An Empirical Study on the Efficiency and Influencing Factors of the Photovoltaic Industry in China and an Analysis of Its Influencing Factors

Abstract

1. Introduction

2. Efficiency Measurement of the PV Industry in China

2.1. Selection of Samples and Indicators

2.2. Analysis of DEA Efficiency Measurement Results

3. Malmquist Index Calculation

4. Efficiency Measurement of the PV Power Generation Industry in China

4.1. Selection of Samples and Indicators

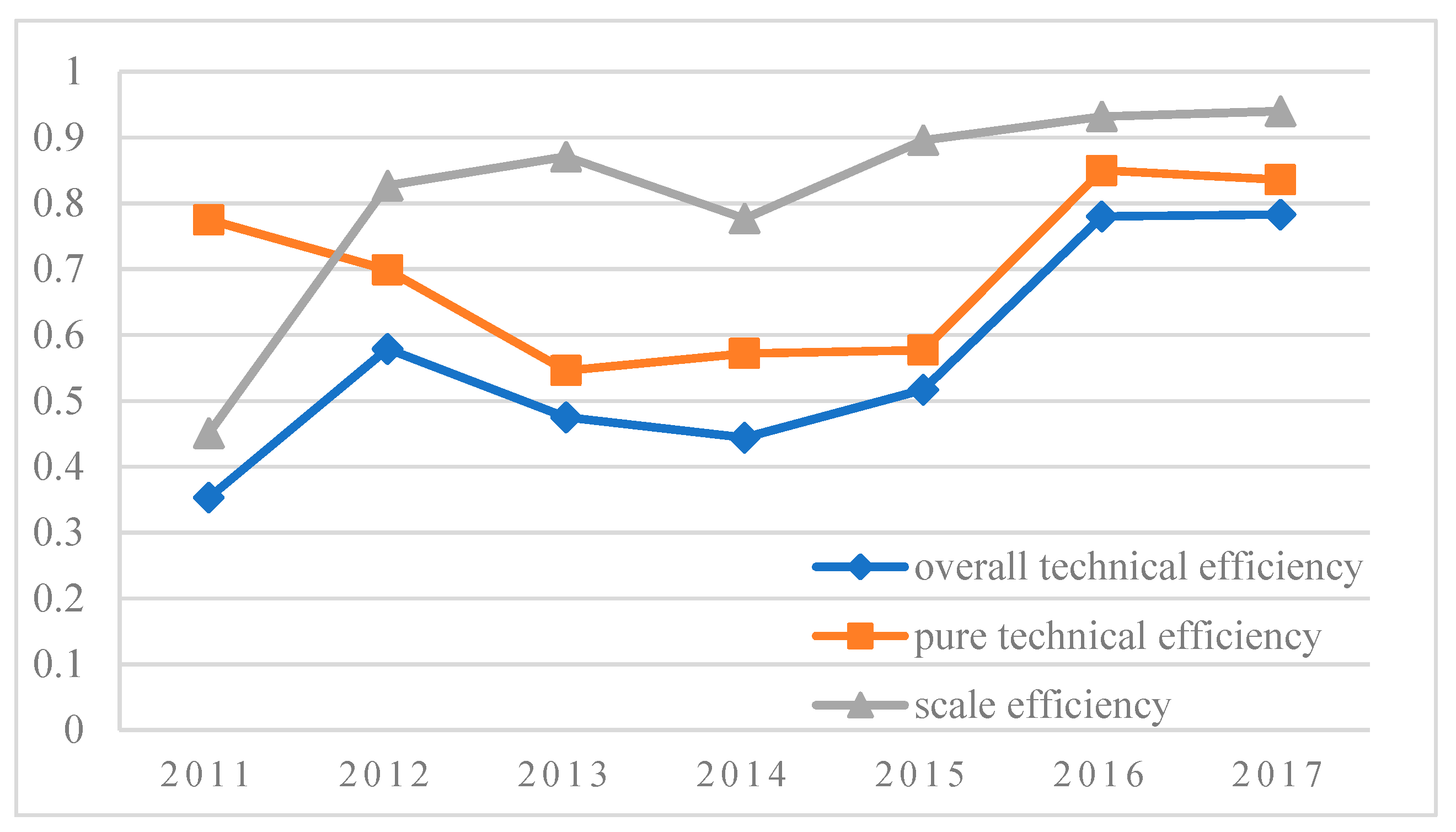

4.2. Analysis of DEA Efficiency Measurement Results

5. Analysis of Factors Affecting the Efficiency of the PV Industry

5.1. Analysis of Factors Affecting the Efficiency of PV Installations

- The asset turnover rate passed the significance test in both models and has a positive correlation with industrial efficiency, indicating that the abundant capital has a significant role in promoting the efficiency of the PV device industry. The higher the abundance of enterprise funds, the more likely the enterprise is to invest money in production equipment upgrading, technology upgrading, production costs reduction, and efficiency level improvement. During the “12th Five-Year Plan” period, the PV device manufacturing industry in China gradually turned to refined development, in which the production cost of polycrystalline silicon links dropped to less than $10/kg, the conversion rate of PV cells and modules reached over 15%, and the localization rate of PV equipment reached 70% or more; the technology upgrade of the PV device industry was significantly accelerated [70]. Therefore, for PV installation enterprises, it is necessary to improve the use of inefficient and idle assets, speed up the recovery of sales funds, and thus improve the overall technical efficiency of the industry.

- The proportion of technicians was found to have a positive relationship with industrial efficiency. In Model 2, a 0.1% level of significance test was passed, indicating that the improvement of R&D capability can promote the development of the device industry. An increase of 1 unit for technicians can increase the overall technical efficiency of the industry by approximately 40%. Compared with accelerating capital turnover, focusing on changes in the structure of employees, the efficiency of the industry can be greatly improved.

- The per capita output value passed the significance test in both model 1 and model 2, showing a positive correlation with industrial efficiency, indicating that the increase in per capita output has a positive impact on the efficiency of the PV industry. Therefore, at the same input level, the higher the labor efficiency level, the higher the overall technical efficiency of the industry.

- The increasing in the ratio of sales cost to total cost had a positive impact on the efficiency of the PV industry, but it did not pass the significance test in both models. At this point, the increase in corporate sales expenses is related to the increase in corporate marketing investment, which has improved the efficiency of the industry. But this effect is not significant. The reason is that China’s installation products are mainly targeted at overseas markets, while overseas political, economic, and trade tariffs, and other policy risks are relatively high. On the other hand, China’s PV installed market is increasing during the 12th Five-Year Plan period. The increased market demand for PV products result in a large number of inefficient enterprises entering the market, exacerbating competition and lowering the profitability level of enterprises, which is not conducive to the sustainable development of the PV device industry.

- The empirical analysis showed that the production scale in model 1 had a negative impact on industrial efficiency, but the impact was not significant. In model 2, after the introduction of the secondary item of scale, the production scale of the primary item had a positive impact on the industrial efficiency, while the secondary item had a negative correlation with the industrial scale, which indicates that the relationship between production scale and industrial efficiency an open-down “U-shaped” relation. It shows that in the initial stage of industrial development, with the expansion of scale, the RTS increases, and the industrial efficiency shows an increasing trend. However, when the scale of the industry reaches a critical point, as the scale of the industry continues to expand, the RTS begins to decline. At the same time, the operating costs of enterprises increase, management becomes ineffective, and productivity turns idle, leading to an inefficiency in the scale of the industry.

- The government subsidy did not pass the significance test in both models, indicating that the incentive effect of the government subsidy on the development of the equipment industry is not good, and the government subsidy needs further improvement. China’s PV subsidies are mainly financial subsidies, which are one-off subsidies. With a lack of post-regulation mechanisms, it is difficult to achieve effective subsidies, and the effect on sustainable development of industries is not obvious. Model 1 without the government subsidy squared item has a negative subsidy coefficient, while the model with squared items has a positive subsidy coefficient and a negative square factor coefficient. We think that because government subsidies may have an inverted U-shaped effect, the government subsidies at this time have not yet reached the inflection point and are still on the left side of the inverted U-shape.

5.2. Analysis of Factors Affecting the Efficiency of the PV Power Generation Industry

6. Conclusions and Suggestion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- De Castro, C.; Mediavilla, M.; Miguel, L.J.; Frechoso, F. Global solar electric potential: A review of their technical and sustainable limits. Renew. Sustain. Energy Rev. 2013, 28, 824–835. [Google Scholar] [CrossRef]

- Ghaffour, N.; Bundschuh, J.; Mahmoudi, H.; Goosen, M.F. Renewable energy-driven desalination technologies: A comprehensive review on challenges and potential applications of integrated systems. Desalination 2015, 356, 94–114. [Google Scholar] [CrossRef]

- Website of National Energy Administration. Related Energy Situation. 2017. Available online: http://www.nea.gov.cn/2018-01/24/c_136920159.htm (accessed on 10 May 2019). (In Chinese)

- Yu, L.; Li, Y.P.; Huang, G.H. Planning municipal-scale mixed energy system for stimulating renewable energy under multiple uncertainties-The City of Qingdao in Shandong Province, China. Energy 2019, 166, 1120–1133. [Google Scholar] [CrossRef]

- Renewable Energy Policy Network for the 21st Century (REN21); Renewables 2017 Global Status Report; REN21 Secretariat: Paris, France, 2017; ISBN 978-3-9818107-6-9.

- Shuai, J.; Chen, C.F.; Cheng, J.; Leng, Z.; Wang, Z. Are China’s solar PV products competitive in the context of the Belt and Road Initiative? Energy policy 2018, 120, 559–568. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global status of recycling waste solar panels: A review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef] [PubMed]

- Tsai, S.B. Using the DEMATEL model to explore the job satisfaction of research and development professionals in china’s photovoltaic cell industry. Renew. Sustain. Energy Rev. 2018, 81, 62–68. [Google Scholar] [CrossRef]

- Xue, J. Photovoltaic agriculture—New opportunity for photovoltaic applications in China. Renew. Sustain. Energy Rev. 2017, 73, 1–9. [Google Scholar] [CrossRef]

- Sun, B.; Yu, Y.; Qin, C. Should China focus on the distributed development of wind and solar photovoltaic power generation? A comparative study. Appl. Energy 2017, 185, 421–439. [Google Scholar] [CrossRef]

- Liu, D.; Hang, X. The politics of curtailment: multi-level governance and solar photovoltaic power generation in China. Environ. Politics 2018, 27, 852–871. [Google Scholar] [CrossRef]

- Su, X.; Masoum, M.A.; Wolfs, P.J. Optimal PV Inverter Reactive Power Control and Real Power Curtailment to Improve Performance of Unbalanced Four-Wire LV Distribution Networks. IEEE Trans. Sustain. Energy 2014, 5, 967–977. [Google Scholar] [CrossRef]

- Liu, P.; Chu, P. Wind power and photovoltaic power: How to improve the accommodation capability of renewable electricity generation in China. Int. J. Energy Res. 2018, 42, 2320–2343. [Google Scholar] [CrossRef]

- Tang, N.; Zhang, Y.; Niu, Y.; Du, X. Solar energy curtailment in China: Status quo, reasons and solutions. Renew. Sustain. Energy Rev. 2018, 97, 509–528. [Google Scholar] [CrossRef]

- Maudos, J.; De Guevara, J.F. Factors explaining the interest margin in the banking sectors of the European Union. J. Bank. Financ. 2004, 28, 2259–2281. [Google Scholar] [CrossRef]

- Casu, B.; Molyneux, P. A Comparative Study of Efficiency in European Banking. Appl. Econ. 2003, 35, 1865–1876. [Google Scholar] [CrossRef]

- Sickles, R.C. Panel estimators and the identification of firm-specific efficiency levels in parametric, semiparametric and nonparametric settings. J. Econom. 2005, 126, 305–334. [Google Scholar] [CrossRef]

- Reddy, K.S.; Nirmala, V. Profit Efficiency and Its Determinants: Evidence from Indian Commercial Banks. J. Transnatl. Manag. 2013, 18, 125–163. [Google Scholar] [CrossRef]

- Olatubi, W.O.; Dismukes, D.E. A data envelopment analysis of the levels and determinants of coal-fired electric power generation performance. Util. Policy 2000, 9, 47–59. [Google Scholar] [CrossRef]

- Granderson, G.; Prior, D. Environmental externalities and regulation constrained cost productivity growth in the US electric utility industry. J. Product. Anal. 2013, 39, 243–257. [Google Scholar] [CrossRef]

- Von Hirschhausen, C.; Cullmann, A.; Kappeler, A. Efficiency analysis of German electricity distribution utilities—Non-parametric and parametric tests. Appl. Econ. 2006, 38, 2553–2566. [Google Scholar] [CrossRef]

- Liu, W.; Lin, B. Analysis of energy efficiency and its influencing factors in China’s transport sector. J. Clean. Prod. 2018, 170, 674–682. [Google Scholar] [CrossRef]

- Campisi, D.; Gitto, S.; Morea, D. An Evaluation of Energy and Economic Efficiency in Residential Buildings Sector: A Multi-Criteria Analisys on an Italian Case Study. Int. J. Energy Econ. Policy 2018, 8, 185–196. [Google Scholar]

- Petrović, M.; Bojković, N.; Stamenković, M. A DEA-based tool for tracking best practice exemplars: The case of telecommunications in EBRD countries. Econ. Ann. 2018, 218, 105–127. [Google Scholar] [CrossRef]

- Li, H.Z.; Kopsakangas-Savolainen, M.; Xiao, X.Z.; Tian, Z.Z.; Yang, X.Y.; Wang, J.L. Cost Efficiency of Electric Grid Utilities in China: A comparison of estimates from SFA-MLE, SFA-Bayes and StoNED-CNLS. Energy Econ. 2016, 55, 272–283. [Google Scholar] [CrossRef]

- Li, S.L. Research on calculation of new energy’s power generation efficiency and analysis on its driving factors. Resour. Sci. 2016, 38, 321–332. [Google Scholar]

- Zhao, H.; Zhao, H.; Guo, S. Operational Efficiency of Chinese Provincial Electricity Grid Enterprises: An Evaluation Employing a Three-Stage Data Envelopment Analysis (DEA) Model. Sustainability 2018, 10, 3168. [Google Scholar] [CrossRef]

- Zheng, B.; Prince, P.E. Purchasing Efficiency Measurement of Selected Chinese PV Panels Using Data Envelopment Analysis (DEA). Undergrad. Rev. 2015, 11, 148–155. [Google Scholar]

- Zou, H.; Du, H.; Ren, J.; Sovacool, B.K.; Zhang, Y.; Mao, G. Market dynamics, innovation, and transition in China’s solar photovoltaic (PV) industry: A critical review. Renew. Sustain. Energy Rev. 2017, 69, 197–206. [Google Scholar] [CrossRef]

- Campisi, D.; Morea, D.; Farinelli, E. Economic sustainability of ground mounted photovoltaic systems: An Italian case study. Int. J. Energy Sect. Manag. 2015, 9, 156–175. [Google Scholar] [CrossRef]

- Branker, K.; Pathak, M.J.M.; Pearce, J.M. A review of solar photovoltaic levelized cost of electricity. Renew. Sustain. Energy Rev. 2011, 15, 4470–4482. [Google Scholar] [CrossRef]

- Kong, Y.; Wu, J. Analysis of the Operational Efficiency of Chinese Listed Coal Enterprises Based on Super Efficiency DEA and Tobit Models. Shanghai Manag. Sci. 2014, 36, 49–54. [Google Scholar]

- Ding, M.; Xu, Z.; Wang, W.; Wang, X.; Song, Y.; Chen, D. A review on China’s large-scale PV integration: Progress, challenges and recommendations. Renew. Sustain. Energy Rev. 2016, 53, 639–652. [Google Scholar] [CrossRef]

- Wei, M.; Patadia, S.; Kammen, D.M. Putting renewables and energy efficiency to work: How many jobs can the clean energy industry generate in the US. Energy Policy 2010, 38, 919–931. [Google Scholar] [CrossRef]

- Van den Heuvel, S.T.; Van den Bergh, J.C. Multilevel assessment of diversity, innovation and selection in the solar photovoltaic industry. Struct. Chang. Econ. Dyn. 2009, 20, 50–60. [Google Scholar] [CrossRef]

- Tanţău, A.D.; Regneală, H.; Coraş, E.L. Layout design as a risk driver for energy efficiency of photovoltaic power systems. Int. J. Manag. Sci. Inf. Technol. 2014, 11, 124–151. [Google Scholar]

- Zhang, L.; Wang, J.; Wen, H.; Fu, Z.; Li, X. Operating performance, industry agglomeration and its spatial characteristics of Chinese photovoltaic industry. Renew. Sustain. Energy Rev. 2016, 65, 373–386. [Google Scholar] [CrossRef]

- Gollop, F.M.; Roberts, M.J. Environmental regulations and productivity growth: The case of fossil-fueled electric power generation. J. Political Econ. 1983, 91, 654–674. [Google Scholar] [CrossRef]

- BAI, X.J.; Song, Y. Environment regulation, technology innovation and efficiency improvement of Chinese thermal power industry. China Ind. Econ. 2009, 8, 68–77. [Google Scholar]

- Wu, L.; Sun, K.; Shi, Z. Research on cost technical efficiency of coal power generation enterprises in China under environmental regulation. China Popul. Resour. Environ. 2018, 8, 31–38. [Google Scholar]

- Chen, S.; Liu, X.; Chang, Q. Empirical analysis on the factors affecting the photovoltaic industry based on Tobit model. Sci. Technol. Manag. Res. 2017, 37, 144–148. [Google Scholar]

- Wang, Y.; Li, Y.; Kong, F.Y. Energy efficiency analysis of Beijing using the DEA-Tobit two stage method. Adv. Mater. Res. 2012, 608–609, 1210–1214. [Google Scholar] [CrossRef]

- Zhang, S.S.; Wang, X.; Zhang, X. The Application of DEA/AHP in Evaluating Comprehensive Benefits of Heating Equipments. In Proceedings of the 2010 International Conference on E-Business and E-Government, Guangzhou, China, 7–9 May 2010. [Google Scholar]

- Medina-Borja, A.; Triantis, K. Modeling social services performance: A four-stage DEA approach to evaluate fundraising efficiency, capacity building, service quality, and effectiveness in the nonprofit sector. Ann. Oper. Res. 2014, 221, 285–307. [Google Scholar] [CrossRef]

- Yu, G.; Huang, Q.; Zhao, X.J.; Wang, W.S. Efficiency Evaluation and Optimization of Green Mining for Coal Enterprises Based on DEA. Appl. Mech. Mater. 2013, 295, 2864–2868. [Google Scholar] [CrossRef]

- Ganji, S.S.; Rassafi, A.A. DEA Malmquist productivity index based on a double-frontier slacks-based model: Iranian road safety assessment. Eur. Transp. Res. Rev. 2019, 11. [Google Scholar] [CrossRef]

- Chiu, Y.H.; Huang, C.W.; Ma, C.M. Assessment of China transit and economic efficiencies in a modified value-chains DEA model. Eur. J. Oper. Res. 2011, 209, 95–103. [Google Scholar] [CrossRef]

- Krivonozhko, V.E.; Førsund, F.R.; Rozhnov, A.V.; Lychev, A.V. Measurement of returns to scale using a non-radial DEA model. Dokl. Math. 2012, 85, 144–148. [Google Scholar] [CrossRef]

- Jha, D.K.; Shrestha, R. Measuring Efficiency of Hydropower Plants in Nepal Using Data Envelopment Analysis. IEEE Trans. Power Syst. 2006, 21, 1502–1511. [Google Scholar] [CrossRef]

- Zervopoulos, P.; Palaskas, T. Applying quality-driven, efficiency-adjusted DEA (QE-DEA) in the pursuit of high-efficiency-high-quality service units: An input-oriented approach. IMA J. Manag. Math. 2011, 22, 401–417. [Google Scholar] [CrossRef]

- Branda, M. Reformulations of input–output oriented DEA tests with diversification. Oper. Res. Lett. 2013, 41, 516–520. [Google Scholar] [CrossRef]

- Titko, J.; Jureviciene, D. DEA Application at Cross-country Benchmarking: Latvian vs Lithuanian Banking Sector. Procedia Soc. Behav. Sci. 2014, 110, 1124–1135. [Google Scholar] [CrossRef]

- Fernandez-Lopez, X.L. Impact of Logistics on Technical Efficiency of World Production (2007–2012). Netw. Spat. Econ. 2015, 26, 1–15. [Google Scholar]

- Ruggiero, J. Measuring technical efficiency. Eur. J. Oper. Res. 2000, 121, 138–150. [Google Scholar] [CrossRef]

- Li, Z.; Crook, J.; Andreeva, G. Dynamic prediction of financial distress using Malmquist DEA. Expert Syst. Appl. 2017, 80, 94–106. [Google Scholar] [CrossRef]

- Yu, Y.; Shi, Q. Two-stage DEA model with additional input in the second stage and part of intermediate products as final output. Expert Syst. Appl. 2014, 41, 6570–6574. [Google Scholar] [CrossRef]

- Imanirad, R.; Cook, W.D.; Zhu, J. Partial Input to Output Impacts in DEA: Production Considerations and Resource Sharing Among Business Sub-Units. Nav. Res. Logist. 2013, 60, 355–380. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Staiger, R.W.; Wolak, F. Measuring Industry Specific Protection: Anti-dumping in the United States. Brookings Papers on Economic Activity. Microeconomics 1994, 1, 51–118. [Google Scholar]

- Krupp, C.M.; Pollard, P.S. Market responses to anti-dumping laws: Some evidence from the U.S. Chemical industry. Can. J. Econ. 1996, 29, 199–227. [Google Scholar] [CrossRef]

- Konings, J.; Vandenbussche, H. Anti-dumping protection and markups of domestic firms: Evidence from firm level data. J. Int. Econ. 2005, 65, 151–165. [Google Scholar] [CrossRef]

- Bown, C.P.; Crowley, M.A. Trade deflection and trade depression. J. Int. Econ. 2007, 72, 176–201. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Feng, Z. The economic effects of anti-dumping and anti-subsidy policies among China, the U.S. and the EU: The photovoltaic industry. Singap. Econ. Rev. 2018, 63, 513–534. [Google Scholar] [CrossRef]

- Zuo, X. China’s PV industry suffered ‘winter: Causes and Counter measures. Econ. Forum 2012, 10, 111–113. [Google Scholar]

- Rácz, V.J.; Vestergaard, N. Productivity and efficiency measurement of the Danish centralized biogas power sector. Renew. Energy 2016, 92, 397–404. [Google Scholar] [CrossRef]

- Li, N.; Jiang, Y.; Yu, Z.; Shang, L. Analysis of agriculture total-factor energy efficiency in China based on DEA and malmquist indices. Energy Procedia 2017, 142, 2397–2402. [Google Scholar] [CrossRef]

- China Electric Power Yearbook. Available online: http://tongji.cnki.net/kns55/navi/HomePage.aspx?id= N2018060073&name=YZGDL&floor=1 (accessed on 10 May 2019).

- Yan, Y.; Qian, Y.; Sharif, H.; Tipper, D. A survey on smart grid communication infrastructures: Motivations, requirements and challenges. IEEE Commun. Surv. Tutor. 2012, 15, 5–20. [Google Scholar] [CrossRef]

- Barros, C.P.; Chen, Z.; Wanke, P. Efficiency in Chinese seaports: 2002–2012. Marit. Econ. Logist. 2016, 18, 295–316. [Google Scholar] [CrossRef]

- Yuan, X.; Zuo, J. Transition to low carbon energy policies in China—from the Five-Year Plan perspective. Energy Policy 2011, 39, 3855–3859. [Google Scholar] [CrossRef]

| No. | Enterprise | Main Products |

|---|---|---|

| 1 | Aikang Technology | PV accessories products, PV brackets |

| 2 | Zhongli Group | Components, cells |

| 3 | Daquan New Energy | Polysilicon, silicon wafer |

| 4 | Foster | Solar battery backplane |

| 5 | Hairun PV | Silicon wafer, cell assembly |

| 6 | Jinjing Technology | PV glass |

| 7 | Jing Yuntong | Silicon wafer, PV equipment |

| 8 | Jinko Energy | PV equipment |

| 9 | Jingsheng Electromechanical | Polysilicon |

| 10 | Jinggong Technology | PV equipment |

| 11 | Kstar | Optical inverter, etc. |

| 12 | Lin Yang Energy | PV modules, cell sheets |

| 13 | Longji shares | Polysilicon, cell sheets, components |

| 14 | CSG Holding | Solar glass, components, battery |

| 15 | TBEA | Inverter |

| 16 | Tianlong Photoelectric | Polycrystalline silicon PV equipment |

| 17 | GCL System Integration Technology | Polysilicon, PV modules |

| 18 | Sunshine power | Optical inverter |

| 19 | Yicheng New Energy | Polysilicon, silicon wafer |

| 20 | Yinxing Energy | PV power generation equipment |

| 21 | Yingli Green Energy | Polysilicon, silicon wafer, battery assembly |

| 22 | Yuhui Sunshine | Silicon wafer, battery assembly |

| 23 | Zhengtai Electric | PV equipment |

| 24 | Tianjin Zhong Huan semiconductor | Polysilicon, silicon wafer |

| 25 | Kehua Hengsheng | Transformer |

| Enterprise | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | Average |

|---|---|---|---|---|---|---|---|---|

| CMC Magnetics | 0.794 | 0.766 | 0.715 | 0.85 | 0.832 | 0.772 | 0.793 | 0.789 |

| Jing Yuntong | 0.969 | 0.732 | 0.526 | 0.765 | 0.875 | 1.000 | 0.918 | 0.826 |

| Jingsheng Electromechanical | 1 | 1 | 0.822 | 1 | 0.971 | 1.000 | 0.986 | 0.968 |

| Longji shares | 0.885 | 0.709 | 0.669 | 0.861 | 0.884 | 0.893 | 0.849 | 0.821 |

| Daquan New Energy | 1 | 0.525 | 0.59 | 1 | 1 | 0.948 | 1.000 | 0.866 |

| Tianlong Photoelectric | 0.786 | 0.161 | 0.357 | 0.348 | 0.219 | 0.816 | 1.000 | 0.527 |

| Yicheng New Energy | 0.834 | 0.774 | 0.687 | 0.836 | 0.815 | 0.849 | 0.690 | 0.784 |

| Jinko Energy | 0.969 | 0.761 | 1 | 1 | 0.987 | 0.837 | 0.800 | 0.908 |

| Zhengtai Electric | 1 | 1 | 1 | 1 | 0.971 | 0.963 | 0.955 | 0.984 |

| Hairun PV | 0.903 | 0.688 | 0.658 | 0.669 | 0.769 | 0.789 | 0.660 | 0.734 |

| Jinjing Technology | 1 | 0.85 | 0.782 | 0.861 | 0.842 | 0.839 | 0.829 | 0.858 |

| Jinggong Technology | 1 | 0.563 | 0.548 | 0.799 | 0.825 | 0.917 | 0.913 | 0.795 |

| Sunshine power | 0.826 | 0.707 | 0.912 | 1 | 1 | 1.000 | 1.000 | 0.921 |

| Kstar | 0.809 | 0.843 | 0.779 | 0.908 | 0.942 | 1.000 | 1.000 | 0.897 |

| Yinxing Energy | 0.906 | 1 | 1 | 1 | 0.885 | 0.960 | 0.905 | 0.951 |

| Yingli Green Energy | 0.82 | 0.775 | 0.78 | 0.796 | 0.742 | 0.734 | 0.663 | 0.759 |

| Yuhui Sunshine | 0.694 | 0.685 | 0.761 | 0.826 | 0.823 | 0.760 | 0.815 | 0.766 |

| Foster | 1 | 1 | 1 | 1 | 1 | 1.000 | 0.999 | 1.000 |

| Lin Yang Energy | 0.833 | 0.913 | 0.886 | 1 | 1 | 0.889 | 0.905 | 0.918 |

| GCL integration | 0.819 | 0.456 | 0.33 | 1 | 1 | 1.000 | 1.000 | 0.801 |

| Aikang Technology | 0.803 | 0.774 | 0.902 | 0.979 | 0.937 | 0.808 | 0.830 | 0.862 |

| CSG | 0.997 | 0.908 | 0.918 | 0.914 | 0.86 | 0.841 | 0.773 | 0.887 |

| Zhongli Group | 1 | 1 | 1 | 0.909 | 0.88 | 0.833 | 0.902 | 0.932 |

| Kehua Hengsheng | 0.796 | 0.79 | 0.735 | 0.881 | 0.886 | 0.975 | 0.892 | 0.851 |

| TBEA | 0.915 | 0.764 | 0.83 | 0.875 | 0.861 | 0.853 | 0.898 | 0.857 |

| Annual Average | 0.889 | 0.729 | 0.739 | 0.867 | 0.847 | 0.891 | 0.879 | - |

| Enterprise | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | Average |

|---|---|---|---|---|---|---|---|---|

| Tianjin Zhong Huan Semiconductor | 0.798 | 0.770 | 0.792 | 0.891 | 0.851 | 0.801 | 0.853 | 0.822 |

| Jing Yuntong | 0.969 | 0.771 | 0.573 | 0.766 | 0.912 | 1.000 | 0.920 | 0.844 |

| Jingsheng Electromechanical | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Longji shares | 0.886 | 0.720 | 0.703 | 0.882 | 0.900 | 1.000 | 1.000 | 0.870 |

| Daquan New Energy | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.978 | 1.000 | 0.997 |

| Tianlong Photoelectric | 1.000 | 0.564 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.938 |

| Yicheng New Energy | 0.853 | 1.000 | 0.717 | 0.841 | 0.840 | 0.861 | 0.732 | 0.835 |

| Jinko Energy | 1.000 | 0.763 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.966 |

| Zhengtai Electric | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Hairun PV | 1.000 | 0.735 | 0.762 | 0.718 | 0.804 | 0.840 | 0.666 | 0.789 |

| Jinjing Technology | 1.000 | 0.856 | 0.807 | 0.868 | 0.844 | 0.905 | 0.883 | 0.881 |

| Jinggong Technology | 1.000 | 0.665 | 0.816 | 0.862 | 1.000 | 0.975 | 0.933 | 0.893 |

| Sunshine power | 0.990 | 0.739 | 0.912 | 1.000 | 1.000 | 1.000 | 1.000 | 0.949 |

| Kstar | 1.000 | 1.000 | 0.895 | 0.929 | 0.949 | 1.000 | 1.000 | 0.968 |

| Yinxing Energy | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.919 | 0.988 |

| Yingli Green Energy | 0.909 | 1.000 | 1.000 | 0.841 | 0.774 | 0.808 | 0.741 | 0.868 |

| Yuhui Sunshine | 0.707 | 0.721 | 0.781 | 0.832 | 0.825 | 0.792 | 1.000 | 0.808 |

| Foster | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Lin Yang Energy | 0.846 | 0.921 | 0.909 | 1.000 | 1.000 | 0.961 | 0.996 | 0.948 |

| GCL System Integration Technology | 0.834 | 0.495 | 0.800 | 1.000 | 1.000 | 1.000 | 1.000 | 0.876 |

| Aikang Technology | 0.863 | 0.820 | 1.000 | 0.985 | 0.962 | 0.833 | 0.831 | 0.899 |

| CSG Holding | 1.000 | 0.940 | 0.993 | 0.927 | 0.887 | 0.947 | 0.891 | 0.941 |

| Zhongli Group | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.942 | 1.000 | 0.992 |

| Kehua Hengsheng | 0.962 | 0.856 | 0.860 | 0.886 | 0.891 | 1.000 | 0.957 | 0.916 |

| TBEA | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Annual Average | 0.941 | 0.839 | 0.884 | 0.925 | 0.934 | 0.946 | 0.933 | - |

| Enterprise | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2017 RTS |

|---|---|---|---|---|---|---|---|---|

| CMC Magnetics | 0.995 | 0.995 | 0.903 | 0.954 | 0.978 | 0.964 | 0.929 | drs |

| Jing Yuntong | 1.000 | 0.949 | 0.918 | 0.998 | 0.959 | 1.000 | 0.998 | irs |

| Jingsheng Electromechanical | 1.000 | 1.000 | 0.822 | 1.000 | 0.971 | 1.000 | 0.986 | drs |

| Longji shares | 0.999 | 0.985 | 0.953 | 0.977 | 0.982 | 0.893 | 0.849 | drs |

| Daquan New Energy | 1.000 | 0.525 | 0.590 | 1.000 | 1.000 | 0.969 | 1.000 | - |

| Tianlong Photoelectric | 0.786 | 0.285 | 0.357 | 0.348 | 0.219 | 0.816 | 1.000 | - |

| Yicheng New Energy | 0.978 | 0.774 | 0.958 | 0.994 | 0.971 | 0.986 | 0.943 | drs |

| Jinko Energy | 0.969 | 0.997 | 1.000 | 1.000 | 0.987 | 0.837 | 0.800 | drs |

| Zhengtai Electric | 1.000 | 1.000 | 1.000 | 1.000 | 0.971 | 0.963 | 0.955 | drs |

| Hairun PV | 0.903 | 0.935 | 0.863 | 0.931 | 0.956 | 0.939 | 0.992 | drs |

| Jinjing Technology | 1.000 | 0.993 | 0.968 | 0.993 | 0.998 | 0.927 | 0.938 | drs |

| Jinggong Technology | 1.000 | 0.847 | 0.671 | 0.926 | 0.825 | 0.941 | 0.979 | irs |

| Sunshine power | 0.834 | 0.956 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | - |

| Kstar | 0.809 | 0.843 | 0.870 | 0.977 | 0.992 | 1.000 | 1.000 | - |

| Yinxing Energy | 0.906 | 1.000 | 1.000 | 1.000 | 0.885 | 0.960 | 0.985 | irs |

| Yingli Green Energy | 0.902 | 0.775 | 0.780 | 0.947 | 0.959 | 0.908 | 0.894 | drs |

| Yuhui Sunshine | 0.982 | 0.950 | 0.973 | 0.994 | 0.997 | 0.960 | 0.815 | irs |

| Foster | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.999 | irs |

| Lin Yang Energy | 0.984 | 0.991 | 0.975 | 1.000 | 1.000 | 0.925 | 0.909 | drs |

| GCL System Integration Technology | 0.982 | 0.920 | 0.413 | 1.000 | 1.000 | 1.000 | 1.000 | - |

| Aikang Technology | 0.930 | 0.944 | 0.902 | 0.994 | 0.974 | 0.970 | 0.998 | drs |

| CSG Holding | 0.997 | 0.966 | 0.925 | 0.986 | 0.969 | 0.888 | 0.867 | drs |

| Zhongli Group | 1.000 | 1.000 | 1.000 | 0.909 | 0.880 | 0.884 | 0.902 | drs |

| Kehua Hengsheng | 0.827 | 0.923 | 0.854 | 0.994 | 0.994 | 0.975 | 0.933 | drs |

| TBEA | 0.915 | 0.764 | 0.830 | 0.875 | 0.861 | 0.853 | 0.898 | drs |

| Annual Average | 0.945 | 0.868 | 0.837 | 0.937 | 0.906 | 0.942 | 0.943 |

| Year | Overall Technical Efficiency Change (EC) | Technological Change (TC) | Pure Technical Efficiency Change (Pech) | Scale Efficiency Change (Sech) | Total Factor Productivity Change (TFP) |

|---|---|---|---|---|---|

| 2011–2012 | 0.763 | 0.951 | 0.821 | 0.929 | 0.725 |

| 2012–2013 | 1.076 | 0.952 | 0.993 | 1.084 | 1.025 |

| 2013–2014 | 1.324 | 0.87 | 1.204 | 1.1 | 1.151 |

| 2014–2015 | 0.978 | 0.987 | 1.069 | 0.915 | 0.966 |

| 2015–2016 | 1.101 | 1.334 | 1.025 | 1.074 | 1.469 |

| 2016–2017 | 0.974 | 1.268 | 0.976 | 0.998 | 1.235 |

| Average annual rate of change | 1.022 | 1.047 | 1.008 | 1.014 | 1.07 |

| Indicator Name | Unit | ||

|---|---|---|---|

| Input indicator | X1 | Cumulative installed capacity | Ten thousand kW |

| X2 | Number of employees | Ten thousand people | |

| X3 | PV power investment | Billion yuan | |

| Output indicator | Y | Power generation | Billion kW·h |

| Area | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | Average Value |

|---|---|---|---|---|---|---|---|---|

| Hebei | 0.335 | 0.339 | 0.482 | 0.850 | 0.850 | 0.571 | ||

| Shanxi | 0.030 | 0.871 | 1.000 | 0.519 | 0.482 | 0.908 | 0.908 | 0.674 |

| Inner Mongolia | 0.103 | 0.545 | 0.356 | 0.579 | 0.824 | 1.000 | 1.000 | 0.630 |

| Liaoning | 0.063 | 0.487 | 0.631 | 0.619 | 0.813 | 0.813 | 0.571 | |

| Shanghai | 0.952 | 0.927 | 1.000 | 0.616 | 0.303 | 0.043 | 0.043 | 0.555 |

| Jiangsu | 0.237 | 0.660 | 0.449 | 0.363 | 0.523 | 0.710 | 0.710 | 0.522 |

| Zhejiang | 0.535 | 0.341 | 0.350 | 0.332 | 0.444 | 0.444 | 0.408 | |

| Anhui | 0.346 | 0.433 | 0.167 | 0.216 | 0.660 | 0.660 | 0.414 | |

| Fujian | 1.000 | 0.350 | 0.386 | 0.472 | 0.479 | 0.479 | 0.528 | |

| Jiangxi | 0.409 | 0.350 | 0.328 | 0.395 | 0.723 | 0.723 | 0.488 | |

| Shandong | 0.762 | 0.702 | 0.620 | 0.416 | 0.362 | 0.603 | 0.603 | 0.581 |

| Henan | 0.150 | 0.535 | 0.832 | 0.832 | 0.587 | |||

| Hubei | 0.529 | 0.292 | 0.467 | 0.332 | 0.830 | 0.830 | 0.547 | |

| Guangdong | 0.083 | 0.230 | 0.111 | 0.122 | 0.393 | 0.591 | 0.591 | 0.303 |

| Hainan | 0.182 | 1.000 | 0.404 | 0.819 | 0.560 | 0.844 | 0.844 | 0.665 |

| Yunnan | 1.000 | 0.662 | 0.623 | 0.688 | 0.696 | 0.986 | 0.986 | 0.806 |

| Tibet | 1.000 | 0.679 | 1.000 | 0.927 | 0.999 | 1.000 | 1.000 | 0.944 |

| Shaanxi | 0.940 | 0.932 | 0.193 | 0.339 | 0.952 | 0.952 | 0.718 | |

| Gansu | 0.519 | 0.553 | 0.487 | 0.518 | 0.689 | 0.986 | 0.986 | 0.677 |

| Qinghai | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.998 | 1.000 |

| Ningxia | 0.887 | 1.000 | 0.751 | 1.000 | 0.848 | 0.963 | 0.963 | 0.916 |

| Xinjiang | 0.637 | 0.203 | 0.895 | 1.000 | 1.000 | 1.000 | 0.789 | |

| Annual average | 0.353 | 0.579 | 0.475 | 0.444 | 0.517 | 0.78 | 0.783 | --- |

| Area | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | Average Value |

|---|---|---|---|---|---|---|---|---|

| Hebei | 0.339 | 0.346 | 0.482 | 0.851 | 0.850 | 0.574 | ||

| Shanxi | 0.524 | 0.881 | 1.000 | 0.540 | 0.482 | 0.909 | 0.908 | 0.749 |

| Inner Mongolia | 0.237 | 0.549 | 0.522 | 0.580 | 0.824 | 1.000 | 1.000 | 0.673 |

| Liaoning | 0.443 | 0.487 | 1.000 | 0.973 | 0.857 | 0.813 | 0.762 | |

| Shanghai | 1.000 | 1.000 | 1.000 | 1.000 | 0.782 | 1.000 | 1.000 | 0.969 |

| Jiangsu | 0.481 | 0.663 | 0.658 | 0.365 | 0.523 | 0.711 | 0.710 | 0.587 |

| Zhejiang | 0.536 | 0.342 | 0.368 | 0.332 | 0.444 | 0.444 | 0.411 | |

| Anhui | 0.530 | 0.449 | 0.269 | 0.216 | 0.660 | 0.660 | 0.464 | |

| Fujian | 1.000 | 0.559 | 1.000 | 1.000 | 1.000 | 0.550 | 0.851 | |

| Jiangxi | 0.544 | 0.359 | 0.456 | 0.395 | 0.723 | 0.723 | 0.533 | |

| Shandong | 1.000 | 0.715 | 0.650 | 0.447 | 0.362 | 0.603 | 0.603 | 0.626 |

| Henan | 0.384 | 0.535 | 0.832 | 0.832 | 0.646 | |||

| Hubei | 0.536 | 0.305 | 0.840 | 0.344 | 0.830 | 0.830 | 0.614 | |

| Guangdong | 0.875 | 0.412 | 0.163 | 0.178 | 0.393 | 0.591 | 0.591 | 0.458 |

| Hainan | 1.000 | 1.000 | 0.944 | 0.899 | 0.702 | 1.000 | 1.000 | 0.935 |

| Yunnan | 1.000 | 0.667 | 0.623 | 0.721 | 0.697 | 0.987 | 0.986 | 0.812 |

| Tibet | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Shaanxi | 0.952 | 0.952 | 0.306 | 0.339 | 0.952 | 0.952 | 0.742 | |

| Gansu | 0.898 | 0.554 | 0.541 | 0.538 | 0.690 | 0.986 | 0.986 | 0.742 |

| Qinghai | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.999 | 1.000 |

| Ningxia | 1.000 | 1.000 | 0.809 | 1.000 | 0.851 | 0.963 | 0.963 | 0.941 |

| Xinjiang | 0.640 | 0.217 | 0.936 | 1.000 | 1.000 | 1.000 | 0.799 | |

| Annual average | 0.775 | 0.699 | 0.546 | 0.572 | 0.577 | 0.85 | 0.836 | --- |

| Area | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2017 RTS |

|---|---|---|---|---|---|---|---|---|

| Hebei | 0.991 | 0.980 | 0.998 | 0.9995 | 1.000 | - | ||

| Shanxi | 0.051 | 0.988 | 1.000 | 0.960 | 0.996 | 0.9996 | 1.000 | - |

| Inner Mongolia | 0.433 | 0.993 | 0.682 | 1.000 | 1.000 | 1.0000 | 1.000 | - |

| Liaoning | 0.142 | 1.000 | 0.631 | 0.636 | 0.9479 | 1.000 | - | |

| Shanghai | 0.952 | 0.927 | 1.000 | 0.616 | 0.388 | 0.0426 | 0.043 | irs |

| Jiangsu | 0.492 | 0.996 | 0.682 | 0.995 | 0.998 | 0.9997 | 1.000 | - |

| Zhejiang | 0.999 | 0.994 | 0.950 | 0.996 | 1.0000 | 1.000 | - | |

| Anhui | 0.653 | 0.964 | 0.623 | 0.999 | 1.0000 | 1.000 | - | |

| Fujian | 1.000 | 0.626 | 0.386 | 0.472 | 0.4792 | 0.872 | irs | |

| Jiangxi | 0.751 | 0.974 | 0.720 | 0.996 | 1.0000 | 1.000 | - | |

| Shandong | 0.762 | 0.981 | 0.954 | 0.931 | 0.995 | 1.0000 | 1.000 | - |

| Henan | 0.390 | 0.999 | 1.0000 | 1.000 | - | |||

| Hubei | 0.988 | 0.957 | 0.556 | 0.965 | 0.9999 | 1.000 | irs | |

| Guangdong | 0.095 | 0.559 | 0.682 | 0.683 | 0.999 | 1.0000 | 1.000 | - |

| Hainan | 0.182 | 1.000 | 0.428 | 0.911 | 0.797 | 0.8438 | 0.844 | irs |

| Yunnan | 1.000 | 0.992 | 0.999 | 0.955 | 0.995 | 0.9991 | 0.999 | irs |

| Tibet | 1.000 | 0.679 | 1.000 | 0.927 | 0.998 | 1.0000 | 1.000 | - |

| Shaanxi | 0.987 | 0.978 | 0.629 | 0.994 | 0.9999 | 1.000 | - | |

| Gansu | 0.578 | 0.999 | 0.901 | 0.962 | 0.993 | 0.9995 | 1.000 | - |

| Qinghai | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.0000 | 1.000 | dis |

| Ningxia | 0.887 | 1.000 | 0.928 | 1.000 | 0.996 | 0.9998 | 1.000 | irs |

| Xinjiang | 0.995 | 0.935 | 0.956 | 1.000 | 1.0000 | 1.000 | - | |

| average | 0.451 | 0.827 | 0.871 | 0.777 | 0.896 | 0.932 | 0.94 |

| Variable Name | Model 1 | Model 2 | ||||

|---|---|---|---|---|---|---|

| Coefficient Value | Standard Deviation | Z Value | Coefficient Value | Standard Deviation | Z Value | |

| Asset turnover | 0.2196576 | 0.0561253 | 3.91 *** | 0.2179421 | 0.0560076 | 3.89 *** |

| Technical staff | 0.3962003 | 0.1291575 | 3.07 *** | 0.4080893 | 0.1279905 | 3.19 *** |

| Per capita output value | 5.173824 | 1.227784 | 4.21 *** | 5.099016 | 1.224846 | 4.16 *** |

| Ratio of sales cost to total cost | 0.0303791 | 0.777543 | 0.36 | 0.0247968 | 0.0774734 | 0.32 |

| Production scale | −4.03 | 0.000761 | 0.940843 | 0.000182 | 0.0001558 | 1.17 |

| Scale square | 2.01 | 1.43 | −1.40 | |||

| government subsidy | −0.0010566 | 0.0363536 | 0.853351 | 0.0069734 | 0.039787 | 0.18 |

| Subsidy square | −00025288 | 0.0101583 | −0.25 | |||

| Variable | Coefficient | Standard Deviation | Z Statistic | p Value |

|---|---|---|---|---|

| ln (GDP) | −0.211334 | 0.1978433 | −1.07 | 0.288 |

| Equipment utilization | 1.093636 | 0.0754971 | 14.49 | 0.000 *** |

| Solar development utilization | 0.0039358 | 0.0074361 | 0.53 | 0.598 |

| Electricity consumption | 0.000016 | 0.0000533 | 0.30 | 0.765 |

| ln (power generation scale) | 0.0451229 | 0.0192829 | 2.34 | 0.021 ** |

| ln (CO2) | −0.1460661 | 0.0570799 | −2.56 | 0.012 ** |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, H.; Liang, L.; Tang, J.; Wang, Q.; Wei, L.; Xie, J. An Empirical Study on the Efficiency and Influencing Factors of the Photovoltaic Industry in China and an Analysis of Its Influencing Factors. Sustainability 2019, 11, 6693. https://doi.org/10.3390/su11236693

Cai H, Liang L, Tang J, Wang Q, Wei L, Xie J. An Empirical Study on the Efficiency and Influencing Factors of the Photovoltaic Industry in China and an Analysis of Its Influencing Factors. Sustainability. 2019; 11(23):6693. https://doi.org/10.3390/su11236693

Chicago/Turabian StyleCai, Hao, Ling Liang, Jing Tang, Qianxian Wang, Lihong Wei, and Jiaping Xie. 2019. "An Empirical Study on the Efficiency and Influencing Factors of the Photovoltaic Industry in China and an Analysis of Its Influencing Factors" Sustainability 11, no. 23: 6693. https://doi.org/10.3390/su11236693

APA StyleCai, H., Liang, L., Tang, J., Wang, Q., Wei, L., & Xie, J. (2019). An Empirical Study on the Efficiency and Influencing Factors of the Photovoltaic Industry in China and an Analysis of Its Influencing Factors. Sustainability, 11(23), 6693. https://doi.org/10.3390/su11236693