Abstract

When construction work is planned on soil with inadequate shear strength, its engineering properties need to be improved. Chemical stabilization is one of the solutions for soil strength improvement. Currently, the most common additive that is used for chemical soil improvement is cement. Cement is an effective solution, but it has several negative effects on the environment. Therefore, the urges for environment-friendly solutions that can replace cement and show good potential for sustainable engineering are rising. One of the promising environment-friendly solutions is the use of biopolymers. Therefore, the main aim of the present study was to investigate the effect of the biopolymer xanthan gum on the strength of different types of soil. Xanthan gum was mixed with three different types of soil: sand, clay, and silty sand. The strength of treated and non-treated soil was experimentally investigated by performing unconfined compression, direct shear, and triaxial tests. From the results, it was observed that xanthan gum significantly increased the strength of each soil, which shows its major potential for the future of sustainable engineering.

1. Introduction

Soil improvement is a process often needed for the construction on an unfavorable soil. There are several ways in which soil strength can be improved. There is physical, biological, and chemical soil improvement. Physical soil improvement can include dynamic compaction, static compaction, and mixing aggregates method, to name a few. The biological approach represents using bacteria that can create calcium carbonate precipitation. That approach is known as MICP (Microbiologically Induced Calcium Carbonate Precipitation). Bacteria, such as Bacillus pasteurii reacts with the calcium in the soil and creates cementitious soil clogs. DeJong et al. [1] introduced Bacillus pasteurii to Ottawa 50–70 sand and reported the cementation of sand which was created by the bacteria.

The chemical improvement of soil represents mixing certain chemicals with the soil that can improve the strength and durability of the soil. Currently, the most popular additive for chemical soil improvement is cement, but the use of cement raises certain environmental concerns. The use of cement can increase the urban water runoff, prevent the growth of plants, and create the heat islands [2] which represent metropolitan areas with significantly high temperatures. Cement does not only affect the environment, but the poisonous effect of cement indirectly affects the health of the population and sources of finances for people living off agriculture and cattle. Certainly, the most concerning fact related to the use of cement is the contribution to the worldwide CO2 emissions. In 2002 CO2 emissions caused by the production of cement were 6% of the total CO2 emissions in the world [3]. Therefore, the search for alternative and sustainable solutions that can improve soil properties is in high demand.

MICP represents a biological approach to this problem and several authors reported the effectiveness of MICP [4,5]. Another approach is the use of biopolymers. In general terms, polymers represent chains of small chemical units. They can be artificial (synthetic polymers) and biopolymers (natural polymers). Biopolymers are extracted from natural materials such as plants, wood, and animal shells. To the best of the authors’ knowledge, no negative effect of biopolymers on the environment has been reported. They are present in the food industry, agriculture, cosmetic industry, and oil drilling industry [6,7,8,9,10]. Furthermore, their potential for the improvement of soil mechanical properties was investigated [11,12,13,14]. Some biopolymers proved effective in reducing the erosion of soil [15,16,17] and the collapsibility of soil [18]. Even though both MICP and biopolymers proved to be effective in improving the mechanical properties of soil, biopolymers have certain advantages over MICP. In particular, the MICP procedure can only be used in coarse-grained soils such as sand. Large pores in the sand are suitable for the habitation of bacteria, but fine soils like clay have narrow pores where bacteria cannot survive [2]. Biopolymers are not a living organism; therefore, they can be used in coarse-grained and fine-grained soils because the narrowness of the pores does not have a negative influence on them. Furthermore, MICP treatment requires a special environment and nutrition for the bacteria in order to keep them alive [19]. On the other hand, biopolymers do not require that treatment.

To demonstrate the potency of biopolymers as a soil improvement additive, the present study focuses on the investigation of the effect of the biopolymer xanthan gum on the improvement of the strength of different types of soil: pure sand, silty sand, and high-plasticity clay. Xanthan gum-amended soil was tested by using the unconfined compression, triaxial, and the direct shear tests.

2. Materials and methods

2.1. Soils Tested

Three types of soil were used for the present study: silty sand, pure sand, and a high-plasticity clay. These soils were selected in order to represent different granulometric groups of soil.

2.1.1. Silty Sand

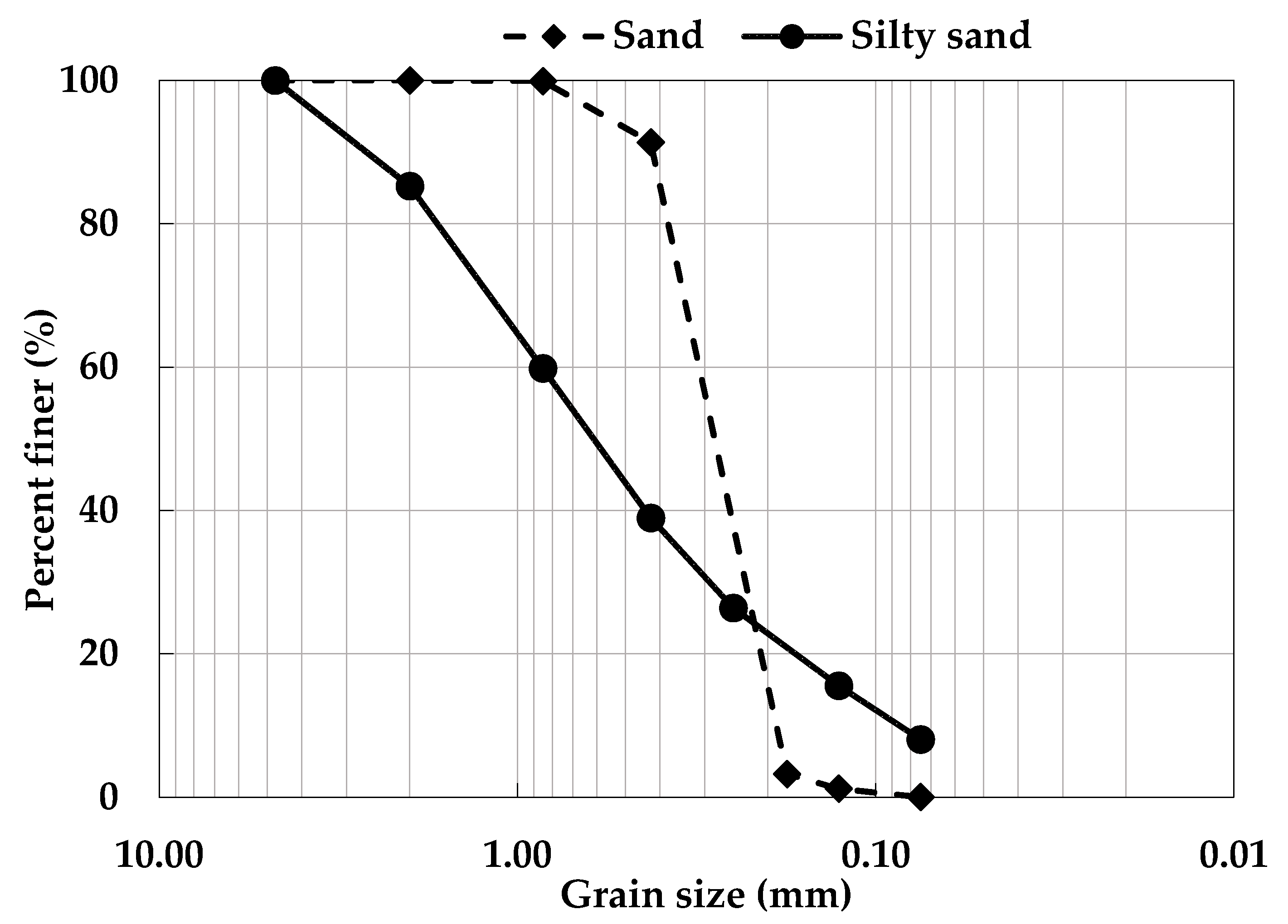

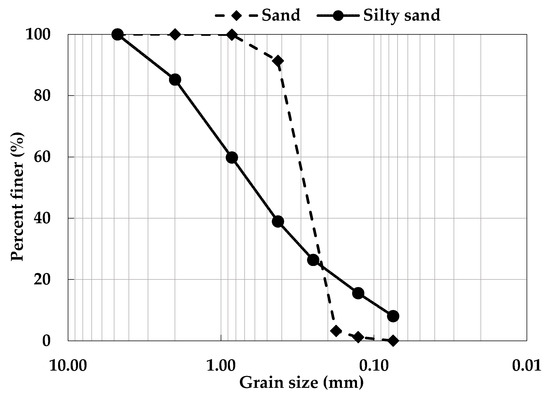

The silty sand for the present study was obtained from a local site close to Opelika in Lee County, Alabama, USA. The silty sand had 9% fine particles (≤0.075 mm) with liquid limit and plastic limit of 49 and 29 respectively, which classifies them as silt with low plasticity according to USCS (Unified Soil Classification System). Sieve analysis was conducted by placing the stack of sieves with different openings on top of each other. Sieves with higher openings were placed on top. The ranges of sieve openings were from 4.75 mm (N°4) to 0.075 mm (N°200). The stack of sieves was shaken for 10 min, while a pan was placed bellow the sieve N°200 to capture all the material smaller than 0.075 mm. The sieve analysis provided the grain size distribution curve (Figure 1) from which the coefficient of curvature and the coefficient of uniformity were calculated as 1.5 and 10, respectively. Therefore, a general classification of this soil, according to USCS, is SW-SM (well-graded sand with silt).

Figure 1.

Grain size distribution of the sand and silty sand.

2.1.2. Pure Sand

Sand used in the present study was obtained from a site close to Destin, Okaloosa County, Florida, USA. It was mostly made of quartz and was highly uniform. Fine particle content was almost non-existent. The grain distribution curve obtained from the sieve analysis is presented in Figure 1 as well. The coefficient of uniformity and the coefficient of curvature that were calculated from the grain distribution curve were 1.46 and 0.93, respectively. Since the presence of gravel and fine particles was practically non-existent, USCS classifies this sand as SP (poorly graded sand).

2.1.3. High-Plasticity Clay

Fine-grained soil that was used for the present study was high-plasticity clay. The liquid limit of the clay was 505, and the plasticity index was 456, classifying this soil as CH (high-plasticity clay) according to USCS. The grain size distribution was not performed on this type of soil because all particles were smaller than 0.075 mm.

2.2. Biopolymer Xanthan Gum

Xanthan gum (XG) is a biopolymer from a group of polysaccharides and is created by the fermentation of a medium containing carbohydrates such as glucose. The fermentation process is induced by the Xanthomonas campestris bacterium [6]. XG increases the viscosity of the solution that it is dissolved in, and it can be dissolved in hot and cold water. Furthermore, XG-solutions are high-plasticity non-Newtonian solutions, and the increase of shear stress decreases their viscosity [6]. Additionally, the molecular structure of XG can be affected by salt, temperature, and microorganisms [6,20].

2.3. Specimen Preparation and Mechanical Testing

Silty sand was ground and sieved through the sieve N°4 with the opening of 4.76 mm. To start the procedure a certain amount of the silty sand was placed into a mixing bowl. XG was hand-mixed slowly into the bowl with the soil in the amount of 1% with respect to the mass of the soil. Once uniformly mixed, water was sprayed into the bowl until the water amount was approximately 16.5% with respect to the mass of the silty sand. The concentration of 1% XG was based on the author’s previous preliminary research. Higher concentrations had the tendency to increase the strength of certain specimens beyond the testing limits.

Choosing the right water content was crucial for this type of preparation of specimens because too high water content creates specimens that are too soft, while on the other hand, too low water content causes non-uniform specimens. The water content of 16.5% was the optimum water content for this type of soil and it was selected as the most appropriate for the preparation of specimens of silty sand. The optimum water content was determined by performing Proctor (compaction) tests. The soil was compacted under different water contents into a cylindrical mold with a height of 11.6 cm and a diameter of 10.2 cm. The water content that the soil had at the maximum dry density was selected as the optimum water content. During the preparation, a small amount of the material was weighed and placed in the oven to ensure that the water content requirements were met (as per ASTM D2216 [21]).

Specimens made of sand were prepared in a similar manner. One percent XG with respect to the mass of soil was mixed into the sand. After that, water was sprayed into the soil-XG mix with constant hand-mixing. The targeted water content for the sand was 12%. That water content was based on the best workability of the sand-water mixture to compact and extrude specimens out of molds.

The same procedure was followed while preparing the clay specimens, but the targeted water content for the clay was 16% because that water content gave the clay relatively good workability. Specimens made with higher water contents were heavily deformed when extruded from the molds. Therefore, higher water contents were omitted for the clay specimens.

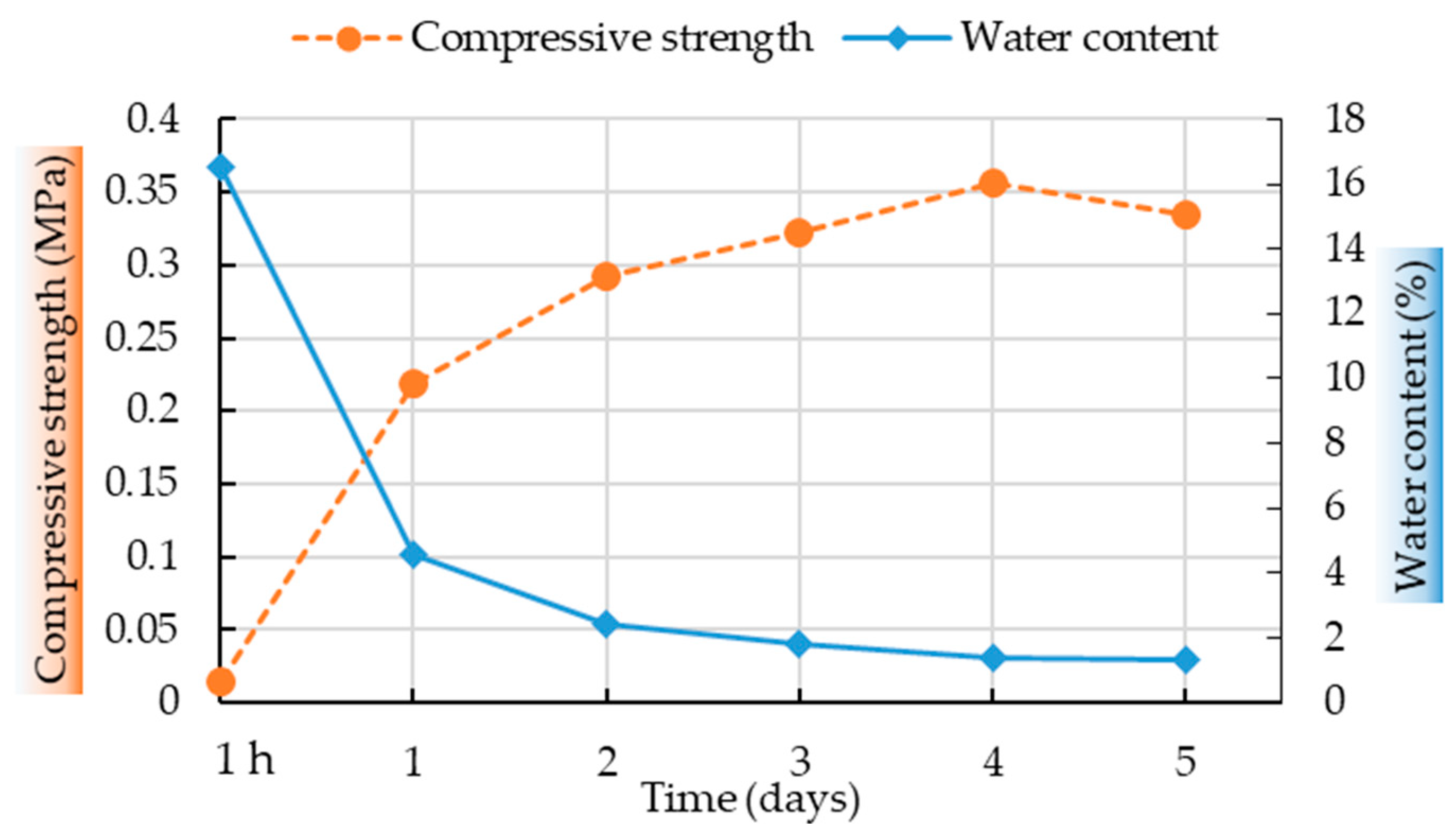

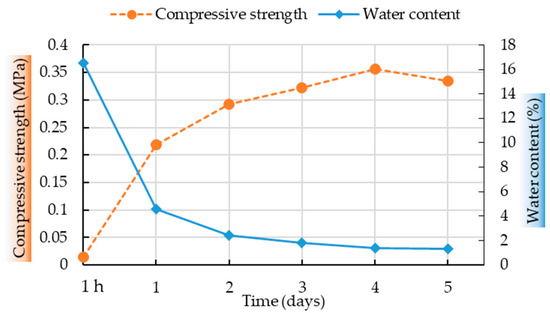

When the mixture of soil, XG, and water was uniformly mixed it was evenly compacted in cylindrical molds. Three types of molds, for three types of tests, were used. The three types of tests were: unconfined compression (UC), unconsolidated undrained triaxial (UU), and direct shear tests (DS). After the compaction, the specimens were extruded from the molds, left in the laboratory at 21 °C and were tested five days later. The five-day period was selected on the observation of the development of the compressive strength of XG-amended silty sand through five days (Figure 2).

Figure 2.

Change in the compressive strength of silty sand with 1% XG through five days.

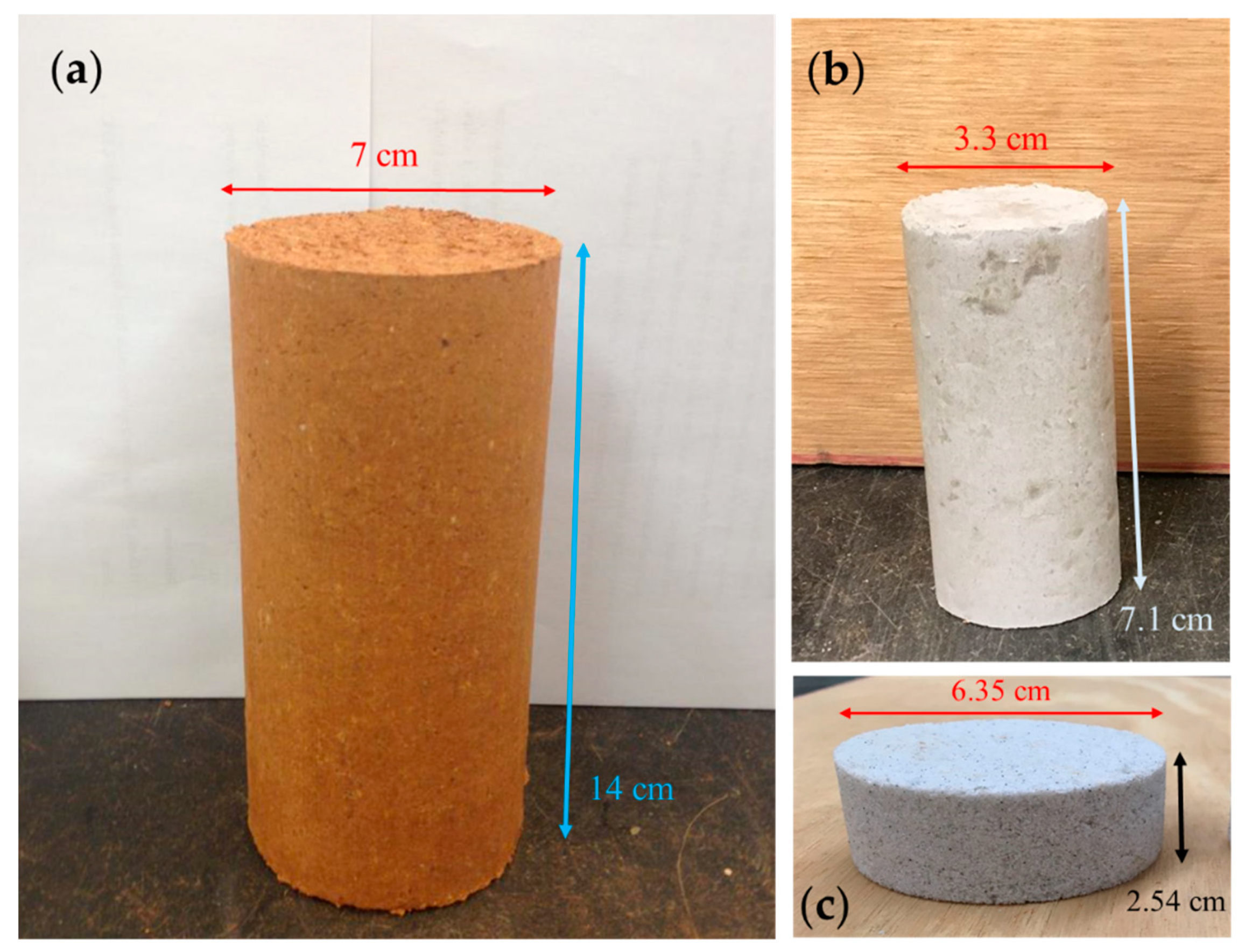

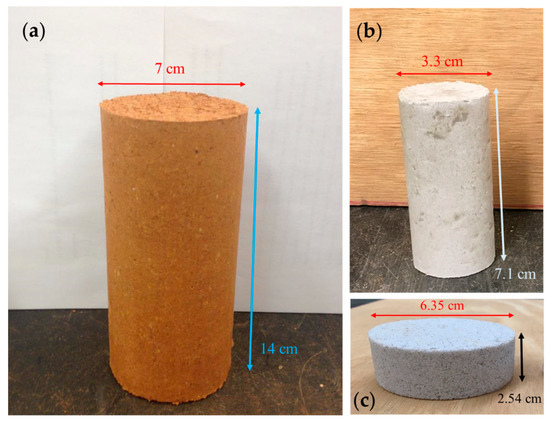

Specimens for the UC test were compacted in five layers in the cylinders with a diameter of 3.3 cm and a height of 7.1 cm (Figure 3b). Each soil layer was pressed 25 times with a force of approximately 150 N. The UC test was performed in accordance with ASTM D2166 [22]. Strain rate was set up to 1.5%/min, whereas the maximum allowed strain was set up as 20%. The UC test was successfully performed on the specimens that were made of amended and plain silty sand and amended and plain clay. Also, the UC test was also performed on specimens that were made of amended sand, however, the sand in a natural state could not be formed into cylindrical specimens needed for this test, and therefore the UC test had to be omitted in that case.

Figure 3.

Examples of the specimens that were used for testing: (a) XG-amended silty sand specimen used for UU test; (b) XG-amended clay specimen used for UC test; (c) XG-amended sand specimen used for DS test.

Specimens for the UU test were compacted in five layers into molds with a diameter of 7 cm and a height of 15 cm (Figure 3a). Silty sand and clay were compacted in five layers with a standardized hammer with a mass of 2.5 kg. The hammer was released 25 times from the height of 30.5 cm to fall free on each soil layer. Each impact sent approximately 7.5 J of energy into the soil. However, the sand was not compacted in the same manner, but it was tapped into the molds to keep the density and structure of the amended sand close to the natural density and structure. After compaction and extraction, the specimens for the UU test had to be trimmed with a knife to ensure a flat surface at the top and bottom and appropriate cylindrical shape. The UU test was performed according to ASTM D2850 [23]. Axial stress was applied under the strain rate of 0.7%/min and under confinement pressure of 103 kPa. This level of the confinement pressure was in the ranges of confinement of similar research which allowed us to compare the results. The same test could be performed with higher or lower confinement pressures since the level of the confining pressure would not affect the maximum value of the deviatoric stress in the UU test.

Specimens for the DS test were compacted in molds with a diameter of 6.35 cm and a height of 2.54 cm (Figure 3c). Similar to the specimens for the UU test, plain and amended sand were tapped into the molds, while silty sand and clay were compacted in four layers where each layer was compressed 25–30 times with a force of 100 N. This test was performed with the guidance of ASTM D3080 [24]. The strain rate for the DS test was 0.06 cm/min and was conducted under different normal pressures (0.1, 0.38 and 0.77 MPa).

All specimens after extraction out of the molds had the dimensions that corresponded to the inner diameters of the molds except the specimens for the triaxial tests that had a height of 14 cm instead of 15 cm because of the required trimming. Examples of specimens used for the testing can be seen in Figure 3. A series of plain specimens were made in the same manner as the amended specimens.

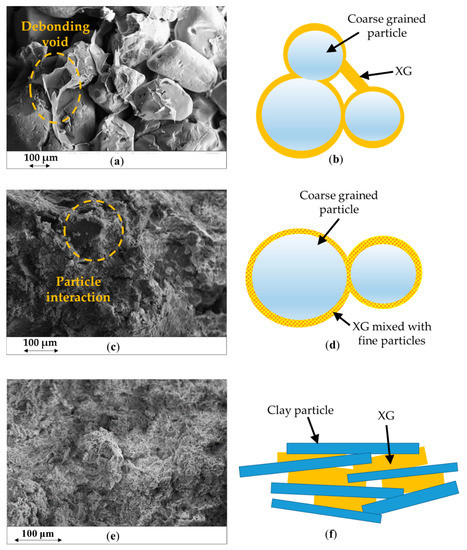

2.4. SEM Imaging

The interaction between biopolymer and different types of soil is not the same. Fine particles and XG are electrically charged which creates an electrostatic bond between XG and fine particles [25]. The electrical charge in coarse-grained soils is practically non-existent; therefore, the bond that is created between coarse-grained material and XG can be presented as a thin film wrapped around coarse particles [26]. A Scanning Electron Microscope (SEM) Zeiss EVO 50 was used to observe the XG-amended soil. Small pieces of XG-amended soil were cut to about 0.2–0.3 cm3 and glued to metal pin stubs with carbon tape. The stubs were coated with a thin layer of gold to prevent charging of the analyzed surface, to promote the emission of secondary electrons so that the specimen conducts evenly, and to provide a homogeneous specimen surface for analysis and imaging.

3. Results and Discussion

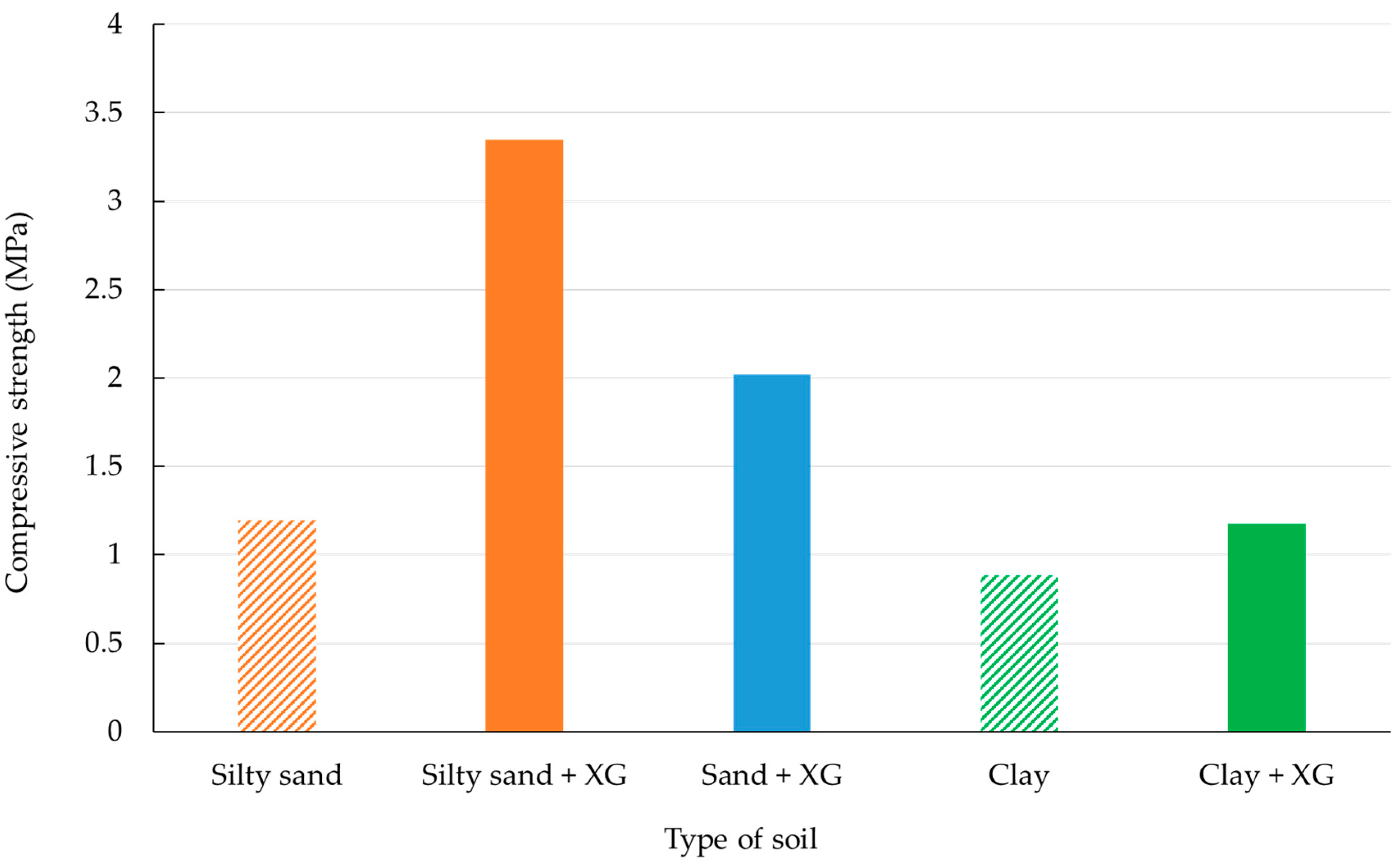

3.1. Unconfined Compression Test

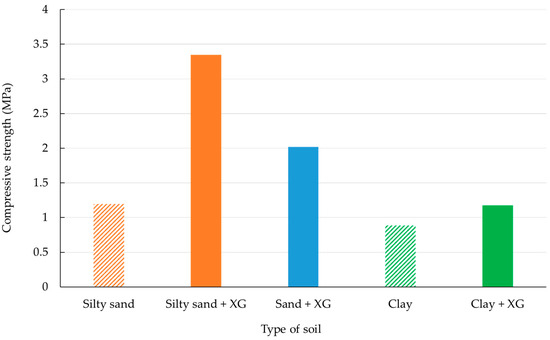

The UC test is commonly used in civil engineering practice to obtain the compressive strength (UCS) of materials like soil and concrete. While loading the specimens under constant axial strain rate, the specimens should fail on their weakest plain after their compressive strength was reached. Figure 4 depicts the effect of XG on the compressive strengths of the studied soils five days after curing. Tests were performed on four specimens of each type and the mean values are presented. Striped columns represent the compressive strength of soil specimens without biopolymers, whereas the specimens with 1% XG are represented with solid columns. There are no results for the plain sand because it is cohesionless, and therefore it could not be formed into specimens for the test. Introducing XG to sand cohesion was achieved, allowing sand to be shaped into desired specimens and to retain the shape for five days. Comparing the compressive strength of silty sand with and without XG, it is evident that the strength of the treated silty sand is significantly higher. The compressive strength increased from 1.2 to 3.35 MPa, which represents an increase of about 180%. The compressive strength of sand treated with XG was 2.02 MPa. That amount of achieved strength is significant considering the fact that the plain sand could not be tested for the unconfined compression. The XG-amended clay showed an increase of about 0.3 MPa with respect to the plain clay. The strength of the clay could have been improved more with the addition of more water during the preparation, but the workability of the used clay with water content above 16% was not appropriate for the unconfined compression test. Therefore, relatively weaker specimens were prepared. The findings are in agreement with previous research [11,25,27,28]. Chang et al. [25] investigated the effect of XG on the UCS of sand, sand with silt and high plasticity clay. In their study, XG increased UCS for all of the mentioned types of soil, and the highest increase was for the sand with silt.

Figure 4.

UC test results: Influence of 1% of XG on different types of soil after five days of curing.

From the results of the unconfined compression test, it is evident that XG increased the compressive strength of the base soils presented in this study. The highest compressive strength was achieved for silty sand when mixed with XG. Therefore, this test indicates that sands with a certain amount of fine particles respond best to XG.

3.2. Unconsolidated Undrained Triaxial Test

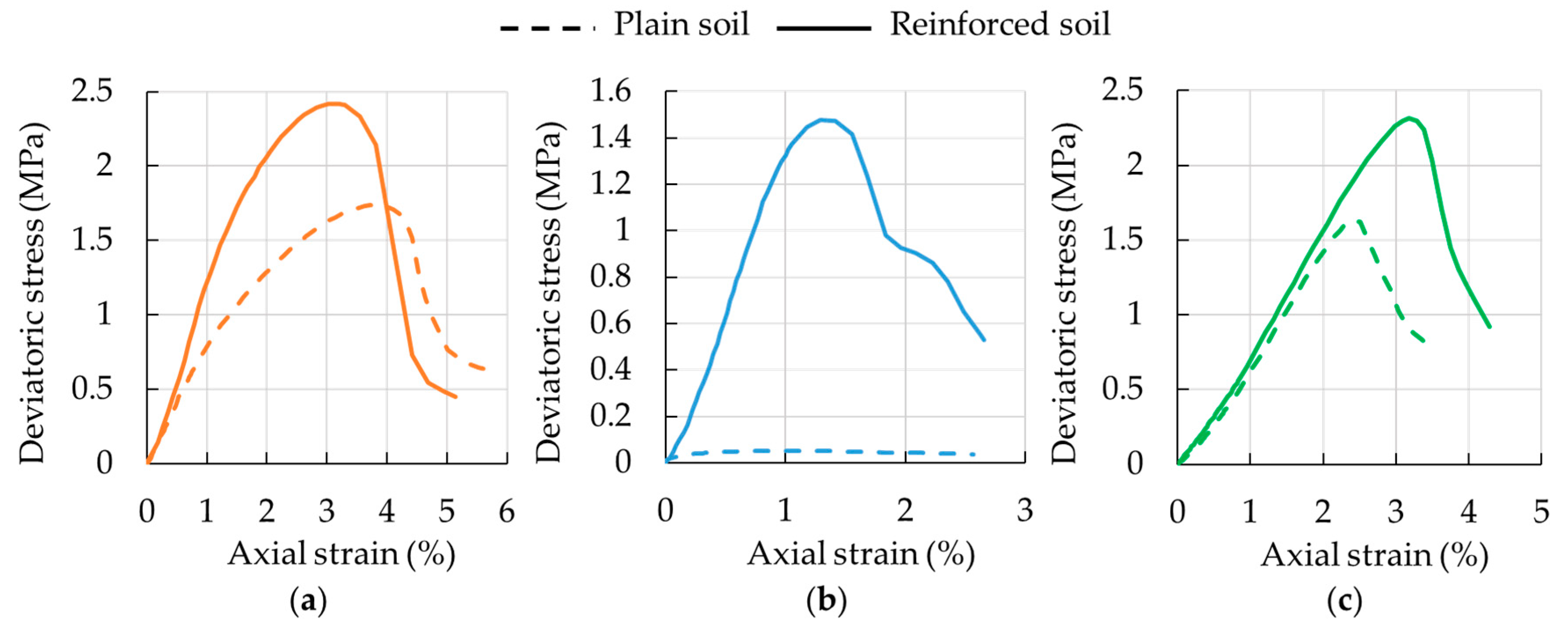

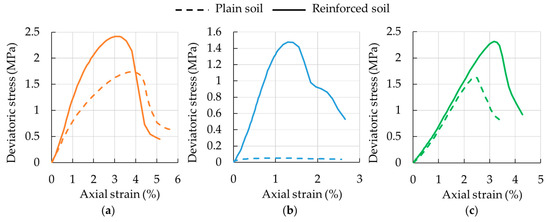

The UU test was performed according to ASTM D2850 [23]. Axial stress was applied under the strain rate of 0.7%/min and under confinement pressure of 103 kPa. This level of the confinement pressure was in the ranges of confinement of similar research which allowed us to compare the results. Figure 5 shows the stress-strain curves for the studied soil tested in a triaxial apparatus after five days of curing. Dashed lines represent the stress-strain curves for the soil specimens with no reinforcement whereas the solid lines represent the soil-specimens with 1% of XG. Figure 5a shows the results for silty sand with and without the biopolymer. The plain silty sand had the maximum deviatoric stress of 1.7 MPa which increased by 42% after the soil was mixed with XG. The UU test on sand showed that sand can achieve the maximum deviatoric stress of 1.47 MPa five days after it was mixed with XG (Figure 5b). The maximum deviatoric stress of the plain sand showed extremely low values which is related to the incohesive state of the plain sand. The strength of the clay was 1.63 MPa before it was mixed with XG, but after the mixing, the strength increased by 42% which is the same percentage as that of the silty sand (Figure 5c).

Figure 5.

UU test results under confining pressure of 103 kPa: Influence of 1% XG on different types of soil: (a) Silty sand; (b) Sand; (c) Clay (please note that the axes are differently scaled).

Results from the UU test showed that the maximum deviatoric strain was achieved for the silty sand mixed with XG, while the maximum deviatoric strain of the clay-XG mixture was only slightly lower. Unlike in the unconfined compression test, the achieved strengths of amended silty sand and clay were not significantly different in the UU test. This indicates that the size of the tested specimens can play an important role in achieving the strength of the soil. On the other hand, the highest increase in strength was achieved in the sand, which is not surprising when considering that the plain sand had a virtually negligible strength compared to other soils that had a significant amount of fine particles. The peak of the deviatoric stress of the plain sand was close to the results of other researches that performed triaxial tests on the plain poorly graded sand under similar confining pressures [11,28]. Furthermore, the same research showed that the addition of XG increases the peak deviatoric stress during the triaxial stress state.

3.3. Direct Shear Test

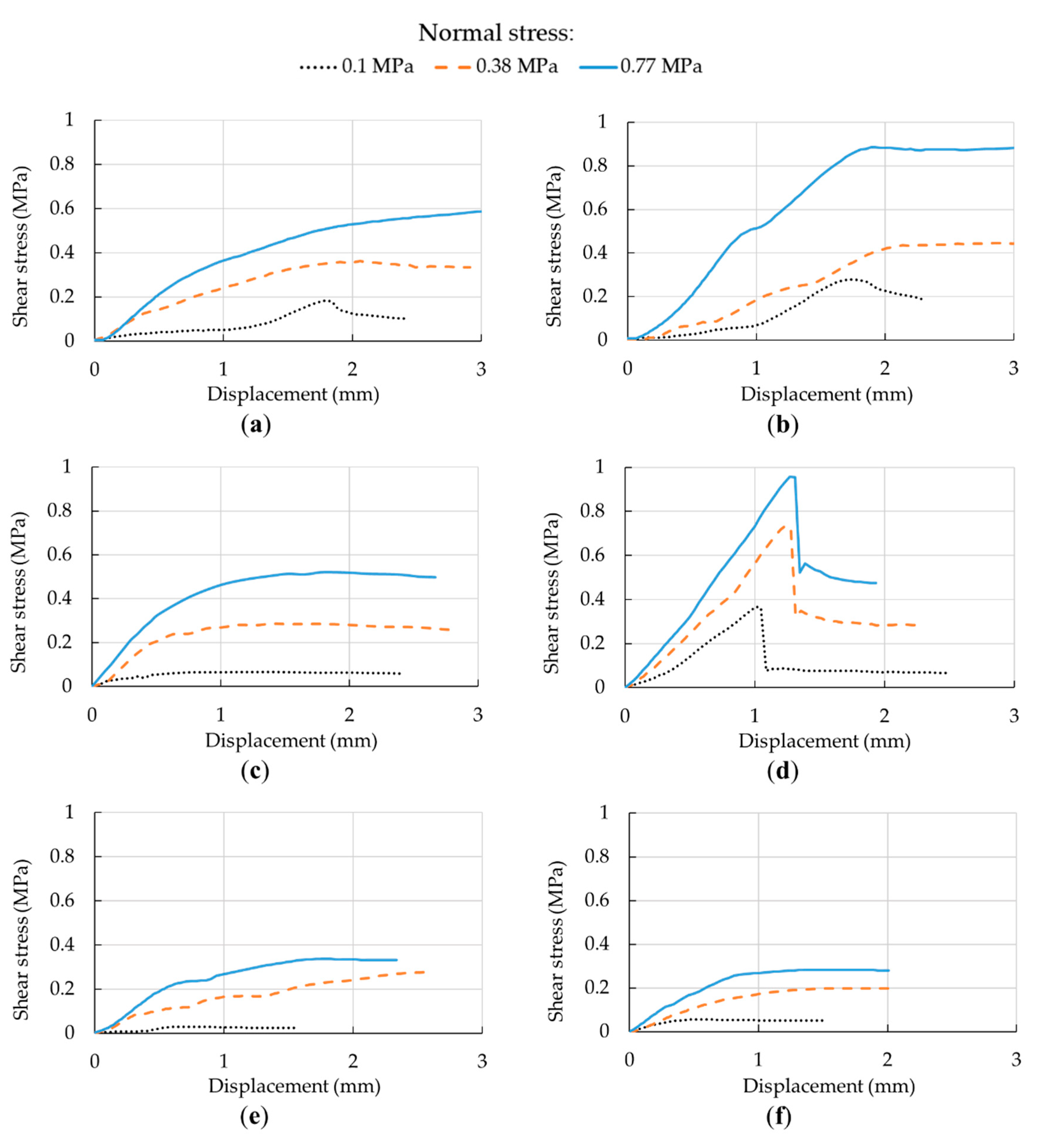

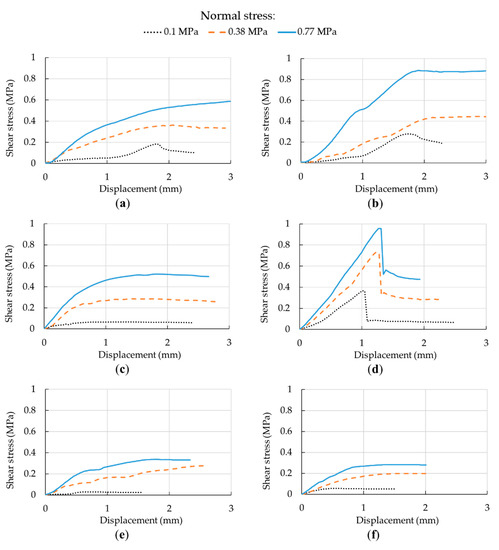

The DS test is suitable to obtain the shear strength parameters of soil, i.e., cohesion and friction angle. It is especially favorable for sands and other cohesionless materials that cannot be tested in the unconfined compression test. The DS test was performed on the plain and XG-amended soils. Figure 6 presents the achieved shear strength-displacement behavior of the tested soils. Each line corresponds to one normal stress that was applied during the process of shearing.

Figure 6.

DS test shear stress-displacement results: (a) Plain silty sand; (b) Silty sand with 1% XG; (c) Plain sand; (d) Sand with 1% XG; (e) Plain clay; (f) Clay with 1% XG.

For the plain silty sand (Figure 6a) the maximum shear stresses were 0.18, 0.36, and 0.60 MPa for the applied normal stresses of 0.1, 0.38 and 0.77 MPa, respectively. Figure 6b shows the results of the achieved shear stresses of XG-treated silty sand. The maximum shear stresses did increase to 0.27, 0.43, and 0.88 MPa for the same applied normal stresses of 0.1, 0.38 and 0.77 MPa, respectively. It is evident that the presence of XG increased the shear strength of the silty sand. The shear stress-displacement behavior of the silty sand was similar before and after it was mixed with XG (Figure 6a,b). The most curves for the plain and XG-amended silty sand reach a peak value for a certain amount of the shear stress and after that the stress intensity stayed constant or decreased, representing a softening behavior. The only exception was noticed for the plain silty sand that was sheared under 0.77 MPa. In that case, the maximum value of the shear stress was never achieved, but it slowly increased until the end of the test. For the shearing of the XG-amended soil under the same amount of load, the shear stress-displacement curve reached the maximum value after which it remained nearly constant. That means that the plain soil under the load of 0.77 MPa had less brittle behavior. Figure 6a,b present the dilatant behavior of the tested samples under the normal pressure of 0.1 MPa. Higher normal pressures created contractency by reducing the freedom of particles to override each other. However, the most significant change for silty sand was the increase in strength of the XG-amended specimens.

Figure 6c shows the results of the direct shear that was performed on the plain sand whereas Figure 6d shows the results of the XG-amended sand. The maximum shear stresses of the plain sand were 0.06, 0.29, and 0.52 MPa for the applied normal stresses of 0.1, 0.38 and 0.77 MPa, respectively. For the applied normal loads of 0.1, 0.38 and 0.77 MPa, the XG-amended sand specimens reached the maximum shear stresses of 0.36, 0.69, and 0.95 MPa, respectively. The change in the behavior is prominent for the sand even though the plain and XG-amended sand showed the contractant behavior. All curves that represent the shearing of the plain sand have a similar trendline where softening continues after the peak value of stress. The behavior of the XG-amended sand is significantly different. Under each normal loading, shear stresses dropped instantly for a significant amount after the highest shear stress was achieved. That change in behavior shows the property of XG to influnce the strength and behavior of sand.

Figure 6e,f present the results of the test performed on the plain clay and XG-amended clay. Both figures show fairly similar results for the tests under different normal stresses and a contractant behavior of the clay. The shear stresses at failure for the treated clay were close in value with the shear stresses at failure for the plain clay. In fact, the shear stress at failure under the normal pressure of 0.77 MPa was slightly higher for the plain clay. The changes in the shear stress-displacement curves were marginal for the clay before and after XG-treatment, indicating no significant change in the behavior during shearing of clay material.

Table 1 summarises the changes in the friction angle and cohesion of the silty sand, sand, and clay.

Table 1.

Influence of 1% XG on friction angle and cohesion.

The results from the direct shear test indicated that XG can change the friction angle in soils that have some level of cohesion such as silty sand and clay, but that it might not significantly change the cohesion for the same soil type. On the other hand, for the cohesionless soils such as sand, XG can significantly increase cohesion but it might not significantly affect the friction angle. Cho and Chang [29] performed a study where gellan gum was used as the biopolymer for soil improvement on sand, clay, and clayey sand. The study showed that gellan gum increased the cohesion of sand, but it did not have a significant influence on the friction angle. The study also showed that gellan gum increased the cohesion of all three types of soil and the friction angle of clay and clayey sand. The present study, which was conducted with XG, showed a small influence of XG on the friction angle of sand and a higher influence on the friction angle of the silty sand. The increase in cohesion was more prominent for the sand which initially had no cohesive properties. This experimental studies on clay showed that XG did not increase the friction angle, but decreased it slightly. Similar results were reported by Ayeldeen et al. [18] who performed the direct shear test on a soil with a high concentration of fine particles. Also, this study showed only a slight influence of XG on the cohesion of clay. It is important to note that the present study was performed with 1% XG. The higher concentrations could have had a stronger effect on the shear strength parameters.

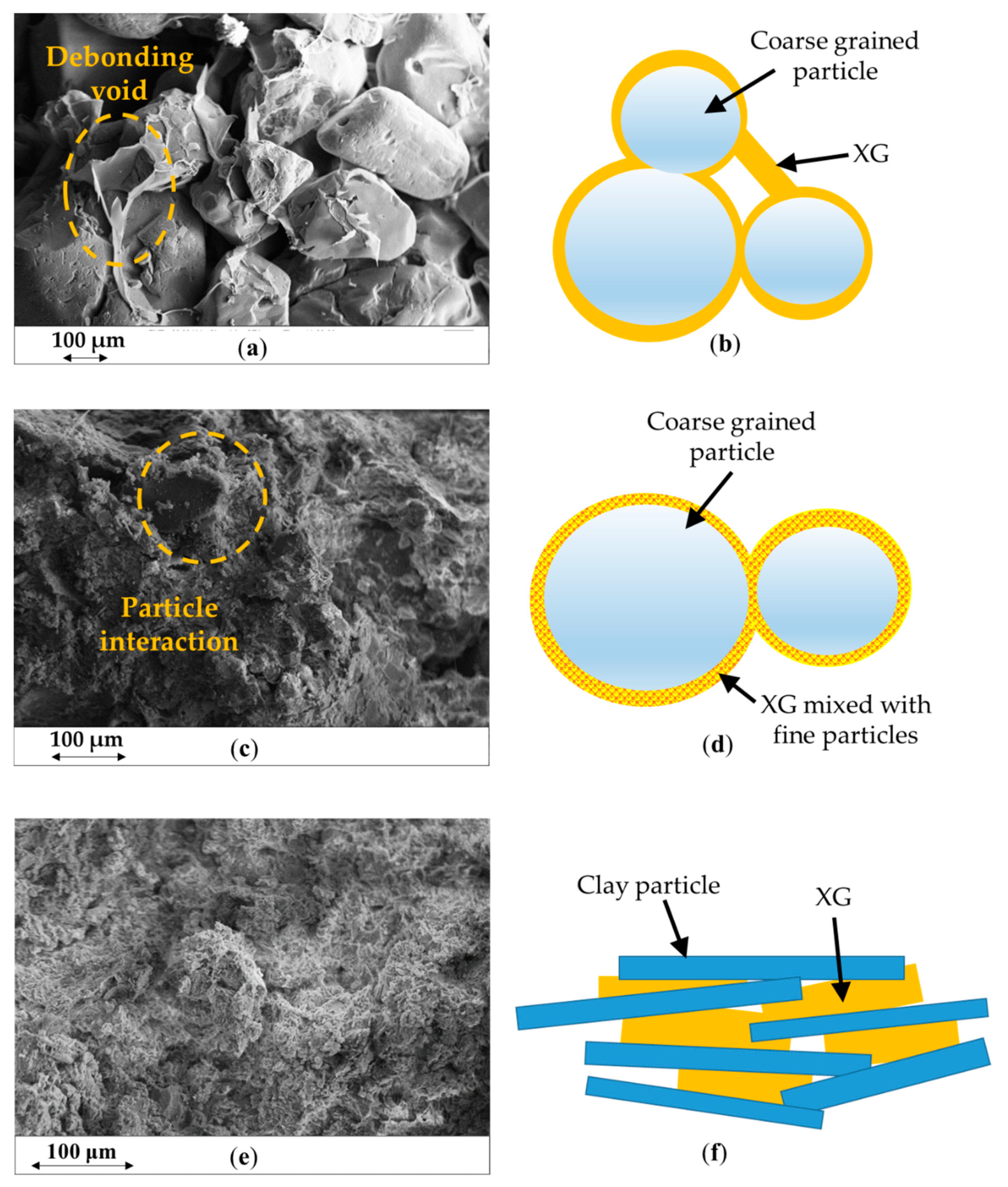

3.4. SEM Analysis

Figure 7 depicts the SEM images of the XG-amended soils used in the present study. The bond created by the biopolymer XG with sand particles is best presented in Figure 7a. The tin film that coated the sand particles was XG formation. Additionally, XG created an interaction between particles that were not in direct contact. Creating a stronger bond between sand particles, XG increased cohesion and stiffness of the sand. Figure 7a also shows a debonding of sand particles. The formation marked in Figure 7a clearly represents a void created by a sand particle that detached from the XG film. This suggests that higher concentrations of XG would create a wider spread of XG, stronger XG mass, and a stronger bond between XG and soil particles which would lead to the greater strength of the amended soil. Figure 7b shows a schematic interaction between coarse sand particles and XG.

Figure 7.

SEM images of XG with: (a) Clay; (c) Silty sand; (e) Sand; Schematic representation of the interaction of XG with: (b) Clay; (d) Silty sand; (f) Sand.

In Figure 7c a different interaction between silty sand and XG can be observed. Observing Figure 7c closely we can see an interaction between a sand particle, XG, and fine particles. The mass surrounding the sand particle was created by the interaction of XG and fine particles. Because of the range of particle sizes, a clear transition between soil and XG could not be identified. The scheme of the interaction of XG, fine particles, and coarse particles is presented in Figure 7d.

Figure 7e shows the SEM image of clay mixed with XG. Due to the small size of clay particles and their electrostatic bond with XG, the clay-XG mixture is a highly homogeneous mass for which it is hard to determine where clay particles stop and where XG links begin. A schematic representation of the clay-XG bond is presented in Figure 7e.

From Figure 7 it can be concluded that the interaction of XG with soil strongly depends on the size of soil particles. Coarse-grained soil experiences a coating with XG mass and bridging of distant coarse-grained particles, while fine particles create a stronger bond with XG through the electrostatic linkage which is more difficult to observe.

4. Conclusions

The main objective of the present study was to investigate the effect of XG on the engineering properties of soils with different granulometry (sand, silty sand, and clay). The strength of soil was investigated by using three mechanical tests: unconfined compression test, unconsolidated undrained triaxial test, and direct shear test. Two types of specimens were prepared for each test, specimens made of plain soil and specimens made of soil with 1% XG. In order to allow specimens to fully cure, tests were conducted five days after the specimens were prepared. Most of the tests reported the improvement in strength for all types of soils that were used.

The unconfined compression test showed that the highest compressive strength was achieved for silty sand. The strength of plain silty sand increased almost three times after XG was added to it. The strength of plain sand could not be determined in the unconfined compression test because without cohesion, sand particles would fall apart without some lateral confinement. However, XG-amended sand showed a compressive strength of 2 MPa.

During the unconsolidated-undrained triaxial test; XG-amended silty sand and XG-amended clay showed a similar magnitude of the maximum deviatoric stress. The highest increase in the maximum deviatoric stress was achieved for the sand because the sand in the natural state had a significantly lower strength.

The direct shear test showed that the presence of XG can increase the shear strength of the sand and silty sand, but the effect on clay was marginal. Furthermore, the direct shear test revealed that XG significantly increases the cohesion in cohesionless soils such as sand, but that it does not have a significant effect on the friction angle of that type of soil. Additionally, the direct shear test showed that the XG affects cohesion in the soils that initially have some level of cohesion (such as silty sand), and that it more affects the friction angle. It should be noted that the present study was conducted with 1% of XG and that higher concentration might affect the soil-strength parameters (friction angle and cohesion) with higher impact.

The SEM images showed that the interaction of XG with soil depends on the size of soil particles. XG coats coarse-grained particles and creates bonds between distant particles. Fine particles in soil have an electrostatic bond with XG which does not occur in coarse-grained soil. Therefore the bond between XG and fine particles is stronger.

In summary, the present study revealed the effectiveness of XG on the improvement of three different types of soil and also shows the potential of XG for the application in civil engineering practice. The authors would suggest two possible ways to utilize XG for soil stabilization. For the stabilization at the ground surface, the suggestion would be to mix the XG mechanically in small quantities with soil and then apply water to the soil-XG composite. For the deeper ground improvement, it would be more appropriate to dissolve XG in water and then mechanically mix the solution with soil. In-situ investigation of XG-treated soil is required to bolster the idea of XG as a medium for sustainable soil stabilization. Therefore, the extensive in-situ research of XG-treated soil should be supported.

Author Contributions

M.M. conceived this research. M.M. and A.S. designed the research approach. A.S. conducted the experiments and wrote the paper. M.M. reviewed and edited the paper.

Funding

This research received no external funding.

Acknowledgments

A special thank you goes to Maria L. Auad whose expertise in chemical science was helpful in the developing of the present study. The authors are also grateful for the help of Michael Miller for help in capturing SEM images presented in this document.

Conflicts of Interest

The authors declare no conflict of interest.

References

- DeJong, J.T.; Fritzges, M.B.; Nüsslein, K. Microbially Induced Cementation to Control Sand Response to Undrained Shear. J. Geotech. Geoenviron. Eng. 2006, 132, 1381–1392. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Cho, G.-C. Introduction of Microbial Biopolymers in Soil Treatment for Future Environmentally-Friendly and Sustainable Geotechnical Engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; De Coninck, H.; Loos, M.; Meyer, L. IPCC Special Report on Carbon Dioxide Capture and Storage; Intergovernmental Panel on Climate Change; Working Group III: Geneva, Switzerland; U.S. Department of Energy, Office of Scientific and Technical Information: New York, NY, USA; Cambridge University Press: Cambridge, UK, 2005.

- Umar, M.; Kassim, K.A.; Ping Chiet, K.T. Biological process of soil improvement in civil engineering: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 767–774. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Katzbauer, B. Properties and applications of xanthan gum. Polym. Degrad. Stab. 1998, 59, 81–84. [Google Scholar] [CrossRef]

- Volman, J.J.; Ramakers, J.D.; Plat, J. Dietary modulation of immune function by β-glucans. Physiol. Behav. 2008, 94, 276–284. [Google Scholar] [CrossRef]

- Bourriot, S.; Garnier, C.; Doublier, J.-L. Phase separation, rheology and microstructure of micellar casein–guar gum mixtures. Food Hydrocoll. 1999, 13, 43–49. [Google Scholar] [CrossRef]

- Shahidi, F.; Synowiecki, J. Isolation and characterization of nutrients and value-added products from snow crab (Chionoecetes opilio) and shrimp (Pandalus borealis) processing discards. J. Agric. Food Chem. 1991, 39, 1527–1532. [Google Scholar] [CrossRef]

- Rosalam, S.; England, R. Review of xanthan gum production from unmodified starches by Xanthomonas comprestris sp. Enzyme Microb. Technol. 2006, 39, 197–207. [Google Scholar] [CrossRef]

- Wiszniewski, M.; Skutnik, Z.; Biliniak, M.; Çabalar, A.F. Some geomechanical properties of a biopolymer treated medium sand. Ann. Wars. Univ. Life Sci. SGGW Land Reclam. 2017, 49, 201–212. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, L.; Budhu, M. Biopolymer Stabilization of Mine Tailings. J. Geotech. Geoenviron. Eng. 2013, 139, 1802–1807. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of Problematic Soils with Biopolymer—An Environmentally Friendly Soil Stabilizer. J. Mater. Civ. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Hataf, N.; Ghadir, P.; Ranjbar, N. Investigation of soil stabilization using chitosan biopolymer. J. Clean. Prod. 2018, 170, 1493–1500. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Shin, H.-D.; Cho, G.-C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 2015, 253–254, 39–47. [Google Scholar] [CrossRef]

- Orts, W.J.; Sojka, R.E.; Glenn, G.M. Biopolymer additives to reduce erosion-induced soil losses during irrigation. Ind. Crops Prod. 2000, 11, 19–29. [Google Scholar] [CrossRef]

- Kavazanjian, E., Jr.; Iglesias, E.; Karatas, I. Biopolymer soil stabilization for wind erosion control. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering; Elsevier: Amsterdam, The Netherlands, 2009; Volume 2, pp. 881–884. [Google Scholar]

- Ayeldeen, M.; Negm, A.; El-Sawwaf, M.; Kitazume, M. Enhancing mechanical behaviors of collapsible soil using two biopolymers. J. Rock Mech. Geotech. Eng. 2017, 9, 329–339. [Google Scholar] [CrossRef]

- Ashraf, M.S.; Azahar, S.B.; Yusof, N.Z. Soil Improvement Using MICP and Biopolymers: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2017, 226, 012058. [Google Scholar] [CrossRef]

- Hou, C.T.; Barnabe, N.; Greaney, K. Biodegradation of xanthan by salt-tolerant aerobic microorganisms. J. Ind. Microbiol. 1986, 1, 31–37. [Google Scholar] [CrossRef]

- D18 Committee. Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass; ASTM International: West Conshohocken, PA, USA, March 2019. [Google Scholar]

- D18 Committee. Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA, July 2016. [Google Scholar]

- D18 Committee. Test Method for Unconsolidated-Undrained Triaxial Compression Test on Cohesive Soils; ASTM International: West Conshohocken, PA, USA, December 2015. [Google Scholar]

- D18 Committee. Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions; ASTM International: West Conshohocken, PA, USA, January 2012. [Google Scholar]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.-C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.-C. Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Wiszniewski, M.; Skutnik, Z. Effects of Xanthan Gum Biopolymer on the Permeability, Odometer, Unconfined Compressive and Triaxial Shear Behavior of a Sand. Soil Mech. Found Eng. 2017, 54, 356–361. [Google Scholar] [CrossRef]

- Ayeldeen, M.K.; Negm, A.M.; El Sawwaf, M.A. Evaluating the physical characteristics of biopolymer/soil mixtures. Arab. J. Geosci. 2016, 9, 371. [Google Scholar] [CrossRef]

- Cho, G.-C.; Chang, I. Cementless Soil Stabilizer–Biopolymer. In Proceedings of the 2018 World Congress on Advances in Civil, Environmental, & Materials Research (ACEM18) Songdo Convensia, Incheon, Korea, 27–31 August 2018. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).