Thermo-Poroelastic Analysis of Induced Seismicity at the Basel Enhanced Geothermal System

Abstract

1. Introduction

2. Materials and Methods

2.1. Frictional Strength and Resistance of Faults

Rate-and-State Models for Interfaces

2.2. Thermo-Hydro-Mechanical 3D Model of Fault Reactivation

2.3. Case Study: The Deep Heat Mining Project in Basel, Switzerland

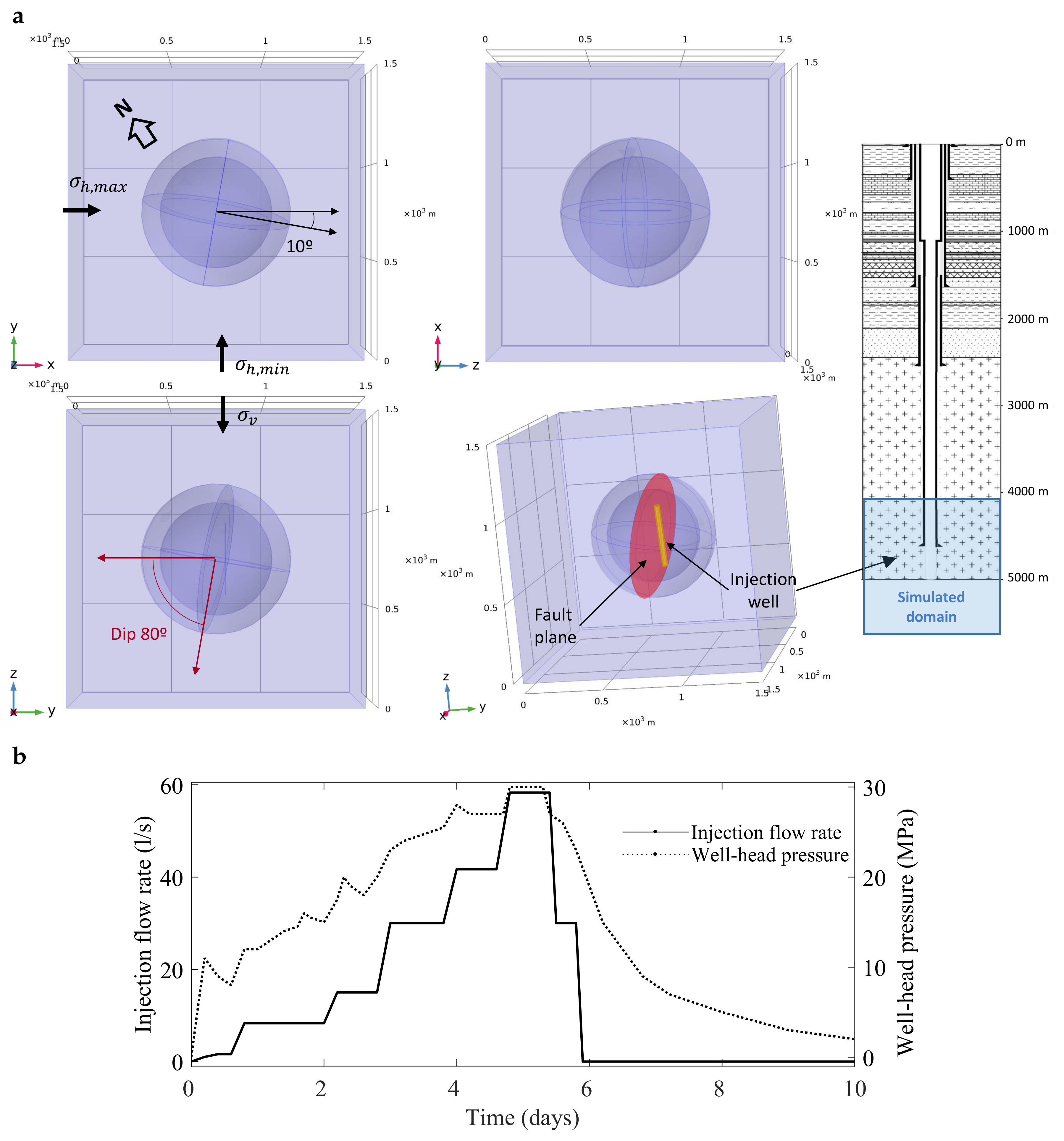

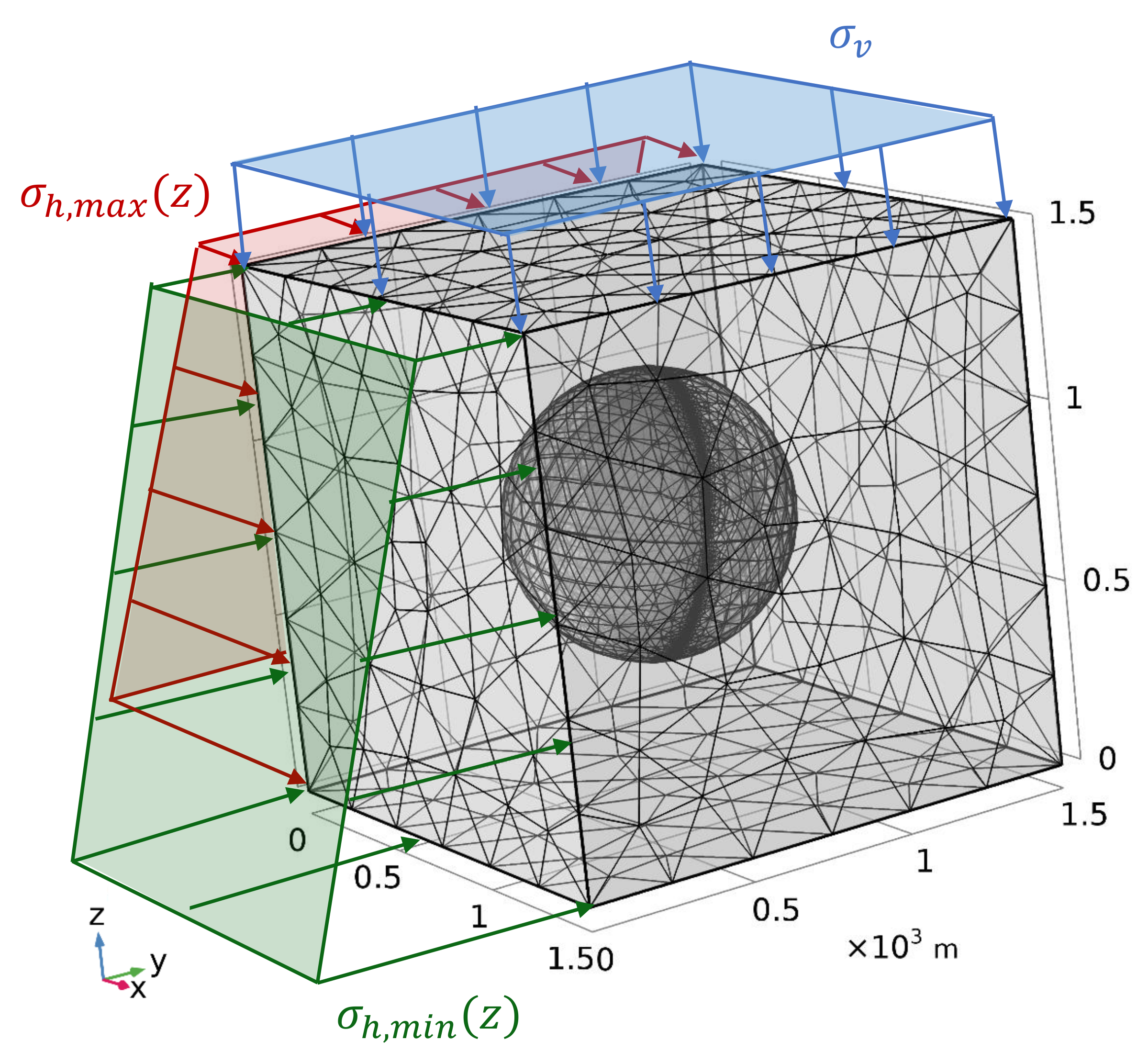

2.4. The Basel 3D Model

3. Results and Discussion

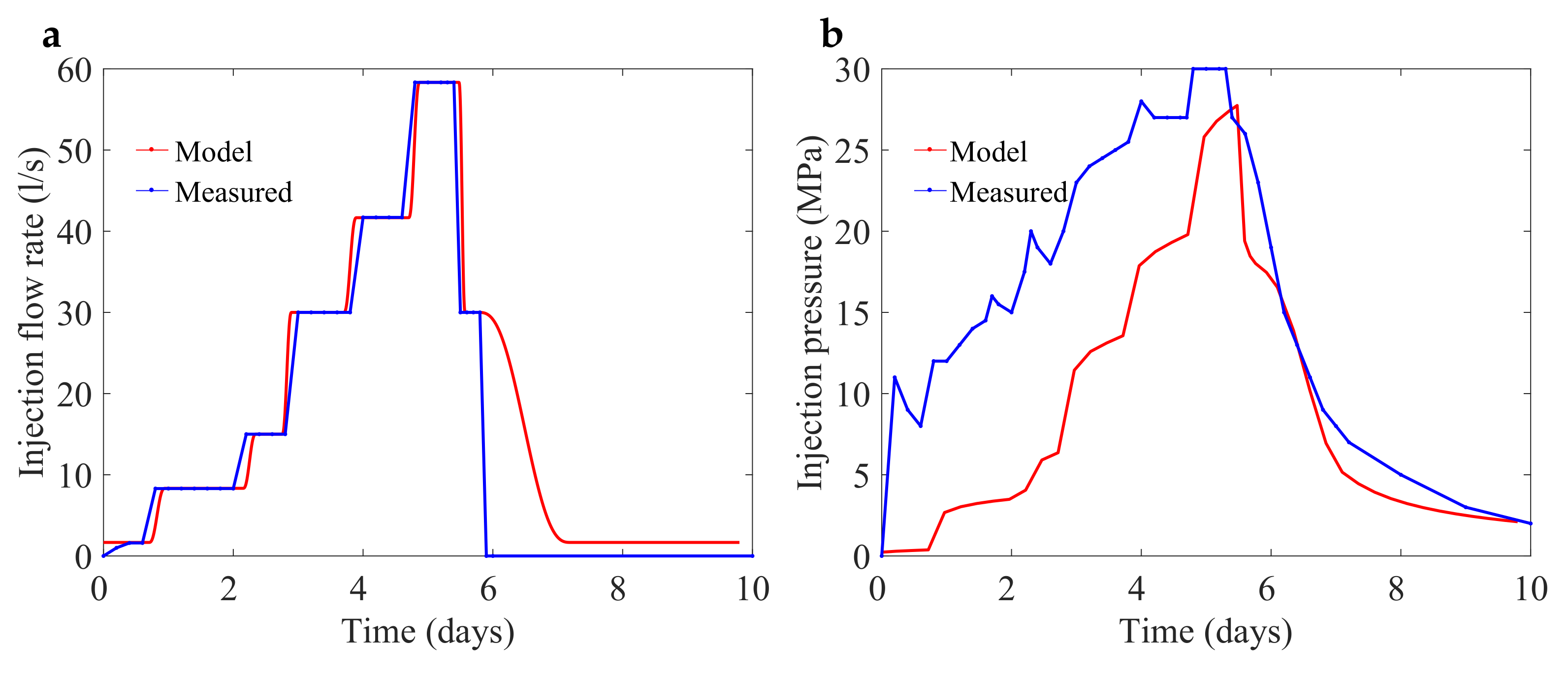

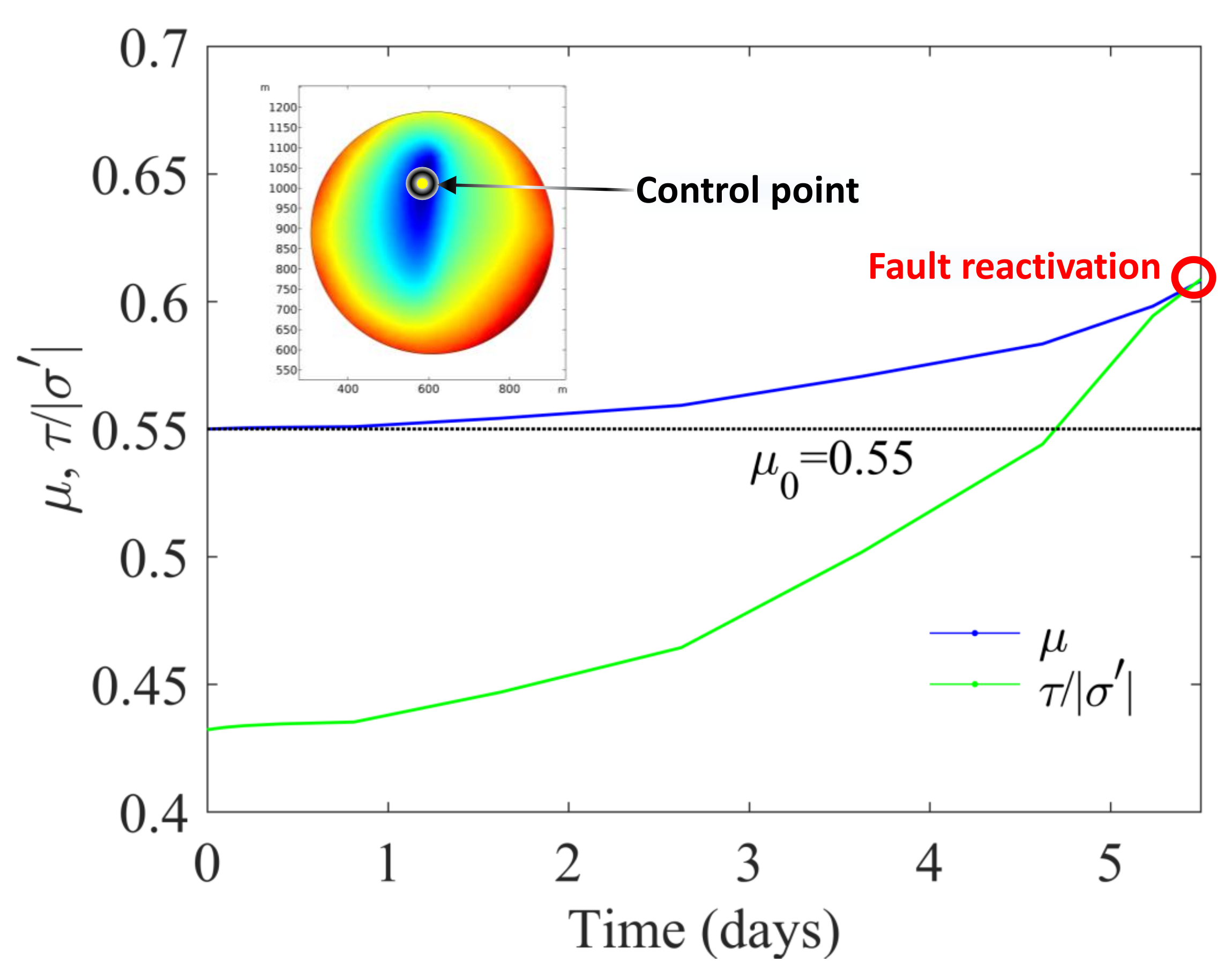

3.1. Calibration

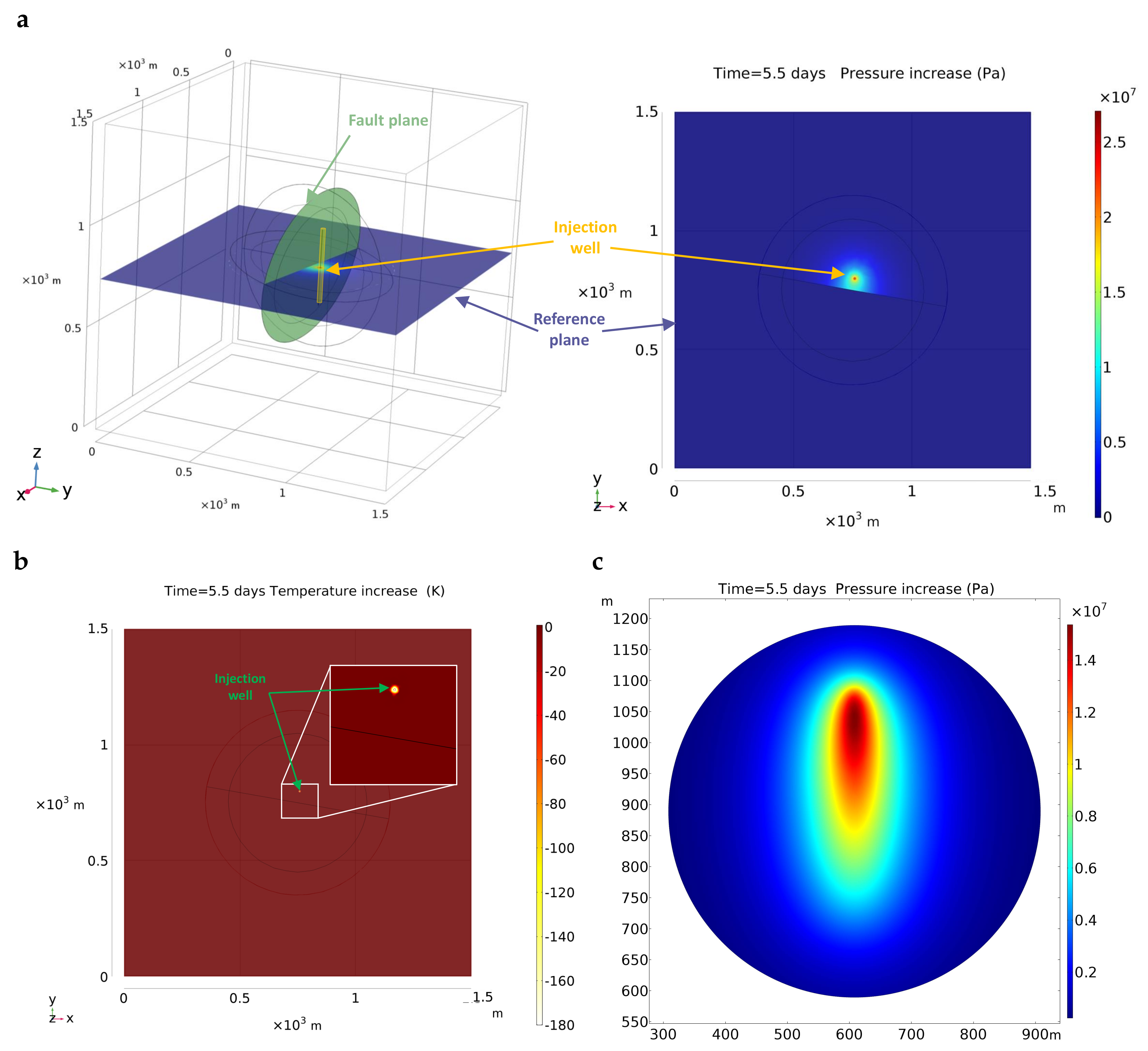

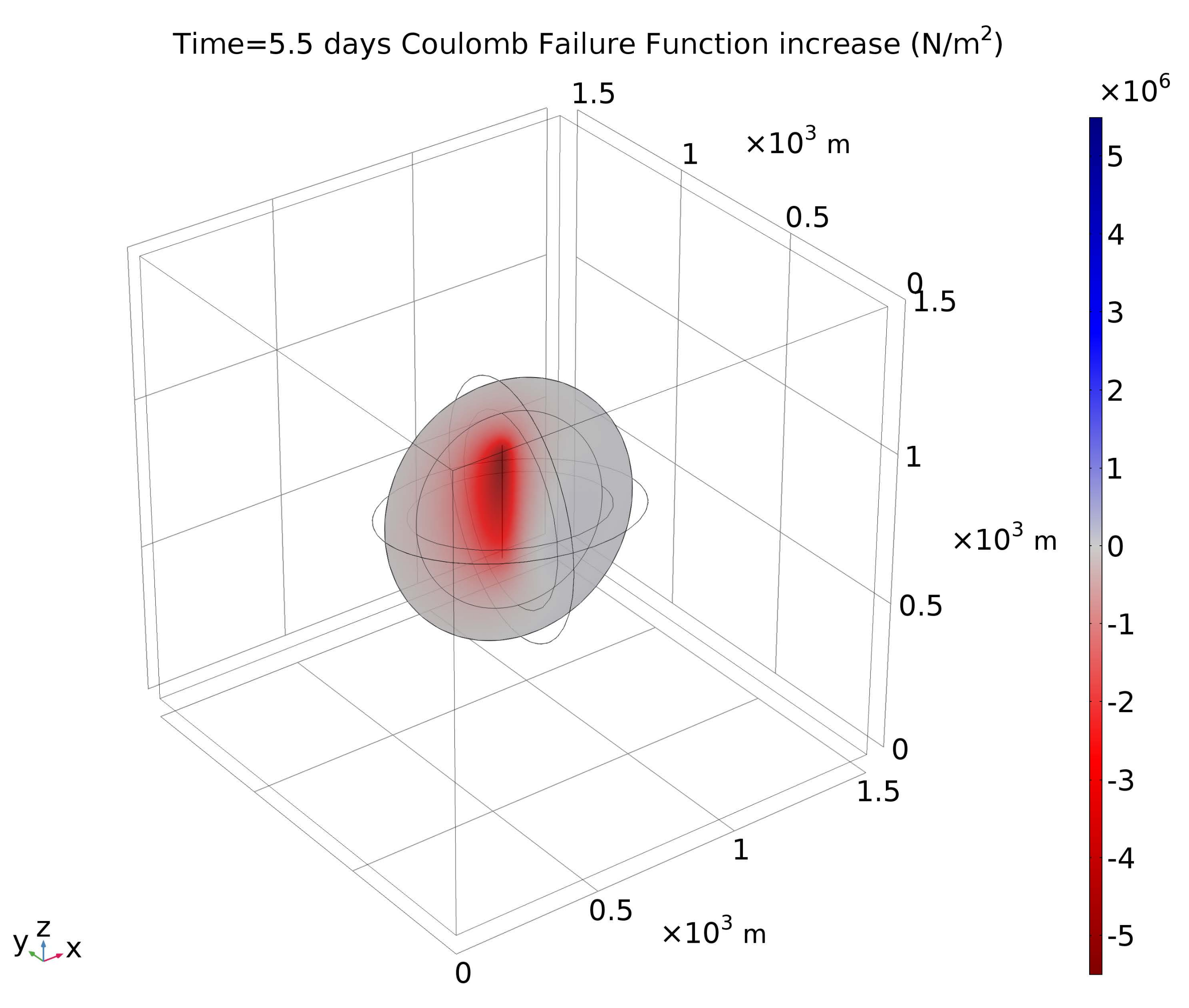

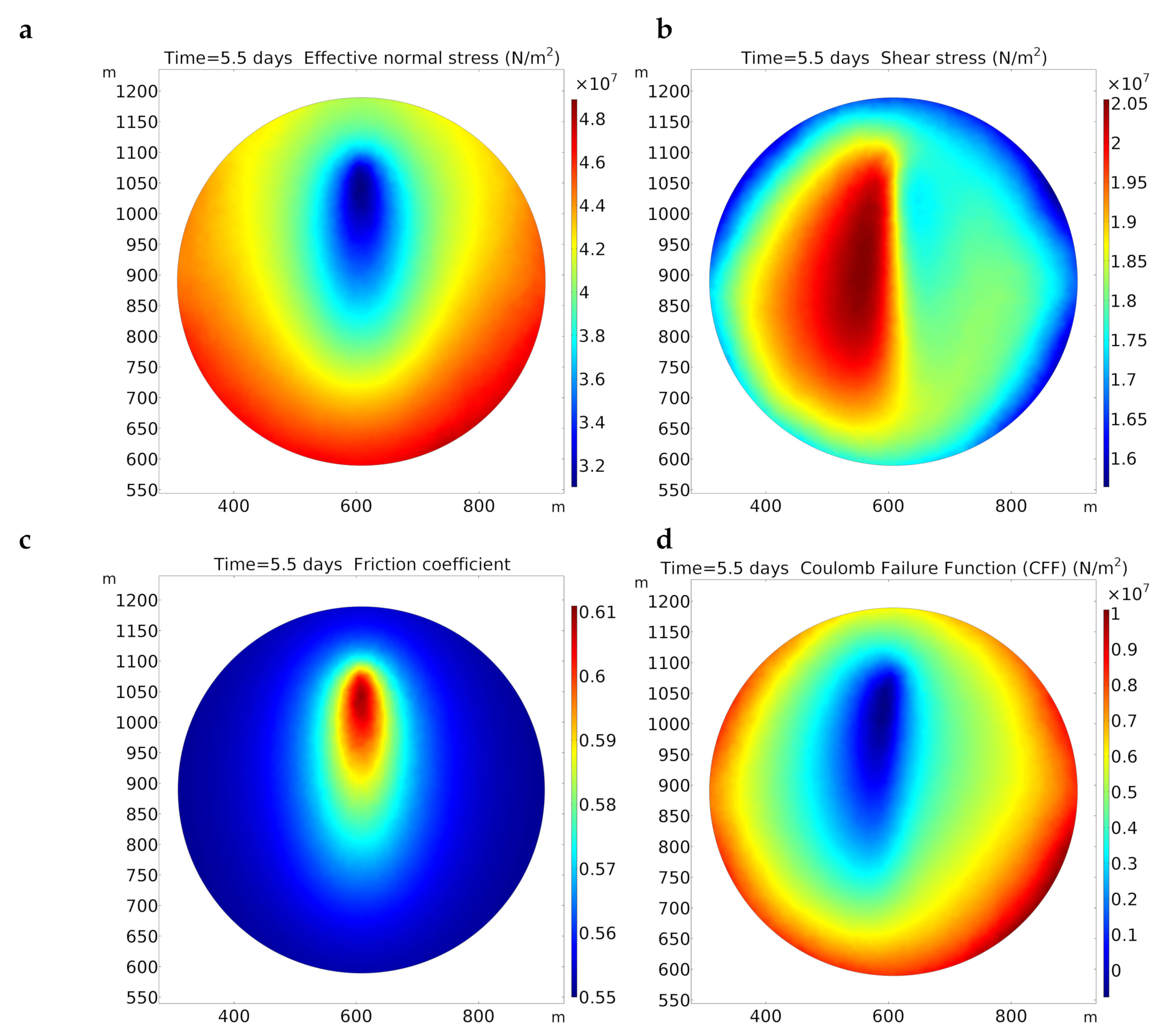

3.2. Fault Reactivation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Colglazier, W. Sustainable development agenda: 2030. Int. J. Rock. Mech. Min. Sci. 2015, 349, 1048–1050. [Google Scholar] [CrossRef] [PubMed]

- MIT-Energy-Initiative. The Future of Geothermal Energy: Impact of Enhanced Geothermal Systems (EGS) on the United States in the 21st Century; Massachusetts Institute of Technology: Cambridge, MA, USA, 2006; pp. 1–372. [Google Scholar]

- Mahbaz, S.; Dehghani-Sanij, A.; Dusseault, M.; Nathwani, J. Enhanced and integrated geothermal systems for sustainable development of Canada’s northern communities. Sustain. Energy Technol. Assess. 2020, 37, 100565. [Google Scholar] [CrossRef]

- Kazemi, A.; Mahbaz, S.; Dehghani-Sanij, A.; Dusseault, M.; Fraser, R. Performance Evaluation of an Enhanced Geothermal System in the Western Canada Sedimentary Basin. Renew. Sustain. Energ. Rev. 2019, 113, 109278. [Google Scholar] [CrossRef]

- Kinney, C.; Dehghani-Sanij, A.; Mahbaz, S.; Dusseault, M.B.; Nathwani, J.S.; Fraser, R. Geothermal Energy for Sustainable Food Production in Canada’s Remote Northern Communities. Energies 2019, 12, 4058. [Google Scholar] [CrossRef]

- Soltani, M.; Kashkooli, F.M.; Dehghani-Sanij, A.R.; Kazemi, A.R.; Bordbar, N.; Farshchi, M.J.; Elmi, M.; Gharali, K.; Dusseault, M.B. A comprehensive study of geothermal heating and cooling systems. Sustain. Cities Soc. 2019, 44, 793–818. [Google Scholar] [CrossRef]

- Soltani, M.; Moradi-Kashkooli, F.; Dehghani-Sanij, A.R.; Nokhosteen, A.; Ahmadi-Joughi, A.; Gharali, K.; Mahbaz, S.B.; Dusseault, M. A comprehensive review of geothermal energy evolution and development. Int. J. Green Energy 2019, 16, 971–1009. [Google Scholar] [CrossRef]

- Rinaldi, A.P.; Rutqvist, J. Joint opening or hydroshearing? Analyzing a fracture zone stimulation at Fenton Hill. Geothermics 2019, 77, 83–98. [Google Scholar] [CrossRef]

- Rinaldi, A.P.; Rutqvist, J.; Sonnenthal, E.L.; Cladouhos, T.T. Coupled THM Modeling of Hydroshearing Stimulation in Tight Fractured Volcanic Rock. Transport Porous Media 2014, 108, 131–150. [Google Scholar] [CrossRef]

- Charléty, J.; Cuenot, N.; Dorbath, L.; Dorbath, C.; Haessler, H.; Frogneux, M. Large earthquakes during hydraulic stimulations at the geothermal site of Soultz-sous-Forêts. Int. J. Rock. Mech. Min. Sci. 2007, 44, 1091–1105. [Google Scholar] [CrossRef]

- Baisch, S.; Vörös, R.; Weidler, R.; Wyborn, D. Investigation of fault mechanisms during geothermal reservoir stimulation experiments in the Cooper Basin, Australia. Bull. Seismol. Soc. Am. 2009, 99, 148–158. [Google Scholar] [CrossRef]

- Fehler, M.C. Stress control of seismicity patterns observed during hydraulic fracturing experiments at the Fenton Hill hot dry rock geothermal energy site, New Mexico. Int. J. Rock. Mech. Min. Sci. 1989, 26, 211–219. [Google Scholar] [CrossRef]

- Parker, R. The Rosemanowes HDR project 1983–1991. Geothermics 1999, 28, 603–615. [Google Scholar] [CrossRef]

- Pine, R.J.; Batchelor, A.S. Downward migration of shearing in jointed rock during hydraulic injections. Int. J. Rock. Mech. Min. Sci. 1984, 21, 249–263. [Google Scholar] [CrossRef]

- Ziagos, J.; Phillips, B.R.; Boyd, L.; Jelacic, A.; Stillman, G.; Hass, E. A technology roadmap for strategic development of enhanced geothermal systems. In Proceedings of the 38th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 11–13 February 2013; pp. 11–13. [Google Scholar]

- Santillán, D.; Juanes, R.; Cueto-Felgueroso, L. Phase field model of fluid–driven fracture in elastic media: Immersed fracture formulation and validation with analytical solutions. J. Geophys. Res. Solid Earth 2017, 122, 2565–2589. [Google Scholar] [CrossRef]

- Santillan, D.; Mosquera, J.; Cueto-Felgueroso, L. Fluid-driven fracture propagation in heterogeneous media: Probability distributions of fracture trajectories. Phys. Rev. E 2017, 96, 053002. [Google Scholar] [CrossRef]

- Santillan, D.; Mosquera, J.; Cueto-Felgueroso, L. Phase-field model for brittle fracture. Validation with experimental results and extension to dam engineering problems. Eng. Fracture Mech. 2017, 178, 109–125. [Google Scholar] [CrossRef]

- Santillán, D.; Juanes, R.; Cueto-Felgueroso, L. Phase field model of hydraulic fracturing in poroelastic media: Fracture propagation, arrest, and branching under fluid injection and extraction. J. Geophys. Res. Solid Earth 2018, 123, 2127–2155. [Google Scholar] [CrossRef]

- Riahi, A.; Damjanac, B. Numerical study of hydro-shearing in geothermal reservoirs with a preexisting discrete fracture network. In Proceedings of the Thirty–Eighth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 11–13 February 2013. [Google Scholar]

- Jeanne, P.; Guglielmi, Y.; Rutqvist, J.; Nussbaum, C.; Birkholzer, J. Permeability Variations Associated With Fault Reactivation in a Claystone Formation Investigated by Field Experiments and Numerical Simulations. J. Geophys. Res. Solid Earth 2018, 123, 1694–1710. [Google Scholar] [CrossRef]

- Finnila, A.; Dershowitz, W.; Doe, T.; McLaren, R. Hydro-Shearing and Hydraulic Fracturing for Enhanced Geothermal Systems in Archetypical Normal, Strike-Slip, and Thrust Faulting Terrains. GRC Trans. 2015, 39, 1–19. [Google Scholar]

- Norbeck, J.H.; McClure, M.W.; Horne, R.N. Field observations at the Fenton Hill enhanced geothermal system test site support mixed-mechanism stimulation. Geothermics 2018, 74, 135–149. [Google Scholar] [CrossRef]

- Weingarten, M.; Ge, S.; Godt, J.W.; Bekins, B.A.; Rubinstein, J.L. High-rate injection is associated with the increase in US mid-continent seismicity. Science 2015, 348, 1336–1340. [Google Scholar] [CrossRef] [PubMed]

- Horton, S. Disposal of hydrofracking waste fluid by injection into subsurface aquifers triggers earthquake swarm in central Arkansas with potential for damaging earthquake. Seismol. Res. Lett. 2012, 83, 250–260. [Google Scholar] [CrossRef]

- Juanes, R.; Hager, B.H.; Herzog, H.J. No geologic evidence that seismicity causes fault leakage that would render large-scale carbon capture and storage unsuccessful. Proc. Natl. Acad. Sci. USA 2012, 109, E3623. [Google Scholar] [CrossRef] [PubMed]

- Vilarrasa, V.; Carrera, J. Geologic carbon storage is unlikely to trigger large earthquakes and reactivate faults through which CO2 could leak. Proc. Natl. Acad. Sci. USA 2015, 112, 5938–5943. [Google Scholar] [CrossRef] [PubMed]

- Brodsky, E.E.; Lajoie, L.J. Anthropogenic seismicity rates and operational parameters at the Salton Sea Geothermal Field. Science 2013, 341, 543–546. [Google Scholar] [CrossRef] [PubMed]

- Majer, E.L.; Baria, R.; Stark, M.; Oates, S.; Bommer, J.; Smith, B.; Asanuma, H. Induced seismicity associated with enhanced geothermal systems. Geothermics 2007, 36, 185–222. [Google Scholar] [CrossRef]

- Scholz, C.H. Earthquakes and friction laws. Nature 1998, 391, 37. [Google Scholar] [CrossRef]

- Cueto-Felgueroso, L.; Vila, C.; Santillan, D.; Mosquera, J.C. Numerical modeling of injection-induced earthquakes using laboratory-derived friction laws. Water Resour. Res. 2018, 54, 1–27. [Google Scholar] [CrossRef]

- Cueto-Felgueroso, L.; Santillán, D.; Mosquera, J.C. Stick-slip dynamics of flow-induced seismicity on rate and state faults. Geophys. Res. Lett. 2017, 44, 4098–4106. [Google Scholar] [CrossRef]

- De Simone, S.; Carrera, J.; Vilarrasa, V. Superposition approach to understand triggering mechanisms of post-injection induced seismicity. Geothermics 2017, 70, 85–97. [Google Scholar] [CrossRef]

- McGarr, A. Maximum magnitude earthquakes induced by fluid injection. J. Geophys. Res. Solid Earth 2014, 119, 1008–1019. [Google Scholar] [CrossRef]

- Mignan, A.; Karvounis, D.; Broccardo, M.; Wiemer, S.; Giardini, D. Including seismic risk mitigation measures into the Levelized Cost of Electricity in enhanced geothermal systems for optimal siting. Appl. Energy 2019, 238, 831–850. [Google Scholar] [CrossRef]

- Scholz, C.H. The Mechanics of Earthquakes and Faulting; Cambridge University Press: Cambridge, UK, 2002. [Google Scholar]

- Deichmann, N.; Giardini, D. Earthquakes Induced by the Stimulation of an Enhanced Geothermal System below Basel (Switzerland). Seismol. Res. Lett. 2009, 80, 784–798. [Google Scholar] [CrossRef]

- Beck, M.; Seitz, G.; Class, H. Volume-based modelling of fault reactivation in porous media using a visco-elastic proxy model. Transp. Porous Media 2016, 114, 505–524. [Google Scholar] [CrossRef]

- Borja, R.; Foster, C. Continuum mathematical modeling of slip weakening in geological systems. J. Geophys. Res. Solid Earth 2007, 112. [Google Scholar] [CrossRef]

- Rutqvist, J.; Birkholzer, J.; Cappa, F.; Tsang, C.F. Estimating maximum sustainable injection pressure during geological sequestration of CO2 using coupled fluid flow and geomechanical fault-slip analysis. Energy Conv. Manag. 2007, 48, 1798–1807. [Google Scholar] [CrossRef]

- Segura, J.M.; Carol, I. Coupled HM analysis using zero-thickness interface elements with double nodes. Part I: Theoretical model. Int. J. Numer. Anal. Meth. Geomech. 2008, 32, 2083–2101. [Google Scholar] [CrossRef]

- Segura, J.M.; Carol, I. Coupled HM analysis using zero-thickness interface elements with double nodes. Part II: Verification and application. Int. J. Numer. Anal. Meth. Geomech. 2008, 32, 2103–2123. [Google Scholar] [CrossRef]

- Ferronato, M.; Gambolati, G.; Janna, C.; Teatini, P. Numerical modelling of regional faults in land subsidence prediction above gas/oil reservoirs. Int. J. Numer. Anal. Meth. Geomech. 2008, 32, 633–657. [Google Scholar] [CrossRef]

- Ghassemi, A.; Tao, Q. Thermo-poroelastic effects on reservoir seismicity and permeability change. Geothermics 2016, 63, 210–224. [Google Scholar] [CrossRef]

- Jha, B.; Juanes, R. Coupled multiphase flow and poromechanics: A computational model of pore pressure effects on fault slip and earthquake triggering. Water Resour. Res. 2014, 50, 3776–3808. [Google Scholar] [CrossRef]

- Morris, J.P.; Hao, Y.; Foxall, W.; McNab, W. A study of injection-induced mechanical deformation at the In Salah CO2 storage project. Int. J. Greenhouse Gas Control 2011, 5, 270–280. [Google Scholar] [CrossRef]

- Rice, J.R. Heating and weakening of faults during earthquake slip. J. Geophys. Res. Solid Earth 2006, 111. [Google Scholar] [CrossRef]

- Dieterich, J.H. Earthquake nucleation on faults with rate-and state-dependent strength. Tectonophysics 1992, 211, 115–134. [Google Scholar] [CrossRef]

- Dieterich, J.H.; Linker, F.M. Fault Stability Under Conditions of Variable Normal Stress. Geophys. Res. Lett. 1992, 19, 1691–1694. [Google Scholar] [CrossRef]

- Kilgore, B.; Beeler, N.M.; Lozos, J.; Oglesby, D. Rock friction under variable normal stress. J. Geophys. Res. Solid Earth 2017, 122, 7042–7075. [Google Scholar] [CrossRef]

- Andrés, S.; Santillán, D.; Mosquera, J.C.; Cueto-Felgueroso, L. Delayed weakening and reactivation of rate-and-state faults driven by pressure changes due to fluid injection. J. Geophys. Res. Solid Earth 2019. [Google Scholar] [CrossRef]

- Wyss, R.; Link, K. Actual Developments in Deep Geothermal Energy in Switzerland. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 19–25 April 2015. [Google Scholar]

- Meier, P.M.; Alcolea Rodríguez, A.; Bethmann, F. Lessons Learned from Basel: New EGS Projects in Switzerland Using Multistage Stimulation and a Probabilistic Traffic Light System for the Reduction of Seismic Risk. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 19–25 April 2015. [Google Scholar]

- Swiss Seismological Service. DHM Project Description. 2019. Available online: http://www.seismo.ethz.ch/en/earthquakes/monitoring/geothermal-energy-basel/Project-Description/ (accessed on 3 December 2019).

- Ladner, F.; Haring, M. Hydraulic Characteristics of the Basel 1 Enhanced Geothermal System. GRC Trans. 2009, 33, 199–203. [Google Scholar]

- Haring, M.O.; Schanz, U.; Ladner, F.; Dyer, B.C. Characterisation of the Basel 1 enhanced geothermal system. Geothermics 2008, 37, 469–495. [Google Scholar] [CrossRef]

- Jacquey, A.B.; Cacace, M.; Blöcher, G.; Watanabe, N.; Huenges, E.; Scheck-Wenderoth, M. Thermo-poroelastic numerical modelling for enhanced geothermal system performance: Case study of the Groß Schönebeck reservoir. Tectonophysics 2016, 684, 119–130. [Google Scholar] [CrossRef]

- Kim, S.; Hosseini, S.A. Hydro-thermo-mechanical analysis during injection of cold fluid into a geologic formation. Int. J. Rock. Mech. Min. Sci. 2015, 77, 220–236. [Google Scholar] [CrossRef]

- Li, C.; Laloui, L. Coupled multiphase thermo-hydro-mechanical analysis of supercritical CO2 injection: Benchmark for the In Salah surface uplift problem. Int. J. Greenhouse Gas Control 2016, 51, 394–408. [Google Scholar] [CrossRef]

- Rutqvist, J.; Birkholzer, J.; Tsang, C.F. Coupled reservoir-geomechanical analysis of the potential for tensile and shear failure associated with CO2 injection in multilayered reservoir-caprock systems. Int. J. Rock. Mech. Min. Sci. 2008, 45, 132–143. [Google Scholar] [CrossRef]

- De Simone, S.; Vilarrasa, V.; Carrera, J.; Alcolea, A.; Meier, P. Thermal coupling may control mechanical stability of geothermal reservoirs during cold water injection. Phys. Chem. Earth 2013, 64, 117–126. [Google Scholar] [CrossRef]

- Vidal-Gilbert, S.; Tenthorey, E.; Dewhurst, D.; Ennis-King, J.; Van Ruth, P.; Hillis, R. Geomechanical analysis of the Naylor Field, Otway Basin, Australia: Implications for CO2 injection and storage. Int. J. Greenhouse Gas Control 2010, 4, 827–839. [Google Scholar] [CrossRef]

- Vilarrasa, V.; Bolster, D.; Olivella, S.; Carrera, J. Coupled hydromechanical modeling of CO2 sequestration in deep saline aquifers. Int. J. Greenhouse Gas Control 2010, 4, 910–919. [Google Scholar] [CrossRef]

- Vilarrasa, V.; Olivella, S.; Carrera, J.; Rutqvist, J. Long term impacts of cold CO2 injection on the caprock integrity. Int. J. Greenhouse Gas Control 2014, 24, 1–13. [Google Scholar] [CrossRef]

- Bowden, F.; Tabor, D. The Friction and Lubrication of Solids I; Clarendon Press: London, UK, 1950. [Google Scholar]

- Baumberger, T.; Caroli, C. Solid friction from stick-slip down to pinning and aging. Adv. Phys. 2006, 55, 279–348. [Google Scholar] [CrossRef]

- Barber, J.R. Multiscale Surfaces and Amontons’ Law of Friction. Tribol. Lett. 2013, 49, 539–543. [Google Scholar] [CrossRef]

- Dieterich, J.H. Modeling of rock friction: 1. Experimental results and constitutive equations. J. Geophys. Res. Solid Earth 1979, 84, 2161–2168. [Google Scholar] [CrossRef]

- Ruina, A. Slip instability and state variable friction laws. J. Geophys. Res. Solid Earth 1983, 88, 10359–10370. [Google Scholar] [CrossRef]

- Putelat, T.; Dawes, J.; Willis, J.R. On the microphysical foundations of rate-and-state friction. J. Mech. Phys. Solids 2011, 59, 1062–1075. [Google Scholar] [CrossRef]

- Marone, C. Laboratory-derived friction laws and their application to seismic faulting. Annu. Rev. Earth Planet. Sci. 1998, 26, 643–696. [Google Scholar] [CrossRef]

- Dieterich, J.H. Time-dependent friction and the mechanics of stick-slip. Pure Appl. Geophys. 1978, 116, 790–806. [Google Scholar] [CrossRef]

- Rice, J.R.; Lapusta, N.; Ranjith, K. Rate and state dependent friction and the stability of sliding between elastically deformable solids. J. Mech. Phys. Solids 2001, 49, 1865–1898. [Google Scholar] [CrossRef]

- Nakatani, M. Conceptual and physical clarification of rate and state friction: Frictional sliding as a thermally activated rheology. J. Geophys. Res. 2001, 106, 13347–13380. [Google Scholar] [CrossRef]

- Rathbun, A.P.; Marone, C. Symmetry and the critical slip distance in rate and state friction laws. J. Geophys. Res. Solid Earth 2013, 118, 3728–3741. [Google Scholar] [CrossRef]

- Bhattacharya, P.; Rubin, A.; Bayart, E.; Savage, H.; Marone, C. Critical evaluation of state evolution laws in rate and state friction: Fitting large velocity steps in simulated fault gouge with time-, slip-, and stress-dependent constitutive laws. J. Geophys. Res. Solid Earth 2015, 120, 6365–6385. [Google Scholar] [CrossRef]

- Nagata, K.; Nakatani, M.; Yoshida, S. A revised rate- and state-dependent friction law obtained by constraining constitutive and evolution laws separately with laboratory data. J. Geophys. Res. 2012, 117, B02314. [Google Scholar] [CrossRef]

- Linker, F.M.; Dieterich, J.H. Effects of Variable Normal Stress on Rock Friction: Observations and Constitutive Equations. J. Geophys. Res. 1992, 97, 4923–4940. [Google Scholar] [CrossRef]

- Hong, T.; Marone, C. Effects of normal stress perturbations on the frictional properties of simulated faults. Geochem. Geophys. Geosyst. 2005, 6, 1–19. [Google Scholar] [CrossRef]

- Kilgore, B.; Lozos, J.; Beeler, N.; Oglesby, D. Laboratory Observations of Fault Strength in Response to Changes in Normal Stress. J. Appl. Mech. 2012, 79, 03100701–03100710. [Google Scholar] [CrossRef]

- Perfettini, H.; Molinari, A. A micromechanical model of rate and state friction: 2. Effect of shear and normal stress changes. J. Geophys. Res. Solid Earth 2017, 122, 2638–2652. [Google Scholar]

- Perfettini, H.; Schmittbuhl, J.; Rice, R.J.; Cocco, M. Frictional response induced by time-dependent fluctuations of the normal loading. J. Geophys. Res. 2001, 106, 13455–13472. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, H.P.; Marder, M. Dynamics of static friction between steel and silicon. Proc. Natl. Acad. Sci. USA 2008, 105, 13264–13268. [Google Scholar] [CrossRef] [PubMed]

- Tal, Y.; Hager, B.H.; Ampuero, J.P. The effects of fault roughness on the earthquake nucleation process. J. Geophys. Res. Solid Earth 2018, 123, 437–456. [Google Scholar] [CrossRef]

- Biot, M.A. General theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Rice, J.R.; Cleary, M.P. Some Basic Stress Diffusion Solutions for Fluid-Saturated Elastic Porous Media With Compressible Constituents. Rev. Geophys. Space Phys. 1976, 14, 227–241. [Google Scholar] [CrossRef]

- Fourier, J.B.J. Théorie Analytique de la Chaleur; Chez Firmin Didot Pére et Fils: Paris, France, 1822. [Google Scholar]

- Deichmann, N.; Krafta, T.; Evans, K. Identification of faults activated during the stimulation of the Basel geothermal project from cluster analysis and focal mechanisms of the larger magnitude events. Geothermics 2014, 52, 84–97. [Google Scholar] [CrossRef]

- Gaucher, E.; Schoenball, M.; Heidbach, O.; Zang, A.; Fokker, P.A.; van Wees, J.D.; Kohl, T. Induced seismicity in geothermal reservoirs: A review of forecasting approaches. Renew. Sustain. Energy Rev. 2015, 52, 1473–1490. [Google Scholar] [CrossRef]

- Cacace, M.; Jacquey, A. Flexible parallel implicit modelling of coupled thermal-hydraulic-mechanical processes in fractured rocks. Solid Earth 2017, 8, 921–941. [Google Scholar] [CrossRef]

- COMSOL. COMSOL Multiphysics Structural Mechanics Module User’s Guide v5.2a; Comsol: Stockholm, Sweden, 2016. [Google Scholar]

| Parameter | Value | Unit | Description |

|---|---|---|---|

| E | 20 | GPa | Young Modulus of the rock |

| 0.25 | – | Poisson ratio of the rock | |

| 2700 | kg/m | Rock Density | |

| 1.6 | – | High tectonic ratio | |

| 0.7 | – | Low tectonic ratio | |

| Tect | MPa | Confinement stress | |

| 1000 | kg/m | Fluid density | |

| 0.00024 | Pa·s | Fluid viscosity | |

| 4 × 10 | Pa | Fluid compressibility | |

| k | 10 | m | Porous media permeability |

| 0.1 | – | Porosity | |

| 2.4 | W/(m·K) | Solid thermal conductivity | |

| 0.6 | W/(m·K) | Fluid thermal conductivity | |

| 800 | J/(kg·K) | Solid heat capacity | |

| 4200 | J/(kg·K) | Fluid heat capacity | |

| T | 293.15 | K | Ambient temperature |

| 1 | – | Biot coefficient | |

| 8 × 10 | – | Thermal expansion coefficient | |

| 0.55 | – | Friction coefficient | |

| c | 0 | MPa | Contact cohesion |

| a | 0.005 | – | Direct effect parameter |

| b | 0.03 | – | Friction evolution parameter |

| 0.0007 | m | Characteristic slip distance | |

| 10 | m/s | Reference velocity | |

| 0.2 | – | Linker-Dieterich normal stress coefficient |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrés, S.; Santillán, D.; Mosquera, J.C.; Cueto-Felgueroso, L. Thermo-Poroelastic Analysis of Induced Seismicity at the Basel Enhanced Geothermal System. Sustainability 2019, 11, 6904. https://doi.org/10.3390/su11246904

Andrés S, Santillán D, Mosquera JC, Cueto-Felgueroso L. Thermo-Poroelastic Analysis of Induced Seismicity at the Basel Enhanced Geothermal System. Sustainability. 2019; 11(24):6904. https://doi.org/10.3390/su11246904

Chicago/Turabian StyleAndrés, Sandro, David Santillán, Juan Carlos Mosquera, and Luis Cueto-Felgueroso. 2019. "Thermo-Poroelastic Analysis of Induced Seismicity at the Basel Enhanced Geothermal System" Sustainability 11, no. 24: 6904. https://doi.org/10.3390/su11246904

APA StyleAndrés, S., Santillán, D., Mosquera, J. C., & Cueto-Felgueroso, L. (2019). Thermo-Poroelastic Analysis of Induced Seismicity at the Basel Enhanced Geothermal System. Sustainability, 11(24), 6904. https://doi.org/10.3390/su11246904