Energy-Efficient Window Retrofit for High-Rise Residential Buildings in Different Climatic Zones of China

Abstract

:1. Introduction

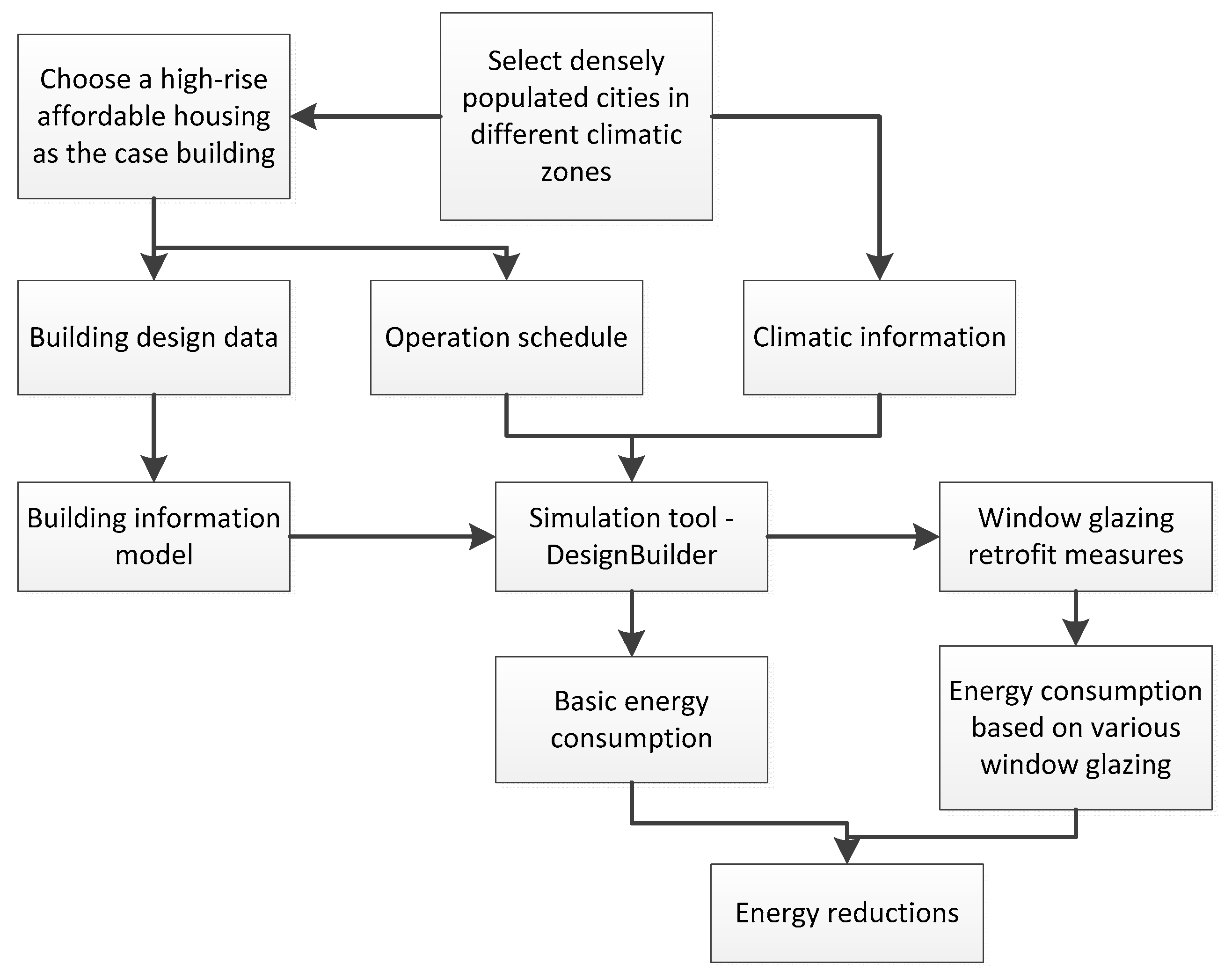

2. Method

- (1)

- identifying the climate zones and their representative high-density cities;

- (2)

- choosing a typical high-rise residential block as a base for modelling and collecting the data needed for its modelling and simulation;

- (3)

- building a BIM model of the block in Autodesk Revit and base energy model in DesignBuilder from the data gathered;

- (4)

- selecting a variety of window glazing types for comparison with the traditional window glazing used;

- (5)

- simulating the heating and cooling loads of the block for each window glazing type in each climate zone;

- (6)

- analyzing the energy consumption involved and conducting a data analysis involving such thermal properties as U-value and SHGC; and

- (7)

- comparing the energy savings predicted from the different types of window glazing and finding the best type for each climate.

- (1)

- modeling in Autodesk Revit and DesignBuilder;

- (2)

- validating the base energy model with the energy consumption results of previous studies;

- (3)

- the use of alternative window glazing to compare with the traditional window design; and

- (4)

- hundreds of iterations simulating the energy reduction of the building model for each type of glazing.

3. Base Case

3.1. The Building

3.2. Data Collection and Site Survey

3.3. Building Data

3.4. Window Glazing

3.5. Modeling

4. Simulation Results

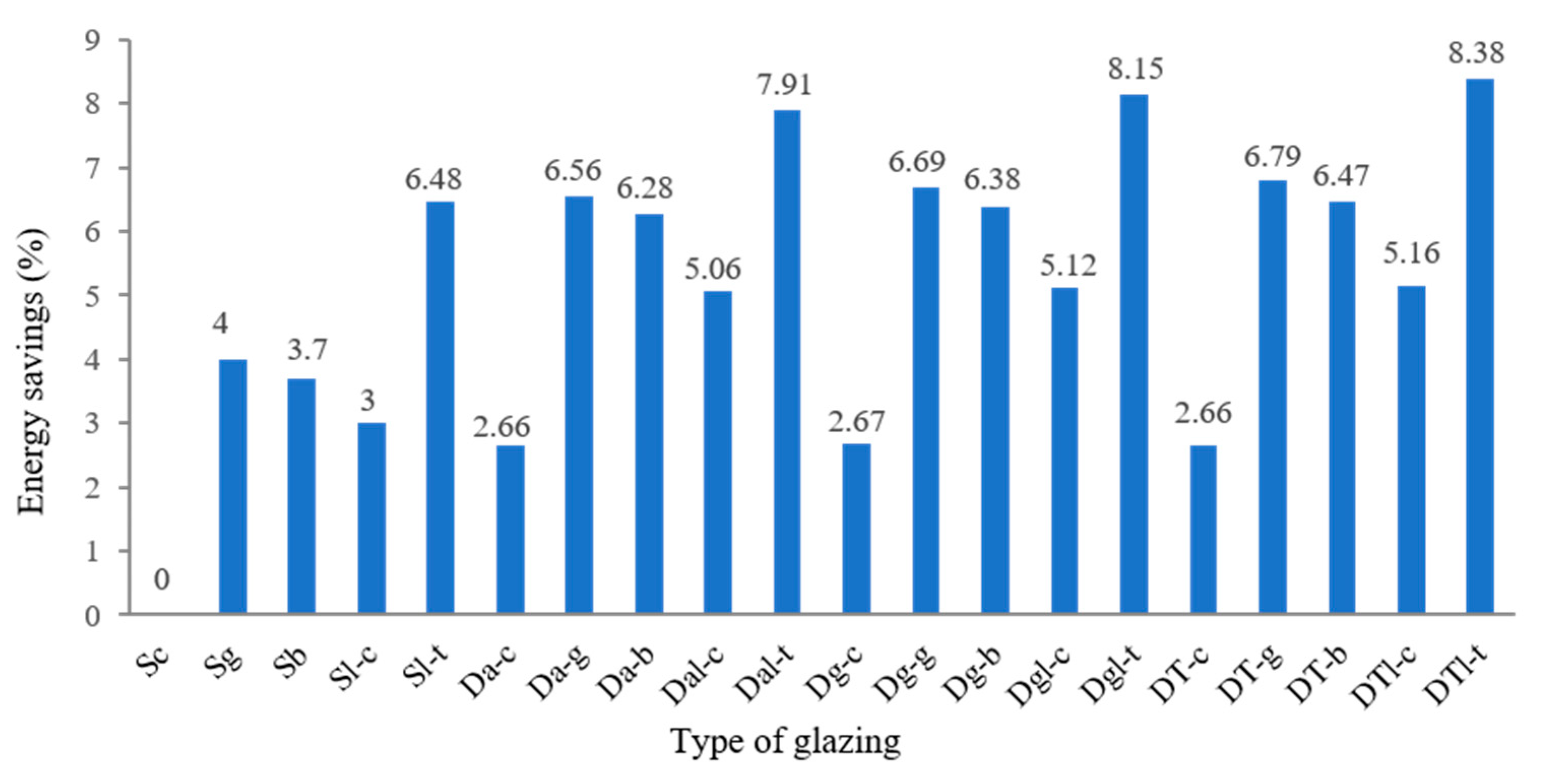

4.1. Window Glazing in the Hot Summer/Warm Winter Climate

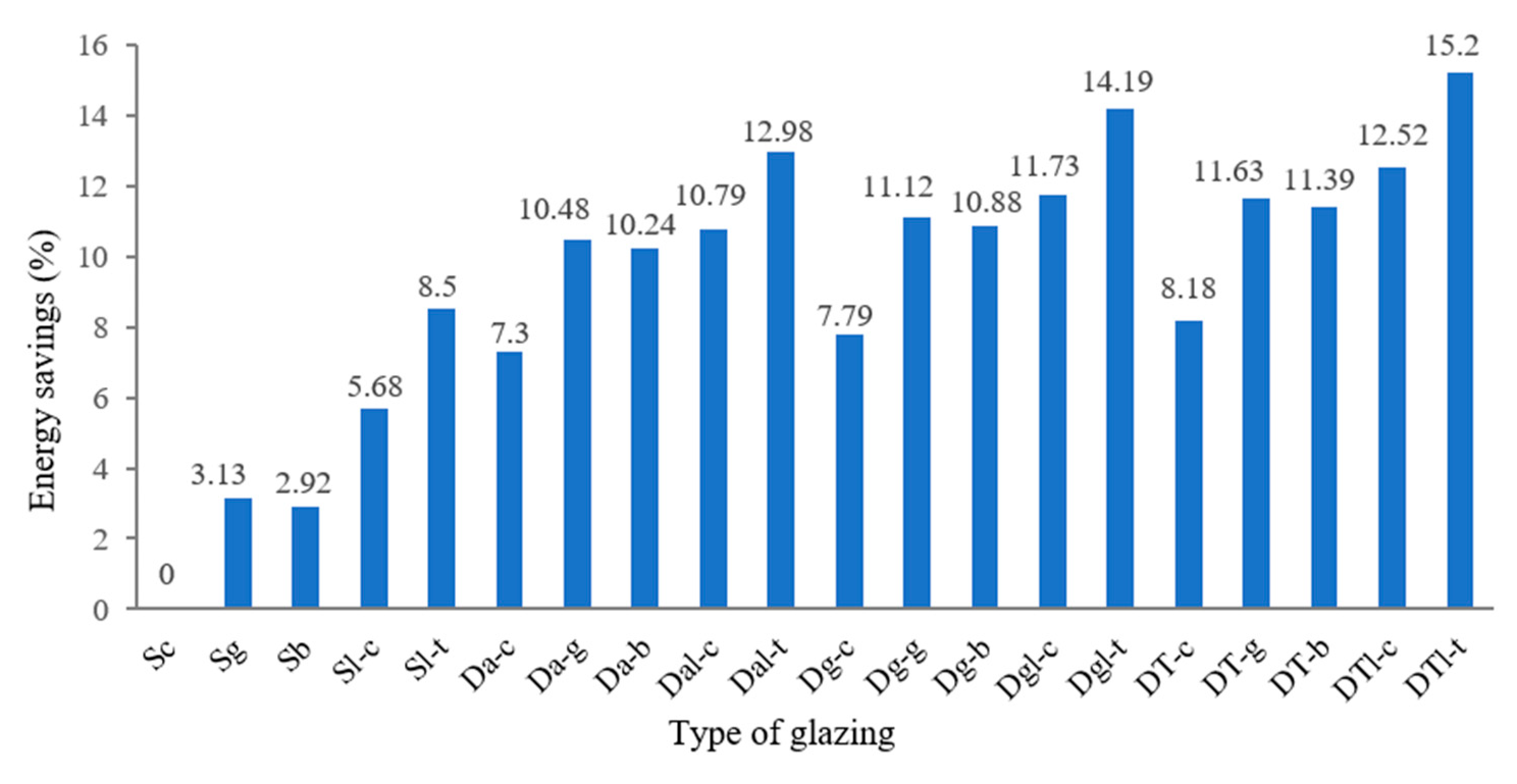

4.2. Window Glazing in the Hot Summer/Cold Winter Climate

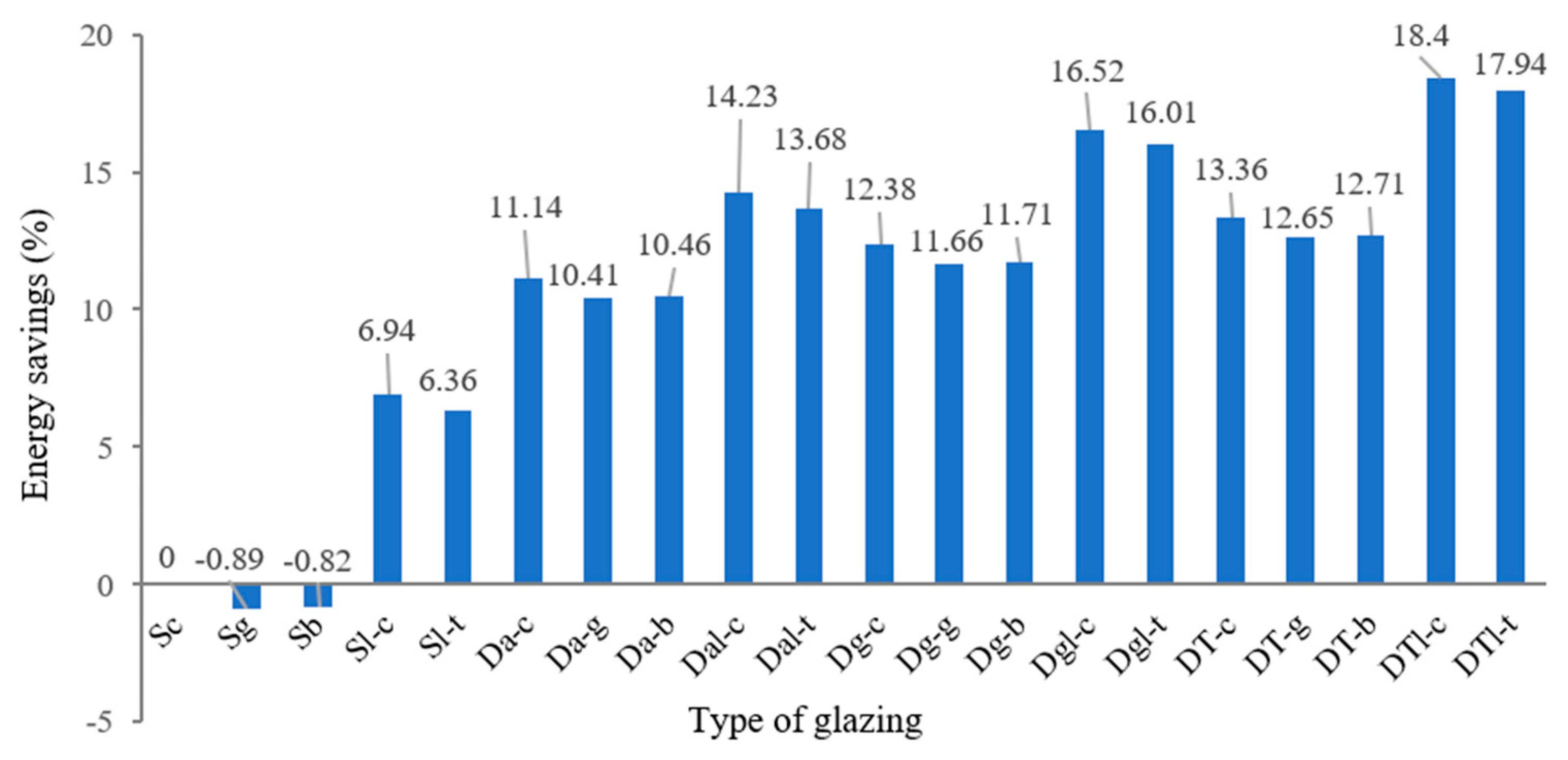

4.3. Window Glazing in the Cold Climate

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Yang, L.; Yan, H.; Lam, J.C. Thermal comfort and building energy consumption implications—A review. Appl. Energy 2014, 115, 164–173. [Google Scholar] [CrossRef]

- Urge-Vorsatz, D.; Cabeza, L.F.; Serrano, S.; Barreneche, C.; Petrichenko, K. Heating and cooling energy trends and drivers in buildings. Renew. Sustain. Energy Rev. 2015, 41, 85–98. [Google Scholar] [CrossRef]

- Kaynakli, O. A review of the economical and optimum thermal insulation thickness for building applications. Renew. Sustain. Energy Rev. 2013, 16, 415–425. [Google Scholar] [CrossRef]

- Zheng, G.; Jing, Y.; Huang, H.; Gao, Y. Application of improved grey relational projection method to evaluate sustainable building envelope performance. Appl. Energy 2011, 87, 710–720. [Google Scholar] [CrossRef]

- Pombo, O.; Allacker, K.; Rivela, B.; Neila, J. Sustainability assessment of energy saving measures: A multi-criteria approach for residential buildings retrofitting—A case study of the Spanish housing stock. Energy Build. 2016, 116, 384–394. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Eom, J.; Clarke, L.; Kim, S.H.; Kyle, P.; Patel, P. China’s building energy demand: Long-term implications from a detailed assessment. Energy 2012, 46, 405–419. [Google Scholar] [CrossRef]

- Ahn, B.L.; Kim, J.H.; Jang, C.Y.; Leigh, S.B.; Jeong, H. Window retrofit strategy for energy saving in existing residences with different thermal characteristics and window sizes. Build. Serv. Eng. Res. Technol. 2016, 37, 18–32. [Google Scholar] [CrossRef]

- Khodaei, H.; Hajiali, M.; Darvishan, A.; Sepehr, M.; Ghadimi, N. Fuzzy-based heat and power hub models for cost-emission operation of an industrial consumer using compromise programming. Appl. Therm. Eng. 2018, 137, 395–405. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, W.; Ghadimi, N. Electricity load forecasting by an improved forecast engine for building level consumers. Energy 2017, 139, 18–30. [Google Scholar] [CrossRef]

- Mohammadi, M.; Talebpour, F.; Safaee, E.; Ghadimi, N.; Abedinia, O. Small-scale building load forecast based on hybrid forecast engine. Neural Process. Lett. 2018, 48, 329–351. [Google Scholar] [CrossRef]

- IEA. Energy Balances of Non-OECD Countries; International Energy Agency (IEA): Pairs, France, 2015. [Google Scholar]

- Yang, W.; Kohler, N. Simulation of the evolution of the Chinese building and infrastructure stock. Build. Res. Inf. 2008, 36, 1–19. [Google Scholar] [CrossRef]

- Güneralp, B.; Zhou, Y.; Ürge-Vorsatz, D.; Gupta, M.; Yu, S.; Patele, P.L.; Fragkias, M.; Li, X.; Seto, K.C. Global scenarios of urban density and its impacts on building energy use through 2050. Proc. Natl. Acad. Sci. USA 2017, 114, 8945–8950. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Tan, H.; Ruan, Y. A future bamboo-structure residential building prototype in China: Life cycle assessment of energy use and carbon emission. Energy Build. 2011, 43, 2638–2646. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Life-cycle assessment and control measures for carbon emissions of typical buildings in China. Build. Environ. 2015, 86, 89–97. [Google Scholar] [CrossRef]

- Yim, S.Y.C.; Ng, S.T.; Hossain, M.U.; Wong, J.M.W. Comprehensive evaluation of carbon emissions for the development of high-rise residential building. Buildings 2018, 8, 147. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T. Influence of waste materials on buildings’ life cycle environmental impacts: Adopting resource recovery principle. Resour. Conserv. Recycl. 2019, 142, 10–23. [Google Scholar] [CrossRef]

- Huang, J.; Lv, H.; Gao, T.; Feng, W.; Chen, Y.; Zhou, T. Thermal properties optimization of envelope in energy-saving renovation of existing public buildings. Energy Build. 2014, 75, 504–510. [Google Scholar] [CrossRef]

- Huang, Y.; Niu, J.L. Optimal building envelope design based on simulated performance: History, current status and new potentials. Energy Build. 2016, 117, 387–398. [Google Scholar] [CrossRef]

- Galvin, R.; Sunikka-Blank, M. Ten questions concerning sustainable domestic thermal retrofit policy research. Build. Environ. 2017, 118, 377–388. [Google Scholar] [CrossRef]

- Heo, Y.; Augenbroe, G.; Graziano, D.; Muehleisen, R.T.; Guzowski, L. Scalable methodology for large scale building energy improvement: Relevance of calibration in model-based retrofit analysis. Build. Environ. 2015, 87, 342–350. [Google Scholar] [CrossRef]

- Synnefa, A.; Vasilakopoulou, K.; De Masi, R.F.; Kyriakodis, G.E.; Londorfos, V.; Mastrapostoli, E.; Karlessi, T.; Santamouris, M. Transformation through renovation: An energy efficient retrofit of an apartment building in Athens. Procedia Eng. 2017, 180, 1003–1014. [Google Scholar] [CrossRef]

- Kim, J.; Son, D.; Jeong, B. Two-stage integer programing model for building retrofit planning for energy saving in South Korea. Sustainability 2017, 9, 2087. [Google Scholar]

- Yang, H.; Liu, L.; Li, X.; Liu, C.; Jones, P. Tailored domestic retrofit decision making towards integrated performance targets in Tianjin, China. Energy Build. 2017, 140, 480–500. [Google Scholar] [CrossRef]

- Regnier, C.; Sun, K.; Hong, T.; Piette, M.A. Quantifying the benefits of a building retrofit using an integrated system approach: A case study. Energy Build. 2018, 159, 332–345. [Google Scholar] [CrossRef]

- Mangan, S.D.; Oral, G.K. Assessment of residential building performances for the different climate zones of Turkey in terms of life cycle energy and cost efficiency. Energy Build. 2016, 110, 362–376. [Google Scholar] [CrossRef]

- Ihm, P.; Park, L.; Krarti, M.; Seo, D. Impact of window selection on the energy performance of residential buildings in South Korea. Energy Policy 2012, 44, 1–9. [Google Scholar] [CrossRef]

- Chan, A.L.; Chow, T.T.; Fong, K.F.; Lin, Z. Investigation on energy performance of double skin facade in Hong Kong. Energy Build. 2009, 41, 1135–1142. [Google Scholar] [CrossRef]

- Sudhakar, K.; Winderl, M.; Priya, S.S. Net-zero building designs in hot and humid climates: A state-of-art. Case Stud. Therm. Eng. 2019, 13, 100400. [Google Scholar] [CrossRef]

- Wan, K.K.W.; Cheung, K.L.; Liu, D.; Lam, J.C. Impact of modelled global solar radiation on simulated building heating and cooling loads. Energy Convers. Manag. 2009, 50, 662–667. [Google Scholar] [CrossRef]

- Lartigue, B.; Lasternas, B.; Loftness, V. Multi-objective optimization of building envelope for energy consumption and daylight. Indoor Built Environ. 2014, 23, 70–80. [Google Scholar] [CrossRef]

- Mehaoued, K.; Lartigue, B. Influence of a reflective glass façade on surrounding microclimate and building cooling load: Case of an office building in Algiers. Sustain. Cities Soc. 2019, 46, 101443. [Google Scholar] [CrossRef]

- Perino, M.; Serra, V. Switching from static to adaptable and dynamic building envelopes: A paradigm shift for the energy efficiency in buildings. J. Facade Des. Eng. 2015, 3, 143–163. [Google Scholar] [CrossRef] [Green Version]

- Giovannini, L.; Favoino, F.; Serra, V.; Zinzi, M. Thermo-chromic glazing in buildings: A novel methodological framework for a multi-objective performance evaluation. In Proceedings of the 10th International Conference on Applied Energy (ICAE), Hong Kong, China, 22–25 August 2018. [Google Scholar]

- Jonsson, A.; Roos, A. Visual and energy performance of switchable windows with antireflection coatings. Sol. Energy 2010, 84, 1370–1375. [Google Scholar] [CrossRef]

- Haglund, K.L. Decision-making methodology & selection tools for high-performance window systems in U.S. climates. In Proceedings of the 2nd Building Enclosure Science & Technology Conference, Portland, OR, USA, 12–14 April 2010; pp. 1–13. [Google Scholar]

- Lee, J.W.; Jung, H.J.; Park, J.Y.; Lee, J.B.; Yoon, Y. Optimization of building window system in Asian regions by analyzing solar heat gain and daylighting elements. Renew. Energy 2013, 50, 522–531. [Google Scholar] [CrossRef]

- Yaşar, Y.; Kalfa, S.M. The effects of window alternatives on energy efficiency and building economy in high-rise residential buildings in moderate to humid climates. Energy Convers. Manag. 2012, 64, 170–181. [Google Scholar] [CrossRef]

- Smith, N.; Isaacs, N.; Burgess, J.; Cox-Smith, I. Thermal performance of secondary glazing as a retrofit alternative for single-glazed windows. Energy Build. 2012, 54, 47–51. [Google Scholar] [CrossRef]

- Chow, T.T.; Fong, K.F.; He, W.; Lin, Z.; Chan, A.L. Performance evaluation of a PV ventilated window applying to office building of Hong Kong. Energy Build. 2007, 39, 643–650. [Google Scholar] [CrossRef]

- Citherlet, T.; Guglielmo, F.D.; Gay, J.B. Window and advanced glazing systems life cycle assessment. Energy Build. 2000, 32, 225–234. [Google Scholar] [CrossRef]

- Lee, E.S.; Claybaugh, E.S.; LaFrance, M. End user impacts of automated electrochromic windows in a pilot retrofit application. Energy Build. 2012, 47, 267–284. [Google Scholar] [CrossRef] [Green Version]

- Gardiner, D.J.; Morris, S.M.; Coles, H.J. High-efficiency multistable switchable glazing using smectic A liquid crystals. Sol. Energy Mater. Sol. Cells 2009, 93, 301–306. [Google Scholar] [CrossRef]

- Clarke, J.A.; Janak, M.; Ruyssevelt, P. Assessing the overall performance of advanced glazing systems. Sol. Energy 1998, 63, 231–241. [Google Scholar] [CrossRef]

- Corgnati, S.P.; Perino, M.; Serra, V. Experimental assessment of the performance of an active transparent façade during actual operating conditions. Sol. Energy. 2007, 81, 993–1013. [Google Scholar] [CrossRef]

- Deb, C.; Lee, S.E. Determining key variables influencing energy consumption in office buildings through cluster analysis of pre- and post-retrofit building data. Energy Build. 2018, 159, 228–245. [Google Scholar] [CrossRef]

- Ginks, N.; Painter, B. Energy retrofit interventions in historic buildings: Exploring guidance and attitudes of conservation professionals to slim double glazing in the UK. Energy Build. 2017, 149, 391–399. [Google Scholar] [CrossRef]

- Hee, W.J.; Alghoula, M.A.; Bakhtyar, B.; Elayeba, O.; Shameri, M.A.; Alrubaih, M.S.; Sopian, K. The role of window glazing on daylighting and energy saving in buildings. Renew. Sustain. Energy Rev. 2015, 42, 323–343. [Google Scholar] [CrossRef]

- Fasi, M.A.; Budaiwi, I.M. Energy performance of windows in office buildings considering daylight integration and visual comfort in hot climates. Energy Build. 2015, 108, 307–316. [Google Scholar] [CrossRef]

- Farzaneh, A.; Monfet, D.; Forgues, D. Review of using Building Information Modeling for building energy modeling during the design process. J. Build. Eng. 2019, 23, 127–135. [Google Scholar] [CrossRef]

- Jeong, W.S.; Kim, J.B.; Clayton, M.J.; Haberl, J.S.; Yan, W. A framework to integrate object-oriented physical modelling with building information modelling for building thermal simulation. J. Build. Perform. Simul. 2016, 9, 50–69. [Google Scholar] [CrossRef]

- Marzouk, M.; Abdelkader, E.M.; Al-Gahtani, K. Building information modeling-based model for calculating direct and indirect emissions in construction projects. J. Clean. Prod. 2017, 152, 351–363. [Google Scholar] [CrossRef]

- Lim, Y.W. Building Information Modeling for indoor environmental performance analysis. Am. J. Environ. Sci. 2015, 11, 55–61. [Google Scholar] [CrossRef] [Green Version]

- Shadram, F.; Mukkavaara, J. An integrated BIM-based framework for the optimization of the trade-off between embodied and operational energy. Energy Build. 2018, 158, 1189–1205. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, X.; Jin, X.; Zhou, X.; Si, B.; Shi, X. Towards adoption of building energy simulation and optimization for passive building design: A survey and a review. Energy Build. 2018, 158, 1306–1316. [Google Scholar] [CrossRef]

- Lam, J.C.; Tsang, C.L.; Li, D.H.; Cheung, S.O. Residential building envelope heat gain and cooling energy requirements. Energy 2005, 30, 933–951. [Google Scholar] [CrossRef]

- Liu, S.; Kwok, Y.T.; Lau, K.K.L.; Chan, P.W.; Ng, E. Investigating the energy saving potential of applying shading panels on opaque façades: A case study for residential buildings in Hong Kong. Energy Build. 2019, 193, 78–91. [Google Scholar] [CrossRef]

- Utility Savings Initiative. Setback Temperature Control. Retrieved from North Carolina. 2010. Available online: https://files.nc.gov/ncdeq/Environmental%20Assistance%20and%20Customer%20Service/IAS%20Energy%20Efficiency/Opportunities/Setback_Temperature_Control.pdf (accessed on 24 August 2019).

- Selvey. What do “Set Point” and “Set Back” Mean? 2012. Available online: https://selveyheating.wordpress.com/2012/08/02/what-do-set-point-and-set-back-mean/ (accessed on 24 August 2019).

- Peng, Y.; Rysanek, A.; Nagy, Z.; Schluter, A. Using machine learning techniques for occupancy-prediction-based cooling control in office buildings. Appl. Energy 2018, 211, 1343–1358. [Google Scholar] [CrossRef]

- Bojic, M.; Yik, F.; Leung., W. Thermal insulation of cooled spaces in high rise residential buildings in Hong Kong. Energy Convers. Manag. 2002, 43, 165–183. [Google Scholar] [CrossRef]

- Bojic, M.; Yik, F.; Sat, P. Energy performance of windows in high-rise residential buildings in Hong Kong. Energy Build. 2002, 34, 71–82. [Google Scholar] [CrossRef]

- Bojic, M.; Yik, F.; Sat, P. Influence of envelope and partition characteristics on the space cooling of high-rise residential buildings in Hong Kong. Build. Environ. 2002, 37, 347–355. [Google Scholar] [CrossRef]

- Fong, K.F.; Lee, C.K. Towards net zero energy design for low-rise residential buildings in subtropical Hong Kong. Appl. Energy 2012, 93, 686–694. [Google Scholar] [CrossRef]

- Chow, T.; Li, C.; Lin, Z. Innovative solar windows for cooling-demand climate. Sol. Energy Mater. Sol. Cells 2010, 94, 212–220. [Google Scholar] [CrossRef]

- Zhou, B. Choosing materials for high-rise building envelope in severe cold region New Building. Mater. Chin. 1994, 11, 6–9. [Google Scholar]

- Beijing Uni-Construction Group Co. Ltd. Report on EEEB Demonstration Project Building No.12 Huixin West Street, Beijing; Sino-German Technical Cooperation Energy Efficiency in Existing Buildings (EEEB): Beijing, China, 2010. [Google Scholar]

- Urumqi Construction Committee. Urumqi CaoChangXiang District Pilot Project Report; Sino-German Technical Cooperation Energy Efficiency in Existing Buildings: Urumchi, China, 2011; pp. 1–128. [Google Scholar]

- Tangshan Bureau of Construction. Tangshan Pilot Project Summary Report and Lessons Learned; Tangshan Bureau of Construction: Tangshan, China, 2008; pp. 1–172.

- Heilongjiang Textile Industry Design Institute. Report on the Energy-Efficient Retrofit of Existing Residential Buildings in Harbin; Heilongjiang Textile Industry Design Institute: Harbin, China, 2012; pp. 1–47. [Google Scholar]

- Huang, X. Impact of external window glazing on building energy saving. Energy Source Environ. 2008, 4, 99–100. (In Chinese) [Google Scholar]

- Lai, C.M.; Wang, Y.H. Energy-saving potential of building envelope designs in residential houses in Taiwan. Energies 2011, 4, 2061–2076. [Google Scholar] [CrossRef]

- Chen, L. Energy-Saving Applicability Research of Low-E Glass Windows in Residential Buildings in the Subtropical Region. Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2012. [Google Scholar]

- Ge, H.; McClung, V.R.; Zhang, S. Impact of balcony thermal bridges on the overall thermal performance of multi-unit residential buildings: A case study. Energy Build. 2013, 60, 163–173. [Google Scholar] [CrossRef]

- Ge, H.; Baba, F. Dynamic effect of thermal bridges on the energy performance of a low-rise residential building. Energy Build. 2015, 105, 106–118. [Google Scholar] [CrossRef]

- Capozzoli, A.; Gorrino, A.; Corrado, V. A building thermal bridges sensitivity analysis. Appl. Energy 2013, 107, 229–243. [Google Scholar] [CrossRef]

- Boafo, F.E.; Ahn, J.G.; Kim, J.T.; Kim, J.H. Computing thermal bridge of vip in building retrofits using DesignBuilder. Energy Procedia 2015, 78, 400–405. [Google Scholar] [CrossRef] [Green Version]

- Cuce, E.; Cuce, P.M. Vacuum glazing for highly insulating windows: Recent developments and future prospects. Renew. Sustain. Energy Rev. 2016, 54, 1345–1357. [Google Scholar] [CrossRef]

- Cuce, E.; Young, C.H.; Riffat, S.B. Thermal performance investigation of heat insulation solar glass: A comparative experimental study. Energy Build. 2015, 86, 595–600. [Google Scholar] [CrossRef]

- Wan, K.S.Y.; Yik, F.W.H. Building design and energy end-use characteristics of high-rise residential buildings in Hong Kong. Appl. Energy 2004, 78, 19–36. [Google Scholar] [CrossRef]

- Cheung, C.K.; Fuller, R.J.; Luther, M.B. Energy-efficient envelope design for high-rise apartments. Energy Build. 2005, 37, 37–48. [Google Scholar] [CrossRef] [Green Version]

- EMSD. Hong Kong Energy End-Use Data; Electrical & Mechanical Services Department (EMSD), The Government of Hong Kong Special Administrative Region: Hong Kong, China, 2015. [Google Scholar]

- Wan, K.K.W.; Li, D.H.W.; Lam, J.C. Assessment of climate change impact on building energy use and mitigation measures in subtropical climates. Energy 2011, 36, 1404–1414. [Google Scholar] [CrossRef]

- Sadrzadehrafiei, S.; Sopian, K.S.M.; Lim, C. Application of advanced glazing to midrise office buildings in Malaysia. In Proceedings of the 9th WSEAS International Conference on Environment, Ecosystems and Development (EED’11), Montreal, QC, Canada, 2011; pp. 197–201. [Google Scholar]

- Liu, H. The Development of Novel Window Systems towards Low Carbon Buildings. Ph.D. Thesis, The University of Nottingham, Nottingham, UK, 2012. [Google Scholar]

- Cuce, E.; Riffat, S.B. A state-of-the-art review on innovative glazing technologies. Renew. Sustain. Energy Rev. 2015, 41, 695–714. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, M.; Shu, C.; Mmereki, D.; Hossain, M.U.; Zhan, X. Impact analysis of window-wall ratio on heating and cooling energy consumption of residential buildings in hot summer and cold winter zone in China. J. Eng. 2015, 2015, 538254. [Google Scholar] [CrossRef] [Green Version]

- Shaeri, J.; Habibi, A.; Yaghoubi, M.; Chokhachian, A. The optimum window-to-wall ratio in office buildings for hot-humid, hot-dry, and cold climates in Iran. Environments 2019, 6, 45. [Google Scholar] [CrossRef] [Green Version]

- Chiesa, G.; Acquaviva, A.; Grosso, M.; Bottaccioli, L.; Floridia, M.; Pristeri, E.; Sanna, E.M. Parametric optimization of window-to-wall ratio for passive buildings adopting a scripting methodology to dynamic-energy simulation. Sustainability 2019, 11, 3078. [Google Scholar] [CrossRef] [Green Version]

- Goia, F. Search for the optimal window-to-wall ratio in office buildings in different European climates and the implications on total energy saving potential. Sol. Energy 2016, 132, 467–492. [Google Scholar] [CrossRef]

- Troup, L.; Phillips, R.; Eckelman, M.J.; Fannon, D. Effect of window-to-wall ratio on measured energy consumption in US office buildings. Energy Build. 2019, 203, 109434. [Google Scholar] [CrossRef]

- Marino, C.; Nucara, A.; Pietrafesa, M. Does window-to-wall ratio have a significant effect on the energy consumption of buildings? A parametric analysis in Italian climate conditions. J. Build. Eng. 2017, 13, 169–183. [Google Scholar] [CrossRef]

- Appelfeld, D.; McNeil, A.; Svendsen, S. An hourly based performance comparison of an integrated micro-structural perforated shading screen with standard shading systems. Energy Build. 2012, 50, 166–176. [Google Scholar] [CrossRef] [Green Version]

- Cappelletti, F.; Gasparella, A.; Romagnoni, P.; Baggio, P. Analysis of the influence of installation thermal bridges on windows performance: The case of clay block walls. Energy Build. 2011, 43, 1435–1442. [Google Scholar] [CrossRef]

- Baldinelli, G.; Bianchi, F. Windows thermal resistance: Infrared thermography aided comparative analysis among finite volumes simulations and experimental methods. Appl. Energy 2014, 136, 250–258. [Google Scholar] [CrossRef]

- Huang, J.; Gurney, K.R. The variation of climate change impact on building energy consumption to building type and spatiotemporal scale. Energy 2016, 111, 137–153. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Gurney, K.R. Impact of climate change on U.S. building energy demand: Financial implications for consumers and energy suppliers. Energy Build. 2017, 139, 747–754. [Google Scholar] [CrossRef] [Green Version]

- Waddicor, D.A.; Fuentes, E.; Siso, L.; Salom, J.; Favre, B.; Jimenez, C.; Azar, M. Climate change and building ageing impact on building energy performance and mitigation measures application: A case study in Turin, northern Italy. Build. Environ. 2016, 102, 13–25. [Google Scholar] [CrossRef]

- Sun, K.; Hong, T. A simulation approach to estimate energy savings potential of occupant behavior measures. Energy Build. 2017, 136, 43–62. [Google Scholar] [CrossRef] [Green Version]

| Consideration | Occupancy Density (People/m2) | General Lighting Power Density (W/m2) | Computer Load (W/m2) | Cooking Equipment (W/m2) | Miscellaneous Equipment (W/m2) |

|---|---|---|---|---|---|

| Building load | 0.1 | 0.6 | 2 | 7 | 4 |

| Operation schedule | 24 h | 6 a.m.–8.a.m. and 4 p.m.–11 p.m. | 6 a.m.–8.a.m. and 4 p.m.–11 p.m. | 6 a.m.–7. 30 a.m. and 5 p.m.–8 p.m. | 24 h |

| Category | Construction | U-Value (W/m2·k) | SHGC |

|---|---|---|---|

| Exterior wall | 5 mm beige stucco (outermost side) | 1.868 | No |

| 30 mm cement plaster | |||

| 200 mm medium-weight concrete block | |||

| 30 mm cement plaster (innermost side) | |||

| Interior wall | 20 mm cement plaster | 1.942 | |

| 150 mm medium-weight concrete block | |||

| 20 mm cement plaster | |||

| Roof | 10 mm clay tile | 0.471 | |

| 30 mm cement plaster | |||

| 50 mm polyurethane foam | |||

| 1 mm bitumen sheet | |||

| 20 mm cement plaster | |||

| 150 mm reinforced concrete | |||

| 20 mm cement plaster | |||

| Upper floor | 10 mm cement plaster | 2.470 | |

| 200 mm reinforced concrete | |||

| 10 mm cement plaster | |||

| Ground floor | 20 mm cement plaster | 3.038 | |

| 170 mm reinforced concrete | |||

| Door | Wooden flush panel hollow core door 6 mm plywood panel 27 mm air gap 6 mm plywood panel | 2.498 | |

| Window glazing | 6 mm single generic clear glass pane; Aluminum window frame; Main window height: 1500 mm Main sill height: 900 mm Main window width: 1200; 1500; 1800 or 2100 mm | 5.78 | 0.819 |

| Consideration | Heating | Cooling | DHW (Domestic Hot Water) | Natural Ventilation |

|---|---|---|---|---|

| HVAC facilities | Unitary air conditioner | Unitary air conditioner | Individual electricity water heater | / |

| Setpoint (set back) | 20 °C (15 °C) | 25 °C (30 °C) | 65 °C | Min fresh air per person |

| Operation schedule | 24 h during heating months | 1. p.m.–7 a.m. during cooling months | 24 h on, with 2.45 L/m2·daily consumption rate | 24 h in non-air conditioning time period |

| Group S: 6 mm single-glazing | |||||||||||||||

| Sc: Clear | Sg: Grey | Sb: Blue | Sl-c: Clear low-e | Sl-t: Tinted low-e | |||||||||||

| U-value (W/m2·k) | 5.778 | 5.778 | 5.778 | 3.44 | 3.44 | ||||||||||

| SHGC | 0.819 | 0.602 | 0.62 | 0.637 | 0.45 | ||||||||||

| Daylight transmittance (%) | 88 | 43 | 57 | 81 | 50 | ||||||||||

| Description | Window frame: aluminum; glass type: 6 mm generic or generic low-e glass | ||||||||||||||

| Group D: 6/6 mm double-glazing with 6 mm filled gas | |||||||||||||||

| Air filled | Argon filled | ||||||||||||||

| Da-c: Clear | Da-g: Grey | Da-b: Blue | Dal-c: Clear low-e | Dal-t: Tinted low-e | Dg-c: Clear | Dg-g: Grey | Dg-b: Blue | Dgl-c: Clear low-e | Dgl-t: Tinted low-e | ||||||

| U-value (W/m2·k) | 3.09 | 3.09 | 3.09 | 2.43 | 2.43 | 2.829 | 2.829 | 2.829 | 1.99 | 1.99 | |||||

| SHGC | 0.7 | 0.485 | 0.503 | 0.569 | 0.398 | 0.702 | 0.481 | 0.499 | 0.568 | 0.388 | |||||

| Daylight transmittance (%) | 78 | 38 | 50 | 72 | 44 | 78 | 38 | 50 | 72 | 44 | |||||

| Description | Window frame: aluminum; glass type: 6 mm generic glass for traditional window, 6 mm coated glass for low-e glazing; filled window gas: 6 mm air or argon | ||||||||||||||

| Group DT: 6/13 mm double-glazing with 13 mm filled air | |||||||||||||||

| DT-c: Clear | DT-g: Grey | DT-b: Blue | Dtl-c: Clear low-e | Dtl-t: Tinted low-e | |||||||||||

| U-value (W/m2·k) | 2.66 | 2.66 | 2.66 | 1.76 | 1.76 | ||||||||||

| SHGC | 0.703 | 0.478 | 0.497 | 0.568 | 0.38 | ||||||||||

| Daylight transmittance (%) | 78 | 38 | 50 | 72 | 44 | ||||||||||

| Description | Window frame: aluminum; glass type: 6 mm generic glass for traditional window, 6 mm coated glass for low-e glazing; filled gas: 13 mm air | ||||||||||||||

| Possible Energy Efficient Window Retrofitting Measures in Studied Climates | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Reduction from Traditional Window (%) | Best Window Choice for Various Requirements | ||||||||||||

| Reduce about 5% | Reduce about 10% | Reduce about 15% | |||||||||||

| Window glazing | Hong Kong | Shanghai | Beijing | Hong Kong | Shanghai | Beijing | Hong Kong | Shanghai | Beijing | Hong Kong | Shanghai | Beijing | |

| 6/6 mm single-glazing | Clear (base model) | 0 | 0 | 0 | |||||||||

| Grey | 4.00% | 3.13% | −0.89% | **** | |||||||||

| Blue | 3.7% | 2.92% | −0.82% | ||||||||||

| Clear low-e | 3% | 5.68% | 6.94% | * | ** | ||||||||

| Tinted-low-e | 6.48% | 8.50% | 6.36% | * | * | ||||||||

| 6/6 mm double-glazing with air filled | Clear | 2.66% | 7.30% | 11.14% | **** | **** | |||||||

| Grey | 6.56% | 10.48% | 10.41% | *** | **** | ||||||||

| blue | 6.28% | 10.24% | 10.46% | ||||||||||

| Clear low-e | 5.06% | 10.79% | 14.23% | ** | |||||||||

| Tinted-low-e | 7.91% | 12.98% | 13.68% | ** | *** | ** | |||||||

| 6/6 mm double-glazing with argon filled | Clear | 2.67% | 7.79% | 12.38% | *** | *** | |||||||

| Grey | 6.69% | 11.12% | 11.66% | ** | *** | * | |||||||

| blue | 6.38% | 10.88% | 11.71% | ||||||||||

| Clear low-e | 5.12% | 11.73% | 16.52% | ** | *** | ||||||||

| Tinted-low-e | 8.15% | 14.19% | 16.01% | *** | **** | *** | |||||||

| 6/13 mm double-glazing with air filled | Clear | 2.66% | 8.18% | 13.36% | ** | ** | **** | ||||||

| Grey | 6.79% | 11.63% | 12.65% | * | ** | ||||||||

| blue | 6.47% | 11.39% | 12.71% | ||||||||||

| Clear low-e | 5.16% | 12.52% | 18.40% | **** | |||||||||

| Tinted-low-e | 8.38% | 15.20% | 17.94% | **** | **** | **** | |||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Q.; Ng, S.T.; Hossain, M.U.; Skitmore, M. Energy-Efficient Window Retrofit for High-Rise Residential Buildings in Different Climatic Zones of China. Sustainability 2019, 11, 6473. https://doi.org/10.3390/su11226473

He Q, Ng ST, Hossain MU, Skitmore M. Energy-Efficient Window Retrofit for High-Rise Residential Buildings in Different Climatic Zones of China. Sustainability. 2019; 11(22):6473. https://doi.org/10.3390/su11226473

Chicago/Turabian StyleHe, Qiong, S. Thomas Ng, Md. Uzzal Hossain, and Martin Skitmore. 2019. "Energy-Efficient Window Retrofit for High-Rise Residential Buildings in Different Climatic Zones of China" Sustainability 11, no. 22: 6473. https://doi.org/10.3390/su11226473