1. Introduction

High-rise apartment buildings comprise one of the primary residential housing types in South Korea, and their number is increasing (i.e., 13.8% in 2007, 15.9% in 2010, 16.7% in 2013, and 19.0% in 2016) [

1]. Many of the existing apartment buildings (i.e., approximately 2.24 million households) were new constructions built between 2011 and 2016 [

1,

2,

3]. This phenomenon has resulted in a substantial rise in heating energy consumption in the residential building sector [

4,

5,

6,

7,

8,

9]. Heating energy consumption has also been affected by climate change, causing the number of heating degree days (HDDs) to multiply. According to data from the Korea Energy Economics Institute (KEEI), the number of HDDs has increased to 2459 in 2015, 2590 in 2016, and 2688 in 2017, due to lower outdoor temperatures during the heating season [

10]. The result is the current surge in heating energy consumption by the residents of South Korea. The consequent increases in energy consumption by residential heating systems is now a major concern [

11,

12,

13].

In South Korea, radiant floor heating systems (i.e., underfloor heating or ondol systems) are the most common form employed in residential heating. Such systems are hydronic, using heated water to increase the ambient temperature [

14,

15,

16,

17,

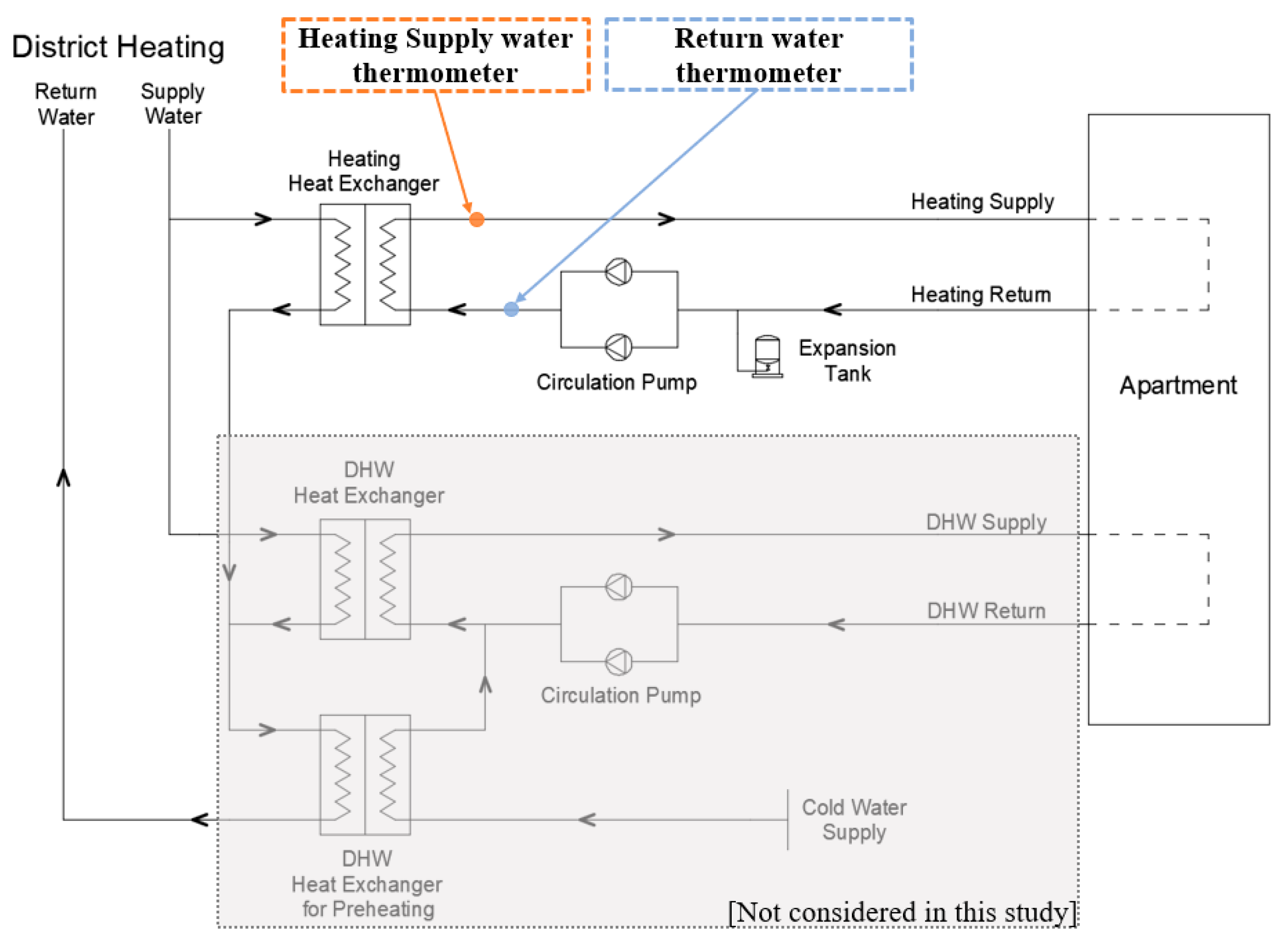

18]. The water is warmed by a heat exchanger located in a mechanical system; the water flows through a polyethylene pipe embedded in an underfloor household unit. The underfloor is heated by the hot water inside the pipe, which radiates warmth; in turn, this heats the indoor air. In this type of system, the supply water temperature receives heat from a heat exchanger connected to a heat source, such as a boiler or district heating power plant. Newly built apartment buildings usually utilize district heating power plants for heat sources (see

Figure 1).

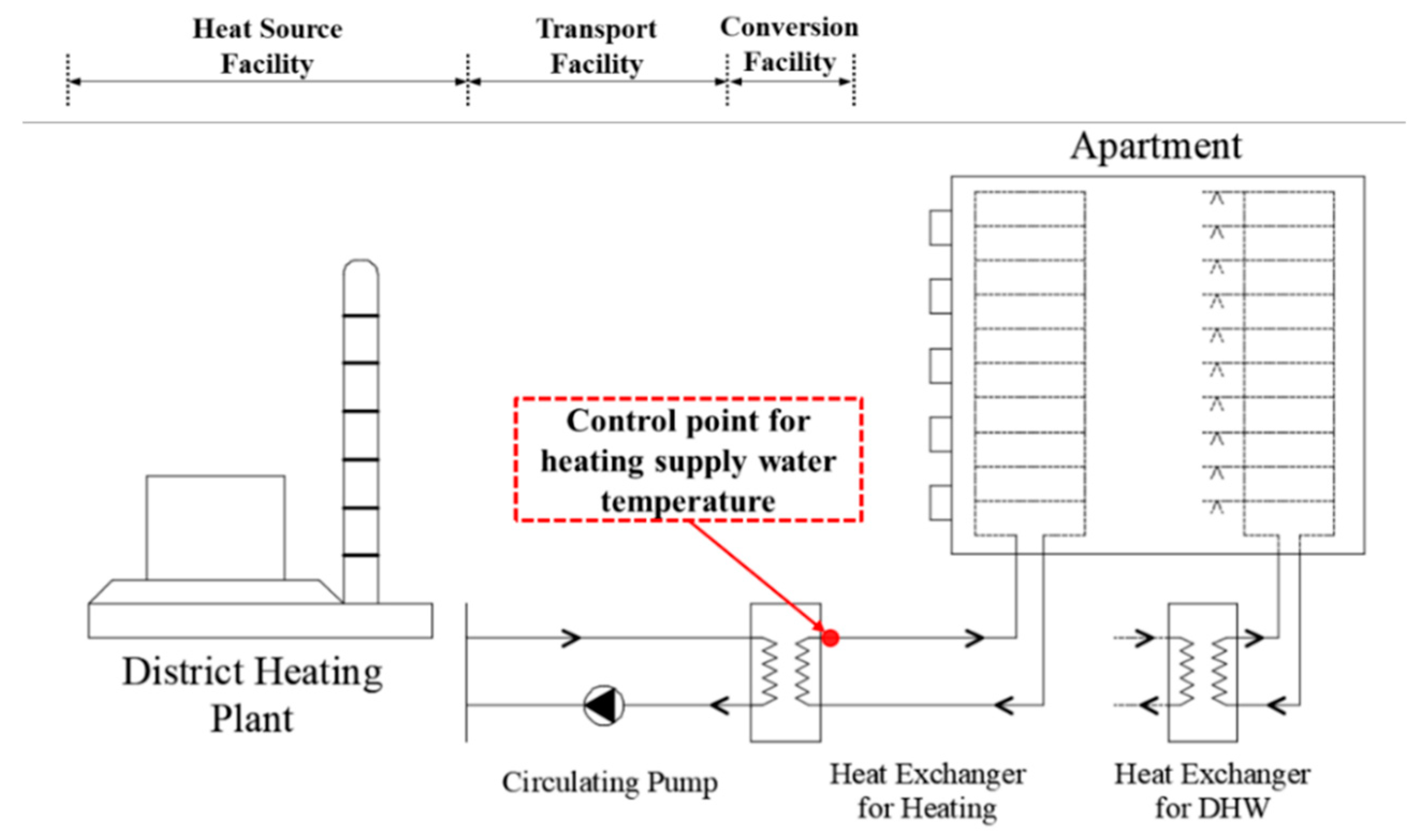

As shown in

Figure 2, a district heating system is composed of three major facilities: the heat source, transport mechanism, and conversion device (i.e., the heat exchanger). Water is circulated through a pipe connected to the three facilities. First, a district heating plant produces high-temperature water (e.g., 100–120 °C) [

19]. Next, the high-temperature water flows through the transport facility to a heat exchanger located in the mechanical room (i.e., technical room) of an apartment building. Then, the high-temperature water exchanges heat with the heating supply water in the heat exchanger for the radiant floor heating system [

20,

21,

22,

23]. At this time, the set-point temperature for the heating supply water becomes one of the control parameters affecting the performance of the radiant floor system. That is, the system’s performance and level of energy efficiency are highly dependent on the set-point temperature. Therefore, effective and efficient control of the heating supply water temperature is needed to achieve energy savings without harming indoor thermal environment.

In general, a method to control the radiant floor heating system is to provide indoor living spaces with appropriate heating and to minimize corresponding energy consumptions. To achieve this, supply water temperatures, water flow rates, system operation modes (e.g., continuous or intermittent), and other factors are manipulated. To determine suitable operation for the variables, several studies were previously conducted.

Athienitis and Shou in 1991 developed a numerical model using heat transfer functions for predicting operative temperatures and simplified Laplace transfer functions for radiant system components. Using the models, the set-point temperatures were modulated to control the radiant heating system. As a result, the study improved system control time using an operative temperature instead of an outdoor air temperature [

24].

Cho and Zaheer-uddin in 1997 examined OTR control strategies using two-parameter control schemes. The study claimed that two-parameter control was simple and effective and showed less temperature swings in floor-slab and zone-air temperatures [

25].

Zhang in 2001 studied temperature control strategies for radiant floor heating systems. For that, Zhang developed a dynamic model using nonlinear differential equations and used three different control strategies to regulate the temperatures in the floor heating system. One of three strategies, called the multistage control, show to better maintain zone air temperatures close to the set-point [

26].

Cho and Zaheer-uddin in 2003 proposed the predictive control strategy. This was an intermittent operation mode based on predicted heat amount (e.g., the total length of time in hours per day) required for the next day. In comparison with the conventional continuous operation mode, the intermittent mode with predictive control strategy resulted in between 10% and 20% energy savings [

27].

Lee et al. in 2004 studied the control methods for radiant floor heating in a high-rise residential building. They classified the current control methods: supply water temperature control, supply water flow rate control, and both together. In addition, they conducted experiment using the three classified control methods to evaluate their control performances in terms of room air temperatures, floor surface temperatures, and rising time of room temperatures [

28].

Olesen in 2007 evaluated energy benefits from controlling a supply water temperature flowing through the pipes embedded in the concrete slabs. The water temperature control was based on outdoor temperature conditions to sufficiently provide cooling in summer and heating in winter. As a result, the study concluded that the water temperature control method provided acceptable indoor thermal comfort and lower energy consumption as well [

29].

Romani et al. in 2016 summarized previously conducted literatures associated with thermally activated building systems (e.g., building thermal mass). They pointed out that one of the major issues for the systems was the slow response time and storage capacity [

30].

Zhang et al. in 2017 conducted an experimental study for a radiant floor heating system coupled with a ground source heat pump system. The study resulted in energy savings and proper thermal comfort by taking advantage of the ground source heat pump [

31].

Based on the above literature review, it was identified that many studies proposed new control methods for a radiant floor heating system to reduce heating energy consumptions and to meet required heating loads. It was also identified, however, that most of the previous studies focused on improving control methods for the demand side (i.e., indoor spaces) or the plant side (e.g., district heating). Thus, there was a lack of studies to control heating supply water temperatures of the supply side of a mechanical room (i.e., technical room). Accordingly, there still needs to improve the control methods for the heating supply water temperatures on the supply side.

In South Korea, the heating water temperature as provided by a heat exchanger located in the mechanical room (i.e., supply side) is conventionally controlled by one of two methods: fixed temperature (FT) or outdoor temperature reset (OTR). However, both share a major technical limitation; they do not reflect changes in residents’ heating use when setting the heating supply water temperature. To improve the control method and overcome this limitation, therefore, this study proposes a new method of controlling the heating supply water temperature at the supply side, named Residential Energy Demand (RED).

2. Research Methodology

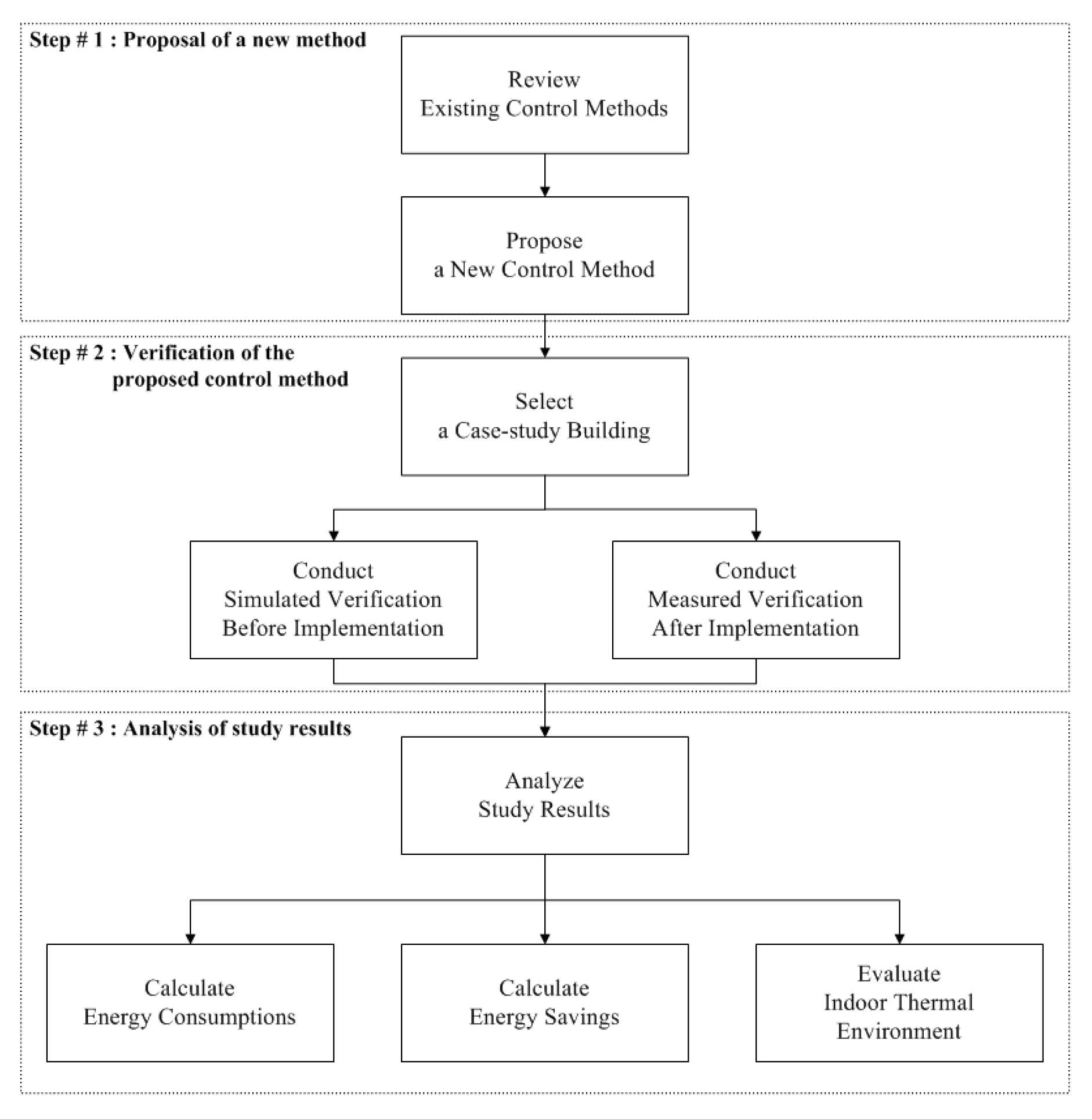

This section describes the overall methodology for conducting this study, which proposes and verifies a new method for controlling heating supply water temperature.

Figure 3 presents the process, which is comprises three major steps: (1) proposal of the new control method, (2) verification of the proposed control method, and (3) analysis of the study results.

The first step was to propose a new control method (i.e., the algorithm) for the heating supply water temperature. To complete this step, the researchers briefly reviewed the conventional, widely used control algorithms for determining heating supply water temperatures. The second step was to verify the proposed control method using a case-study structure (i.e., a high-rise residential building located in the city of Daejeon in South Korea). The verification process comprised two steps: simulation-based verification before implementation of the proposed control method, and measurement-based verification after implementation.

For the simulation-based verification, this study calculated the heating supply water temperatures for the case-study building, using the proposed RED control method. The calculated temperatures were compared with the measured temperatures determined using the existing OTR control process for the case-study building. The results of the comparison presented the energy savings made possible by using the RED method. This verification was conducted before implementing the RED control method in the actual heating control system (i.e., the building energy management system, or BEMS) for the case-study building. The measurement-based verification was conducted after implementation of the RED process in the actual heating control system. Researchers compared the measured temperature data for the heating supply water after using both the OTR and RED controls. In addition, an evaluation of the indoor thermal environment was conducted to measure the controls’ respective impacts on the indoor temperature. To do so, thermometers (i.e., HOBO dataloggers) were installed in nine indoor environments (i.e., households).

The third step was to analyze the study results, including the heating supply water temperatures, amounts of energy consumption, respective energy savings, and resultant indoor temperatures. Based on this analysis, the proposed control method compared favorably to the conventional (i.e., OTR) control process.

2.1. Heating Supply Water Temperature Control Methods

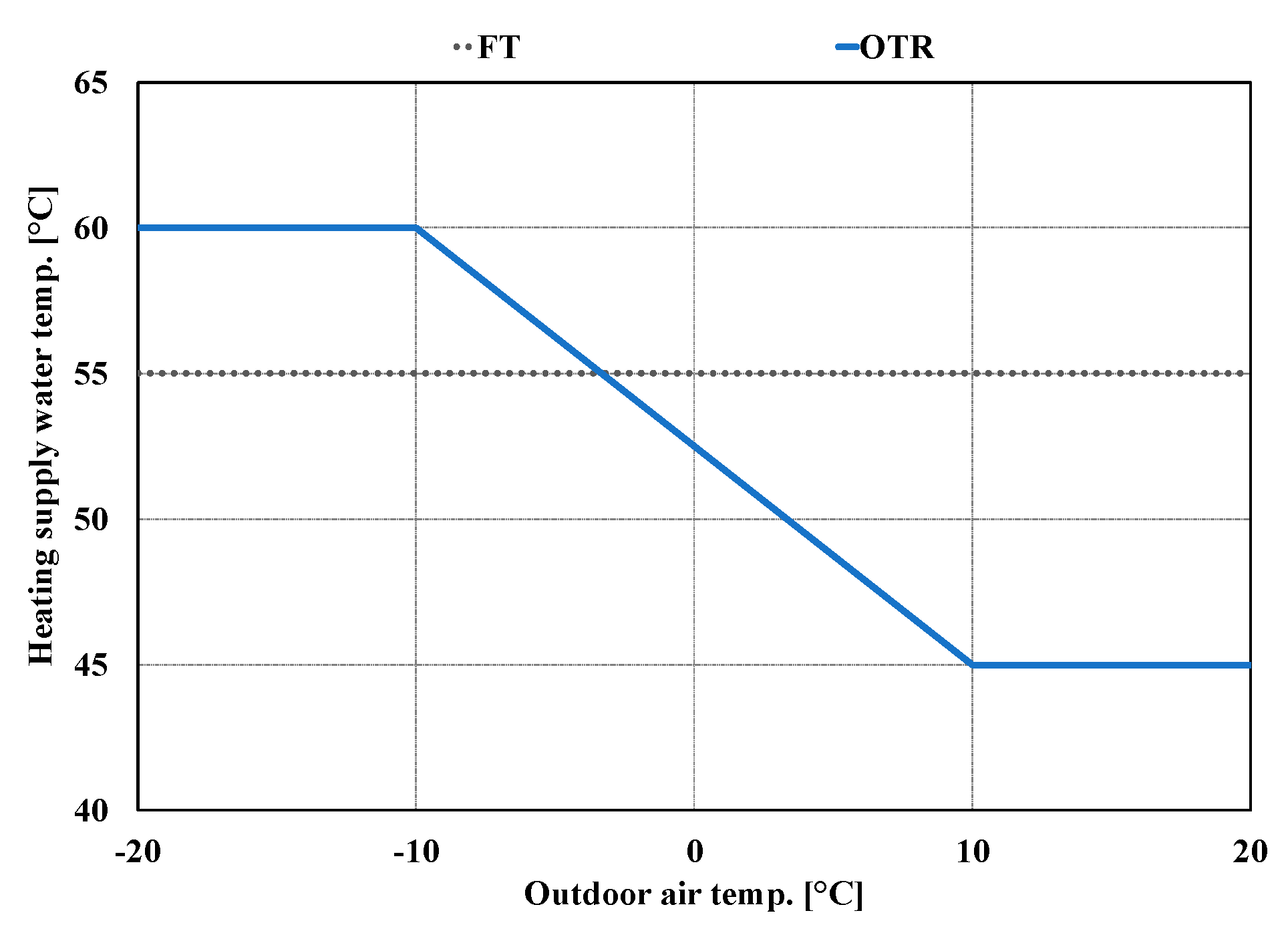

In South Korea, the FT and OTR processes are conventionally used to control a heating supply water temperature (see

Figure 4). In the FT control process, an operator sets the heating water temperature that is supplied from a heat exchanger located in a mechanical room; that temperature is a fixed value, usually ranging between 45 °C and 60 °C. In general, the set-point for the heating supply temperature is decided by the operator’s experience. Due to this feature, it cannot be modulated according to changes in the external environment or residents’ heating use characteristics. That is, the FT control method is old fashioned, and was most commonly employed before the public became aware of the need to reduce the use of heating energy. The FT control method is illustrated in the following equation:

where

is the set-point temperature for the heating water (°C), and

is the temperature as fixed by the system operator (°C).

The OTR control method is the most widely used process for setting a heating supply water temperature [

32,

33]. OTR has the ability to reduce unnecessary heating energy loss, as compared to the FT method. The energy benefit is achieved by the OTR method’s modulation of set-point temperatures for the heating water, according to changes in the outdoor thermal environment (i.e., outdoor air temperature). The general algorithm for the OTR control method is written in the following equations:

If

If

,

where

is the outdoor air temperature (°C),

is the highest set-point temperature for the heating water (°C),

is the slope of the OTR control,

is the high limit of the outdoor air temperature (e.g., 10 °C for this study),

is the low limit of the outdoor air temperature (e.g., −10 °C for this study),

is the reference temperature (in general, 47~52 °C) for the OTR control, and

is the lowest set-point temperature for the heating water (°C).

However, both conventional control methods have a major flaw; they do not consider changes in residents’ heating usage. When the outdoor temperature decreases and no residents are in the apartment, the OTR control sets a higher point for the heating supply water temperature, regardless of the heating usage. In this type of case, the heating supply continuously circulates highly heated water through the piping system. This results in energy loss from the piping, and also decreases the overall efficiency of the heating system. To reduce energy loss, the heating supply water temperature should be modulated by adding another control factor (i.e., the residents’ heating use). Unfortunately, the existing control methods do not take changes in heating energy usages into account when setting the heating supply water temperature.

To overcome this barrier, a new optimal control method is needed that simultaneously considers both changes in the outdoor air temperature and residents’ heating usages. Therefore, this study proposes a new control method that will improve the conventional OTR control process, named Residential Energy Demand (RED).

2.2. Proposed RED Control Method

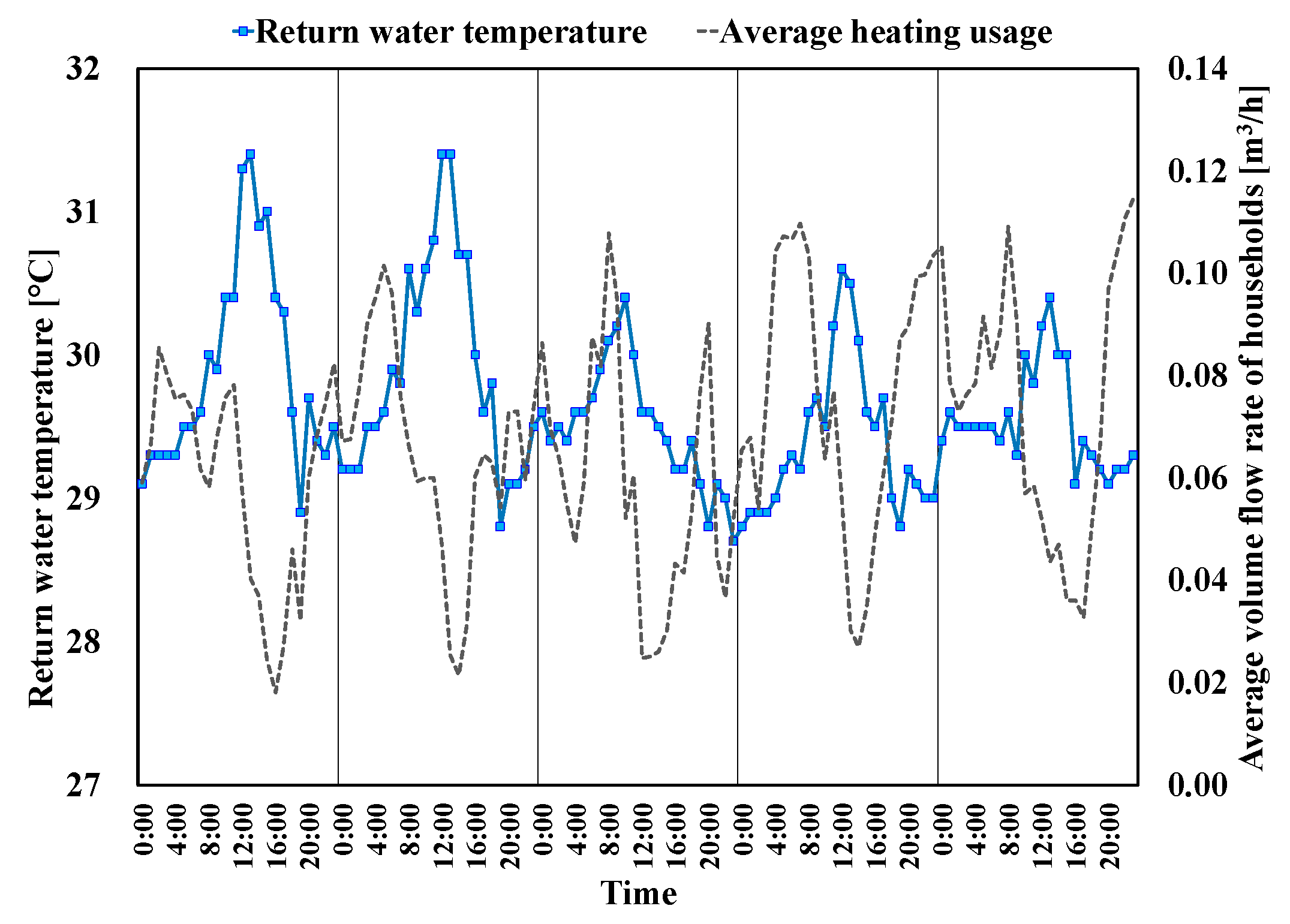

The RED control was developed to consider residents’ changes in heating demands when the heating supply water temperature is set. To accomplish this goal, this study assumed that the heating usages (i.e., demands) should be highly related with the return water temperatures. To prove the assumption, this study compared the data between return water temperatures and hourly volume flow rates of each households. To determine the heating usages, at this point, it should be noted that this study referenced hourly average volume flow rates, which represent a quantity of hot water flowing through the heating pipe for the radiant heating system at each household. To conduct the comparison between the volume flow rate (i.e., heating usages) and return water temperatures, this study used the measured data during the before-implementation period for the case-study descried in

Section 3.1. The comparison results can be shown in

Figure 5 based on the hourly measured data (6–10 February 2017), and it was observed that the return water temperature is inversely proportional to residents’ heating usage. That is, the return water temperature increases as the heating consumptions decreases, and vice versa. Based on the comparison results, the above assumption seems to be reasonable and this study concluded that the return water temperatures reflect residents’ heat use patterns of heating usage of the residents. According to this, the proposed RED method uses the values of the return water temperatures to account for the amount of the heating usages.

This study proposes an analytical solution named the RED control method. The RED control determines a heating supply water temperature based on integrated changes from the outdoor air temperature (i.e., conventional OTR control [

21]) and residents’ heating demands (i.e., the above concepts in

Section 2.2). The summarized algorithm developed for the RED control method appears in the following equations:

If

,

If

,

where

is the corrected heating supply water temperature (°C),

is the previous return water temperature (°C),

is the current return water temperature (°C),

is the current calculation of heating supply water temperatures (°C),

is the current set of heating supply water temperatures (°C), and

is the previous set of heating supply water temperatures (°C).

3. Results

3.1. Case-Study Building Complex

A case-study building complex (i.e., an apartment complex) was used to verify the RED control algorithm proposed in this study. The apartment complex consisted of nine buildings located in Daejeon, South Korea. The total number of households in the apartment complex was 1216, and the number of floors varied from 12 to 25. Further information about the apartment complex can be found in

Table 1. The complex utilized district heating as its heat source for the heating and hot water supply systems and was equipped with an underfloor radiant heating system. To control the heating system via the proposed RED control algorithm, this research used the Energy Management System (EMS) interface already installed in the apartment complex. The EMS was also used to collect the measured data (e.g., temperatures of the outdoor air, supply water, return water, heating needs, etc.), based on the operation of the heating system. The collected data were used to identify the operating status of the apartment complex and calculate the energy consumptions and savings obtained from using the proposed RED control method.

To evaluate influence of the implemented control algorithm on the indoor thermal environment, the researchers installed thermometers (i.e., HOBO data loggers) in the living rooms of nine households. The nine households were determined to represent all of the housing units, based on vertical (i.e., low, middle, and high) and horizontal (i.e., left, middle, and right) divisions.

3.2. Existing Operation Status of the Case-Study Building Complex

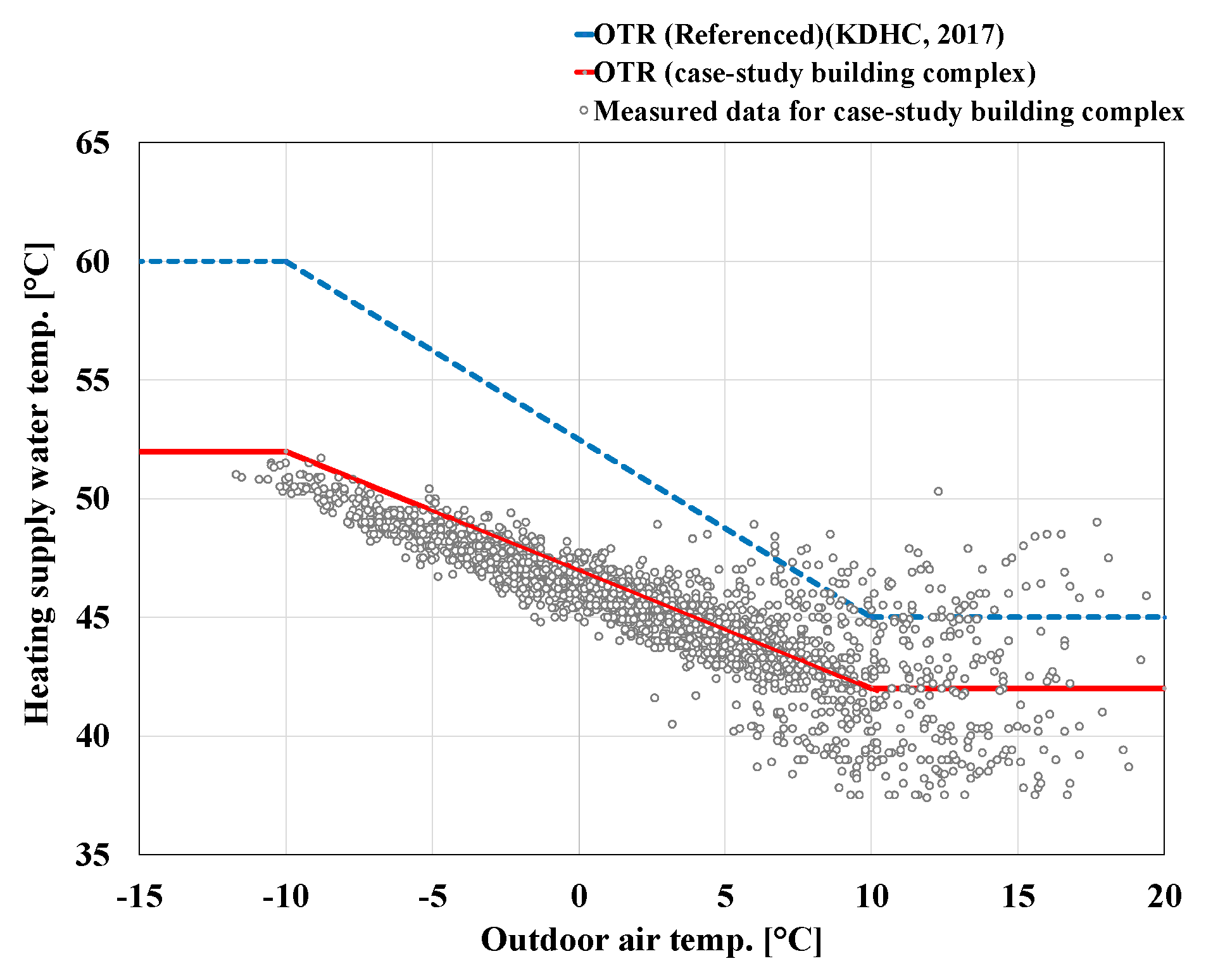

Based on the measured data collected through the EMS of the case-study building complex, this study analyzed the existing operating status of the heating supply temperature control before implementation of the proposed RED control method. For this analysis, the measured heating supply water temperatures and outdoor air temperatures were used.

Figure 6 presents the changes in the water temperatures supplied from the mechanical rooms to the household units in the case-study building complex. The figure also includes changes in the OTR control temperatures, as referenced by the Korea District Heating Corporation (KDHC) (KDHC 2017). The case-study building complex utilized the OTR control method for heating, a system that linearly controls the heating supply water temperature (i.e., secondary exit temperature at the heat exchanger, as shown in

Figure 2). That is, the temperature was modulated based on the calculation logic for the water’s set-point temperature, according to changes in the outdoor air temperature. Using the measured data from the case-study building complex, it was identified that the heating supply water temperature linearly modulated between 52 °C and 43 °C when the outdoor air temperature varied from −10 °C to 10 °C. However, the set-point range for the heating supply water used in the existing OTR control appeared to be lower than the referenced OTR control provided by the KDHC. The reason for this was that the KDHC used set-point temperatures ranging between 60 °C and 45 °C.

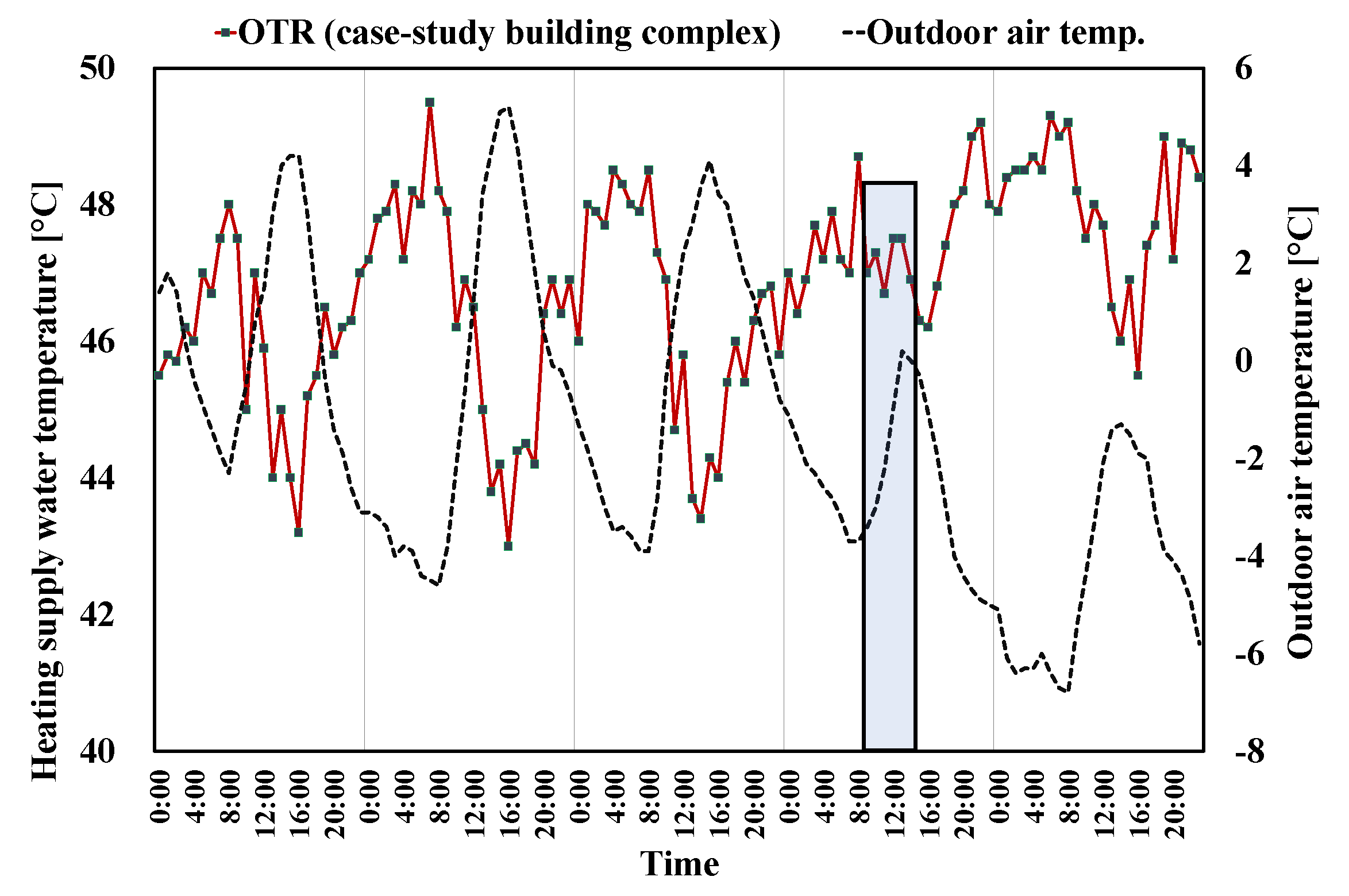

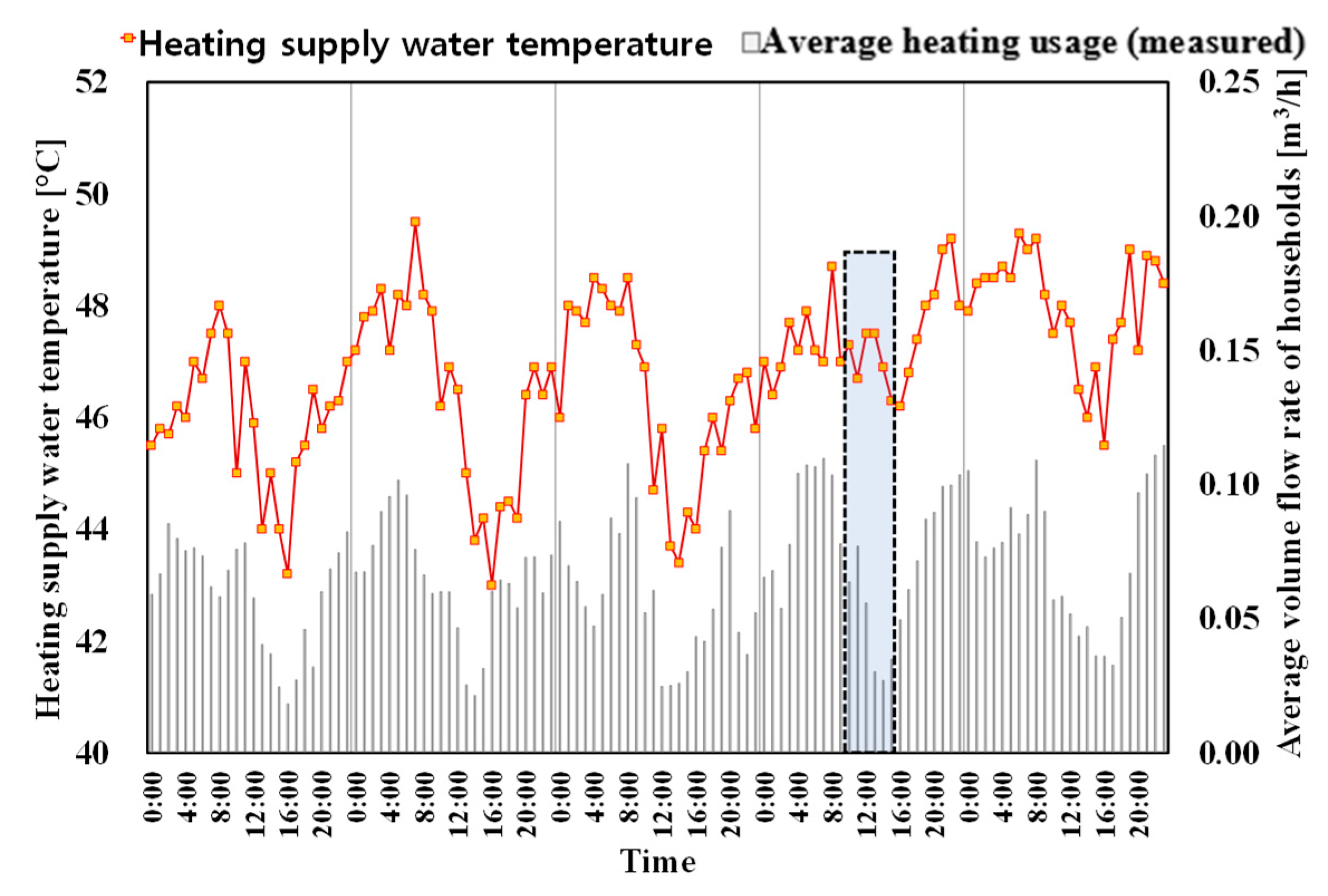

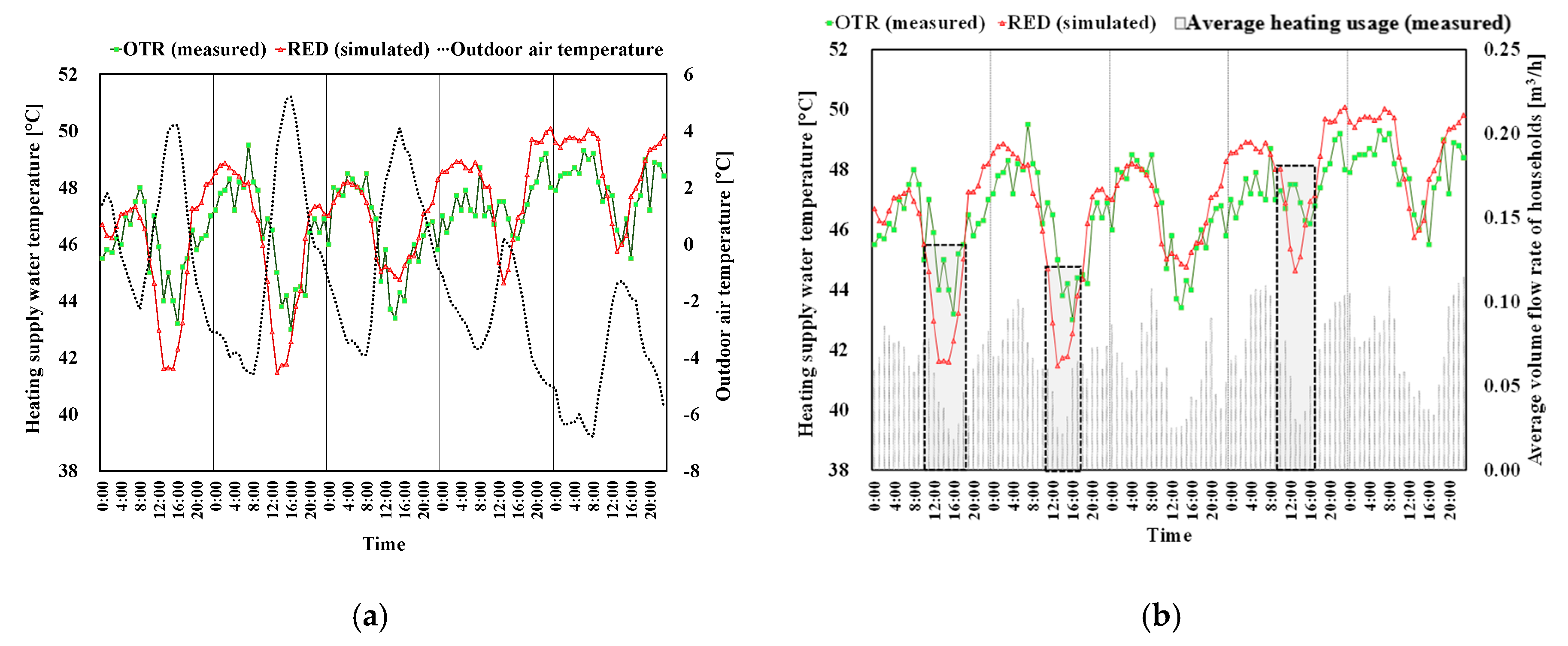

Figure 7 and

Figure 8 present the analysis of the hourly measured data (6–10 February 2017).

Figure 7 shows the variations in the heating supply water temperatures as compared to the outdoor air temperatures. As a result of

Figure 7, it was concluded that the heating supply water temperatures mostly were in inverse proportion to the changes in outdoor air temperature. The resulting relationship seems to be reasonable for the OTR control.

Figure 8 shows the variations in the heating supply water temperatures as compared to the heating energy usages. As mentioned in

Section 2.2, the hourly average volume flow rate for households were referenced to determine the heating usages. As a result of

Figure 8, it was observed that the heating supply water temperature was set to be higher, even if the heating usage (i.e., demand for heating) was relatively smaller and the outdoor air temperature was relatively higher (see the boxes with blue-colored and dashed line in

Figure 7 and

Figure 8). It was concluded that the heating supply water temperatures were not modulated based on changes in the heating consumptions of residents. That is, there is possibility of that the OTR control method provides unnecessary overheating when residents require less.

3.3. Simulation-Based Verification Before Implementation

For the initial verification process before implementation of the proposed RED control method, researchers conducted a simulation to examine whether the proposed method was a valid means of controlling a heating supply water temperature. The calculated temperatures by the proposed RED control method were compared to the measured temperatures produced from using the existing control method (i.e., OTR) for equivalent periods, as before.

Figure 9a shows the results of the comparison of the two control methods plotted for the changes in the heating supply water temperatures against the changes in outdoor air temperature. During the simulation period, the outdoor air temperature changed from −7 °C to 5 °C. According to this variation, the heating supply water temperatures from both control methods followed a similar pattern (e.g., increases and decreases in temperature).

Figure 9b presents the comparison results for changes in the heating supply water temperatures against changes in residents’ average hourly heating usage by residents. As compared to the OTR method, the RED control set relatively higher heating supply water temperatures when more heating usage occurred, and vice versa (see the gray-colored boxes in

Figure 9b).

These results imply that the proposed RED control method improves temperature control, such that it reduces unnecessary over- and under-heating when residents’ heating needs change. Therefore, it can be concluded that the proposed RED control method saves heating energy by providing less heating when heating requirements decrease and improves the indoor thermal environment by providing more heating when the converse occurs.

3.4. Measurement-Based Verification after Implementation

The applicability of the RED control method was also confirmed through the simulation-based verification process outlined in

Section 3.3. The RED control was then implemented in the case-study building complex for measurement-based verification. The results are analyzed below. This section provides a description of the secondary verification process after implementation of the proposed RED control method in an actual heating system. To achieve this goal, researchers measured operation data, such as heating supply water temperature and volume flow rate for both control methods. The two methods were applied to the same heat exchanger in a mechanical room designated for heating supply water temperature control. This was accomplished by cross-operation, every other week (i.e., one week of OTR control, and the following week with RED, repeated). The entire measurement period was eight weeks (1 February–15 March 2018).

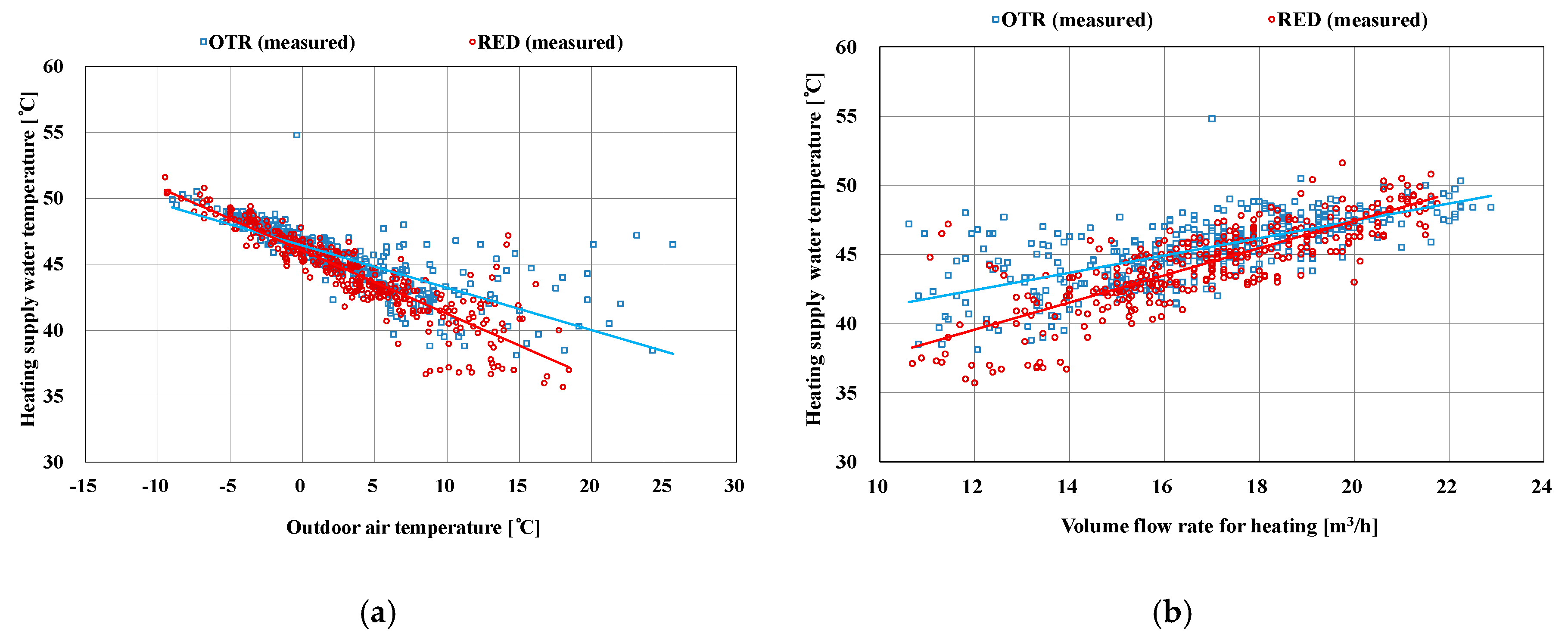

Figure 10a shows the relationships between the heating supply water temperature and outdoor air temperature for both the existing OTR and proposed RED control methods, based on the measured data. In the figure, the points represent the actual measured temperatures; the regression lines were added to illustrate the change trends in the heating supply water temperature, as compared to the outdoor air temperature. In general, both of the control methods inversely modulated the heating supply water temperature according to the outdoor air temperature. However, when the outdoor air temperature fell below −3 °C, the RED control supplied heating water of a relatively higher temperature than did the OTR method. Conversely, when the outdoor air temperature was higher than −3 °C, the RED control supplied heating water at a lower temperature.

Figure 10b presents a comparison of the heating supply water temperatures for each control method and the corresponding heating usages. When the volume flow rate for heating (i.e., the heating usages) was below 20 m

3/h, the RED control method supplied heating water at a lower temperature than did the OTR control. Conversely, when the volume flow rate for heating was above 20 m

3/h, the RED control supplied heating water at a higher temperature than did the OTR control.

Based on the analysis of the measured data, the RED control generally resulted in energy savings when the outdoor air temperature rose or the heating usage decreased. Therefore, this study confirmed that the proposed RED control method was an improvement over the conventional OTR process because it considered changes in the outdoor environment and residents’ energy usages at the same time. However, it should also be also noted that the RED control method may consume more energy if the outdoor air temperature is lower than −3 °C or the volume flow rate for heating is above 20 m3/h. In such extreme cases, there should be another control limit (e.g., setting a maximum set-point temperature) to avoid excessive energy consumption, but such an additional control limit was not employed in this study.

3.5. Energy Consumptions and Savings

This section presents the heating energy consumptions and savings from two separate verification periods and draws comparisons between the OTR and RED control methods. The results of the heating energy consumption amounts and savings were determined by both simulation and direct measurement. To calculate the heating energy consumption, this study used the following equation:

where

is the hourly average consumption of heating energy (

),

is a density of water (

),

is the hourly average volume flow rate (

),

is the specific heat of the water (kcal/kg °C),

is the hourly average heating supply water temperature (°C), and

is the hourly average return water temperature (°C).

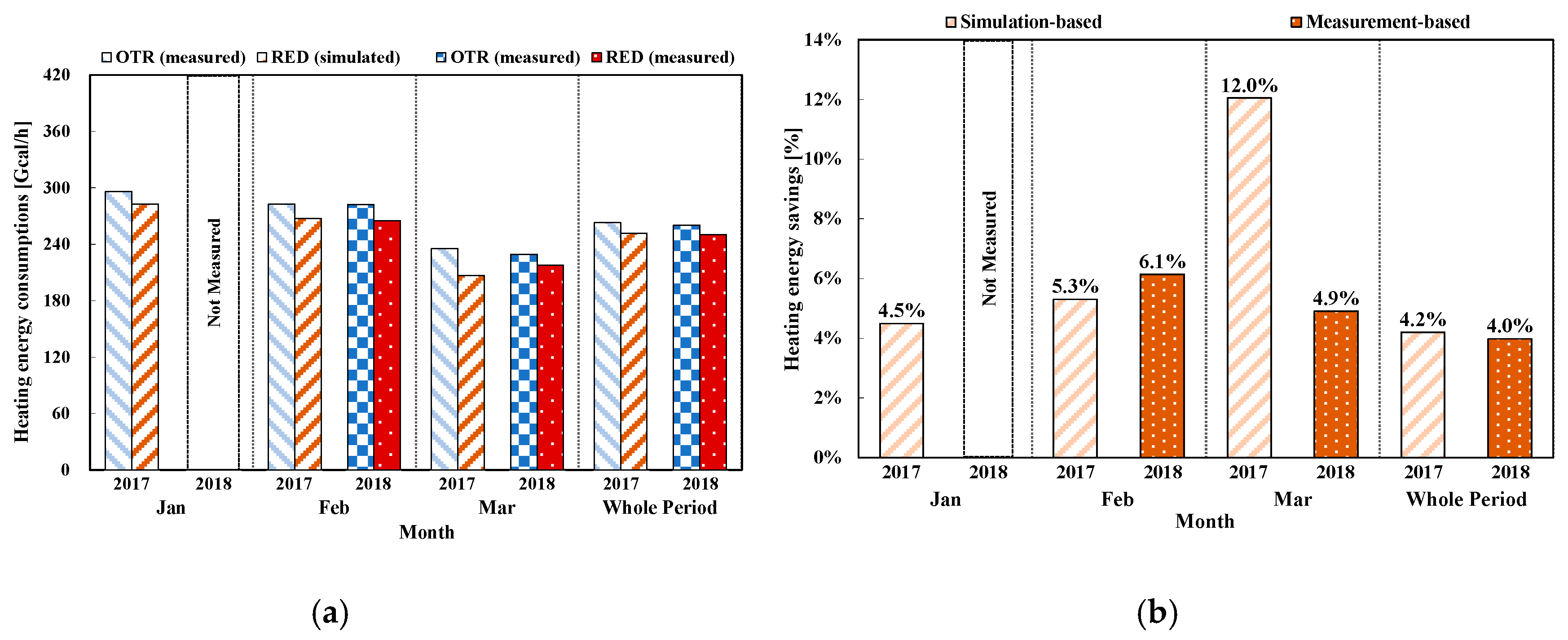

Table 2 offers a summary of the energy consumptions and savings per month during the verification periods, and

Figure 11 graphically illustrates these results. Based on an analysis of the simulation, the hourly average heating energy consumption by month varied from 235.09 Gcal/h to 295.98 Gcal/h when using OTR, and 206.78 Gcal/h to 282.68 Gcal/h when using RED. Thus, the RED method consumed less heating energy than did the OTR method. The hourly average heating energy savings per month in 2017 ranged from approximately 4.49% to 12.04%. In addition, it was observed that the hourly average savings during the entire three-month period was 4.19%.

Based on an analysis of the direct measurements collected after implementation, the hourly average heating energy consumption per month ranged from 229.14 Gcal/h to 282.20 Gcal/h when using OTR, and 217.90 Gcal/h to 264.87 Gcal/h when using RED. As in the simulation analysis, the RED method consumed less heating energy than did the OTR process. The resulting savings for each month in 2018 was between 4.91% and 6.14%, and approximately 3.98% for the entire three months. In general, it can be concluded that the RED control method has great potential to save heating energy, simply by improving the heating system’s control algorithm and without installing any special control equipment.

3.6. Evaluation of the Indoor Thermal Environment

This study evaluated the indoor thermal environment resulting from a change in the method for controlling the heating supply water temperature and determined such a change’s effect on the indoor thermal comfort of residents. For this evaluation, researchers installed thermometers (i.e., HOBO data loggers) in the living rooms of nine households and measured the indoor air temperature and relative humidity (RH). The measurement period was the same as the above-described RED control, and the data were measured at intervals of about 5-min.

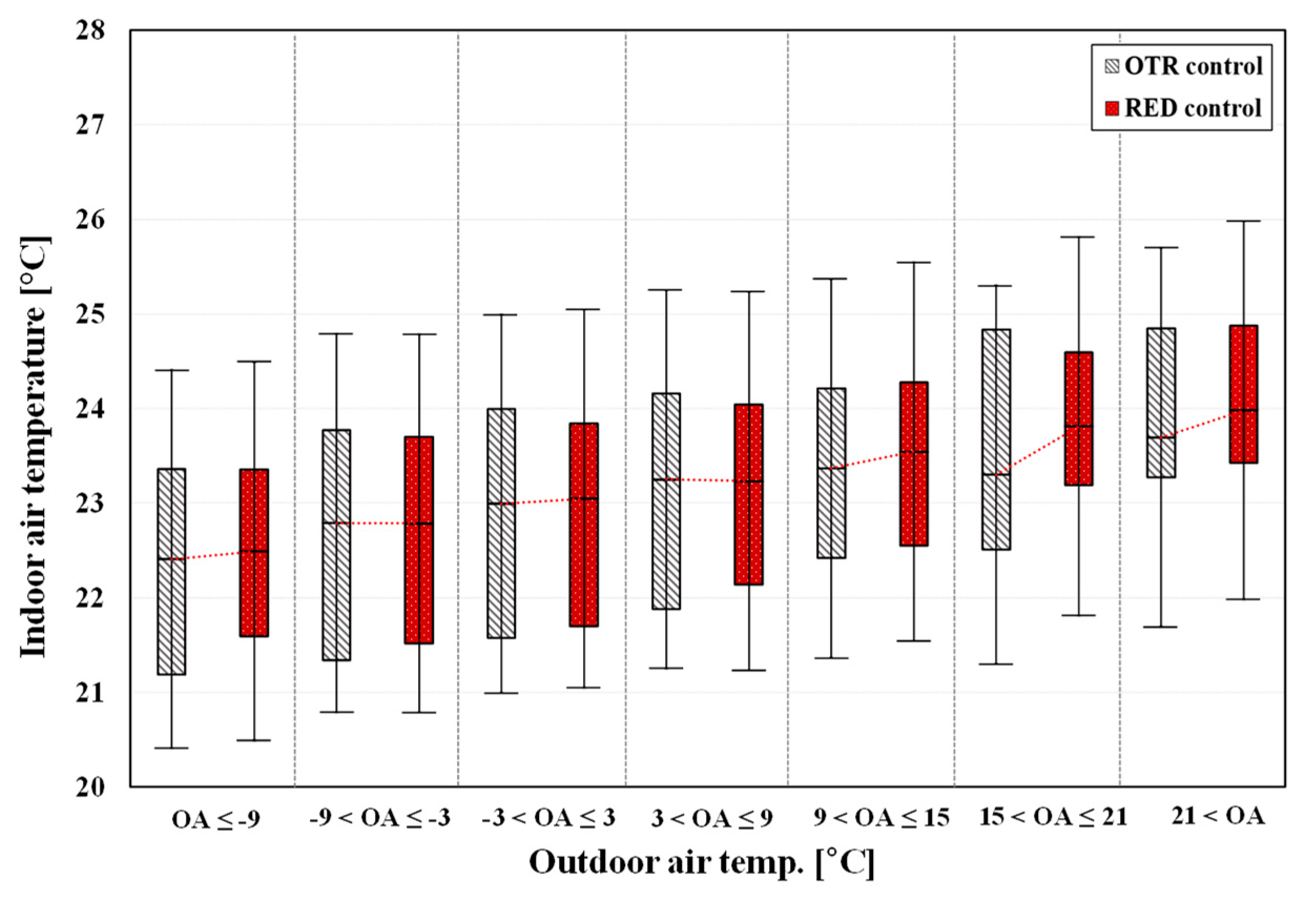

Table 3 and

Figure 12 present the data collected. As seen in

Table 3, the OTR control resulted in an average indoor air temperature of 22.86 °C; values were distributed within a range of 20.09 °C to 25.47 °C. The RED control produced an average temperature of 23.01 °C, with values within a range of 20.07 °C to 25.23 °C. With regards to the mean indoor temperature values for entire household units, the RED control produced a temperature increase of approximately 1.4% (0.17 °C) over the OTR control. The average relative humidity after implementing the RED algorithm increased approximately 6.3% (i.e., an RH of 2.68%).

As shown in

Figure 12, the RED control kept the indoor air temperature at a higher level than did the existing OTR control, especially when the outdoor air temperature was higher than 9 °C. In addition, the indoor temperature ranges (25~75% values of the box-and-whisker plot) for the RED were narrower. This means that the RED may help to keep indoor temperatures more stable. Thus, it can be concluded that the residents’ heating usage as considered by the RED control method positively influenced the indoor thermal environment, and consequently, use of the RED control algorithm improves the indoor thermal environment in terms of the temperature.

4. Summary and Conclusions

High-rise residential buildings in South Korea use radiant floor heating systems as their primary form of climate control. In such systems, a heating supply water temperature is supplied by a heat exchanger located in a mechanical room; this comprises one of the most critical control parameters when determining a system’s efficiency. Conventionally, either the FT or OTR control method is used to set a heating supply water temperature. However, neither control method considers changes in residents’ heating energy usages by residents. The result is overheating, and thus a waste of heating energy.

To improve upon such inefficient control methods, this study proposed a new process for setting a heating supply water temperature, named Residential Energy Demand (RED) control in this study. To verify this method, researchers performed two verification processes via a case-study: a simulation-based verification before implementation of the RED algorithm, and a measurement-based verification after its installation. In addition, influences on the indoor thermal environment were evaluated by measuring both the indoor temperature and relative humidity. Based on the results of the analyses conducted, the following conclusions can be made:

From the measured data collected through the EMS of the case-study building complex, this study identified that the existing control method for a heating supply water temperature was the OTR process. That is, a heating supply water temperature is usually modulated based on OTR calculation logic, according to changes in the outdoor air temperature. However, it was observed that the heating supply water temperature was set to be higher even if the heating usage regularly decreased, due to lower outdoor air temperatures. Therefore, this study concluded that the OTR control method was likely to supply unnecessary overheating when residents did not actually require an increase in temperature.

Based on the results of the simulation-based verification before implementation, both the conventional OTR and proposed RED control methods set the heating supply water temperature according to changes in the outdoor air temperature. However, the RED process additionally considered changes in heating usage. As a result, using the RED system reduced the heating energy consumed by about 4.19% over the OTR control for the entire three months examined. Therefore, it can be concluded that the proposed RED control method saves heating energy by providing less heating when the heating requirements decrease.

Based on the results of the measurement-based verification after implementation of the RED algorithm, the average heating consumptions for the entire measurement period were 260.36 Gcal/h and 249.98 Gcal/h for the OTR and RED methods, respectively. It was determined that the heating savings was about 3.98%. In addition, the indoor thermal environment was evaluated for the same time period. The mean value of the measured indoor temperatures produced by using the RED control were approximately 0.17 °C higher than when the OTR process was used. The average relative humidity also increased about 6.3% when using the RED control. Therefore, this study concluded that the RED control saved heating energy and also improved the indoor thermal environment in terms of both temperature and humidity.

In general, this study verified the proposed RED method as a means of controlling a heating supply water temperature, finding that such a method provides more heating when residents require higher temperatures, and vice versa. This process has great potential to save heating energy and improve the indoor thermal environment. However, one problem needs to be resolved. The RED control method may consume more energy if the outdoor air temperature stays below −3 °C or the volume flow rate for heating is sustained above 20 m3/h. One possible solution is to set certain control limits (e.g., a maximum set-point temperature) to avoid excessive energy consumption. Therefore, further research on this issue is required to set the suitable control limits. In addition, this study focused on improving a control method for the heating supply water temperature (i.e., outlet water temperature at a heat exchanger) of a mechanical room.