1. Introduction

The loss prevention and waste reduction of perishable foods such as fresh green vegetables is a ubiquitous problem in cold chain among current practices [

1,

2,

3,

4]. It mainly results from microbial-decay due to time–temperature abuse [

5] and from biochemical and physiological loss related to micro-environmental compromises. It is precisely because of the correlation between the atmosphere and quality loss in the packaging [

6,

7] that the monitoring and controlling the process environment in vegetable cold chain can reduce losses. Losses during the cold chain contribute a lot to the losses of green produce in the cold chain. For example, losses in storage accounted for about 15–20% and in distribution about 5–10% for vegetable [

3], which has an undesirable impact on the environment and resources [

8], as well as social welfare in China. Increasing demand for fresh produce and the severity of food losses force us to turn to a safer and greener vegetable cold chain. Thus, responding to these issues in cold chain practices, packaging, and ongoing improvement in loss prevention [

9] is imperative.

Efficient packaging practices are the crux for preservation and processes management, including storage and distribution, which effectively reduce the loss and securing safety of fresh vegetables [

10] in cold chain. Although it has been widely explored that reducing decay rate and loss ratio as important means to relieve the losses of fresh green products from a more comprehensive perspective [

11] during cold chain. Proper packaging handling and pre-processing under low temperatures can effectively reduce losses throughout the cold chain. Packaging efficiency depends on packaging practices, including modified atmosphere packaging (MAP) [

12], intelligent packaging [

13], active packaging [

14], and other packaging practices [

15]. They [

13,

16] also confirm the advanced intelligent packaging as tools to reduce food losses. Besides, packaging, which can be considered as the smallest traceability unit [

17], also plays important roles in reducing mechanical damage. Therefore, continually improving packaging practices can greatly reduce fresh vegetable loss and improve the efficacy of the cold chain.

In terms of packaging practices, packaging practices for fresh vegetables in refrigerated container can reduce the loss, which can bring considerable advantages. Role differences of packaging materials in packaging practices have attracted our attention [

18]. Many studies [

19,

20] aim at solving the inefficient supply from a comprehensive technical perspective under the real cold chain. Nevertheless, these packaging practices [

21] and the influence of packaging materials attributes [

22] for sustainability are still undermining the final loss prevention and waste elimination. Therefore, considering perishable and low-value characteristics of fresh vegetables, ensuring the packaging efficiency and safety is important [

23]. Thus, for continuous improvement of a widely used packaging practice, a packaging efficiency evaluation is necessary.

However, current evaluation methods mainly focus on limited indicators, mainly temperature and humidity [

24,

25], while the analysis for gas parameters, packaging material input, and whole process performance has been neglected. Traditional practices based on experiments for continually improving the packaging design are iterative and time-consuming [

26]. Previous studies focus on the evaluation of the overall chain from non-stop monitoring [

27], but few of them introduces the specific package practices and the subtle differences between varieties. Although a fruit simulator for the real package environment acquisition is used [

28], it is not applied to the comprehensive assessment for the packaging efficiency. As for packaging materials, they [

29] point out the relationships between waste and materials to the environment, but environmental protection [

30], economy [

31], and safety [

32] were not evaluated from the perspective of loss prevention [

33]. For loss prevention effects, researchers [

34] focused on packaging mode research [

35], but few of them succeed in an integrated assessment framework for continual improvement. Overall, current methods failed to achieve an effective measurement of packaging efficiency and its continual improvement, especially for packaging practices in real vegetable cold chains.

Therefore, the limitations of current evaluation methods and the mismatches to the packaging practices call for comprehensive methods. Due to consumers’ preference for naturally preserved vegetables [

36] and the concern with products’ safety, more attention is needed to improve the efficiency of cold chain sustainability and to consider the environmentally-friendly properties of packaging materials and their function in loss prevention. In addition, current LCA (life cycle assessment) [

37,

38,

39] and comparative analysis methods [

40,

41] for packaging evaluations mainly focus on packaging materials used and their environmental impacts [

31], but fail to mention loss prevention performance [

42] in practice. Fortunately, evaluation methods based on dynamic monitoring of the packaging in specific scenarios can effectively evaluate the packaging efficiency in actual cold chain. Besides, continuous monitoring and evaluation of the process information of packaging in specific scenarios [

43] are in line with the continual improving requirements of vegetable cold chain practices. In short, a holistic evaluation method for ongoing improvement of the packaging efficiency in practical cold chain is needed and promising.

The contribution of this article is to propose a comprehensive framework and method for the packaging efficiency evaluation in real cold chain, and test in assessing the packaging efficiency of a current packaging mode for fresh green produce. It also gives some recommendations on the packaging efficiency for vegetable cold chain in practice with respect to sustainability.

2. Materials and Methods

2.1. Properties of the Fresh Vegetable Cold Chain Investigated

It is well recognized that the loss prevention of perishable food in cold chain is a difficult task, especially when taking the processing flow and packaging practices into consideration in real cold chains. Since proper packaging with high packaging efficiency helps address this issue, judicious interpretation of the critical control points contributes in objectively measurable ways to the aim of both loss prevention and safety, which are tightly related to packaging efficiency.

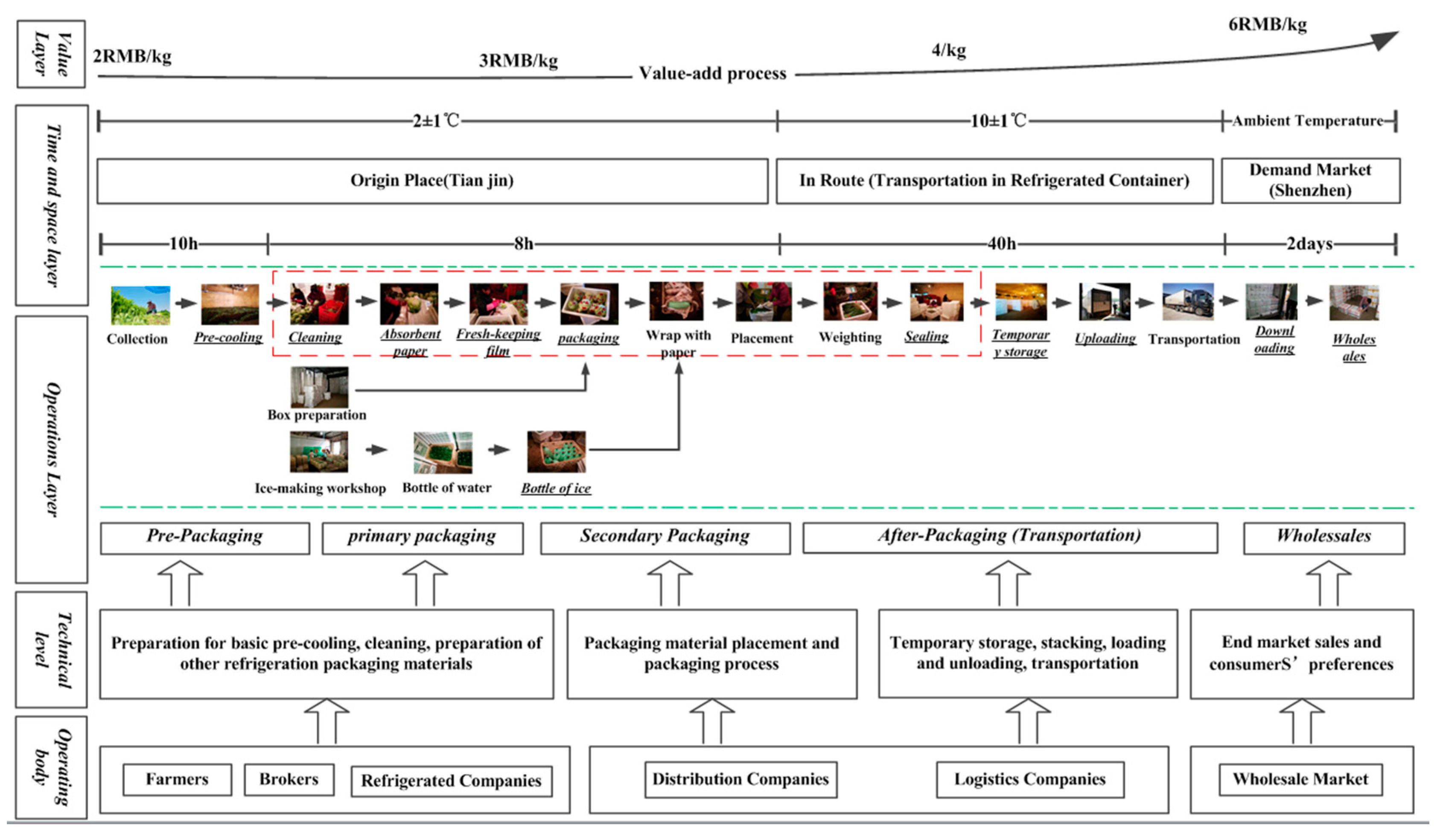

As presented in

Figure 1, it is the vegetable cold chain and the research scope in this paper. It contains the operational entity layer, the technical layer, the specific operations layer, the space-time layer and the value layer, and is also an extension of the fresh vegetable cold chain investigated. In the hierarchical structures that constitutes the cold chain for fresh vegetables, the operating layer is the key to the fresh vegetables in the cold chain, and it is also the content that can directly reflect and affect the loss of vegetables in the cold chain.

In this paper, modular two-layer packaging is carried out, because this mode is typical and widely used in China. From Tianjin to Shenzhen, China, this referenced cold chain was chosen. With such a time-distance that almost covers the whole vegetable market in China, it can represent most green produce cold chains. With the standard reefer container (IAA) by vehicle, the temperature is better kept at 10 °C. Normally, fresh leafy vegetables are perishable and have a relatively short shelf life (5–14 days). Vegetables here were graded, cleaned, pre-cooled, and then entered into the packaging process.

The multi-stage linked process of packaging practices with different materials input has spatiotemporal property. It reflects the complexity of the vegetable cold chain, and also affects loss prevention and thus the packaging efficiency. Considering the relatively short shelf life of fresh vegetables, packaging can prolong the post-harvest preservation time, ensuring a longer transit-time. High packaging efficiency can play an important role in loss prevention, even when considering the food loss resulting from cleaning and packaging. Therefore, reducing the loss of fresh vegetables needs to comprehensively consider the above factors through the analysis of packaging efficiency and continuous improvement under this scenario, and therefore provide solution references for other vegetables in the cold chain.

2.2. Packaging Efficiency Assessment Framework and Evaluation Method

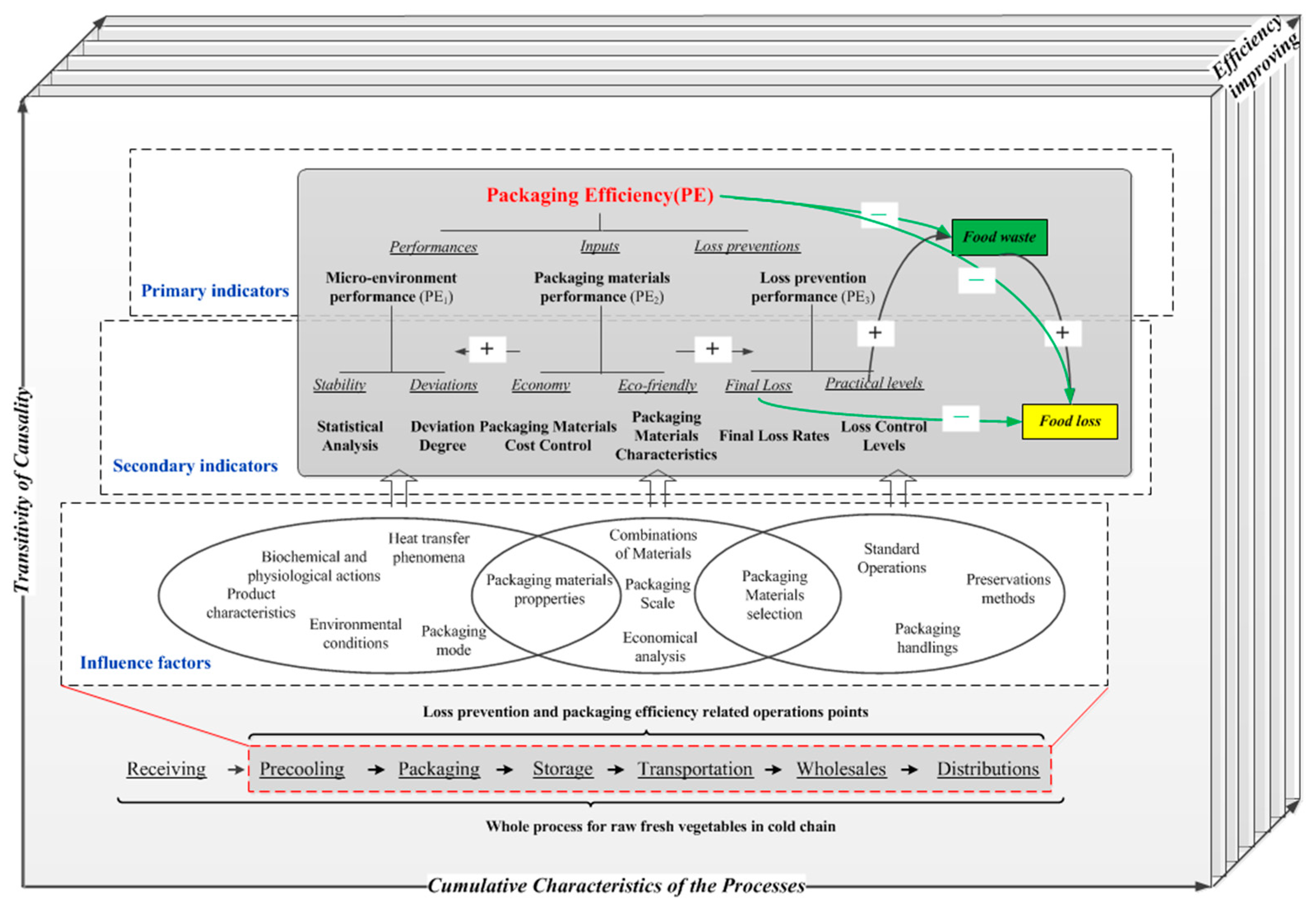

To achieve the evaluation and optimization of packaging efficiency in current practices, to realize the visualization of the efficiency of the packaging in refrigerated container, formalization, and calculation of the packaging efficiency based PEAF (Packaging Efficiency Assessment Framework) for continual improvement is inevitable. The packaging efficiency evaluation covers the entire packaging process and can realize the monitoring and control of the packaging efficiency in the process for fresh vegetable cold chain. Based on these structural factors and improved indictors, which have an interacting influence on the losses in vegetable cold chains (

Figure 2), we redefined packaging efficiency from the input, performance, and results. Moreover, the figure also shows the main loss prevention flow through improving packaging efficiency of the whole cold chain process.

The cold chain analysis for the fresh vegetable cold chain can orient to the packaging materials input, the dynamic performance of the packaging, and the final packaging results. Thus, the packaging efficiency (PE) refers to a comprehensive analysis of the whole process in fresh green produce cold chain. Then, these three intersecting orientations are related with three categories of efficiency, namely input efficiency, performance efficiency, and loss prevention efficiency. The different packaging types of packaging efficiency are listed below.

Definition 1. PE1 (micro-environmental performances) refers to the ability to maintain the microenvironment stable embodied in the fluctuations of temperature, humidity, and gas content information, in the package. Specifically, the performance of n different monitoring parameters is included, and the performance of each monitoring parameter is represented by the fluctuation of indicators such as variance. For example, this article contains five parameters, namely temperature, humidity, carbon dioxide, ethylene, and oxygen.whereis the weight coefficient for ith parameters; n is the number of monitored parameters;is the ith parameters’ performance.,

,

, andare the range, the standard deviation, the deviations and the effective value of the ith key parameter;,

,

, andare the corresponding acceptable values in packaging, and,

,

,

are the weight coefficients for trade-offs, respectively. Definition 2. PE2 (packaging materials performances) mainly present the impact of packaging materials, including the cost inputs and the characters of packaging materials used in the packaging process. This specifically refers to the performance of the cost of n different packaging materials, and the cost of material is composed of the discount rate and the material’s own safety and environmental characteristics.wherestands for the characteristics performance of each material used;is the weight coefficient for MC;andis the weighting factor for price cost of materials and recyclability feasibility.is the discount for packaging material. In addition,,

,

,

andare the values for lifetime of specific material, the feasibility of reuse, the number of cycles for reuse, safety of reuse for food, and the difficulty in reuse according to the corresponding gradations of each material, respectively. Definition 3. PE3 (loss prevention performances in practices) used for evaluating the final loss prevention effect of the packaging, which reflected by the final average loss rate and the evenness degree of actual loss rate in each process. It specifically refers to the actual remaining amount of agricultural products and the fluctuations of loss rates in each link.where CLR is the final average cumulative loss rate; and NL is the number of the packaging related process;is the proportion of loss rate in each link for whole loss rate.,

is the weighting factor for the balance of two parts. Definition 4. PE (overall packaging efficiency) mainly refers to the weighted sum of the three types of efficiency, which comprehensively features the input, performance and results of the packaging. It refers to the weighted sum of each efficiency, and the weight division is given in the results and discussion.where,

, and

indicate the weight values of three efficiency types respectively. Packaging efficiency involves the atmosphere performances, materials input and loss prevention. This design is mainly for the purpose to exhibit the classification and give weights to each efficiency, and then to assign different attention to continual improvements in a reasonable way.

2.3. Experimental Scheme

In order to test the proposed packaging efficiency evaluation methodology, we chose two leafy vegetables, which are perishable and vulnerable with short shelf life that are easy to assess, in the real cold chain as the evaluation object. Then, specific packaging practices were selected via our field investigations as the reference cold chain.

The specific practice is as follows. With the simple packaging modular design, it is a typical fresh vegetable cold chain operated by a commercial operator in China. With the given specification of internal dimensions (320 × 380 × 480 mm) and external (340 × 400 × 600 mm), the Styrofoam box is a consistent and space-efficient package in refrigerated containers. In order to be suitable for extended transportation, packaging materials such as ice bottles were used, which is aimed at maintaining temperature control [

44]. The materials used for this simple packaging also include the active paper and fresh-keeping film.

The scheme is to evaluate the operations—especially the efficiency of the packaging—in a specific scenario, without compromising the packaging practices. Mentioned above, the packaging mode is widely used for common low-value fresh vegetables. Therefore, the experiment here aims to evaluate and continually improve the packaging efficiency of the modular packaging mode in the refrigerated container. The specific experimental setting is as follows.

It is meaningful to achieve the ongoing improvement to reduce loss and waste of fresh produce in cold chain through comprehensive packaging efficiency assessment. Since modularized packaging [

45] is convenient for operation and management [

46] in supply process, it is taken as the ultimate delivery unit as well as the smallest packaging unit in the referenced cold chain. Therefore, it is convenient to evaluate packaging efficiency, we label it as a functional unit (FU). Besides, papers wrapped on ice bottles also prevent vegetable loss from the direct chilling injury caused by direct contact.

Table 1 manifests the two selected typical leafy vegetables with the same packaging specifications.

For more specific evidence regarding packaging efficiency differentiation in the refrigerated container, they were monitored in the same batch. Packaging practices and transportation process follow the current specific requirements of the raw vegetables supply operator. In addition, operating environment is also in accordance with the previous practices in this article.

2.4. Data Acquisition and Analysis

Information of micro-environment was retrieved by the monitoring devices, including temperature, humidity, and gas content. Apparatus based on IoT used for data acquisition were carefully placed inside the vegetable package to minimize the disturbances on the packaging, without jeopardizing the reliability of the resulting shelf-life prediction [

47] in our specific field test (

Figure 3). Environmental data during storage and distribution is also obtained via this equipment. Besides the atmospheric data, the cold chain operators also provide data relevant to loss prevention and the details of packaging materials used during the whole process. The monitoring devices are shown in

Table 2. The accuracy and solutions used for monitoring and energy consumption can meet the need for evaluation of current packaging mode in fresh vegetable cold chain.

We used MATLAB (R2018a) as tool for data treatment and analysis. Then, the calculated value was used to analyze the packaging efficiency of the two packaging units from abovementioned dimensions. In addition, the visualized packaging efficiency was also applied to assess the causes of the differences in performance between the packages, and therefore more targeted suggestions can be proposed for packaging redesign.

3. Results and Discussion

3.1. PE1 (Micro-Environmental Performance) Evaluation

Packaging influences the change in the multiple microenvironment parameters inside the package, which in turn affects packaging efficiency. Although temperature control is good in the refrigerated container, there is still obvious fluctuations in the transport phase, which last for 40 h. In addition to the increment in temperature and humidity, the fluctuations of the monitored gas components were also relatively obvious. Thus, the packaging method and transportation process together affects the microenvironment performance of the package.

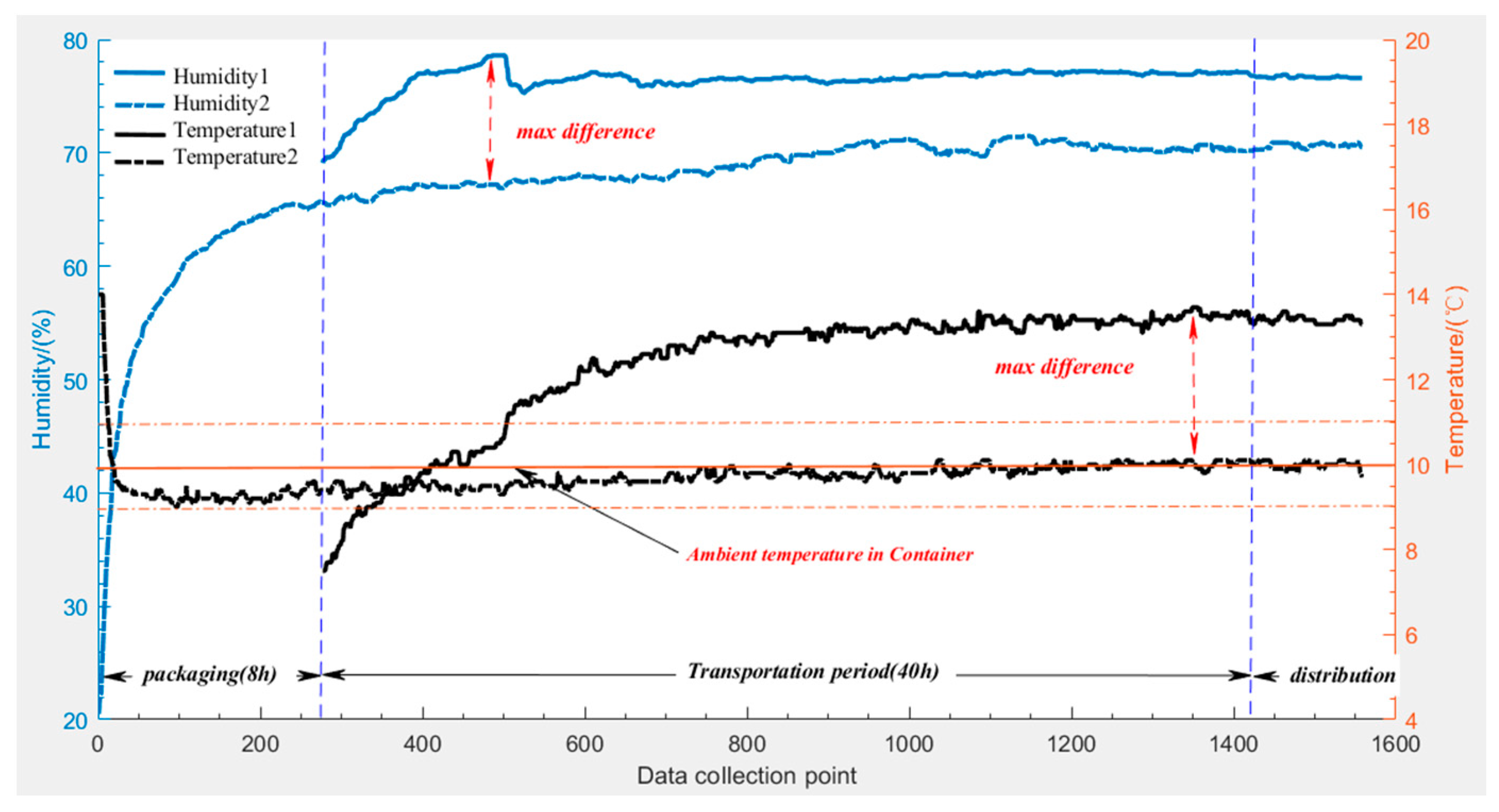

Temperature and humidity rises slowly, and finally keeps a relatively stable condition in the packaging in the reference chain (

Figure 4). This may be due to the influence of packaging and the gradually restricted respiration rate. The temperature we monitored starts to rise slowly along with the extension of transportation duration, mainly due to the respiration heat generated by the vegetables. Meanwhile, the humidity also increased to a certain extent near the saturated state at the current temperature. The max difference in humidity between the two packages occurs at the beginning of the process, which is the most vigorous phase of respiration. The latter reduction may be the result of condensation, but still maintains a gap of around 6%. The temperature also has a similar phenomenon that the maximum difference occurs in the latter and is related to its metabolic rate and respiratory heat. Thus, the environment in the packaging experienced a big change, which may lead to subsequent losses.

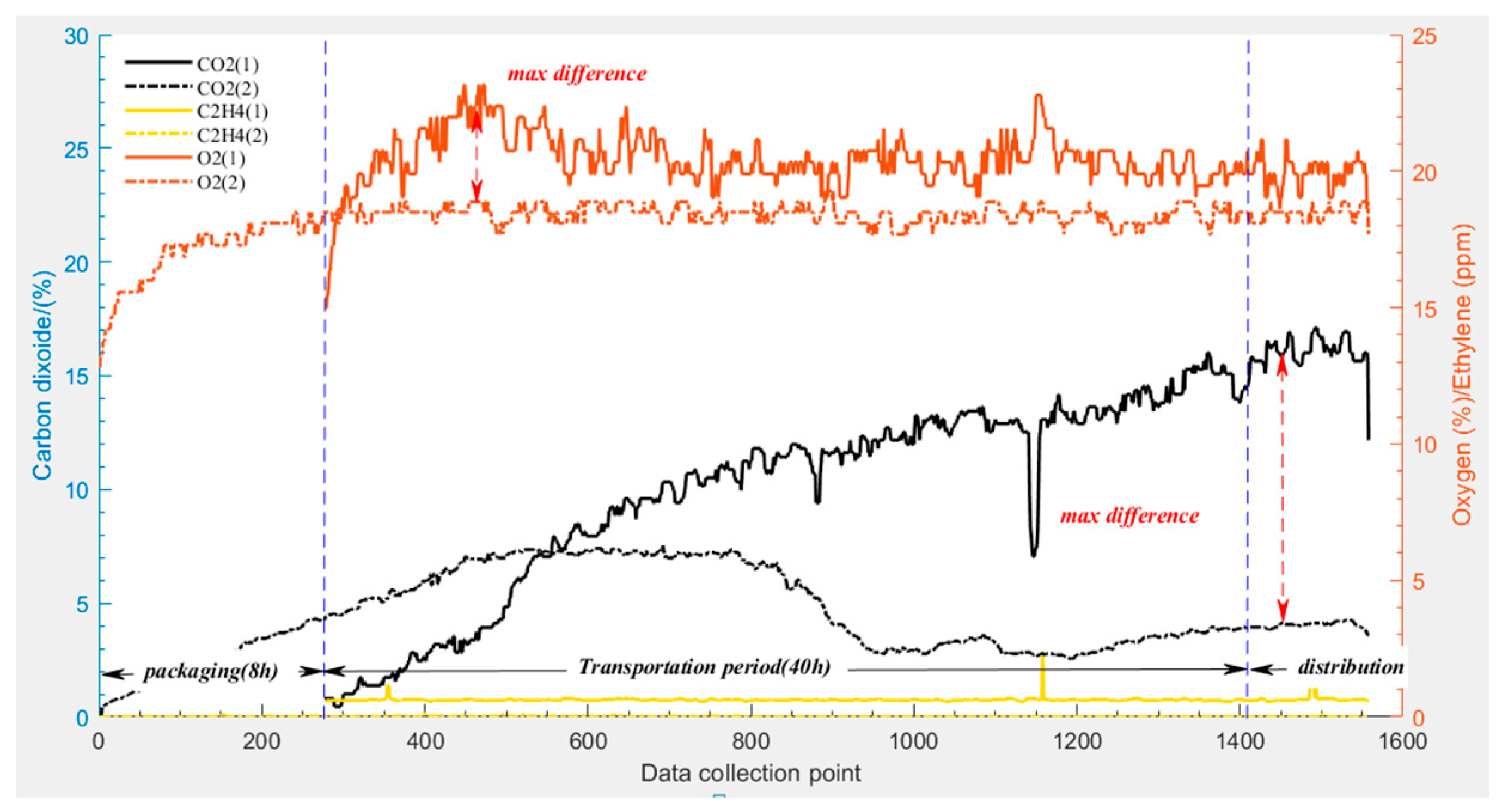

The oxygen content in the two FUs has a similar tendency to rise first and then slowly decreases, which related with the hysteretic and uneven diffusion process of the gas components in sealed packaging (

Figure 5). Carbon dioxide concentrations are accumulated over time in a non-stationary process, indicating that they change in different rate in the process. The difference between the two different units may relate with the difference in respiratory rate caused by the different varieties. It also confirms the existence of the packaging stress and the packaging efficiency differences between the varieties in this packaging mode. Between the micro-environmental information of the two units, the biggest difference in oxygen occurs in the initial stage, and carbon dioxide occurs at the end of the dispatching process. Moreover, the ethylene content is relatively small, which is a key parameter which tends to be overlooked, but it is visible here.

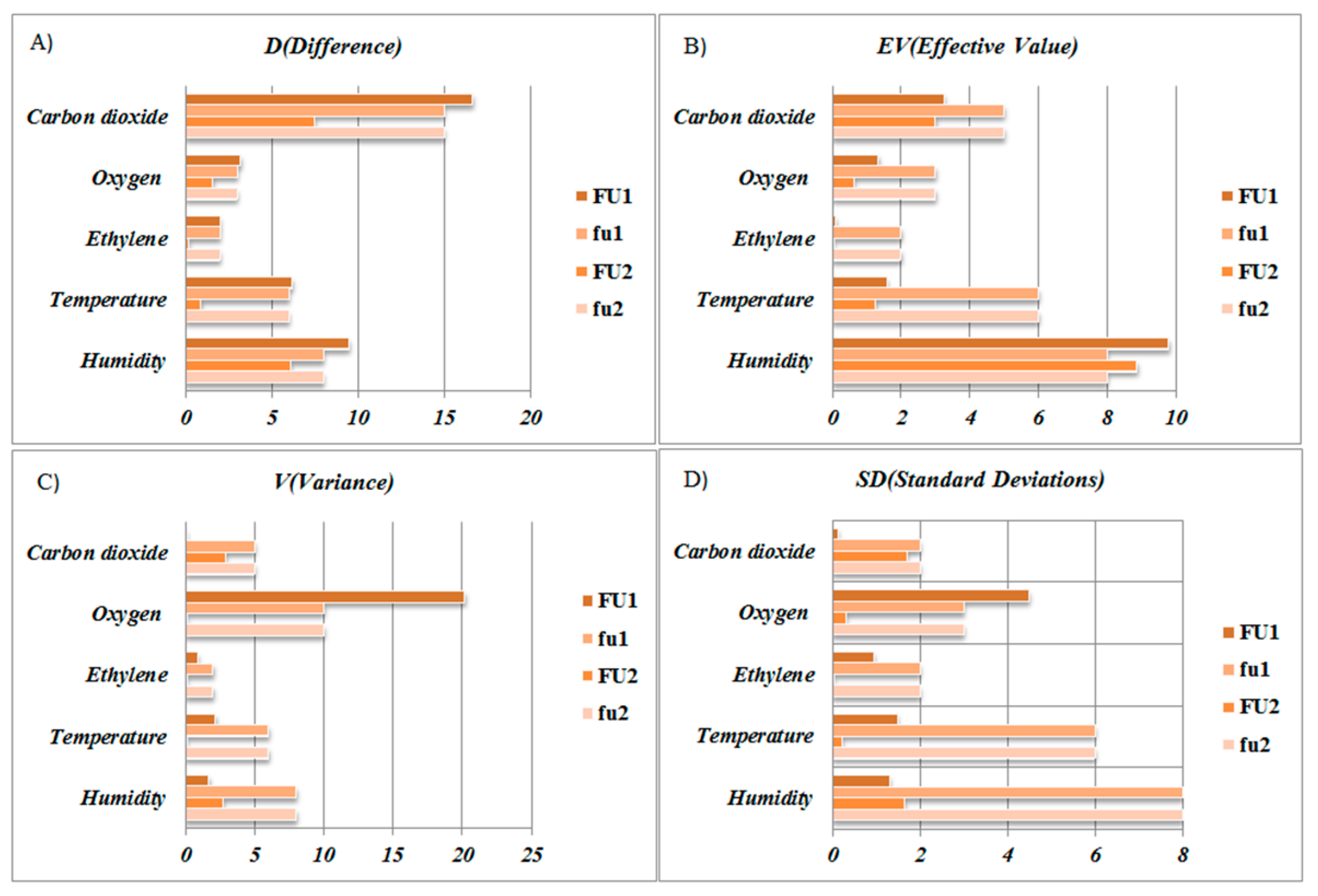

Indeed, environment differences between the packed objects reflect the differences in the packages. The differences between the FUs are depicted in

Figure 6. They increase the visualization of environmental data for packaged fresh vegetables and the responsiveness of the cold chain, and are useful for the packaging improving. It is also obviously worth noting that the performance in the environment during transport should be emphasized. Moreover, the differences in the micro-environmental fluctuations in the two units and in the effective cumulative values of the individual parameters are both significant. For the initial calculation, the weight of each part is built on the average distribution. Therefore, we can get the PE1:

Although attempts were made to improve performances of the package in terms of shelf life [

21], reducing the micro-environmental fluctuations in vegetable cold chain [

5] is still a big challenge, and this challenge was underestimated. Therefore, packaging improvement should give priority to the performance of the microenvironment parameters. In this case, ice bottles placed in packaging reduces the degree of fluctuations in those parameters. Through evaluation and selection of the appropriate advantageous materials in material packaging, such as active materials, specific gas eliminators and slow release agents [

48], and different additives [

49], these physical preservation methods can improve the temperature and gas compositions compromises that are negative. Thereby, further research should pay more attention to the means how to combine the corresponding cooling materials with packaging methods towards more stable environment in the packaging, in order to reduce the food surrounding environmental compromise and improve packaging efficiency in the refrigerated container.

Therefore, the combination of technologies has proven beneficial to cold chain monitoring [

50] for keep stable environment in packaging, and the trends from the insight of multi-sensors are imperative in loss prevention in cold chain. Thus, it has a positive significance for the optimization of packaging efficiency [

35] based on the microenvironment performance.

3.2. PE2 (Packaging Materials Performance) Evaluation

The choice of packaging materials and their specific application affects the economy and recyclability of the packaging. Given the key packaging materials used in the case were confirmed, it is necessary to assess these characteristics of packaging materials for optimum packaging materials combinations, especially in non-stop transportation and large-scale cases.

The choice and combination of specific materials determines the properties of the package itself and affect the external characteristics of the package. Thus, this packaging efficiency can be effectively improved by using better alternative packaging materials. For example, the unit price of the package, the life cycle, the possibility of recycling and the degree for reusability and the safety is important to the packaged vegetables.

Table 3 shows the properties of key packaging materials used in the case. They discussed the packaging feasibility of biodegradable materials [

33], indicating packaging redesign from the perspective of sustainability can significantly contribute to waste reduction, reuse, and recycling [

32]. On these grounds, we roughly divided each material into three grades according to the material characteristics and empirically set the reference value as 32. According to the role the materials played in loss prevention, we give different weights to them. Hence, we should emphasize the means to combine the corresponding materials with their characteristics towards more environmentally-efficient packaging and more cost-efficient packaging.

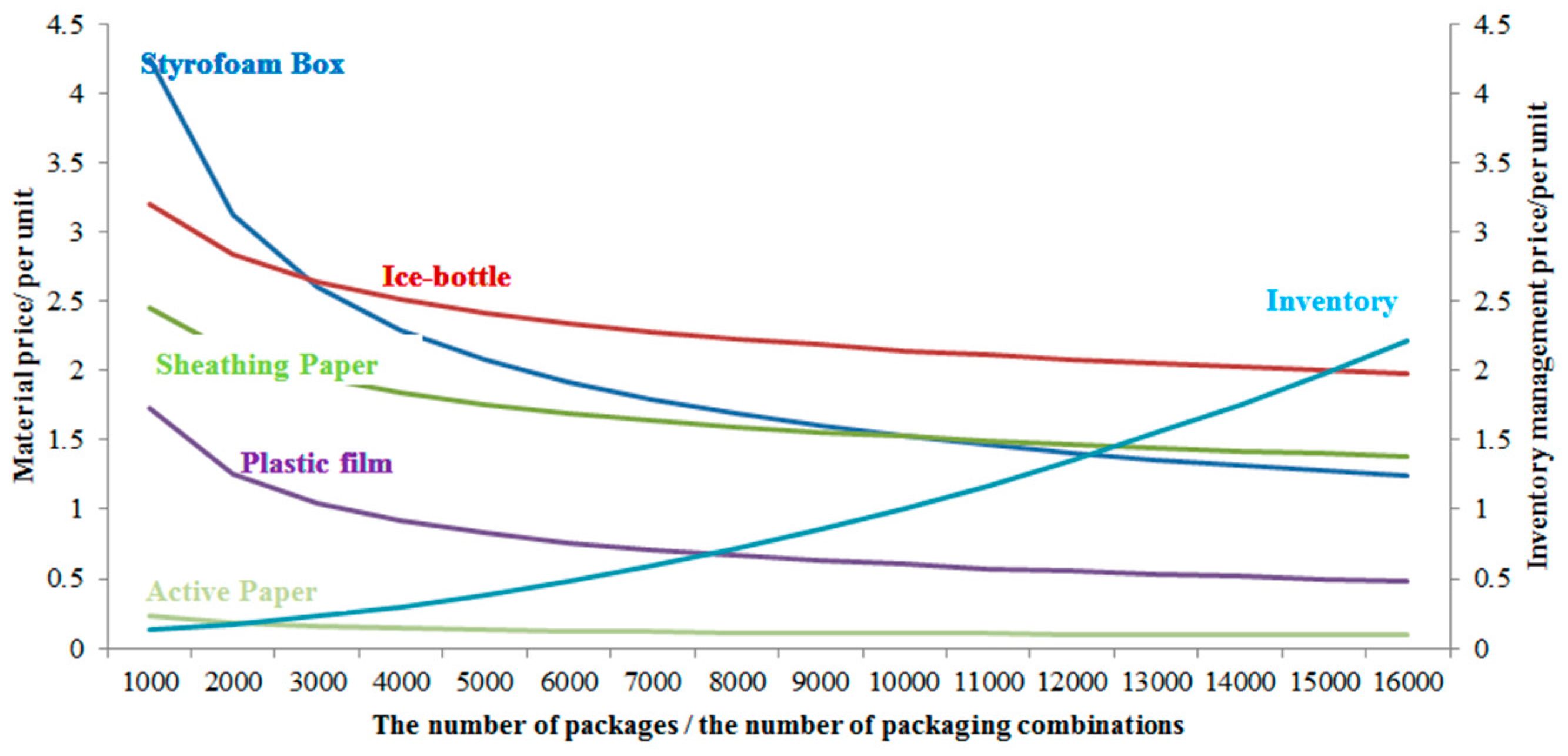

Previous studies have paid attention to the cost of packaging materials [

51], but they do not show how to reduce costs and to fit fresh vegetable in cold chain. Meanwhile, considering the impact of consumption and inventory, proper management can control their costs. The price curve of the packaging materials involved in the case was discussed (

Figure 7). It manifests that the recommended optimal packaging units’ amount range for various key materials is (10197, 10209), with the minimum material cost at 6.9064 RMB for each package. In addition, packaging design, packaging amount and inventory management have obvious economic impacts on packaging materials. Therefore, the trade-off between optimal units’ amounts and cost can effectively improve this packaging efficiency in real fresh vegetable cold chains.

Based on properties of packaging materials, we give equal weight to

and

, then the PE2

With same packaging mode, the PE2 value here is the same. As mentioned, the choice and combination of packaging materials are based on the characteristics of different materials and were partly determined by the specific requirements of the reference cold chain. The effect of the materials, comprehensive recyclability [

52], and materials safety for green produce are important. Therefore, PE2 value can be used as a reliable analysis tool for packaging material selection, which is similar with the study of [

49]. On the condition that the packaging material combination meets the overall preservation demands, it is feasible to increase this packaging efficiency and eliminate the packaging material waste, especially the environmental characteristics of the whole package through the adjustment of a single or several packaging material. Certainly, it also can effectively promote the operating costs of the entire packaging practice, making it easier to popularize and to meet the packaging needs of low-value products.

3.3. PE3 (Loss Prevention Performance) Evaluation

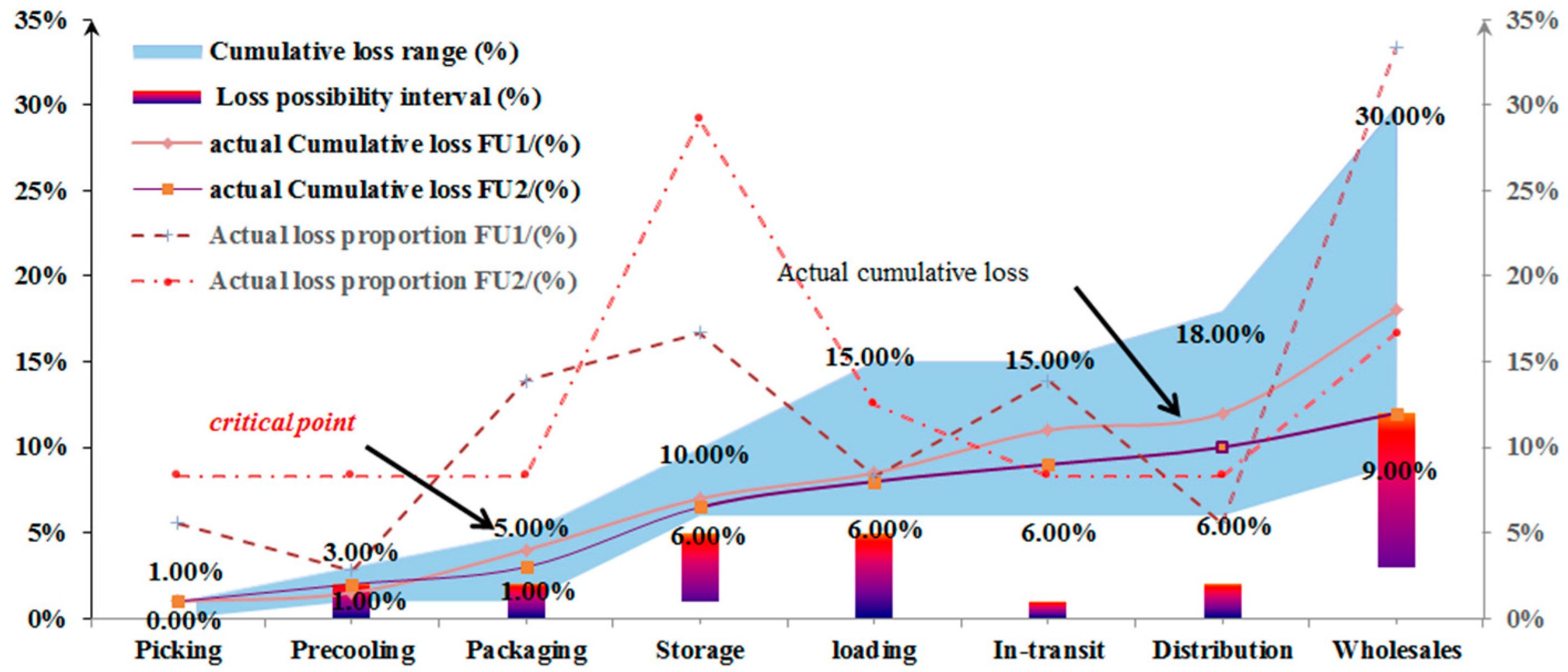

The cumulative effect of each operation reflects the final loss rate of the packaged leafy vegetables. There is no obvious impact on the appearance of slightly squeezed vegetables and net weight of the two kinds of units, due to relatively low temperature in packaging. However, based on the statistics data of the loss rate of different links and final losses (those parts that are not suitable for consumption) provided by the operators, certain deficiencies in current packaging practices and distribution process are fully exposed. Meanwhile, this phenomenon is also consistent with the performance analysis of the micro-environmental information and the packaging materials used. Moreover, there is a difference in the actual loss rate between the two vegetables, which related to different tolerance to packaging environment. Thus, loss prevention effects related to packaging efficiency are specifically exhibited in each operation (

Figure 8).

Packaging method has a cascading effect on the quality loss, which effectively reduce the quality loss during shipment and food waste after transportation. Nevertheless, there is still room for improvement. The key point for the actual loss is after packaging, and the loss rate starts to increase in the chain. Although the loss rate is low during transportation, it has a great impact on the follow-up links such as distribution and wholesale. It accounts for 30% of the actual total loss, and the loss possibility between each link fluctuates a lot. Since process control has a higher impact on packaging efficiency than merely the loss prevention results, we take

= 0.4,

= 0.6. Therefore, we can calculate the PE3

The differences between the different vegetable varieties in the packaging practices were ignored, especially when analyzing the final cumulative effect in the whole process. Since packaging functions throughout the entire process, suitable packaging can guarantee a longer shelf life and reduce the food loss probability through mitigating damage and delaying maturity [

53]. It also justifies that packaging design should focus on the reduction of losses. Besides, loss distribution in different process also assisted the conclusion that the actual food loss needs to be controlled from all process in the cold chain. Thus, reducing waste and preventing loss is a key consideration in sustainable packaging practices.

3.4. Integrity Evaluation of Packaging Efficiency

The overall assessment included the calculation of the overall efficiency and a visual comparison of these packaging efficiency. It will facilitate the specific efficiency improvement in the cold chain. Based on the above-mentioned packaging types, evaluation of subtle differences between the FUs and the difference between such loss prevention effects between breeds, which were not explicitly stated before, also provide a reference for the efficient cold chain management.

Specifically, we assessed the packaging efficiency performances in a comprehensive way. With the above results, it proved that the packaging practices mentioned for fresh vegetables in the Styrofoam box is promising, but there is still room for improvement in real cold chains. With the continuous push for loss prevention, loss prevention performance weights out the input performance and process performance, so

= 0.3,

= 0.3,

= 0.4. Thus, we can calculate the PE

Comparative analysis of different types of packaging efficiency makes the assessment obvious. It well visualized the differences among the packaging efficiency in the further improvement of the packaging process, which indeed helps to eliminate the differences accordingly. The same symptom is true for packaging input, PE2. Gaps of packaging efficiency were mainly reflected in the packaging performance and the loss prevention effect of the packaging, which deeply manifest the differences of two vegetables with the same packaging. In addition, it can be seen that the PE1 of FU1 was higher than that of FU2; and loss prevention has a similar trend in that the PE3 of FU1 is higher than that of FU2. Similarly, the overall packaging efficiency has the same results. Therefore, current packaging practice is more suitable for fresh Chinese parsley than spinach with higher packaging efficiency.

As aforementioned, it differs between fresh produces that the status of fresh produces, packaging requirements and efficiency of the process in commercial shipments. Therefore, it has great guiding significance to formulate a better packaging mode for fresh vegetables suitable for China’s actual situation. In addition, efficient packaging also has a positive impact on the purchase intention of the consumer [

54]. Thus, improving the fresh produce packaging process may be a better way to improve packaging efficiency in cold chains.

This evaluation method makes the visualization of the efficiency types feasible. It demonstrates that the differences between the efficiency in packaging are the combined effects produced from the variety, material and level of operations, which related to the choice of packaging materials, the variety and characteristics of the packaging. As the evaluation and continuous improvement of the packaging practices, package designers should treat efficiency differences of key points in a more targeted manner. The internal microenvironment performance can be improved through the efficient packaging modes. The economic and environmental performance is determined by the selection of materials, and the loss prevention can be enhanced via each packaging process. Then, the overall packaging efficiency can improve for the elimination of differences in targeted efficiency.

Since high-level practices can ensure the safety of packaged perishable food [

55], current packaging mode can be effectively promoted in the low-level cold chain practice in developing countries [

56] for further loss prevention. Thus, this methodology can be used to further exhibit the demonstrated advantage in cold chain, especially fresh green produces.

3.5. Performance Analysis of Efficiency for Efficient Packaging and Ongoing Loss Preventions

The packaging efficiency evaluation has a positive effect in further promoting loss prevention in cold chain. It will facilitate the use of corresponding postharvest preservation technology, which can improve the margins, thereby achieving the goal of cleaner production.

Table 4 shows the performance analysis of the packaging efficiency evaluation before and after carrying out this evaluation, and

Table 5 manifests the packaging efficiency involved in each operation and suggestions for the packaging practices improvements.

Given traditional evaluation methods are time-consuming, it provides a path for monitoring and improving the packaging performance for green produce in a very repeatable way based on multi-sensor monitoring. However, the weight value of each part for specific packaging efficiency needs to be elaborately optimized with actual requirements. Therefore, continuous validation and further improvement of the method is needed. Some problems have been neglected, such as selection of key factors, quantitative accuracy, and data quality. However, the highlight of this paper is the evaluation method, and experiment is carried out with typical leafy vegetable materials in a real cold chain. Thus, continuous improvement for the current packaging mode also has far-reaching significance to achieve sustainability.

Improving the efficiency of the packaging practices mentioned is in conformity with the social struggle and concerns for cleaner production and food safety. Although we failed to give details of the differences between the quality attributes, it is yet sufficient from a management perspective to conclude that the loss of the green produce in the current packaging mode can be ameliorated through improving specific packaging efficiency types.

In the long term, packaging efficiency for fresh produce in cold chain could be improved by phasing out poor-environmental friendly materials and mending according to these suggestions for cleaner packaging [

57]. Specifically, the evaluation indicates the optimization direction to certain efficiency in each main operation process.

We provided recommendations from packaging material input, packaging process performances, and final loss prevention effect, involved in each packaging process with clear definitions. Moreover, the recommendations are related to the specific packaging efficiency and the impacts of environmental factors. Therefore, more active and targeted efforts can be made according to specific packaging efficiency involved in practice. In addition, related parties should enhance each operation process with more green practices and more recyclable materials selection to achieve a more efficient packaging practice. Meanwhile, more attention should be paid to the packaging effect differences between varieties in the entire cold chain, and different treatments for different vegetables should be adopted to achieve a comprehensive improvement for packaging practices.

These suggestions for targeted efficiency in operations have important implications for cold chain operators. Suggestions highlight the consciousness to improve specific packaging efficiency types, and therefore the overall level of practices in fresh vegetable cold chain. Cutting costs under the effective trade-offs among losses, costs, and environmental protection facilitates the packaging and logistics companies. For consumers, improved packaging and demonstrated advantages [

58] also ensure the vegetables’ quality status when reaching the consumers, and guarantees the safety indirectly. Therefore, ongoing improvement of current packaging practices, and further minimizing the loss and the negative environmental impacts from the perspective of sustainability is a positive direction.

4. Conclusions

The holistic packaging efficiency evaluation method provides improved indicators for the evaluation of packaging efficiency for fresh vegetables in cold chain, and the analysis can continuously promote loss prevention and waste elimination. Besides, the differences between the packages were confirmed. The main factors affecting packaging efficiency are micro-environmental fluctuations, characteristics of packaging materials used, and actual loss prevention effects, which were interrelated in the case of vegetable packaging practice in cold chains in China. Thus, it is a feasible and sustainable evaluation approach to measure subtle packaging differences in refrigerated containers, and this approach can be used for continuous improvement of the fresh vegetables packaging practices.

For current packaging practice mentioned, these improved indicators indeed provide a path for better environmental performance and cleaner production. It is significant to re-examine the current packaging practices towards more efficient packaging from a more comprehensive and loss-prevention-oriented perspective for cleaner production. It also has proven to be a promising methodology with demonstrated advantages in visualization of the improved indicators. Taking the packaging method in practice, ongoing efficiency improvement is better for loss prevention in cold chains, especially in China. In addition, it also confirms that efficient packaging practices can effectively facilitate loss prevention in real cold chains.

The performance analysis of packaging efficiency evaluation showed that it can be used for guiding, further loss prevention and the extended awareness of related operators for efficient packaging practices. The targeted-awareness and continuous improvement for specific packaging efficiency has positive significance for continuous loss prevention in real cold chains. Besides, the nuances between different packaging efficiencies were underestimated, and differentiation management can further add to the value of fresh vegetables in cold chains. Therefore, insights into consciousness of improving specific packaging efficiencies are necessary. Variety-targeted packaging design and efficient packaging practices originating from different operational stages can facilitate the continuous improvement of loss prevention in fresh vegetable cold chains. Speaking differently, they will guarantee safety and green supply processes to achieve sustainable cold chain, with better perception among losses, costs, and environmental protection.

In line with the aim to facilitate statistical analysis and improve the effectiveness of the results, future research should be supported by more data. Therefore, the data acquisition method and the data quality for modeling should be enhanced. Although from a more comprehensive perspective, the selection and quantification of evaluation parameters are not well-designed. The instrument-measured quality index and nutritional indicators of fresh produce are not considered in the manuscript. Therefore, it should be enhanced in next research. Besides, the optimization of weights to given parameters should be conducted. After that, the analysis of the packaging efficiency evaluation and its relationships with real chain should be further enhanced. Last but not least, as an approximate calculation method for ongoing packaging efficiency improvement, recommendations for targeted packaging efficiency and visualization effect of packaging efficiency need to be revised and validated by more tests and used for other fresh produce.