3. Research Methodology

Given the importance of using Industry 4.0’s new tools and technologies, which make a substantial contribution to improving business performance, we conducted a study of companies in Romania. Industry 4.0 represents the fourth industrial revolution with a major impact on the production of the future, which integrates innovative elements and technologies such as big data analytics, Internet of things and others, and which ensures constant communication and connection in addressing customer services. Through this study, we wanted to find out the future intention of companies to implement new tools and technologies that impact their performance. The quantitative market research had the following objectives:

Objectives 1: Identify the companies’ experience in implementing analytics in supply chain and the difficulties encountered in this process.

Objectives 2: Identify strategy adoption by companies for implementing large data analytics (including the supply chain) and determine its main development priorities.

Objectives 3: Identify the existence of professional capabilities needed to develop insights through BDA.

Objectives 4: Identify the supply-chain analytics tools used by companies and the future intended implementation of new tools and technologies to gain valuable supply-chain insights.

Objectives 5: Highlight the results obtained by companies following the use of BDA in the supply chain.

Objectives 6: Measure the influence of experience, strategies, professional capabilities, annual sales revenues, and industry on the future intention of companies to implement new tools and technologies to gain valuable supply-chain insights.

Taking into account the objectives of the study, we formulated the following research hypotheses:

Hypotheses 1: There is no link between the size of the company and its experience in implementing analytics in supply chain.

Hypotheses 2: There is a link between the size of the company and its strategy for implementing BDA.

Hypotheses 3: There is a link between years of operating experience and professional capabilities to develop insights through BDA.

Hypotheses 4: Most of the Romanian companies intend to implement new tools and technologies to gain valuable supply-chain insights.

Hypotheses 5: The company’s experience influences its future intention to implement new tools and technologies to gain valuable supply-chain insights.

Hypotheses 6: The strategies adopted by companies to implement BDA influences their future intention to implement new tools and technologies to gain valuable supply-chain insights.

Hypotheses 7: Professional capabilities influence the future intention of companies to implement new tools and technologies to gain valuable supply-chain insights.

Hypotheses 8: Annual sales revenue influences the future intention of companies to implement new tools and technologies to gain valuable supply-chain insights.

Hypotheses 9: Industry influences the future intention of companies to implement new tools and technologies to gain valuable supply-chain insights.

To achieve the above-mentioned objectives, but also to test the model proposal, it was necessary to collect data from different companies. The study was conducted between January and March 2019. The relevant population for our study (

www.insse.ro) was identified in the metadata database of the National Institute of Statistics in Romania. Starting from the information provided, the sampling base was defined and built. The process ended with a cross-listing of 550 companies. In view of some errors (such as inactive, noncontact, or already dissolved), the sampling base (list) was reduced to 460 enterprises. After companies were identified, contact with their managers was established to receive the survey agreement and know which managers were to get the online questionnaire, included in an e-mail link to be completed later.

The research method used in the quantitative study was a survey by sampling, using the questionnaire as the data collection tool. It included closed questions, measured with nominal and ordinal scales. The study was carried out with the support of six interviewers with experience in the field. Managers who agreed to participate in the survey received an electronic link via e-mail for the online questionnaire. The process ended with the conclusion of participation agreements with 226 companies included in the list. The response rate was 90.7%, i.e., 205 managers provided complete and useful answers for this research (

Appendix A,

Table A1). The collected data were analyzed with the SPSS package, using the frequency and contingency tables, the hi-square test, the Student’s

t-test, factorial correspondence analysis, and the binary logistic regression model.

In this respect, the binary logistic regression model was used, which indicates the relation between a nominal variable Y (value 1 = success; 0 = failure) and k factorial variables. Factorial variables are quantitative or categorical, while Y is a binary variable that has a Bernoulli type distribution, with the parameter p = P (Y = 1). The general equation underlying the linear logistic regression model is [

96]:

where P is the probability of getting a certain behavior or intent (yes answer);

x1,

x2,

x3, …,

xk are independent variables included in the model; and

β0,

β1,

β2, …,

βk are the model coefficients obtained according to the dependence of the values of the variables.

4. Results and Discussions

The first research goal (O

1) was to identify the companies’ experience in implementing BDA in SCM and the difficulties encountered in this process. Using the chi-square test, we can see the distribution of companies according to the experience gained in implementing BDA in the SC in five size categories in

Table 1. In total, there are more than four times as many experienced companies (164) as companies with no experience (41).

From the analysis of the differences between observed and expected frequencies, it can be seen that there are differences in the levels of all subgroups formed by the crossing of two variables. In the subgroups of companies with more than 250 employees, observed experience is higher than expected (58 > 48.8 and 46 > 36.8), and in companies with lack of experience in implementing analytics in the supply chain, expected frequency is higher than observed (12.2 > 3 and 9.2 > 0).

As can be seen in

Table 2, the critical report has a value of 68,226, and for number of degrees of freedom df = 4. Since the significance level is 0.000, which is less than α = 0.05, the hypothesis is rejected, and the alternative hypothesis is accepted, according to which there is a connection between the size of the company and the experience accumulated in the implementation of BDA in SC.

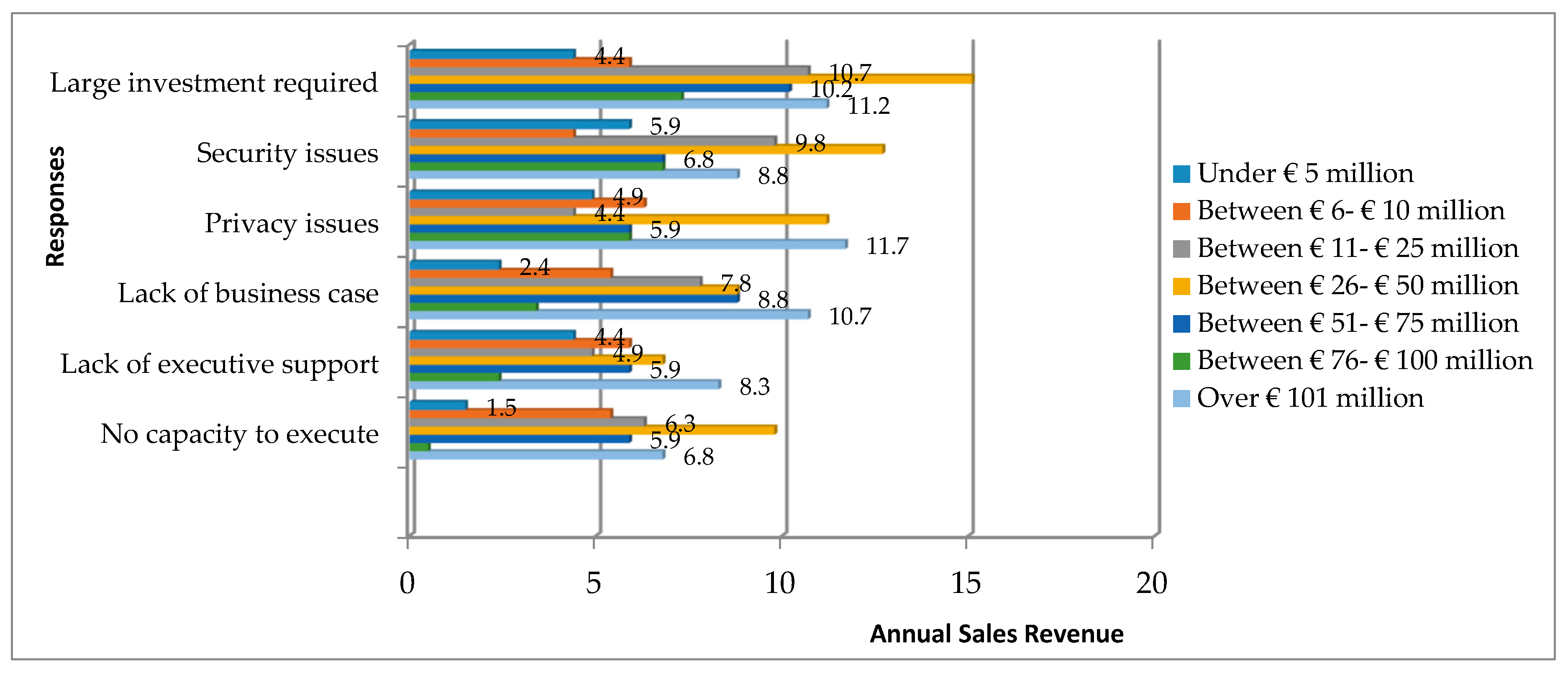

From the analysis of the answers, it can be seen that there are certain differences between companies (grouped by income-based size) regarding the difficulties encountered in the process of BDA implementation in SCM. Managers of companies with annual sales revenue up to €10 million said that the first three potential barriers to implementation were “Large investment required” (10.3%), “Security issues” (10.3%), and “Lack of executive support” (10.3%). Companies with annual sales revenues of over €11 million encountered obstacles related to “Large investment required” (54.6%), “Security issues” (44.8%), and “Privacy issues” (39%). All respondents faced difficulties involving “Lack of business case” (47.3%), “Lack of executive support” (38.5%), and “No capacity to execute” (36.1%) (

Figure 1).

The second research goal (O

2) was to identify companies adopting a strategy for implementing BDA in SCM and determining their main development priorities. Using the same chi-square test, some differences can be seen between company size and BDA implementation strategy. Study results indicate that 9 out of 10 companies adopted a strategy for implementing BDA that also involved the SC; 23 companies of the sample (with up to 249 employees) had not yet adopted a strategy (

Table 3). In the subgroups of companies with more than 50 employees, the observed strategy is higher than expected (51 > 48.8, 61 > 54.2, and 46 > 40.8) and in the absence of BDA strategy the expected frequency is higher than the observed (6.2 > 4, 6.8 > 0, and 5.2 > 0).

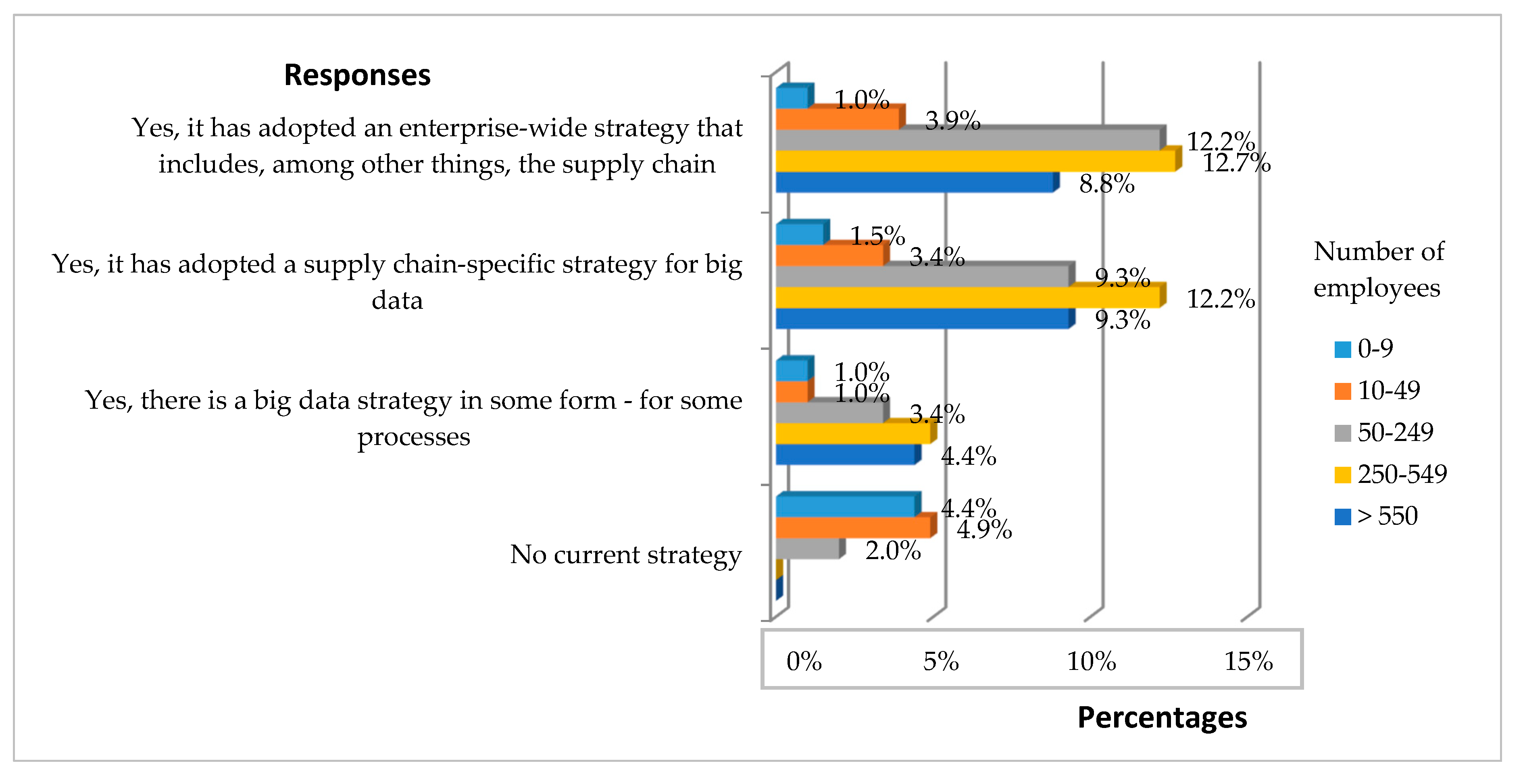

From the data presented in

Figure 2, it is noted that 38.5% (79) of the managers of companies included in the survey sample stated that they adopted an enterprise-wide strategy that includes, among other things, the SC. Only 35.6% (73) of surveyed companies had adopted a supply-chain-specific strategy for BD, while only 11.2% (23) had applied a BD strategy in some form for some processes.

The difference is also confirmed by applying the chi-square (X

2) test, which means the existence of a link between two variables (

Table 4). The calculated value of X

2calc is 65,002, higher than X

20.05;4 = 9.49, so hypothesis H

2 is accepted, which means that we can guarantee with 95% probability that there is a connection between the variables company size and strategy for implementing BDA.

It is noted that all calculated coefficients (Phi, Cramer’s and Contingency Coefficient) have small values (close to zero) and the significance levels are less than 0.05, so we can identify a weak link between company size and adoption of a strategy for implementing BDA (

Table 5).

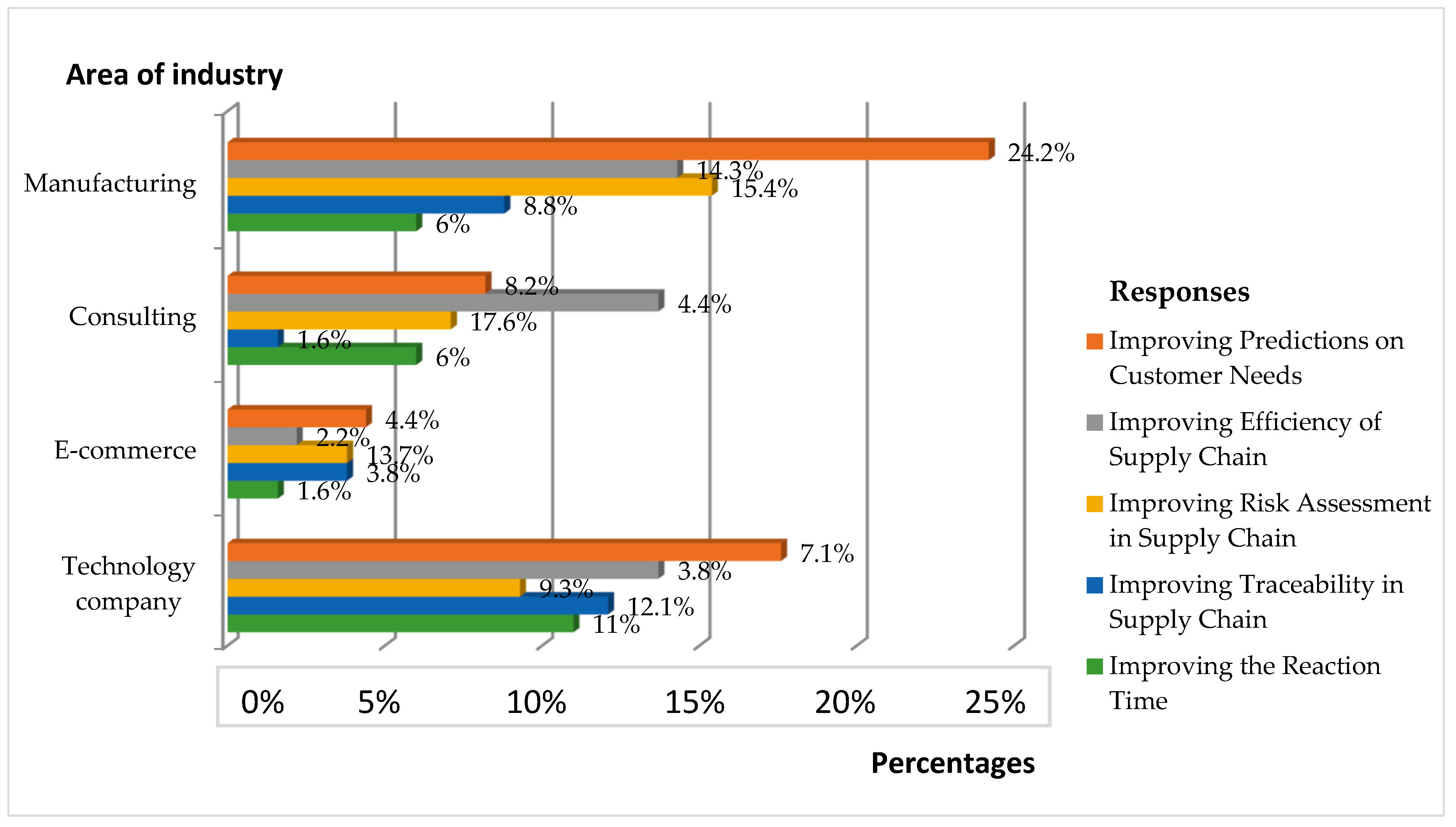

The results show that 24.2% of companies in manufacturing have adopted a strategy based on improving predictions of customer needs. Similarly, 7.1% of technology companies and 4.4% of e-commerce companies said improving predictions of customer needs is the top strategic priority in implementing BDA. Only companies in consulting (4.4%) recognize that improving the efficiency of the supply chain is the priority in their own strategy (

Figure 3).

The third research goal (O3) was to identify the existence of professional capabilities needed to develop insights through BDA.

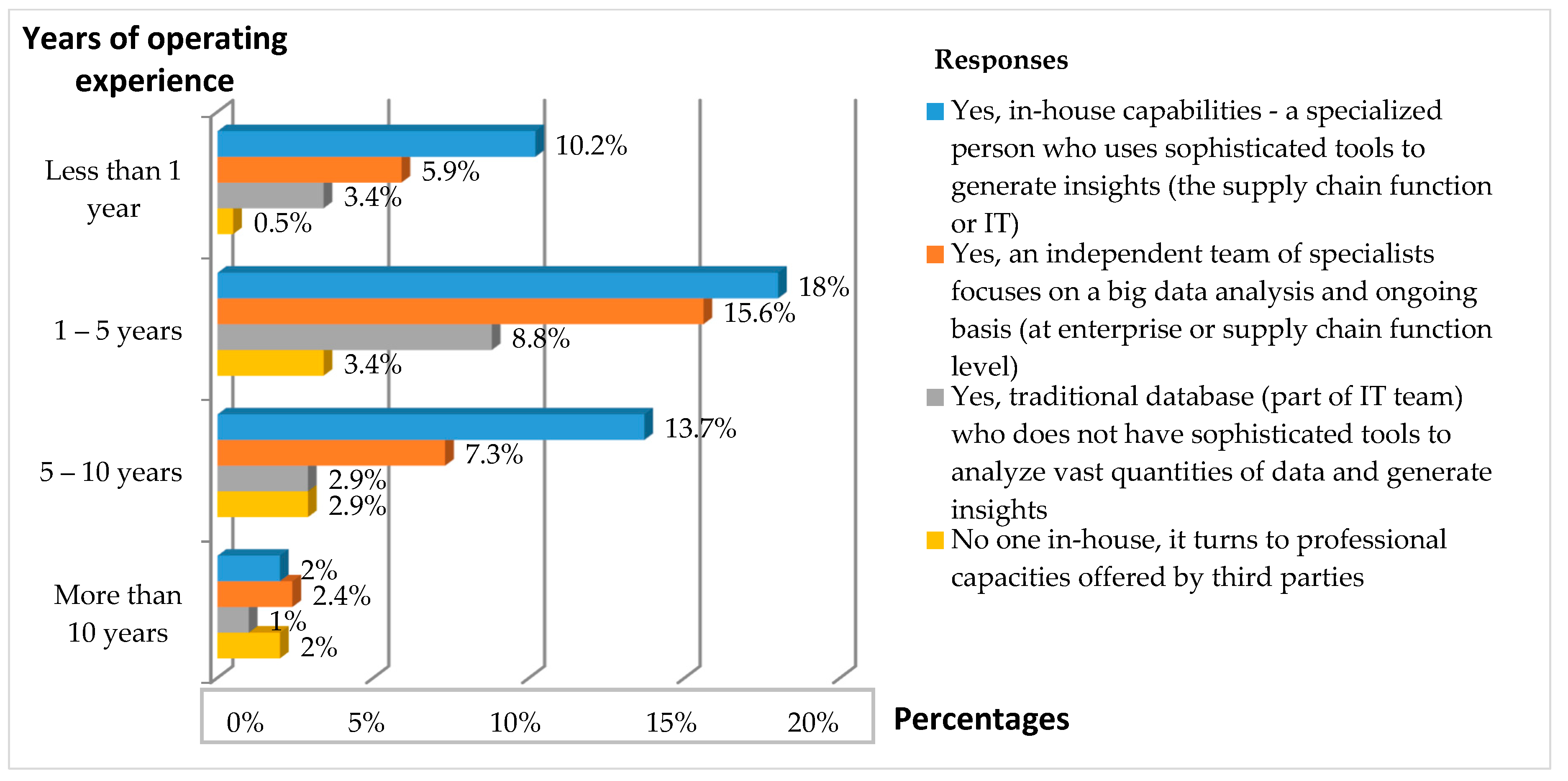

The distribution of companies by professional capability to develop insights through BDA based on years of operating experience is presented in

Table 6. Of the 18 companies that do not have such professional capacity, 13 have a history in the Romanian market up to 5 years. Of the 187 companies that have this professional capacity, 46.56% have been in the domestic market for up to 5 years and 26.2% for up to 10 years.

As indicated in

Table 6, the observed and expected frequencies in all subgroups formed by crossing the variables occupational capabilities and years of operational experience have different but close values. For companies with experience of up to five years, the observed professional capacity is higher than expected (40 > 37.4 and 87 > 85.7), with a corresponding decrease if there is no capacity, for which the expected frequency is greater than the observed (3.6 > 1 and 8.3 > 7).

For number of degrees of freedom df = 3, the critical ratio is 8.570 and the significance level is 0.036, less than p = 0.05. Therefore, the hypothesis is rejected, and the alternative hypothesis is accepted, according to which there is a connection between years of operational experience and professional capability to develop insights through BDA (

Table 7).

Of the 68 companies (31.2%) that have an independent team of data specialists focused on BDA on an ongoing basis, only 21.5% have up to five years of operating experience and 9.7% have over five years. Four out of 10 companies surveyed said they had a specialist in the IT or supply department with the necessary training who knows how to use sophisticated tools to generate insights (

Figure 4). Analyzing the managers’ responses, we can say that most of the companies that did not resort to professional capacities offered by third parties hesitated or were not able to attract specialized personnel with training in the use of sophisticated tools to generate insights or this priority was not included in their strategy.

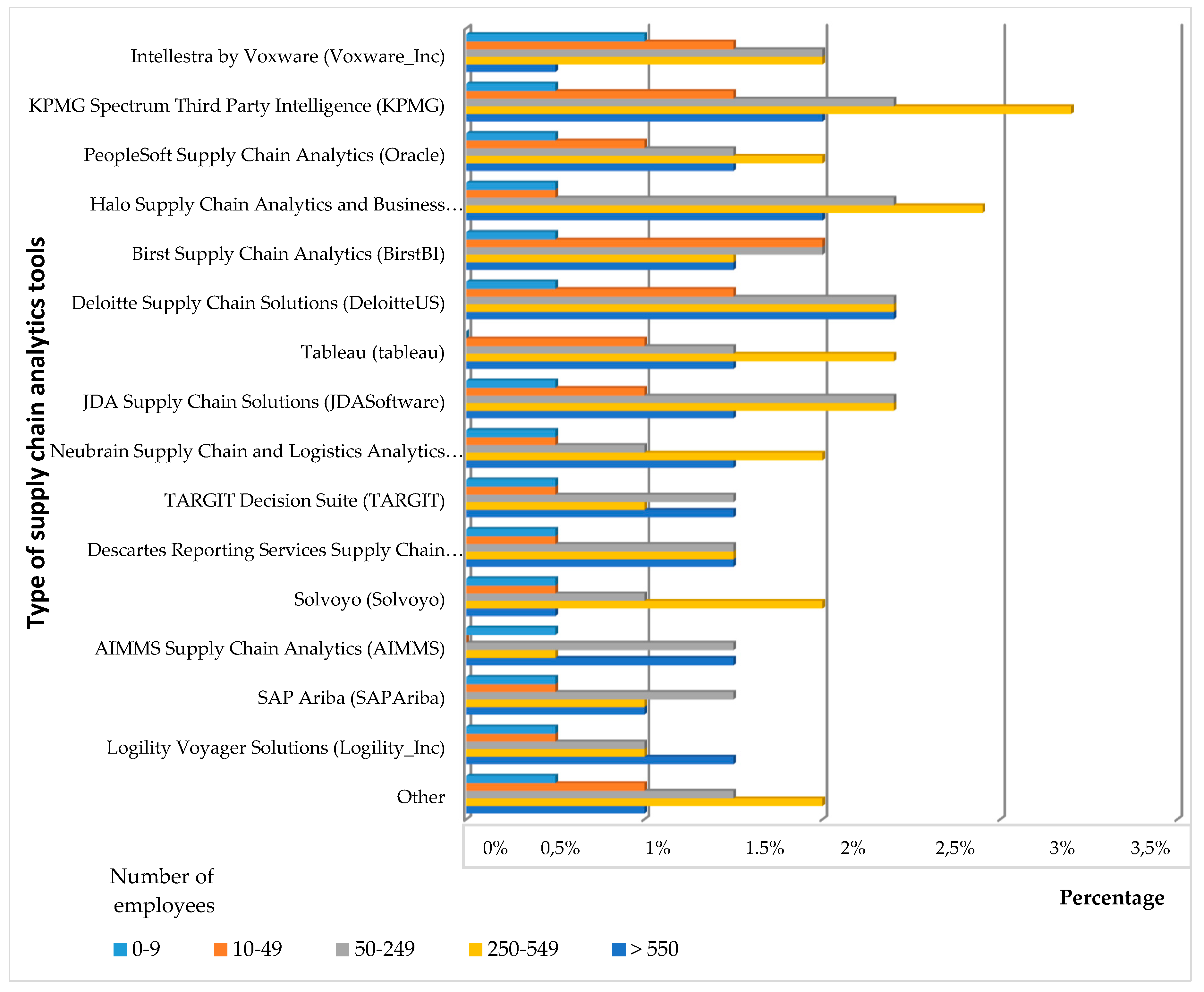

The fourth objective (O

4) was to identify the supply-chain analytics tools used by companies and the future intended implementation of new tools and technologies to gain valuable supply-chain insights. Large companies (with more than 250 employees) use several supply-chain analytics tools, including KPMG Spectrum Third-Party Intelligence, Halo Supply-Chain Analytics and Business Intelligence Software, and Neubrain Supply Chain and Logistics Analytics Software (

Figure 5). Deloitte Supply-Chain Solutions, KPMG Spectrum Third-Party Intelligence, and SAP Ariba are useful software solutions preferred by companies with more than 550 employees. About 5.9% of sample companies use other software solutions and data analytics tools such as Relax, FusionOps, Blue Ridge Supply-Chain Analytics and Inventory Analytics Software, IMI Supply-Chain Analytics, and Qlik Supply-Chain Analytics.

Given the company’s intention to deploy new tools and technologies to gain valuable supply-chain insights, only 41% of entities are interested in engaging in such actions; the remaining 59% have not allocated budgets for such initiatives.

To verify hypothesis H

4, that most Romanian companies intend to implement new tools and technologies to gain valuable supply-chain insights, Student’s

t-test was used.

Table 8 shows the statistical significance of the difference between the percentage of companies that want to implement new techniques (41%) and the value of the test (50%), given that most of the Romanian entities want to be involved in such future actions.

Table 8 shows the value of the critical ratio t

calc = −2.621, which is less than the value in the distribution law table of the unilateral right test t

0.05;205 = 1.64. Moreover, the significance level

p = 0.009 < 0.05, and the difference between the two values is negative. We therefore accept the null hypothesis (H

4); we cannot guarantee with 95% probability that the percentage of companies in the population surveyed is more than 50% and we reject the alternative hypothesis.

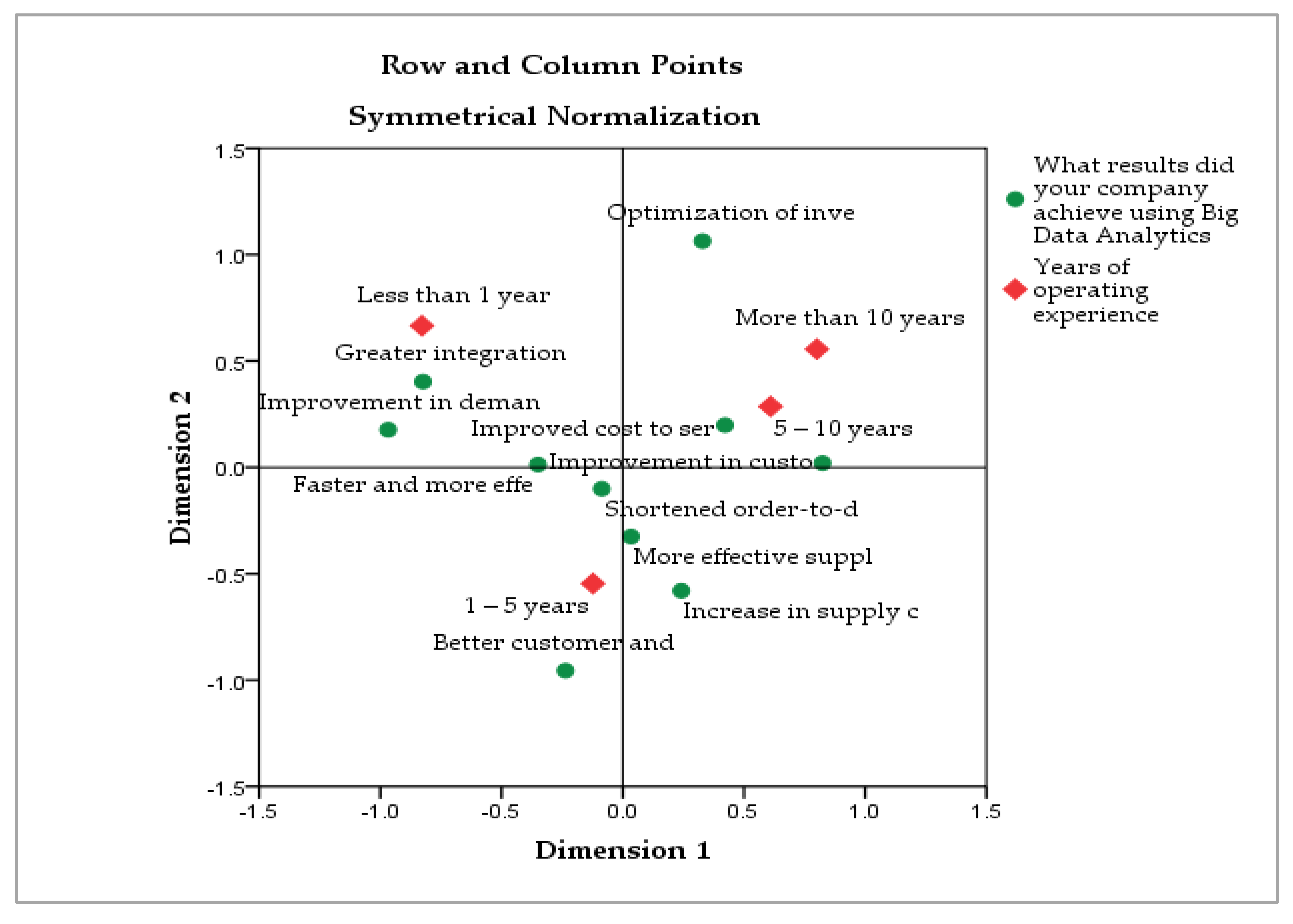

The fifth objective of the research (O

5) was to highlight the results obtained by companies following the use of BDA in SCM. Correspondence factor analysis was used to describe the relationship between the variables years of operating experience and results obtained after using BDA in SCM. The analysis of the data in

Table 9 indicates that the calculated value of the test X

2calc is 37.650 and the minimum significance level is 0.048 < 0.050, therefore the alternative hypothesis is accepted (i.e., the distribution of the variable differs from the normal distribution). Here, too, we can see that the first component explains a spread of 46.1%, the second of 39.7%, and the last one of 14.2%.

Companies with more than five years’ seniority are in opposition to the group of companies with less than one year and between one and five years. They are strongly associated with benefits such as “Improvement in customer service and demand fulfillment,” “Improved cost to serve,” “Increase in supply-chain efficiency,” and “Optimization of inventory and asset productivity.” Other companies with less than one year’s seniority in the domestic market indicated “Greater integration across the supply chain” and “Optimizing inventory and asset productivity” (

Figure 6).

Instead, the fewer benefits that have been gained by companies operating in the market for nearly five years have been linked to “Optimized inventory and asset productivity,” “Shortened order-to-delivery cycle times,” “Improvement in demand driven operations,” and “Improved cost to serve.” However, benefits such as “Increase in supply-chain efficiency,” “Better customer and supplier relationships,” “Faster and more effective response time to supply-chain issues,” and “More efficient supply and operation process and decision-making” have been strongly associated with these companies.

The ultimate goal of the research (O6) was to measure the influence of experience, strategy, professional capabilities, annual sales revenue, and industry on the future intention of companies to implement new tools and technologies to gain valuable supply chain insights.

In the binary logistic regression model, the following independent variables (factorials) are included: Experience (x1), Annual Sales Revenue (x2), Strategy (x3), Professional Capabilities (x4), and Industry (x5). The use of these variables is required to test hypotheses H5–H9.

The dependent variable included in the model is given by the future intention of companies to implement new tools and technologies to obtain valuable supply-chain insights.

Table 10 presents empirical model parameter estimates using the binary logistic regression method.

Using the model’s coefficients (B) from

Table 10, we completed the binary logistic regression as Equation (2):

The probability of engaging in future actions to implement new tools and technologies to gain valuable supply-chain insights is high for companies with high annual sales revenue (0.030 < 0.05 (Sig.)), they have the professional capabilities to develop insights through big data analytics (0.029 < 0.05 (Sig.)) and greater experience in implementing analytics in the supply chain (0.007 < 0.05 (Sig.)). The probability is low that the industry (0.326 > 0.05 (Sig.)) and adoption strategy for implementing big data analytics (0.875 > 0.05 (Sig.)) will influence these actions.

The results obtained from testing the binary logistic regression model indicate that at a confidence level of 95%, hypotheses H6 and H9 are rejected and hypotheses H5, H7, and H8 are valid.

5. Conclusions

Massive volumes of data coming from different sources have a positive effect on real-time decision-making. The variety of data sources, the quality of the data to be integrated, and their visualization are some of the challenges for big data analytics integration. The survey results indicate that 80% of Romanian companies have accumulated big data analytics experience, integrating different software solutions into the supply chain. Big companies (with more than 250 employees) allocate large annual budgets to undertake projects aimed at implementing big data analytics in the supply chain or to employ specialists in the field. The difficulties encountered in the implementation of big data analytics in the supply chain by companies with annual sales revenues of up to €10 million are related to large investment requirements, security issues, and lack of executive support. Entities with annual sales over €11 million have encountered obstacles related to security and privacy issues.

Moreover, 90% of respondents have adopted an enterprise-wide strategy (that includes the supply chain), facilitating the use of big data to add business value. Some of these entities have adopted a dedicated supply-chain strategy (35.6%), and 11.2% have applied a big data strategy in some form for some processes. Some manufacturing (24.2%) and e-commerce (4.4%) companies have adopted a strategy that focuses on improving predictions of customer needs, while consulting companies (4.4%) have as a priority improving the efficiency of the supply chain. To develop insights through big data analytics, Romanian companies need professional capabilities; about 91.22% of entities use such capacities and are 5–10 years old. Of these, 43.9% have a specialized team using sophisticated tools to generate insights, 31.2% have an independent team, and 16.1% have a traditional database (part of the IT team).

Company managers admit that technological changes have changed work processes lately, with investments in training and staff development for large data analytics needed. Companies with over five years of experience in the market that have benefited from the expertise of specialists have achieved results including “Improvement in customer service and demand fulfillment,” “Improved cost to serve,” “Increase in supply-chain efficiency,” and “Optimization of inventory and asset productivity.” Other companies that are smaller and newer in the Romanian landscape, benefiting from the support of teams of specialists, have obtained results related to “Greater integration across the supply chain,” “Faster and more efficient response time to supply-chain issues,” and “Optimization of inventory and asset productivity.”

Managers agree that new capabilities and technologies are needed to transform, manage, and analyze company-wide information. The main challenges they face are the acceptance and use of new technologies, as well as their regulation. The most notable problems to overcome are based on the difficulty of analyzing large volumes of data to achieve timely accurate results, and the need for standardization, interoperability, security, confidentiality, expertise, and funding to develop big data analytics infrastructure and integrate sets of already available data.

Managers recognize that their concerns include identifying new methods, tools, and statistical technology approaches, such as cloud computing and security technologies, to be rigorously explored. Big data analytics is an opportunity to use new types of data to create more agile businesses to solve problems that were previously considered unsolvable, leading to better business results. This will lead to radical changes in business operations that change from the use of a model based mainly on the experience of decision-makers to an information model that gives real value to the business and organization itself.

Starting from the objectives presented and analyzed in our study, we propose the following possible future research directions: (1) Studying the opportunities, challenges, advantages and disadvantages of BD in large companies and/or SMEs in the state or private sector; (2) Studying how BD systematically affects the economic value in the business environment; (3) Studying the implementation of BD in various sectors of activity and the efficiency of using the information obtained in making decision process; (4) Studying the capabilities and benefits of using BDA in optimizing SCM; (5) Studying the impact of BDA on SCM by using various tools dedicated to analyzing information.