Energy Sustainability Analysis (ESA) of Energy-Producing Processes: A Case Study on Distributed H2 Production

Abstract

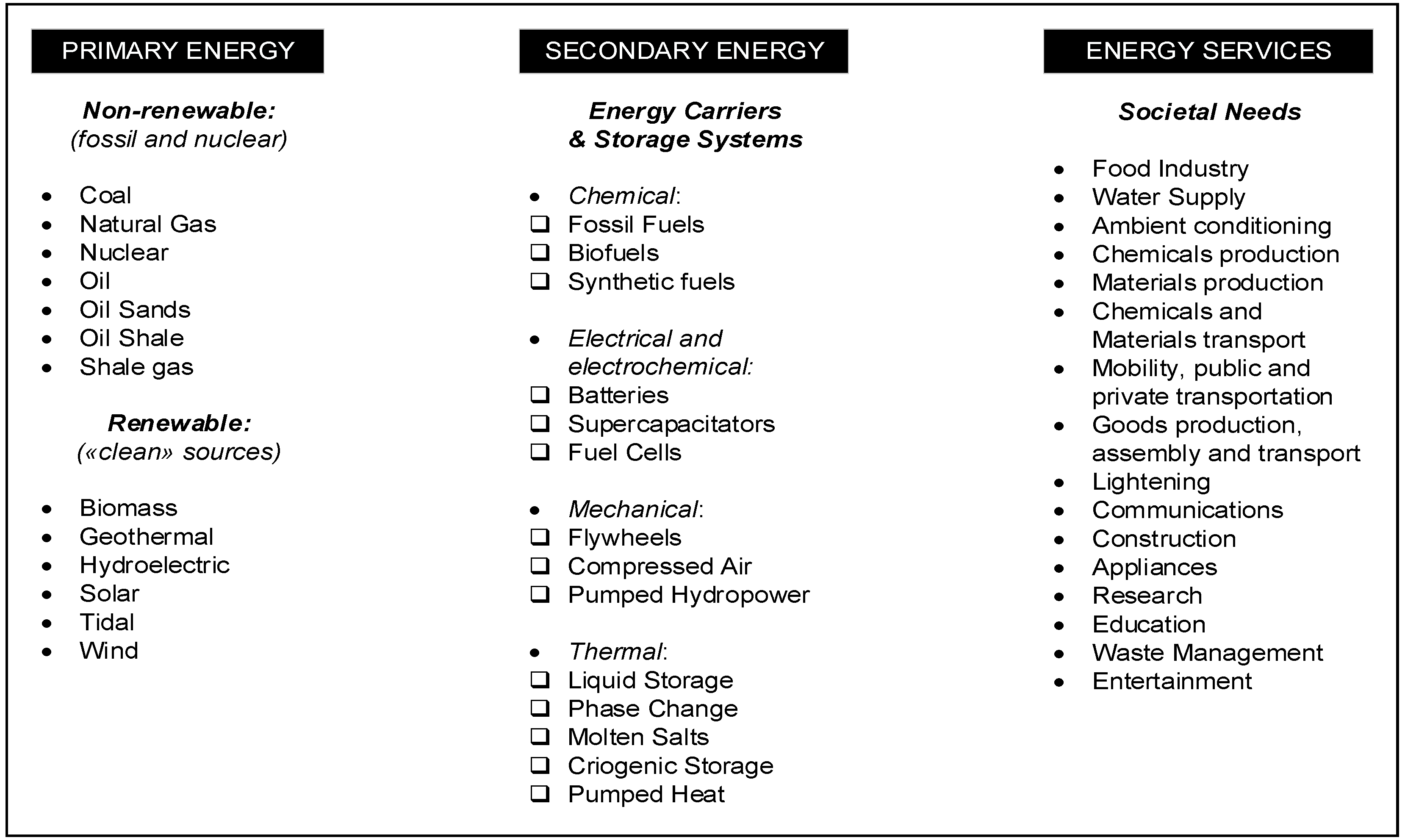

1. Introduction

2. Methodology

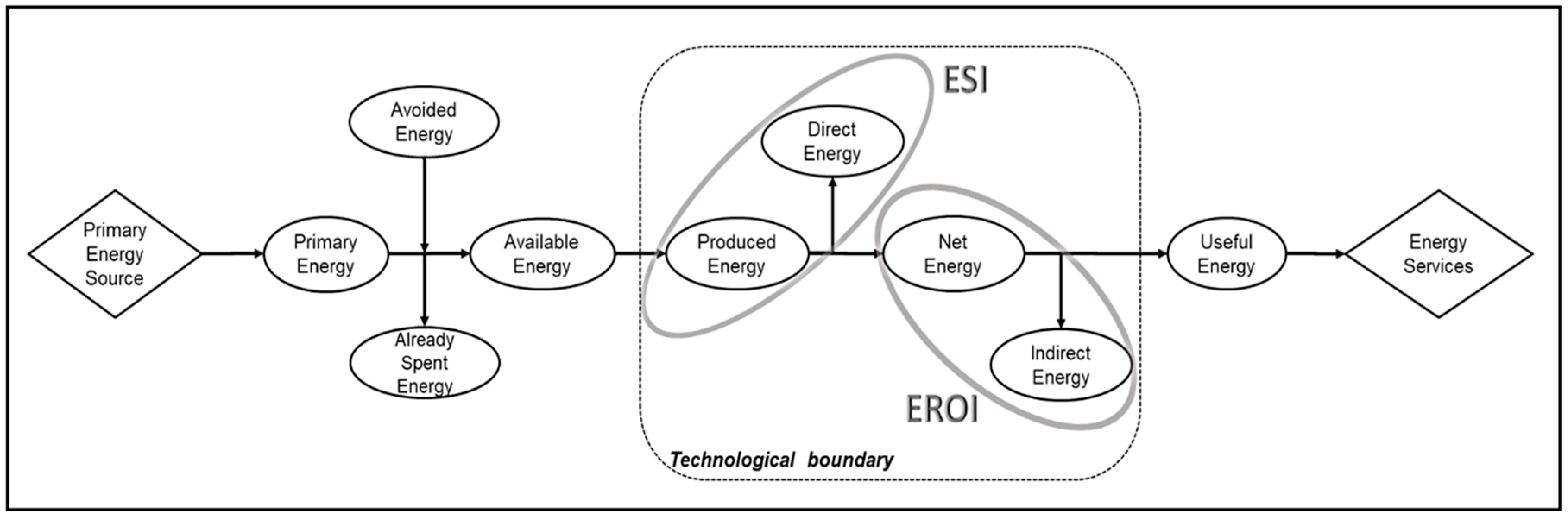

2.1. Energy Sustainability Analysis (ESA)

2.2. Boundaries of Analysis

2.3. Energy Sustainability Index (ESI)

2.4. Analogical Model (AM)

2.5. Energy Return on Invested (EROI) and Energy Payback Time (EPT)

3. Case Study: Distributed H2 Production

3.1. Steam-Methane Reforming (SMR)

- Catalytic Burner (CATBUR), where methane is fed from a gas cylinder, i.e., high purity >99.995% mol/mol) and mixed with air, in an excess of O2 of 50–60% of the stoichiometric ratio, to provide the temperature conditions of the highly endergonic reaction of steam-reforming,

- the proper Steam-REFormer (SREF), where water or water vapor are mixed with methane, to permit the steam-reforming reaction to take place (see Table 2) using the heat produced in the burner (ΔHreaction = +206 kJ/mol CH4),

- the output gases are then sent to the Water-Gas Shift (WGS) reactor, where carbon monoxide is further oxidized to carbon dioxide. Water is required for this step as a reactant and as cooling agent due to the temperature differences with the previous units, (ΔHreaction = −41 kJ/mol CO),

- the final unit is the Preferential Oxidation unit (PROX), which aims at oxidizing some of the reaction by-products of the previous stages into CO2, in order to meet the gas output stream specifications. This unit requires air input (O2) and cooling water, and it is composed by two sections (PROX1 and PROX2), which operate at different temperatures, in the 125–130 °C and 100–105 °C ranges, respectively.

3.2. Solar-Powered Water Electrolysis (SPWE)

3.3. Two-Stage Anaerobic Digestion (TSAD)

4. Results and Discussion

4.1. Direct Energy and ESI

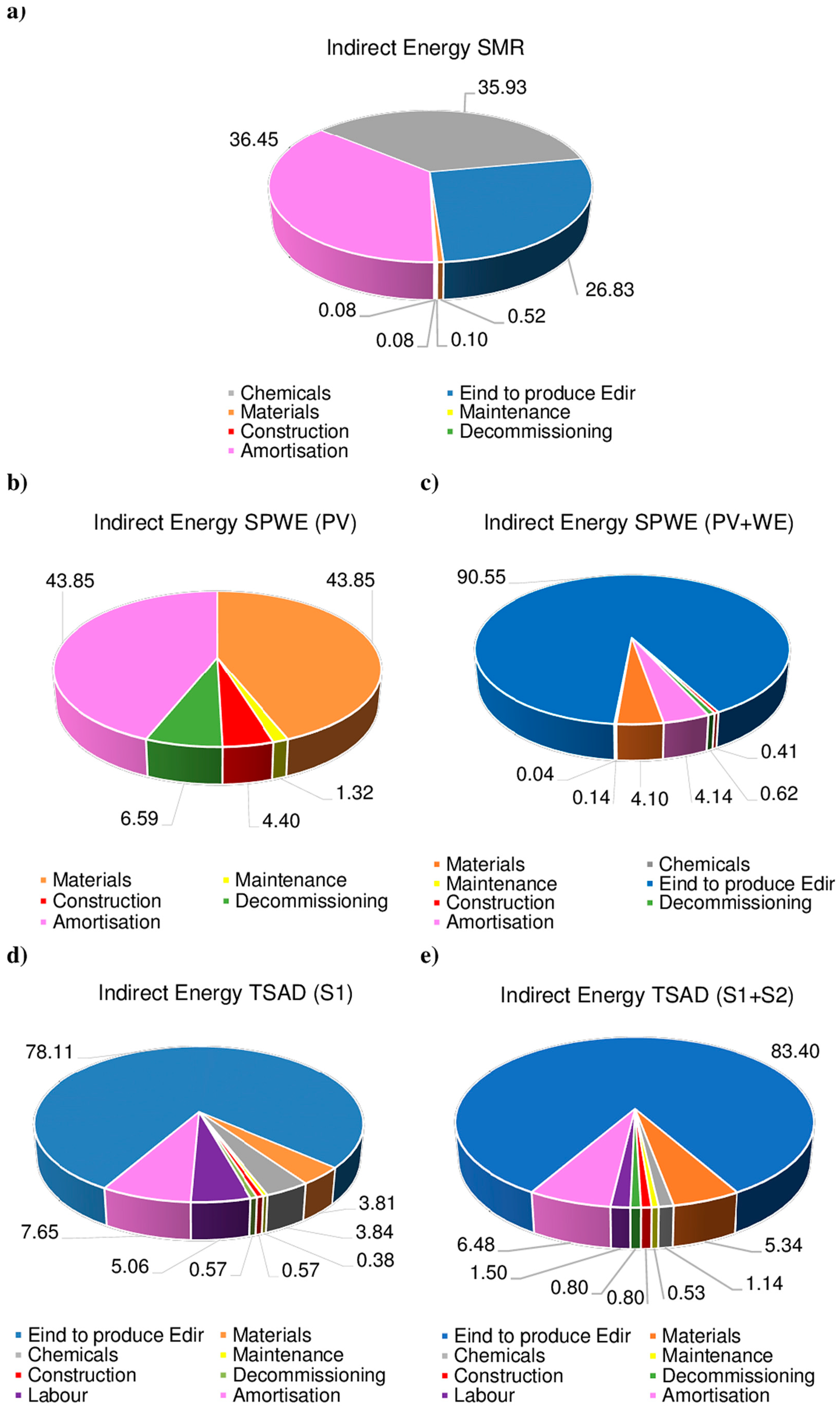

4.2. Materials Input (MI) and Indirect Energy

- −

- SMR: indirect energy was mainly constituted by three key contributions: the energy of chemicals (35.93%), the Eamor which is 36.45% and the Eind to prod edir (26.83%), which corresponds to the energy costs of methane production (Figure 5a).

- −

- SPWE: for the PV alone system, most of the indirect energy (87.70%) corresponded to materials and amortization in equal proportions since there are no chemical flows requested for operation, the Emaint and Econst fractions are low, together representing 5.72%, while the Edecomm corresponds to 6.59% (Figure 5b). For the case of SPWE (Figure 5c), the flow of indirect energy significantly increased, mainly due to the grid power input, which was necessary to supply the electrolyzer during the hours when there is no SI and/or when it was not sufficient to run under optimal conditions. For SPWE the distribution of the indirect energy changed, and the Eind to produce edir amounted to 90.55%, the Eamor 4.14%, and the Emat 4.10%.

- −

- TSAD: The system configuration of only S1 and two-stages (S1+S2) presented a distribution of indirect energy mainly constituted (78.11–83.40%) by the Eindto produce edir, which was the energy required for maintaining operative mixing and temperature conditions, while materials represented a modest fraction (3.80–5.34%), as well as the share of chemicals (1.14–3.84%). The Econst and Edecomm were relatively low (<1%) for both cases under analysis. The Elabor, which was assumed to be an operator during the 365 days of the year, resulted in a fraction of 5.06% for the case of S1, while for the system (S1 + S2) it represented only 1.50%. Finally, the share of Eamor resulted in 7.65% for S1 and the S1 + S2 system in 6.48% (Figure 5d,e).

4.3. EROI and EPT

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Georgescu-Roegen, N. The Promethean Condition of Viable Technologies. Mater. Soc. 1983, 7, 425–435. [Google Scholar]

- Lotka, A.J. Elements of Physical Biology. Nature 1925, 116, 461. [Google Scholar]

- Sacher, E. Grundzüge Einer Mechanik der Gesellschaft; Fischer: Salzburg, Austria, 1881. [Google Scholar]

- Geddes, P. An Analysis of the Principles of Economics. Proc. R. Soc. Edinburgh 1884, 12, 943–980. [Google Scholar] [CrossRef]

- Clausius, R. Über die Energievorräte der Natur und ihre Verwertung zum Nutzen der Menschheit; Max Cohen & Sohn: Bonn, Germany, 1885. [Google Scholar]

- Soddy, F. Cartesian Economics: The Bearing of Physical Science Upon State Stewardship; Students’ Unions of Birkbeck College; The London School of Economics: London, UK, 1922. [Google Scholar]

- Georgescu-Roegen, N. Energy and Economic Myths: Institutional and Analytical Economic Essays, 1st ed.; Pergamon: Oxford, UK, 1976. [Google Scholar]

- Vivien, F.-D.; Nieddu, M.; Befort, N.; Debref, R.; Giampietro, M. The Hijacking of the Bioeconomy. Ecol. Econ. 2019, 159, 189–197. [Google Scholar] [CrossRef]

- Kerschner, C.; Wächter, P.; Nierling, L.; Ehlers, M.H. Degrowth and Technology: Towards feasible, viable, appropriate and convivial imaginaries. J. Clean. Prod. 2018, 197, 1619–1636. [Google Scholar] [CrossRef]

- The World Bank/International Energy Agency (IEA). Energy use (kg of oil equivalent per capita)|Data. Available online: https://data.worldbank.org/indicator/eg.use.pcap.kg.oe (accessed on 24 April 2019).

- European Commission. Directive of the European Parliament and of the Council amending Directive 2012/27/EU on Energy Efficiency; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Gomez Camacho, C.E.; Muto, G.; Ruggeri, B. Electrical energy network efficiencies evaluation as milestones for smart grids development: Italy’s case study. In IEEE PES Innovative Smart Grid Technologies Conference Europe Proceedings (ISGT-Europe); IEEE PES: Piscataway, NJ, USA, 2017; pp. 1–6. [Google Scholar]

- Thurber, C.; Dugas, L.R.; Ocobock, C.; Carlson, B.; Speakman, J.R.; Pontzer, H. Extreme events reveal an alimentary limit on sustained maximal human energy expenditure. Sci. Adv. 2019, 5, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Sanfilippo, S.; Raimondi, A.; Ruggeri, B.; Fino, D. Dietary vs. transport: An analysis of environmental burdens pertaining to a typical workday. Int. J. Consum. Stud. 2012, 36, 133–140. [Google Scholar] [CrossRef]

- Harjanne, A.; Korhonen, J.M. Abandoning the concept of renewable energy. Energy Policy 2019, 127, 330–340. [Google Scholar] [CrossRef]

- McManus, M.C.; Taylor, C.M. The changing nature of life cycle assessment. Biomass Bioenergy 2015, 82, 13–26. [Google Scholar] [CrossRef]

- Jägemann, C.; Fürsch, M.; Hagspiel, S.; Nagl, S. Decarbonizing Europe’s power sector by 2050–Analyzing the economic implications of alternative decarbonization pathways. Energy Econ. 2013, 40, 622–636. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Holmberg, H.; Siitonen, S.; Laukkanen, T.; Tuomaala, M.; Niskanen, T. Comparison of Indirect CO2-emissions of Different Renewable Transport Fuels. Energy Procedia 2015, 72, 19–26. [Google Scholar] [CrossRef]

- Quakernaat, J. Hydrogen in a global long-term perspective. Int. J. Hydrogen Energy 1995, 20, 485–492. [Google Scholar] [CrossRef]

- Dahbi, S.; Aziz, A.; Messaoudi, A.; Mazozi, I.; Kassmi, K.; Benazzi, N. Management of excess energy in a photovoltaic/grid system by production of clean hydrogen. Int. J. Hydrogen Energy 2018, 43, 5283–5299, no. 10. [Google Scholar] [CrossRef]

- Moriarty, P.; Honnery, D. Prospects for hydrogen as a transport fuel. Int. J. Hydrogen Energy 2019, 44, 16029–16037. [Google Scholar] [CrossRef]

- Dodds, P.E.; Staffell, I.; Hawkes, A.D.; Li, F.; Grünewald, P.; McDowall, W.; Ekins, P. Hydrogen and fuel cell technologies for heating: A review. Int. J. Hydrogen Energy 2015, 40, 2065–2083. [Google Scholar] [CrossRef]

- Eberle, U.; Felderhoff, M.; Schüth, F. Chemical and physical solutions for hydrogen storage. Angew. Chem. Int. Ed. 2009, 48, 6608–6630. [Google Scholar] [CrossRef] [PubMed]

- Parnell, J.; Blamey, N. Global hydrogen reservoirs in basement and basins. Geochem. Trans. 2017, 18, 1–8, no. 2. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Ghoshal, S.K. Hydrogen the future transportation fuel: From production to applications. Renew. Sustain. Energy Rev. 2015, 43, 1151–1158. [Google Scholar] [CrossRef]

- Di Addario, M.; Malavè, A.C.L.; Sanfilippo, S.; Fino, D.; Ruggeri, B. Evaluation of sustainable useful index (SUI) by fuzzy approach for energy producing processes. Chem. Eng. Res. Des. 2016, 107, 153–166. [Google Scholar] [CrossRef]

- Costanza, R. Embodied energy and economic valuation. Science 1980, 210, 1219–1224. [Google Scholar] [CrossRef] [PubMed]

- Hubbert, M.K. Nuclear energy and the fossil fuel. Am. Pet. Inst. Drill. Prod. Pract. 1956, 7–25. [Google Scholar]

- Delina, L.L. Accelerating Sustainable Energy Transition(s) in Developing Countries: The Challenges of Climate Change and Sustainable Development; Routledge: London, UK, 2017. [Google Scholar]

- Brebbia, C.A.; Sendra, J.J. Towards Energy Sustainability; WIT Press: Southampton, UK, 2018. [Google Scholar]

- Kist, D.L.; Cano, R.; Sapkaite, I.; Pérez-Elvira, S.I.; Monteggia, L.O. Macrophytes as a Digestion Substrate. Assessment of a Sonication Pretreatment. Waste Biomass Valoriz. 2018, 1–11. [Google Scholar] [CrossRef]

- Malave, A.C.L.; Fino, D.; Gómez, C.E.; Camacho, C.E.G.; Ruggeri, B. Experimental tests on commercial Sweet Product Residue (SPR) as a suitable feed for anaerobic bioenergy (H2+CH4) production. Waste Manag. 2018, 71, 626–635. [Google Scholar] [CrossRef] [PubMed]

- Ruggeri, B.; Tommasi, T.; Sanfilippo, S. BioH2 & BioCH4 Through Anaerobic Digestion: From Research to Full-scale Applications; Springer: London, UK, 2015. [Google Scholar]

- Hall, C.A.S.; Lambert, J.G.; Balogh, S.B. EROI of different fuels and the implications for society. Energy Policy 2014, 64, 141–152. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Balogh, S.; Murphy, D.J.R. What is the minimum EROI that a sustainable society must have? Energies 2009, 2, 25–47. [Google Scholar] [CrossRef]

- Harvey, L.D.D. Energy Efficiency and the Demand for Energy Services; Earthscan: London, UK, 2010. [Google Scholar]

- Hall, C.A.S. Synthesis to Special Issue on New Studies in EROI (Energy Return on Investment). Sustainability 2011, 3, 2496–2499. [Google Scholar] [CrossRef]

- Fizaine, F.; Court, V. Energy expenditure, economic growth, and the minimum EROI of society. Energy Policy 2016, 95, 172–186. [Google Scholar] [CrossRef]

- Atlason, R.S. EROI and the Icelandic society. Energy Policy 2018, 120, 52–57. [Google Scholar] [CrossRef]

- Lambert, J.G.; Hall, C.A.S.; Balogh, S.; Gupta, A.; Arnold, M. Energy, EROI and quality of life. Energy Policy 2014, 64, 153–167. [Google Scholar] [CrossRef]

- Hall, C.A.S. Energy Return on Investment as Master Driver of Evolution. In Energy Return on Investment: A Unifying Principle for Biology, Economics and Sustainability; Springer: London, UK, 2016; pp. 59–72. [Google Scholar]

- Raugei, M.; Frischknecht, R.; Olson, C.; Sinha, P.; Heath, G. Methodological Guidelines on Net Energy Analysis of Photovoltaic Electricity; International Energy Agency–Photovoltaic Power Systems Programme: Shanghai, China, 2016. [Google Scholar]

- Frischknecht, R.; Wyss, F.; Büsser, S.; Knöpfel, T.; Lützkendorf, M.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Noris, F.; Musall, E.; Salom, J.; Berggren, B.; Jensen, S.Ø.; Lindberg, K.; Sartori, I. Implications of weighting factors on technology preference in net zero energy buildings. Energy Build. 2014, 82, 250–262. [Google Scholar] [CrossRef]

- Georgescu-Roegen, N. Dynamic models and economic growth. World Dev. 1975, 3, 765–783. [Google Scholar] [CrossRef]

- Suh, S.; Huppes, G. Methods for Life Cycle Inventory of a product. J. Clean. Prod. 2005, 13, 687–697. [Google Scholar] [CrossRef]

- Simonen, K. Life Cycle Assessment; Routledge: London, UK, 2014. [Google Scholar]

- Trabold, T.; Babbitt, C.W. Sustainable Food Waste-to-Energy Systems; Elsevier: London, UK, 2018. [Google Scholar]

- Wiesen, K.; Wirges, M. From cumulated energy demand to cumulated raw material demand: The material footprint as a sum parameter in life cycle assessment. Energy. Sustain. Soc. 2017, 7, 1–13. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Practical Handbook of Material Flow Analysis; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Ruggeri, B.; Sanfilippo, S.; Tommasi, T. Sustainability of (H2 + CH4) by Anaerobic Digestion via EROI Approach and LCA Evaluations. In Life Cycle Assessment of Renewable Energy Sources; Springer: London, UK, 2013; pp. 169–194. [Google Scholar]

- Huijbregts, M.A.J.; Hellweg, S.; Frischknecht, R.; Hendriks, H.W.M.; Hungerbühler, K.; Hendriks, A.J. Cumulative Energy Demand As Predictor for the Environmental Burden of Commodity Production. Environ. Sci. Technol. 2010, 44, 2189–2196. [Google Scholar] [CrossRef] [PubMed]

- Patel, M. Cumulative energy demand (CED) and cumulative CO2 emissions for products of the organic chemical industry. Energy 2003, 28, 721–740. [Google Scholar] [CrossRef]

- Ecoinvent data v2.0-Swiss Centre for Life Cycle Inventories. 2007. Available online: www.ecoinvent.org (accessed on 7 March 2019).

- Ecoinvent data v3.5-Swiss Centre for Life Cycle Inventories. 2018. Available online: www.ecoinvent.org (accessed on 7 March 2019).

- Algunaibet, I.M.; Pozo, C.; Galán-Martín, Á.; Guillén-Gosálbez, G. Quantifying the cost of leaving the Paris Agreement via the integration of life cycle assessment, energy systems modeling and monetization. Appl. Energy 2019, 242, 588–601. [Google Scholar] [CrossRef]

- Zhao, H.; Lin, B. Assessing the energy productivity of China’s textile industry under carbon emission constraints. J. Clean. Prod. 2019, 228, 197–207. [Google Scholar] [CrossRef]

- Puig, R.; Fullana-i-Palmer, P.; Baquero, G.; Riba, J.-R.; Bala, A. A Cumulative Energy Demand indicator (CED), life cycle based, for industrial waste management decision making. Waste Manag. 2013, 33, 2789–2797. [Google Scholar] [CrossRef]

- Silversand, F.A. Fuel Processor for Small-Scale Production of Hydrogen-Experimental Study. Available online: http://www.sgc.se/ckfinder/userfiles/files/SGC139.pdf (accessed on 6 February 2019).

- Jannasch, A.-K.; Silversand, F. Reliability Study of a Small-Scale Fuel Processor System STUR-10 kWH2. Available online: http://www.sgc.se/ckfinder/userfiles/files/SGC151.pdf (accessed on 6 February 2019).

- Dobó, Z.; Palotás, Á.B. Impact of the voltage fluctuation of the power supply on the efficiency of alkaline water electrolysis. Int. J. Hydrogen Energy 2016, 41, 11849–11856, no. 28. [Google Scholar] [CrossRef]

- Gomez Camacho, C.E.; Ruggeri, B.; Mangialardi, L.; Persico, M.; Luongo Malave, A.C. Continuous two-step anaerobic digestion (TSAD) of organic market waste: Rationalising process parameters. Int. J. Energy Environ. Eng. 2019, 11, 1–15. [Google Scholar] [CrossRef]

- Pachapur, V.L.; Kutty, P.; Pachapur, P.; Brar, S.K.; Le Bihan, Y.; Galvez-Cloutier, R.; Buelna, G. Seed Pretreatment for Increased Hydrogen Production Using Mixed-Culture Systems with Advantages over Pure-Culture Systems. Energies 2019, 12, 530. [Google Scholar] [CrossRef]

- Lombardelli, G.; Pirone, R.; Ruggeri, B. LCA Analysis of different MSW treatment approaches in the light of energy and sustainability perspectives. Chem. Eng. Trans. 2017, 57, 469–474. [Google Scholar]

- Fiore, S.; Ruffino, B.; Campo, G.; Roati, C.; Zanetti, M.C. Scale-up evaluation of the anaerobic digestion of food-processing industrial wastes. Renew. Energy 2016, 96 Pt A, 949–959. [Google Scholar] [CrossRef]

- Pierie, F.; van Someren, C.E.J.; Benders, R.M.J.; Bekkering, J.; van Gemert, W.J.T.; Moll, H.C. Environmental and energy system analysis of bio-methane production pathways: A comparison between feedstocks and process optimizations. Appl. Energy 2015, 160, 456–466. [Google Scholar] [CrossRef]

- Ferroni, F.; Hopkirk, R.J. Energy Return on Energy Invested (ERoEI) for photovoltaic solar systems in regions of moderate insolation. Energy Policy 2016, 94, 336–344. [Google Scholar] [CrossRef]

- Ferroni, F.; Hopkirk, R.J. Energy Return on Energy Invested (ERoEI) for photovoltaic solar systems in regions of moderate insolation: A comprehensive response. Energy Policy 2017, 102, 377–384. [Google Scholar] [CrossRef]

- Breyer, C.; Görig, M. “Energy Learning Curves of PV Systems. Wiley Environ. Prog. Sustain. Energy 2016, 35, no. 3. [Google Scholar]

- Leccisi, E.; Raugei, M.; Fthenakis, V. The energy and environmental performance of ground-mounted photovoltaic systems—A timely update. Energies 2016, 9, 622. [Google Scholar] [CrossRef]

| Eind,i | Description |

|---|---|

| Echem | Indirect energy used to produce the chemicals of the process |

| Emat | Indirect energy used to produce the materials of the process |

| Eind to prod edir | Indirect energy used to produce and use the direct energy of the process |

| Emaint | Indirect energy used for maintenance purposes |

| Elabor | Indirect energy used to sustain the human labor |

| Econstr | Indirect energy used for construction purposes |

| Edecomm | Indirect energy used for decommissioning purposes |

| Eamort | Indirect energy allocated for the amortization of materials and chemicals of the replacement facility |

| Combustion Reaction (CATBUR) | CH4 + 2O2 → CO2 + 2H2O |

| Reforming reaction (SREF) | CH4 + H2O → CO + 3H2 |

| Water-Gas Shift reaction (WGS) | CO + H2O → CO2 + H2 |

| Oxidation reactions (PROX) | C + O2 → CO2 |

| 2CO + O2 → 2CO2 | |

| 2H2 + O2 → 2H2O | |

| CH4 + 2O2 → CO2 + 2H2O |

| CATBUR | SREF | WGS | PROX | |

|---|---|---|---|---|

| Dimensions [cm] | 10 × 10 × 10 | 23 × 8 × 8 | 13 × 7 × 10 | 7 × 4 × 10 8 × 5 × 10 |

| Catalysts mesh [cm] | 7 × 7 | 7 × 30 | 7 × 7 | 7 × 7 7 × 7 |

| Catalysts [% w/w Me] | Pd5%/Al2O3 | Pt5%/Al2O3 | Pt5%/ZrO2 | Rh5%/Al2O3 |

| Working Temperature [°C] | 900–920 | 360–645 | 390–440 | 105–125 |

| Chemicals Flow | ||||

| CH4 [NL/min] | 6.000 | 16.000 | - | - |

| Air [NL/min] | 107.000 | - | - | 7.500 |

| Demineralized water [L/min] | 0.051 | - | 0.024 | - |

| String | Curvature [m−1] | Curvature Ratio [%] | Irradiated Surface [m2] |

|---|---|---|---|

| I | 0.057107 | 59.86 | 23.75 |

| II, III | 0.058582 | 61.41 | 47.50 |

| IV, V | 0.044705 | 46.86 | 47.50 |

| VI, VII | 0.094688 | 99.26 | 47.50 |

| VIII | 0.095393 | 100.00 | 23.75 |

| PV Cells | Inverter | Water Dissociator | |||

|---|---|---|---|---|---|

| Dimensions | |||||

| Size [mm] | 801 × 1491 | Size [mm] | 434 × 295 × 214 | Size [cm] | 115 × 95 × 140 |

| Weight [kg] | 66 | Weight [kg] | 25 | Weight [kg] | 420 |

| Units [-] | 160 | Units [-] | 8 | Units [-] | 1 |

| Technical Specifications | |||||

| Power-PMPP [W] | 102.2 | PAC, nominal [W] | 1500 | H2 FlowMAX [Nm3/h] | 2.47 |

| Voltage-UMPP [V] | 18.9 | PAC,max [W] | 1700 | O2 FlowMAX [Nm3/h] | 1.23 |

| Current-IMPP [A] | 5.4 | Harm. Dist.Max [%] | <4% | PressureMAX [bar] | 1.80 |

| VOpen Circuit [V] | 23.4 | Output Voltage-VAC [V] | 198–251 | Gas purity [%] | ≥99.5 |

| IShort-Circuit [A] | 5.8 | FrequencyOutput-fAC [Hz] | 49.8–50.2 | ConsumptionMAX [kW] | 13.5 |

| Max. efficiency-ηMAX | ≥93.5 | Supply VoltageAC [V] | 400 | ||

| Power Consumption [W] | <5 | Frequency [Hz] | 50–60 | ||

| PowerStand-by [W] | <0.1 | Distillated WaterMAX [L/h] | 2.20 | ||

| Electrolyte Solution [L] | 25 | ||||

| Electrolyte [% w/w] | 18 NaOH | ||||

| H2-Bioreactor | CH4-Bioreactor | |

|---|---|---|

| Working Temperature [°C] | 35.0 | 35.0 |

| Mean Ambient temperature [°C] | 13 | 13 |

| Power input, pre-treatment [kW/m3] | 0.2 | - |

| Power input, mixing [kW/m3] | 0.1 | 0.20 |

| Mixing application time [h/h] | 1/1 | 0.25/1.00 |

| Hydrogen potential [NLH2/kgDM] | 79.04 | - |

| Methane potential [NLCH4/kgDM] | - | 247.32 |

| Hydraulic Retention Time [d] | 2 | 15 |

| Mean gas composition [%] | CH4: <1 CO2: 65 ± 5 H2: 35 ± 5 | CH4: 72 ± 5 CO2: 28 ± 5 H2: <1 |

| Served inhabitants [p] | 10,000 |

| MSW [kg/(d·p)] | 1.50 |

| Separate Collection [%] | 50.00 |

| OFMSW [%] | 55.00 |

| LHVOFMSW [MJ/kgDM] | 17.00 |

| H2-Bioreactor | CH4-Bioreactor | |

|---|---|---|

| Volume - V [m3] | 21.18 | 158.81 |

| Diameter – D [m] | 1.75 | 8.46 |

| Height - h [m] | 8.75 | 2.82 |

| D/h | 0.2 | 3 |

| Cement-ε1 [m] | 0.30 | 0.30 |

| Insulator-ε2 [m] | 0.08 | 0.08 |

| Component | Amount [kg] | CED [MJ/kg] | Material Description | |

|---|---|---|---|---|

| Steam-Methane Reforming (SMR) | ||||

| Block Unit | Total | 1.12 × 101 | 5.25 × 101 | Stainless Steel 304 X5CrNi18 (304) |

| Catalyst Mesh Wires | CATBUR | 9.12 × 10−2 | 9.50 × 103 | Pd5%/Al2O3; Replacement each 8 months |

| SREF | 1.01 × 10−1 | 9.84 × 103 | Pt5%/Al2O3; Replacement each 8 months | |

| WGS | 4.78 × 10−1 | 9.89 × 103 | Pt5%/ZrO2; Replacement each 8 months | |

| PROX | 3.37 × 10−2 | 1.45 × 104 | Rh5%/Al2O3; Replacement each 12 months | |

| Auxiliaries | Total | 1.00 × 101 | 5.25 × 101 | Pumps, blower and pipelines |

| Solar-Powered Water Electrolysis (SPWE) | ||||

| PV | 1.06 × 104 | 6.64 × 101 | Materials covering 190 m2; Polycrystalline silicon | |

| Structure | 3.17 × 103 | 1.10 × 101 | 70% Wood Class II/30% Construction Steel Fe520 I | |

| Inverter | 4.00 × 102 | 1.36 × 102 | Inverter 1500W; (Replacement 10 years) | |

| Electrolyzer | 1.68 × 103 | 2.39 × 101 | Electrolyzer; (Replacement 5 years) | |

| Two-Stage Anaerobic Digestion (TSAD) | ||||

| Mixer | 2.32 × 102 | 5.25 × 101 | Stainless Steel 304 X5CrNi18 (304) | |

| S1 | Cement | 2.36 × 104 | 3.58 × 100 | General purpose cement |

| Insulation | 2.85 × 103 | 9.52 × 101 | Polystyrene foam slab | |

| PVC | 3.82 × 101 | 6.86 × 101 | PVC calendared sheet (Digester Dome) | |

| Auxiliaries | 2.65 × 102 | 5.25 × 101 | Integrated value pumps and pipelines | |

| S2 | Cement | 9.06 × 104 | 3.58 × 100 | General purpose cement |

| Insulation | 1.09 × 104 | 9.52 × 101 | Polystyrene foam slab | |

| PVC | 1.46 × 102 | 6.86 × 101 | PVC calendered sheet (Digester Dome) | |

| Auxiliaries | 1.02 × 103 | 5.25 × 101 | Integrated value pumps and pipelines | |

| Primary Energy Source | Fossil | Solar Radiation | Biomass | |||

|---|---|---|---|---|---|---|

| (SMR) | (PV) | (PV + WE) | (S1) | (S2) | ||

| Primary Energy [MJ] | 6.01 × 106 | 2.50 × 107 | 2.50 × 107 | 1.79 × 108 | 1.79 × 108 | |

| Avoided Energy [MJ] | - | - | - | 1.26 × 107 | 1.26 × 107 | |

| Already Spent Energy [MJ] | 5.56 × 105 | - | - | 1.97 × 107 | 1.97 × 107 | |

| Available Energy [MJ] | 5.46 × 106 | 2.50 × 107 | 2.50 × 107 | 1.72 × 108 | 1.72 × 108 | |

| Produced Energy [MJ] | 6.15 × 106 | 2.27 × 106 | 6.15 × 106 | 8.96 × 106 | 1.02 × 108 | |

| Direct Energy | Heat [MJ] | 2.25 × 106 | - | - | 1.27 × 107 | 1.69 × 107 |

| Power [MJ] | 3.57 × 100 | 1.26 × 104 | 6.02 × 106 | 2.58 × 106 | 9.26 × 106 | |

| Indirect Energy | Materials [MJ] | 8.19 × 103 | 7.91 × 105 | 8.31 × 105 | 3.85 × 105 | 1.81 × 106 |

| Chemicals [MJ] | 5.66 × 105 | - | 8.49 × 103 | 3.88 × 105 | 3.88 × 105 | |

| Maintenance [MJ] | 1.64 × 103 | 2.38 × 104 | 2.78 × 104 | 3.85 × 104 | 1.81 × 105 | |

| Eind to produce Edir [MJ] | 4.23 × 105 | - | 1.84 × 107 | 7.89 × 106 | 2.83 × 107 | |

| Construction [MJ] | 1.23 × 103 | 7.93 × 104 | 8.33 × 104 | 5.77 × 104 | 2.72 × 105 | |

| Decomm. [MJ] | 1.23 × 103 | 1.19 × 105 | 1.25 × 105 | 5.77 × 104 | 2.72 × 105 | |

| Labour [MJ] | - | - | - | 5.11 × 105 | 5.11 × 105 | |

| Amortisation [MJ] | 5.74 × 105 | 7.91 × 105 | 8.39 × 105 | 7.73 × 105 | 2.20 × 106 | |

| Enet [MJ] | 3.90 × 106 | 2.26 × 106 | 1.28 × 105 | −6.33 × 106 | 7.60 × 107 | |

| Eind [MJ] | 1.58 × 106 | 1.80 × 106 | 2.03 × 107 | 1.01 × 107 | 3.40 × 107 | |

| Euseful [MJ] | 2.32 × 106 | 4.55 × 105 | −2.01 × 107 | −1.64 × 107 | 4.20 × 107 | |

| H2 production [Nm3] | 5.72 × 105 | - | 5.72 × 105 | 8.33 × 105 | - | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez-Camacho, C.E.; Ruggeri, B. Energy Sustainability Analysis (ESA) of Energy-Producing Processes: A Case Study on Distributed H2 Production. Sustainability 2019, 11, 4911. https://doi.org/10.3390/su11184911

Gómez-Camacho CE, Ruggeri B. Energy Sustainability Analysis (ESA) of Energy-Producing Processes: A Case Study on Distributed H2 Production. Sustainability. 2019; 11(18):4911. https://doi.org/10.3390/su11184911

Chicago/Turabian StyleGómez-Camacho, Carlos E., and Bernardo Ruggeri. 2019. "Energy Sustainability Analysis (ESA) of Energy-Producing Processes: A Case Study on Distributed H2 Production" Sustainability 11, no. 18: 4911. https://doi.org/10.3390/su11184911

APA StyleGómez-Camacho, C. E., & Ruggeri, B. (2019). Energy Sustainability Analysis (ESA) of Energy-Producing Processes: A Case Study on Distributed H2 Production. Sustainability, 11(18), 4911. https://doi.org/10.3390/su11184911