2.1. Sustainabilty Development Goals

The Sustainable Development Goals (SDGs) address the global challenges, including poverty, inequality, climate, environmental degradation, prosperity, peace, and justice. They are interconnected and are set for the year 2030. SDG 7 is focused on energy. This goal is especially important as it interlinks with all other Sustainable Development Goals. Universal access to energy, energy efficiency, and the wider spread of renewable energy are crucial for creating sustainable and inclusive communities and resilience to environmental issues such as climate change. Access to electricity is closely linked with improvements in human development, including productivity (SDG 8), health and safety (SDG 3), gender equality (SDG 5), and education (SDG 4) [

11]. The correlation between human development and electricity consumption per capita was proved by Goldemberg et al. [

12].

Mexico has undertaken many initiatives towards sustainable development and the SDG 7. The country has a high potential for development of renewable energies, solar, and wind power, with potential for bioenergy, hydropower, and geothermal power as well [

13,

14]. Nevertheless, the Mexican electric power sector is characterized for the prevalence of fossil fuels (82%) in the energy mix [

15]. Mexico is a country with a high degree of electricity coverage, but challenges still remain in isolated rural areas. In this context, the utilization of renewable energy sources for electric power generation becomes an important factor in achieving the SDGs. Nonetheless, technologies face significant barriers in their wide usage, such as establishing appropriate financial sources and mechanisms to allow widespread use of the renewable energy in the national power mix [

16].

AD technology can contribute significantly to the implementation of SDGs, not only through generating low carbon energy and fertilizers, but also through the reduction of methane emissions from food and farming wastes, providing energy security, reducing poverty, and improving waste management and sanitation. AD offers decentralization of energy generation. Rural and remote communities that are not connected to the electricity grids are able to produce their own from the waste and the agricultural residues and become energy self-sufficient. Also, AD is a reliable energy source compared to other renewables. Once started and stabilized, the plant produces biogas on a continuous basis independently of external factors, such as the sun or wind [

17].

2.2. Energy Reform in Mexico

The government of Mexico under the president Enrique Peña Nieto, who served from December 2012 until November 2018, aimed to transition the country to cleaner and more diversified sources of energy. The Energy Reform, which took place in 2014, was implemented to increase energy security, minimize the negative effects of fossil fuel dependence, and minimize environmental impacts [

18]. Mexican Energy Reform consists of the introduction of the Electricity Industry Law and the Federal Commission of Electricity Law, along with other regulations arising from the amendments to articles 25, 27, and 28 of the Constitution. This legal framework created better conditions for renewable energy sources. The government also set the clear clean energy goals: to generate 35% of its electricity from clean energy by 2024 and to reduce greenhouse gas emissions by 22% by 2030.

Before the reform, most of the functions of the electricity market were concentrated at Comisión Federal de Electricidad (CFE), the state-owned electric utility of Mexico. In a nutshell, the goal of the reform is to open parts of energy sector to private investors, while retaining control over transmission and distribution channels [

19].

The reform introduced new stakeholders to the market and gave more freedom to the energy generators. The Energy Reform allows private firms to compete against the state companies for the production, distribution, and retail of energy [

20]. Power stations received the right to participate in the electricity system under three schemes: sell electricity on the wholesale market, through contracts directly to the Suppliers or Qualified Users, and through auctions organized by CENACE, Centro Nacional de Control de Energía (National Center of Energy Control) [

21].

Mexico’s new president starting from January 2019, Andres Manuel Lopez Obrador (AMLO), made energy sovereignty the center of political agenda. However, to achieve this goal AMLO emphasizes existing hydroelectric, diesel, fuel oil, and coal fired power plants, while eliminating market mechanisms that had allowed for investment in wind and solar capacity at record low prices [

22]. For instance, the fourth clean power auction was postponed indefinitely [

23].

Energy from biomass can play a central role in achieving ambitious CO

2 reduction, sustainability, and energy sovereignty targets in Mexico. Biogas is particularly important because it can be used flexibly to generate heat, gas, electricity, or liquid fuels, and it can readily be stored and transported if upgraded to biomethane [

24]. However, use of biomass for biogas production for energy purposes may compete with food production for the available area. In light of this competition for space, it is desirable to include previously unused biomass fractions, such as the organic fraction of MSW into new sources for energy production [

25]. The advantage here is no competition with food and no land use competition due to the fact that the input into the biogas fermenter is considered as waste, although the AD technology has to cope with non-technological barriers, such as public acceptance, availability of incentives, distribution infrastructure, and shortage of institutional and regulatory support [

26].

2.3. Anaerobic Digestion Technology

Anaerobic digestion (AD) is a microbiological process of decomposition of organic matter in the absence of oxygen. The key process phases of AD are hydrolysis, acidogenesis, acetogenesis, and methanogenesis. In the course of these stages, complex organic molecules are broken down into simpler ones and intermediate products are converted to methane, carbon dioxide, and water. The main components of biogas are methane (48–65%), carbon dioxide (36–41%), nitrogen (up to 17%), and traces of other gases, such as hydrogen sulphide (H

2S) and siloxanes. Anaerobic digestion and biogas production are influenced by parameters such as the total solids content (TS), the volatile solids content (VS), the carbon and nitrogen ratio (C/N), the particle size, the temperature, the pH, and the inoculum type [

27].

The digestion process takes place at mesophilic (35–42 °C) or thermophilic (45–60 °C) temperature conditions. Two process types are mainly adopted, namely wet or dry fermentation. In the first case, the input has a solid concentration below 12%, whereas, in dry digestion plants, solid concentration is higher than 20%. Concerning the continuity, AD technologies can be classified into batch and continuous systems. In a batch system, the reactor is filled with the feedstock and left for a pre-defined period, during which digestion and biogas production take place. At the end of the period, the reactor is emptied, and the process restarts. In a continuous system, the biomass is regularly fed into the reactor, and, at the same time, effluent is discharged. All wet digestion processes are operated continuously, whereas, for dry fermentation, both batch and continuous processes are applied [

27]. Moreover, one-stage or two-stage processes can be differentiated. In a one-stage system, all biochemical reactions take place in one reactor, while a two-stage system consists of two reactors [

28].

Worldwide, the biodegradable fraction of the MSW (i.e., food and biomass residues, paper, and cardboard) varies between 30% and 65% [

7]. In this respect, several studies [

29,

30,

31,

32] show that MSW is a potential primary energy source, especially the organic fraction of the municipal solid waste (OFMSW), thanks to the amount of biogas that can be produced through anaerobic digestion (AD). Therefore, AD is seen as a proper waste management solution in terms of solving the problem of waste generation and renewable energy production [

33,

34].

In practice, biogas is used onsite, for heating, local energy production and, in larger facilities, for district heating. Since biogas is a low-value fuel, it is not economically feasible to transport it for long distances beyond the site where it is generated. Also, biogas cannot be easily shipped, considering its corrosive potential. In contrast, upgraded biomethane could be more economically distributed to its point of use [

26].

A by-product of AD, digestate, can be used as a fertilizer, which can help to avoid the negative impact of the production and use of chemical fertilizers. Most food waste plants have a pasteurization unit for deactivating the pathogens present in the waste, which allows the use of the digestate in gardening operations [

35]. The most important minerals in fertilizers are nitrogen (N), phosphorus (P), and potassium (K) [

36]. Industrial nitrogen production relies on the Haber-Bosch manufacturing process, an energy-intensive nitrogen-fixation process that accounts for 1.2% of global energy consumption [

37]. Phosphorus and potassium, on the other hand, are obtained through mining. The phosphorous production chain is fragile because 77% of the world’s phosphate reserves are concentrated in just one country—Morocco. That is not the case with potassium fertilizers, which are mined and produced in many parts of the world. However, though potassium itself does not pose environmental risks, the mining activities may cause long-lasting ecological damage [

38].

2.4. Case Study: Mexico City

Mexico City, the capital and the most populated city in the country, is an increasingly globalized and spatially growing city in which MSW is a critical issue in terms of urban and environmental governance. The city consists of 16 boroughs and is spread over an area of 1485 km

2. The estimated population of 9 Million [

39] generates 12,998 Mg of MSW per day, from which only 10,678 Mg are collected through public services [

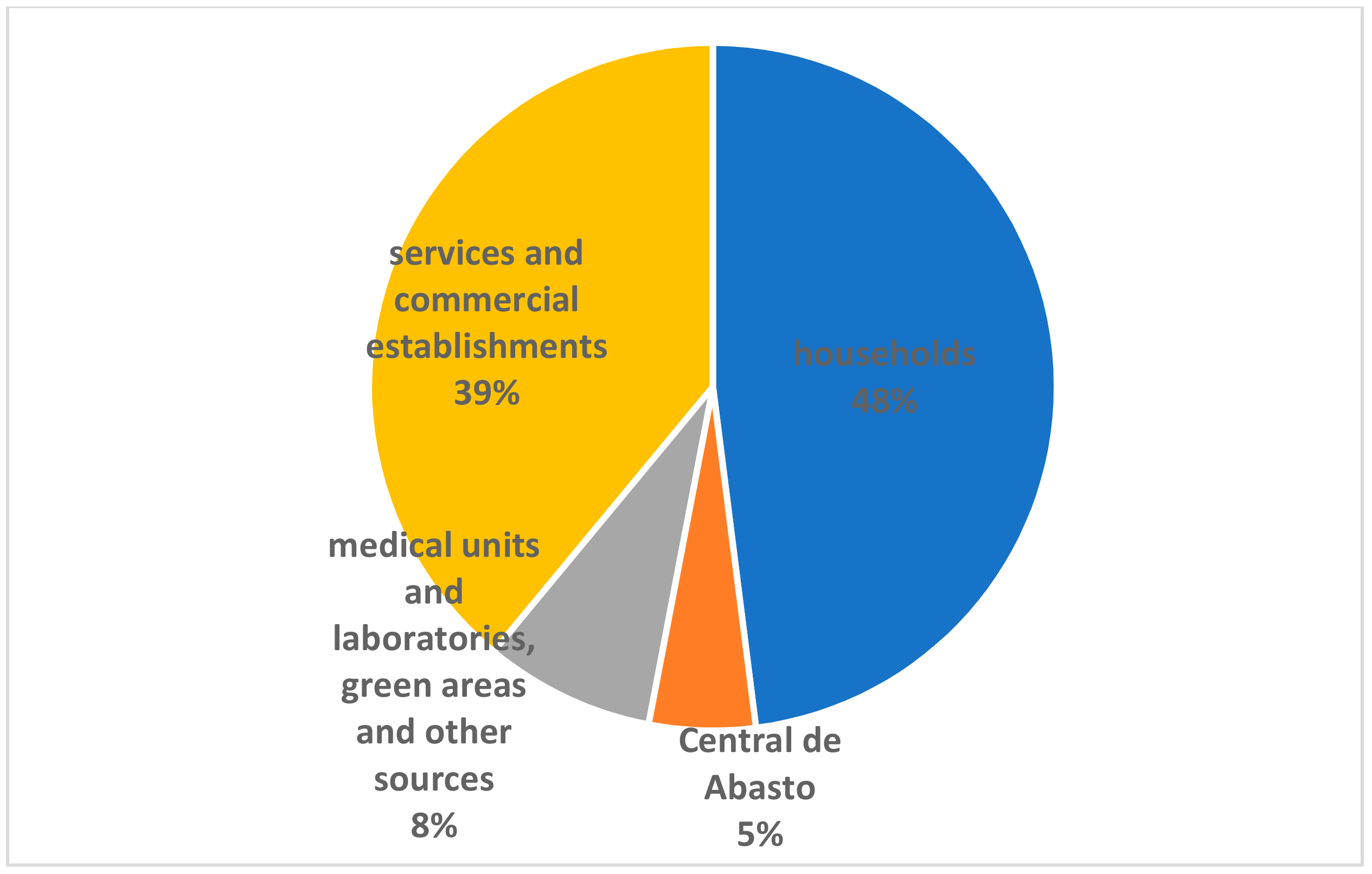

40], while 48% of the generated waste stem from households, 39% from services and commercial establishments, 5% from Central de Abasto (the biggest wholesale market), and the remaining 8% from medical units and laboratories, green areas, and other sources (see

Figure 1). Lack of proper solid waste management infrastructure is a striking problem due to the rapidly growing population. Further pressure is caused because people in urban areas consume 2–3 times more natural resources than rural inhabitants [

41].

The MSW management system of the city consists of twelve transfer stations, three separation and eight composting plants, and 5 landfills located outside of the city. As in the case with more than two-thirds of waste generated in Latin America and the Caribbean, the majority of MSW in Mexico-City is disposed of at the landfills [

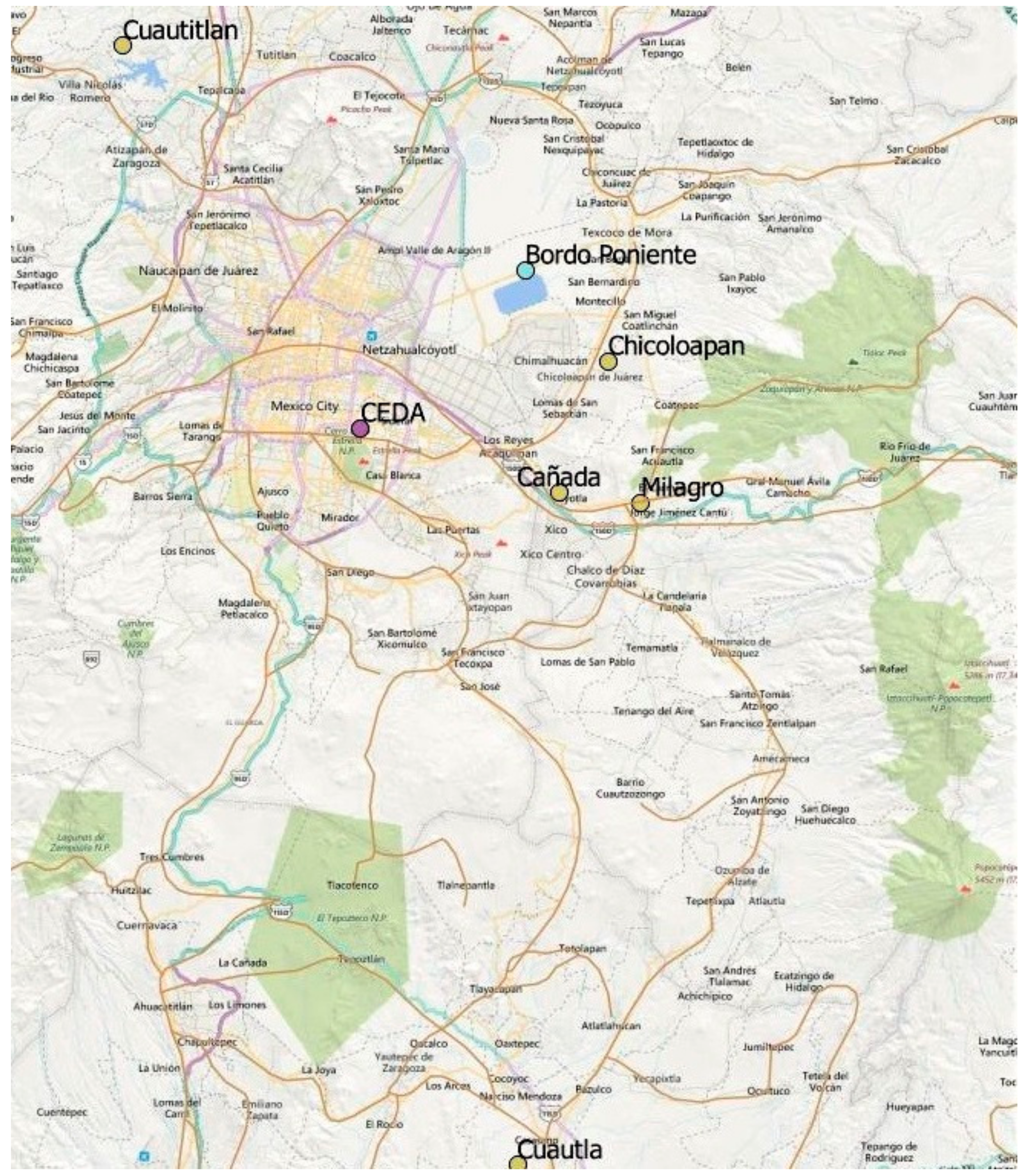

7]. Since 2011, when the only local landfill Bordo Poniente was closed, the city has had to send its waste for final disposal to nearby states. The landfills for final disposal are the following: Milagro, Cañada, Cuautitlán, Chicoloapan, and Cuautla [

40]. Transportation costs are high, and moreover, the access to the landfills has become an instrument of pressure in the conflicts between different political parties governing in neighboring Mexico State and Mexico City. To reduce the amount of waste sent to the landfill, in 2011, the city reinforced the source separation system, which was first introduced in 2003. According to this, household waste needed to be separated into two fractions: organics and inorganics. Unfortunately, the separation does not work properly, and the average separation efficiency for organics is 46% [

40]. This system was designed to improve the treatment of organic fraction with the help of several composting plants. In July 2017, the new environmental regulation for Mexico City NADF-024-AMBT-2013 came into force [

42]. This norm aims to increase the amount of separately collected recyclable materials, and thereby decrease the quantity of landfilled material. Non-recyclables were supposed to be treated in the incineration plant. The regulation introduces separation into four fractions: recyclables, non-recyclables, organic, and special waste, including Waste Electrical and Electronic Equipment (WEEE) and bulky waste. However, this type of segregation has not been implemented at full scale, and the separation efficiency is still low. The tender opened by the city was won the company from France Veolia [

43]. However, the plan to construct a thermovalorization plant was paused after the change of the City’s government [

6]. The possible reasons for that are the high capital and operating costs, ash generated, and gaseous pollutants to the atmosphere in case of inadequate air pollution control [

29]. There is a belief in Mexico that due the poor government control, the emission standards would not be respected during operation of the plant.

Since the incineration project is now paused in Mexico City, other alternatives should be discussed. Due to the high organic fraction and the lower set-up time, anaerobic digestion as a treatment method for organics should be considered. Interest in AD in Mexico has grown significantly in the last years, especially in the agricultural sector to treat cattle manure. The agricultural biogas plants represent covered lagoons with no mechanical agitation [

44]. In 2012, there were 966 biodigesters treating animal slurries in Mexico [

45].

The most feasible MSW feedstock are the residues from the wholesale market Central de Abasto (Supply Centre of Mexico City) (CEDA), which comprises 5% of total MSW generated in the city. Based on the composition study from 2017, these residues are mostly organics with low levels of contaminants. It needs to be mentioned that the main prerequisite for the AD is source-separated organics. In the case of waste from Central de Abasto, this condition could be fulfilled.

CEDA is a significant point of food distribution in Mexico City. It was founded in 1982. This 327-hectare terminal is the largest of its kind in the world, with 5000 businesses and over 300,000 visitors per day. The Central de Abasto buys and distributes 30% of national fruit and vegetable production, with a value of around USD 9 billion per year, provides approximately 70,000 jobs and represents a central hub in the extensive network of formal and informal food-related activities in Mexico City [

46]. The production of residues is seasonal, associated with the harvest times of different products [

47].

For the purpose of this study, the AD plant is to be constructed in the borough of Tláhuac, which is still rural in character. It is located on the south east edge of the district and has the area available for the plant and agricultural fields to accept the produced digestate. Also, Tláhuac is the neighbor municipality to Iztapalapa, where the CEDA market is located. The distance from CEDA to the center of Tláhuac is 20 km. Therefore, the implementation of the project would reduce the emission of pollutants to the atmosphere through the reduced transportation distance.

2.5. Anaerobic Plant Design

Continuous wet anaerobic digestion technology is chosen for this project because it is a proven technology for treatment of OFMSW [

27,

48]. The AD plant consists of eight digesters with a total volume of 51,472 m

3. An average retention time of 63 days was achieved through the number of digesters. The gas storage capacity has a maximum of 21,900 m

3. The combined heat and power (CHP) units generates approximately 6 MW electrical and 6 MW thermal energy. The heat produced from the engine is recovered to provide heat to the reactors and evaporator for the digestate.

The pretreatment system consists of a hammer mill with contaminant separation and a grit separation tank. Process water is also added to make the input pumpable. The biogas cleaning system consists of water removal and a reduction of the sulfur content by the addition of iron chloride in the digesters and carbon filters before the engines. Before the digestates are used as a fertilizer, they pass through a heat treatment in the pasteurizers followed by a separator to remove the remaining contamination, after which it is sent to an evaporation unit to decrease the water content and increase nutrient concentrations in the fertilizer. Process water is also generated in this step. The CHP system consists of two engines of 3 MW each. The plant has a control and monitoring system achieving a high degree of automation.

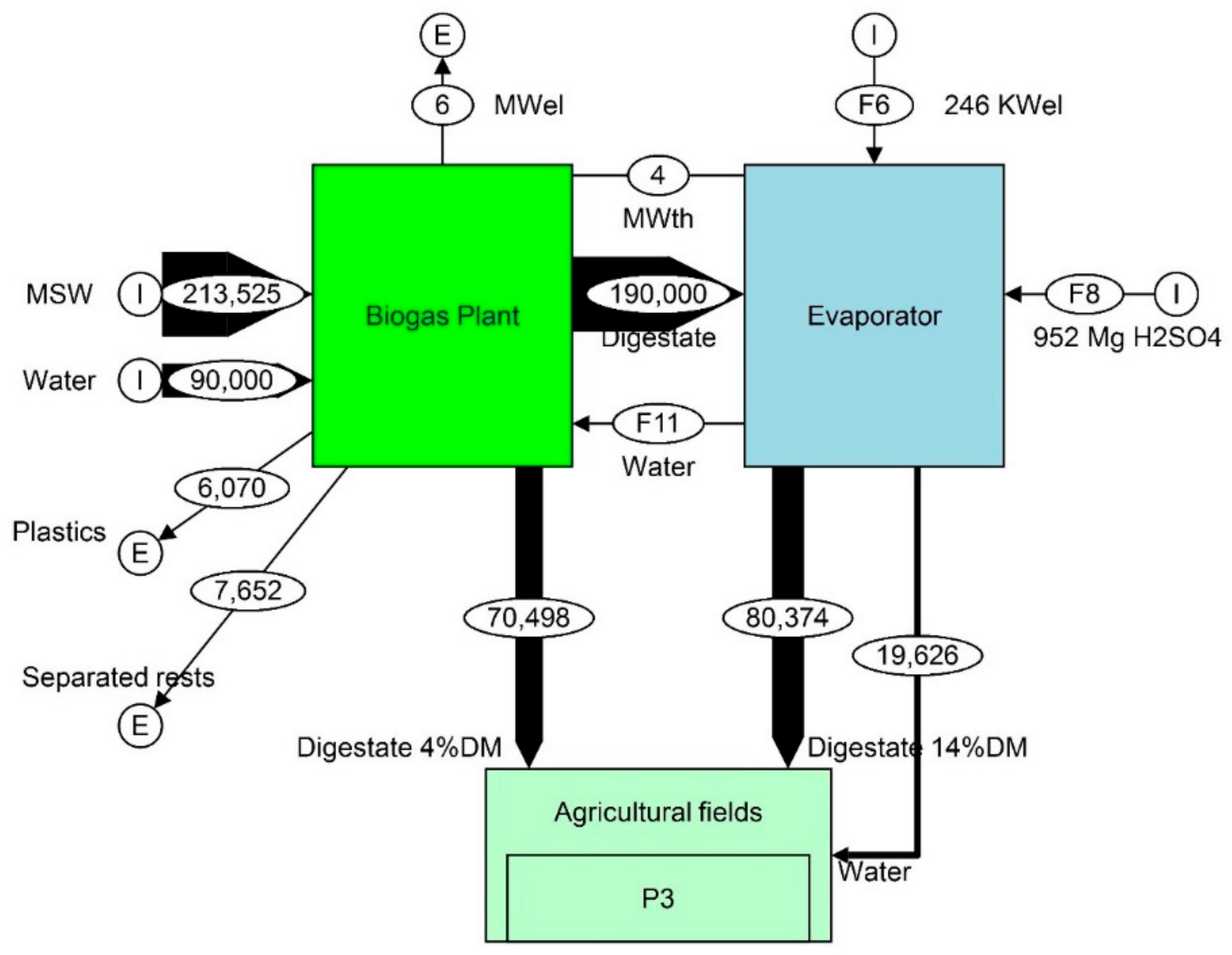

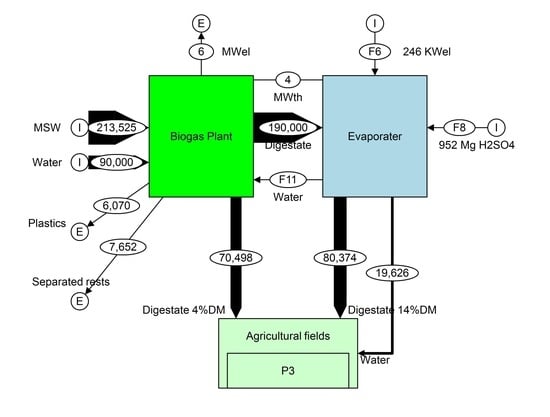

The mass flow diagram of the AD project discussed in this study is presented in

Figure 2. The organic waste is delivered to the plant, where the contamination is sorted out. The part of the digestate is sent to the evaporator to reduce the water quantity, and then to the agricultural fields as a fertilizer. Sulphur acid is added to the digestate to fix the nitrogen in the evaporation process and convert it to a valuable plant fertilizer. The thermal power applied in the evaporator is the waste heat from the CHP unit, which is not used for self-supply of the plant. It is not enough to process the whole amount of output product; 70,498 Mg of digestate is sent directly to the fields.