Optimum Design and Energy Performance of Hybrid Triple Glazing System with Vacuum and Carbon Dioxide Filled Gap

Abstract

1. Introduction

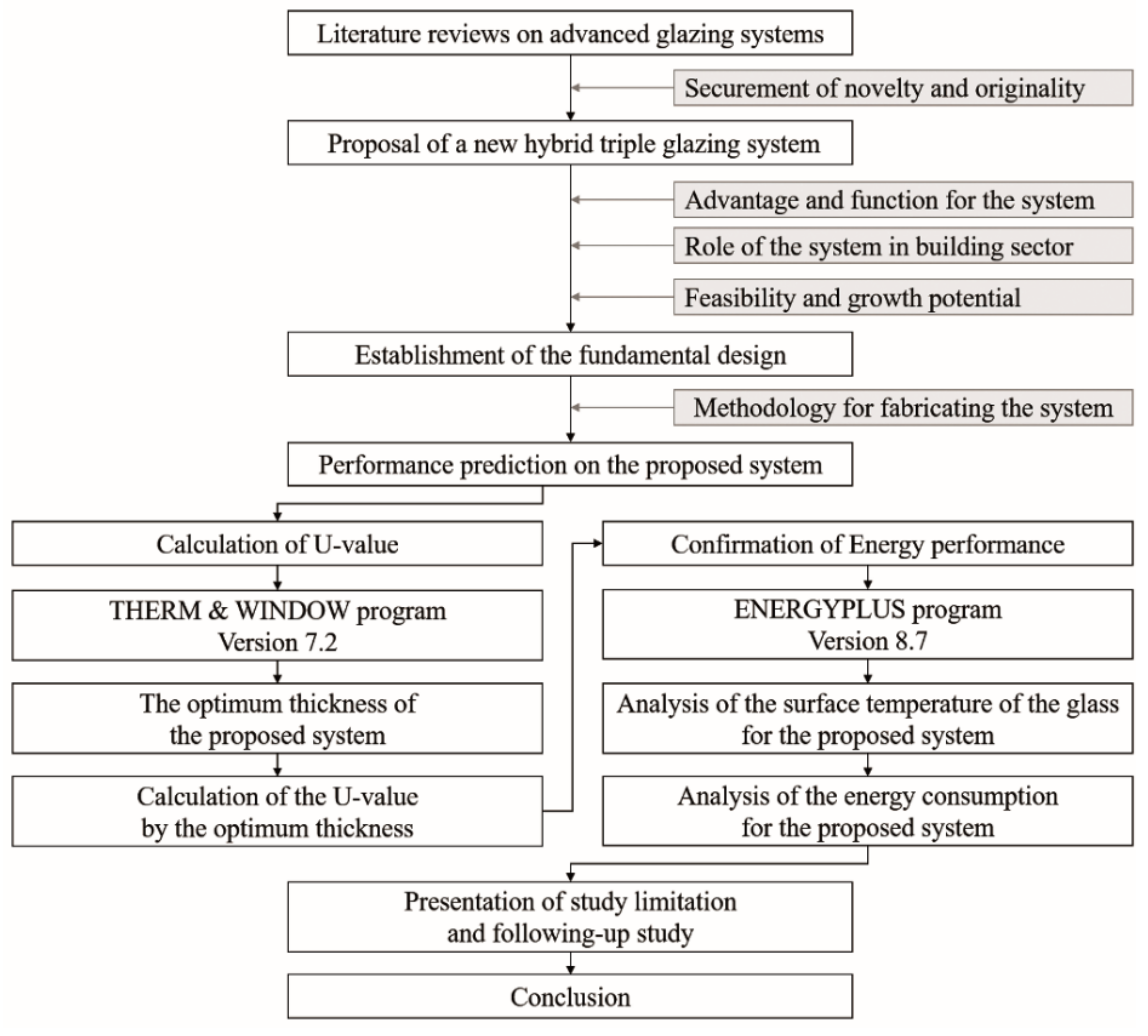

2. Materials and Methods

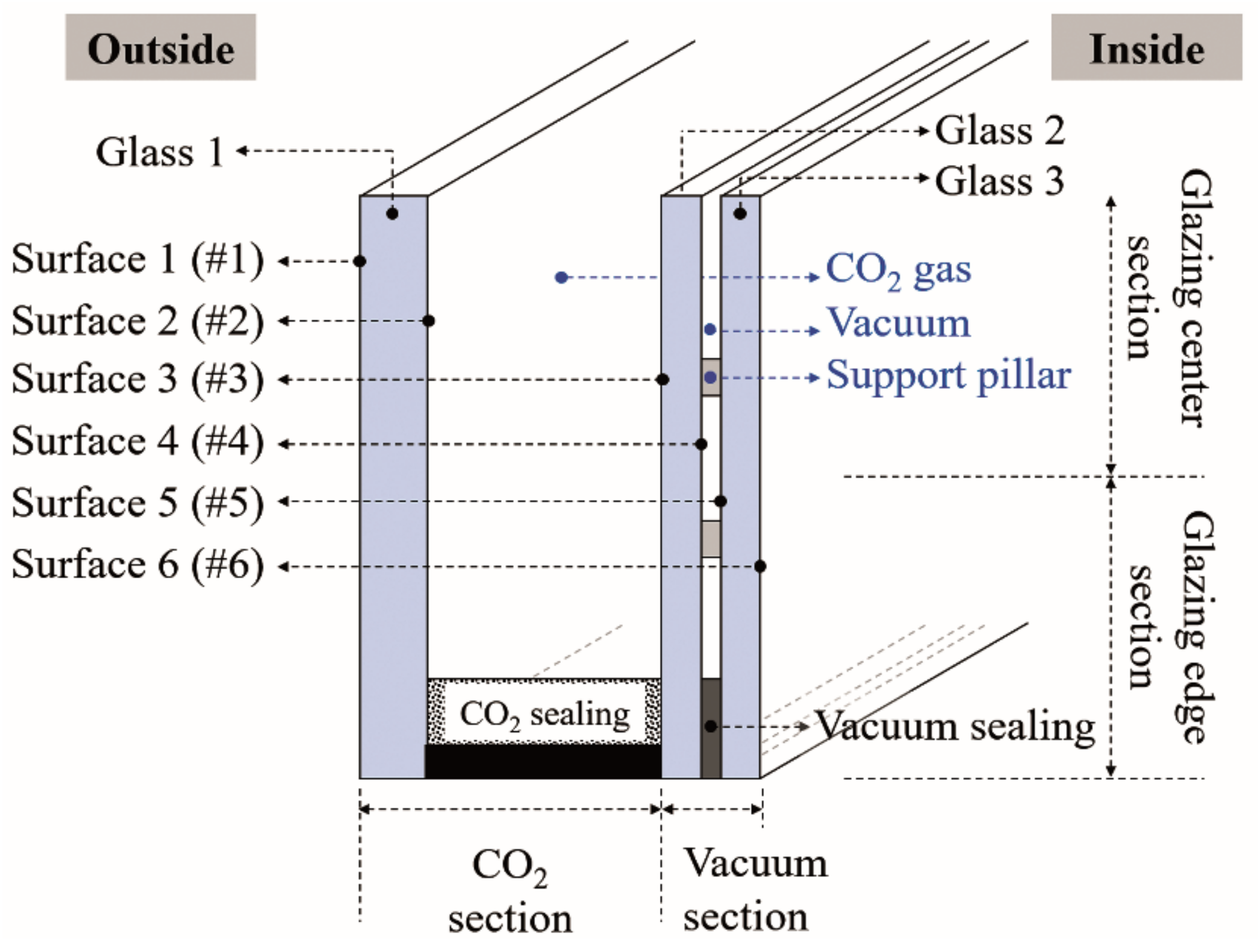

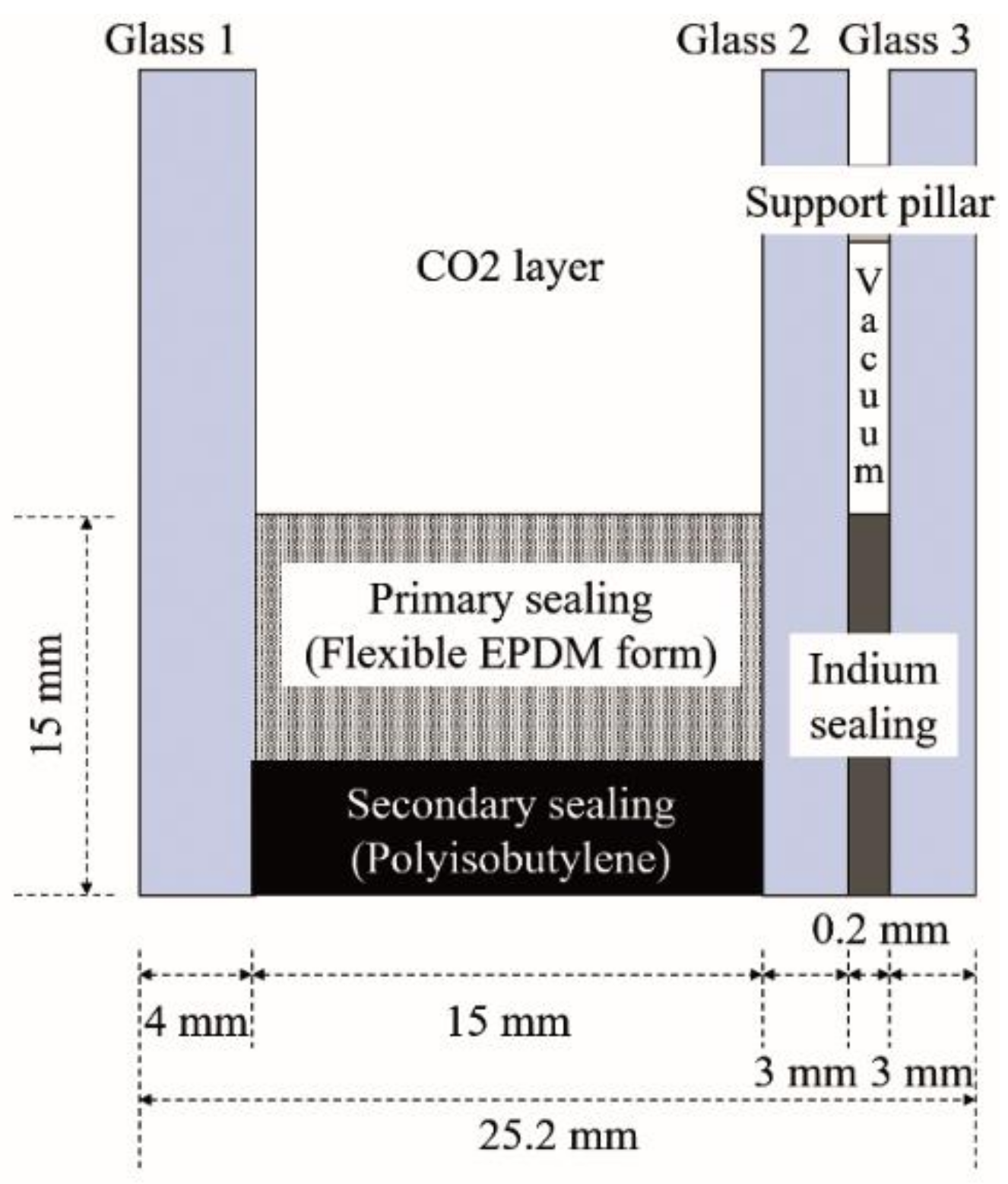

2.1. Structure of Hybrid Triple Glazing System

2.2. Elements of the Vacuum Section

2.3. Elements of the CO2 Section

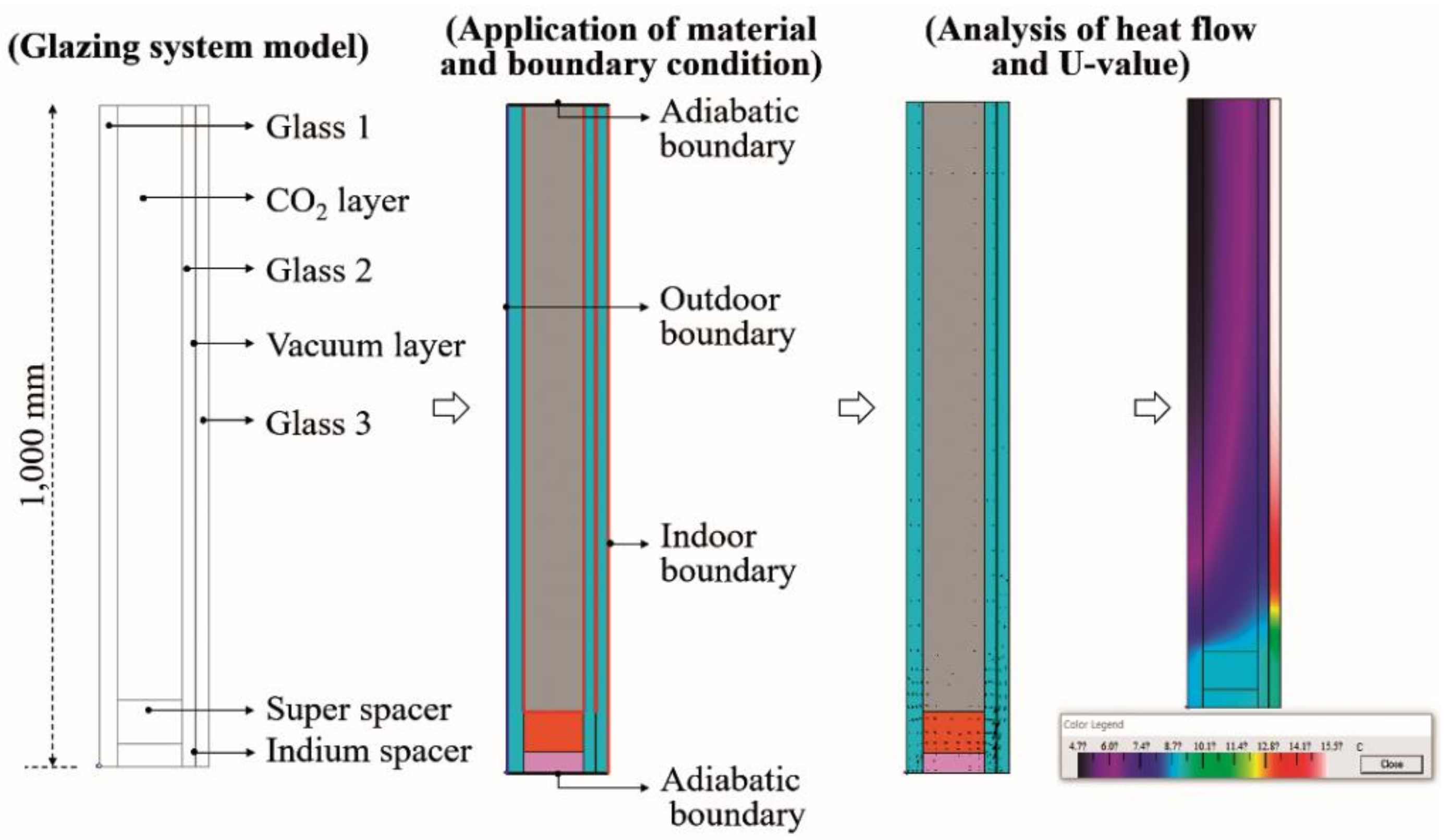

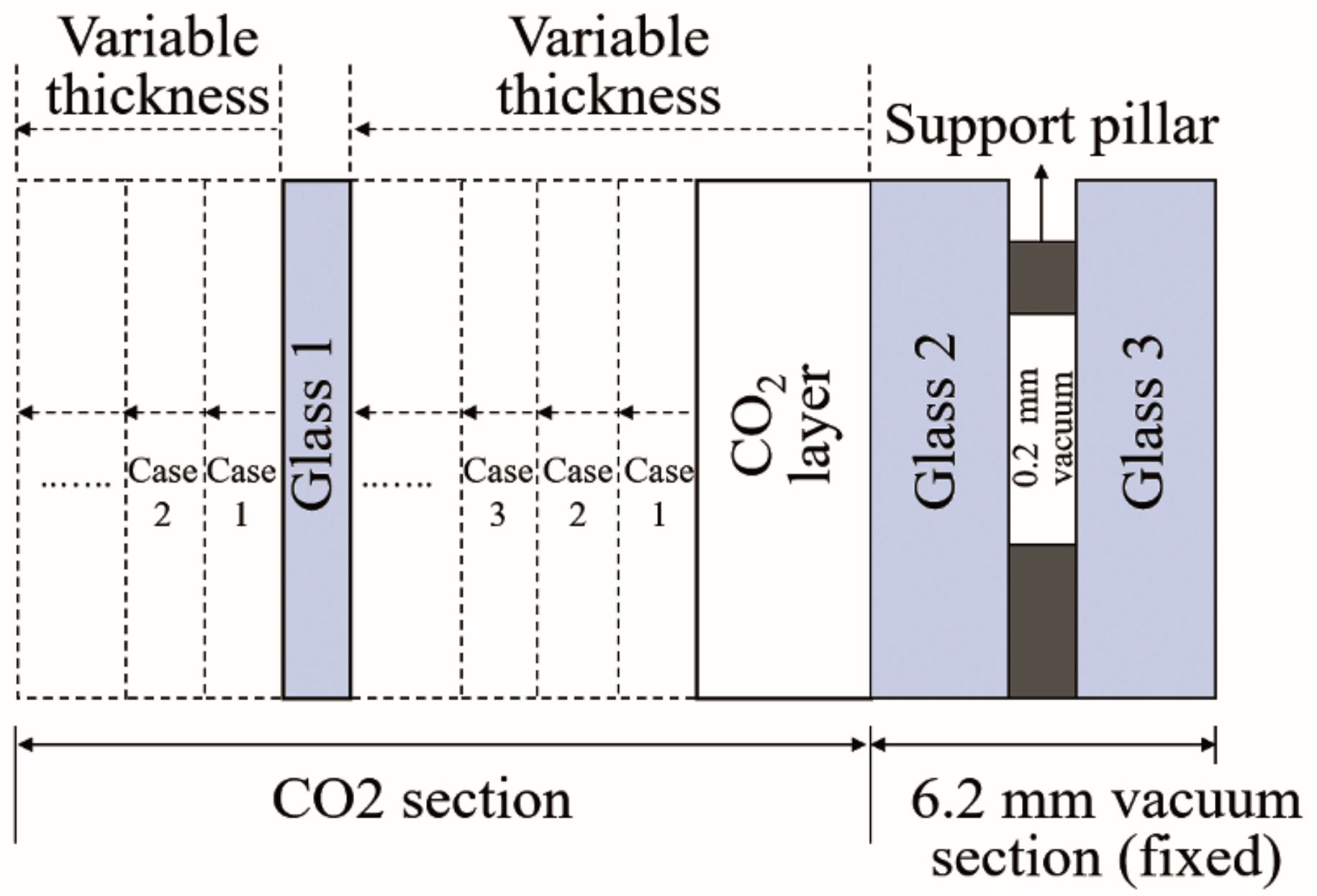

2.4. Calculation of Optimum Thickness and U-Value of Glazing System

2.5. Application of Glazing System to a Building

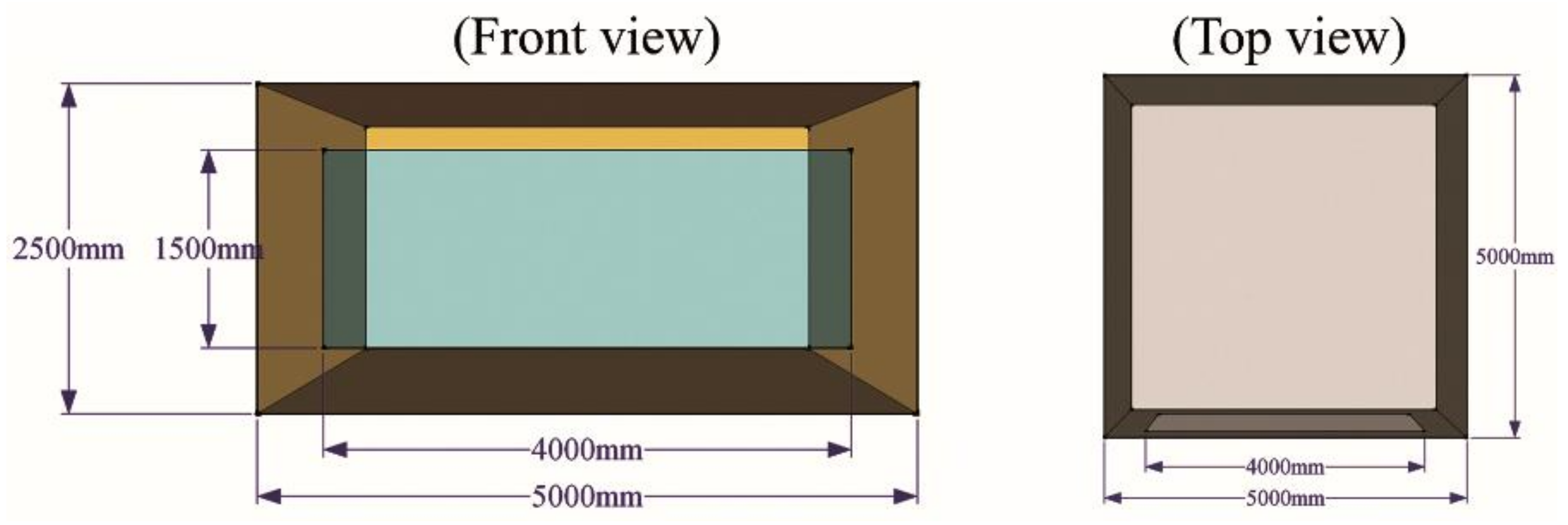

2.5.1. Building Structure

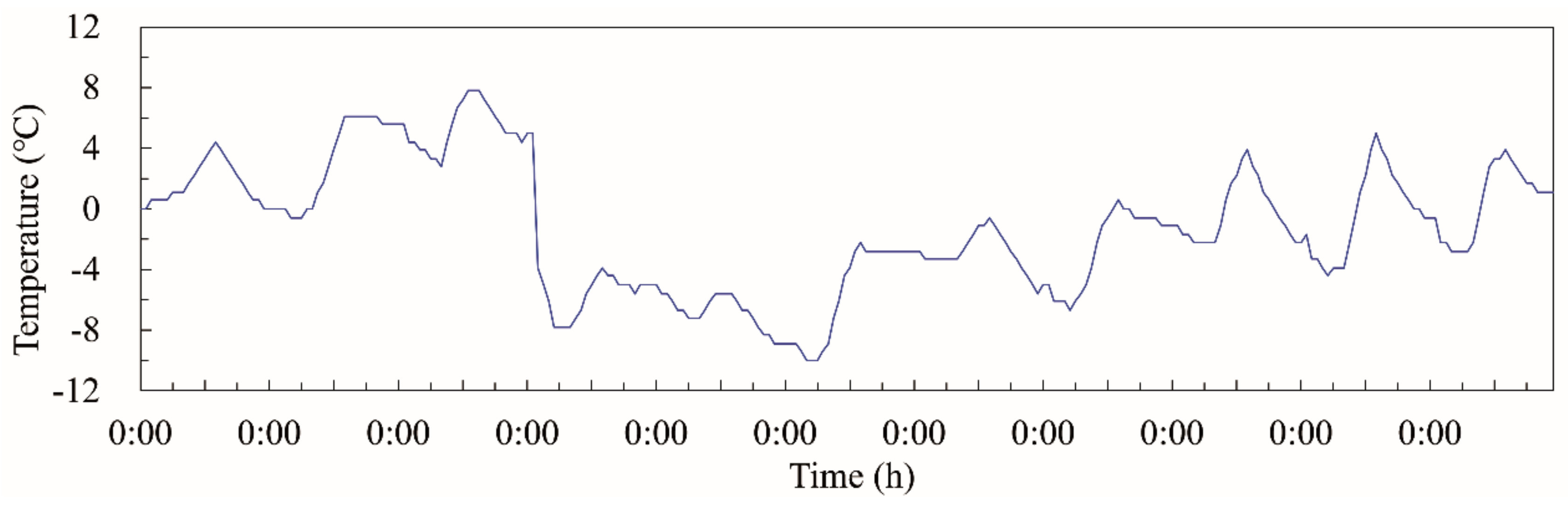

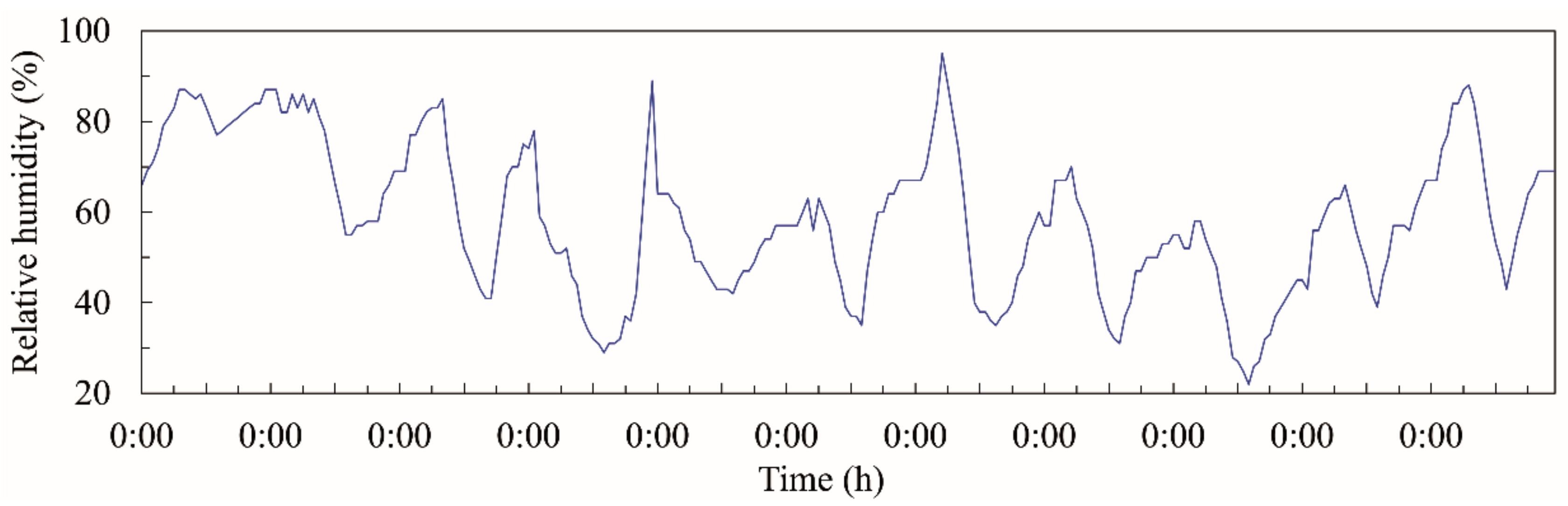

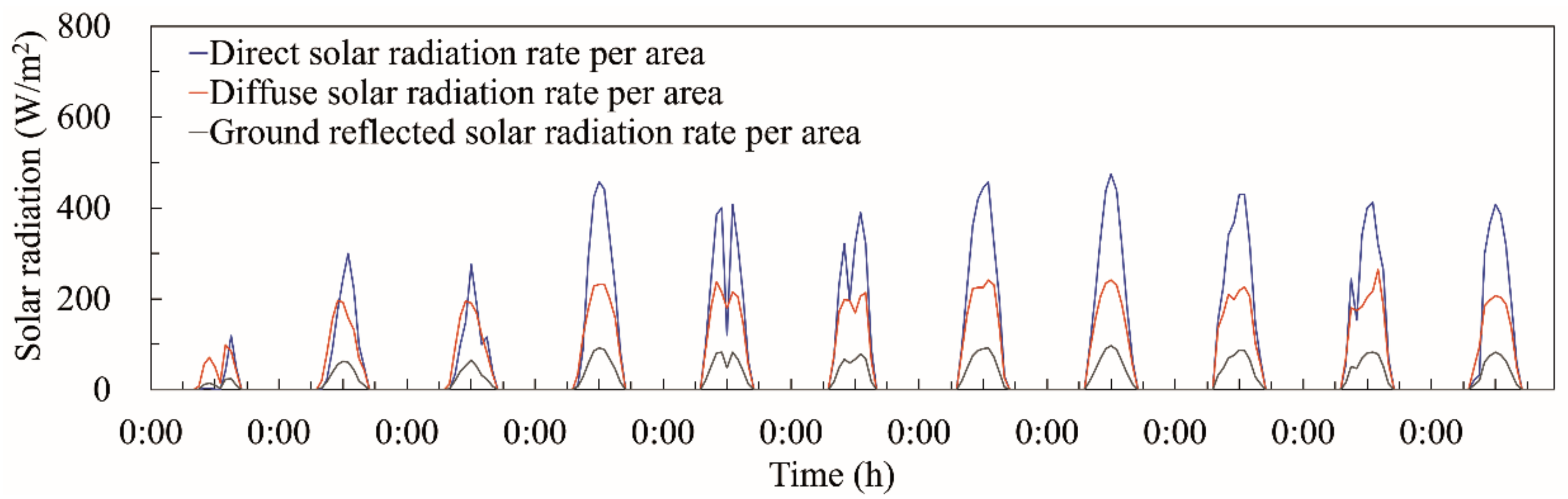

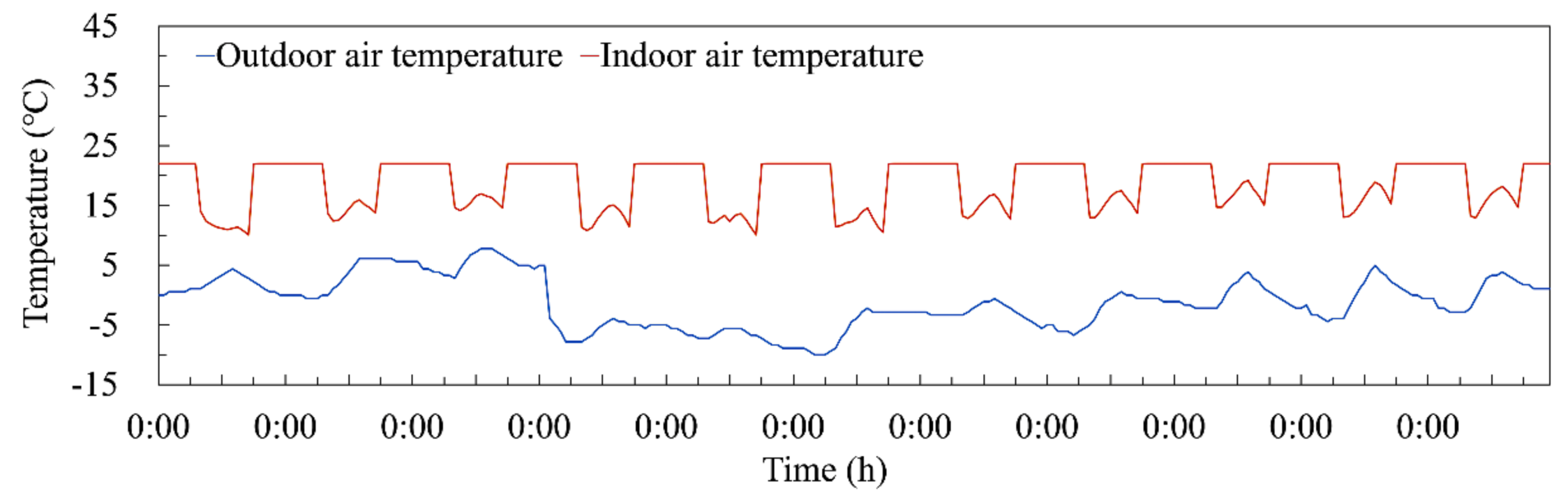

2.5.2. Outdoor Conditions

2.5.3. Indoor Conditions

3. Results and Discussion

3.1. Indoor Temperature and Control

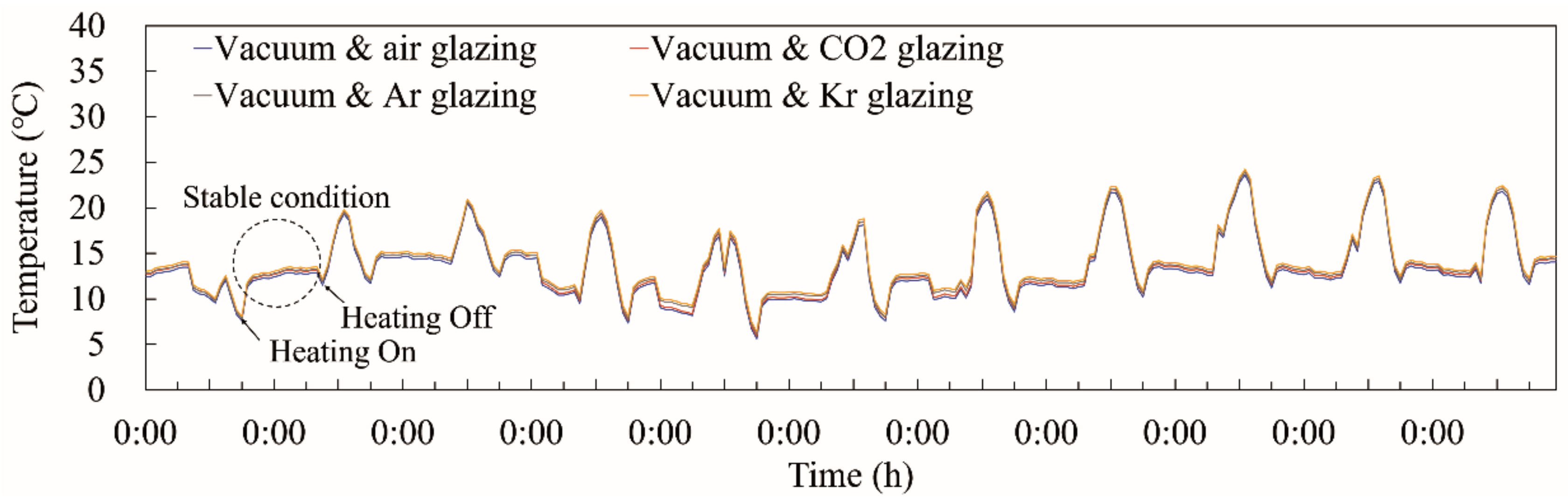

3.2. Surface Temperature of the Indoor Glazing Glass

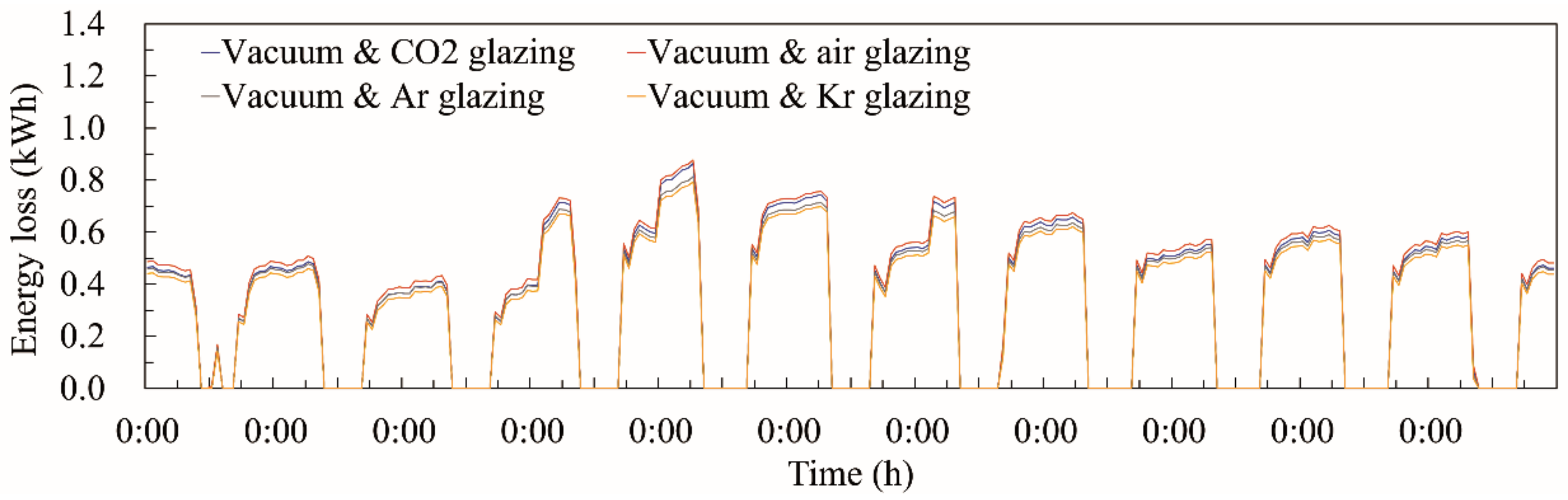

3.3. Energy Loss from Glazing

3.4. Heating Energy Consumption of Building

3.5. Research Limitations and Future Plans

4. Conclusions

- (1).

- CO2 is a greenhouse gas and its use is strictly controlled both domestically and internationally. However, as CCS and CCU technologies are gaining increasing attention, it is now possible to utilize CO2 as a resource. This is done by processing the collected greenhouse gases. The glazing of windows will be practically the only factor for using pure CO2 gas as a resource in buildings. Because glazing requires an adiabatic gas and an edge sealing technology that seals the gas gap, there is a slight risk of the CO2 gas injected into the glazing being released into the atmosphere.

- (2).

- If CO2 gas is used in building glazing, the following three advantages are observed. First, as in our previous study, CO2 gas in glazing has very similar insulation performance as that of Ar gas. Thus, the price of glazing can be lowered by replacing existing, expensive Ar gas with cheap CO2 gas. Second, similar to forests, buildings can function as CO2/greenhouse gas absorbers. Third, it can help reduce CO2 treatment costs.

- (3).

- Recent research trends in glazing have focused on the development of super-insulated glazing with extremely low U-values. However, by using only CO2 gas and two sheets of glass, the U-value of glazing to the zero-point level required for super-insulated glazing can be reduced. Therefore, hybrid triple glazing with vacuum and CO2 sections was designed by introducing vacuum glazing developed from existing studies for the super-insulated performance of glazing using CO2 gas.

- (4).

- The optimum thickness of the proposed hybrid triple glazing was determined using the Therm & Window program, and the U-value was calculated. The thickness of the vacuum section was applied to a total thickness of 6.2 mm, following the results of previous studies. Meanwhile, the thickness of the CO2 section was determined by analyzing the change and decrease rate in U-value by increasing the thickness of the CO2 gap and glass by 1 mm. Therefore, the optimal thicknesses of the CO2 gap and glass were analyzed to be 15 and 4 mm, respectively. Therefore, total thickness of the proposed hybrid triple glazing, including both the vacuum and CO2 sections, is most suitable at 25.2 mm with a corresponding U-value of 0.259 W/m2·K.

- (5).

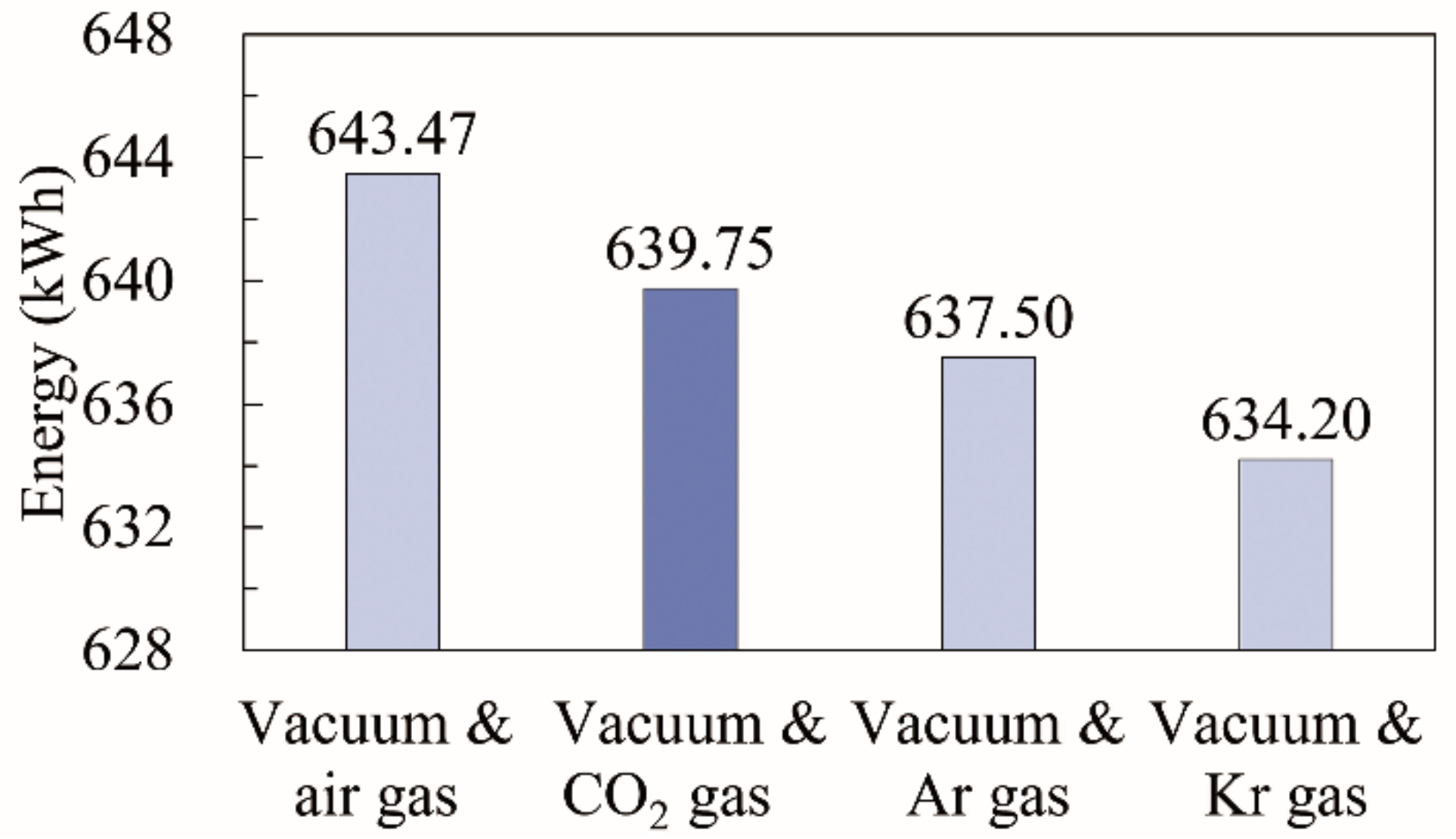

- The energy performance of the hybrid triple glazing was analyzed using the EnergyPlus program. It was necessary to compare the performance gaps between the proposed and advanced glazing presented in previous studies. However, owing to the limitations of the simulation program, the conventional insulation gas, air, Ar, and Kr gas were used as alternatives. The thickness of the glazing was maintained. However, the CO2 gas was changed to air, Ar, and Kr gas, and the energy consumption of the building was analyzed. Therefore, the energy performance of the hybrid triple glazing with vacuum and a CO2 gap was analyzed to be extremely similar to that of vacuum and Ar gas.

- (6).

- Given the limitations of the study, it was essential to compare the proposed glazing performance with those of advanced glazing proposed in previous studies. However, owing to the limitations of the program, it is currently impossible to conduct the comparative analysis. However, as in the calculation results of U-value, the hybrid triple glazing with vacuum and a CO2 gap exhibited a considerably better U-value than multi-layer, electrochromic, self-cleaning, PCM, and PV glazing, and values extremely close to the U-values of the triple vacuum and suspended glazing. Suspended glazing is the latest type of glazing developed and has received considerable interest. Therefore, it is thought that the proposed glazing could be utilized as next-generation glazing to absorb greenhouse gases in buildings and reduce energy consumption.

Author Contributions

Funding

Conflicts of Interest

References

- Erdem, C.; Saffa, B.R. A state-of-the art review on innovative glazing technologies. Renew. Sustain. Energy Rev. 2015, 41, 695–714. [Google Scholar] [CrossRef]

- Jelle, B.P.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 96, 1–28. [Google Scholar] [CrossRef]

- Hee, W.J.; Alghoul, M.A.; Bakhtyar, B.; OmKalthum, E.; Shameri, M.A.; Alrubaih, M.S.; Sopian, K. The role of window glazing on daylighting and energy saving in buildings. Renew. Sustain. Energy Rev. 2015, 42, 323–343. [Google Scholar] [CrossRef]

- Yueping, F.; Trevor, H.; Neil, H.; Philip, C.E.; Brian, N. Comparison of vacuum glazing thermal performance predicted using two-and three-dimensional models and their experimental validation. Sol. Energy Mater. Sol. Cells 2009, 93, 1492–1498. [Google Scholar] [CrossRef]

- Yueping, F.; Trevor, J.H.; Neil, H. Predicted thermal performance of triple vacuum glazing. Sol. Energy 2010, 84, 2132–2139. [Google Scholar] [CrossRef]

- Aritra, G.; Brian, N. Durability of switching behaviour after outdoor exposure for a suspended particle device switchable glazing. Sol. Energy Mater. Sol. Cells 2017, 163, 178–184. [Google Scholar] [CrossRef]

- Qi, L.; Yipin, W.; Jinyuan, Y.; Guifu, G. Impact resistance and static strength analysis of an extremely simplified micro hotplate with novel suspended film. Sens. Actuators A Phys. 2018, 208, 495–504. [Google Scholar] [CrossRef]

- Piccolo, A.; Pennisi, A.; Simone, F. Daylighting performance of an electrochromic window in a small scale test-cell. Sol. Energy 2009, 83, 832–844. [Google Scholar] [CrossRef]

- Piccolo, A.; Simone, F. Effect of switchable glazing on discomfort glare from windows. Build. Environ. 2009, 44, 1171–1180. [Google Scholar] [CrossRef]

- Ruben, B.; Bjorn, P.J.; Arild, G. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Baek, S.; Kim, S. Determination of optimaum hot-water temperatures for PCM radiant floor-heating systems based on the wet construction method. Sustainability 2018, 10, 4004. [Google Scholar] [CrossRef]

- IsmailJ, K.A.R.; Henriquez, R. Thermally effective windows with moving phase change material curtains. Appl. Therm. Eng. 2001, 21, 1909–1923. [Google Scholar] [CrossRef]

- Mohammed, M.F.; Amar, M.K.; Siddique, A.K.R.; Said, A.H. A review on phase change energy storage: Materials and applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Tady, Y.Y.F.; Yang, H. Study on thermal performance of semi-transparent building-integrated photovoltaic glazings. Energy Build. 2008, 40, 341–350. [Google Scholar] [CrossRef]

- Henrik, D.; Bengt, P.; Bjorn, K. System analysis of a multifunctional PV/T hybrid solar window. Sol. Energy 2012, 86, 903–910. [Google Scholar] [CrossRef]

- Erdem, C.; Pinar, M.C. Effects of concavity level on heat loss, effectiveness and efficiency of a longitudinal fin exposed to natural convection and radiation. Int. J. Numer. Methods Heat Fluid Flow 2013, 23, 1169–1178. [Google Scholar] [CrossRef]

- Akira, F.; Xintong, Z. Titanium dioxide photocatalysis: Present situation and future approaches. Comptes Rendus Chim. 2006, 9, 750–760. [Google Scholar] [CrossRef]

- Raquel, P.; Garikoitz, B.; Arrate, M.; Josu, G.; Ana, A. Development of multifunctional sol–gel coatings: Anti-Reflection coatings with enhanced self-cleaning capacity. Sol. Energy Mater. Sol. Cells 2010, 94, 1081–1088. [Google Scholar] [CrossRef]

- Krister, M.; Bjorn, P.J. Self-cleaning glazing products: A state-of-the-art review and future research pathways. Sol. Energy Mater. Sol. Cells 2013, 109, 126–141. [Google Scholar] [CrossRef]

- Erdem, C.; Pinar, M.C.; Christopher, J.W.; Saffa, B.R. Optimizing insulation thickness and analysing environmental impacts of aerogel-based thermal superinsulation in buildings. Energy Build. 2014, 77, 28–39. [Google Scholar] [CrossRef]

- Erdem, C.; Pinar, M.C.; Christopher, J.W.; Saffa, B.R. Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Mar, P.F.; Andrei, B.D.; Evangelos, T. CO2 utilization pathways: Techno-economic assessment and market opportunities. Energy Procedia 2014, 63, 7968–7975. [Google Scholar] [CrossRef]

- Sara, B.; Samuel, K.; Niall, M.D.; Nigel, B.; Adam, H. An assessment of CCS costs, barriers and potential. Energy Strateg. Rev. 2018, 22, 61–81. [Google Scholar] [CrossRef]

- Bae, J.; Seo, H.; Ahn, E.; Lee, J. Patent trend analysis of carbon capture/storage/utilization technology. Korean Soc. Econ. Environ. Geol. 2017, 50, 389–400. [Google Scholar] [CrossRef]

- Baek, S.; Park, J.C. Analysis on thermal performance of double-pane unit filled carbon dioxide. Soc. Air Cond. Refrig. Eng. Korea 2015, 2015, 220–223. [Google Scholar]

- Manz, H.; Menti, U.P. Energy performance of glazings in European climates. Renew. Energy 2012, 37, 226–232. [Google Scholar] [CrossRef]

- Kassai, M.; Ge, G.; Simonson, C.J. Dehumidification performance investigation of run-around membrane energy exchanger system. Therm. Sci. 2016, 20, 1927–1938. [Google Scholar] [CrossRef]

- National Fenestration Rating Council. Therm 7/Window7 NFRC Simulation Manual. 2017. Available online: https://windows.lbl.gov/sites/default/files/Downloads/NFRCSim7-July2017.pdf (accessed on 4 September 2019).

- Carli Inc. Conrad 5 & Viewer 5 Technical and Programming Documentation. 2006. Available online: https://windows.lbl.gov/sites/all/files/Downloads/conrad-and-viewer-06-20-06.pdf (accessed on 4 September 2019).

- Kassai, M.; Simonson, C.J. Performance investigation of liquid-to-air membrane energy exchanger under low solution/air heat capacity rates ratio conditions. Build. Serv. Eng. Res. Technol. 2015, 36, 535–545. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Input Output Reference. 2019. Available online: https://energyplus.net/sites/all/modules/custom/nrel_custom/pdfs/pdfs_v9.1.0/InputOutputReference.pdf (accessed on 4 September 2019).

- U.S. Department of Energy. Engineering Reference. 2019. Available online: https://energyplus.net/sites/all/modules/custom/nrel_custom/pdfs/pdfs_v9.1.0/EngineeringReference.pdf (accessed on 4 September 2019).

- Yueping, F.; Trevor, J.H.; Farid, A.; Neil, H.; Philip, C.E.; Brian, N.; Seth, M. Indium alloy-sealed vacuum glazing development and context. Renew. Sustain. Energy Rev. 2014, 37, 480–501. [Google Scholar] [CrossRef]

- Van Den Bergh, S.; Hart, R.; Petter Jelle, B.; Gustavsen, A. Window spacers and edge seals in insulating glass units: A state-of-the art review and future perspectives. Energy Build. 2013, 58, 263–280. [Google Scholar] [CrossRef]

- Korean Standard Service Network. Standard Test Method for Thermal Resistance for Windows and Doors. 2017. Available online: https://www.kssn.net/search/stddetail.do?itemNo=K001010113352 (accessed on 4 September 2019).

- Passive House Institute Korea. Republic of Korea Standard Weather Data. 2017. Available online: http://www.phiko.kr/bbs/board.php?bo_table=z3_01&wr_id=2479 (accessed on 4 September 2019).

- National Law Information Center. Building Energy Conservation Design Standards 2018. Available online: http://www.law.go.kr/admRulLsInfoP.do?admRulSeq=2100000106860 (accessed on 4 September 2019).

- Korean Institute of Architectural Sustainable Environment and Building System. Building Airtightness Criteria 2013. Available online: http://www.kiaebs.org/board/?_0000_method=view&ncode=a003&num=11&page=1 (accessed on 4 September 2019).

- Kassai, M. Experimental investigation of carbon dioxide cross-contamination in sorption energy recovery wheel in ventilation system. Build Serv. Eng. Res. Technol. 2018, 39, 463–474. [Google Scholar] [CrossRef]

- Ren, X.Y.Y.; Zhang, C.B.; Zhao, Y.; Boxem, G.; Zeiler, W.; Li, T.T. A data mining-based method for revealing occupant behavior patterns in using mechanical ventilation systems of Dutch dwellings. Energy Build. 2019, 193, 99–110. [Google Scholar] [CrossRef]

| No. | Type of Glazing | Type of Gap | U-Value at Center (W/m2·K) |

|---|---|---|---|

| 1 | Multi-layer | Insulating gas | 0.70 |

| 2 | Triple vacuum | Vacuum with pillar (Double vacuum gap) | 0.24 |

| 3 | Suspended | Insulating gas with film | 0.28 |

| 4 | Electrochromic | Insulating gas with chromogenic material | 0.62 |

| 5 | PCM | Insulating gas with PCM | 0.50 |

| 6 | Photovoltaic | Insulating gas | 1.10 |

| 7 | Self-cleaning | Insulating gas | 1.20 |

| 8 | Aerogel | Aerogel | 0.40 |

| Glass Name | SGG COOL-LITE XTREME 50-22 II | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | 3 mm | |||||||||

| Conductivity | 1.0 W/m·K | |||||||||

| Optical Characteristic | Total solar radiation | Visible rays | Emissivity | |||||||

| Tsol1 | Tsol2 | Rsol1 | Rsol2 | Tvis1 | Tvis2 | Rvis1 | Rvis2 | Emis1 | Emis2 | |

| 0.175 | 0.175 | 0.571 | 0.372 | 0.516 | 0.516 | 0.118 | 0.137 | 0.016 | 0.840 | |

| Tsol1 | Solar radiation ratio transmitted through the front surface of the glass (surface 1, 3, and 5 in Figure 3) | |||||||||

| Tsol2 | Solar radiation ratio transmitted through the back surface of the glass (surface 2, 4, and 6 in Figure 3) | |||||||||

| Rsol1 | Solar radiation ratio reflected through the front surface of the glass (surface 1, 3, and 5 in Figure 3) | |||||||||

| Rsol2 | Solar radiation ratio reflected through the back surface of the glass (surface 2, 4, and 6 in Figure 3) | |||||||||

| Tvis1 | Visible ray ratio transmitted through the front surface of the glass (surface 1, 3, and 5 in Figure 3) | |||||||||

| Tvis2: | Visible ray ratio transmitted through the back surface of the glass (surface 2, 4, and 6 in Figure 3) | |||||||||

| Rvis1 | Visible ray ratio reflected through the front surface of the glass (surface 1, 3, and 5 in Figure 3) | |||||||||

| Rvis2 | Visible ray ratio reflected through the back surface of the glass (surface 2, 4, and 6 in Figure 3) | |||||||||

| Emis1 | Surface emissivity through the front surface of the glass (surface 1, 3, and 5 in Figure 3) | |||||||||

| Emis2 | Surface emissivity in through the back surface of the glass (surface 2, 4, and 6 in Figure 3) | |||||||||

| Type | Mixed Vacuum-Air | |

|---|---|---|

| Thickness | 0.2 mm | |

| Molecular weight | 28.970 mol | |

| Pressure | 0.1332 Pa = 0.01 Torr | |

| Gap conductance | 0.106787 W/m2·K | |

| Support pillar | Type | Circular |

| Radius | 0.2 mm | |

| Spacing | 30 mm | |

| Type | Material | Width (mm) | Hight (mm) | Conductivity (W/m·K) |

|---|---|---|---|---|

| Solid | Indium | 0.2 | 15 | 83.7 |

| Insulating Gas | Carbon Dioxide (CO2) | |

|---|---|---|

| Molecular Weight (mol/g) | 44.010 | |

| Pressure (Pa) | 101,325 | |

| Prandtl Number (Pr) | 0.7808 | |

| Conductivity coefficients | A (W/m·K) | 0.00037 |

| B (W/m·K2) | 0.00002954 | |

| C (W/m·K3) | 0.00000008 | |

| Viscosity coefficients | A (kg/m·s) | 0.00000116 |

| B (kg/m·s·K) | 0.00000006 | |

| C (kg/m·s·K2) | 0 | |

| Specific heat coefficients | A (J/kg·K) | 558.8 |

| B (J/kg·K2) | 1.04960001 | |

| C (J/kg·K3) | 0.00023876 | |

| Type | Material | Hight (mm) | Conductivity (W/m·K) | |

|---|---|---|---|---|

| Solid | Primary sealing | Flexible EPDM* form (Including desiccant) | 15 | 0.18 |

| Secondary sealing | Polyisobutylene (PIB) | |||

| Air Temperature | Wind Velocity | Convection Heat Transfer Coefficient | Solar Radiation | |

|---|---|---|---|---|

| (°C) | (m/s) | (W/m2·K) | (W/m2) | |

| Indoor | 20 | 1.2 | 9.1 | - |

| Outdoor | 0 | 4.2 | 21.2 | 558 |

| Site Location | Seoul, South Korea | Latitude | 37.34 |

|---|---|---|---|

| Longitude | 126.57 | ||

| Building structure | Reinforced concrete | ||

| Size of building | Length 5 m × Width 5 m × Height 2.5 m | ||

| Direction of building | Corrected South | ||

| Size of window | 4 × 1.5 m | ||

| Weather data | Seoul standard weather data (EPW*) | ||

| Run period | From December 1 to December 10 (10 days) | ||

| Structure | Type of Material | Thickness (m) | Conductivity (W/m·K) | Thermal Transmittance (W/m2·K) |

|---|---|---|---|---|

| Floor | Concrete slab | 0.21 | 1.4 | 0.178 (Domestic standard: 0.180) |

| Insulation | 0.17 | 0.034 | ||

| Autoclaved lightweight concrete | 0.04 | 0.15 | ||

| Finishing mortar | 0.04 | 0.72 | ||

| Finishing material | 0.005 | 0.16 | ||

| Wall | Concrete wall | 0.18 | 1.4 | 0.258 (Domestic standard: 0.260) |

| Insulation | 0.12 | 0.034 | ||

| Gypsum panel | 0.01 | 0.17 | ||

| Roof | Finishing mortar | 0.08 | 0.72 | 0.142 (Domestic standard: 0.150) |

| Concrete slab | 0.21 | 1.4 | ||

| Insulation | 0.09 | 0.035 | ||

| Air cavity | 0.1 | 0.025 | ||

| Gypsum panel | 0.01 | 0.17 |

| Type of Input | Time Gap | Unit | Value |

|---|---|---|---|

| Occupant | 00:00–08:00 | Person | 4 |

| 08:00–18:00 | 0 | ||

| 18:00–00:00 | 4 | ||

| Light | 00:00–06:00 | Fraction (0 ≤ Light ≤ 1) | 0.1 |

| 06:00–08:00 | 1 | ||

| 08:00–18:00 | 0 | ||

| 18:00–22:00 | 1 | ||

| 22:00–00:00 | 0.1 | ||

| Infiltration | 00:00–24:00 | 1.0 air change per hour | 1 |

| Ventilation | 00:00–08:00 | 0.5 air change per hour | 0.5 |

| 08:00–18:00 | 0 | ||

| 18:00–00:00 | 0.5 | ||

| Heating Control | 00:00–08:00 | Temperature (°C) | 22 |

| 08:00–18:00 | 10 | ||

| 18:00–00:00 | 22 |

| Type | All-Air Method | |

|---|---|---|

| Indoor conditions | Heating set-point | 22 °C |

| Heating limit | No limit | |

| Cooling set-point | 25 °C | |

| Cooling limit | No limit | |

| Supply air | Maximum heating temperature | 50 °C |

| Maximum heating humidity | 0.0156 (kg/kg Dry air) | |

| Maximum cooling temperature | 10 °C | |

| Maximum cooling humidity | 0.0077 (kg/kg Dry air) | |

| Temperature control | Heating & cooling set-point | |

| Airflow rate control | Autosize | |

| Return air | Heat recovery type | Enthalpy |

| Sensible heat recovery rate | 0.9 | |

| Latent heat recovery rate | 0.9 | |

| Outdoor air | Outdoor air condition | Weather data |

| Flow rate control | Autosize | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, S.; Kim, S. Optimum Design and Energy Performance of Hybrid Triple Glazing System with Vacuum and Carbon Dioxide Filled Gap. Sustainability 2019, 11, 5543. https://doi.org/10.3390/su11195543

Baek S, Kim S. Optimum Design and Energy Performance of Hybrid Triple Glazing System with Vacuum and Carbon Dioxide Filled Gap. Sustainability. 2019; 11(19):5543. https://doi.org/10.3390/su11195543

Chicago/Turabian StyleBaek, Sanghoon, and Sangchul Kim. 2019. "Optimum Design and Energy Performance of Hybrid Triple Glazing System with Vacuum and Carbon Dioxide Filled Gap" Sustainability 11, no. 19: 5543. https://doi.org/10.3390/su11195543

APA StyleBaek, S., & Kim, S. (2019). Optimum Design and Energy Performance of Hybrid Triple Glazing System with Vacuum and Carbon Dioxide Filled Gap. Sustainability, 11(19), 5543. https://doi.org/10.3390/su11195543