Factors Influencing Construction Waste Generation in Building Construction: Thailand’s Perspective

Abstract

1. Introduction

2. Literature Review

2.1. Reduce, Reuse, and Recycle

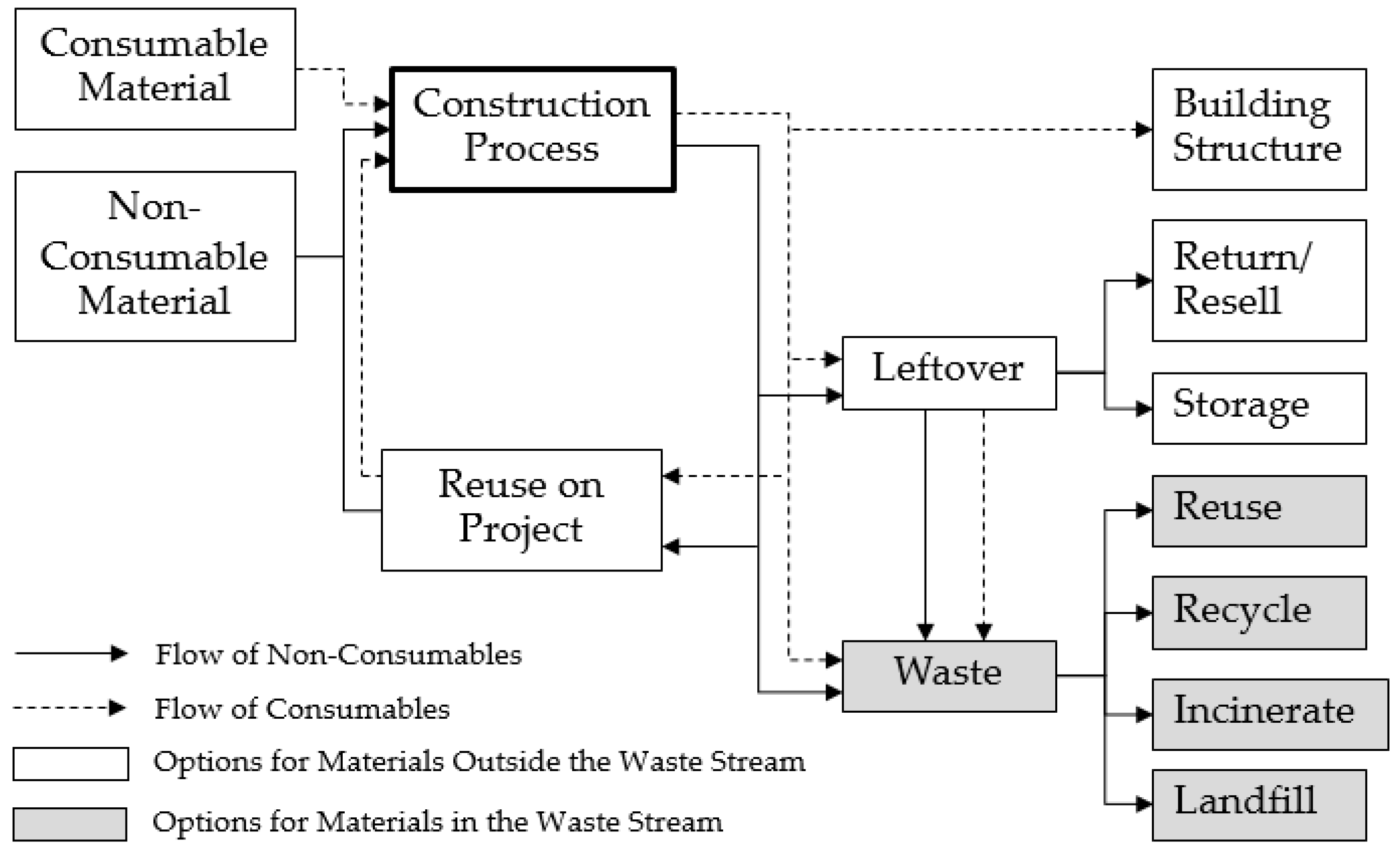

2.2. Construction Waste

2.3. Types of Waste from Construction Materials

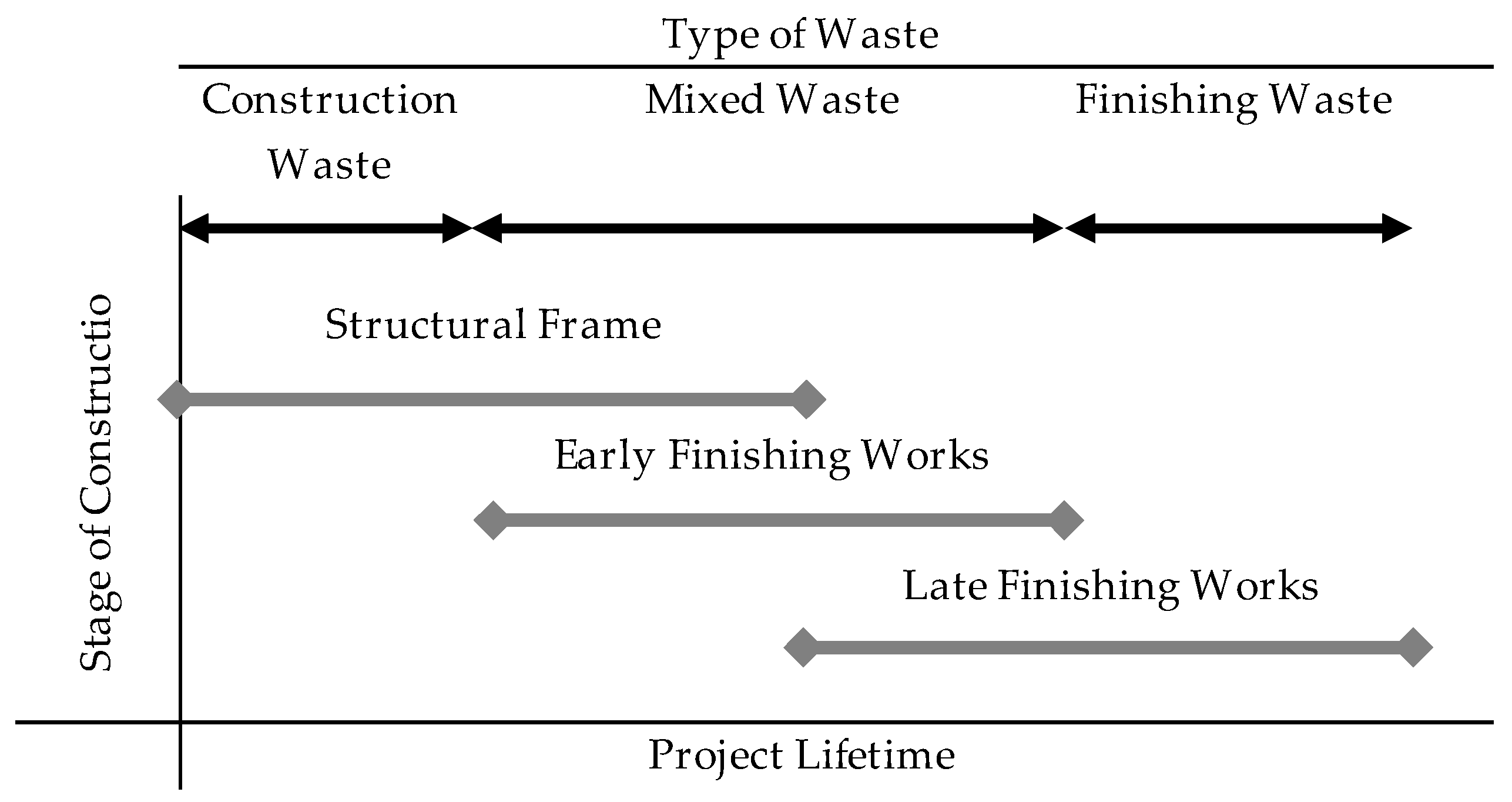

2.4. Construction Waste Categories

2.5. Construction Material Waste Generation Factors

2.6. Categorization of Construction Material Waste Generation Factors

2.7. Design and Documents(DEDO)

2.8. Material and Procurement (MAPR)

2.9. Construction Methods and Planning (COPL)

2.10. Human Resources (HUMA)

3. Research Methodologies

3.1. Instrument

- A comprehensive list of 28 construction waste generation factors that were identified through the literature. The literature review identified 166 factors that affect construction waste. These factors were cross referenced and reduced to 28 based on the following two steps that were suggested by Wambeke et al. [60]: (1) removing factors that were only suitable for specific projects and tasks, and (2) combining similar factors under the same category. These causes were grouped into four categories according to their sources. Factors that cause construction waste in this paper are shown in Table 5 below.

- The content validity and appropriateness of the questions in the questionnaire were reviewed by academics and construction practitioners to verify comprehensibility and relevancy of the contents.

- A pilot survey was conducted to test the reliability of the content and the design of the survey. The questionnaires were sent out to a sample group of thirty construction personnel. The total internal consistency reliability coefficients were 0.985.

- The final questionnaire is divided into two parts. The first part covers the general background of the respondents. The second part covers respondents’ reflection on the levels of influence/importance/significance of the construction waste generation factors within each of their building construction projects. Respondents are asked to rate their levels of agreement to a statement on five levels: (1) strongly disagree; (2) disagree; (3) neither agree nor disagree; (4) agree; (5) strongly agree.

3.2. Sampling

3.3. Analysis Techniques

4. Results

4.1. Respondents

4.2. Relative Important Index (RII)

4.2.1. Design and Documentations (DEDO)

4.2.2. Human Resource (HUMA)

4.2.3. Construction Methods and Planning (COPL)

4.2.4. Material and Procurement (MAPR)

5. Discussion

6. Conclusions

7. Recommendations

Author Contributions

Funding

Conflicts of Interest

References

- United Nations. World Population Prospects: The 2017 Revision, Key Findings and Advance Tables. 2017. Available online: https://esa.un.org/unpd/wpp/publications/files/wpp2017_keyfindings.pdf (accessed on 19 August 2018).

- Dimick, D. As World’s Population Booms, Will Its Resources Be Enough for Us? Available online: https://news.nationalgeographic.com/news/2014/09/140920-population-11billion-demographics-anthropocene/ (accessed on 19 August 2018).

- United Nations. World Urbanization Prospects: The 2018 Revision. Available online: https://esa.un.org/unpd/wup/Publications/Files/WUP2018-KeyFacts.pdf (accessed on 20 August 2018).

- UN Environment. Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector. Global Status Report 2017. Available online: http://www.worldgbc.org/sites/default/files/UNEP 188_GABC_en %28web%29.pdf (accessed on 25 August 2018).

- Sharman, J. Construction Waste and Sustainability. 2017. Available online: https://www.thenbs.com/knowledge/construction-waste-and-sustainability (accessed on 17 October 2017).

- EPDHK. Hong Kong Environment Waste Data. 2016. Available online: https://www.epd.gov.hk/epd/english/environmentinhk/waste/data/stat_treat.html (accessed on 15 December 2016).

- Bossink, B.A.G.; Brouwers, H.J.H. Construction Waste: Quantification and Source Evaluation. J. Constr. Eng. Manag. 1996, 122, 55–60. [Google Scholar] [CrossRef]

- Mager, J. Chile’S Second Biennial Update Report on Climate Change. Available online: www.theGEF.org (accessed on 1 July 2017).

- Contreras, M.; Teixeira, S.R.; Lucas, M.C.; Lima, L.C.N.; Cardoso, D.S.L.; da Silva, G.A.C.; dos Santos, A. Recycling of construction and demolition waste for producing new construction material (Brazil case-study). Constr. Build. Mater. 2016, 123, 594–600. [Google Scholar] [CrossRef]

- Katz, A.; Baum, H. A novel methodology to estimate the evolution of construction waste in construction sites. Waste Manag. 2011, 31, 353–358. [Google Scholar] [CrossRef] [PubMed]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Yonetani, H. Construction and Demolition Waste Management in Japan. 2017. Available online: http://www.uncrd.or.jp/content/documents/2661Parallel Roundtable-Presentation-Hideko Yonetani.pdf (accessed on 26 August 2018).

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- Ling, F.Y.Y.; Lim, M.C.H. Implementation of a Waste Management Plan for Construction Projects in Singapore. Archit. Sci. Rev. 2002, 45, 73–81. [Google Scholar] [CrossRef]

- Lingard, H.; Graham, P.; Smithers, G. Employee perceptions of the solid waste management system operating in a large Australian contracting organization: Implications for company policy implementation. Constr. Manag. Econ. 2000, 18, 383–393. [Google Scholar] [CrossRef]

- Coventry, S.; Woolveridge, C.; Patel, V. Waste Minimisation and Recycling in Construction: Boardroom Handbook; Construction Industry Research and Information Association: London, UK, 1999. [Google Scholar]

- Addis, W. Building with Reclaimed Components and Materials: A Design Handbook for Reuse and Recycling; Earthscan: London, UK, 2006. [Google Scholar]

- Dajadian, S.A.; Koch, D.C. Waste management models and their applications on construction sites. Int. J. Constr. Eng. Manag. 2014, 3, 91–98. [Google Scholar] [CrossRef]

- Thailand Pollution Control Department. Study of the Guideline for Construction and Demolition Waste Management in Thailand. Available online: http://www.pcd.go.th/public/publications/print_waste.cfm?task=wastemana50_1 (accessed on 15 January 2018).

- Franklin Associates. Characterization of Building-Related Construction and Demolition Debris in the United States. Available online: https://www.epa.gov/sites/production/files/2016-03/documents/charact_bulding_related_cd.pdf (accessed on 27 September 2017).

- Deloittle. Construction and Demolition Waste Management in United Kingdom. Available online: http://ec.europa.eu/environment/waste/studies/deliverables/CDW_UK_Factsheet_Final.pdf (accessed on 5 December 2017).

- Edge Environment. Construction and Demolition Waste Guide-Recycling and Re-use Across the Supply Chain. Available online: https://www.environment.gov.au/system/files/resources/b0ac5ce4-4253-4d2b-b001-0becf84b52b8/files/case-studies.pdf (accessed on 17 July 2017).

- GOVHK. Construction Waste. Available online: https://www.gov.hk/en/residents/environment/waste/constructionwaste.htm (accessed on 18 August 2018).

- Poon, C.S.; Yu, A.T.W.; Wong, S.W.; Cheung, E. Management of construction waste in public housing projects in Hong Kong. Constr. Manag. Econ. 2004, 22, 675–689. [Google Scholar] [CrossRef]

- Sepa. Guidance on Using the European Waste Catalogue (EWC) to Code Waste. Available online: www.sepa.org.uk/media/162682/sepa-waste-thesaurus.pdf (accessed on 19 July 2017).

- GOV.UK. Print Classify Different Types of Waste. Available online: https://www.gov.uk/how-to-classify-different-types-of-waste/print (accessed on 18 August 2018).

- ICF Incorporated. Construction and Demolition Waste Landfills. Available online: https://nepis.epa.gov/Exe/ZyNET.exe/9101Q651.TXT?ZyActionD=ZyDocument&Client=EPA&Index=1995+Thru+1999&Docs=&Query=&Time=&EndTime=&SearchMethod=1&TocRestrict=n&Toc=&TocEntry=&QField=&QFieldYear=&QFieldMonth=&QFieldDay=&IntQFieldOp=0&ExtQFieldOp=0&XmlQuery= (accessed on 1 August 2017).

- Gavilan, R.M.; Bernold, L.E. Source Evaluation of Solid Waste in Building Construction. J. Constr. Eng. Manag. 1994, 120, 536–552. [Google Scholar] [CrossRef]

- Poon, C.S.; Yu, A.T.; Ng, L. On-site sorting of construction and demolition waste in Hong Kong. Resour. Conserv. Recycl. 2001, 32, 157–172. [Google Scholar] [CrossRef]

- Begum, R.A.; Siwar, C.; Pereira, J.J.; Jaafar, A.H. A benefit-cost analysis on the economic feasibility of construction waste minimisation: The case of Malaysia. Resour. Conserv. Recycl. 2006, 48, 86–98. [Google Scholar] [CrossRef]

- Uyasatean, U.; Utwarujikulchai, U. Estimation of building-related C&D waste generation and composition in Bangkok. Nat. Resour. J. 2007, 5, 133–140. [Google Scholar]

- Bergsdal, H.; Bohne, R.A.; Brattebø, H. Projection of Construction and Demolition Waste in Norway. J. Ind. Ecol. 2008, 11, 27–39. [Google Scholar] [CrossRef]

- Lau, H.H.; Whyte, A.; Law, P. Composition and Characteristics of Construction Waste Generated by Residential Housing Project. Int. J. Environ. Res. 2008, 2, 261–268. [Google Scholar]

- Kofoworola, O.F.; Gheewala, S.H. Estimation of construction waste generation and management in Thailand. Waste Manag. 2009, 29, 731–738. [Google Scholar] [CrossRef] [PubMed]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef] [PubMed]

- Llatas, C. A model for quantifying construction waste in projects according to the European waste list. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef]

- Faniran, O.; Caban, G. Minimizing waste on construction project sites. Eng. Constr. Archit. Manag. 1998, 5, 182–188. [Google Scholar] [CrossRef]

- Alwi, S.; Hampson, K.; Mohamed, S. Waste in the Indonesian construction projects. In Proceedings of the 1st International Conferences of CIB W107—Creating a Sustainable Construction Industry in Developing Countries, Stellenbosch, South Africa, 11–13 November 2002; Volume 23, pp. 541–549. [Google Scholar]

- Ekanayake, L.L.; Ofori, G. Building waste assessment score: Design-based tool. Build. Environ. 2004, 39, 851–861. [Google Scholar] [CrossRef]

- Osmani, M.; Price, a.; Glass, J. Architect and contractor attitudes to waste minimisation. Proc. Ice Waste Resour. Manag. 2006, 159, 65–72. [Google Scholar] [CrossRef]

- Wan, S.K.; Kumaraswamy, M.M.; Liu, D.T. Contributors to Construction Debris from Electrical and Mechanical Work in Hong Kong Infrastructure Projects. J. Constr. Eng. Manag. 2009, 135, 637–646. [Google Scholar] [CrossRef]

- Al-Hajj, A.; Hamani, K. Material waste in the UAE construction industry: Main causes and minimization practices. Archit. Eng. Des. Manag. 2011, 7, 221–235. [Google Scholar] [CrossRef]

- Nagapan, S.; Rahman, I.A.; Asmi, A.; Hameed, A.; Zin, R.M. Identifying Causes of Construction Waste - Case of Central Region of Peninsula Malaysia. Int. J. Integr. Eng. 2012, 4, 22–28. [Google Scholar]

- Muhwezi, L.; Chamuriho, L.M.; Lema, N.M. An investigation into Materials Wastes on Building Construction Projects in Kampala-Uganda. J. Eng. Res. 2012, 1, 11–18. [Google Scholar]

- Mbote, R.P.; Kimtai, A.K.; Makworo, M. An Investigation on the Influence of Factors Causing Material Waste on Construction Cost of Residential Building Frame. A Case of Northern Region of Nairobi. Int. J. Eng. Res. Technol. (IJERT) 2016, 5, 436–447. [Google Scholar]

- John, A.O.; Itodo, D.E. Professionals’ views of material wastage on construction sites and cost overruns. Organ. Technol. Manag. Constr. Int. J. 2013, 5, 747–757. [Google Scholar] [CrossRef]

- Adewuyi, T.O.; Otali, M. Evaluation of causes of construction material waste-case of rivers state, Nigeria. Ethiop. J. Environ. Stud. Manag. 2013, 6, 746–753. [Google Scholar] [CrossRef]

- Khanh, H.D.; Kim, S.Y. Identifying causes for waste factors in high-rise building projects: A survey in Vietnam. KSCE J. Civ. Eng. 2014, 18, 865–874. [Google Scholar] [CrossRef]

- Fadiya, O.O.; Georgakis, P.; Chinyio, E. Quantitative Analysis of the Sources of Construction Waste. J. Constr. Eng. 2014, 2014, 1–9. [Google Scholar] [CrossRef]

- Bekr, G.A. Study of the Causes and Magnitude of Wastage of Materials on Construction Sites in Jordan. J. Constr. Eng. 2014, 2014, 1–6. [Google Scholar] [CrossRef]

- Domingo, N. Assessment of the Impact of Complex Healthcare Features on Construction Waste Generation. Buildings 2015, 5, 860–879. [Google Scholar] [CrossRef]

- Karim, K.; Marosszeky, M. Process monitoring for process re-engineering—Using key performance indicators. In Proceedings of the International Conference on Construction Process Reengineering, CPR, San Antonio, TX, USA, 17–20 November 1999. [Google Scholar]

- Formoso, C.T.; Soibelman, L.; De Cesare, C.; Isatto, E.L. Material Waste in Building Industry: Main Causes and Prevention. J. Constr. Eng. Manag. 2002, 128, 316–325. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.O.; Alaka, H.A.; Owolabi, H.A. Critical management practices influencing on-site waste minimization in construction projects. Waste Manag. 2017, 59, 330–339. [Google Scholar] [CrossRef] [PubMed]

- Xia, B.; Chan, A.P.C. Measuring complexity for building projects: A Delphi study. Eng. Constr. Archit. Manag. 2012, 19, 7–24. [Google Scholar] [CrossRef]

- Skoyles, E.R. Materials wastage—A misuse of resources. Batim. Int. Build. Res. Pract. 1976, 4, 232. [Google Scholar] [CrossRef]

- Ali, A.S.; Smith, A.; Pitt, M.; Choon, C.H. Contractors’ perception of factors contributing to project delay: Case studies of commercial projects in Klang Valley, Malaysia. J. Des. Built Environ. 2007, 7, 1–17. [Google Scholar]

- Arain, F.M.; Pheng, L.S.; Assaf, S.A. Contractors’ Views of the Potential Causes of Inconsistencies between Design and Construction in Saudi Arabia. J. Perform. Constr. Facil. 2006, 20, 74–83. [Google Scholar] [CrossRef]

- Barrett, P.; Stanley, C. Better Construction Briefing. Blackwell Science. Available online: https://www.wiley.com/en-us/Better+Construction+Briefing-p-9780632051021 (accessed on 20 August 2018).

- Wambeke, B.W.; Hsiang, S.M.; Liu, M. Causes of Variation in Construction Project Task Starting Times and Duration. J. Constr. Eng. Manag. 2011, 137, 663–677. [Google Scholar] [CrossRef]

- Holt, G.D. Asking questions, analysing answers: Relative importance revisited. Constr. Innov. 2014, 14, 2–16. [Google Scholar] [CrossRef]

- Othman, A.A.E.; Hassan, T.M.; Pasquire, C.L. Analysis of factors that drive brief development in construction. Eng. Constr. Archit. Manag. 2005, 12, 69–87. [Google Scholar] [CrossRef]

- Gündüz, M.; Nielsen, Y.; Özdemir, M. Quantification of Delay Factors Using the Relative Importance Index Method for Construction Projects in Turkey. J. Manag. Eng. 2013, 29, 133–139. [Google Scholar] [CrossRef]

- Aziz, R.F. Ranking of delay factors in construction projects after Egyptian revolution. Alex. Eng. J. 2013, 52, 387–406. [Google Scholar] [CrossRef]

- Sasidharani, B.; Jayanthi, R. Material Waste Management In Construction Industries. Int. J. Sci. Eng. Res. (IJ0SER) 2015, 3, 3221. [Google Scholar]

- Love, P.E.D.; Holt, G.D.; Shen, L.Y.; Li, H.; Irani, Z. Using systems dynamics to better understand change and rework in construction project management systems. Int. J. Proj. Manag. 2002, 20, 425–436. [Google Scholar] [CrossRef]

- Chandrakanthi, M.; Hettiaratchi, P.; Prado, B.; Ruwanpura, J.Y. Optimization of the waste management for construction projects using simulation. In Proceedings of the IEEE 34th Conference on Winter Simulation: Exploring New Frontiers, San Diego, CA, USA, 8–11 December 2002; Volume 2, pp. 1771–1777. [Google Scholar] [CrossRef]

- Teo, M.M.; Loosemore, M.; Masosszeky, M.; Karim, K. Operatives’ Attitudes towards Waste on Construction Project; Glasgow Caledonian University: Glasgow, Scotland, 2000; Volume 2, Available online: http://www.arcom.ac.uk/-docs/proceedings/ar2000-509-517_Teo_et_al.pdf (accessed on 15 September 2018).

| Country | Percentage of Waste | References |

|---|---|---|

| England | 32% | Sharman [5] |

| Hong Kong | 28% | EPDHK [6] |

| Netherland | 28% | Bossink and Brouwers [7] |

| Australia | 20–30% | |

| United States | 20–29% | |

| Germany | 19% | |

| Finland | 13–15% | |

| Chili | 34% | Mager [8] |

| Brazil | 50% | Contreras et al. [9] |

| Denmark | 27% | Katz and Baum [10] |

| Israel | 60% | Allwood et al. [11] |

| Japan | 20% | Yonetani [12] |

| Canada | 27% | Yeheyis et al. [13] |

| EU [25] | England [26] | United States [27] | |

|---|---|---|---|

| Asphalt | ✓ | ✓ | ✓ |

| Soil | ✓ | ✓ | ✓ |

| Electrical work | ✓ | ||

| Insulation | ✓ | ✓ | ✓ |

| Brick and concrete | ✓ | ✓ | ✓ |

| Steel | ✓ | ✓ | ✓ |

| Cement | ✓ | ||

| Paint | ✓ | ✓ | |

| Paper | ✓ | ||

| Petroleum | ✓ | ✓ | |

| Roof | ✓ | ||

| Vinyl | ✓ | ||

| Gypsum | ✓ | ✓ | |

| Wood | ✓ | ✓ | ✓ |

| Contaminated Wood | ✓ | ||

| Glues and fillings | ✓ | ||

| Miscellaneous | ✓ |

| Research | Year | Country | Type of Building |

|---|---|---|---|

| Gavilan and Bernold [28] | 1994 | USA | Residential |

| Bossink and Brouwers [7] | 1996 | Netherlands | Residential |

| Franklin [20] | 1998 | USA | Residential |

| Poon et al. [29] | 2001 | Hong Kong | Not specific |

| Begum et al. [30] | 2006 | Malaysia | Residential |

| Uyasatean and Utwarujikulchai [31] | 2007 | Thai | Residential |

| Bergsdal et al. [32] | 2008 | Norway | Residential |

| Lau et al. [33] | 2008 | Malaysia | Residential |

| Kofoworola and Gheewala [34] | 2009 | Thai | Not specific |

| Guzmán et al. [35] | 2009 | Spain | Residential |

| Llatas [36] | 2011 | Spain | Residential |

| Type of Construction Waste | Gavilan and Bernold [28] | Bossink and Brouwers [7] | Franklin [20] | Poon et al. [29] | Begum et al. [30] | Uyasatean and Utwarujikulchai [31] | Bergsdal et al. [32] | Lau et al. [33] | Kofoworola and Gheewala [34] | Guzmán et al. [35] | Llatas [36] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete | 13% | 8% | 18% | 57% | 77% | 24% | 8% | 12% | |||

| Brick | 12% | 3% | 2.5% | 6% | 12% | 14% | 46% | 14% | 46% | 8% | |

| Wood | 35% | 11% | 7% | 14% | 56% | 14% | 4% | ||||

| Dirt/Earth | 0.5% | 31% | 65% | ||||||||

| Tile/Ceramic | 1% | 1% | 3% | 4% | 54% | ||||||

| Drywall | 15% | 14% | 6% | 6% | 4% | ||||||

| Stone | 29% | 1% | 5% | ||||||||

| Rebar | 22% | 5% | |||||||||

| Other Paper | 4% | 7% | 5% | 5% | |||||||

| Piles | 17% | 3% | |||||||||

| Metal | 4% | 1% | 4% | 1% | 2% | 1% | 3% | ||||

| Rubber | 14% | ||||||||||

| Mortar | 8% | ||||||||||

| Untreated Wood | 16% | ||||||||||

| Misc. Waste | 30% | 23% | 57% | 16% | 1% | 28% | 4% | 28% | 8% | 22% | |

| Total | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% |

| Factor Category | Factor Label | Factor Name | References |

|---|---|---|---|

| Design and Documentation (DEDO) | D1 | Change to design | [7,28,37,38,40,41,43,47,49,50,51] |

| D2 | Document problems | [7,38,39,40,44,47,48,49,50] | |

| D3 | Design errors | [28,37,38,40,42,43,46] | |

| D4 | Construction drawing errors | [28,38,39,40,44,47,51] | |

| D5 | Complicated design | [39,44,47,50,51] | |

| Material and Procurement (MAPR) | M1 | Improper material storage | [7,28,37,38,39,40,41,42,46,47,48,49,50,51] |

| M2 | Material quality problems | [7,38,39,42,44,47,48,50] | |

| M3 | Material ordering problems | [7,37,39,41,42,47,49,50] | |

| M4 | Improper material handling | [28,37,38,42,46,47,48,50] | |

| M5 | Material transporting problems | [28,39,42,47,49,50,51] | |

| M6 | Packaging problems | [28,39,42,46,50] | |

| M7 | Defective materials | [41,47] | |

| M8 | Damaged materials | [47] | |

| Construction Methods and Planning (COPL) | C1 | Coordination problems | [28,38,39,40,41,43,44,47,48,50,51] |

| C2 | Control and supervision | [37,38,43,44,46,47,48,49] | |

| C3 | Construction methods | [28,38,40,41,47,48,49] | |

| C4 | Poor waste management | [28,44,46,47,49,50] | |

| C5 | Tools and equipment misuse/malfunction | [7,28,39,47,49] | |

| C6 | Misuse of material | [28,38,39,47,48] | |

| C7 | Rework | [41,43,46,47,50] | |

| C8 | Wrong teams /subcontractors selection | [38,41,42,43,47] | |

| C9 | By-process waste | [7,28,37,40] | |

| C10 | Construction errors | [41,43,46] | |

| C11 | Ineffective planning and scheduling | [38,41,43,44,47,48,51] | |

| H1 | Incompetent workers | [7,37,38,39,40,41,44,46,47,48,49,50] | |

| Human Resources (HUMA) | H2 | Designers’ inexperience | [7,39,40,43,44,46,50] |

| H3 | Inattentive working attitudes and behaviours | [39,41,44,50] | |

| H4 | Lack of suppliers’ involvement | [37,47,50] |

| Characteristic | Frequency | |

|---|---|---|

| Gender | Male | 162 (91%) |

| Female | 9 (9%) | |

| Age group | Under 30 | 26 (14.61%) |

| 30 to 40 | 29 (16.29%) | |

| 41 to 50 | 77 (43.26%) | |

| 50 and over | 46 (25.84%) | |

| Position | Managing director | 5 (2.81%) |

| Project manager | 56 (31.46%) | |

| Project engineering | 38 (21.35%) | |

| Project director | 18 (10.11%) | |

| Assistant project manager | 2 (1.12%) | |

| Site engineering | 16 (8.99%) | |

| Project architecture | 14 (7.87%) | |

| Site architecture | 5 (2.81%) | |

| Foreman | 24 (13.48%) | |

| Building size (m2) | <500 | 36 (20.22%) |

| 500–2000 | 23 (12.92%) | |

| 2001–4000 | 22 (12.36%) | |

| 4001–10,000 | 32 (17.98%) | |

| 10,001–30,000 | 46 (25.84%) | |

| Experience in construction | <5 years | 22 (12.36%) |

| 5–10 years | 42 (23.60%) | |

| 11–15 years | 66 (37.08%) | |

| 16–20 years | 31 (17.42%) | |

| 20 years< | 17 (9.55%) | |

| Education | Vocational | 38 (21.35%) |

| Bachelor | 83 (46.63%) | |

| Master | 56 (31.46%) | |

| Ph.D. | 1 (0.56%) | |

| Building type | Private Residential | 40 (22.47%) |

| Condominium & apartment | 50 (28.09%) | |

| Public building | 53 (29.78%) | |

| Industrial | 15 (8.43%) | |

| Government | 20 (11.24%) | |

| Building height (Meter) | <15 | 89 (50.00%) |

| 15–23 | 41 (23.03%) | |

| 23< | 48 (26.97%) |

| Factor Label | Factor | Number of Respondents Scoring | RII | Rank | ||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||||

| D1 | Change to design | 2.00 | 22.00 | 50.00 | 70.00 | 34.00 | 0.726 | 1 |

| H3 | Inattentive working attitudes and behaviours | 9.00 | 35.00 | 42.00 | 61.00 | 31.00 | 0.679 | 2 |

| M1 | Improper material storage | 11.00 | 28.00 | 51.00 | 65.00 | 23.00 | 0.669 | 3 |

| H2 | Designers’ inexperience | 7.00 | 42.00 | 45.00 | 54.00 | 30.00 | 0.665 | 4 |

| H1 | Incompetent workers | 6.00 | 43.00 | 47.00 | 52.00 | 30.00 | 0.664 | 5 |

| D5 | Complicated design | 9.00 | 36.00 | 53.00 | 51.00 | 29.00 | 0.662 | 6 |

| D3 | Design errors | 6.00 | 46.00 | 48.00 | 51.00 | 27.00 | 0.653 | 7 |

| C11 | Ineffective planning and scheduling | 9.00 | 39.00 | 63.00 | 38.00 | 29.00 | 0.644 | 8 |

| C2 | Control and supervision | 10.00 | 42.00 | 62.00 | 36.00 | 28.00 | 0.634 | 9 |

| C4 | Poor waste management | 20.00 | 31.00 | 46.00 | 61.00 | 20.00 | 0.634 | 9 |

| C8 | Wrong teams/subcontractors selection | 12.00 | 46.00 | 52.00 | 38.00 | 30.00 | 0.631 | 10 |

| M3 | Material ordering problems | 11.00 | 42.00 | 55.00 | 53.00 | 17.00 | 0.626 | 11 |

| D4 | Construction drawing errors | 13.00 | 51.00 | 42.00 | 46.00 | 26.00 | 0.624 | 12 |

| M4 | Improper material handling | 13.00 | 40.00 | 56.00 | 54.00 | 15.00 | 0.620 | 13 |

| D2 | Documents problems | 8.00 | 52.00 | 54.00 | 44.00 | 20.00 | 0.618 | 14 |

| C3 | Construction methods | 13.00 | 50.00 | 46.00 | 49.00 | 20.00 | 0.615 | 15 |

| M5 | Material transporting problems | 13.00 | 42.00 | 61.00 | 49.00 | 13.00 | 0.608 | 16 |

| C7 | Reworks | 14.00 | 45.00 | 59.00 | 40.00 | 20.00 | 0.608 | 16 |

| C9 | By Process waste | 20.00 | 40.00 | 55.00 | 50.00 | 13.00 | 0.596 | 17 |

| C1 | Coordination problems | 19.00 | 52.00 | 50.00 | 37.00 | 20.00 | 0.585 | 18 |

| C5 | Tools and equipment misuse/malfunction | 16.00 | 48.00 | 63.00 | 35.00 | 16.00 | 0.585 | 18 |

| M7 | Defective materials | 18.00 | 47.00 | 56.00 | 49.00 | 8.00 | 0.580 | 19 |

| C10 | Construction errors | 21.00 | 53.00 | 49.00 | 35.00 | 20.00 | 0.578 | 20 |

| M6 | Packaging problems | 20.00 | 53.00 | 50.00 | 46.00 | 9.00 | 0.567 | 21 |

| H4 | Lack of suppliers involvement | 22.00 | 55.00 | 50.00 | 38.00 | 13.00 | 0.561 | 22 |

| M8 | Damaged materials | 24.00 | 57.00 | 48.00 | 36.00 | 13.00 | 0.552 | 23 |

| M2 | Material quality problems | 33.00 | 53.00 | 42.00 | 34.00 | 16.00 | 0.540 | 24 |

| C6 | Misuse of material | 38.00 | 52.00 | 42.00 | 28.00 | 18.00 | 0.528 | 25 |

| Factor Category | RII | Rank |

|---|---|---|

| Design and Documentation (DEDO) | 0.656 | 1 |

| Human Resources (HUMA) | 0.642 | 2 |

| Construction Methods and Planning (COPL) | 0.603 | 3 |

| Material and Procurement (MAPR) | 0.595 | 4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luangcharoenrat, C.; Intrachooto, S.; Peansupap, V.; Sutthinarakorn, W. Factors Influencing Construction Waste Generation in Building Construction: Thailand’s Perspective. Sustainability 2019, 11, 3638. https://doi.org/10.3390/su11133638

Luangcharoenrat C, Intrachooto S, Peansupap V, Sutthinarakorn W. Factors Influencing Construction Waste Generation in Building Construction: Thailand’s Perspective. Sustainability. 2019; 11(13):3638. https://doi.org/10.3390/su11133638

Chicago/Turabian StyleLuangcharoenrat, Chakkrit, Singh Intrachooto, Vachara Peansupap, and Wandee Sutthinarakorn. 2019. "Factors Influencing Construction Waste Generation in Building Construction: Thailand’s Perspective" Sustainability 11, no. 13: 3638. https://doi.org/10.3390/su11133638

APA StyleLuangcharoenrat, C., Intrachooto, S., Peansupap, V., & Sutthinarakorn, W. (2019). Factors Influencing Construction Waste Generation in Building Construction: Thailand’s Perspective. Sustainability, 11(13), 3638. https://doi.org/10.3390/su11133638