Can Hydropower Still Be Considered a Clean Energy Source? Compelling Evidence from a Middle-Sized Hydropower Station in China

Abstract

1. Introduction

2. Materials and Methods

2.1. Methods to Calculate GHG Emissions Amount

2.2. Background

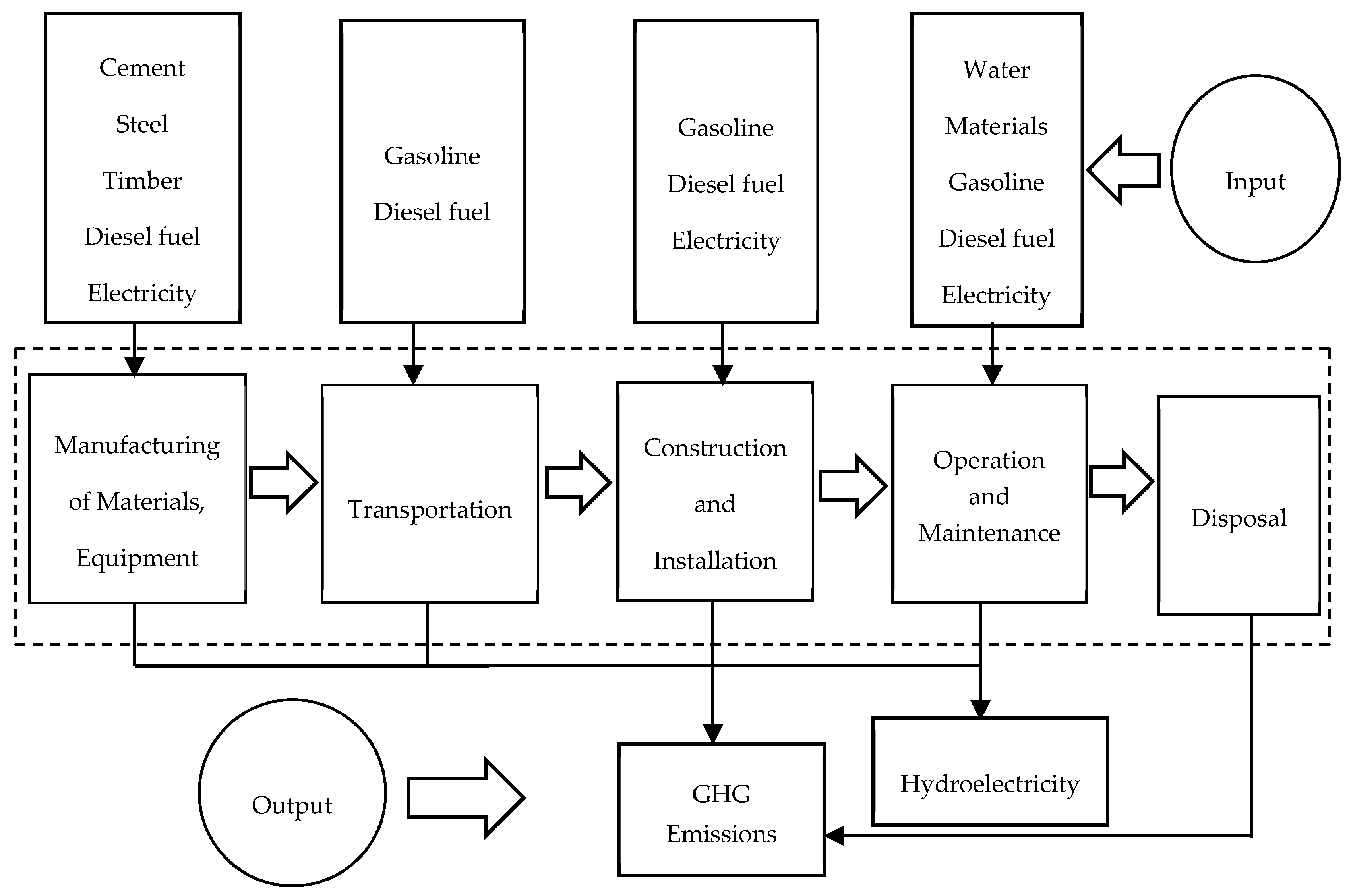

2.3. System Boundaries

2.4. Inventory Analysis

2.4.1. Manufacturing of Materials and Equipment

2.4.2. Transportation

2.4.3. Construction and Installation

2.4.4. Operation and Maintenance Stage

2.4.5. Disposal

2.5. Data Sources

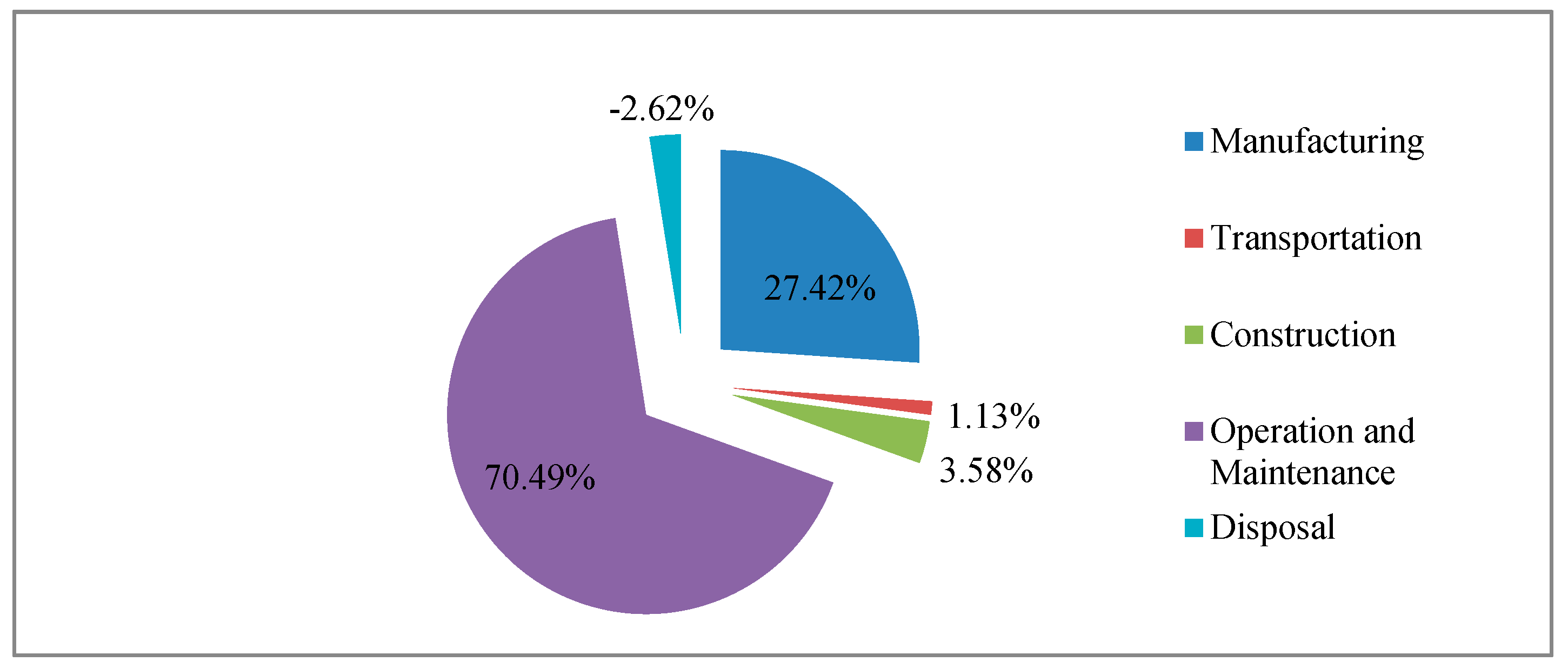

3. Results

4. Discussion

4.1. Sensitivity Analysis

4.2. Uncertainty

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, H.; Yan, Z. Present situation and future prospect of hydropower in China. Renew. Sustain. Energy Rev. 2009, 6, 1652–1656. [Google Scholar] [CrossRef]

- Marín, C.E.; Marín, R.G.; Guerrero, A.E.A. The resurgence of small hydropower in Spain and its current situation. Rev. Geogr. Norte Gd. 2017, 67, 115–143. [Google Scholar]

- Dai, H.C.; Mao, J.Q.; Zheng, T.G. Assessment of greenhouse gas emissions from a large subtropical reservoir in China. J. Environ. Prot. Ecol. 2013, 2, 430–437. [Google Scholar]

- Giles, J. Methane quashes green credentials of hydropower. Nature 2006, 444, 1026. [Google Scholar] [CrossRef] [PubMed]

- Sorensen, E.; Harrison, J. Reservoirs are Underappreciated Source of Greenhouse Gases [EB/ON]. Available online: https://news.wsu.edu/2016/09/28/reservoirs-play-substantial-role-global-warming/ (accessed on 13 June 2018).

- Varun, B.I.K.; Prakash, R. LCA of renewable energy for electricity generation systems—A review. Renew. Sustain. Energy Rev. 2009, 5, 1067–1073. [Google Scholar] [CrossRef]

- Raadal, H.L.; Gagnon, L.; Modahl, I.S.; Hanssen, O.J. Life cycle greenhouse gas emissions from the generation of wind and hydro-power. Renew. Sustain. Energy Rev. 2011, 7, 3417–3422. [Google Scholar] [CrossRef]

- Dolan, S.L.; Heath, G.A. Life cycle greenhouse gas emissions of utility-scale wind power: Systematic review and harmonization. J. Ind. Ecol. 2012, S1, S136–S154. [Google Scholar] [CrossRef]

- Whitaker, M.; Heath, G.A.; Donoughue, P.O.; Vorum, M. Life cycle greenhouse gas emissions of coal-fired electricity generation: Systematic review and harmonization. J. Ind. Ecol. 2012, S1, S53–S72. [Google Scholar] [CrossRef]

- Turconi, R.; Boldrin, A.; Astrup, T. Life cycle assessment (LCA) of electricity generation technologies: Overview, comparability and limitations. Renew. Sustain. Energy Rev. 2013, 28, 555–565. [Google Scholar] [CrossRef]

- Arvesen, A.; Nes, R.N.; Hertwich, E.G.; Huertas-Hernando, D. Life cycle assessment of an offshore grid interconnecting wind farms and customers across the North Sea. Int. J. Life Cycle Assess. 2014, 4, 826–837. [Google Scholar] [CrossRef]

- Fu, Y.Y.; Liu, X.; Yuan, Z.W. Life-cycle assessment of multi-crystalline photovoltaic systems in China. J. Clean. Prod. 2015, 86, 180–190. [Google Scholar] [CrossRef]

- Gagnon, L.; Belanger, C.; Uchiyama, Y. Life-cycle assessment of electricity generation options: The status of research in year 2001. Energy Policy 2002, 14, 1267–1278. [Google Scholar] [CrossRef]

- Gagnon, L.; Vate, J.F.V. Greenhouse gas emissions from hydropower: The state of research in 1996. Energy Policy 1997, 1, 7–13. [Google Scholar] [CrossRef]

- Pang, M.; Zhang, L.; Wang, C.; Liu, G. Environmental life cycle assessment of a small hydropower plant in China. Int. J. Life Cycle Assess. 2015, 6, 796–806. [Google Scholar] [CrossRef]

- Varun, P.R.; Bhat, I.K. Life cycle greenhouse gas emissions estimation for small hydropower schemes in India. Energy 2012, 1, 498–508. [Google Scholar] [CrossRef]

- Hanafi, J.; Riman, A. Life cycle assessment of a mini hydro power plant in Indonesia: A case study in Karai River. Procedia Cirp 2015, 29, 444–449. [Google Scholar] [CrossRef]

- Kadiyala, A.; Kommalapati, R.; Huque, Z. Evaluation of the life cycle greenhouse gas emissions from hydroelectricity generation systems. Sustainability 2016, 6, 539. [Google Scholar] [CrossRef]

- Pascale, A.; Urmee, T.; Moore, A. Life cycle assessment of a community hydroelectric power system in rural Thailand. Renew. Energy 2011, 11, 2799–2808. [Google Scholar] [CrossRef]

- Jungbluth, N.; Büsser, S.; Frischknecht, R.; Flury, K.; Stucki, M. Feasibility of environmental product information based on life cycle thinking and recommendations for Switzerland. J. Clean. Prod. 2012, 4, 187–197. [Google Scholar] [CrossRef]

- Duchemin, E.; Lucotte, M.; Canuel, R.; Chamberland, A. Production of the greenhouse gases CH4 and CO2 by hydroelectric reservoirs of boreal region. Glob. Biogeochem. Cycles 1995, 9, 529–540. [Google Scholar] [CrossRef]

- Abril, G.; Guérin, F.; Richard, S.; Delmas, R.; Galy-Lacaux, C.; Gosse, P.; Tremblay, A.; Varfalvy, L.; Santos, M.A.D.; Matvienko, B. Carbon dioxide and methane emissions and the carbon budget of a 10-year old tropical reservoir. Glob. Biogeochem. Cycles 2005, 19, 1–16. [Google Scholar] [CrossRef]

- Guérin, F.; Abril, G.; Richard, S.; Burban, B.; Reynouard, C.; Seyler, P.; Delmas, R. Methane and carbon dioxide emissions from tropical reservoirs: Significance of downstream rivers. Geophys. Res. Lett. 2006, 33, L21407. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). National Greenhouse Gas List Guide in 2006. Beijing: National Greenhouse Gas Inventory Program Group; IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- Gong, X.; Li, H.Y.; Liao, W.G. Calculation of greenhouse gas emission of reservoir based on life cycle. Water Power 2012, 10, 8–12. (In Chinese) [Google Scholar]

- Development Report of China’s Hydropower Industry: Current Status of Hydropower Development in China in 2017. Available online: http://news.bjx.com.cn/html/20180207/879489.shtml (accessed on 23 May 2018).

- Wang, Q.; Zhang, X. Model energy improvement of inventory analysis on upstream phase-Based on life cycle assessment. J. Tongji Univ. (Nat. Sci.) 2009, 4, 520–524. (In Chinese) [Google Scholar]

- Yang, Q.M. Quantificational Life Cycle Assessment of Environmental Impact of Construction Productions. Ph.D. Thesis, Tianjin University, Tianjin, China, 2009. (In Chinese). [Google Scholar]

- Zhao, X.J.; Zhao, T.Q.; Zhen, H. Greenhouse gas emission from reservoir and its influence factors. Environ. Sci. 2008, 8, 2377–2384. [Google Scholar]

- Tremblay, A.; Varfalvy, L.; Roehm, C.; Garneau, M. Greenhouse Gas Emissions—Fluxes and Processes; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Zhang, W.J.; Xiao, H.A.; Tong, C.L.; Su, Y.; Xiang, W.; Huang, D.; Syers, J.K.; Wu, J. Estimating organic carbon storage in temperate wetland profiles in Northeast China. Geoderma 2008, 146, 311–316. [Google Scholar] [CrossRef]

- Lin, M. Greenhouse Gas Fluxes on the Water-Air Interface of Poyang Lake. Master’s Thesis, Beijing Forestry University, Beijing, China, 2012. (In Chinese). [Google Scholar]

- Ardente, F.; Beccali, M.; Cellura, M.; Brano, V.L. Energy performances and life cycle assessment of an Italian wind farm. Renew. Sustain. Energy Rev. 2008, 1, 200–217. [Google Scholar] [CrossRef]

- Wang, C.B.; Zhang, L.X.; Yang, S.Y.; Pang, M.Y. A hybrid life-cycle assessment of nonrenewable energy and greenhouse-gas emissions of a village-level biomass gasification project in China. Energies 2012, 5, 2708–2723. [Google Scholar] [CrossRef]

- Cao, L.; Diana, J.S.; Keoleian, G.A.; Lai, Q.M. Life cycle assessment of Chinese Shrimp Farming Systems Targeted for export and domestic sales. Environ. Sci. Technol. 2011, 15, 6531–6538. [Google Scholar] [CrossRef]

- Yu, D.C. China Electric Power-Yearbook; China Electric Power Press: Beijing, China, 2018. [Google Scholar]

- Wang, Y.H. The China Energy Statistical Yearbook; China Statistics Press: Beijing, China, 2017. Available online: http://www.stats.gov.cn/tjsj/tjcbw/201806/t20180612_1604117.html (accessed on 5 August 2019).

- Zhang, Q.F.; Karney, B.; MacLean, H.L.; Feng, J.C. Life cycle inventory of energy use and greenhouse gas emissions for two hydropower projects in China. J. Infra. Syst. 2007, 13, 271–279. [Google Scholar] [CrossRef]

- Operation of China’s Electric Power Industry in 2018. Available online: http://www.chyxx.com/industry/201901/710861.html (accessed on 12 February 2019).

| Power Generation Technologies | Thermal Power | Hydropower | Wind Power | Solar Power | Nuclear Power | Total Installed Capacity |

|---|---|---|---|---|---|---|

| Installed capacity | 1143.67 | 352.26 | 184.26 | 174.63 | 44.66 | 1899.67 |

| Proportion | 60.21% | 18.54% | 9.70% | 9.20% | 2.35% | 100.00% |

| Engineering Materials | Quantity |

|---|---|

| Earth-Rock Excavation | 3.90 × 106 m3 |

| Earthwork Landfill | 2.67 × 106 m3 |

| Concrete Casting | 1.19 × 106 m3 |

| Metal Structure Installation | 3.87 × 104 m3 |

| Cement | 3.27 × 105 t |

| Steel | 4.31 × 104 t |

| Diesel Fuel | 1.32 × 104 t |

| Explosive | 1.20 × 103 t |

| Process | Unit Product | Main GHG Emissions | ||

|---|---|---|---|---|

| CO2 | CH4 | N2O | ||

| Produce | 1 kWh electricity | 8.92 × 10−4 | 6.52 × 10−9 | 8.82 × 10−9 |

| 1 kg diesel fuel | 6.53 × 10−4 | 1.24 × 10−8 | 6.41 × 10−9 | |

| Use | 1 kWh electricity | 6.24 × 10−6 | 4.56 × 10−10 | 6.17 × 10−10 |

| 1 kg diesel fuel | 3.10 × 10−3 | 1.18 × 10−7 | — | |

| Total | 1 kWh electricity | 9.54 × 10−4 | 6.98 × 10−9 | 9.44 × 10−9 |

| 1 kg diesel fuel | 3.75 × 10−3 | 1.30 × 10−7 | 6.41 × 10−9 | |

| Unit Materials | Main GHG Emissions | ||

|---|---|---|---|

| CO2 | CH4 | N2O | |

| 1 t Lime | 4.58 × 10−4 | 2.01 × 10−3 | 3.17 × 10−6 |

| 1 t Cement | 5.74 × 10−1 | 2.10 × 10−3 | 3.30 × 10−6 |

| 1 m3 Natural Aggregate Concrete | 3.52 × 10−1 | 4.60 × 10−4 | 7.23 × 10−7 |

| 1 m3 Normal concrete block | 1.46 × 10−5 | 4.28 × 10−4 | 7.57 × 10−7 |

| 1 m3 Steel | 8.20 | 1.80 × 10−4 | — |

| GHG Emissions | |||

|---|---|---|---|

| CO2 | CH4 | N2O | |

| Diesel emissions coefficient | 3.16 | 1.28 × 10−4 | 2.56 × 10−5 |

| Season | GHG Emissions (g/m2•d) | ||

|---|---|---|---|

| CO2 (A) | CH4 (B) | N2O (C) | |

| Spring (Q1) | 3.97 × 10−1 | 6.00 × 10−3 | 6.85 × 10−5 |

| Summer (Q2) | 5.11 × 10−1 | 1.23 × 10−2 | 9.29 × 10−5 |

| Autumn (Q3) | 3.82 × 10−1 | 6.96 × 10−3 | 3.60 × 10−5 |

| Winter (Q4) | 1.75 × 10−2 | 1.68 × 10−3 | 5.40 × 10−5 |

| Each day [Qd = (Q1 + Q2 + Q3 + Q4/)4] | 3.28 × 10−1 | 6.75 × 10−3 | 6.30 × 10−5 |

| Stages | GHG Emissions | Subtotal CO2eq D = 1 + B*21 + C*310 | Percentage | |||

|---|---|---|---|---|---|---|

| CO2 (A) | CH4 (B) | N2O (C) | ||||

| Materials Manufacturing | 9.77 × 10+5 | 2.01 × 10+3 | 2.10 | 1.02 × 10+6 | 27.42% | |

| Materials Transportation | 4.17 × 10+4 | 1.69 | 3.38 × 10−1 | 4.19 × 10+4 | 1.13% | |

| Construction | 1.33 × 10+5 | 2.33 | 9.14 × 10−1 | 1.33 × 10+5 | 3.58% | |

| Operation and Maintenance | Station Operation | 4.96 × 10+5 | 4.14 | 4.75 | 4.96 × 10+5 | 70.49% |

| Reservoir Inundation | 1.43 × 10+6 | 2.94 × 10+4 | 2.74 × 10+2 | 2.13 × 10+6 | ||

| Disposal | −9.33 × 10+4 | −2.05 × 10+2 | — | −9.76 × 10+4 | −2.62% | |

| Total | 2.98 × 10+6 | 3.12 × 10+4 | 2.82 × 10+2 | 3.72 × 10+6 | 100.00% | |

| Input | Amount (t, kWh) | Variation (%) | GHG Emissions | Sub-Total | Proportion | ||

|---|---|---|---|---|---|---|---|

| CO2 | CH4 | N2O | |||||

| Cement | 3.27 × 10+5 | −5 | −9.37 × 10+3 | −3.43 × 10+1 | −5.39 × 10−2 | −1.01 × 10+4 | −0.275% |

| −10 | −1.87 × 10+4 | −6.86 × 10+1 | −1.08 × 10−1 | −2.02 × 10+4 | −0.530% | ||

| Steel | 4.31 × 10+4 | −5 | −1.77 × 10+4 | −3.88 × 10+1 | — | −1.85 × 10+4 | −0.503% |

| −10 | −3.53 × 10+4 | −7.76 × 10+1 | — | −3.70 × 10+4 | −1.060% | ||

| Electricity | 6.00 × 10+7 | −5 | −2.85 × 10+3 | −4.40 × 10−1 | −5.90 × 10−1 | −3.04 × 10+3 | −0.083% |

| −10 | −5.70 × 10+3 | −8.80 × 10−1 | −1.18 | −6.08 × 10+3 | −0.166% | ||

| Diesel fuel | 1.32 × 10+4 | −5 | −2.48 × 10+3 | −8.58 × 10−2 | −4.23 × 10−3 | −2.48 × 10+3 | −0.068% |

| −10 | −4.95 × 10+3 | −1.72 × 10−1 | −8.46 × 10−3 | −4.96 × 10+3 | −0.136% | ||

| Total | — | −5 | −3.24 × 10+4 | −7.36 × 10+1 | −6.48 × 10−1 | −3.41 × 10+4 | −0.929% |

| −10 | −6.47 × 10+4 | −1.47 × 10+2 | −1.30 | −6.82 × 10+4 | −1.854% | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Gui, F.; Li, Q. Can Hydropower Still Be Considered a Clean Energy Source? Compelling Evidence from a Middle-Sized Hydropower Station in China. Sustainability 2019, 11, 4261. https://doi.org/10.3390/su11164261

Li X, Gui F, Li Q. Can Hydropower Still Be Considered a Clean Energy Source? Compelling Evidence from a Middle-Sized Hydropower Station in China. Sustainability. 2019; 11(16):4261. https://doi.org/10.3390/su11164261

Chicago/Turabian StyleLi, Xuerong, Faliang Gui, and Qingpeng Li. 2019. "Can Hydropower Still Be Considered a Clean Energy Source? Compelling Evidence from a Middle-Sized Hydropower Station in China" Sustainability 11, no. 16: 4261. https://doi.org/10.3390/su11164261

APA StyleLi, X., Gui, F., & Li, Q. (2019). Can Hydropower Still Be Considered a Clean Energy Source? Compelling Evidence from a Middle-Sized Hydropower Station in China. Sustainability, 11(16), 4261. https://doi.org/10.3390/su11164261