Industry 4.0 to Accelerate the Circular Economy: A Case Study of Electric Scooter Sharing

Abstract

1. Introduction

2. Literature Review

2.1. Barriers of CE

2.2. Innovations in Industry 4.0

- (1)

- IoT: Ashton coined the term IoT in 1999. The fundamental idea of IoT is to use a number of distributed sensors or gadgets (i.e., “things”) lying in an unpredictable vast environment (a house, a large urban area, or a greater region) [42]. These things could collect a massive amount of raw data (structured or unstructured) and translate them into relevant information.

- (2)

- Cloud computing (CC): CC could be accessed by using web-based technologies, combining internet connectivity and pay-per-use systems in a new business model for IT provisioning [43,44]. Normally, three different types of service models are categorized as: Infrastructure as a Service (IaaS), Platform as a Service (PaaS), and Software as a Service (SaaS).

- (3)

- Cyber physical systems (CPS): CPS was first proposed by the US National Science Foundation in 2006. The original purpose of CPS is to reveal cross-cutting fundamental scientific and engineering principles that underpin the integration of cyber and physical elements across all application sectors [45,46].

- (4)

- Data-driven analytics (DDA): DDA involves the analysis of large volumes of heterogeneous and multi-source data generated along the life cycle of industrial production [47]. The common predictive techniques that are often used by data scientists include regression modeling, decision trees, Bayesian networks, Artificial Neural Networks (ANNs), Support Vector Machine (SVM), and nearest neighbor algorithms [48].

- (5)

- Artificial intelligence (AI): Artificial intelligence according to Mayr et al. [49] is a commonly used term for engineered learning tools or perception-based modeling, as well as a problem-driven solution-making system that could be used to derived certain problems. AI are also well defined as a focus on human performance or rationality, where their implementation could be to the benefit of the users. Nowadays, AI are used from research facilities to marketing departments, and from large manufacturing industries to small farms, producing a high yield per dollar spent on using traditional equipment.

2.3. Industry 4.0 in Support of CE

- (1)

- Smart circular systems. IoT changes the way to create value in the business sector as the information that is generated by the interconnected devices, machines, and products evolves in a fundamental component in value creation, such as maintenance, re-use, repair, and recycle. Through IoT, there is a capability to foster CE through the connection of people and things by mobile devices, which derives significant economic opportunities for both individuals and businesses in multiple domains [56,57,58,59,60].

- (2)

- Cloud manufacturing (CM) and sustainable process manufacturing. CM increases in sustainability are identified: (1) collaborative design; (2) greater automation; (3) improved process resilience; and (4) enhanced waste reduction, re-use, and recovery [61]. By using the CC model in mobility and transportation management systems, managers can reduce the total cost of provided services for residents, carbon footprint, and remanufactured WEEE [62,63,64,65].

- (3)

- Data-driven analysis can be used to help enterprises understand their sustainability performance [66,67,68,69] and create value (value proposition, value creation and delivery, and value capture [70,71]). It refers to all the tools and techniques that analyze the vast and varied business data management to generate useful insights for decision making. The analytical tools include mathematics, optimization, simulation, statistics, and other techniques.

- (4)

- There is a lot of research related to energy and cyber physical systems. Ma, Zhang, Lv, Yang and Wu [45] presented architecture of energy cyber physical system-enabled management for energy-intensive manufacturing industries to promote the implementation of a cleaner production strategy. Lu et al. [72] provided an energy-efficient CP production network.

- (5)

- (6)

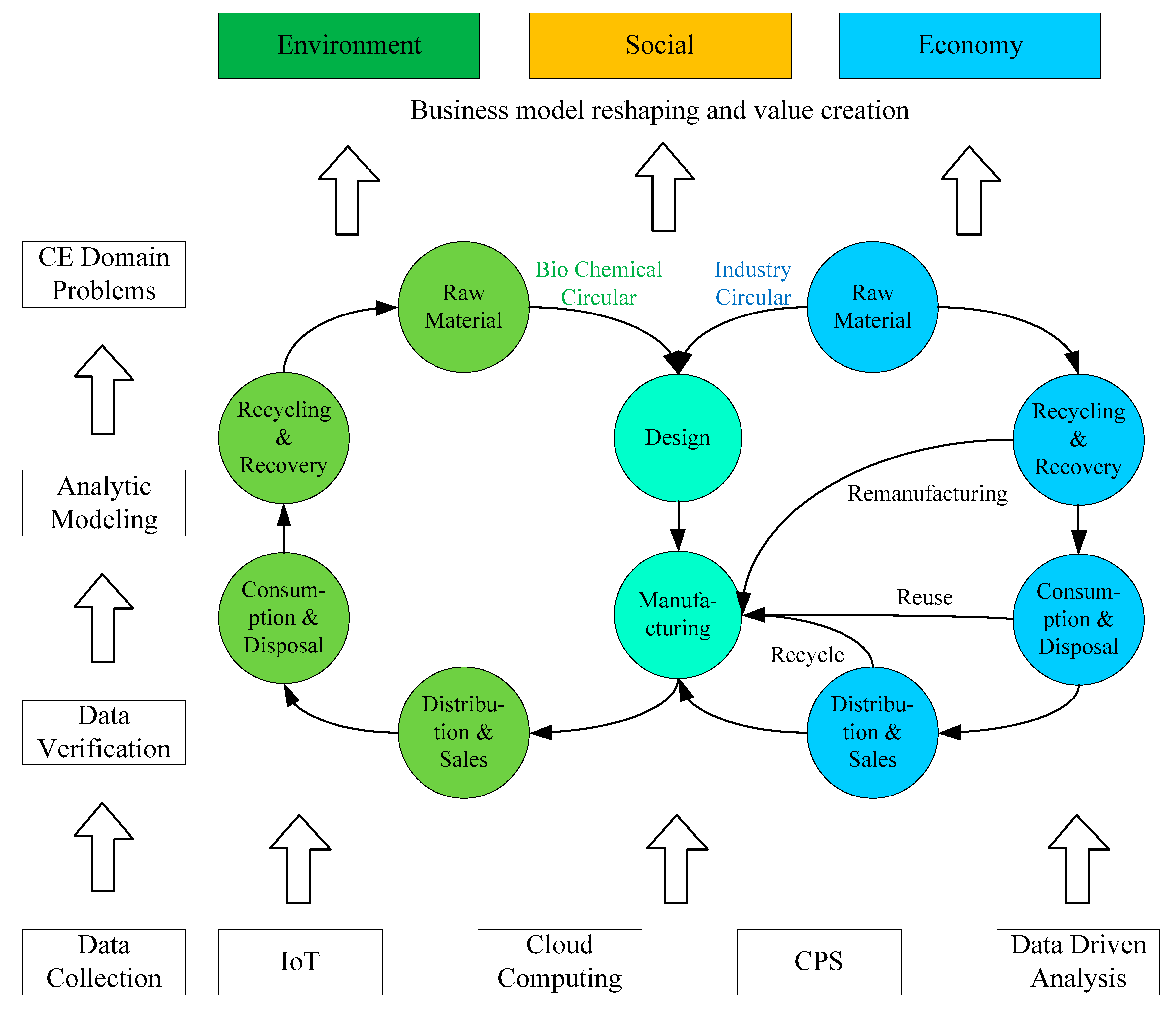

3. Industry 4.0-Supported CE

3.1. Framework of Industry 4.0-Supported CE

- (1)

- To help the transition from linear production to circular production, the collected data should be screened and cleaned based on the expert’s domain knowledge. In a real system, a large amount of big data will be collected; however, most of the data could be considered noise data. Therefore, the data have to be analyzed by using cluster methods. However, most of the time, it will take a lot of time to clean and verify the data.

- (2)

- In order to store and analyze the data, the enterprises should consider building their private cloud or public cloud for computing. With Industry 4.0, high computing speed is needed to deal with vast amounts of real-time data. Sometimes, this technology is also based on the supply chain requirements.

- (3)

- For some special scenarios that have a probability of happening, finding possible solutions through CPS could also help, especially those in the circular economy situations.

- (4)

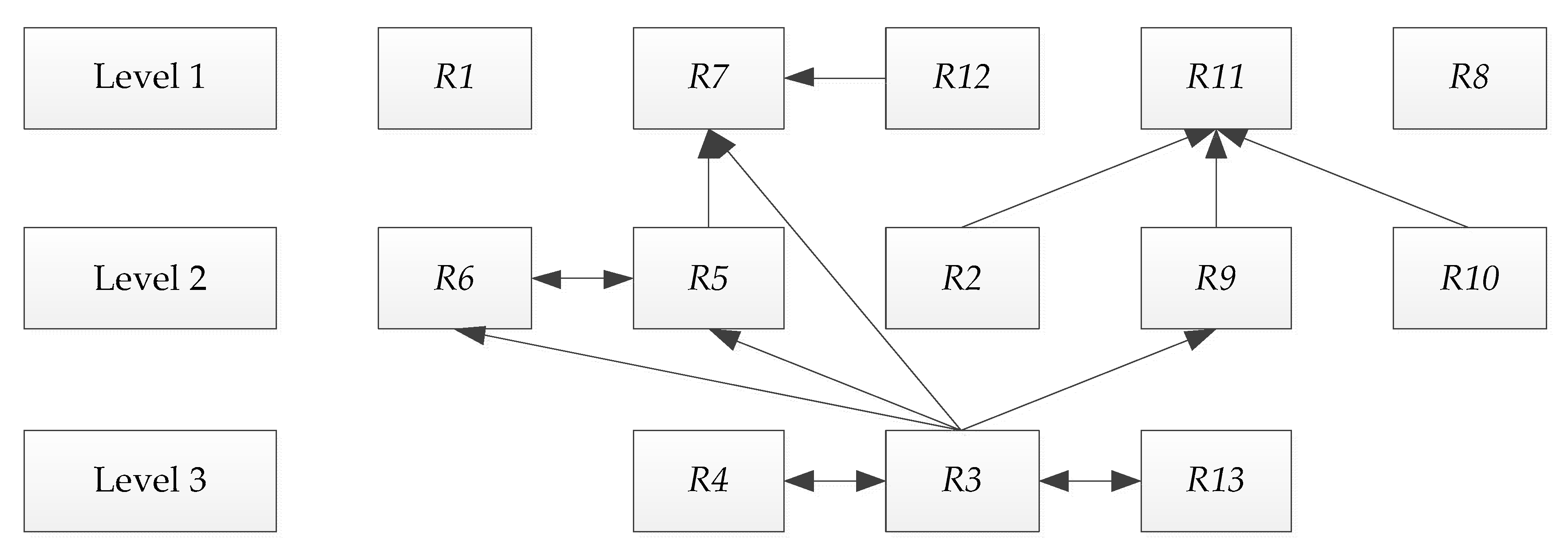

3.2. Interpretive Structural Modeling

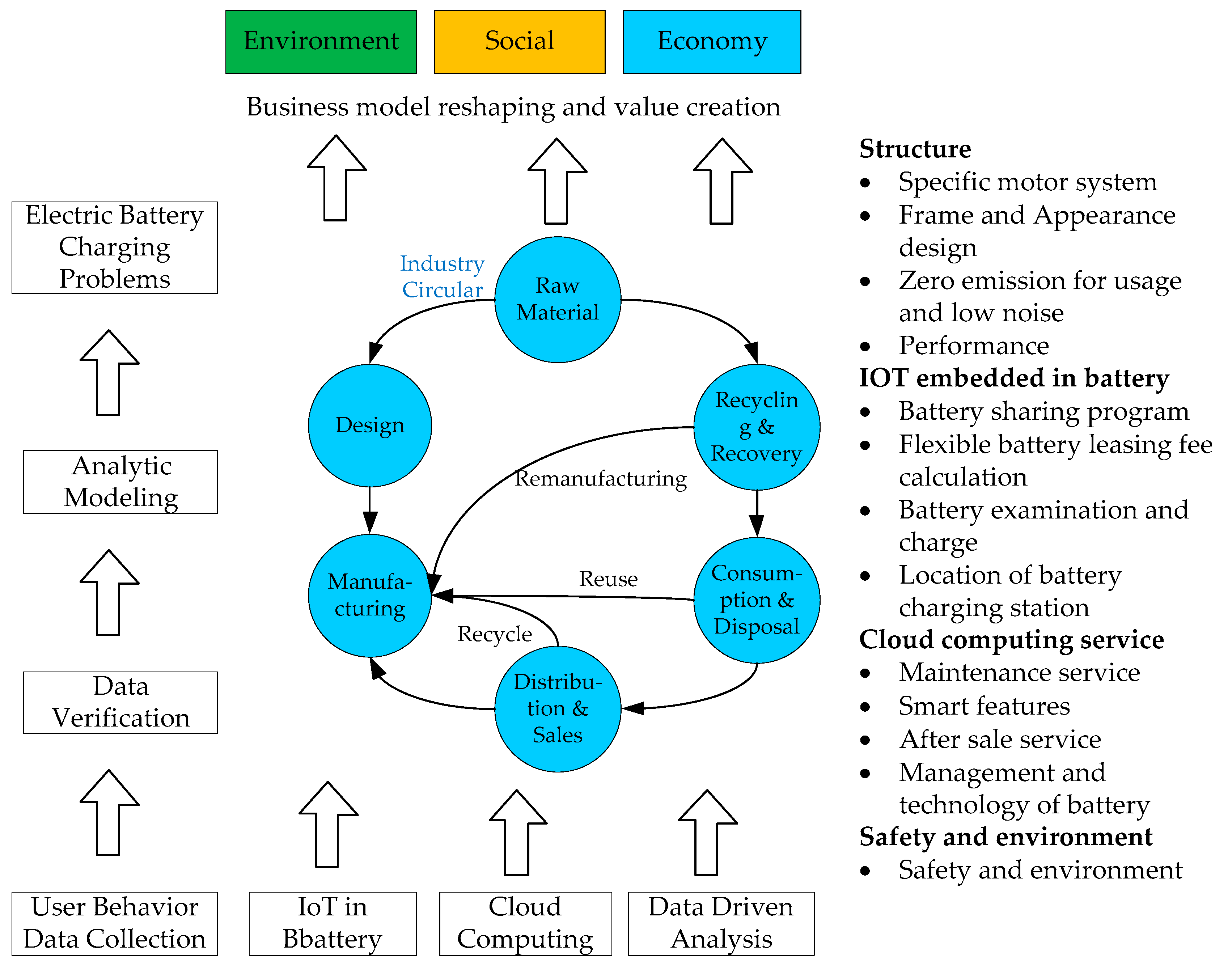

4. Electric Scooter Case of Industry 4.0-Supported CE

4.1. Factors of Accelerating the Sharing Economy in Circular Economy via Industry 4.0

4.2. Data Collection and Analysis of ISM

4.3. Summary of Case Studies

5. Conclusions

- (1)

- Legislative and policy landscape. Research toward CE and Industry 4.0 have shown that inflexible or outdated laws are a big barrier to implementation, and that without strong legal and financial support by the government, such policies may create insurmountable inertia against CE.

- (2)

- Socio-cultural limitations. More advanced nations have developed human and knowledge capital that are capable of supporting the implementation of both Industry 4.0 and the CE.

- (3)

- Corporate culture. Research has shown that firms that have adopted more sustainable business practices outperform their peers However, the fundamental problem for the implementation of Industry 4.0 is data collection and analysis, which can potentially improve the management of material flow in conjunction with various CE tools such as material flow accounting (MFA).

- (4)

- Inter-firm co-dependencies. The final challenge is to create a co-value chain for the circular economy. This challenge can only be solved by creating and maintaining mutual trust between firms, and by creating venues where the use of Industry 4.0 tools can be expanded.

Author Contributions

Funding

Conflicts of Interest

References

- UN. The Sustainable Development Goals. 2019. Available online: https://ec.europa.eu/europeaid/policies/sustainable-development-goals_en (accessed on 10 September 2019).

- EU. Europe Moving Towards a Sustainable Future: Contribution of the Multi-Stakeholder Platform on the implementation of the Sustainable Goals in the EU; Reflection Paper. 2018. Available online: https://ec.europa.eu/info/sites/info/files/sdg_multi-stakeholder_platform_input_to_reflection_paper_su1077 (accessed on 10 September 2019).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of the 21st Century Business; New Society: Gabriola Island, BC, Canada, 1997. [Google Scholar]

- Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.A. What Gets Measured, Gets Done: Development of a Circular Economy Measurement Scale for Building Industry. Sustainability 2018, 10, 2340. [Google Scholar] [CrossRef]

- Hu, Y.; He, X.; Poustie, M. Can Legislation Promote a Circular Economy? A Material Flow-Based Evaluation of the Circular Degree of the Chinese Economy. Sustainability 2018, 10, 990. [Google Scholar] [CrossRef]

- Commission of European Communities. Towards a Circular Economy: A Zero Waste Program for Europe, Communiction No. 398; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143 (Suppl. C), 37–46. [Google Scholar] [CrossRef]

- Foundation, E.M. What is a Circular Economy? Available online: https://www.ellenmacarthurfoundation.org/circular-economy/infographic (accessed on 14 April 2019).

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources adn the Environment; Pearson Education Limited: London, UK, 1990. [Google Scholar]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Seuring, S. A review of modeling approaches for sustainable supply chain management. Decis. Support Syst. 2013, 54, 1513–1520. [Google Scholar] [CrossRef]

- Hobson, K.; Lynch, N.; Lilley, D.; Smalley, G. Systems of practice and the Circular Economy: Transforming mobile phone product service systems. Environ. Innov. Soc. Transit. 2018, 26, 147–157. [Google Scholar] [CrossRef]

- Visvanathan, C.; Adhikari, R.; Ananth, A.P. 3R Practices for Municipal Solid Waste Management in Asia. In Proceedings of the Kalmar ECO-TECH ‘07 and The Second Baltic Symposium on Environmental Chemistry, Kalmar, Sweden, 26–28 November 2007. [Google Scholar]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking circular business: A framework of barriers and drivers. J. Clean. Prod. 2019, 212, 90–98. [Google Scholar] [CrossRef]

- Balanay, R.; Halog, A. Charting Policy Directions for Mining’s Sustainability with Circular Economy. Recycling 2016, 1, 219–231. [Google Scholar] [CrossRef]

- Kuo, T.C.; Lin, S.-H.; Tseng, M.-L.; Chiu, A.S.F.; Hsu, C.-W. Biofuels for vehicles in Taiwan: Using system dynamics modeling to evaluate government subsidy policies. Resour. Conserv. Recycl. 2019, 145, 31–39. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Tan, R.R.; Chiu, A.S.F.; Chien, C.-F.; Kuo, T.C. Circular economy meets industry 4.0: Can big data drive industrial symbiosis? Resour. Conserv. Recycl. 2018, 131, 146–147. [Google Scholar] [CrossRef]

- Cai, Z.; Bourgeois, A.; Tong, W. Guest editorial: Special issue on Internet of Things. Tsinghua Sci. Technol. 2017, 22, 343–344. [Google Scholar]

- Rajput, S.; Singh, S.P. Connecting circular economy and industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Alcayaga, A.; Wiener, M.; Hansen, E.G. Towards a framework of smart-circular systems: An integrative literature review. J. Clean. Prod. 2019, 221, 622–634. [Google Scholar] [CrossRef]

- Johnsen, T.E.; Miemczyk, J.; Howard, M. A systematic literature review of sustainable purchasing and supply research: Theoretical perspectives and opportunities for IMP-based research. Ind. Mark. Manag. 2015. [Google Scholar] [CrossRef]

- Gupta, S.; Palsule-Desai, O.D. Sustainable supply chain management: Review and research opportunities. Iimb Manag. Rev. 2011, 23, 234–245. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Dejax, P.; Miemczyk, J.; Péton, O. Sustainable supply chain network design: An optimization-oriented review. Omega 2015, 54, 11–32. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Kohtala, C. Addressing sustainability in research on distributed production: An integrated literature review. J. Clean. Prod. 2015, 106, 654–668. [Google Scholar] [CrossRef]

- De Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Eco-innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef]

- The Circularity Gap Report: An Analysis of the Circular State of the Global Economy. Available online: https://www.greengrowthknowledge.org/resource/circularity-gap-report-analysis-circular-state-global-economy (accessed on 22 October 2019).

- Shpak, N.; Odrekhivskyi, M.; Doroshkevych, K.; Sroka, W. Simulation of Innovative Systems under Industry 4.0 Conditions. Soc. Sci. 2019, 8, 202. [Google Scholar] [CrossRef]

- Alam, M.T.; Porras, J. Architecting and Designing Sustainable Smart City Services in a Living Lab Environment. Technologies 2018, 6, 99. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, Q.; Pannek, J. Development of Operator Theory in the Capacity Adjustment of Job Shop Manufacturing Systems. Appl. Sci. 2019, 9, 2249. [Google Scholar] [CrossRef]

- Molina-Sánchez, E.; Leyva-Díaz, J.C.; Cortés-García, F.J.; Molina-Moreno, V. Proposal of Sustainability Indicators for the Waste Management from the Paper Industry within the Circular Economy Model. Water 2018, 10, 1014. [Google Scholar] [CrossRef]

- Molina-Moreno, V.; Leyva-Díaz, J.C.; Llorens-Montes, F.J.; Cortés-García, F.J. Design of Indicators of Circular Economy as Instruments for the Evaluation of Sustainability and Efficiency in Wastewater from Pig Farming Industry. Water 2017, 9, 653. [Google Scholar] [CrossRef]

- EEA. Circular Economy in Europe. Developing the Knowledge Base, EEA Reports. 2016. Available online: https://publications.europa.eu/en/publication-detail/-/publication/0cc8128f-d6d3-11e5-8fea-01aa75ed71a1/language-en (accessed on 10 September 2019).

- FORA. Green Business Models in the Nordic Region; Nordic Council of Ministers: Copenhagen, Denmark, 2010. [Google Scholar]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.D.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Calderoni, L.; Magnani, A.; Maio, D. IoT Manager: An open-source IoT framework for smart cities. J. Syst. Archit. 2019. [Google Scholar] [CrossRef]

- Novais, L.; Maqueira, J.M.; Ortiz-Bas, Á. A systematic literature review of cloud computing use in supply chain integration. Comput. Ind. Eng. 2019, 129, 296–314. [Google Scholar] [CrossRef]

- Maqueira-Marín, J.M.; Bruque-Cámara, S.; Minguela-Rata, B. Environment determinants in business adoption of Cloud Computing. Ind. Manag. Data Syst. 2017, 117, 228–246. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Lv, J.; Yang, H.; Wu, J. Energy-cyber-physical system enabled management for energy-intensive manufacturing industries. J. Clean. Prod. 2019, 226, 892–903. [Google Scholar] [CrossRef]

- Wang, W.; Hong, T.; Li, N.; Wang, R.Q.; Chen, J. Linking energy-cyber-physical systems with occupancy prediction and interpretation through WiFi probe-based ensemble classification. Appl. Energy 2019, 236, 55–69. [Google Scholar] [CrossRef]

- Rossit, D.A.; Tohmé, F.; Frutos, M. A data-driven scheduling approach to smart manufacturing. J. Ind. Inf. Integr. 2019. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Luo, Z.; Wamba, S.F.; Roubaud, D. Can big data and predictive analytics improve social and environmental sustainability? Technol. Forecast. Soc. Chang. 2019, 144, 534–545. [Google Scholar] [CrossRef]

- Mayr, A.; Weigelt, M.; Masuch, M.; Meiners, M.; Hüttel, F.; Franke, J. Application Scenarios of Artificial Intelligence in Electric Drives Production. Procedia Manuf. 2018, 24, 40–47. [Google Scholar] [CrossRef]

- Stain, K.M.; Jari, K.-O. Bridging Industry 4.0 and Circular Economy: A New Research Agenda for Finland? 2018. Available online: https://ffrc.wordpress.com/2018/09/12/bridging-industry-4-0-and-circular-economy/ (accessed on 18 April 2019).

- Garcia-Muiña, E.F.; González-Sánchez, R.; Ferrari, M.A.; Settembre-Blundo, D. The Paradigms of Industry 4.0 and Circular Economy as Enabling Drivers for the Competitiveness of Businesses and Territories: The Case of an Italian Ceramic Tiles Manufacturing Company. Soc. Sci. 2018, 7, 255. [Google Scholar] [CrossRef]

- Imran, M.; Hameed, W.; Haque, A. Influence of Industry 4.0 on the Production and Service Sectors in Pakistan: Evidence from Textile and Logistics Industries. Soc. Sci. 2018, 7, 246. [Google Scholar] [CrossRef]

- Imran, M.; Jian, Z.; Haque, A.; Urbański, M.; Nair, S.L.S. Determinants of Firm’s Export Performance in China’s Automobile Industry. Sustainability 2018, 10, 4078. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Ioannis, A. A Framework for Pairing Circular Economy and the Internet of Things. In Proceedings of the 2018 IEEE International Conference on Communications (ICC), Kansas City, MO, USA, 20–24 May 2018. [Google Scholar]

- Lanza, J.; Sánchez, L.; Muñoz, L.; Galache, J.A.; Sotres, P.; Santana, J.R.; Gutiérrez, V. Large-Scale Mobile Sensing Enabled Internet-of-Things Testbed for Smart City Services. Int. J. Distrib. Sens. Netw. 2015, 11. [Google Scholar] [CrossRef]

- Tao, F.; Wang, Y.; Zuo, Y.; Yang, H.; Zhang, M. Internet of Things in product life-cycle energy management. J. Ind. Inf. Integr. 2016, 1, 26–39. [Google Scholar] [CrossRef]

- Trentesaux, D.; Borangiu, T.; Thomas, A. Emerging ICT concepts for smart, safe and sustainable industrial systems. Comput. Ind. 2016, 81, 1–10. [Google Scholar] [CrossRef]

- Romero, D.; Noran, O. Towards Green Sensing Virtual Enterprises: Interconnected Sensing Enterprises, Intelligent Assets and Smart Products in the Cyber-Physical Circular Economy. Ifac-Pap. 2017, 50, 11719–11724. [Google Scholar] [CrossRef]

- Fisher, O.; Watson, N.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Cloud manufacturing as a sustainable process manufacturing route. J. Manuf. Syst. 2018, 47, 53–68. [Google Scholar] [CrossRef]

- Nowicka, K. Cloud Computing in Sustainable Mobility. Transp. Res. Procedia 2016, 14, 4070–4079. [Google Scholar] [CrossRef]

- Singh, A.; Mishra, N.; Ali, S.I.; Shukla, N.; Shankar, R. Cloud computing technology: Reducing carbon footprint in beef supply chain. Int. J. Prod. Econ. 2015, 164, 462–471. [Google Scholar] [CrossRef]

- Wang, X.V.; Wang, L. From Cloud manufacturing to Cloud remanufacturing: A Cloud-based approach for WEEE recovery. Manuf. Lett. 2014, 2, 91–95. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.V.; Gao, L.; Váncza, J. A cloud-based approach for WEEE remanufacturing. CIRP Ann. 2014, 63, 409–412. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Gunasekaran, A.; Dubey, R.; Altay, N.; Childe, S.J.; Fosso-Wamba, S. The role of Big Data in explaining disaster resilience in supply chains for sustainability. J. Clean. Prod. 2017, 142, 1108–1118. [Google Scholar] [CrossRef]

- Rehman, M.H.U.; Chang, V.; Batool, A.; Wah, T.Y. Big data reduction framework for value creation in sustainable enterprises. Int. J. Inf. Manag. 2016, 36, 917–928. [Google Scholar] [CrossRef]

- Song, M.; Cen, L.; Zheng, Z.; Fisher, R.; Liang, X.; Wang, Y.; Huisingh, D. How would big data support societal development and environmental sustainability? Insights and practices. J. Clean. Prod. 2017, 142, 489–500. [Google Scholar] [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.-L.; Lim, M.K.; Hu, J.; Tan, K. Toward sustainability: Using big data to explore the decisive attributes of supply chain risks and uncertainties. J. Clean. Prod. 2017, 142, 663–676. [Google Scholar] [CrossRef]

- Whalen, K.A. Three circular business models that extend product value and their contribution to resource efficiency. J. Clean. Prod. 2019, 226, 1128–1137. [Google Scholar] [CrossRef]

- Gupta, S.; Chen, H.; Hazen, B.T.; Kaur, S.; Santibañez Gonzalez, E.D.R. Circular economy and big data analytics: A stakeholder perspective. Technol. Forecast. Soc. Chang. 2018. [Google Scholar] [CrossRef]

- Lu, Y.; Peng, T.; Xu, X. Energy-efficient cyber-physical production network: Architecture and technologies. Comput. Ind. Eng. 2019, 129, 56–66. [Google Scholar] [CrossRef]

- Jha, S.K.; Bilalovic, J.; Jha, A.; Patel, N.; Zhang, H. Renewable energy: Present research and future scope of Artificial Intelligence. Renew. Sustain. Energy Rev. 2017, 77 (Suppl. C), 297–317. [Google Scholar] [CrossRef]

- Zahraee, S.M.; Khalaji Assadi, M.; Saidur, R. Application of Artificial Intelligence Methods for Hybrid Energy System Optimization. Renew. Sustain. Energy Rev. 2016, 66 (Suppl. C), 617–630. [Google Scholar] [CrossRef]

- Mat Daut, M.A.; Hassan, M.Y.; Abdullah, H.; Rahman, H.A.; Abdullah, M.P.; Hussin, F. Building electrical energy consumption forecasting analysis using conventional and artificial intelligence methods: A review. Renew. Sustain. Energy Rev. 2017, 70 (Suppl. C), 1108–1118. [Google Scholar] [CrossRef]

- Sharpe, R.G.; Goodall, P.A.; Neal, A.D.; Conway, P.P.; West, A.A. Cyber-Physical Systems in the re-use, refurbishment and recycling of used Electrical and Electronic Equipment. J. Clean. Prod. 2018, 170, 351–361. [Google Scholar] [CrossRef]

- Xie, G.; Zeng, G.; Jiang, J.; Fan, C.; Li, R.; Li, K. Energy management for multiple real-time workflows on cyber–physical cloud systems. Future Gener. Comput. Syst. 2017. [Google Scholar] [CrossRef]

- Sung, T.K. Industry 4.0: A Korea perspective. Technol. Forecast. Soc. Chang. 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Kumar, S.; Luthra, S.; Haleem, A. Customer involvement in greening the supply chain: An interpretive structural modeling methodology. J. Ind. Eng. Int. 2013, 9, 1–13. [Google Scholar] [CrossRef]

- Kuo, T.C.; Ma, H.-Y.; Huang, S.H.; Hu, A.H.; Huang, C.S. Barrier analysis for product service system using interpretive structural model. Int. J. Adv. Manuf. Technol. 2010, 49, 407–417. [Google Scholar] [CrossRef]

- BSI. BSI: 2017: The Rise of the Circular Economy; BSI: London, UK, 2017. [Google Scholar]

| Barriers | Description | Authors |

|---|---|---|

| Technology |

| Kalmykova, Sadagopan and Rosado [11] de Jesus and Mendonça [31] Kircherr et al. Kirchherr, Piscicelli, Bour, Kostense-Smit, Muller, Huibrechtse-Truijens and Hekkert [21] CE [32] |

| Economic/Financial/Market |

| |

| Institutional/Regulatory |

| |

| Social/Cultural |

|

| Manage Indicators | Descriptions | Authors |

|---|---|---|

| Innovative and smart system | To produce innovative policy; to provide the subjects of innovative activity with the necessary resources; commercialization; and the practical use of new knowledge | [33,34] |

| Collaborative consumption | To control capacity planning directly with customers and suppliers To implement integration approaches between these processes To participate directly in the process of creation | [35] |

| Measurement and optimization | To optimization of waste management in industrial processes | [36,37] |

| Service- and function-based business models | Service-based business models provide transparency for customers about the costs of the whole use phase, whereas uncertainties exist about the costs of maintenance, repair, and replacement in purchase-based models | [38,39] |

| Structure | |

|---|---|

| R1 | Specific motor system. It includes the motor, motor control, and cooling system, especially for the liquid cooled permanent magnet synchronous system. |

| R2 | Frame and appearance design. It includes a personalized spectrum edgeless dashboard, changeable faceplate, extra-large luggage compartment for full-size helmet storage with a trunk light and USB charge port, and so on. |

| R3 | Zero emission for usage and lower noise. |

| R4 | Performance. It includes acceleration, maximum speed, and maximum riding range per battery swap. |

| IoT embedded in the battery | |

| R5 | Battery-sharing program. The battery could be leased and shared instead of purchasing. User could swap the two batteries in one minute. |

| R6 | Flexible battery-leasing fee calculation. The user could pay the basic fee plus extra cost for extra Amp/Hr. |

| R7 | Battery examination and charging stations. The health of the battery could be monitored and predicted for recycling. |

| R8 | Location of battery-charging stations. Since the IoT is embedded in each battery, the optimization problem related to the numbers and locations of charging stations is the user’s focus. |

| Cloud computing service | |

| R9 | Maintenance service. The maintenance shop location could be analyzed based on the battery exchange stations. |

| R10 | Smart features. It includes smart sensors and wireless communication technology. All the data could be collected for the analysis of big data. |

| R11 | After sale service. The strategies could be determined based on the big data analysis, such as the maintenance policy, battery fee calculation, and so on. |

| R12 | Management and technology of battery. Each battery has its own specific number as its profile. The security is also a very important issue. |

| Safety and environment | |

| R13 | Safety and environment. Zero emission for our environment. |

| R13 | R12 | R11 | R10 | R9 | R8 | R7 | R6 | R5 | R4 | R3 | R2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | O | O | O | O | O | O | O | O | O | O | O | O |

| R2 | O | O | V | O | O | O | O | O | O | O | O | |

| R3 | X | O | O | O | V | O | V | V | V | X | ||

| R4 | O | O | O | V | O | O | O | O | O | |||

| R5 | O | O | O | O | O | O | V | X | ||||

| R6 | O | O | A | O | O | A | A | |||||

| R7 | O | A | O | O | O | O | ||||||

| R8 | O | O | A | A | O | |||||||

| R9 | O | O | V | O | ||||||||

| R10 | O | O | V | |||||||||

| R11 | O | O | ||||||||||

| R12 | O |

| R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | R10 | R11 | R12 | R13 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| R3 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 |

| R4 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R5 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| R6 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| R10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| R11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R13 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | R10 | R11 | R12 | R13 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| R3 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 |

| R4 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R5 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| R6 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| R8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| R9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 |

| R10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| R11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| R12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| R13 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | R10 | R11 | R12 | R13 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| R2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| R3 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| R4 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| R5 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| R6 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| R7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| R8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| R9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 |

| R10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| R11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| R12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| R13 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| Level | Si | Reachability Set (Ri) | Antecedent Set (Ai) | Ri∩Ai |

|---|---|---|---|---|

| 1 | R1 | 1 | 1 | 1 |

| R2 | 2.11 | 2 | 2 | |

| R3 | 3.4.5.6.7.9.11.13 | 3.4.13 | 3.4.13 | |

| R4 | 3.4.5.6.7.9.11.13 | 3.4.13 | 3.4.13 | |

| R5 | 5.6.7 | 3.4.5.6.13 | 5.6 | |

| R6 | 5.6.7 | 3.4.5.6.13 | 5.6 | |

| R7 | 7 | 3.4.5.6.7.13 | 7 | |

| R8 | 8 | 8 | 8 | |

| R9 | 9.11 | 3.4.9.13 | 9 | |

| R10 | 10.11 | 10 | 10 | |

| R11 | 11 | 2.3.4.9.10.11.13 | 11 | |

| R12 | 12 | 12 | 12 | |

| R13 | 3.4.5.6.7.9.11.13 | 3.4.13 | 3.4.13 | |

| 2 | R2 | 2 | 2 | 2 |

| R3 | 3.4.5.6.9.13 | 3.4.13 | 3.4.13 | |

| R4 | 3.4.5.6.9.13 | 3.4.13 | 3.4.13 | |

| R5 | 5.6 | 3.4.5.6.13 | 5.6 | |

| R6 | 5.6 | 3.4.5.6.13 | 5.6 | |

| R9 | 9 | 3.4.9.13 | 9 | |

| R10 | 10 | 10 | 10 | |

| R13 | 3.4.5.6.9.13 | 3.4.13 | 3.4.13 | |

| 3 | R3 | 3.4.13 | 3.4.13 | 3.4.13 |

| R4 | 3.4.13 | 3.4.13 | 3.4.13 | |

| R13 | 3.4.13 | 3.4.13 | 3.4.13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham, T.T.; Kuo, T.-C.; Tseng, M.-L.; Tan, R.R.; Tan, K.; Ika, D.S.; Lin, C.J. Industry 4.0 to Accelerate the Circular Economy: A Case Study of Electric Scooter Sharing. Sustainability 2019, 11, 6661. https://doi.org/10.3390/su11236661

Pham TT, Kuo T-C, Tseng M-L, Tan RR, Tan K, Ika DS, Lin CJ. Industry 4.0 to Accelerate the Circular Economy: A Case Study of Electric Scooter Sharing. Sustainability. 2019; 11(23):6661. https://doi.org/10.3390/su11236661

Chicago/Turabian StylePham, Trang Thi, Tsai-Chi Kuo, Ming-Lang Tseng, Raymond R. Tan, Kimhua Tan, Denny Satria Ika, and Chiuhsiang Joe Lin. 2019. "Industry 4.0 to Accelerate the Circular Economy: A Case Study of Electric Scooter Sharing" Sustainability 11, no. 23: 6661. https://doi.org/10.3390/su11236661

APA StylePham, T. T., Kuo, T.-C., Tseng, M.-L., Tan, R. R., Tan, K., Ika, D. S., & Lin, C. J. (2019). Industry 4.0 to Accelerate the Circular Economy: A Case Study of Electric Scooter Sharing. Sustainability, 11(23), 6661. https://doi.org/10.3390/su11236661