Evaluating the Performance of Systemic Innovation Problems of the IoT in Manufacturing Industries by Novel MCDM Methods

Abstract

1. Introduction

2. Literature Review

2.1. Configuring or Reconfiguring an Innovation Policy Portfolio for Systemic Innovation

2.2. Systemic Functions of the TIS

2.3. Performance Evaluation and Innovation Systems

2.4. MCDM in Performance Evaluation

2.5. Research Gaps

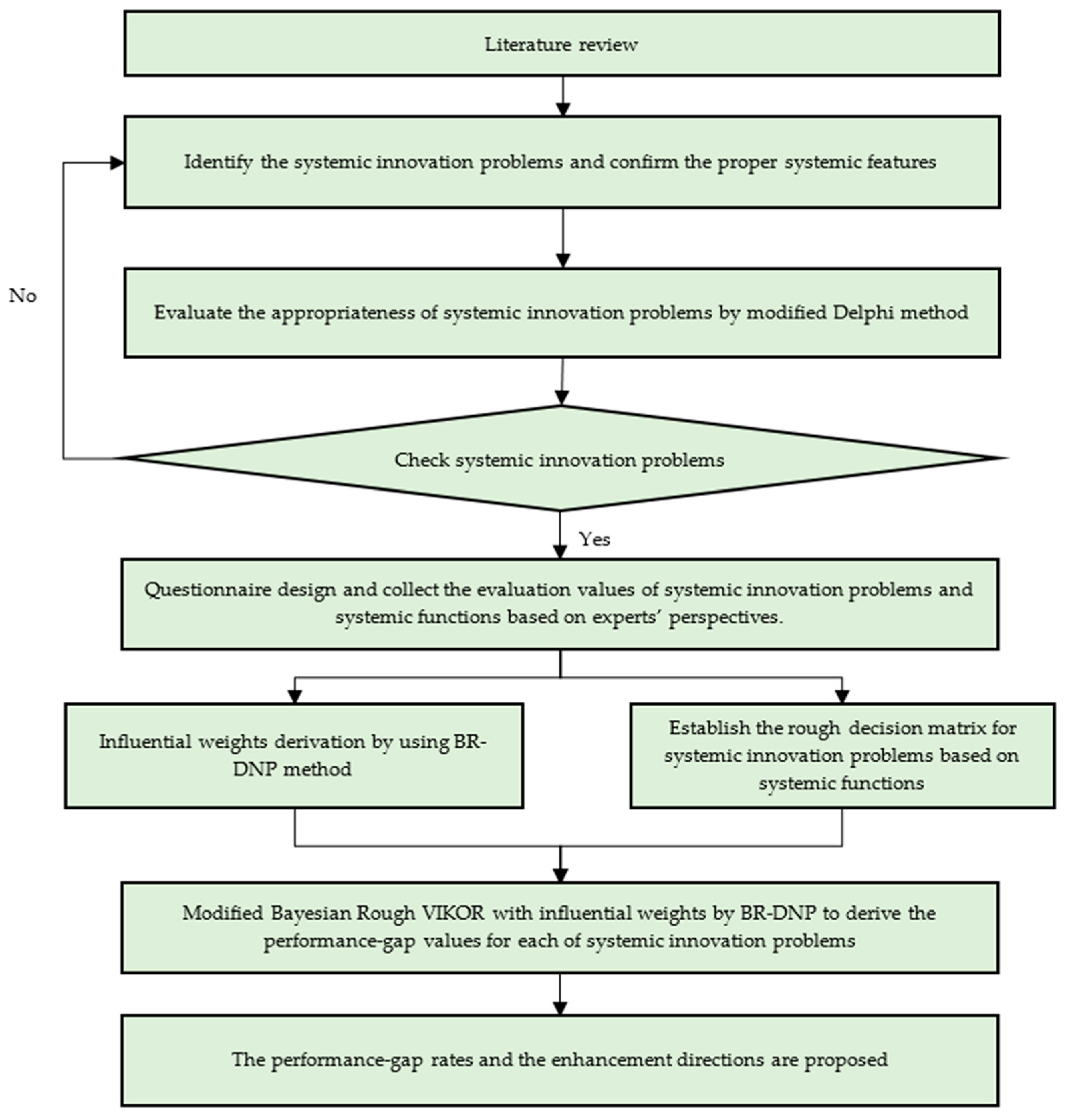

3. Proposed Evaluation Framework for Systemic Innovation Problems

3.1. Modified Delphi Method

3.2. Bayesian Rough DEMATEL Based ANP Approach (BR-DNP)

3.3. Modified Bayesian Rough VIKOR (MBR-VIKOR)

4. Empirical Study

4.1. Background and Problem Description

4.2. Data Collection

4.3. The Derivation of Systemic Innovation Problems by Modified Delphi Method

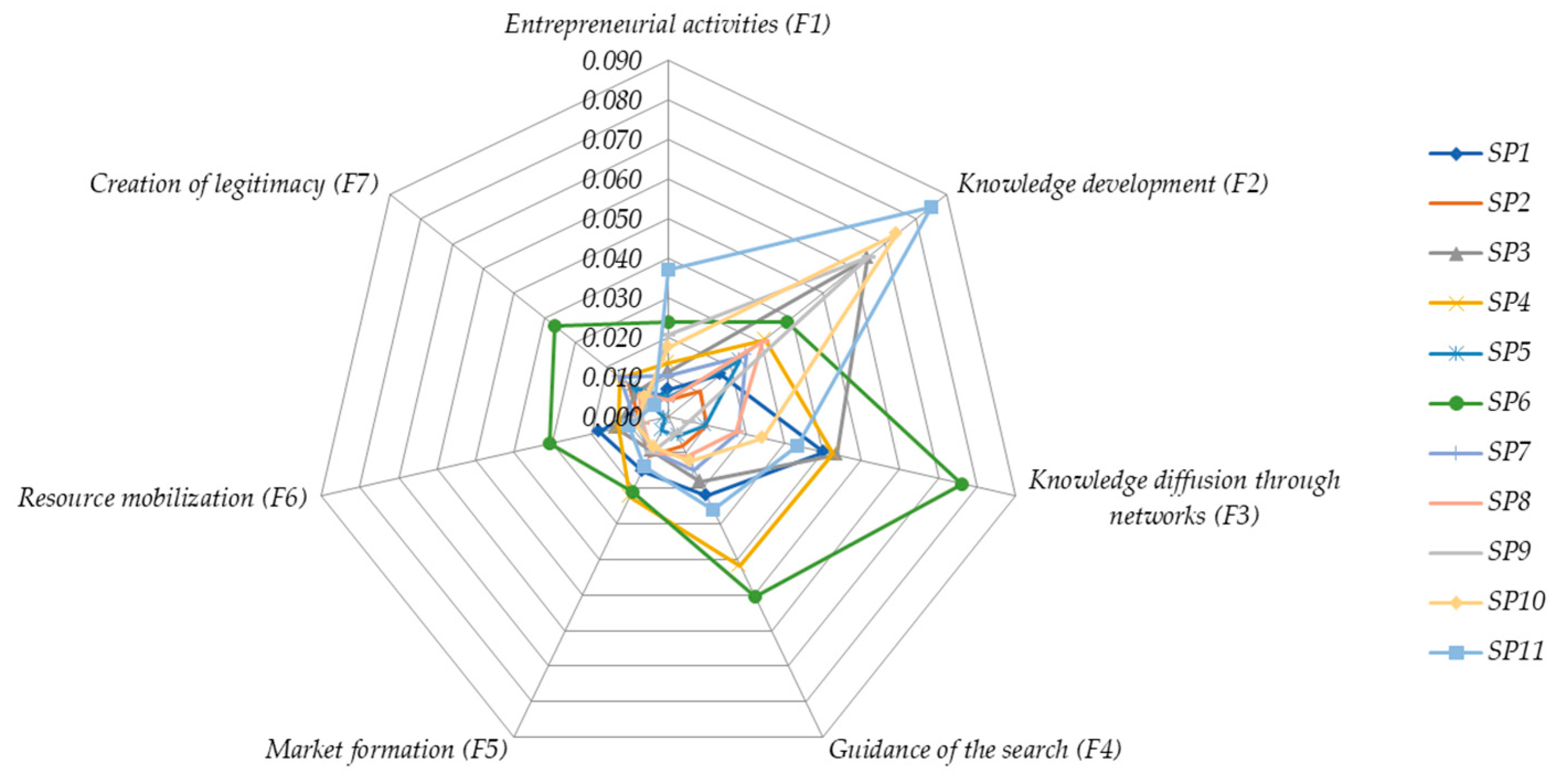

4.4. Derivations of the Influential Weights by the BR-DNP Method

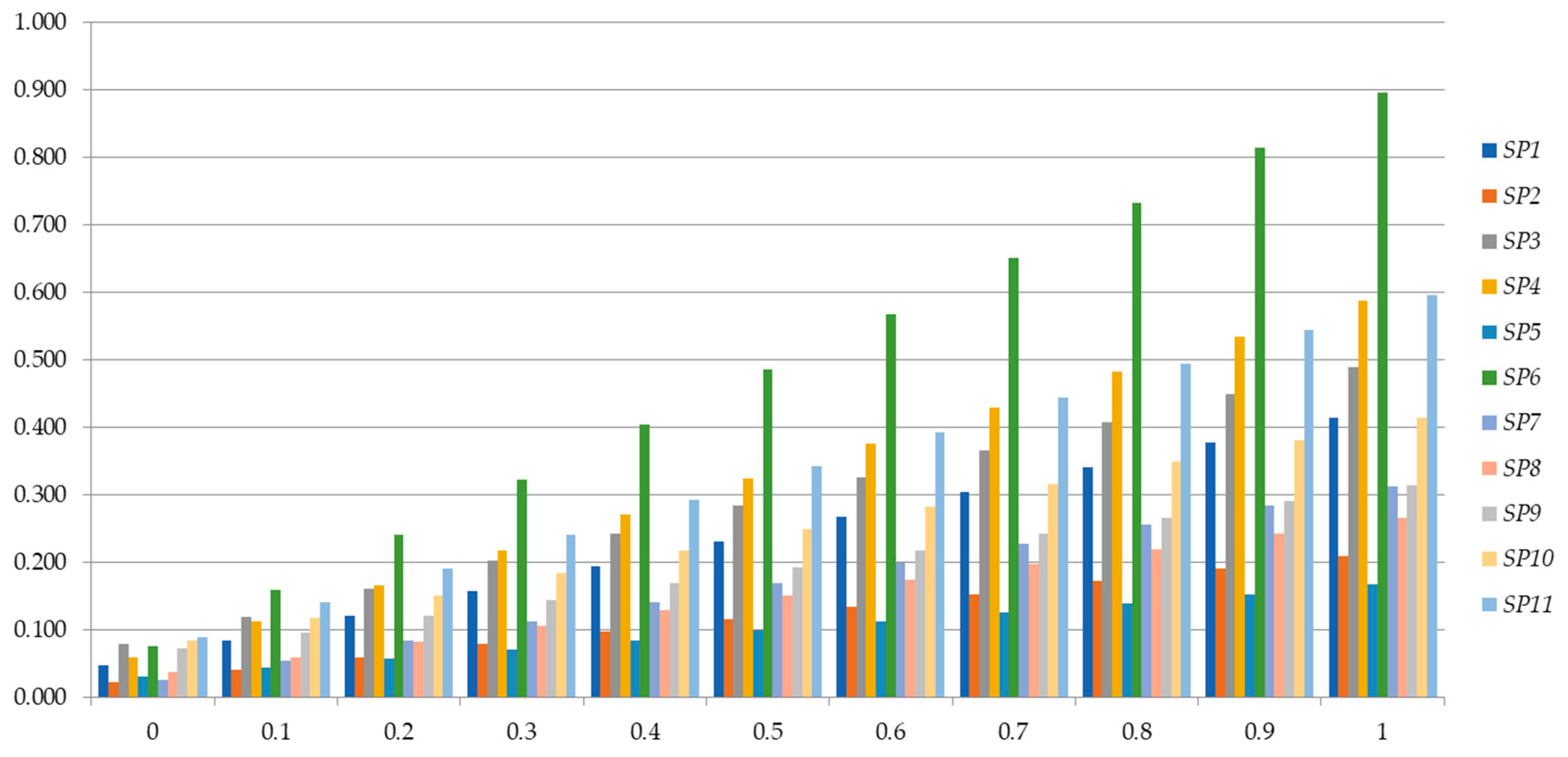

4.5. Assessing the Gap between the Current Status and the Aspired Level by the MBR-VIKOR

5. Discussion and Implications

5.1. Gaps for Each Systemic Innovation Problems

5.1.1. Lack of Uniform Technical Standards (SP1)

5.1.2. Insufficient Innovation Intensity (SP2)

5.1.3. Regulatory Constrains for IoT Development (SP3)

5.1.4. Insufficient Infrastructure for IoT Development (SP4)

5.1.5. Insufficient Interdisciplinary Collaboration (SP5)

5.1.6. Lack of Advanced Sensor Technology for IoT Applications (SP6)

5.1.7. Shortage of Effective Services for Innovation Applications (SP7)

5.1.8. Insufficient Capabilities of System and Platform Integration (SP8)

5.1.9. Lack of Professionals (SP9)

5.1.10. Low Level of Industrial Upgrading for SMEs (SP10)

5.1.11. Weak Advocacy Coalition (SP11)

5.2. The Implications in Industrial Sustainabillity for IoT Industries

5.3. Advances in Methodologies and Innovation Policy Analyses

5.4. Limitations and Future Research Possibilities

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| VD1 | |||||||

|---|---|---|---|---|---|---|---|

| Functions/Criteria | SP1 | SP2 | … | SP9 | SP10 | SP11 | |

| F1 | e1 | (4;4) | (3;2) | … | (4;3) | (3;2) | (2;1) |

| e3 | (4;4) | (3;2) | … | (2;1) | (2;2) | (2;1) | |

| e4 | (3;3) | (3;3) | … | (3;3) | (1;1) | (0;1) | |

| F2 | k1 | (2;2) | (2;2) | … | (2;0) | (1;1) | (0;3) |

| k3 | (2;2) | (1;1) | … | (1;1) | (1;0) | (0;3) | |

| F3 | kd1 | (0;0) | (0;0) | … | (2;2) | (3;3) | (0;4) |

| kd3 | (0;0) | (0;0) | … | (3;3) | (1;0) | (2;2) | |

| kd4 | (0;0) | (1;1) | … | (3;3) | (1;0) | (2;2) | |

| F4 | g1 | (0;3) | (0;0) | … | (3;3) | (1;0) | (0;2) |

| g2 | (3;1) | (2;2) | … | (4;4) | (1;1) | (2;2) | |

| g3 | (1;1) | (2;2) | … | (3;3) | (1;1) | (0;2) | |

| g4 | (1;0) | (3;3) | … | (2;2) | (4;1) | (0;0) | |

| F5 | m1 | (0;0) | (0;0) | … | (2;2) | (1;1) | (0;3) |

| m2 | (0;0) | (1;1) | … | (2;2) | (1;1) | (2;2) | |

| m3 | (0;3) | (1;1) | … | (3;3) | (2;1) | (0;0) | |

| m4 | (3;0) | (2;2) | … | (3;3) | (2;1) | (4;0) | |

| F6 | r1 | (0;2) | (2;2) | … | (0;1) | (0;1) | (0;3) |

| r3 | (2;0) | (3;3) | … | (3;3) | (1;1) | (3;2) | |

| r4 | (0;0) | (0;0) | … | (3;3) | (4;1) | (0;2) | |

| r5 | (0;0) | (0;0) | … | (3;3) | (2;2) | (0;2) | |

| F7 | c1 | (2;2) | (2;2) | … | (2;2) | (1;1) | (2;3) |

| c2 | (1;1) | (1;1) | … | (2;2) | (2;2) | (2;2) | |

| c3 | (0;0) | (0;0) | … | (3;3) | (2;2) | (2;1) | |

| ⁝ | |||||||

| VD15 | |||||||

| Functions/criteria | SP1 | SP2 | … | SP9 | SP10 | SP11 | |

| F1 | e1 | (3;4) | (3;4) | … | (3;4) | (2;4) | (2;4) |

| e3 | (3;4) | (3;4) | … | (3;4) | (2;4) | (2;4) | |

| e4 | (4;4) | (4;4) | … | (4;4) | (4;4) | (2;2) | |

| F2 | k1 | (4;4) | (4;4) | … | (4;4) | (4;4) | (2;2) |

| k3 | (4;4) | (4;4) | … | (4;4) | (4;4) | (2;2) | |

| F3 | kd1 | (4;4) | (4;4) | … | (4;4) | (4;4) | (3;3) |

| kd3 | (4;4) | (4;4) | … | (2;2) | (4;4) | (2;2) | |

| kd4 | (4;4) | (3;3) | … | (4;4) | (4;4) | (2;2) | |

| F4 | g1 | (4;4) | (4;4) | … | (4;4) | (4;4) | (4;4) |

| g2 | (4;4) | (4;4) | … | (4;4) | (4;4) | (4;4) | |

| g3 | (4;4) | (4;4) | … | (4;4) | (4;4) | (4;4) | |

| g4 | (4;4) | (4;4) | … | (4;4) | (4;4) | (4;4) | |

| F5 | m1 | (3;3) | (4;4) | … | (3;3) | (3;3) | (3;3) |

| m2 | (4;4) | (1;1) | … | (1;1) | (3;3) | (3;3) | |

| m3 | (4;4) | (4;4) | … | (4;4) | (4;4) | (4;4) | |

| m4 | (4;4) | (4;4) | … | (4;4) | (4;4) | (4;4) | |

| F6 | r1 | (3;3) | (4;4) | … | (4;4) | (4;4) | (4;4) |

| r3 | (4;4) | (4;4) | … | (4;4) | (4;4) | (4;4) | |

| r4 | (4;4) | (4;4) | … | (4;4) | (4;4) | (4;4) | |

| r5 | (2;2) | (2;2) | … | (2;2) | (2;2) | (2;2) | |

| F7 | c1 | (4;4) | (4;4) | … | (4;4) | (4;4) | (4;4) |

| c2 | (3;3) | (3;3) | … | (3;3) | (3;3) | (3;3) | |

| c3 | (4;4) | (2;2) | … | (3;3) | (3;3) | (3;3) | |

| Criteria | SP1 | SP2 | … | SP9 | SP10 | SP11 |

|---|---|---|---|---|---|---|

| e1 | [3.751, 3.982] | [2.863, 3.788] | … | [2.361, 3.681] | [2.207, 2.875] | [1.692, 2.727] |

| e3 | [3.360, 3.840] | [2.704, 3.554] | … | [1.748, 2.119] | [2.403, 3.469] | [1.748, 2.119] |

| e4 | [1.738, 3.169] | [3.360, 3.840] | … | [2.738, 3.124] | [1.903, 3.521] | [1.225, 2.038] |

| k1 | [2.329, 3.721] | [2.947, 3.834] | … | [1.725, 2.881] | [1.439, 2.476] | [1.049, 2.520] |

| k3 | [2.678, 3.707] | [2.329, 3.727] | … | [1.853, 3.347] | [1.814, 3.518] | [1.049, 2.520] |

| kd1 | [1.091, 3.049] | [1.813, 3.656] | … | [2.569, 3.564] | [3.284, 3.782] | [0.893, 2.400] |

| ⁝ | ⁝ | ⁝ | ⁝ | ⁝ | ⁝ | ⁝ |

| r5 | [0.394, 1.914] | [0.417, 2.393] | … | [2.538, 2.929] | [2.099, 1.249] | [0.934, 2.496] |

| c1 | [2.349, 3.130] | [0.579, 1.862] | … | [2.065, 2.628] | [1.261, 3.840] | [1.964, 3.491] |

| c2 | [2.042, 3.002] | [1.168, 2.726] | … | [2.071, 2.462] | [2.108, 0.000] | [1.879, 3.320] |

| c3 | [0.693, 2.347] | [1.574, 2.881] | … | [3.000, 3.000] | [2.108, 3.674] | [1.791, 3.152] |

| Criteria | SP1 | SP2 | … | SP9 | SP10 | SP11 |

|---|---|---|---|---|---|---|

| e1 | [3.284, 3.782] | [3.125, 3.793] | … | [2.679, 3.786] | [2.274, 3.078] | [1.404, 2.803] |

| e3 | [3.218, 3.716] | [3.007, 3.651] | … | [1.530, 2.379] | [2.250, 3.239] | [1.561, 2.757] |

| e4 | [1.578, 2.947] | [3.284, 3.782] | … | [2.738, 3.124] | [1.370, 2.922] | [1.180, 2.282] |

| k1 | [2.153, 3.692] | [3.125, 3.793] | … | [0.916, 2.494] | [1.214, 2.321] | [1.130, 2.927] |

| k3 | [2.863, 3.778] | [2.966, 3.789] | … | [1.333, 2.667] | [0.885, 2.812] | [1.130, 2.927] |

| kd1 | [1.651, 3.069] | [2.806, 3.784] | … | [2.222, 3.111] | [3.111, 3.556] | [1.315, 3.058] |

| ⁝ | ⁝ | ⁝ | ⁝ | ⁝ | ⁝ | ⁝ |

| r5 | [0.394, 1.914] | [0.417, 2.393] | … | [2.538, 3.929] | [2.099, 2.859] | [1.136, 2.604] |

| c1 | [2.349, 3.130] | [0.579, 1.862] | … | [2.065, 2.628] | [1.261, 2.609] | [2.020, 3.543] |

| c2 | [2.042, 3.002] | [1.168, 2.726] | … | [2.071, 2.462] | [2.108, 2.858] | [1.870, 3.320] |

| c3 | [0.693, 2.347] | [1.574, 2.881] | … | [3.000, 3.000] | [2.108, 2.858] | [1.680, 3.130] |

Appendix B

References

- Edquist, C. Design of innovation policy through diagnostic analysis: Identification of systemic problems (or failures). Ind. Corp. Chang. 2011, 20, 1725–1753. [Google Scholar] [CrossRef]

- Kao, Y.-S.; Nawata, K.; Huang, C.-Y. Systemic Functions Evaluation based Technological Innovation System for the Sustainability of IoT in the Manufacturing Industry. Sustainability 2019, 11, 2342. [Google Scholar] [CrossRef]

- Kieft, A.; Harmsen, R.; Hekkert, M.P. Toward ranking interventions for Technological Innovation Systems via the concept of Leverage Points. Technol. Forecast. Soc. Chang. 2018, in press. [Google Scholar] [CrossRef]

- Reichardt, K.; Negro, S.O.; Rogge, K.S.; Hekkert, M.P. Analyzing interdependencies between policy mixes and technological innovation systems: The case of offshore wind in Germany. Technol. Forecast. Soc. Chang. 2016, 106, 11–21. [Google Scholar] [CrossRef]

- Söderholm, P.; Hellsmark, H.; Frishammar, J.; Hansson, J.; Mossberg, J.; Sandström, A. Technological development for sustainability: The role of network management in the innovation policy mix. Technol. Forecast. Soc. Chang. 2019, 138, 309–323. [Google Scholar] [CrossRef]

- Tonelli, F.; Evans, S.; Taticchi, P. Industrial sustainability: Challenges, perspectives, actions. Int. J. Bus. Innov. 2013, 7, 143–163. [Google Scholar] [CrossRef]

- Sixt, G.N.; Klerkx, L.; Griffin, T.S. Transitions in water harvesting practices in Jordan’s rainfed agricultural systems: Systemic problems and blocking mechanisms in an emerging technological innovation system. Environ. Sci. Policy 2017, 84, 235–249. [Google Scholar] [CrossRef]

- Kebede, K.Y.; Mitsufuji, T. Technological innovation system building for diffusion of renewable energy technology: A case of solar PV systems in Ethiopia. Technol. Forecast. Soc. Chang. 2017, 114, 242–253. [Google Scholar] [CrossRef]

- Wesche, J.; Negro, S.; Dütschke, E.; Raven, R.; Hekkert, M. Configurational innovation systems–Explaining the slow German heat transition. Energy Res. Soc. Sci. 2019, 52, 99–113. [Google Scholar] [CrossRef]

- Kivimaa, P.; Kern, F. Creative destruction or mere niche support? Innovation policy mixes for sustainability transitions. Res. Policy 2016, 45, 205–217. [Google Scholar] [CrossRef]

- Wieczorek, A.J.; Hekkert, M.P.; Coenen, L.; Harmsen, R. Broadening the national focus in technological innovation system analysis: The case of offshore wind. Environ. Innov. Soc. Transit. 2015, 14, 128–148. [Google Scholar] [CrossRef]

- Tigabu, A.D.; Berkhout, F.; van Beukering, P. Technology innovation systems and technology diffusion: Adoption of bio-digestion in an emerging innovation system in Rwanda. Technol. Forecast. Soc. Chang. 2015, 90, 318–330. [Google Scholar] [CrossRef]

- Wieczorek, A.J.; Hekkert, M.P. Systemic instruments for systemic innovation problems: A framework for policy makers and innovation scholars. Sci. Public Policy 2012, 39, 74–87. [Google Scholar] [CrossRef]

- De Lacalle, L.L.; Lamikiz, A.; Salgado, M.A.; Herranz, S.; Rivero, A. Process planning for reliable high-speed machining of moulds. Int. J. Prod. Res. 2002, 40, 2789–2809. [Google Scholar] [CrossRef]

- De Lacalle, L.L.; Lamikiz, A.; Muñoa, J.; Salgado, M.A.; Sánchez, J.A. Improving the high-speed finishing of forming tools for advanced high-strength steels (AHSS). Int. J. Adv. Manuf. Technol. 2006, 29, 49–63. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A.; Muñoa, J.; Sánchez, J.A. The CAM as the centre of gravity of the five-axis high speed milling of complex parts. Int. J. Prod. Res. 2005, 43, 1983–1999. [Google Scholar] [CrossRef]

- Advantech. WebAccess/CNC: Utilizing Machine Tool Networking to Realize the Blueprint of an Intelligent Factory. 2017. Available online: https://www.advantech.com/resources/case-study/151303f8-7070-4e6a-af79-99394097fcf6 (accessed on 10 August 2019).

- Abellan-Nebot, J.V.; Subirón, F.R. A review of machining monitoring systems based on artificial intelligence process models. Int. J. Adv. Manuf. Technol. 2010, 47, 237–257. [Google Scholar] [CrossRef]

- Karayel, D. Prediction and control of surface roughness in CNC lathe using artificial neural network. J. Mater. Process. Technol. 2009, 209, 3125–3137. [Google Scholar] [CrossRef]

- Hailey, W. Challenge or Threat: How AI is Striking CNC Manufacturing. 2019. Available online: https://www.waykenrm.com/ai-striking-cnc-manufacturing.html (accessed on 10 August 2019).

- Planko, J.; Cramer, J.; Hekkert, M.P.; Chappin, M.M. Combining the technological innovation systems framework with the entrepreneurs’ perspective on innovation. Technol. Anal. Strateg. Manag. 2017, 29, 614–625. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, X.; Lim, M.K.; He, Y.; Li, L. Sustainable recycling partner selection using fuzzy DEMATEL-AEW-FVIKOR: A case study in small-and-medium enterprises (SMEs). J. Clean. Prod. 2018, 196, 489–504. [Google Scholar] [CrossRef]

- Song, W.; Cao, J. A rough DEMATEL-based approach for evaluating interaction between requirements of product-service system. Comput. Ind. Eng. 2017, 110, 353–363. [Google Scholar] [CrossRef]

- Pamucar, D.; Chatterjee, K.; Zavadskas, E.K. Assessment of third-party logistics provider using multi-criteria decision-making approach based on interval rough numbers. Comput. Ind. Eng. 2019, 127, 383–407. [Google Scholar] [CrossRef]

- Pamučar, D.; Stević, Ž.; Zavadskas, E.K. Integration of interval rough AHP and interval rough MABAC methods for evaluating university web pages. Appl. Soft Comput. 2018, 67, 141–163. [Google Scholar] [CrossRef]

- Bergek, A.; Jacobsson, S.; Carlsson, B.; Lindmark, S.; Rickne, A. Analyzing the functional dynamics of technological innovation systems: A scheme of analysis. Res. Policy 2008, 37, 407–429. [Google Scholar] [CrossRef]

- Schmoch, U.; Rammer, C.; Legler, H. National Systems of Innovation in Comparison: Structure and Performance Indicators for Knowledge Societies; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar]

- Tigabu, A.D.; Berkhout, F.; van Beukering, P. The diffusion of a renewable energy technology and innovation system functioning: Comparing bio-digestion in Kenya and Rwanda. Technol. Forecast. Soc. Chang. 2015, 90, 331–345. [Google Scholar] [CrossRef]

- Kieft, A.; Harmsen, R.; Hekkert, M.P. Interactions between systemic problems in innovation systems: The case of energy-efficient houses in the Netherlands. Environ. Innov. Soc. Transit. 2017, 24, 32–44. [Google Scholar] [CrossRef]

- Bergek, A.; Hekkert, M.; Jacobsson, S.; Markard, J.; Sandén, B.; Truffer, B. Technological innovation systems in contexts: Conceptualizing contextual structures and interaction dynamics. Environ. Innov. Soc. Transit. 2015, 16, 51–64. [Google Scholar] [CrossRef]

- Purkus, A.; Hagemann, N.; Bedtke, N.; Gawel, E. Towards a sustainable innovation system for the German wood-based bioeconomy: Implications for policy design. J. Clean. Prod. 2018, 172, 3955–3968. [Google Scholar] [CrossRef]

- Turner, J.A.; Klerkx, L.; Rijswijk, K.; Williams, T.; Barnard, T. Systemic problems affecting co-innovation in the New Zealand Agricultural Innovation System: Identification of blocking mechanisms and underlying institutional logics. Njas-Wagening. J. Life Sci. 2016, 76, 99–112. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Neri, A. Modelling barriers to the adoption of industrial sustainability measures. J. Clean. Prod. 2017, 168, 1482–1504. [Google Scholar] [CrossRef]

- Hermans, F.; Geerling-Eiff, F.; Potters, J.; Klerkx, L. Public-private partnerships as systemic agricultural innovation policy instruments–Assessing their contribution to innovation system function dynamics. Njas-Wagening. J. Life Sci. 2019, 88, 76–95. [Google Scholar] [CrossRef]

- Hekkert, M.P.; Negro, S.O. Functions of innovation systems as a framework to understand sustainable technological change: Empirical evidence for earlier claims. Technol. Forecast. Soc. Chang. 2009, 76, 584–594. [Google Scholar] [CrossRef]

- Freeman, C. Technology Policy and Economic Performance; Pinter Publishers: Great Britain, UK, 1989. [Google Scholar]

- Arbolino, R.; De Simone, L.; Carlucci, F.; Yigitcanlar, T.; Ioppolo, G. Towards a sustainable industrial ecology: Implementation of a novel approach in the performance evaluation of Italian regions. J. Clean. Prod. 2018, 178, 220–236. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Z.; Zhu, Q. Performance evaluation of China’s high-tech innovation process: Analysis based on the innovation value chain. Technovation 2018, 74, 42–53. [Google Scholar] [CrossRef]

- Lin, C.-L.; Shih, Y.-H.; Tzeng, G.-H.; Yu, H.-C. A service selection model for digital music service platforms using a hybrid MCDM approach. Appl. Soft Comput. 2016, 48, 385–403. [Google Scholar] [CrossRef]

- Lu, M.-T.; Lin, S.-W.; Tzeng, G.-H. Improving RFID adoption in Taiwan’s healthcare industry based on a DEMATEL technique with a hybrid MCDM model. Decis. Support Syst. 2013, 56, 259–269. [Google Scholar] [CrossRef]

- Liu, C.-H.; Tzeng, G.-H.; Lee, M.-H. Improving tourism policy implementation – The use of hybrid MCDM models. Tour. Manag. 2012, 33, 413–426. [Google Scholar] [CrossRef]

- Gao, R.; Nam, H.O.; Ko, W.I.; Jang, H. Integrated system evaluation of nuclear fuel cycle options in China combined with an analytical MCDM framework. Energy Policy 2018, 114, 221–233. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Güleryüz, S. Evaluation of Renewable Energy Resources in Turkey using an integrated MCDM approach with linguistic interval fuzzy preference relations. Energy 2017, 123, 149–163. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.-H. Extended VIKOR method in comparison with outranking methods. Eur. J. Oper. Res. 2007, 178, 514–529. [Google Scholar] [CrossRef]

- Hsu, Y.-G.; Shyu, J.Z.; Tzeng, G.-H. Policy tools on the formation of new biotechnology firms in Taiwan. Technovation 2005, 25, 281–292. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, B.; Xu, C.; Li, L. Site selection decision framework using fuzzy ANP-VIKOR for large commercial rooftop PV system based on sustainability perspective. Sustain. Cities Soc. 2018, 40, 454–470. [Google Scholar] [CrossRef]

- Qin, J.; Liu, X.; Pedrycz, W. An extended VIKOR method based on prospect theory for multiple attribute decision making under interval type-2 fuzzy environment. Knowl.-Based Syst. 2015, 86, 116–130. [Google Scholar] [CrossRef]

- Parkouhi, S.V.; Ghadikolaei, A.S. A resilience approach for supplier selection: Using fuzzy analytic network process and grey VIKOR techniques. J. Clean. Prod. 2017, 161, 431–451. [Google Scholar] [CrossRef]

- Tiwari, V.; Jain, P.K.; Tandon, P. Product design concept evaluation using rough sets and VIKOR method. Adv. Eng. Inform. 2016, 30, 16–25. [Google Scholar] [CrossRef]

- Pamučar, D.; Mihajlović, M.; Obradović, R.; Atanasković, P. Novel approach to group multi-criteria decision making based on interval rough numbers: Hybrid DEMATEL-ANP-MAIRCA model. Expert Syst. Appl. 2017, 88, 58–80. [Google Scholar] [CrossRef]

- Hekkert, M.P.; Suurs, R.A.; Negro, S.O.; Kuhlmann, S.; Smits, R.E. Functions of innovation systems: A new approach for analysing technological change. Technol. Forecast. Soc. Chang. 2007, 74, 413–432. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Shyu, J.Z.; Tzeng, G.-H. Reconfiguring the innovation policy portfolios for Taiwan’s SIP Mall industry. Technovation 2007, 27, 744–765. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Kao, Y.-S. UTAUT2 based predictions of factors influencing the technology acceptance of phablets by DNP. Math. Probl. Eng. 2015, 2015, 603747. [Google Scholar] [CrossRef]

- Hanine, M.; Boutkhoum, O.; Agouti, T.; Tikniouine, A. A new integrated methodology using modified Delphi-fuzzy AHP-PROMETHEE for Geospatial Business Intelligence selection. Inf. Syst. E Bus. Manag. 2017, 15, 897–925. [Google Scholar] [CrossRef]

- Tsai, H.-Y.; Chang, C.-W.; Lin, H.-L. Fuzzy hierarchy sensitive with Delphi method to evaluate hospital organization performance. Expert Syst. Appl. 2010, 37, 5533–5541. [Google Scholar] [CrossRef]

- Jeng, D.J.-F.; Huang, K.-H. Strategic project portfolio selection for national research institutes. J. Bus. Res. 2015, 68, 2305–2311. [Google Scholar] [CrossRef]

- Rajagopal, R.; Del Castillo, E. A Bayesian approach for multiple criteria decision making with applications in Design for Six Sigma. J. Oper. Res. Soc. 2007, 58, 779–790. [Google Scholar] [CrossRef]

- Abdullahi, S.; Pradhan, B.; Jebur, M.N. GIS-based sustainable city compactness assessment using integration of MCDM, Bayes theorem and RADAR technology. Geocarto Int. 2015, 30, 365–387. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Ahn, K.-U.; Park, C.-S. Decision making of HVAC system using Bayesian Markov chain Monte Carlo method. Energy Build. 2014, 72, 112–121. [Google Scholar] [CrossRef]

- Dragicevic, S.; Celar, S.; Turic, M. Bayesian network model for task effort estimation in agile software development. J. Syst. Softw. 2017, 127, 109–119. [Google Scholar] [CrossRef]

- Tzeng, G.-H.; Shen, K.-Y. New Concepts and Trends of Hybrid Multiple Criteria Decision Making; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Opricovic, S.; Tzeng, G.-H. Defuzzification within a multicriteria decision model. Int. J. Uncertain. Fuzziness Knowl.-Based Syst. 2003, 11, 635–652. [Google Scholar] [CrossRef]

- Pineda, P.J.G.; Liou, J.J.; Hsu, C.-C.; Chuang, Y.-C. An integrated MCDM model for improving airline operational and financial performance. J. Air Transp. Manag. 2017, 68, 103–117. [Google Scholar] [CrossRef]

- Zhu, G.-N.; Hu, J.; Qi, J.; Gu, C.-C.; Peng, Y.-H. An integrated AHP and VIKOR for design concept evaluation based on rough number. Adv. Eng. Inform. 2015, 29, 408–418. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.-H. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Yu, P.-L. A class of solutions for group decision problems. Manag. Sci. 1973, 19, 936–946. [Google Scholar] [CrossRef]

- Rothwell, R. Successful industrial innovation: Critical factors for the 1990s. R D Manag. 1992, 22, 221–240. [Google Scholar] [CrossRef]

- Arnaiz-González, Á.; Fernández-Valdivielso, A.; Bustillo, A.; de Lacalle, L.N.L. Using artificial neural networks for the prediction of dimensional error on inclined surfaces manufactured by ball-end milling. Int. J. Adv. Manuf. Technol. 2016, 83, 847–859. [Google Scholar] [CrossRef]

| Functions | Symbol | Features/Criteria |

|---|---|---|

| Entrepreneurial activities (F1) | e1 | Experimenting new applications of IoT |

| e3 | Entry of firms to IoT markets | |

| e4 | System for innovation and incubation | |

| Knowledge development (F2) | k1 | Conducting feasibility studies |

| k3 | Developing complementary technologies | |

| Knowledge diffusion through networks (F3) | kd1 | Training of professionals |

| kd3 | Organizing conference/workshops/seminars/meetings | |

| kd4 | Demonstrations and exhibitions | |

| Guidance of the search (F4) | g1 | Setting collective goals for IoT development |

| g2 | Design of favorable rules and regulations | |

| g3 | Publicizing expectations | |

| g4 | Providing direction of development | |

| Market formation (F5) | m1 | Providing subsidies |

| m2 | Government procurement programs | |

| m3 | Regulatory reform | |

| m4 | Standardizations | |

| Resource mobilization (F6) | r1 | Providing R&D budgets |

| r3 | Launching IoT related education programs | |

| r4 | Mobilizing human resources | |

| r5 | Funding scale up on IoT projects | |

| Creation of legitimacy (F7) | c1 | Strength of lobby actions |

| c2 | Rise and growth of interest groups | |

| c3 | Social acceptability |

| Systemic Innovation Problems | Symbols |

|---|---|

| Lack of uniform technical standards | SP1 |

| The innovation intensity is insufficient | SP2 |

| Regulatory constrains for IoT development | SP3 |

| Lack of sufficient infrastructure for IoT development | SP4 |

| Low level of interdisciplinary collaboration | SP5 |

| Lack of advanced sensor technology for IoT application | SP6 |

| Lack of effective innovation application services | SP7 |

| Low capability of system and platform integration | SP8 |

| Lack of professionals | SP9 |

| Low level of industrial upgrading for SMEs | SP10 |

| Weak advocacy coalition | SP11 |

| No. | Gender | Experiences | SP1 | SP2 | SP3 | SP4 | SP5 | SP6 | SP7 | SP8 | SP9 | SP10 | SP11 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Male | 15 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 2 | Male | 15 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 3 | Male | 20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 4 | Male | 20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | No |

| 5 | Male | 15~20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 6 | Male | 15~20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 7 | Male | >20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | No |

| 8 | Male | 15 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 9 | Male | 15~20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 10 | Male | 15~20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 11 | Male | 15~20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 12 | Male | 15~20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 13 | Male | 15~20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 14 | Male | >20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| 15 | Male | >20 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | No |

| Agree (Yes) | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 12 | ||

| Disagree (No) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | ||

| Agree % | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 80% | ||

| Disagree % | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 20% | ||

| Functions | Local Weight | Ranking | Criteria | Local Weight | Ranking | Global Weight | Ranking |

|---|---|---|---|---|---|---|---|

| F1 | 0.172 | 1 | e1 | 0.375 | 1 | 0.065 | 3 |

| e3 | 0.358 | 2 | 0.062 | 4 | |||

| e4 | 0.267 | 3 | 0.046 | 7 | |||

| F2 | 0.168 | 2 | k1 | 0.493 | 2 | 0.083 | 2 |

| k3 | 0.507 | 1 | 0.085 | 1 | |||

| F3 | 0.143 | 4 | kd1 | 0.364 | 1 | 0.052 | 5 |

| kd3 | 0.312 | 2 | 0.045 | 8 | |||

| kd4 | 0.324 | 1 | 0.046 | 6 | |||

| F4 | 0.160 | 3 | g1 | 0.259 | 1 | 0.042 | 9 |

| g2 | 0.259 | 2 | 0.041 | 10 | |||

| g3 | 0.238 | 4 | 0.038 | 14 | |||

| g4 | 0.243 | 3 | 0.039 | 11 | |||

| F5 | 0.142 | 5 | m1 | 0.240 | 3 | 0.034 | 16 |

| m2 | 0.271 | 1 | 0.038 | 13 | |||

| m3 | 0.230 | 4 | 0.033 | 18 | |||

| m4 | 0.259 | 2 | 0.037 | 15 | |||

| F6 | 0.119 | 6 | r1 | 0.227 | 3 | 0.027 | 22 |

| r3 | 0.326 | 1 | 0.039 | 12 | |||

| r4 | 0.200 | 4 | 0.024 | 23 | |||

| r5 | 0.247 | 2 | 0.029 | 21 | |||

| F7 | 0.096 | 7 | c1 | 0.327 | 2 | 0.031 | 19 |

| c2 | 0.355 | 1 | 0.034 | 17 | |||

| c3 | 0.318 | 3 | 0.030 | 20 |

| Criteria | Local Weights | Global Weights | The Performance Gap of Systemic Innovation Problems | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SP1 | SP2 | SP3 | SP4 | SP5 | SP6 | SP7 | SP8 | SP9 | SP10 | SP11 | |||

| F1 | 0.172 | – | 0.007 | 0.004 | 0.011 | 0.014 | 0.005 | 0.024 | 0.010 | 0.004 | 0.021 | 0.018 | 0.037 |

| e1 | 0.375 | 0.065 | 0.001 | 0.005 | 0.017 | 0.014 | 0.003 | 0.014 | 0.003 | 0.006 | 0.011 | 0.022 | 0.040 |

| e3 | 0.358 | 0.062 | 0.002 | 0.007 | 0.007 | 0.012 | 0.007 | 0.035 | 0.015 | 0.002 | 0.045 | 0.015 | 0.039 |

| e4 | 0.267 | 0.046 | 0.017 | 0.001 | 0.010 | 0.015 | 0.004 | 0.022 | 0.013 | 0.005 | 0.007 | 0.015 | 0.032 |

| F2 | 0.168 | – | 0.017 | 0.010 | 0.064 | 0.031 | 0.023 | 0.038 | 0.025 | 0.030 | 0.065 | 0.074 | 0.085 |

| k1 | 0.493 | 0.083 | 0.021 | 0.006 | 0.050 | 0.026 | 0.031 | 0.050 | 0.026 | 0.037 | 0.072 | 0.085 | 0.080 |

| k3 | 0.507 | 0.085 | 0.013 | 0.015 | 0.079 | 0.037 | 0.015 | 0.026 | 0.024 | 0.024 | 0.058 | 0.063 | 0.090 |

| F3 | 0.143 | – | 0.040 | 0.010 | 0.044 | 0.043 | 0.009 | 0.076 | 0.018 | 0.018 | 0.005 | 0.024 | 0.033 |

| kd1 | 0.364 | 0.052 | 0.025 | 0.008 | 0.012 | 0.008 | 0.003 | 0.077 | 0.009 | 0.002 | 0.010 | 0.002 | 0.033 |

| kd3 | 0.312 | 0.045 | 0.048 | 0.014 | 0.057 | 0.060 | 0.015 | 0.075 | 0.026 | 0.027 | 0.003 | 0.044 | 0.032 |

| kd4 | 0.324 | 0.046 | 0.048 | 0.007 | 0.062 | 0.060 | 0.011 | 0.076 | 0.019 | 0.024 | 0.002 | 0.026 | 0.034 |

| F4 | 0.160 | – | 0.022 | 0.008 | 0.018 | 0.042 | 0.006 | 0.050 | 0.015 | 0.011 | 0.004 | 0.012 | 0.026 |

| g1 | 0.259 | 0.042 | 0.044 | 0.007 | 0.019 | 0.046 | 0.005 | 0.056 | 0.013 | 0.017 | 0.004 | 0.019 | 0.025 |

| g2 | 0.259 | 0.041 | 0.004 | 0.023 | 0.014 | 0.042 | 0.011 | 0.055 | 0.019 | 0.014 | 0.001 | 0.016 | 0.015 |

| g3 | 0.238 | 0.038 | 0.020 | 0.002 | 0.035 | 0.039 | 0.003 | 0.042 | 0.016 | 0.012 | 0.004 | 0.013 | 0.023 |

| g4 | 0.243 | 0.039 | 0.020 | 0.002 | 0.005 | 0.040 | 0.003 | 0.048 | 0.012 | 0.003 | 0.009 | 0.002 | 0.042 |

| F5 | 0.142 | – | 0.015 | 0.011 | 0.010 | 0.023 | 0.004 | 0.021 | 0.009 | 0.010 | 0.010 | 0.009 | 0.014 |

| m1 | 0.240 | 0.034 | 0.014 | 0.012 | 0.021 | 0.033 | 0.006 | 0.015 | 0.009 | 0.008 | 0.013 | 0.008 | 0.013 |

| m2 | 0.271 | 0.038 | 0.038 | 0.019 | 0.012 | 0.025 | 0.003 | 0.030 | 0.014 | 0.011 | 0.018 | 0.011 | 0.019 |

| m3 | 0.230 | 0.033 | 0.008 | 0.012 | 0.003 | 0.019 | 0.004 | 0.020 | 0.008 | 0.012 | 0.004 | 0.007 | 0.013 |

| m4 | 0.259 | 0.037 | 0.001 | 0.002 | 0.003 | 0.014 | 0.002 | 0.018 | 0.007 | 0.009 | 0.005 | 0.009 | 0.011 |

| F6 | 0.119 | – | 0.018 | 0.007 | 0.014 | 0.013 | 0.001 | 0.031 | 0.008 | 0.007 | 0.007 | 0.009 | 0.010 |

| r1 | 0.227 | 0.027 | 0.019 | 0.001 | 0.007 | 0.006 | 0.001 | 0.020 | 0.008 | 0.005 | 0.019 | 0.012 | 0.009 |

| r3 | 0.326 | 0.039 | 0.022 | 0.002 | 0.022 | 0.019 | 0.002 | 0.055 | 0.011 | 0.008 | 0.006 | 0.016 | 0.013 |

| r4 | 0.200 | 0.024 | 0.012 | 0.010 | 0.010 | 0.005 | 0.001 | 0.018 | 0.005 | 0.004 | 0.001 | 0.001 | 0.007 |

| r5 | 0.247 | 0.029 | 0.019 | 0.016 | 0.015 | 0.022 | 0.001 | 0.030 | 0.008 | 0.009 | 0.004 | 0.006 | 0.012 |

| F7 | 0.096 | – | 0.006 | 0.013 | 0.010 | 0.016 | 0.012 | 0.037 | 0.016 | 0.010 | 0.007 | 0.008 | 0.005 |

| c1 | 0.327 | 0.031 | 0.004 | 0.021 | 0.010 | 0.015 | 0.015 | 0.043 | 0.023 | 0.013 | 0.007 | 0.012 | 0.005 |

| c2 | 0.355 | 0.034 | 0.007 | 0.014 | 0.017 | 0.024 | 0.017 | 0.044 | 0.020 | 0.009 | 0.010 | 0.008 | 0.007 |

| c3 | 0.318 | 0.030 | 0.007 | 0.003 | 0.003 | 0.007 | 0.003 | 0.023 | 0.005 | 0.007 | 0.003 | 0.003 | 0.002 |

| Gaps | 0.231 | 0.116 | 0.284 | 0.324 | 0.099 | 0.486 | 0.170 | 0.151 | 0.193 | 0.250 | 0.343 | ||

| Ranking | 6 | 2 | 8 | 9 | 1 | 11 | 4 | 3 | 5 | 7 | 10 | ||

| SP | v = 0 | Ranking | v = 0.1 | Ranking | v = 0.2 | Ranking | v = 0.3 | Ranking | v = 0.4 | Ranking | v = 0.5 | Ranking | v = 0.6 | Ranking | v = 0.7 | Ranking | v = 0.8 | Ranking | v = 0.9 | Ranking | v = 1.0 | Ranking |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SP1 | 0.048 | 5 | 0.085 | 5 | 0.121 | 6 | 0.158 | 6 | 0.194 | 6 | 0.231 | 6 | 0.268 | 6 | 0.304 | 6 | 0.341 | 6 | 0.378 | 6 | 0.414 | 6 |

| SP2 | 0.023 | 1 | 0.041 | 1 | 0.060 | 2 | 0.079 | 2 | 0.097 | 2 | 0.116 | 2 | 0.135 | 2 | 0.153 | 2 | 0.172 | 2 | 0.191 | 2 | 0.210 | 2 |

| SP3 | 0.079 | 9 | 0.120 | 9 | 0.161 | 8 | 0.202 | 8 | 0.243 | 8 | 0.284 | 8 | 0.326 | 8 | 0.367 | 8 | 0.408 | 8 | 0.449 | 8 | 0.490 | 8 |

| SP4 | 0.060 | 6 | 0.113 | 7 | 0.166 | 9 | 0.218 | 9 | 0.271 | 9 | 0.324 | 9 | 0.377 | 9 | 0.429 | 9 | 0.482 | 9 | 0.535 | 9 | 0.588 | 9 |

| SP5 | 0.031 | 3 | 0.044 | 2 | 0.058 | 1 | 0.071 | 1 | 0.085 | 1 | 0.099 | 1 | 0.112 | 1 | 0.126 | 1 | 0.140 | 1 | 0.153 | 1 | 0.167 | 1 |

| SP6 | 0.077 | 8 | 0.159 | 11 | 0.241 | 11 | 0.323 | 11 | 0.404 | 11 | 0.486 | 11 | 0.568 | 11 | 0.650 | 11 | 0.732 | 11 | 0.814 | 11 | 0.896 | 11 |

| SP7 | 0.026 | 2 | 0.055 | 3 | 0.084 | 4 | 0.112 | 4 | 0.141 | 4 | 0.170 | 4 | 0.198 | 4 | 0.227 | 4 | 0.256 | 4 | 0.285 | 4 | 0.313 | 4 |

| SP8 | 0.037 | 4 | 0.060 | 4 | 0.083 | 3 | 0.106 | 3 | 0.129 | 3 | 0.151 | 3 | 0.174 | 3 | 0.197 | 3 | 0.220 | 3 | 0.243 | 3 | 0.266 | 3 |

| SP9 | 0.072 | 7 | 0.096 | 6 | 0.120 | 5 | 0.145 | 5 | 0.169 | 5 | 0.193 | 5 | 0.218 | 5 | 0.242 | 5 | 0.266 | 5 | 0.291 | 5 | 0.315 | 5 |

| SP10 | 0.085 | 10 | 0.118 | 8 | 0.151 | 7 | 0.184 | 7 | 0.217 | 7 | 0.250 | 7 | 0.283 | 7 | 0.316 | 7 | 0.349 | 7 | 0.382 | 7 | 0.415 | 7 |

| SP11 | 0.090 | 11 | 0.140 | 10 | 0.191 | 10 | 0.241 | 10 | 0.292 | 10 | 0.343 | 10 | 0.393 | 10 | 0.444 | 10 | 0.494 | 10 | 0.545 | 10 | 0.595 | 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kao, Y.-S.; Nawata, K.; Huang, C.-Y. Evaluating the Performance of Systemic Innovation Problems of the IoT in Manufacturing Industries by Novel MCDM Methods. Sustainability 2019, 11, 4970. https://doi.org/10.3390/su11184970

Kao Y-S, Nawata K, Huang C-Y. Evaluating the Performance of Systemic Innovation Problems of the IoT in Manufacturing Industries by Novel MCDM Methods. Sustainability. 2019; 11(18):4970. https://doi.org/10.3390/su11184970

Chicago/Turabian StyleKao, Yu-Sheng, Kazumitsu Nawata, and Chi-Yo Huang. 2019. "Evaluating the Performance of Systemic Innovation Problems of the IoT in Manufacturing Industries by Novel MCDM Methods" Sustainability 11, no. 18: 4970. https://doi.org/10.3390/su11184970

APA StyleKao, Y.-S., Nawata, K., & Huang, C.-Y. (2019). Evaluating the Performance of Systemic Innovation Problems of the IoT in Manufacturing Industries by Novel MCDM Methods. Sustainability, 11(18), 4970. https://doi.org/10.3390/su11184970