1. Introduction

In 2016, the five-year average pork production reached 36.4% of the total meat production in the world, which is much higher than that of beef production (20.2%) and mutton production (4.5%) [

1]. In China, the five-year average percentage of pork production of total meat production reached 64.1% [

1]. This large supply for pork stimulates the growth of the pig-raising sector. Especially in China, to gain the most benefits from pig-raising, the conventional household pig-raising systems, which are thousands of years old, have changed to large-scale and intensive pig production [

2,

3]. In order to pursue fast-growing and high final weight, Chinese farmers tended to raise crossbred pigs instead of the local pig breed and to supply more concentrated and fine feed. This transformation of the pig-raising sector has caused a series of environmental problems. Improper treatment of waste has caused nutrient pollution in the soil and water bodies [

4]. The gases released from pigpens, such as ammonia, hydrogen sulfide, and greenhouse gases, can be offensive and may cause air pollution [

5]. In addition, the excessive use of antibiotics and heavy metal additives may harm the environment [

6].

An ecological breeding system is a kind of system which is beneficial to the environment. Through modern science and technology and system engineering methods based on ecological and economic principles, such as the application of the biological agents instead of chemical agents to disinfect and control odor, the application of the slatted floor to reduce the water wasting, and no use of the heavy-metal or synthetic additives in the diets, ecological breeding systems could have economic benefits and protect natural resources [

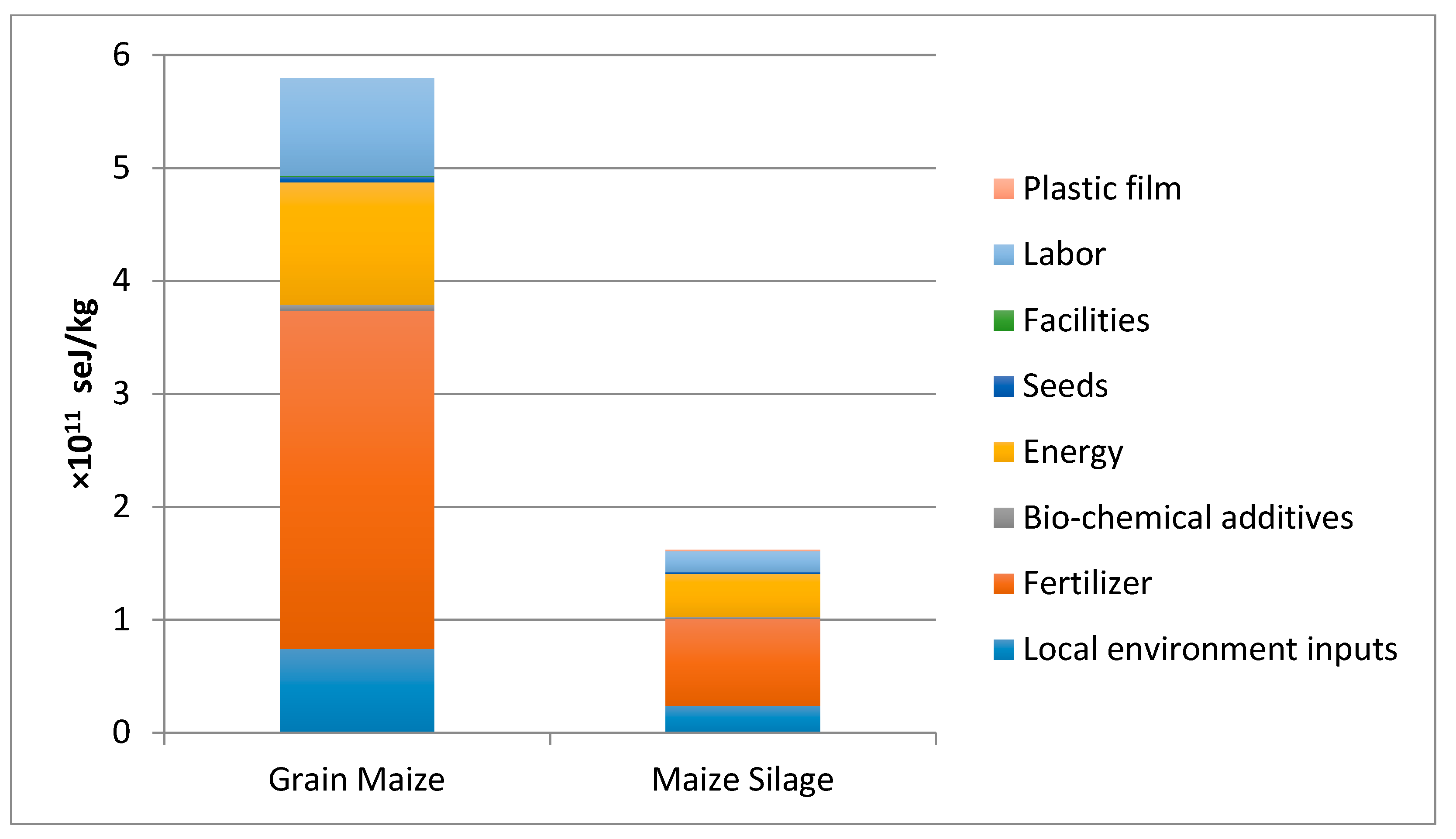

7]. Furthermore, there was a structural difference between ecological pig-raising systems (EPRSs) and intensive systems: The feed consumed in the intensive systems was all bought from the market instead of planting. So intensive systems just considered the accessibility of the feed purchased from the market and tried to feed more livestock in the limited areas instead of considering the planting structure or plant species to raise livestock [

8]. EPRS would consider the reuse of the waste produced by livestock. However, intensive systems just discharge the waste into the septic-tank or wastewater treatment plant. Ecological pig-raising systems (EPRSs) aim to decrease the environmental impacts of pig-raising and increase the quality of pork products. However, EPRSs have two main disadvantages that have limited the improvements realized: a long fattening period and a high amount of required inputs [

9]. The long fattening period of the EPRS is unavoidable. However, the EPRSs can use two methods to reduce inputs: reduce the cost of the feed (adding a large percentage of plant fiber or improving crop yields) and choosing suitable pig breeds. According to other research, pigs can extract some energy from cellulose with the aid of bacteria in their intestinal tract [

10,

11,

12]. Moreover, the process of making silage can release cellular nutrient content thus increasing the concentration of available nutrients accessible to the animal [

13]. Furthermore, the pigs could exploit about 50% forage-based protein [

14] or extract up to 25% of the total energy from fermentation products [

15]. Thus, it is very helpful to improve the environment-friendly performances when crude fiber or something similar added in the diet during the fattening period [

16,

17]. In theory, maize silage could replace a large part of the maize used as feed, as a more effective means of supplying nutrients to the animals. Another important factor in pig-raising is the pig breeds. Different pig breeds have different growth rates and different tolerances for roughage. In this study, we investigated the influence of maize silage added to the feed and the chosen pig breeds on the effectiveness of the raising systems based on an integrated analysis that combined emergy evaluation and economic analysis with an evaluation of livestock carrying capacity.

Many studies have performed joint economy and emergy analyses of livestock production systems [

18,

19]. However, studies also evaluating livestock carrying capacity are rare, as the latter requires a large amount of chemical analysis data. Most of such studies collected data through the survey questionnaire methods instead of collecting the data directly [

20,

21,

22]. Meanwhile, most of these studies have focused on the economic benefits of large-scale and intensive livestock production systems [

21,

23]. Few studies have focused on the analysis of organic livestock production systems. However, these studies mainly focus on the compassion of different models without optimization methods of the existing systems. Furthermore, some studies have focused on the effects of feeding silage on pig activities, pork quality, and slaughter performance [

24,

25,

26], while ignoring effects on the entire system. Consequently, this study set three mimic experiments to assess performances of different EPRSs on the environment, economy, and livestock carrying capacity using a comprehensive evaluation method.

The objectives of this study were to (1) assess overall differences in performance trends due to different feed ingredients and pig breeds and (2) offer suggestions for better management methods for EPRSs. Consequently, we chose two pig breeds: three-breed crossbred pigs, which are raised widely and grow quickly, and the Tuhe black pig (a local Chinese breed), which has a higher tolerance for roughage. In addition, we examined different maize silage concentrations added in the feed during the fattening period. Three different EPRSs were studied at one site. Besides, we evaluated environmental impact, emergy sustainability, economic benefit, and livestock carrying capacity of these three systems through an integrated analysis method to ensure that the results were comprehensive.

2. Materials and Methods

2.1. Study Site

We set up three EPRSs on Beiqiu Farm (37°00′ N, 116°34′ E) as described below, which is in Yucheng County, Shandong Province, China. Beiqiu Farm has a warm temperate semi-humid monsoon climate. Its mean annual frost-free period and temperature are 200 d year−1 and 13.1 °C, respectively. Its mean annual solar radiation, hours of sunshine and precipitation are 5225 MJ·m−2, 2640 h and 582 mm, respectively.

The scale and structure of Beiqiu Farm indicated that it was a typical family farm that combined crop planting and livestock breeding in the alluvial plain of the Yellow River [

27]. The total area of this farm is approximately 15.3 ha with a winter wheat-summer maize double cropping area of 8 ha, an ecological livestock production area of 1.5 ha, a greenhouse planting area of 1 ha, agro-processing workshops, a waste treatment system, and a farmyard recreation area. The EPRS on this farm has existed since 2010. In the usual production mode used on this farm, pigs are fed a diet of only maize grain, soya bean meal, and wheat bran meal for approximately five months.

2.2. Experimental Design

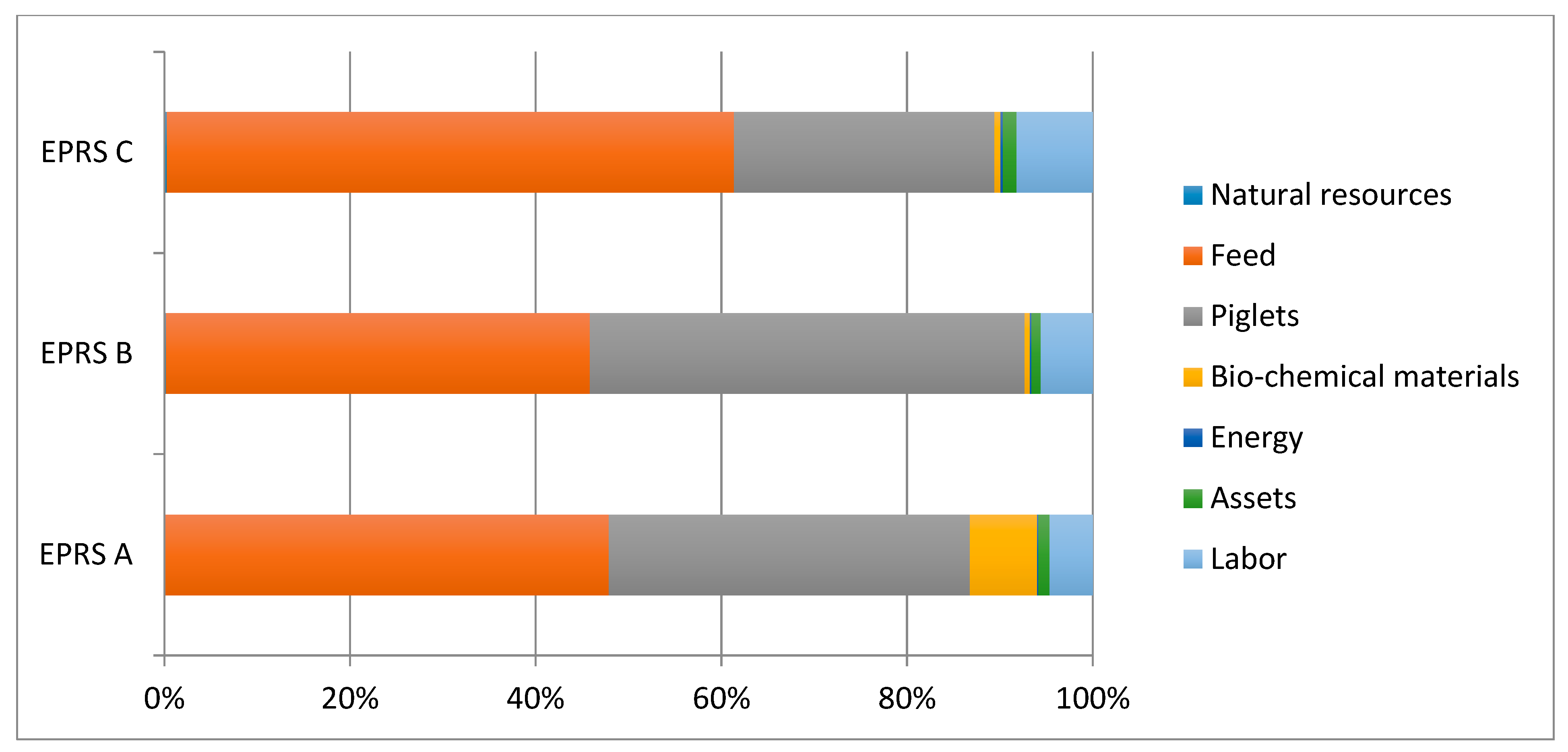

The study involved 3 feeding groups with 2 sexes, and each group contained 8 pigs; the experiment started on 27 July 2017 and ended on 11 January 2018. 16 crossbred Duroc × (Landrace × Northeastern Indigenous) pigs and 8 Tuhe black pigs were fed in 20 m

2 pens. Half of the pigs were barrows and half were gilts. Each pen contained 4 pigs (2 of each sex), and the pens had concrete slatted floors. When purchased as piglets, the 16 crossbred pigs had a mean (±1 standard deviation (SD)) weight of 26.21 ± 3.41 kg and were randomly distributed into 4 pens. The pigs in two of these pens were fed the farm’s standard diet (maize grain, soya bean meal, and wheat bran meal) (EPRS A) (

Table 1). For the other two pens of crossbred pigs, sun-dried maize silage replaced some of the maize grain in the diet (EPRS B). When purchased as piglets, the 8 Tuhe black pigs had a mean (±1 SD) weight of 10.65 ± 1.23 kg and were randomly distributed into 2 pens. The Tuhe black pigs were fed with the feed containing the same sun-dried maize silage as EPRS C.

All pens were cleaned by a manure scraper under the floor without water flushing. In summer, the temperature was maintained below 30 °C via two axial flow fans and wet curtains. At temperatures below 0 °C, all windows and doors were closed, and no heating was applied. Each day, pens were disinfected by a spray solution containing 125 mL of a biological agent (ETS Gold Liquid Enzyme, ETS (Tianjin) Biotechnology Development Co. Ltd., Tianjin, China) in 20 L of water.

To create the diets of EPRS B and EPRS C, some of the maize grain of the EPRS A diet was replaced by sun-dried maize silage; the percentages of the other ingredients remained the same. The pig-raising experiment was divided into 4 phases: the adaptive phase (<30 kg), phase I (30–40 kg), phase II (40–50 kg), and phase III (>50 kg). In the adaptive phase which lasted for 3 weeks, the percentage of the sun-dried maize silage (by mass) increased by 10% each week until it reached 30%. The percentage of maize silage increased from 30% in phase I to 40% in phase III (

Table 1). The feeds were mixed by a grinder with a 20 mesh sieve. All groups were offered sufficient feed twice a day and ad libitum water via nipple drinkers.

2.3. Data Collection

Pigs were weighed using an electronic cage scale (Lilang XK3190, Changzhouliliang electronics Co. Ltd., Changzhou, China) at the beginning and end of each phase. During the weighting process, we just let the pigs walk across the channel. Then this kind of electronic cage scale could weigh pigs one by one with little stress reaction to the pigs. The amount of water and electricity used during the entire raising period was recorded by meters. The amounts of feed consumed were recorded every day. The weights of manure and urine excreted during the entire period were calculated as:

Since pigs discharged the waste in a special area, it was available to predict the discharge activities and to collect. Manure and urine samples were collected by a long-handled water ladle and then weighed on an electronic scale (Weiheng WH-A04, Shanghai Weiheng electronics Co. Ltd., Shanghai, China) twice every phase. In addition, the frequency of excretion was recorded by a video camera (Xiaofang iSC5, Xiaomi technology co. LTD, Beijing, China). Data on building materials and equipment were obtained from the farm’s account books.

Manure samples were stored at −20 °C. Before drying, samples were thawed until reaching room temperature. Then, samples were dried in the oven at 105 °C for 30 min and at 70 °C for 48 h. Before chemical analysis, samples were ground and passed through 0.25 mm sieves. Nitrogen and moisture contents were detected with NY/T 2017-2011 and NY/T 302-1995 methods, respectively.

2.4. Emergy Analysis

Emergy analysis shows internal relationships among parts of a system using energy systems language (ESL) [

28]. This method uses solar energy (solar emjoules (seJ)) as the standard unit [

29]. All-natural resources, economic inputs, materials, and energy can be transformed into the same unit by suitable formulas [

29]; thus, different systems can be compared.

ESL diagrams show the main components of the three EPRS evaluations and the relationships among them (

Figure 1). The inputs driving the EPRSs came mainly from the local environmental resources (E

L) and economic inputs from markets (F). Based on aggregated system diagrams, all data should be collected and recorded in a table. These data were then transformed to the emergy values via multiplication by suitable unit emergy values (UEVs). All inputs were composed of a renewable fraction (R) and a nonrenewable fraction (N), and the value of each fraction is calculated using renewability factors (RNFs). The pig live weight produced by the EPRS (Y1) flowed out of the system into the market. Besides, the manure produced by the EPRS (Y2) also flowed out of the system as waste. To simplify the calculation, we treated Y2 as a by-product which contained 0 seJ. In general, the available energies of rain and wind are regarded as both being derived from solar energy. In this study, only the largest value of these three items will be considered in the emergy analysis. The emergy of topsoil loss was calculated using soil organic carbon (SOC) concentration [

29]. Thus, the factor of topsoil loss from the E

L was canceled out as the SOC concentration of the entire North China Plain increased over the past 30 years under conventional tillage methods [

30]. Three years of local SOC data from the Yucheng Comprehensive Experiment Station also verified this trend (

Supplementary Material D). The comparisons among the different systems mainly depended on the emergy index. In this case, we chose the units emergy value (UEV), emergy yield ratio (EYR), environmental loading ratio (ELR), and emergy sustainability index (ESI) as the index by which we characterized the system (

Table 2) [

31,

32]. The UEV of Chinese Yuan (emergy/dollar ratio) was also called emdollar which reflected the purchased power of a local currency. Generally, the higher emdollar one area had, the less developed it was [

33]. As the near-linear correlation between real GDP and total emergy inputs [

34], the UEV of the Chinese Yuan (¥) in 2017 was 3.31 × 10

11 seJ/¥ under 12.0 × 10

24 seJ/year baseline which was calculated based on the UEV (7.27 × 10

11 seJ/¥ with 9.26 × 10

24 seJ/year baseline) calculated by Yang (2010) in 2005 and the GDP deflator of 2005 to 2017 (2.84) [

33,

35]. In this study, the global emergy baseline was 12.00 × 10

24 seJ/year. All UEVs from other baselines were converted to the same baseline by multiplying by a coefficient [

36].

2.5. Economic Analysis

The economic analysis was based mainly on inputs and outputs of the EPRSs (

Supplementary Material C), which were used to calculate 3 economy-based indices: yield-based economic profit (Py), area-based economic profit (Pa), and the ratio of income to cost (I:C) (

Table 3). Py is a common index reflecting the earning ability per unit production. Pa calculates the area needed in the production process based on Py. I:C shows the rate of return during the production process. Prices of materials and products were obtained from the account books of Beiqiu Farm in 2017.

2.6. Livestock Carrying Capacity Evaluation

The evaluation of livestock carrying capacity estimated the maximum number of livestock that could be raised per unit area without degrading the land area used to produce feed [

38]. Two indices were calculated. The first carrying capacity (L1) was calculated as the amount of feed this area could provide (Equation (2)), based on the diets consumed in the experiment [

39,

40]. Due to the main planting structure (winter wheat-summer maize cropping system) in North China plain, L1 was calculated by the yield of the wheat and maize. In 2017, the supplement of the soybean meal to the pig-raising sector is sufficient in Shandong Province without sharp price fluctuation. So, quantity of the soybean meal could be purchased in the market was assigned to market supply capacity which was not a limit factor for L1.

where A

i (ha) is the planting area for crop

i; Y

i (kg/ha/year) is the yield of crop

i; C

i (kg/year) is the mean amount of feed from crop

i that livestock consumed per year.

The second carrying capacity (L2) was determined by the amount of nitrogen or phosphorus from the livestock that could be used to fertilize the land [

41,

42] (Equation (3)). L2 was calculated by the data of nitrogen or phosphorus that was dependent on the land tillage method. Generally, in China, the L2 of crop field was calculated by the amount of nitrogen. Meanwhile, L2 of the land planted vegetables was calculated from the amount of phosphorus [

43]. In our experiment, the field was only planted grains; thus, we took the amount of nitrogen into calculation.

where K (%) is the fraction of the manure fertilizer applied per year; N (kg) is the amount of nitrogen consumed by the crops per year; M (kg) is the amount of nitrogen from livestock manure; γ (%) is the fraction of nitrogen from total fertilizer; ε (%) is the nitrogen retention rate of the manure fertilizer per year; θ (%) is the manure nitrogen utilization efficiency of the crop per year.

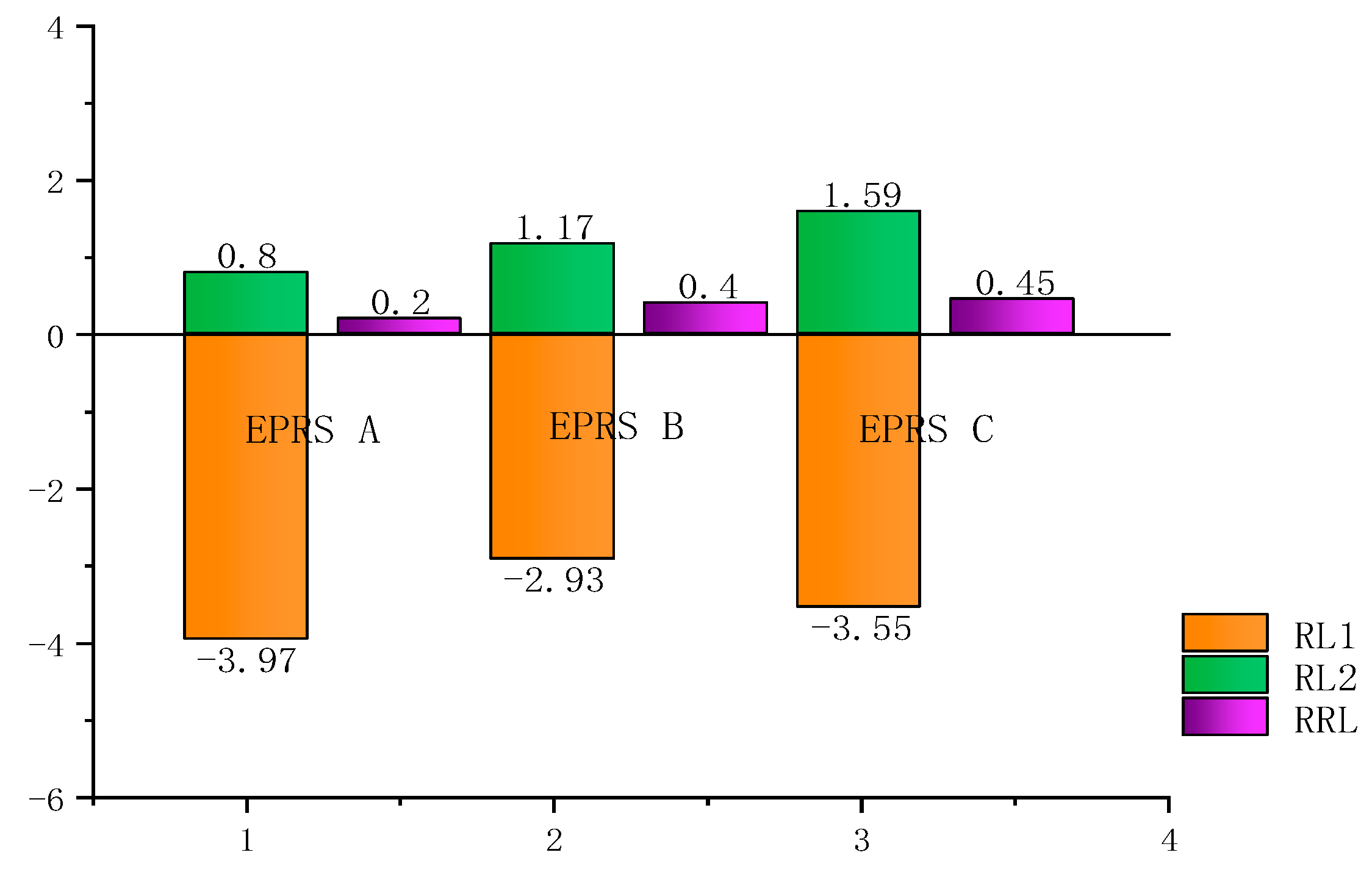

To compare the two breeds in more detail, we created additional indices: RL1 and RL2 (m

2/kg) (the reciprocals of L1 and L2, respectively; they reflected the land area needed to produce 1 kg of final live weight) and RRL (Equation (4), the ratio RL2:RL1; it reflected the degree of nutrient element recycling. Performance increases as RRL increases).

In order to clarify the RRL, we divided L1 and L2 to negative and positive index, respectively. To some extent, the more organic fertilizer (especially from EPRSs) is applied instead of chemical fertilizer, the more beneficial it will be to the environment and sustainability [

44,

45]. That means the calculation of L1 was based on the outputs of the land. However, the calculation of L2 was based on inputs of the land which can be regarded as a feedback process. Consequently, we defined L1 as a negative index and L2 as a positive index.

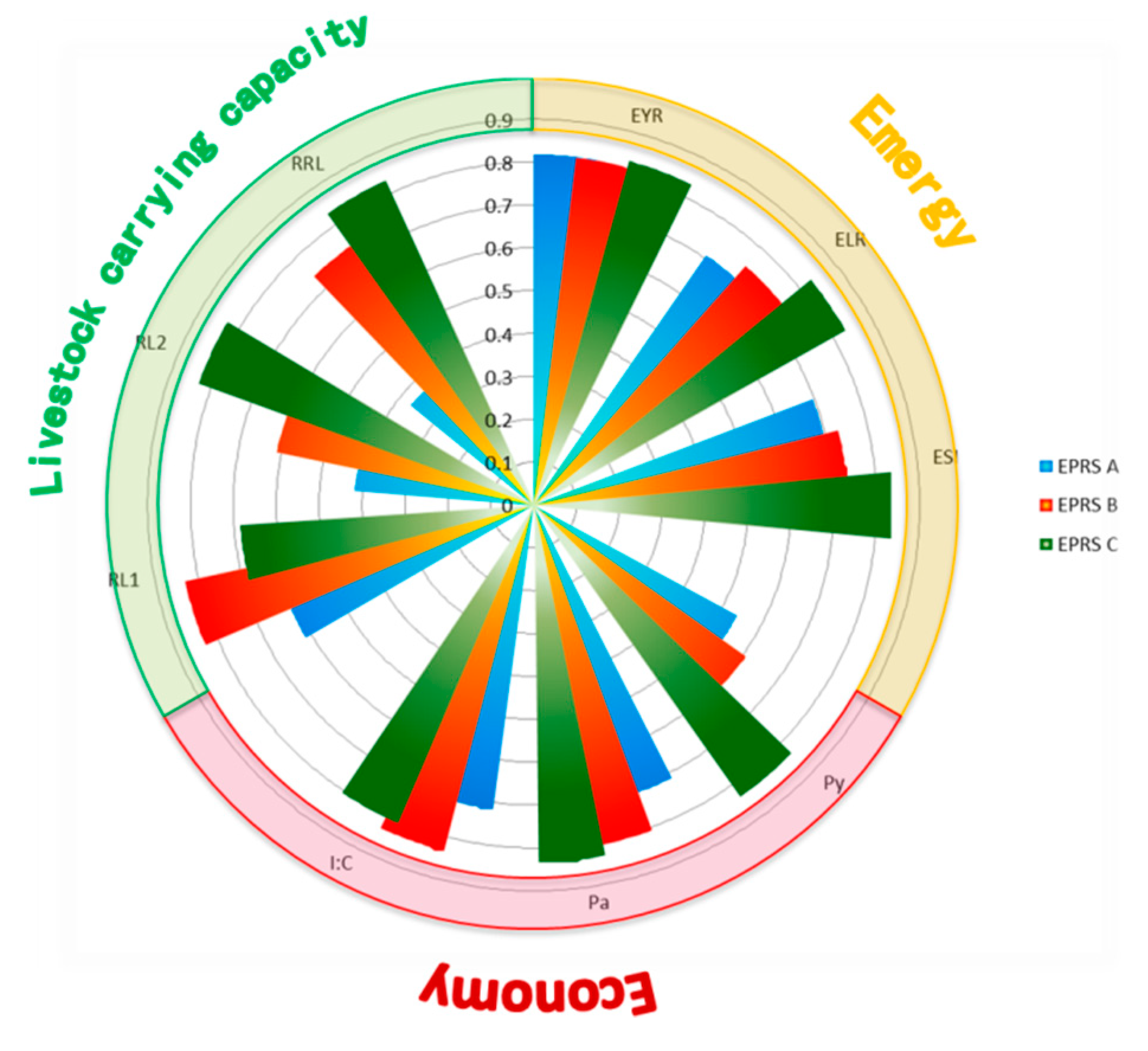

2.7. Integrated Analysis

To integrate the analyses, we displayed the main emergy, economic, and carrying capacity indices in a rose diagram to show the performance of each EPRS. Reciprocals of negatively correlated indices (the performance of negatively correlated indices are the less the better) were calculated. Each index’s upper limit was set as 1.2 times that of the maximum value, and then each index was shown as a percentage of the upper limit. The integrated performance was determined mainly by the area that each system covered in each of the three sectors.

5. Conclusions

With the market demand increasing for pork produced with lower environmental impacts, many ecological pig-raising systems have been created in China. However, integrated analysis based on emergy evaluation, economic analysis, and livestock carrying capacity evaluation provided a comprehensive assessment of differences among the EPRSs.

In this study, having up to 40% sun-dried maize silage in feed did not affect the final weight of same breed pigs. However, the unit emergy value (UEV), environmental loading ratio (ELR), and emergy sustainability index (ESI) of such systems were much better than those of the system whose feed contained only traditional grain crops (maize, wheat, soya bean). In addition, the area planted to feed the pigs decreased and the area that could be fertilized increased when the feed contained maize silage. Pig breed was another important factor. The Tuhe black pig, as a traditional Chinese pig, had disadvantages of higher cost (especially for piglets) and lower yield. However, due to the flavor of its pork, the Tuhe black pig had a much higher price per kg live weight than the crossbred pig. Furthermore, the Tuhe black pig had greater ability to digest crude fiber. As expected, Tuhe black pig had better economic benefits, emergy performances, and livestock carrying capacity than the crossbred pig.

In conclusion, the ecological pig sector raised indoor on North China plain could try to choose local pig breeds and add non-food crops in the feed to increase economic benefits and improve environmental consequences.