Circular Strategies Enabled by the Internet of Things—A Framework and Analysis of Current Practice

Abstract

1. Introduction

2. Background

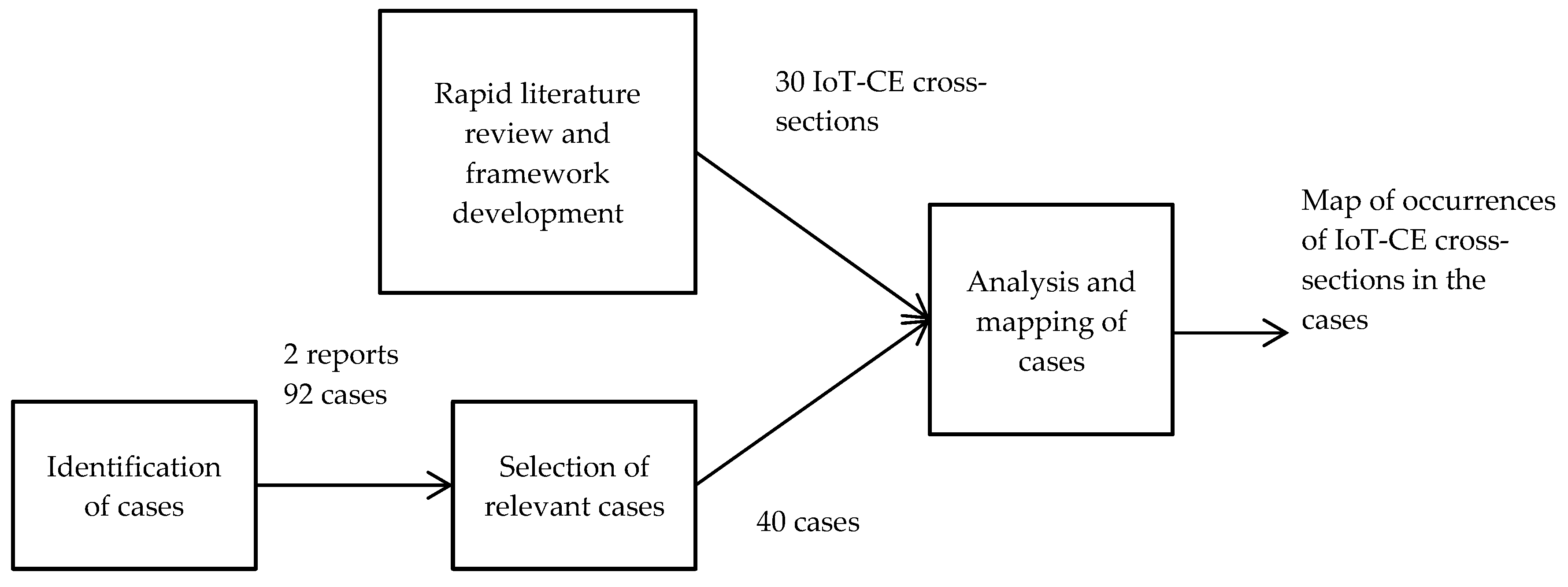

3. Method

3.1. Rapid Literature Review and Framework Development

3.2. Identification of Cases from Practice

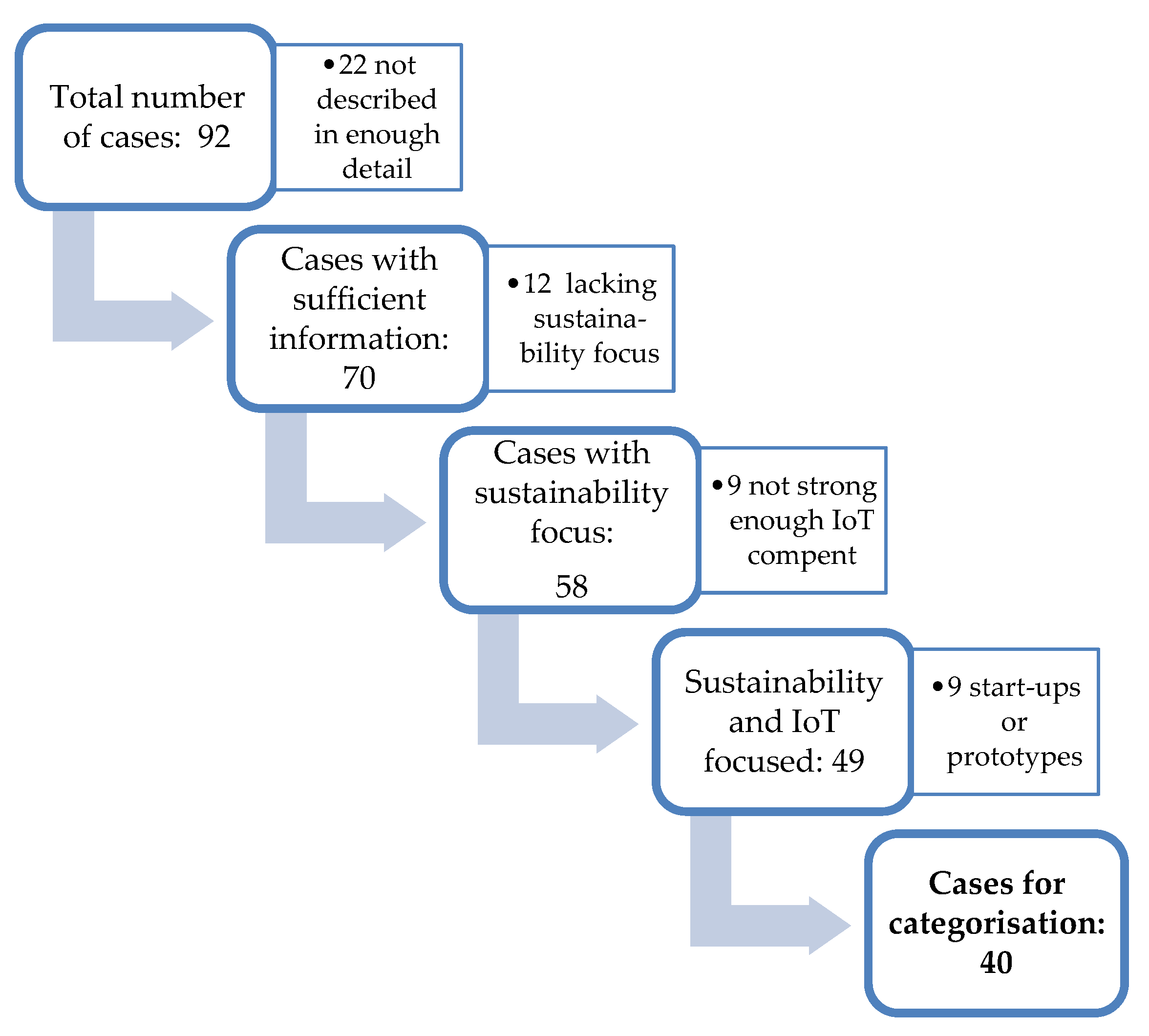

3.3. Selection of Relevant Cases

3.4. Analysis and Mapping of Cases

4. Framework

4.1. IoT Capabilities

4.1.1. Categories in Literature

4.1.2. Categories Selected

4.2. Circular Strategies

4.2.1. Categories in Literature

4.2.2. Categories Selected

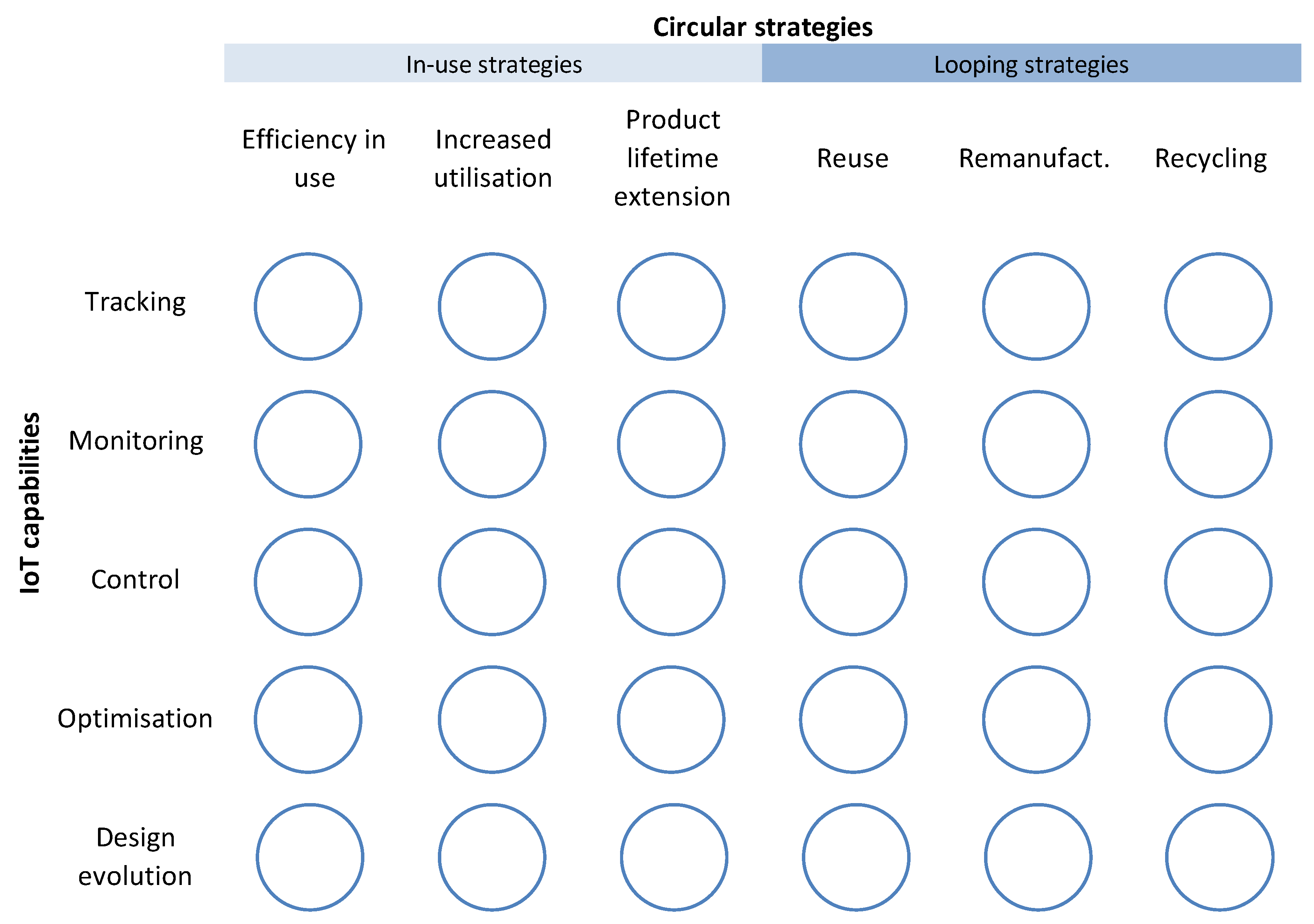

4.3. Final Framework

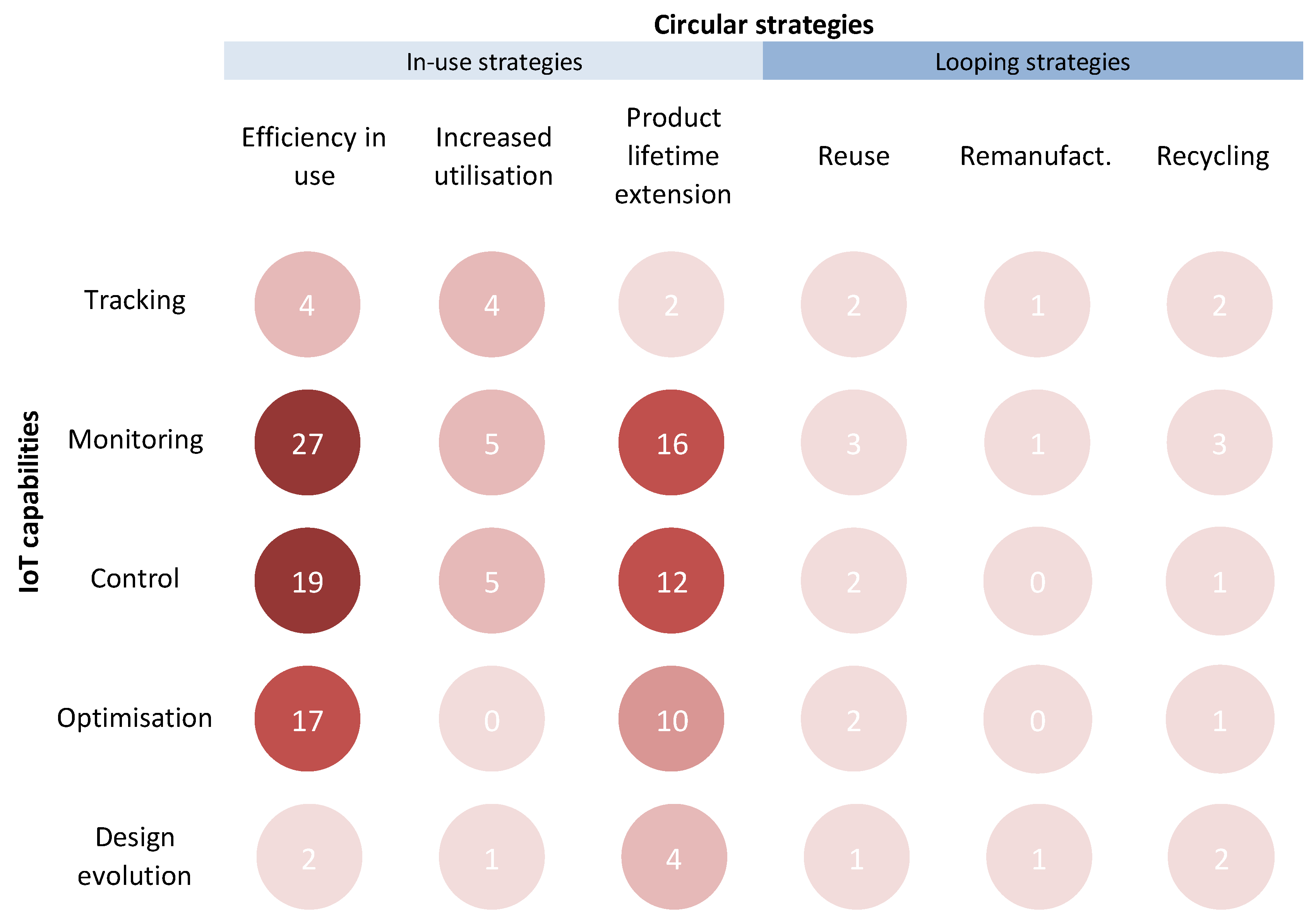

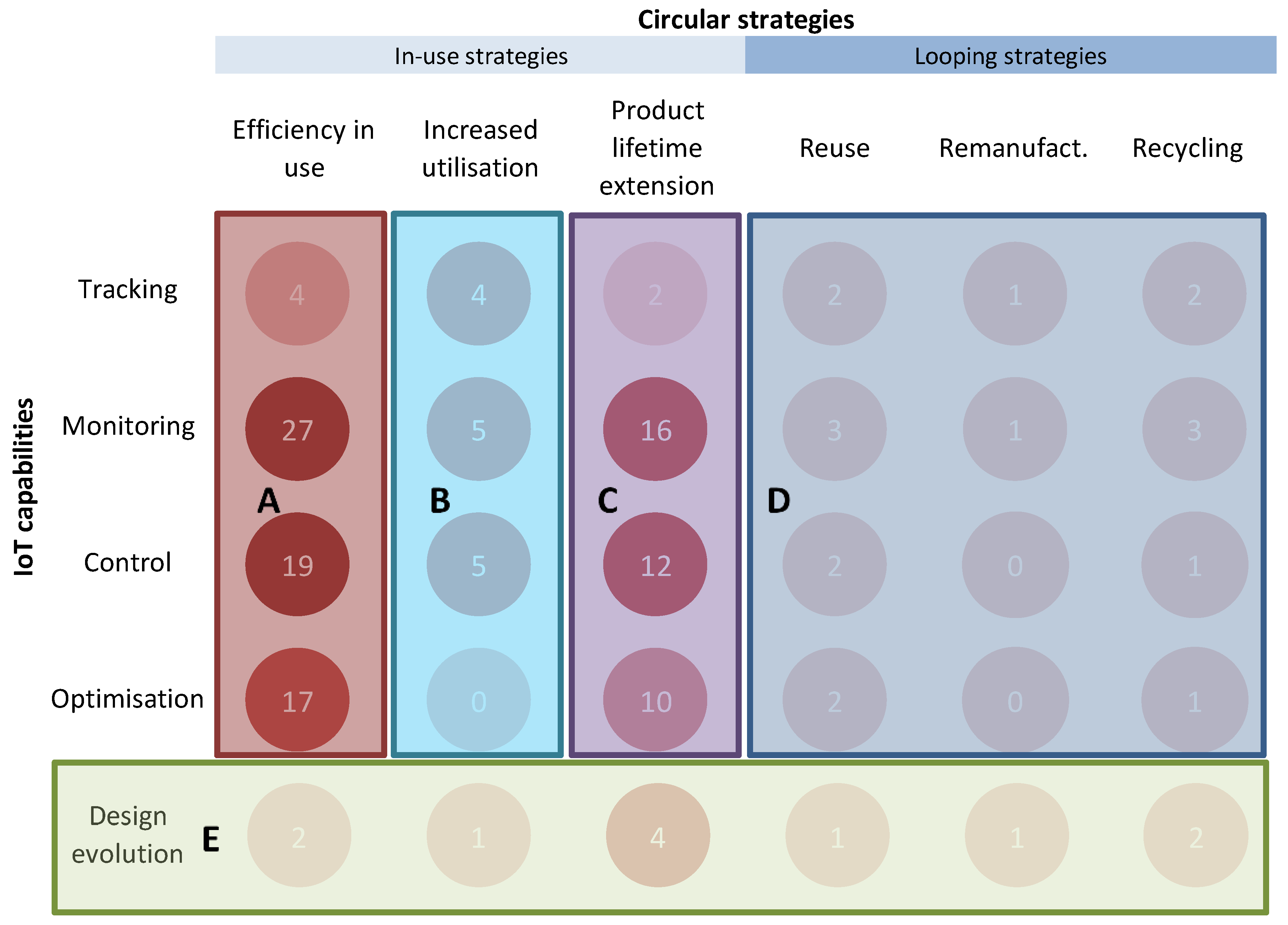

5. Mapping the Cases to the Framework

6. Discussion

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Company | Type of Product or Service | Description | IoT Capability as Categorized | CE Aspect | CE Strategy as Categorized | Primary Source | Additional Source(s) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tracking | Monitoring | Control | Optimization | Design Evo. | Eff. in Use | Inc. utilizat. | Life. ext. | Reuse | Reman | Recycl. | ||||||

| A.O. Smith | Heaters and boilers | Remote fault monitoring [1] | x | Minimize down-time for repairs and reduce lost revenue caused by interruption in hot water delivery [2] | x | [1] Porter and Heppelmann | [2] http://www.aosmithconnect.com/ | |||||||||

| ABB | Electric grid equipment | Conditions monitoring (e.g. temperature changes in transformers), sending alerts to control centre to warn for possible overload conditions [1] | x | x | Prevents overload conditions [1]. | x | [1] Porter and Heppelmann | |||||||||

| AGCO (Agcommand) | Farm machinery | Monitors use, condition and environment to optimize overall farm performance [1]. Automated machine health alerts to identify problems early [2] | x | x | x | Optimize overall farm efficiency [1] improve machine health. [2] | x | x | [1] Porter and Heppelmann | [2] https://www.agcotechnologies.com/products/detail/agcommand/ | ||||||

| Arup | Bridge | Structural health monitoring systems which gives warnings of structural problems, allows targeted inspections/interventions to ensure smooth operations and prolong the bridge’s service life. Approximately 1000 sensors will provide data of the bridge’s condition, enabling predictive maintenance. [1] | x | x | x | Enables predictive maintenance and prolongs the bridge’s service life [1] | x | [1] EMF | https://www.arup.com/projects/q/queensferry-crossing | |||||||

| Auscott Limited | Irrigation | Monitors water flows, on-the-field-sensing, weather data. [1] optimized irrigation application and direct yield or field productivity increases resulting from reduced water wastage [1] The cotton-bale tracking system allows managers to monitor cotton quality variability [1] remote sensing / control systems are employed with irrigation scheduling based on soil moisture data. [2] | x | x | x | x | Reduced water wastage [1] | x | [1] EMF | [2] http://www.auscott.com.au/Farming/default.aspx | ||||||

| Big Ass | Ceiling fans | Fans regulate speed on basis of temperature and humidity [1]. Works with air conditioning system to make them more effective [2] | x | x | By incorporating Big Ass Fans into building automation systems and using controls, energy savings become easy and automatic. [2] | x | [1] Porter and Heppelmann | [2] http://docs.bigassfans.com/ae-files/BAS-Energy-Brochure.pdf | ||||||||

| Car2Go | Car-sharing service | Car sharing based on tracking of the car, and monitoring of the time the user has used the car. The user can unlock the car through the app. | x | x | x | A larger number of people can reach their destination with fewer assets [1] | x | [1] EMF | [2] https://www.car2go.com/US/en/#152741 [3] https://www.car2go.com/US/en/faq/ | |||||||

| Carrier Corporation (Infinity) | HVAC and building control | The control knows to conserve energy while you are not home. [2] | x | x | The Infinity® System bundles efficient performance with precise energy reporting. It can reduce your utility bills and increase your energy savings. [2] | x | [1] Porter and Heppelmann | [2] https://www.carrier.com/residential/en/us/innovation/#infinity | ||||||||

| Cisco | Space management in real estate | Real time occupancy sensing allows for more intense use of building. Provides energy consumption data (e.g. lights, HVAC, blinds). [1] | x | More intense use of the workspace. Energy savings. [1] | x | x | [1] EMF | |||||||||

| Cisco Energy Management (CEM) | Energy management system | Measure and manage energy use (and CO2 emissions) at manufacturing facility [1] | x | Goal of reducing energy consumption by 20%. [1] | x | [1] EMF | ||||||||||

| Current (GE) | Energy management system | Integrates data from the building’s systems and responds in real time [1] | x | x | x | Deliver energy savings and operational efficiency improvements. [2] | x | [1] EMF | [2] https://www.currentbyge.com/offices | |||||||

| Delta Development | Elevators | Conditions monitoring and optimized maintenance. IoT data can help identify products that can be reused in a different setting. [1] | x | x | x | Improved maintenance and reuse. [1] | x | x | [1] EMF | [2] http://www.deltadevelopment.eu/en/sustainability | ||||||

| Diebold | ATM | Status monitoring and analysis. Machine can be serviced remotely [2] or the company deploys a technician who has been given a detailed diagnosis of the problem, a recommended repair process, and, often, the needed parts. Remote updates. [1] | x | x | Fault detection, remote service. Informed repairs. Remote updates. [1] | x | [1] Porter and Heppelmann | [2] http://www.s4growth.com/publications/whitepapers/dieboldwhitepaper.pdf | ||||||||

| DriveNow | Car sharing | Tracks location of cars. User can access the car through the app. Price based on the time the user uses the car. | x | x | x | A larger number of people can reach their destination with fewer assets. [1] | x | [1] EMF [2] Porter and Heppelmann | [3] https://www.drive-now.com/gb/en/london | |||||||

| Enevo | Smart bin | Automatically generated schedules and optimized routes taking into account future fill level projections, truck availability, traffic information, road restrictions, container and content types the vehicle can collect etc. New schedules and routes are planned not only looking at the current situation, but considering the future outlook as well. [2] | x | x | Collections based on Enevo’s smart plans significantly reduces costs, emissions, road wear, vehicle wear, noise pollution, and work hours. [2] | x | [1] EMF | [2] https://www.eiseverywhere.com/ereg/retrieve_upload.php?MTI1NTk1NzFfNzE4MjUzNQ== | ||||||||

| Enlighted | Energy management system | IoT- based energy service system, [1] uses sensor data about energy, occupancy and environment. links to a lighting control system and facilitates integration with third-party building automation and demand response systems. [2] | x | x | Claim it saves their clients 60–70% on lighting and 20–30% on heating/cooling efficiency. [1] | x | [1] EMF | [2] http://www.enlightedinc.com/system-and-solutions/iot-system/energy-manager/ | ||||||||

| GE Aviation (TrueChoice) | Jet engines | Optimize engine performance by identifying discrepancies between expected and actual performance [1]. Remote diagnostics for minimizing maintenance while maximizing fleet efficiency. [3] | x | x | x | Insights from data has resulted in reduced fuel use [1], and it enables efficient maintenance. [3] | x | x | [1] Porter and Heppelmann [2] EMF | [3] https://www.geaviation.com/commercial/truechoice-commercial-services/truechoice-flight-hour | ||||||

| GE Wind power | Wind turbines | Wind turbines that automatically change gear according to wind conditions [1] increases wind farm’s output by up to 10%, taking into account environmental conditions. [3] backed by data driven insights through intelligent monitoring, detection and diagnostic capabilities. Specialized upgrades, repairs, and exchange techniques to ensure superior turbine performance. [2] | x | x | x | More power output (efficiency) [3] and improved maintenance [2] | x | x | [1] EMF | [2] https://www.ge.com/content/dam/gepogep-renewables/global/ee_US/documents/wiwi-services/_WindServiWin_Brochure.pdf [3] https://www.ge.com/renewableenergy/wind-energy/turbine-services/platform-upgrades | ||||||

| HP (Instant ink) | Printing as a service | The printer monitors how it is being used, as well as ink levels in the cartridges. New cartridges are ordered automatically, and the user gets an envelope to send the used one back for recycling. Printer use data helps inform system designs, and future product designs, to improve serviceability, durability [1] | x | x | x | Cartridge recycling [2] | x | x | [1] EMF | [2] http://www.hp.com/hpinfo/globalcitizenship/09gcreport/enviro/reuse/programs.html | ||||||

| Hubway (now Bluebikes) | Bike-sharing | Location tracking, real-time bike and dock availability. User can unlock the bike with the app. Collects and shows information about your number of rides and total miles ridden. [2] | x | x | x | More efficient utilization of products that are used intermittently [1] | x | [1] Porter and Heppelmann | [2] www.bluebikes.com | |||||||

| IBM | Reuse optimization tool | Tracking location and availability. Conditions monitoring. Integrates data about design specifications, components list and materials. Optimization model to support decision about recovery option. Based on these insight, companies can build a CE business case [1] | x | x | x | Optimal reuse option of a product can be made: weather to refurbish, remanufacture or harvest key components, or recycle materials. [1] | x | x | x | [1] EMF | ||||||

| JohnDeere (Farmsight) | Farm machinery, irrigation | Monitors yield per hectare, which can be used to optimize irrigation and the use of fertilizers and pesticides. Optimize overall farm performance. | x | x | x | Reduced water, fertilizer, and pesticide use. [1] | x | [1] Porter and Heppelmann, [2] EMF | [3] http://smartagservices.jd-dealer.co.uk/Services/Smart-FarmSight | |||||||

| Joy Global | Mining equipment | Machines autonomously coordinate with other equipment to improve mining efficiency. Monitoring of performance and faults. Can be controlled from a control centre on the surface. The system can optimize performance across the fleet of equipment in the mine. [1] | x | x | x | Fault detection and predictive service indicators facilitates maintenance. The system can improve mining efficiency. [1] | x | x | [1] Porter and Heppelmann | |||||||

| Libelium | Sensor kit and manage-ment platform for precision agriculture | Monitoring of environmental factors and condition of crops. [1] | x | Reduce the amount of pesticides, fertilizers and water used. [1] | x | [1] EMF | ||||||||||

| Nest | Thermo-stats | Monitors energy use and energy demand on grid, can be remotely controlled, maximizes comfort while minimizing energy consumption [1] | x | x | x | Minimize energy consumption, and energy use during peak demand periods [1] | x | [1] Porter and Heppelmann [2] EMF | ||||||||

| Opower (now Oracle) | Energy data management | Stores and analyzes energy use from smart meters in cloud platform [2] from which energy reports can be written. [1] | x | Incentivizing users to reduce their energy bill. [1] | x | [1] EMF | [2] https://www.oracle.com/se/corporate/acquisitions/opower/index.html | |||||||||

| Philips light-as-a-service | Lighting | Optimizes power consumption based on live data of use patterns. Checks system operations and monitors faults. [1] | x | x | x | Lower power consumption [1]. Manage all maintenance and repair work, optimize the installation’s performance throughout the life of the contract. [2] | x | x | [1] EMF | [2] http://images.philips.com/is/content/PhilipsConsumer/PDFDownloads/Global/Services/ODLI20170905_001-UPD-en_AA-7035_Philips-Managed_Services_Digi_WTO_01_digital-version.pdf | ||||||

| Philips Lighting (CityTouch) | Street lighting | Tracking of products and parts. Monitoring of energy use and environmental factors. Remote control and automatic dimming. Allows managers to optimize asset use time and predictively maintain their system. By increasing the ability to manage heterogeneous use cycles of the different asset components in detail, the model enables the looping of assets or asset components through additional use cycles. [1] | x | x | x | x | Extends the use cycle. Enables looping of components through additional cycles. Increased energy efficiency. [1] | x | x | x | [1] EMF | |||||

| Philips Lighting (Hue) | Lighting | Lightbulbs can be controlled via app [1]. Automatically turns on and off based on monitoring presence and daylight. [2] | x | x | Makes your home "smarter, comfortable and energy efficient". | x | [1] Porter and Heppelmann | [2] http://www2.meethue.com/en-us/about-hue/ | ||||||||

| Rolls-Royce (TotalCare) | Jet engines | Engine conditions monitoring gives insight into how to redesign the engine [1] and how to optimize maintenance [2] | x | x | x | More productive and more durable, long-lasting design [1]. Better planned maintenance and repair. [2] | x | x | [1] EMF | [2] https://www.rolls-royce.com/media/our-stories/discover/2017/totalcare.aspx | ||||||

| Schindler PORT technology | Elevators | Predicting elevator demand patterns, calculating the fastest time to destination, and assigning the appropriate elevator to move passengers quickly. [1] Usage patterns are recorded. The system can learn about passenger needs to optimize flow. If current or forecasted waiting times fall below a defined acceptable value, ECO mode switches the unrequired elevators into standby mode. [2] | x | x | x | More efficient traffic handling means fewer stops and starts, reducing energy demand. Increases traffic handling capacity: Schindler Destination Interface can increase system efficiency by up to 50%. ECO mode allows intelligent reduction of the elevators’ energy consumption. [2] | x | [1] Porter and Heppelmann | [2] https://www.schindler.com/content/us/internet/en/mobility-solutions/products/destination-technology/port-technology/_jcr_content/contentPar/downloadlist_464827542/downloadList/8_1471287019098.download.asset.8_1471287019098/schindler-port-brochure.pdf | |||||||

| Schneider Electric | Building management systems | Gathers data about energy use and other building performance metrics. Uses monitoring and, for some customers, remote control to minimize energy consumption [1] | x | x | x | Minimize energy consumption. [1] | x | [1] Porter and Heppelmann | [2] https://www.schneider-electric.com/en/work/solutions/system/s4/building-systems-smartstruxure/ | |||||||

| Sensity Systems | Lighting control system | Monitors presence of people and automatically adjusts lighting based on that [1] | x | x | Lighting owners are able to reduce energy costs and implement a variety of "Smart City" applications and services. [2] | x | [1] EMF | [2] http://www.verizon.com/about/news/verizon-accelerates-smart-communities-acquisition-sensity-systems | ||||||||

| Spire | Satellite-based data monitoring | Tracking of e.g. trucks, aircrafts and trains. Spire also collects other kinds of data, about for example weather and climate. [1] | x | Enabling lowered fuel consumption from optimal routing. [1] | x | [1] EMF | [2] https://spire.com/data/ | |||||||||

| Sunpower | Solar panels | Monitors energy output and performance. Connects to other devices in the home to optimize the timing of activities in a way that matches power generation from the solar power system. [1] | x | x | x | Improved energy management. [1] | x | [1] EMF | [2] https://us.sunpower.com/business-government/large-commercial/sunpower-commercial/ | |||||||

| Tesla | Electric vehicles | Fault monitoring. Car can schedules repairs autonomously. Remote service and upgrades. Learn from real world performance in design improvements. [1] | x | x | x | Fault detection, service, repairs, and upgrades. [1] | x | [1] Porter and Heppelmann | ||||||||

| TOMRA | Reverse vending machines | Measures material composition and uses decision-making algorithm to separate waste. Can communicate location and load to enable route planning. [1] Notifications if it needs service. [2] | x | x | Precise and efficient recycling. [1] Maintenance of machine. [2] | x | x | x | [1] EMF | [2] https://www.tomra.com/en/collection/reverse-vending/digital | ||||||

| Trane | HVAC | Company as moved from focussing on HVAC equipment production to complete building performance [1]. Mobile platform to control and manage buildings more efficiently, reducing cost and providing a better indoor environment while energy efficiency is maximized. Monitoring of e.g. refrigerant leaks can give remote alarms to control system. [2] | x | x | x | Optimize performance and energy efficiency [2] | x | [1] Porter and Heppelmann | [2] https://www.trane.com/commercial/global/europe/en/controls/building-management-controls.html | |||||||

| Whirlpool | Washing machines | Monitors washing cycles. Remote control through app [3]. Maintenance notifications. Connected to NEST to find optimal time for washing. [2] | x | x | x | Predictive maintenance notification. [3] Connected to NEST to plan washing to save energy and avoid grid-peaks. [2] | x | x | [1] Porter and Heppelmann | [2] https://www.whirlpool.com/home-innovations/connected-appliances.html [3] http://www.whirlpool.co.uk/world-of-whirlpool/connectivity.content.html | ||||||

| Zipcar | Car-sharing service | Vehicle tracking help users find the car when they need it. Vehicle telematics allows Zipcar to monitors driver behaviour and understand how vehicles are being used, ultimately leading to better service availability for members [2]. The cars are unlocked by the user who has reserved it, with mobile application [3]. | x | x | x | x | Real-time access to vehicles when needed. [1] | x | [1] Porter and Heppelmann | [2] http://www.zipcar.be/en/static/privacy [3] http://www.zipcar.be/en/how-it-works | ||||||

References

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: London, UK, 2013. [Google Scholar]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Balkenende, R.; Bocken, N.; Bakker, C. Design for the Circular Economy. In The Routledge Handbook of Sustainable Design; Egenhoefer, R.B., Ed.; Routledge: London, UK, 2017; pp. 1–19. [Google Scholar] [CrossRef]

- Bocken, N.; De Pauw, I.; Bakker, C.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Qu, M.; Yu, S.; Chen, D.; Chu, J.; Tian, B. State-of-the-art of design, evaluation, and operation methodologies in product service systems. Comput. Ind. 2016, 77, 1–14. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy-a review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Manzini, E.; Vezzoli, C. A strategic design approach to develop sustainable product service systems: Examples taken from the ‘environmentally friendly innovation’ Italian prize. J. Clean. Prod. 2003, 11, 851–857. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Whitmore, A.; Agarwal, A.; Da Xu, L. The Internet of Things—A survey of topics and trends. Inf. Syst. Front. 2015, 17, 261–274. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Intelligent Assets: Unlocking the Circular Economy Potential; Ellen MacArthur Foundation: London, UK, 2016. [Google Scholar]

- GESI and Accenture. #SystemTransformation: How Digital Solutions Will Drive Progress towards the Sustainable Development Goals; Global e-Sustainability Initiative (GeSI): Brussels, Belgium, 2016. [Google Scholar]

- Lacy, P. Using digital tech to spin the circular economy. Accenture Outlook. 2015. Available online: https://www.accenture.com/cr-en/insight-outlook-using-digital-tech-spin (accessed on 25 September 2019).

- Ng, I.C.L.; Wakenshaw, S.Y.L. The Internet-of-Things: Review and research directions. Int. J. Res. Mark. 2017, 34, 3–21. [Google Scholar] [CrossRef]

- Stankovic, J.A. Research directions for the internet of things. IEEE Internet Things J. 2014, 1, 3–9. [Google Scholar] [CrossRef]

- Li, S.; Da Xu, L.; Zhao, S. The internet of things: A survey. Inf. Syst. Front. 2015, 17, 243–259. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J.E. How smart, connected products are transforming competition. Harv. Bus. Rev. 2014. Available online: https://hbr.org/2014/11/how-smart-connected-products-are-transforming-competition (accessed on 25 September 2019).

- Kortuem, G.; Kawsar, F.; Fitton, D.; Sundramoorthy, V. Smart objects as building blocks for the internet of things. IEEE Internet Comput. 2010, 14, 44–51. [Google Scholar] [CrossRef]

- Baines, T.; Lightfoot, H. Information and Communication Technologies. In Made to Serve: How Manufacturers Can Compete through Servitization and Product-Service Systems; Baines, T., Lightfoot, H., Eds.; John Wiley & Sons Incorporated: Chichester, UK, 2013; pp. 169–180. [Google Scholar] [CrossRef]

- Alcayaga, A.; Wiener, M.; Hansen, E.G. Towards a Framework of Smart-Circular Systems: An Integrative Literature Review. J. Clean. Prod. 2019, 221, 622–634. [Google Scholar] [CrossRef]

- Nobre, G.C.; Tavares, E. Scientific literature analysis on big data and internet of things applications on circular economy: A bibliometric study. Scientometrics 2017, 111, 463–492. [Google Scholar] [CrossRef]

- Tseng, M.L.; Tan, R.R.; Chiu, A.S.F.; Chien, C.F.; Kuo, T.C. Circular economy meets industry 4.0: Can big data drive industrial symbiosis? Resour. Conserv. Recycl. 2018, 131, 146–147. [Google Scholar] [CrossRef]

- Okorie, O.; Salonitis, K.; Charnley, F.; Moreno, M.; Turner, C.; Tiwari, A. Digitisation and the Circular Economy: A Review of Current Research and Future Trends. Energies 2018, 11, 3009. [Google Scholar] [CrossRef]

- Pagoropoulos, A.; Pigosso, D.C.A.; McAloone, T.C. The Emergent Role of Digital Technologies in the Circular Economy: A Review. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef]

- Salminen, V.; Ruohomaa, H.; Kantola, J. Digitalization and Big Data Supporting Responsible Business Co-Evolution. In Advances in Human Factors, Business Management, Training and Education; Kantola, J.I., Barath, T., Nazir, S., Andre, T., Eds.; Springer International Publishing: Switzerland, 2017; pp. 1055–1067. [Google Scholar] [CrossRef]

- Spring, M.; Araujo, L. Product biographies in servitization and the circular economy. Ind. Mark. Manag. 2017, 60, 126–137. [Google Scholar] [CrossRef]

- Jensen, J.P.; Remmen, A. Enabling Circular Economy Through Product Stewardship. Procedia Manuf. 2017, 8, 377–384. [Google Scholar] [CrossRef]

- Roy, R.; Stark, R.; Tracht, K.; Takata, S.; Mori, M. Continuous maintenance and the future–Foundations and technological challenges. Cirp Ann. Manuf. Technol. 2016, 65, 667–688. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Gligoric, N.; Krco, S.; Hakola, L.; Vehmas, K.; De, S.; Moessner, K.; Jansson, K.; Polenz, I.; Van Kranenburg, R. SmartTags: IoT Product Passport for Circular Economy Based on Printed Sensors and Unique Item-Level Identifiers. Sensors 2019, 19, 586. [Google Scholar] [CrossRef] [PubMed]

- Lightfoot, H.W.; Baines, T.; Smart, P. Examining the information and communication technologies enabling servitized manufacture. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1964–1968. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lleshaj, A.; Lombardi, M.; Sciarretta, N.; Di Gravio, G. A BIM-based PSS approach for the management of maintenance operations of building equipment. Buildings 2019, 9, 139. [Google Scholar] [CrossRef]

- Grubic, T.; Jennions, I. Remote monitoring technology and servitised strategies–factors characterising the organisational application. Int. J. Prod. Res. 2018, 56, 2133–2149. [Google Scholar] [CrossRef]

- Ardolino, M.; Saccani, N.; Gaiardelli, P.; Rapaccini, M. Exploring the Key Enabling Role of Digital Technologies for PSS Offerings. Procedia CIRP 2016, 47, 561–566. [Google Scholar] [CrossRef]

- Ardolino, M.; Rapaccini, M.; Saccani, N.; Gaiardelli, P.; Crespi, G.; Ruggeri, C. The role of digital technologies for the service transformation of industrial companies. Int. J. Prod. Res. 2018, 56, 2116–2132. [Google Scholar] [CrossRef]

- Lindström, J.; Hermanson, A.; Hellis, M.; Kyösti, P. Optimizing Recycling Management Using Industrial Internet Supporting Circular Economy: A Case Study of an Emerging IPS 2. Procedia CIRP 2017, 64, 55–60. [Google Scholar] [CrossRef]

- Kiritsis, D. Closed-loop PLM for intelligent products in the era of the Internet of things. Comput. Aided Des. 2011, 43, 479–501. [Google Scholar] [CrossRef]

- Moreno, M.; Turner, C.; Tiwari, A.; Hutabarat, W.; Charnley, F.; Widjaja, D.; Mondini, L. Re-distributed Manufacturing to Achieve a Circular Economy: A Case Study Utilizing IDEF0 Modeling. Procedia CIRP 2017, 63, 686–691. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Mays, N.; Roberts, E.; Popay, J. Synthesising research evidence. In Studying the Organisation and Delivery of Health Services: Research Methods; Fulop, N., Allen, P., Clarke, A., Black, N., Eds.; Routledge: London, UK, 2001; pp. 188–220. [Google Scholar]

- Grubic, T. Servitization and remote monitoring technology: A literature review and research agenda. J. Manuf. Technol. Manag. 2014, 25, 100–124. [Google Scholar] [CrossRef]

- Porter, M.E. How smart, connected products are transforming companies. Harv. Bus. Rev. 2015. Available online: https://hbr.org/2015/10/how-smart-connected-products-are-transforming-companies (accessed on 25 September 2019).

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Futur. Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. Understanding the Internet of Things: Definition, potentials, and societal role of a fast evolving paradigm. Ad Hoc Netw. 2016, 56, 122–140. [Google Scholar] [CrossRef]

- Xia, M.; Li, T.; Zhang, Y.; De Silva, C.W. Closed-loop design evolution of engineering system using condition monitoring through internet of things and cloud computing. Comput. Netw. 2016, 101, 5–18. [Google Scholar] [CrossRef]

- Bogers, S.; Frens, J.; Van Kollenburg, J.; Deckers, E.; Hummels, C. Connected Baby Bottle: A Design Case Study Towards A Framework for Data-Enabled Design. In Proceedings of the 2016 ACM Conference on Designing Interactive Systems, Brisbane, QLD, Australia, 4–8 June 2016; pp. 301–311. [Google Scholar] [CrossRef]

- Atterer, R.; Wnuk, M.; Schmidt, A. Knowing the user’s every move: User activity tracking for website usability evaluation and implicit interaction. In Proceedings of the 15th International Conference on World Wide Web, Edinburgh, Scotland, UK, 23–26 May 2006; pp. 203–212. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.; Hultink, E.J. Review: The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W.; Bollinger, A. Cradle-to-cradle design: Creating healthy emissions-a strategy for eco-effective product and system design. J. Clean. Prod. 2007, 15, 1337–1348. [Google Scholar] [CrossRef]

- Tukker, A. Eight types of product-service system: Eight ways to sustainability? Experiences from suspronet. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Den Hollander, M.; Bakker, C.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Bakker, C.; Wang, F.; Huisman, J.; den Hollander, M. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Moreno, M.; de los Rios, C.; Rowe, Z.; Charnley, F. A conceptual framework for circular design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

| Source | IoT Capability Described | Categories of IoT Capabilities | ||||||

|---|---|---|---|---|---|---|---|---|

| Tracking | Monitoring | Control | Optimization | Design Evolution | Autonomy | Processing/Networking/Communication | ||

| Porter and Heppelman [16] | Monitoring | x | ||||||

| Control | x | |||||||

| Optimization | x | |||||||

| Autonomy | x | |||||||

| Grubic [40] | Diagnostic | x | ||||||

| Prognostic | x | |||||||

| Feedback to R&D | x | |||||||

| Lightfoot et al. [30] | Visibility of condition, operating characteristics, time in use | x | ||||||

| Visibility of location | x | |||||||

| Feedback from the use phase to product and service design | x | |||||||

| Kortuem et al. [17] | Sensing | x | ||||||

| Processing | x | |||||||

| Networking | x | |||||||

| Whitemore et al. [9] | Identifying, Tracking and Tracing | x | ||||||

| Sensing, Monitoring | x | |||||||

| Networking | x | |||||||

| Processing | x | |||||||

| Control | x | |||||||

| Data-supported decision making | x | |||||||

| Development of new business models | x | |||||||

| Gubbi et al. [42] | Automatic identification | x | ||||||

| Monitoring | x | |||||||

| Actuation | x | |||||||

| Automated decision making | x | x | ||||||

| User interaction and communication | x | |||||||

| Atzori et al. [8] | Identification | x | ||||||

| Sensing | x | |||||||

| Communication | x | |||||||

| Atzori et al. [43] | Readable, recognizable, locatable, addressable | x | ||||||

| Controllable | x | |||||||

| Embedded sensors and actuators | x | x | ||||||

| Self-governance and self-management | x | |||||||

| Xia et al. [44] | Closed-loop design evolution | x | ||||||

| Condition monitoring | x | |||||||

| IoT Capability | Definition as Used in this Paper |

|---|---|

| Tracking | Information is available about a product’s identity, location, or unique composition. |

| Monitoring | Information is available about a product’s use, condition, or environment. This includes alerts and notifications. |

| Control | Product functionality can be controlled through software, based on predefined options. This includes pushing regular updates. |

| Optimization | Goal-based improvements of operations are supported by using advanced algorithms. |

| Design Evolution | The design of a product or service can be improved based on data feedback from other lifecycle phases. This includes functional upgrades as well as the development of new products and services. |

| Source | CE Strategy Described | Categories of CE Strategies | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Efficiency in Use | Increased Utilization | Product Lifetime Extension | Reuse | Remanufacturing | Recycling | Material Efficiency | Systems Change | ||

| Ellen MacArthur foundation [1] | Share | x | |||||||

| Maintain/prolong | x | ||||||||

| Reuse/redistribute | x | ||||||||

| Refurbish/remanufacture | x | ||||||||

| Recycle | x | ||||||||

| Bocken et al. [4] | Long-life products | x | |||||||

| Product life extension | x | x | |||||||

| Closing resource flows | x | ||||||||

| Bakker et al. [52] | Material efficiency | x | |||||||

| Longer product life | x | ||||||||

| Product repair | x | ||||||||

| Product refurbishment | x | x | |||||||

| Product remanufacturing | x | ||||||||

| Product/material recycling | x | ||||||||

| Balkenendet al. [3] | Durability | x | |||||||

| Upgrading | x | ||||||||

| Adapting | x | ||||||||

| Repair | x | ||||||||

| Refurbishment | x | x | |||||||

| Parts harvesting | x | x | |||||||

| Remanufacturing | x | ||||||||

| Recycling | x | ||||||||

| Moreno et al. [53] | Design for resource conservation | x | x | ||||||

| Design for multiple cycles | x | x | |||||||

| Design for long life use of products | x | x | |||||||

| Design for systems change | x | ||||||||

| den Hollander et al. [51] | Design for long use | x | |||||||

| Design for extended use | x | ||||||||

| Design for recovery | x | ||||||||

| Design for recycling | x | ||||||||

| Circular Strategy | Definition as Used in this Paper |

|---|---|

| Efficiency in use | Energy, water, and other inputs are used more efficiently during a product’s use phase. |

| Increased utilization | Time periods during which a product is not used by anyone are identified and reduced. |

| Product lifetime extension | A product’s lifetime is extended by minimizing wear, through predictive, preventive or reactive maintenance and repair, or through updates. |

| Reuse | A product or component is identified, assessed and transferred from one user to another. The process can involve maintenance steps, such as cleaning. |

| Remanufacturing | A product is inspected and treated to restore its original functionality, as a preparation for the next use cycle. The process can include reparations and replacements of worn parts. |

| Recycling | The constituent materials of a product or component are assessed, sorted, and treated so that they can be used again. |

| IoT Capability | Examples of use of IoT Capability for ‘Efficiency in Use’ |

|---|---|

| Tracking |

|

| Monitoring |

|

| Control |

|

| Optimization |

|

| IoT Capability | Examples of Use of IoT Capability for ‘Increased Utilization’ |

|---|---|

| Tracking |

|

| Monitoring |

|

| Control |

|

| IoT Capability | Examples of Use of IoT Capability for ‘Product Lifetime Extension’ |

|---|---|

| Tracking |

|

| Monitoring |

|

| Control |

|

| Optimization |

|

| IoT Capability | Examples of Use of IoT Capability for ‘Looping’ |

|---|---|

| Tracking |

|

| Monitoring |

|

| Control |

|

| Optimization |

|

| CE Strategy | Example of Use of ‘Design Evolution’ for Circular Strategy |

|---|---|

| Efficiency in use |

|

| Increased utilization |

|

| Product lifetime extension |

|

| Looping |

|

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ingemarsdotter, E.; Jamsin, E.; Kortuem, G.; Balkenende, R. Circular Strategies Enabled by the Internet of Things—A Framework and Analysis of Current Practice. Sustainability 2019, 11, 5689. https://doi.org/10.3390/su11205689

Ingemarsdotter E, Jamsin E, Kortuem G, Balkenende R. Circular Strategies Enabled by the Internet of Things—A Framework and Analysis of Current Practice. Sustainability. 2019; 11(20):5689. https://doi.org/10.3390/su11205689

Chicago/Turabian StyleIngemarsdotter, Emilia, Ella Jamsin, Gerd Kortuem, and Ruud Balkenende. 2019. "Circular Strategies Enabled by the Internet of Things—A Framework and Analysis of Current Practice" Sustainability 11, no. 20: 5689. https://doi.org/10.3390/su11205689

APA StyleIngemarsdotter, E., Jamsin, E., Kortuem, G., & Balkenende, R. (2019). Circular Strategies Enabled by the Internet of Things—A Framework and Analysis of Current Practice. Sustainability, 11(20), 5689. https://doi.org/10.3390/su11205689