Configuring New Business Models for Circular Economy through Product–Service Systems

Abstract

1. Introduction

2. Research Method

2.1. Research Approach

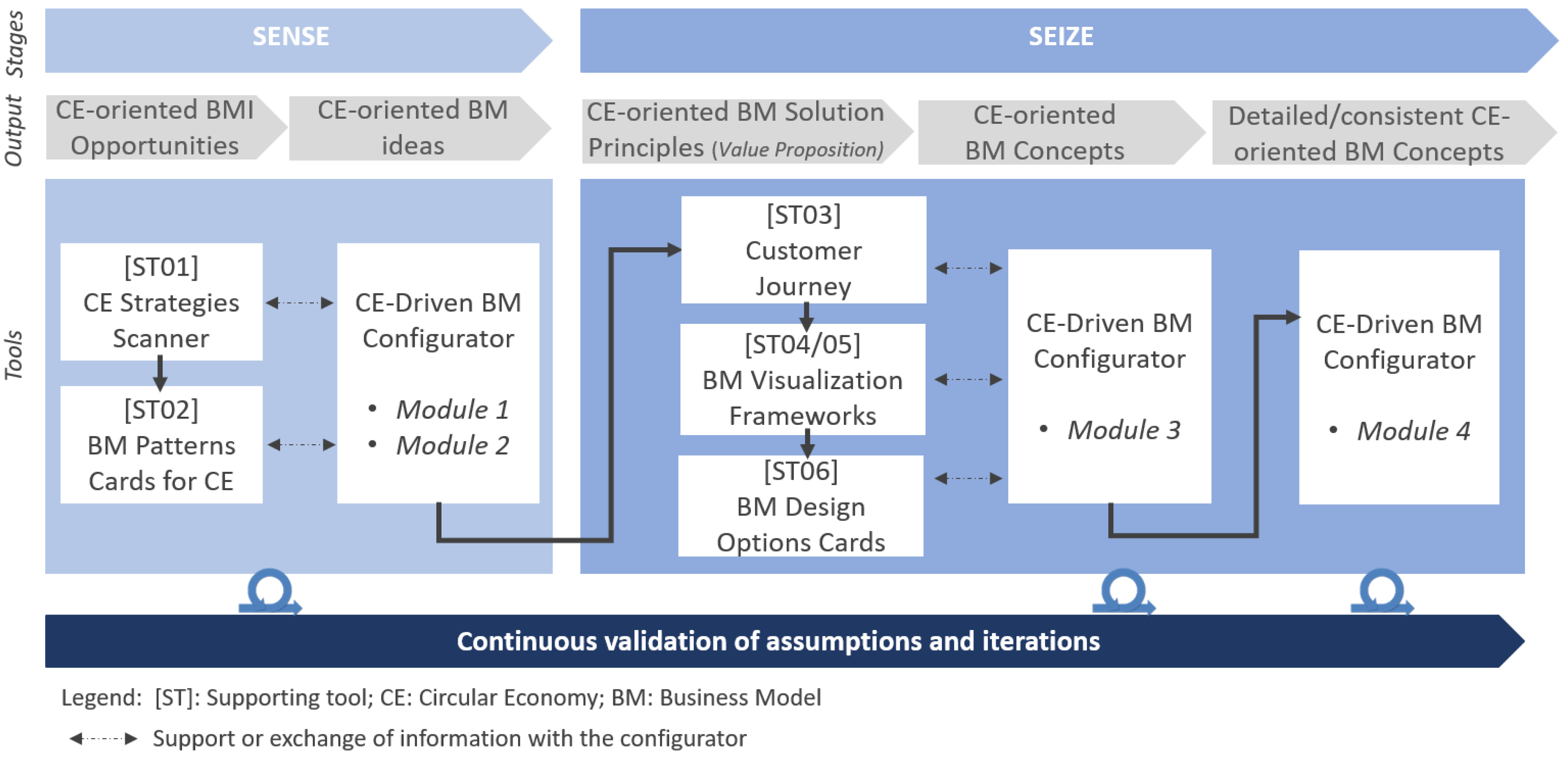

2.2. The CE-Oriented BMI Process and the CE-Driven BM Configurator

- Sensing and making sense of CE opportunities in the ecosystem;

- Seizing the opportunities by designing and assessing new CE-oriented value generation architectures (i.e., CE-oriented BM concepts); and

- Transforming/renewing operational capabilities accordingly in order to implement the CE-oriented BMs.

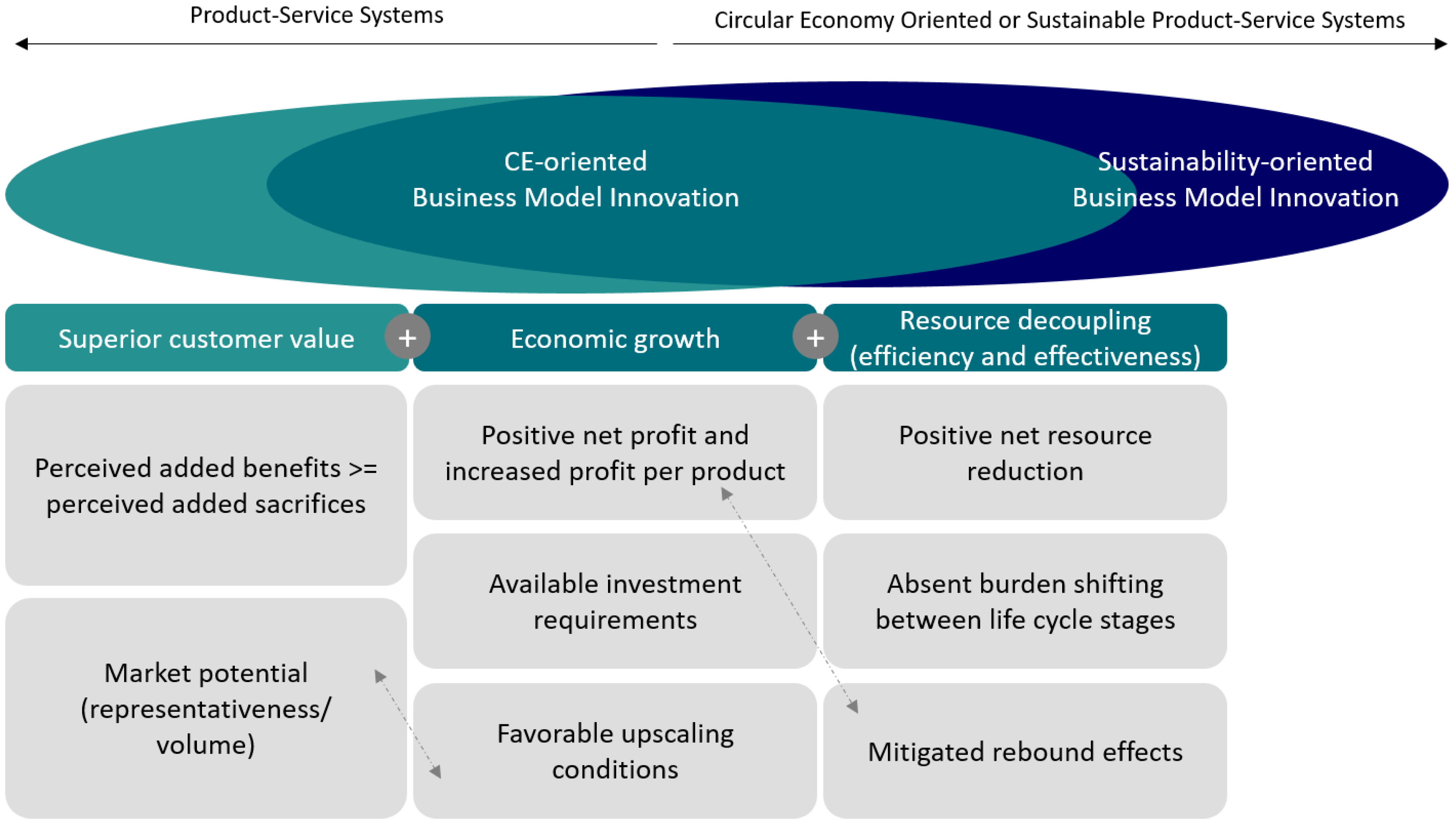

- Facilitating the proposal of business models based on PSS and with a focus on CE, including patterns that address economic and resource decoupling problems/opportunities (Section 3.2);

- Enabling practical application and providing guidance on how to use and combine the patterns along the stages of ideation, design, and evaluation of business models for CE, including simulation of different configurations (scenarios) (Figure 1 and Figure 2; and Section 3.2);

- Introducing a sectorial contextualization to enable more precise and in-depth business model configurations for CE.

3. Action Research Cycles and Their Results

3.1. The Companies Participating in the Action Research Cycles

3.1.1. Action Research Cycle A

3.1.2. Action Research Cycle B

3.2. Application and Results of the CE-Driven BM Configurator for Designing and Assessing CE-Oriented BMs Based on PSS

3.2.1. Action Research Cycle A

3.3.2. Action Research Cycle B

4. Discussion

- Breakeven delays with negative initial cash flow for access or use-oriented (pay-per-use or leasing) PSS (AR A and B) [38];

- Customer requirement of all-inclusive furniture portfolio/solutions (AR A) [39];

- Long usage time and technical simplicity of office furniture (AR A and B) [39];

- Applicability in regions where customers are geographically widespread (AR A) [39].

- Potential customers are likely to be companies that have a lot of short-term project work (AR A) [39];

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Configuring new business models for circular economy: From patterns and design options to action. In Proceedings of the 4th International Conference on New Business Models, Berlin, Germany, 1–3 July 2019. [Google Scholar]

- Stahel, W.R. The Performance Economy, 2nd ed.; Palgrave Macmillan UK: London, UK, 2010; ISBN 978-1-349-36919-5. [Google Scholar]

- Böhringer, C.; Rutherford, T.F. The Circular Economy–An Economic Impact Assessment. Report to SUN-IZA 2015. pp. 1–33. Available online: https://www.sun-institute.org/wc/files/report-circular-economy.pdf (accessed on 4 July 2019).

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- McAloone, T.C. Transitioning to the Circular Economy: What does It Take to Go from Efficiency to Effectivness? Available online: http://circitnord.com/wp-content/uploads/2019/04/Transitioning-to-the-Circular-Economy-What-does-it-take-to-go-from-efficiency-to-effectivness_Tim-C_-McAloone_Professor_-DTU-.pdf (accessed on 2 June 2019).

- Schulte, U.G. New business models for a radical change in resource efficiency. Environ. Innov. Soc. Transit. 2013, 9, 43–47. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Nußholz, J. Circular Business Models: Defining a Concept and Framing an Emerging Research Field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef]

- de Pádua Pieroni, M.; Blomsma, F.; McAloone, T.C.; Pigosso, D.C.A. Enabling circular strategies with different types of product/service-systems. Procedia CIRP 2018, 73, 179–184. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Olivetti, E.A.; Cullen, J.M.; Potting, J.; Lifset, R. Taking the Circularity to the Next Level: A Special Issue on the Circular Economy. J. Ind. Ecol. 2017, 21, 476–482. [Google Scholar] [CrossRef]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef]

- Tukker, A.; Tischner, U. Product-services as a research field: Past, present and future. Reflections from a decade of research. J. Clean. Prod. 2006, 14, 1552–1556. [Google Scholar] [CrossRef]

- de Pádua Pieroni, M.; Pigosso, D.C.A.; McAloone, T.C. Sustainable Qualifying Criteria for Designing Circular Business Models. Procedia CIRP 2018, 69, 799–804. [Google Scholar] [CrossRef]

- Haase, R.P.; Pigosso, D.C.A.; McAloone, T.C. Product/Service-System Origins and Trajectories: A Systematic Literature Review of PSS Definitions and their Characteristics. Procedia CIRP 2017, 64, 157–162. [Google Scholar] [CrossRef]

- Vezzoli, C.; Ceschin, F.; Carel, J.; Kohtala, C. Why have ‘Sustainable Product-Service Systems’ not been widely implemented? Meeting new design challenges to achieve societal sustainability. J. Clean. Prod. 2012, 35, 288–290. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; McAloone, T.C. Supporting the Development of Environmentally Sustainable PSS by Means of the Ecodesign Maturity Model. Procedia CIRP 2015, 30, 173–178. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business model innovation for circular economy: Integrating literature into a conceptual process model. In Proceedings of the 22nd International Conference on Engineering Design (ICED19); Manuscript In Press. 2019. [Google Scholar]

- Amshoff, B.; Dülme, C.; Echterfeld, J.; Gausemeier, J. Business model patterns for disruptive technologies. Int. J. Innov. Manag. 2015, 19, 1540002. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef]

- Wells, P. Economies of Scale Versus Small Is Beautiful. Organ. Environ. 2016, 29, 36–52. [Google Scholar] [CrossRef]

- Andreasen, M.M. 45 Years with design methodology. J. Eng. Des. 2011, 22, 293–332. [Google Scholar] [CrossRef]

- Van de Ven, A.H. Engaged Scholarship: A Guide for Organizational and Social Research; Oxford University Press: Oxford, UK, 2007; ISBN 9780199226306. [Google Scholar]

- Mathiassen, L. Designing Engaged Scholarship: From Real-World Problems to Research Publications. Engag. Manag. Rev. 2017, 1, 2. [Google Scholar] [CrossRef]

- Baskerville, R.L. Investigating Information Systems with Action Research. Commun. Assoc. Inf. Syst. 1999, 2, 1–32. [Google Scholar] [CrossRef]

- Chiasson, M.; Germonprez, M.; Mathiassen, L. Pluralist action research: A review of the information systems literature. Inf. Syst. J. 2009, 19, 31–54. [Google Scholar] [CrossRef]

- Puhakainen, P.; Siponen, M. Improving Employees’ Compliance Through Information Systems Security Training: An Action Research Study. MIS Q. 2010, 34, 757–778. [Google Scholar] [CrossRef]

- Coughlan, P.; Coghlan, D. Action research for operations management. Int. J. Oper. Prod. Manag. 2002, 22, 220–240. [Google Scholar] [CrossRef]

- Forrest, A.; Hilton, M.; Ballinger, A.; Whittaker, D. Circular Economy Opportunities in the Furniture Sector; European Environmental Bureau: Brussels, Belgium, 2017. [Google Scholar]

- White, G. European Union Furniture Sector Scoping Study; International Tropical Timber Organisation/FLEGT Independent Market Monitor: Yokohama, Japan, 2018. [Google Scholar]

- Statistic Sweden Furniture Sweden. Available online: https://www.tmf.se/siteassets/statistik/branschstatistik/mobler/annual-statistics---2017-for-2016.pdf (accessed on 7 May 2019).

- Danish Business Authority Furniture-CSRgov. Available online: http://csrgov.dk/furniture (accessed on 7 May 2019).

- Bosch, T.; Verploegen, K.; Grösser, S.N.; van Rhijn, G. Sustainable Furniture that Grows with End-Users. In Dynamics of Long-Life Assets; Springer International Publishing: Cham, Switzerland, 2017; pp. 303–326. ISBN 9783319454382. [Google Scholar]

- Besch, K. Product-service systems for office furniture: Barriers and opportunities on the European market. J. Clean. Prod. 2005, 13, 1083–1094. [Google Scholar] [CrossRef]

- Dul, J.; Hak, T. Case Study Methodology in Business Research, 1st ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Teece, D.J. Business models and dynamic capabilities. Long Range Plann. 2017, 51, 1–10. [Google Scholar] [CrossRef]

- Hellek, K.; McAloone, T.C.; Avlonitis, V.; Garcia i Mateu, A.; Andersen, J.B.; Mougaard, K.; Neugebauer, L.; Hsuan, J. PSS Tool Book: A Workbook in the PROTEUS Series, PRO-04; Technical University of Denmark (DTU): Kongens Lyngby, Denmark, 2013; ISBN 978-87-90416-90-4. [Google Scholar]

- Kwon, M.; Lee, J.; Hong, Y.S. Product-service system business modelling methodology using morphological analysis. Sustainability 2019, 11, 1376. [Google Scholar] [CrossRef]

- Remane, G.; Hanelt, A.; Tesch, J.F.; Kolbe, L.M. The business model pattern database—A tool for systematic business model innovation. Int. J. Innov. Manag. 2017, 21, 1750004. [Google Scholar] [CrossRef]

- Barquet, A.P.B.; de Oliveira, M.G.; Amigo, C.R.; Cunha, V.P.; Rozenfeld, H. Employing the business model concept to support the adoption of product-service systems (PSS). Ind. Mark. Manag. 2013, 42, 693–704. [Google Scholar] [CrossRef]

- Matthyssens, P.; Vandenbempt, K.; Berghman, L. Value innovation in business markets: Breaking the industry recipe. Ind. Mark. Manag. 2006, 35, 751–761. [Google Scholar] [CrossRef]

- Perey, R.; Benn, S.; Agarwal, R.; Edwards, M. The place of waste: Changing business value for the circular economy. Bus. Strateg. Environ. 2018, 27, 631–642. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain-Policy Report; PBL Publishers: The Hague, The Netherlands, 2017. [Google Scholar]

- Gassmann, O.; Frankenberger, K.; Sauer, R. Exploring the Field of Business Model Innovation; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-41143-9. [Google Scholar]

- Gassmann, O.; Frankenberger, K.; Csik, M. The Business Model Navigator: 55 Models That Will Revolutionise Your Business; Pearson Education Ltd.: Harlow, UK, 2014. [Google Scholar]

- Ritchey, T. General Morphological Analysis: A general method for non-quantified modelling. In Proceedings of the16th EURO Conference on Operational Analysis, Brussels, Belgium, July 1998. [Google Scholar]

- Brehmer, M.; Podoynitsyna, K.; Langerak, F. Sustainable business models as boundary-spanning systems of value transfers. J. Clean. Prod. 2018, 172, 4514–4531. [Google Scholar] [CrossRef]

- Kraaijenhagen, C.; Van Open, C.; Bocken, N. Circular Business: Collaborate and Circulate; Circular Collaboration: Amersfoort, The Netherlands, 2016; ISBN 9789082490206. [Google Scholar]

- Biloslavo, R.; Bagnoli, C.; Edgar, D. An eco-critical perspective on business models: The value triangle as an approach to closing the sustainability gap. J. Clean. Prod. 2018, 174, 746–762. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation; Self Published: Amsterdam, The Netherlands, 2010; ISBN 9780470876411. [Google Scholar]

- Richardson, J. The business model: An integrative framework for strategy execution. Strateg. Chang. 2008, 17, 133–144. [Google Scholar] [CrossRef]

- Antikainen, M.; Lammi, M.; Paloheimo, H. Creating value for consumers in CE-Tools as a service Creating value for consumers in CE-Tools as a service. In Proceedings of the XXVIII ISPIM Innovation Conference—Composing the Innovation Symphony, Vienna, Austria, 18–21 June 2017. [Google Scholar]

- Kravchenko, M.; McAloone, T.C.; Pigosso, D.C.A. Implications of developing a tool for sustainability screening of circular economy initiatives. Procedia CIRP 2019, 80, 625–630. [Google Scholar] [CrossRef]

- Azevedo, S.; Godina, R.; Matias, J. Proposal of a Sustainable Circular Index for Manufacturing Companies. Resources 2017, 6, 63. [Google Scholar] [CrossRef]

- Zink, T.; Geyer, R. Circular Economy Rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- Franklin-Johnson, E.; Figge, F.; Canning, L. Resource duration as a managerial indicator for Circular Economy performance. J. Clean. Prod. 2016, 133, 589–598. [Google Scholar] [CrossRef]

- Pieroni, M.; Marques, C.; Campese, C.; Guzzo, D.; Mendes, G.; Costa, J.; Rosa, M.; de Oliveira, M.G.; Macul, V.; Rozenfeld, H. Transforming a Traditional Product Offer into PSS: A Practical Application. Procedia CIRP 2016, 47, 412–417. [Google Scholar] [CrossRef][Green Version]

- Pieroni, M.; Pigosso, D.; McAloone, T. Exploring the synergistic relationships of circular business model development and product design. In Proceedings of the International Design Conference—Design, Dubrovinik, Croatia, 21–24 May 2018; pp. 2715–2726. [Google Scholar]

- Laubscher, M.; Marinelli, T. Integration of Circular Economy in Business. In Proceedings of the Going Green-Care Innovation, Vienna, Austria, 17–20 November 2014. [Google Scholar]

- Smith, D.J. Power-by-the-hour: The role of technology in reshaping business strategy at Rolls-Royce. Technol. Anal. Strateg. Manag. 2013, 25, 987–1007. [Google Scholar] [CrossRef]

- Schaltegger, S.; Freund, F.L.; Hansen, E.G. Business cases for sustainability: The role of business model innovation for corporate sustainability. Int. J. Innov. Sustain. Dev. 2012, 6, 95. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Schuit, C.S.C.; Kraaijenhagen, C. Experimenting with a circular business model: Lessons from eight cases. Environ. Innov. Soc. Transit. 2018, 28, 79–95. [Google Scholar] [CrossRef]

| BM Idea | BM Opportunities (Patterns) | Customer Value Potential | Structural Waste Source/Type | Decoupling Potential (based on [17]) |

|---|---|---|---|---|

| 1—‘Digital platform to facilitate access to/or use of modular furniture systems through short-term contracts.’ | 1—Access-based solution (use-oriented PSS) | Customer segments (especially B2B) requiring lower total cost of ownership and higher flexibility (e.g., such as project-based organizations); convenience of frequent customization and aesthetic changes required (styling of offices, fairs and events). | ‘Real’ product-life shortened—i.e., consumption patterns/use causing inferior longevity than design specifications. | Reduce the need to produce new products to fulfil needs. |

| 2—‘Furniture bank—digital platform to enable 'depositing furniture in one location and taking out in another place’ | 2—Access-based solution (use-oriented PSS) | Customer segments (especially B2C) requiring temporary solutions (e.g., exchange workers) or having dynamic lifestyle (moving frequently to different geographical locations). | ‘Real’ product-life shortened—i.e., consumption patterns/use causing inferior longevity than design specifications. | Reduce the need to produce new products to fulfil needs. |

| 3—‘Optimal workspaces/ people’s environment.’ | 3—Functional-based solutions with complete life-cycle services (result-oriented PSS) | Offices, particularly the ones adopting open-space structures. | Unnecessary configurations/amount of products; ‘Real’ product-life shortened—i.e., consumption patterns/use causing inferior longevity than design specifications. | Displace more resource intensive systems. |

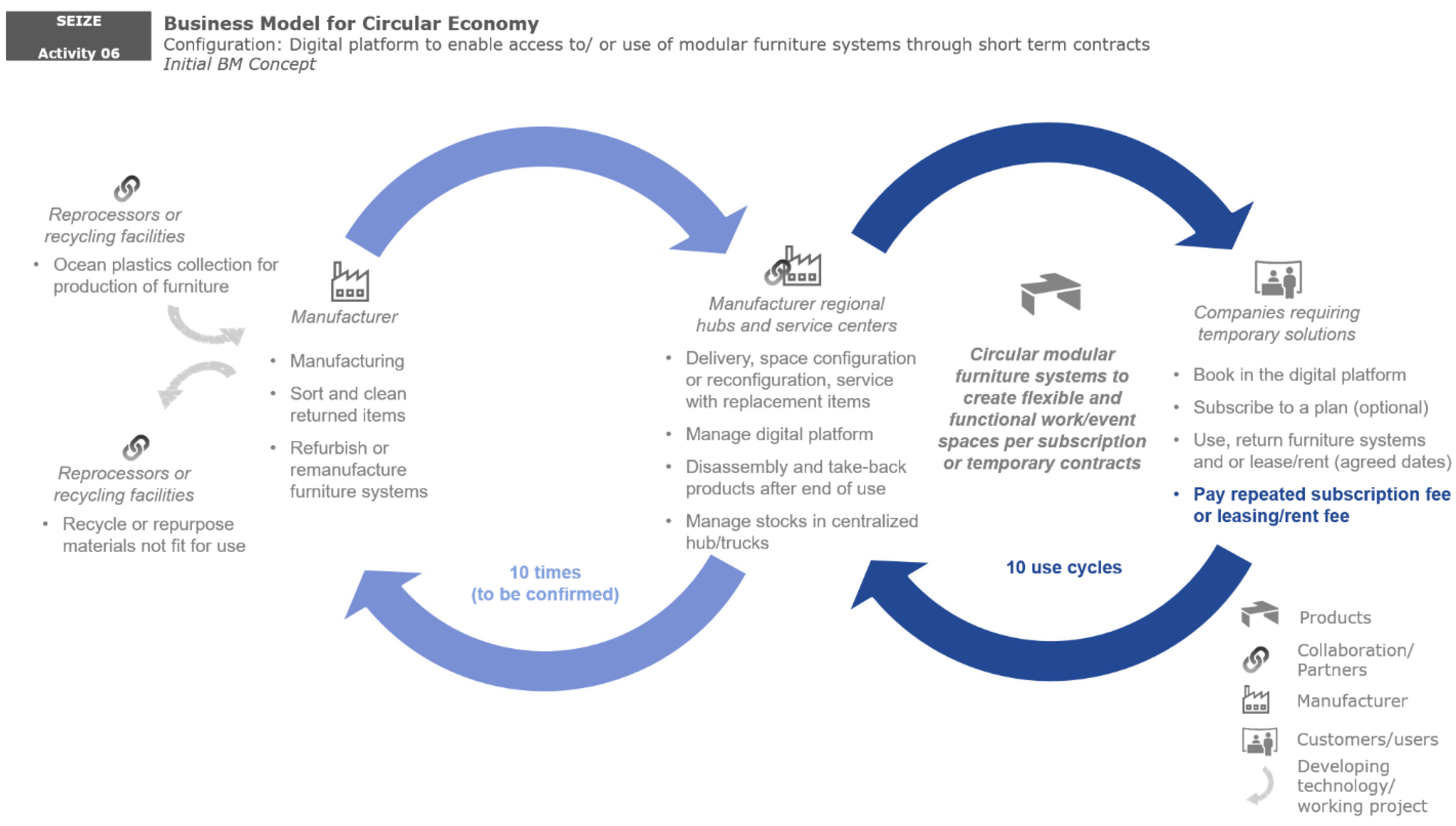

| PSS BM concept | Digital platform to enable access to/or use of modular furniture systems through short-term contracts (rental, leasing, or subscription). | |

|---|---|---|

| Segment/customers | B2B (e.g., project-based organizations, offices, event venues) | |

| Requirement is fulfilled when… | Results: | |

| PSS → Economic growth | ||

Ensure acceptable net profit  | … profit enabled by new BM concept > = (at least equal to) long-term profit of current business model. | Return on investment, net present value and profit margins (including profit per asset/product) for different subscription, leasing fees, and contract periods were calculated. This helped to adjust a feasible subscription/leasing fee to enable at least a comparable or superior profitability to current BM (in the long term). Pricing definition also considered customer needs/expectations. |

Foresee and mitigate investment requirements | … breakeven of the new BM concept occurs in an acceptable period, and if external financing capital is necessary it is also available. | Although profitable (positive return on investment), the concept incurs in a delayed breakeven of 10 years. Mitigation: Investigation of scenarios for cofinancing of this solution with the participation of investors in the first years. |

Adjust for and mitigate upscaling challenges | … volume of returning products (for recirculation) justifies/pays off the required investments. This involves dealing with economies of scale. | The estimated return of products and volumes of sales do not pay off investment in refurbishing facilities and marketing campaigns required for launching this concept (i.e., negative return on investment in the first decade). Mitigation: This concept will be offered in metropolis to guarantee enough volume. |

| PSS → Superior customer value | ||

Ensure added benefits and avoid or mitigate sacrifices | … added benefits for customers > (are perceived as higher than) added sacrifices in relation to current BM. | Considered added benefits: lower investment costs; simplicity of concept; flexibility to renew furniture constantly. Sacrifices: B2B is used to procure comprehensive furniture packages, with a diversified portfolio to fulfil an entire workspace. As sacrifices are considered larger than benefits, this criterion was not fulfilled. Mitigation: apply the concept for events (e.g., industry fairs) and with the new products being developed. Suitable characteristics: they are not a niche product; would be less affected by changes of taste and fashion than the current product; could be maintained in the event venues for multiple uses; combined with the modular systems they would fulfil the key needs of event participants. |

| PSS → Absolute resource decoupling (effectiveness and efficiency) | ||

Ensure net resource reduction | …resources needed for needs fulfilment without subscription > (are higher than) resources needed for needs fulfilment with subscription. | 20–45% potential resource reduction (calculated with indicator utility 1; due to no need to produce new products). Opportunities for improvement in other concepts: not possible to capture the ‘full circularity potential’ of the product (could be used/refurbished for 10 cycles, but it is reaching 2 cycles in this configuration) imposed by market requirements regarding the time taken for products to be returned back and made available for new contracts. |

Avoid burden shifting between life cycle stages | … “additional resources are not required during production and end-of-life.” | The furniture needs to be designed for easy disassembly and high durability. However, since modular product design was already part of the incumbent BM, this could help avoid burden shifting. One potential risk is shifting the burden to the end-of-life by substituting the current raw material MDF to ocean plastics, in case that recyclability of the latter is not possible. |

Mitigate rebound effects | … “value-adding low-resource intensive services mitigate or exceed any potential costs-savings.” | By not having the upfront investment, customers (especially in the case of offices or project-based organizations) could spend these savings with other resources. Mitigation: this could be absent in the case of events’ solutions because currently, the venue owners are not necessarily the owners of modular furniture/materials for space creation of stands. |

| Final BM Idea | Original Selected BM Pattern | Combined Patterns | Customer Value Potential | Structural Waste Source/Type | Decoupling Potential (Based on [17]) |

|---|---|---|---|---|---|

| 1—‘Furniture for social meeting places to last a lifetime with services for life-extension …trade in or we pick up your used furniture for free.’ | 1—Products with through-life care (product-oriented PSS) | Incentivized product return for next-life sales | 1st life: customer segments (especially B2B) requiring modernization or refurbishment of previously acquired products (30 years in use) or ‘often’ changes in aesthetics. 2nd or further lives: customer segments interested in ‘greener choices’ (e.g., public procurement). | Lack of solutions for life-extension; ‘real’ product-life shortened—i.e., consumption patterns/use causing inferior longevity (sometimes 6 years) than design specifications (over 20 years). | Reduce the need to produce new products to fulfil needs. |

| 2—‘Furniture for social meeting places to last a lifetime with services for life-extension and efficient management of urban spaces …trade in or we pick up your used furniture for free.’ | 2—Products with efficient maintenance management (product-oriented PSS) | 1—Products with through-life care (product-oriented PSS) + Incentivized product return for next-life sales | 1st life: customer segments (especially B2B) requiring modernization or refurbishment of previously acquired products (30 years in use) or ‘often’ changes in aesthetics. 2nd or further lives: customer segments interested in ‘greener choices’ (e.g., public procurement). | Lack of solutions for life-extension; ‘real’ product-life shortened—i.e., consumption patterns/use causing inferior longevity (sometimes 6 years) than design specifications (over 20 years) or lack of proper care (maintenance). | Reduce the need to produce new products to fulfil needs, and reduce the need for resources during use. |

| 3—‘Best fit/ configuration furniture for social meeting spaces at a ‘monthly maintenance budget.’ | 3—Access-based solution (use-oriented PSS) | Own reverse operations (e.g., reprocess, refurbish for reuse in a new contract) | Customer segments (especially B2G) requiring solutions with lower up-front investment; available budget for maintenance or operational expenses. Or, customer segments (B2C) requiring changes in aesthetics. | ‘Real’ product-life shortened—i.e., consumption patterns/use causing inferior longevity (sometimes 6 years) than design specifications (over 20 years). | Reduce the need to produce new products to fulfil needs. |

| PSS BM concept 1. | Sales of long-life outdoor furniture with through-life care services and buy-back schemes. | |

|---|---|---|

| Segment/customers | B2B and B2G | |

| Requirement is fulfilled when… | Results: | |

| PSS → Economic growth | ||

Ensure acceptable net profit | … profit enabled by new BM concept > = (at least equal to) long-term profit of current business model. | Return on investment, net present value and profit margins (including profit per asset/product) for different buy-back fees and an average of substitution were calculated. This helped to adjust a feasible price for products or services contracts to enable comparable profitability to current BM (in the long term). Pricing definition also took into consideration customer needs/expectations. |

Foresee and mitigate investment requirements | … breakeven of the new BM concept occurs in an acceptable period for the company, and if external financing capital is necessary it is also available. | The concept presented an acceptable pay-back period for the company (around 6 years), but estimated costs have to be reviewed after negotiation with partners. |

Adjust for and mitigate upscaling challenges | … volume of returning products (for recirculation) justifies/pays off the required investments. This involves dealing with economies of scale. | The volume of returning products is small to justify investments in refurbishing facilities. Mitigation: outsource or find local partners with the appropriate capabilities/techniques. |

| PSS → Superior customer value | ||

Ensure added benefits and avoid or mitigate sacrifices | … added benefits for customers > (are perceived as higher than) added sacrifices in relation to current BM. | Considered added benefits: environmental conscious/compliant option for end-of-use; convenience to ‘get rid of old furniture’ at the end of use; lower controlled maintenance costs; affordable option/lower investment. Sacrifices: in the case of B2G, it could be complex to convince subcontractors to sort specific furniture from the projects (in the case of renovations) to take back. Mitigation: establish partnerships and implement attractive buy-back. |

| PSS → Absolute resource decoupling (effectiveness and efficiency) | ||

Ensure net resource reduction | …resources needed for needs fulfilment without subscription > (are higher than) resources needed for needs fulfilment with subscription. | 7–28% potential resource reduction (calculated with indicators utility and longevity 1; due to life-extension and no need to produce new products). |

Avoid burden shifting between life cycle stages | … “additional resources are not required during production and end of life.” | The furniture needs to be designed for easy disassembly. This could have an effect on durability. |

Mitigate rebound effects | … “value-adding low-resource intensive services mitigate or exceed any potential costs-savings.” | Rebound with the increased demand for resources could occur either if 2nd life furniture (refurbished or remanufactured) is perceived as of inferior functionality or if it is priced lower when compared to new ones [60]. In the discussed BM concepts, price differentiation was considered. Mitigation: prices should be equalized in the long term. |

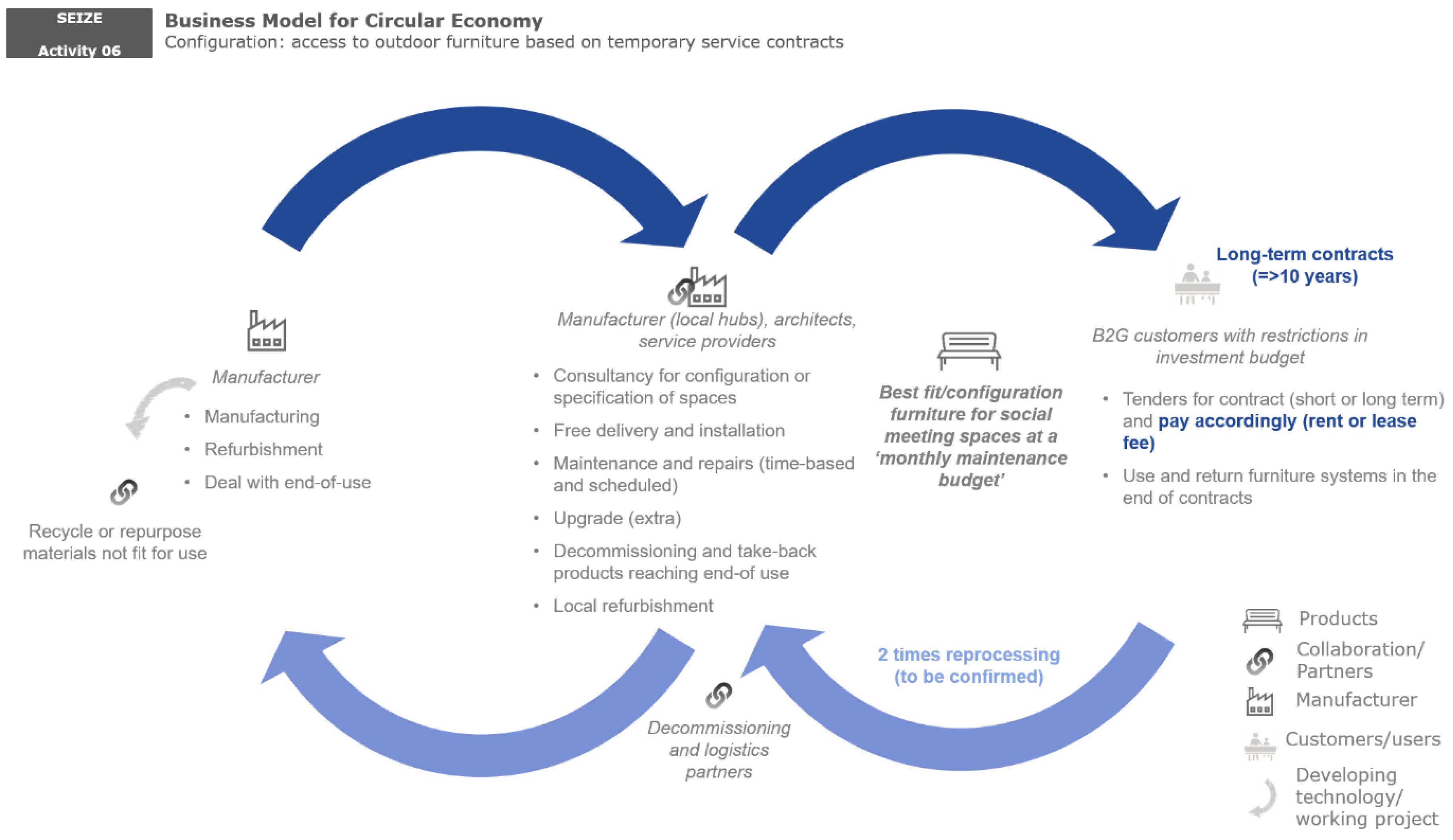

| PSS BM concept 2 | Access to outdoor furniture based on temporary service contracts. | |

|---|---|---|

| Segment/customers | B2G customers with restrictions in the investment budget B2C customers with short-term projects or temporary spaces | |

| Requirement is fulfilled when… | Results: | |

| PSS → Economic growth | ||

Ensure acceptable net profit | … profit enabled by new BM concept > = (at least equal to) long-term profit of current business model. | Return on investment, net present value and profit margins (including profit per asset/product) for different contract periods and prices were calculated. This helped to adjust a feasible price for services contracts to enable comparable profitability to current BM (in the long term). Pricing definition also took into consideration customer needs/expectations. |

Foresee and mitigate investment requirements | … breakeven of the new BM concept occurs in an acceptable period for the company, and if external financing capital is necessary it is also available. | The concept presented delayed pay-back period (around 9 years). Mitigation: the company would self-finance initial projects for strategic purposes. |

Adjust for and mitigate upscaling challenges | … volume of returning products (for recirculation) justifies/pays off the required investments. This involves dealing with economies of scale. | The volume of returning products is small to justify investments in refurbishing facilities during the beginning of the implementation. Mitigation: outsource or find local partners with the appropriate capabilities/techniques. |

| PSS → Superior customer value | ||

Ensure added benefits and avoid or mitigate sacrifices | … added benefits for customers > (are perceived as higher than) added sacrifices in relation to current BM. | Considered added benefits: lower upfront investment; more value received to money; convenience; environmental conscious/compliant option for end-of-use. Sacrifices: binding of 10-year contract (should not be critical). |

| PSS → Absolute resource decoupling (effectiveness and efficiency) | ||

Ensure net resource reduction | …resources needed for needs fulfilment without subscription > (are higher than) resources needed for needs fulfilment with subscription. | 14–28% potential resource reduction (calculated with indicators utility and longevity 1; due to life-extension and no need to produce new products). |

Avoid burden shifting between life cycle stages | “additional resources are not required for production/end-of-life.” | The furniture needs to be designed for easy disassembly. This could affect durability. |

Mitigate rebound effects | “value-adding low-resource intensive services mitigate or exceed any potential costs-savings.” | By not having the upfront investment, customers could spend these savings with other resources. In the case of B2G, this is considered as a mitigated risk since they are already with ‘limited budget for investment’ upfront. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

P. P. Pieroni, M.; C. McAloone, T.; C. A. Pigosso, D. Configuring New Business Models for Circular Economy through Product–Service Systems. Sustainability 2019, 11, 3727. https://doi.org/10.3390/su11133727

P. P. Pieroni M, C. McAloone T, C. A. Pigosso D. Configuring New Business Models for Circular Economy through Product–Service Systems. Sustainability. 2019; 11(13):3727. https://doi.org/10.3390/su11133727

Chicago/Turabian StyleP. P. Pieroni, Marina, Tim C. McAloone, and Daniela C. A. Pigosso. 2019. "Configuring New Business Models for Circular Economy through Product–Service Systems" Sustainability 11, no. 13: 3727. https://doi.org/10.3390/su11133727

APA StyleP. P. Pieroni, M., C. McAloone, T., & C. A. Pigosso, D. (2019). Configuring New Business Models for Circular Economy through Product–Service Systems. Sustainability, 11(13), 3727. https://doi.org/10.3390/su11133727