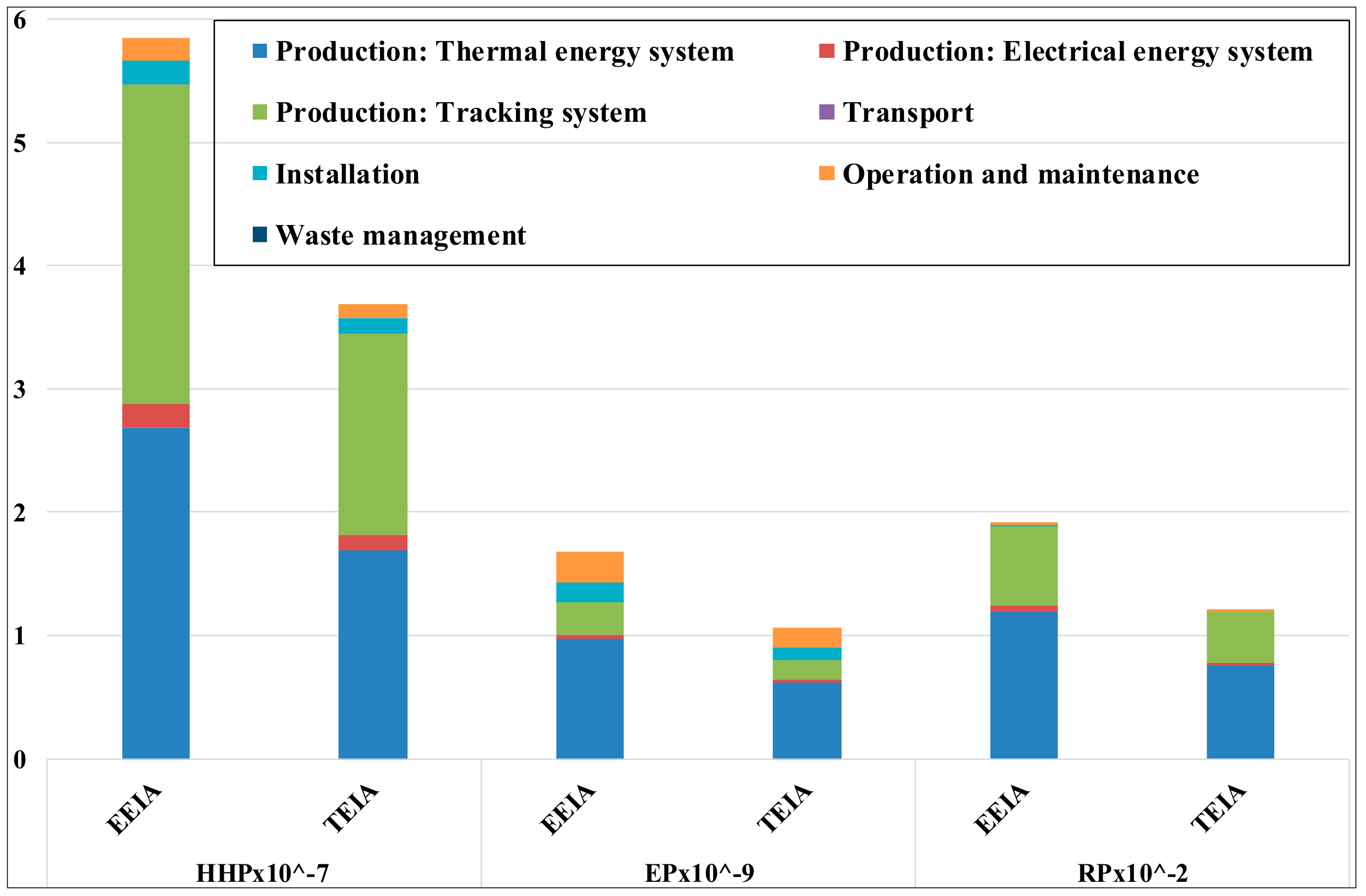

At the endpoint level as shown in

Figure 7, the main contributors to HHP and RP are the

production: thermal energy and

tracking systems while the main contributors to EP are the

production: thermal energy system and

operation and maintenance. The

production: thermal energy system contribution to the environmental impacts are mostly due to the raw materials acquisition/production and manufacturing of the demineralized water storage tank that are mostly accounted for by metalworking (mainly hot steel alloy rolling), welding and glass wool manufacturing process. Also, the

production: tracking system contribution is mostly due to the raw materials acquisition/product and manufacturing of the structural support and axle that are mostly accounted for by metalworking (mainly hot steel alloy rolling). The

production: electrical energy system contribution can be traced to the raw materials acquisition/production and manufacturing of the electrical wire connections. The contribution towards

operation and maintenance was due to the use of on-site land, demineralized water for thermal energy extraction and cleaning of reflective mirror, and lithium for greasing the metallic structural support while

installation was due to the use of on-site land and energy consumed by during the installation of the HCPV/T 2000x system.

These results were used to identify the hotspots within the system boundary in accordance to the EC [

50,

51], which state that the most relevant lifecycle stages are those that contribute over 80% (before normalization and weighting) to any of the baseline impact category indicators.

Figure 8 shows that at the midpoint level, the

production: thermal energy system,

production: tracking system,

operation and maintenance subsystem boundaries are the identified hotspots, because on average across the 18 environmental impact category indicators, they are responsible for 92% of the environmental impacts (50%, 29% and 13% respectively). However,

Figure 7 shows that at the endpoint level, the

production: thermal energy system and

production: tracking system subsystem boundaries are the identified hotspots, because on average across the 3 environmental impact category indicators, they are responsible for 87% of the environmental impacts (55% and 32% respectively). The identification of

production: tracking system as a hotspot and its cause is in agreement with [

15,

52] who reported that the LCA study of HCPV system identify the tracking system as a hotspot.

4.2. Comparison of Midpoint Results with Literature

The midpoint environmental impact indicators of the HCPV/T 2000x system from this study were compared with the results reported in the literature that investigated the midpoint environment impact of the cogeneration systems for the case studies in Italy, Mexico and the UK (

Table 5 and

Table 6). In addition,

Table 7 and

Figure 9 show the comparison of the lifecycle environmental impacts of this study in comparison to RES and non-RES technologies in six world regions (China, OECD Europe, OECD North America, Latin America, Africa and Middle East), and the global scale. The median values of the literature case studies were reported in

Table 5 and

Table 7 and

Figure 9 because different scenarios (SC) or types of energy system technology were studied and it was less affected by outliers. In order to maintain consistency, the impact indicator units of MWh were converted to kWh.

Table 5 presents several system boundary environmental EEIA of the HCPV/T 2000x system compared with the cradle to grave of the Wood Biomass-Combined Heat and Power (WB-CHP) [

46] and Anaerobic Digestion-Combined Heat and Power-Organic Rankine Cycle CHP (AD-CHP-ORC) [

47] systems located in Italy. The WB-CHP system uses wood-based biomass from the forest and agricultural activities as a source of heat to produce electrical energy. The analyzed WB-CHP considered four alternative SC of biomass sources: “residues from natural regeneration forestry and industrial activities as feedstock” (SC1), rotation forestry of poplar (SC2), rotation forestry of willow (SC3) and “residues from natural forests and from traditional poplar plantations” (SC4). It was found that the GWP, TAP, FDP, POFP and MEP of the HCPV/T 2000x system were 8–585% lower than the WB-CHP system. In opposite, the remaining impact indicators were 6–89% higher than WB-CHP system. The main reason for the higher environmental impacts seems to be the processes that include: biomass transportation from forest stands to power plant site, biomass combustion in CHP system and diesel consumption in forest machinery for the production of biomass feedstock used in SC2, SC3 and SC4, all of which contributes to the emission of substances; mainly nitrogen oxides (NO

x), CO

2 and Particulate matter (PM) [

46]. The AD-CHP-ORC system uses the AD process as a source of low-grade heat to produce electrical energy. The FDP, TAP, GWP, and MEP of the HCPV/T 2000x system were 30–4224% lower while the remaining impact indicators were 8–94% higher than the AD-CHP-ORC system. The main reason for increasing of the environmental impacts of the AD-CHP-ORC system is probably as a result diesel consumption for feedstock production and transport (resulting in the emission of NO

x, CO

2, PM), and methane (CH

4) and nitrogen dioxide (NO

2) emissions from digestate during storage [

46,

47].

Table 5 also presents system boundary GWP and/or TAP for EEIA and TEIA of the HCPV/T 2000x system compared with the cradle to grave of the Stirling Engine micro-CHP (SE-micro-CHP) [

48] and industrial CHP systems [

49] for the case studies in the UK. The SE-micro-CHP system is similar in shape and size to a residential domestic gas boiler while the industrial CHP plant is an operational plant that both produces electrical and thermal energy. The system boundary of GWP for EEIA and TEIA of the HCPV/T 2000x system showed to be lower for 182% and 183% respectively while the TAP higher for 90% and 108% comparing to the SE-micro-CHP system. The system boundary GWP for EEIA of the of the HCPV/T 2000x system showed to be 49% lower comparing to the industrial CHP. The main reason for the higher GWP of SE-micro-CHP system is probably as a result of fuel (natural gas) combustion [

48,

49].

Table 6 presents several operation and maintenance subsystem boundary environmental EEIA and TEIA of the HCPV/T 2000x system compared with the operational lifecycle stage of the Steam Turbine-CHP (ST-CHP), Gas Turbine- Heat Recovery Steam Generator-CHP (GT-HRSG-CHP), Gas Turbine-Post Combustion Carbon Capture-CHP and (GT-PCC-HRSG-CHP) systems for the case studies in Mexico [

54]. The ST-SHP system is a conventional plant, which uses high-pressure steam, while the GT-HRSG-CHP and GT-PCC-HRSG-CHP systems retrofitted from the ST-SHP system are gas turbine systems incorporated with HRSG, and PCC-HRSG respectively. It was found that the HCPV/T 2000x system operation and maintenance subsystem boundary EEIA and TEIA GWP, TAP, POFP, PMFP and FDP were 707–15474% lower than the ST-CHP and GT-HRSG-CHP systems. In addition, the HCPV/T 2000x system operation and maintenance subsystem boundary EEIA and TEIA TAP, HTP, POFP, PMFP, FETP, METP and FDP were 24–6577% lower than GT-PCC-HRSG-CHP system. The main reason for the higher environmental impacts of ST-CHP, GT-HRSG-CHP and GT-PCC-HRSG-CHP systems is probably as a result of fuel (natural gas) combustion, which contributes to the emission of substances; mainly NO

x, CO

2, carbon monoxide (CO), PM, CH

4, and Volatile Organic Compounds (VOC). The ST-CHP and GT-PCC-HRSG-CHP systems have highest and lowest environmental impacts respectively, because of the reduction in fuel (natural gas) for combustion by the GT-PCC-HRSG-CHP systems [

54].

Table 7 presents several system boundary environmental EEIA of the HCPV/T 2000x system compared with the lifecycle environmental impacts of RES (PV, CSP, Hydropower and Wind power) and non-RES (Coal and Natural gas) systems respectively, for six world regions; China—Coal and Natural gas systems, OECD Europe—Wind power systems, OECD North America—PV systems, Latin America—Hydropower systems, and Africa and Middle East—CSP systems. It can be seen that for all impacts, the PV systems are 50%–96%, CSP systems 60%–96%, hydropower systems 43%–98% and wind systems 60%–98% lower than the HCPV/T 2000x system. The higher environmental impact of the HCPV/T 2000x system is probably as a result of higher input of raw materials, energy and heating processes during the production of the thermal energy and tracking systems. The non-RES systems in comparison with HCPV/T 2000x system presented different values for the different EEIA, as follows: the GWP, FEP and POFP of Coal systems were 13%–306% lower while TAP, HTP, PMFP and FDP of the HCPV/T 2000x system 34%–97% higher; the GWP and TAP of Natural gas systems 27%–198% lower while FEP, HTP, POFP, PMFP and FDP of the HCPV/T 2000x system 5%–99% higher [

53]. The environmental impact of the HCPV/T 2000x system is higher probably as a result of the higher primary energy demand required during raw materials acquisition/production and manufacturing of the thermal energy and tracking systems.

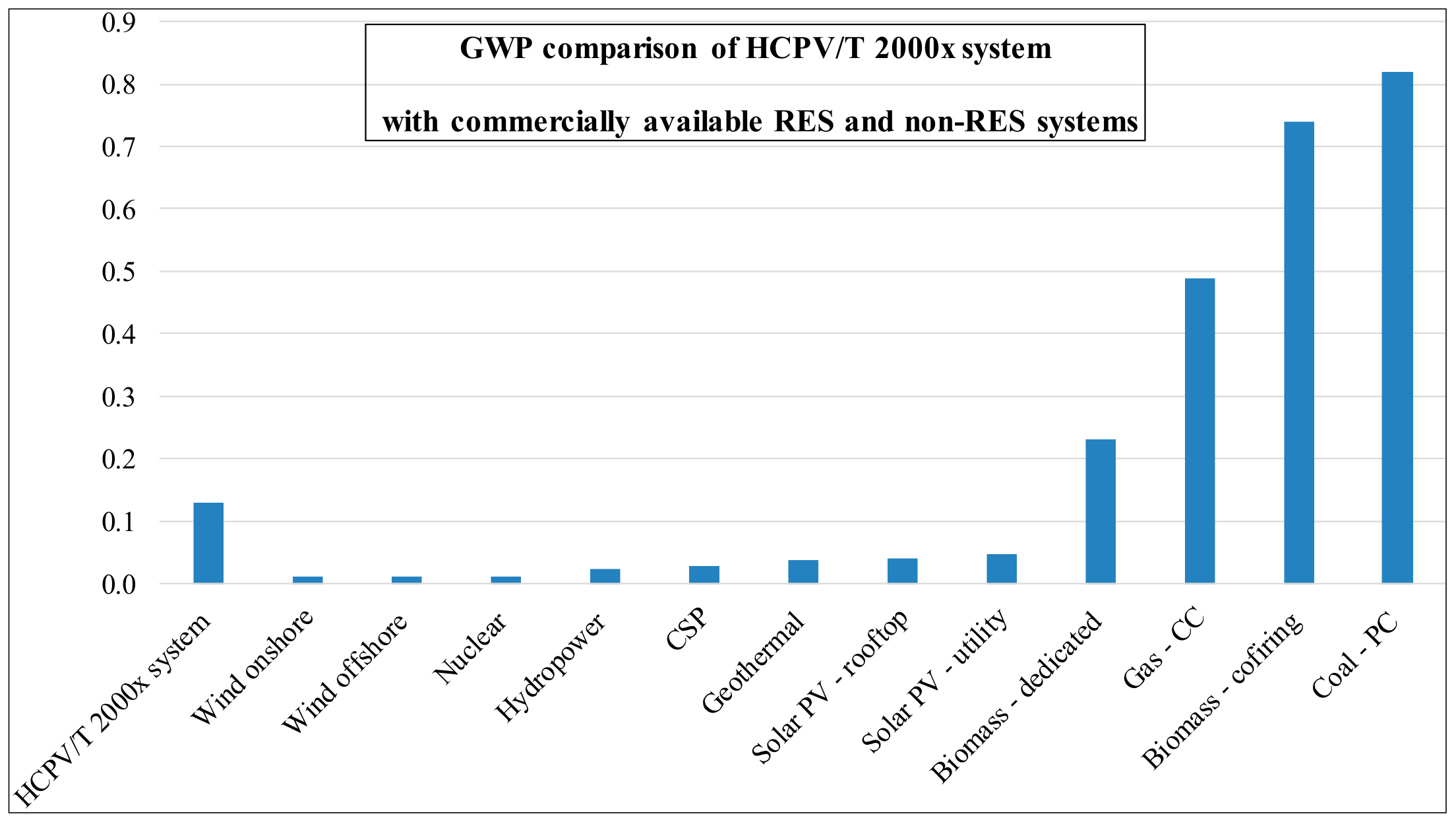

Figure 9 presents the system boundary GWP for EEIA compared with commercially available RES and non-RES systems based on the global average of lifecycle GWP. The RES technologies are wind offshore, solar PV—rooftop, wind onshore, CSP geothermal and solar PV—utility while the non-RES technologies are nuclear, coal power plant (pulverized plant), gas power plant (combined cycle), biomass power plant (co-firing), biomass power plant and hydropower. The GWP of the RES systems is 63–92% lower than the HCPV/T 2000x system. The GWP of the non-RES technologies (except for nuclear) is 77%–532% higher than the HCPV/T 2000x system while the GWP of the nuclear is 91% lower. The main reason for the higher GWP of the non-RES systems is probably as a result of fossil fuel combustion [

53] while for the RES systems, it is as a result of the higher primary energy demand required during raw materials acquisition/production and manufacturing of the thermal energy and tracking systems [

15,

52].

Summary of comparison.

The system boundary (including the operation and maintenance subsystem boundary) environmental impacts (including GWP) of the HCPV/T 2000x system is lower than lifecycle environmental impacts of the non-RES systems (including fuel-based CHP systems). This is mainly due to the fuel (natural gas and diesel) combustion/consumption by the CHP system. However, comparison with RES systems shows higher environmental impacts in most categories. In many cases there are explanations why and need to be looked at system by system.

As an example, the system boundary GWP of HCPV/T 2000x system for EEIA (estimated at 130 g CO

2-eq/kWh) was compared with the literature findings. The estimated GWP for HCPV systems was found to be no more than 50 g CO

2-eq/kWh [

8]. It should be noted that those literature case studies did not include a reverse return system, which is the most significant contributor to the thermal energy system of the HCPV/T 2000x system. As mentioned in

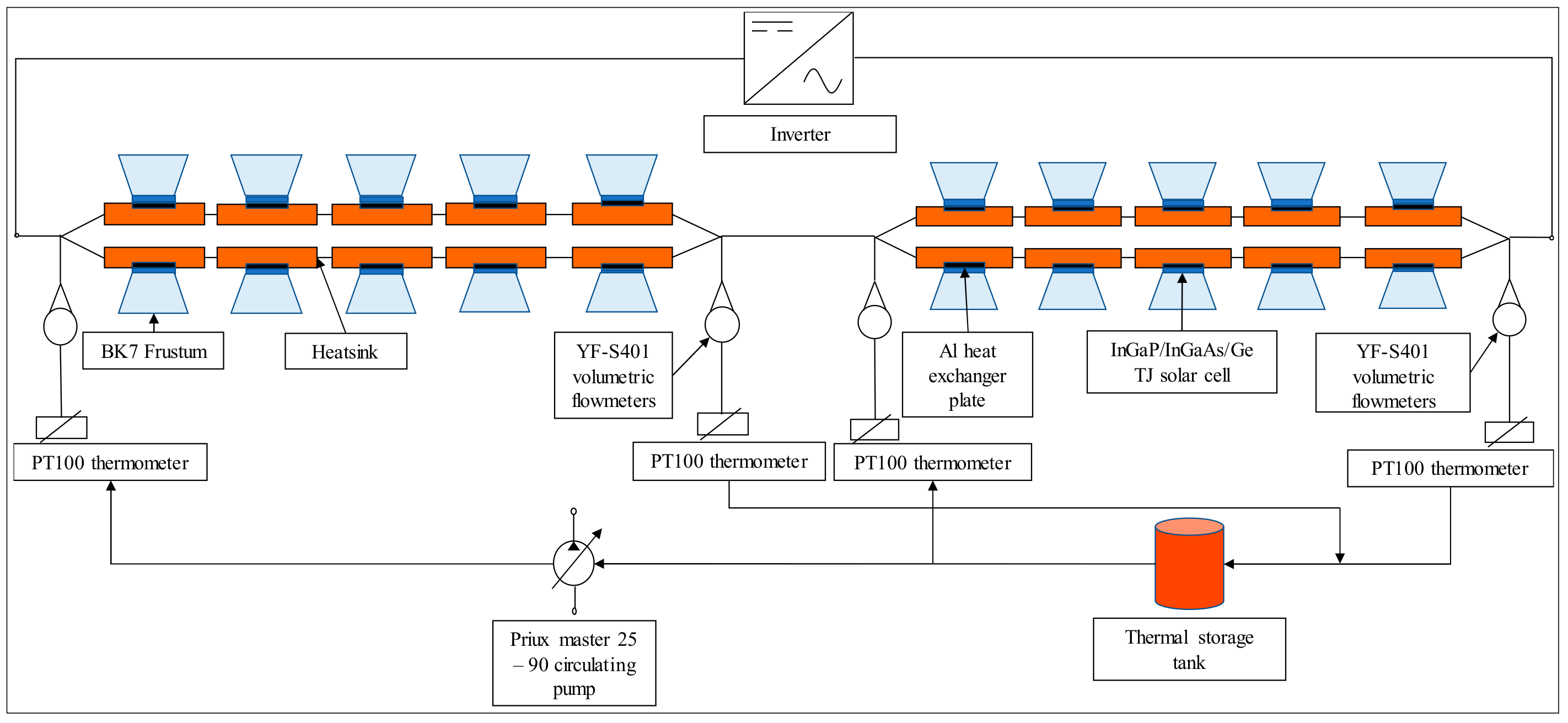

Table 1, the reverse return system consists of several components that include active heat sink, and pipes with supply and return connection to the demineralized water storage tank. The demineralized water storage tank is the main contributor to the reverse return system due to the raw materials acquisition/production and manufacturing of the demineralized water storage tank; that are mostly accounted for by metalworking (mainly hot steel alloy rolling), welding and glass wool manufacturing process. The discontinuation of the GWP by the reverse return system (82 g CO

2-eq/kWh) leads to the reduced GWP of 48 g CO

2-eq/kWh which is similar to CPV/HCPV systems [

8].

4.3. Energy and Environmental Impact Performance Gap

One of the problems with commercial grade silicon PV cell is the reduction in efficiency as the cell temperature increases due to the lack of effective cooling of the cells in order to maintain its optimum operating temperature. The temperature coefficient is used to quantify the degree to which the cell temperature influences its efficiency. The review by Dubey et al. [

56], estimated the average temperature coefficient of the commercial-grade silicon PV cell to be ~0.45%/°C. The issue of the relatively high temperature coefficient can be overcome by using MJSC with relatively low temperature coefficient. For instance, the temperature coefficient of InGaP/InGaAs/Ge solar cell is 0.04%/°C [

57]. However, high concentration ratio increases solar radiation flux density required by the MJSC, which has an influence on the MJSC efficiency. The study by Chen et al. [

19], shows an initial increase in electrical and thermal efficiency at low concentration ratio but decreases and increases respectively, at high concentration ratio. Therefore, HCPV/T systems that receive high solar radiation flux requires cooling technology in order to minimize the reduction in electrical efficiency. In this study, the HCPV/T 2000x system has an active cooling system (which consists of active heat sink and reverse return system) that simultaneously cools the InGaP/InGaAs/Ge solar cell, extracts thermal energy and produce electrical energy. As a result, the overall efficiency of the HCPV/T 2000x system is ~80%. The extraction of thermal energy replaces the need for traditional system such as a boiler [

10]. In addition to the high efficiency of the HCPV/T 2000x system, the combined lifecycle environmental impact for EEIA and TEIA is lower than fuel-based CHP, traditional non-RES, and potentially lower than RES if the defined thermal energy functionality unit of 1 kWh is met by fuel-based CHP and/or traditional non-RES.

The theoretical study of an HCPV/T system by Renno and Petito [

58], showed that the system can be used to satisfy electric, heating and cooling demand for domestic application in the south of Italy. In Italy, the typical annual household electricity and hot water demand in 2016 were ~2000 kWh/household/year each [

21,

22]. Therefore, the operational HCPV/T 2000x system located in Palermo, Sicily (south of Italy) can be applied as a stand-alone system used to satisfy almost 80% of electricity for a typical residential house as well as 100% of hot water demand. The application of the HCPV/T 2000x system as a stand-alone system instead of grid-connected eliminates the infrastructural challenges of grid connection (including its associated environmental impacts) and replaces the need for traditional system non-RES [

58].

The limitation of using HCPV/T systems in regions of high DNI can be mitigated by adopting the prospect highlighted by Islam et al. [

6], which is the electricity generation and exportation from desert regions of the MENA to Europe. Therefore, HCPV/T 2000x system can be potentially centralized at a large scale in the regions of MENA, Mediterranean and the Sun Belt, in order to supply electricity to neighboring regions with low DNI. The environmental impact associated with the power transmission from those regions can be potentially mitigated by displacing traditional non-RES systems.