Increasing population growth and, consequently, growing fossil fuel consumption along with its limited availability, combined with the effects of greenhouse gas emissions from these fuels, threaten the wellbeing of humans and the environment. Thus, the need for clean and renewable energy sources is recognized now more than ever [

1,

2]. Geothermal energy is a renewable energy source that is likely to be highly sought after in the foreseeable future because of its large availability and low environmental impact. Statistics show a significant increase in the use of the geothermal energy sources [

3]. Lucia et al. [

4] carried out a review on different ground source typologies of heat pumps and introduced an approach for their modelling, from the viewpoints of thermodynamics. They suggested two possible ways for second law optimization of these systems for their future developments; one was based on a dynamic approach and the other one was based on using a control algorithm, operating on a set of variable configuration parameters on the basis of a time-running calculation for minimum entropy. Numerous cycles have been introduced and analyzed that use low-temperature energy sources [

5,

6]. Amongst these, the organic Rankine cycle (ORC) and its various configurations have been broadly used in geothermal power plants. The ORC can also be combined with the vapor-compression refrigeration cycle (VCC) to produce cooling [

7]. The VCC, because of its high cooling capacity and smaller size compared to absorption refrigeration systems of the same cooling capacity, has been widely used in cooling systems [

8]. Based on machine learning techniques, Palagi and Sciubba [

9] proposed a methodology for optimizing the thermodynamic cycle as well as the radial in-flow turbine employed in a small-scale ORC. In this method the physical model of the thermodynamic cycle is converted into a set of continuous and differentiable functions. They reported that the approach had a higher accuracy and a lower computational time. Kim and Perez-Blanco [

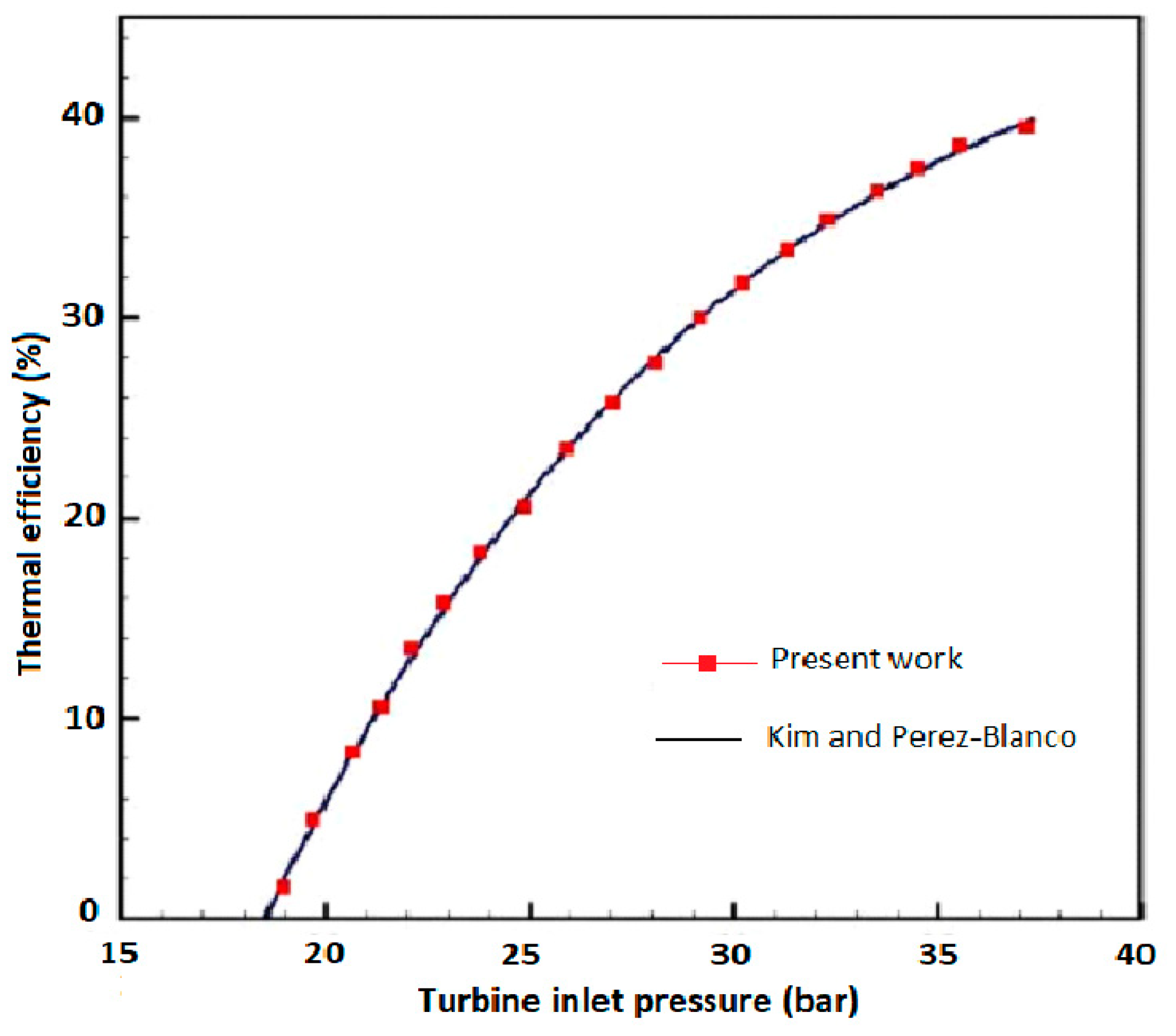

10] conducted a functional study of a cogeneration system combining an ORC and a VCC. The effects of decision parameters, such as turbine inlet temperature (TIT) and pressure and mass flow split ratio, on the system performance including the amount of produced power, cooling, thermal, and exergy efficiencies were studied. The results indicated that the system has good potential for effective use of low-temperature thermal resources. Moles et al. [

11] investigated a combined ORC–VCC system using a low-temperature heat source. In this study, two fluids with low global warming potentials were considered as working fluids for the VCC and two different fluids were used in the ORC. Thermal performance factors between 0.3 and 1.1 were achieved for various working conditions. The electric performance factor, which is defined as the ratio of the produced cooling rate to the ORC pump power consumption, varied from 15 to 110. The variation of the VCC working fluid had a minor impact on the system thermal efficiency. Wall [

12] optimized the performance of a single-stage heat-pump cycle from the viewpoints of thermoeconomics. In the optimization process the decision variables were selected as the efficiencies of the compressor, condenser, evaporator, and electric motor. Karellas and Brimakis [

13] thermodynamically modeled and economically analyzed a tripartite system that combined heat and power generation and cooling, based on the combined ORC and VCC system. Tajni et al. [

14] examined a new hybrid cycle comprising an ORC and a VCC, in which a low-temperature heat source was used, like solar or geothermal heat. The principal goal of this study was to analyze the operation of the proposed cycle to generate electricity and refrigeration simultaneously. Vasta et al. [

15] experimentally studied a cascade chiller comprising adsorption and vapor compression units. The system COP was reported to be as high as 5.7 for a 95 °C driving temperature in the adsorber. Mirzaei et al. [

16] conducted thermodynamic and thermoeconomic analyses of an ORC driven by waste heat using multiple working fluids. Higher produced power and lower total production costs were observed for the cases using m-xylene, p-xylene, and ethylbenzene as working fluids.

Braimakis et al. [

17] analyzed a double-stage ORC from an exergy viewpoint. They investigated the effects of parameters like evaporator pressure and condenser temperature on the exergy efficiency. Appropriate parameter variations raised the exergy efficiency by 25%. Sun et al. [

7] investigated several ORC combinations, including the combined ORC–absorption refrigeration cycle (ARC) and the combined ORC–ejector refrigeration cycle. The authors observed that the combination of ORC–ARC has the highest exergy efficiency of the combinations considered. Chang et al. [

18] proposed a combined cooling, heating, and power (CCHP) system based on a proton-exchange membrane (PEM) fuel cell and solar heat. The system comprises a PEM fuel cell, an ARC, and VCC subsystems. The system exhibited thermal efficiencies of 75% and 85% in summer and winter, respectively.

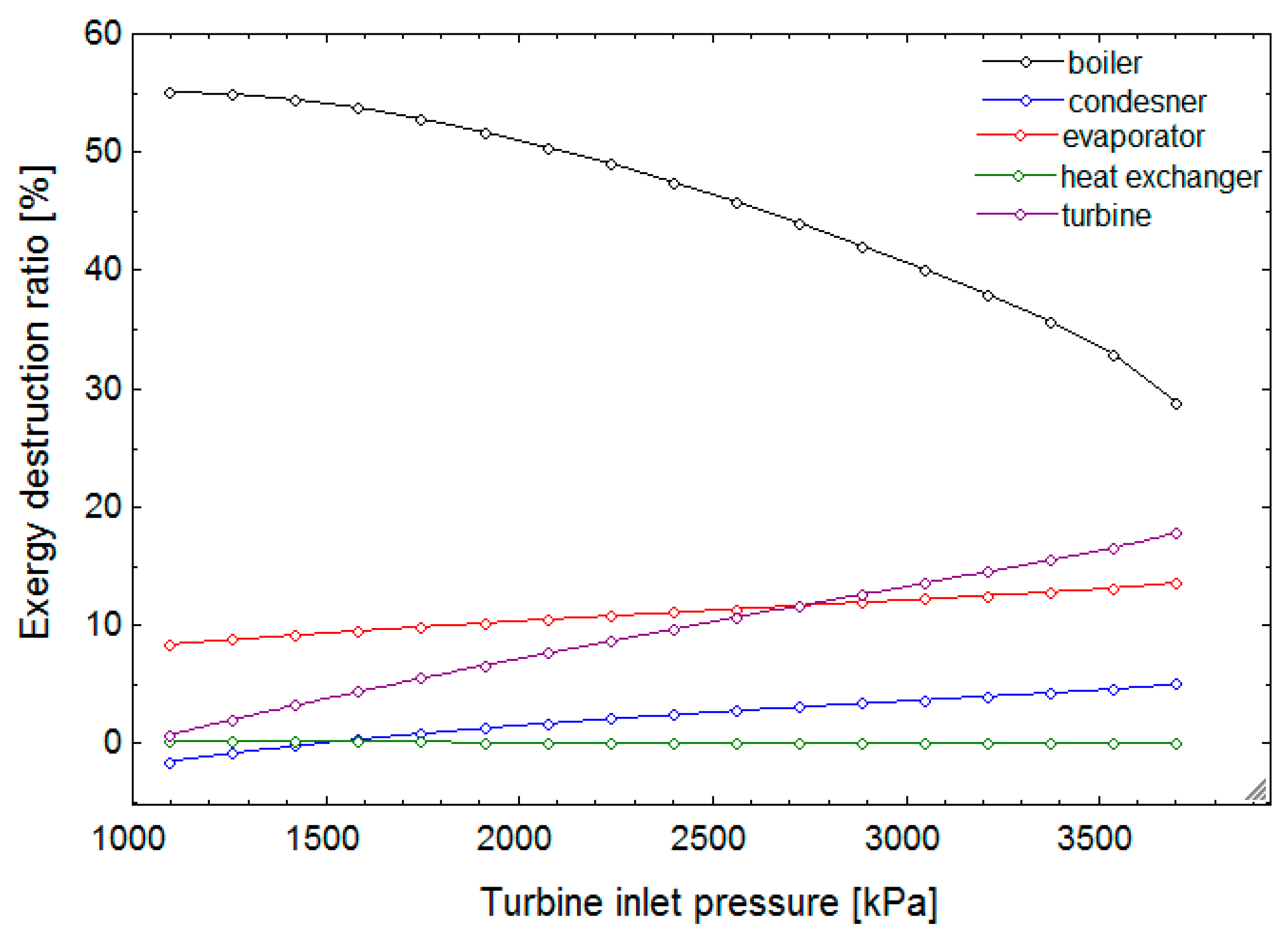

Javaherdeh et al. [

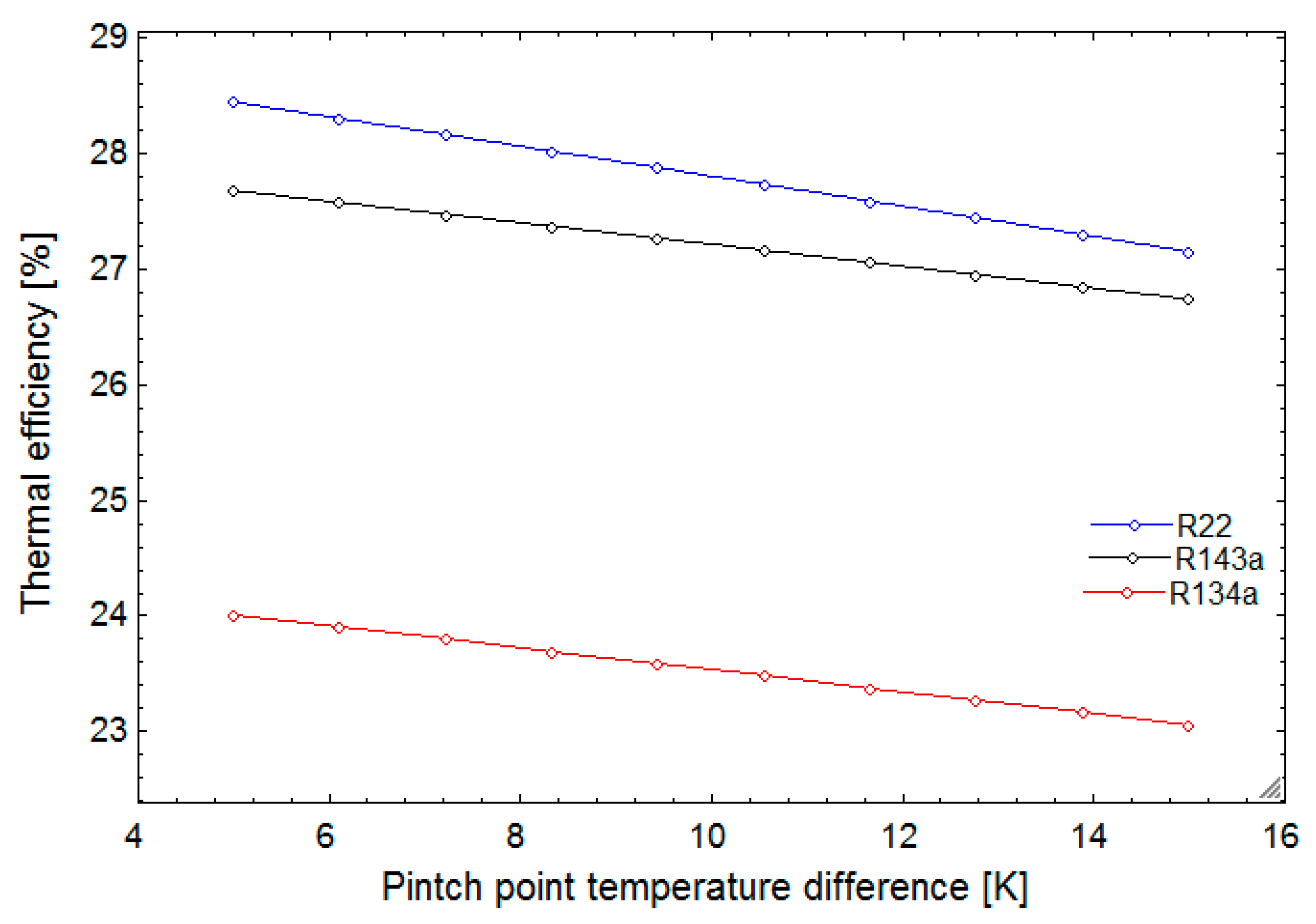

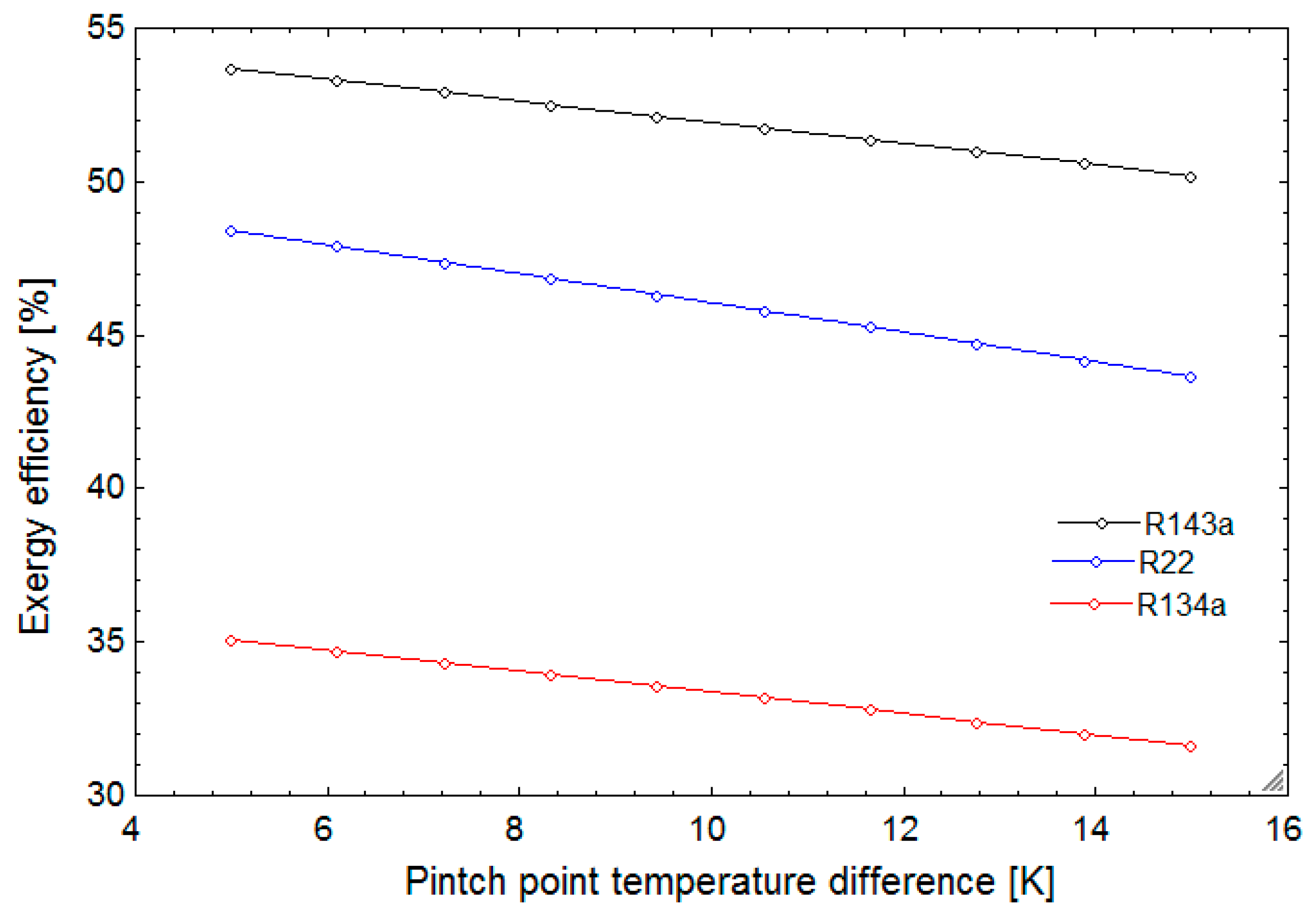

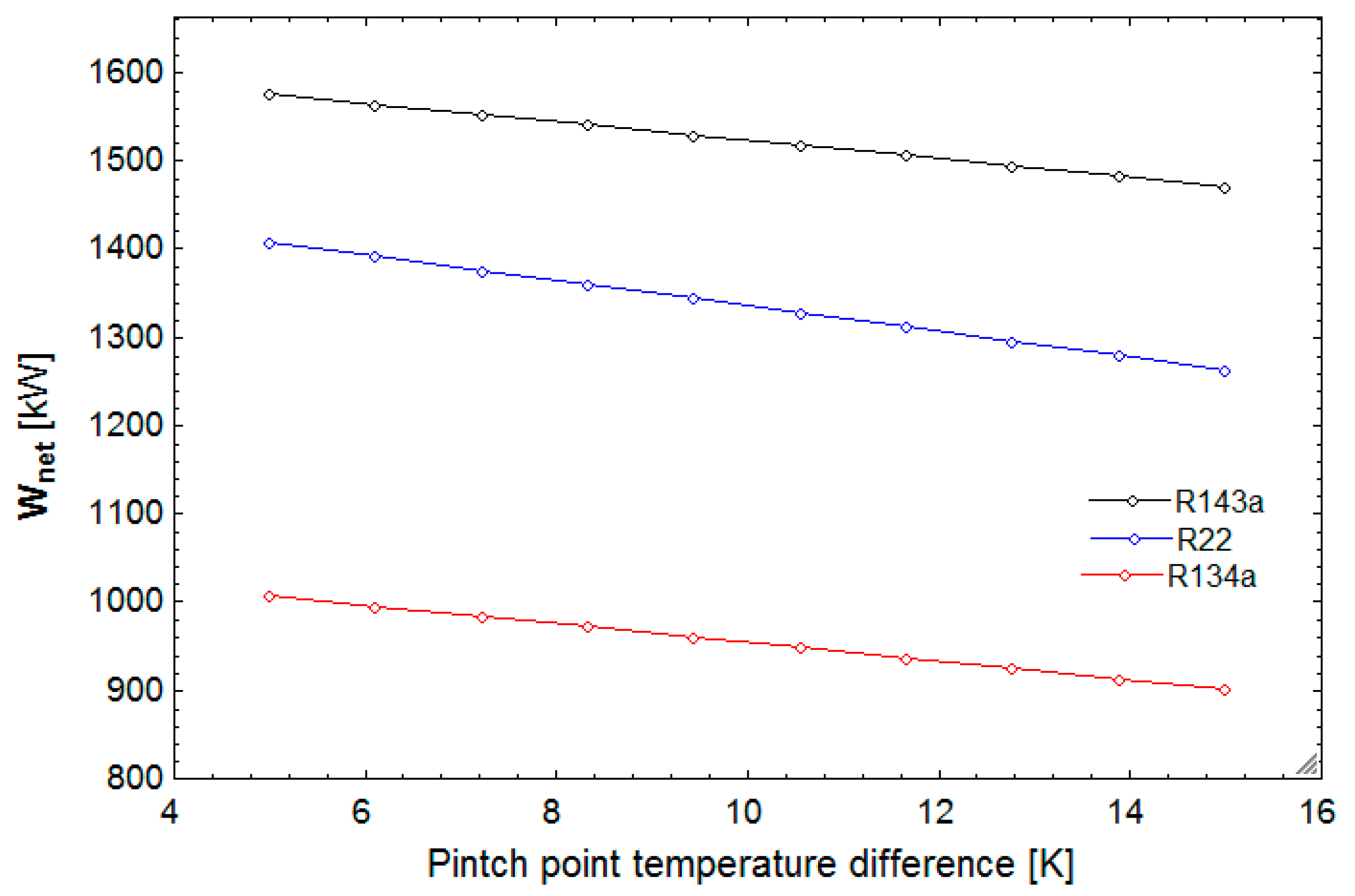

19] simulated the ORC–VCC with the recycling of high-temperature waste gases, and assessed the system from energy and exergoeconomic viewpoints. In the combined cycle, high-temperature waste gas was initially used to drive the VCC evaporator. After driving off its heat in the evaporator, the cooled exiting gas was used as the low-temperature input to the ORC evaporator. The effects of varying such parameters as evaporator temperature, vapor condenser temperature, and pinch-point temperature difference on the produced power, the total irreversibility, energy and exergy efficiencies, and exergoeconomic variables were investigated. It was observed that the energy and exergy efficiencies were 27% and 52%, respectively, while the exergoeconomic factor was 12.5%, for the combined cycle. These results indicate that there are higher exergy destructions in components such as the evaporator, the turbine, and the condenser, and that these devices should be modified to improve the cost-efficiency balance of the system.

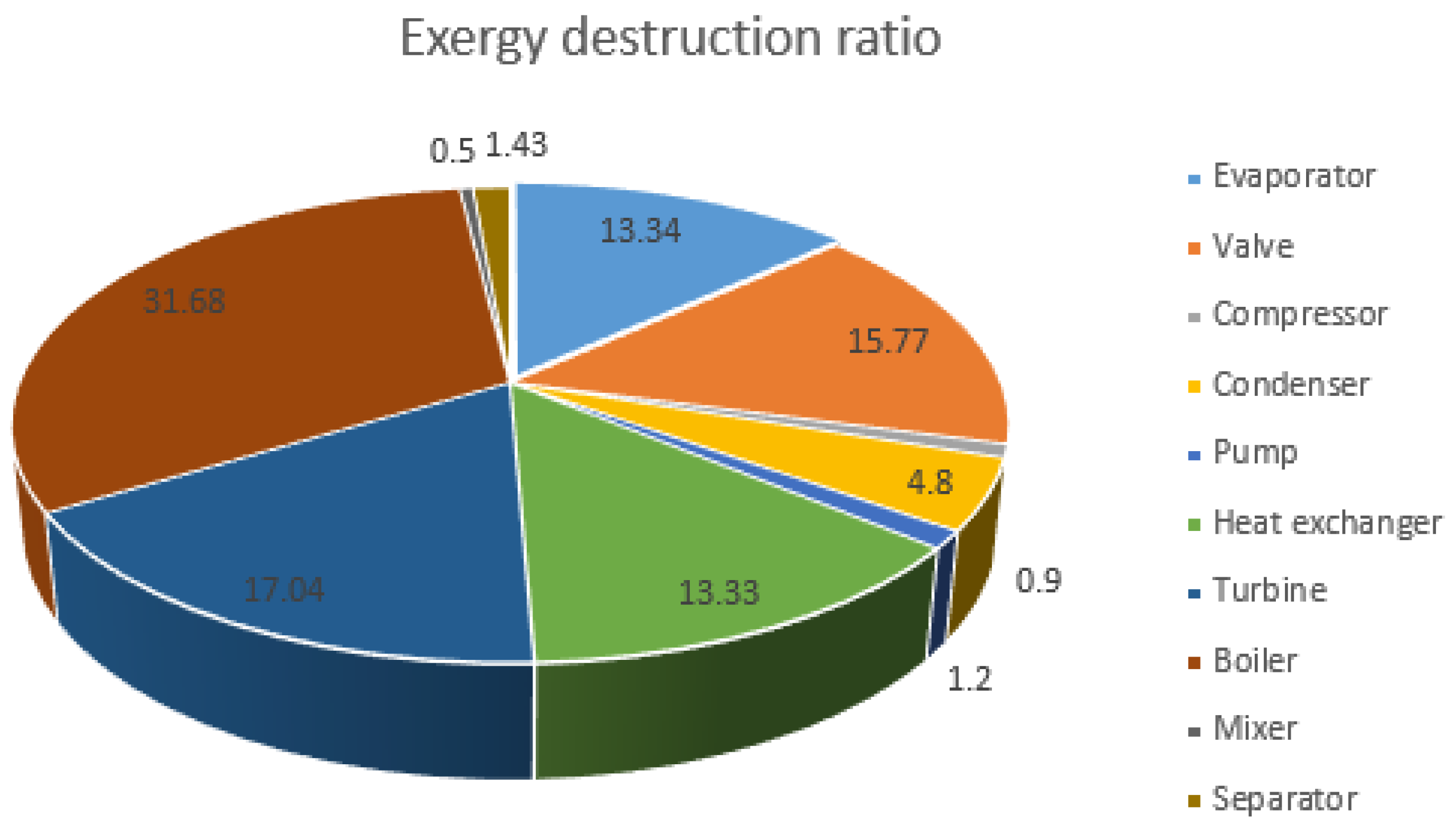

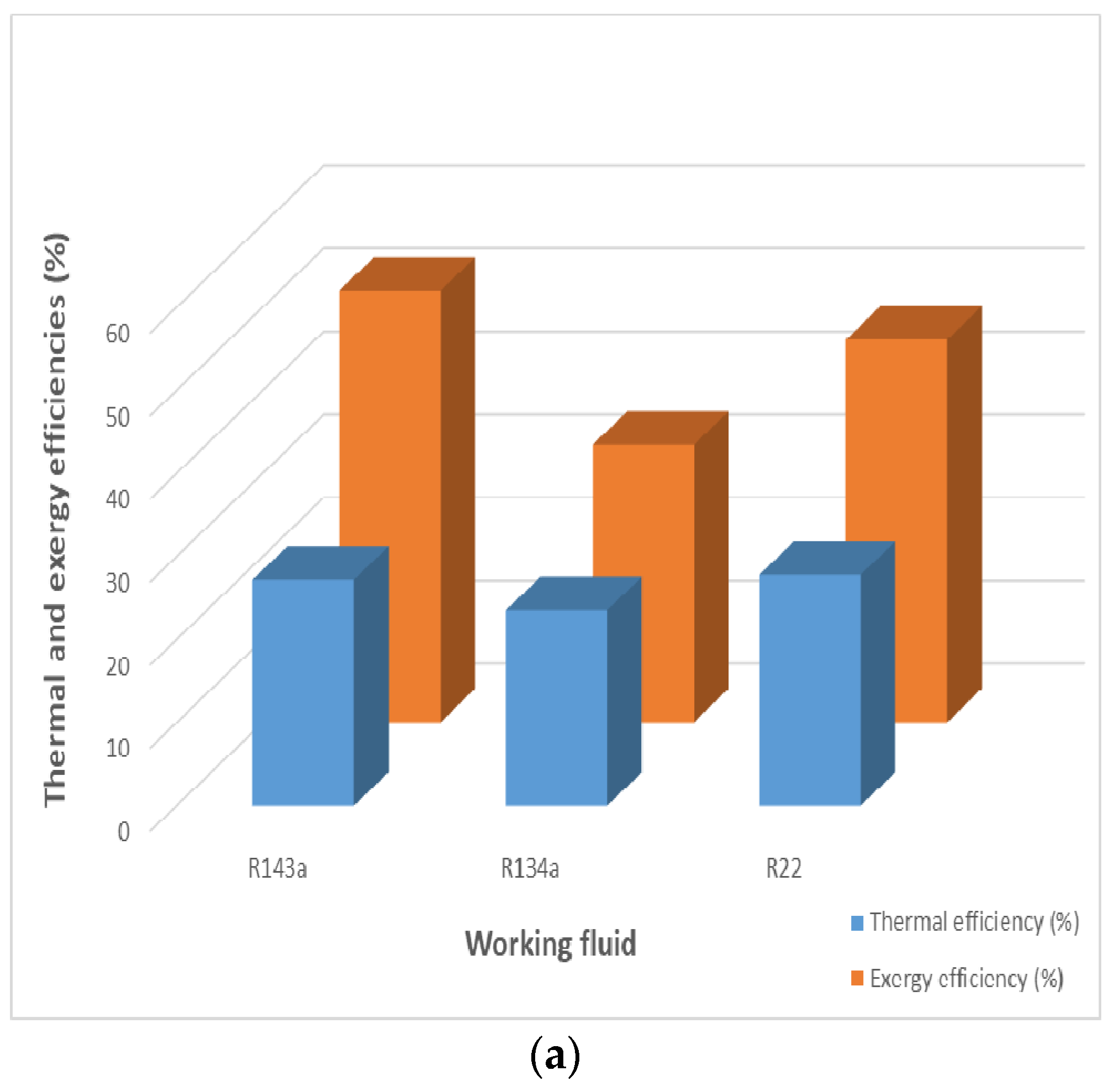

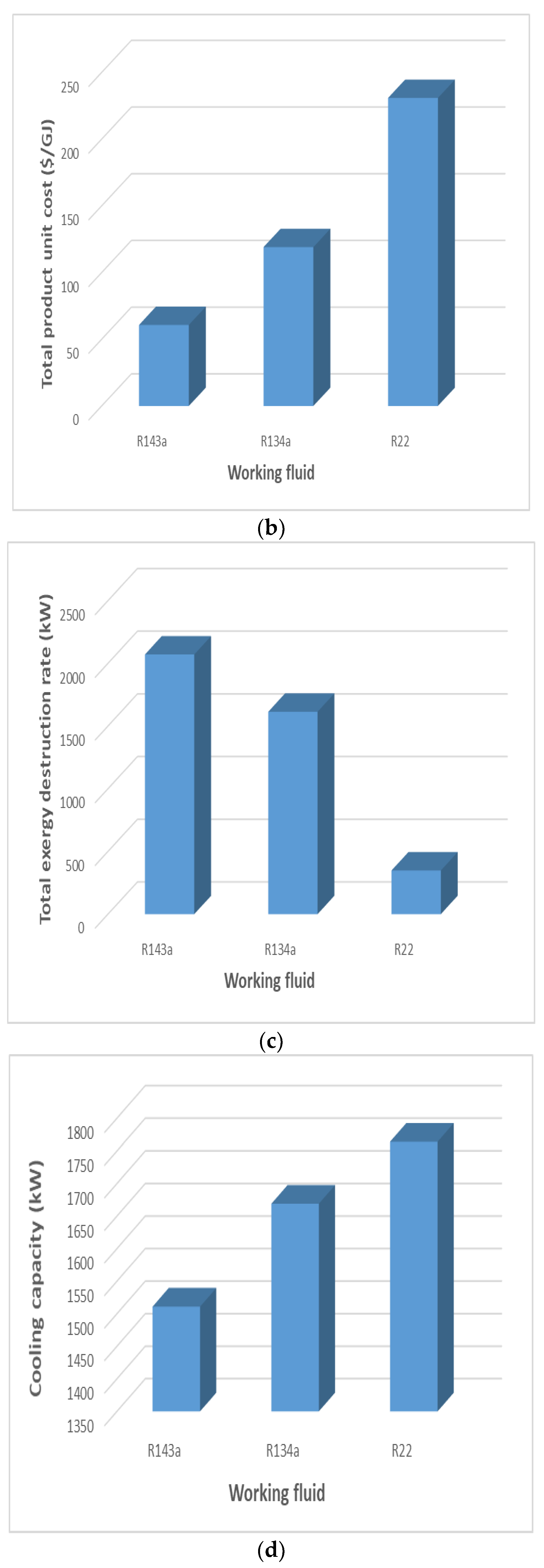

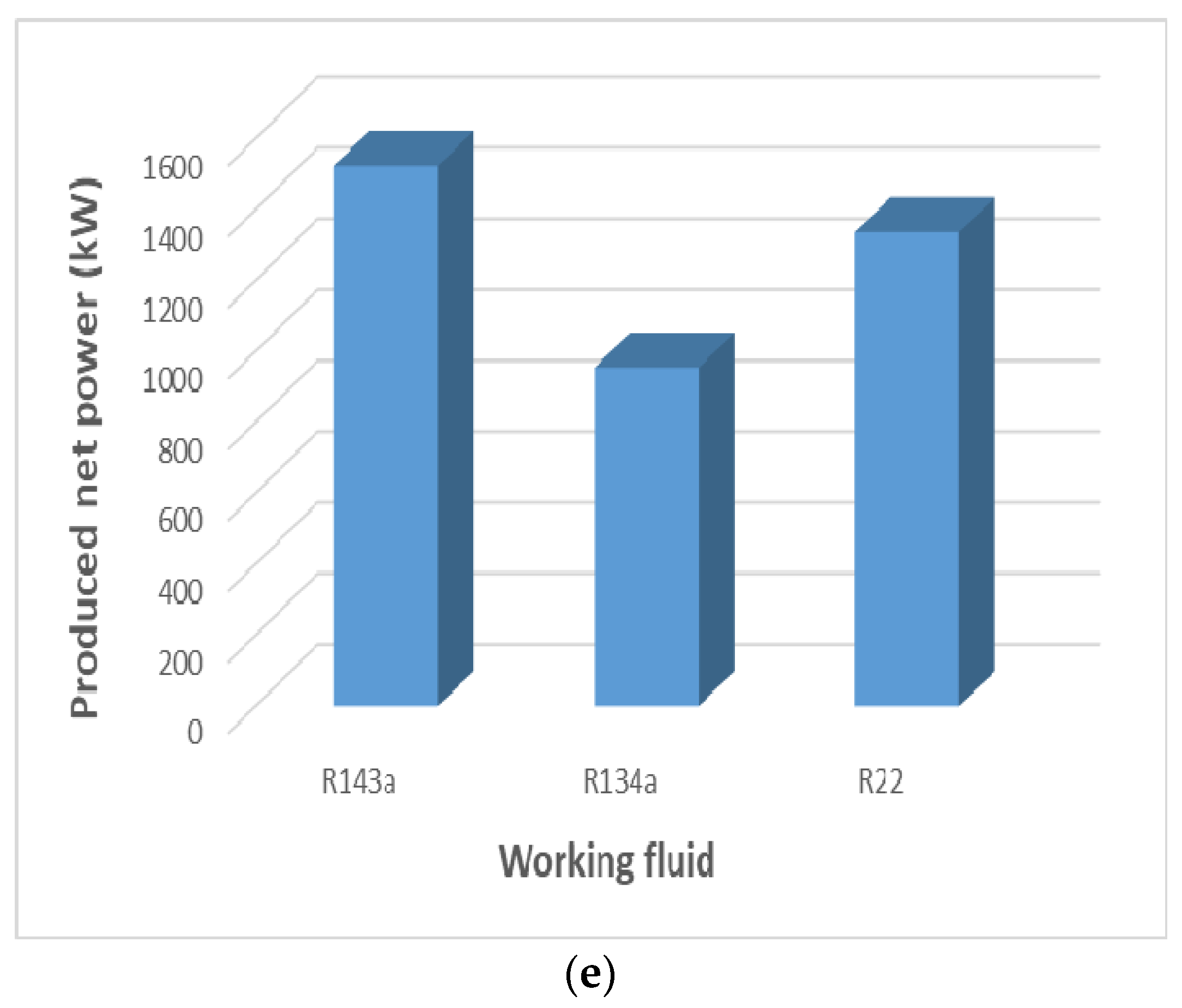

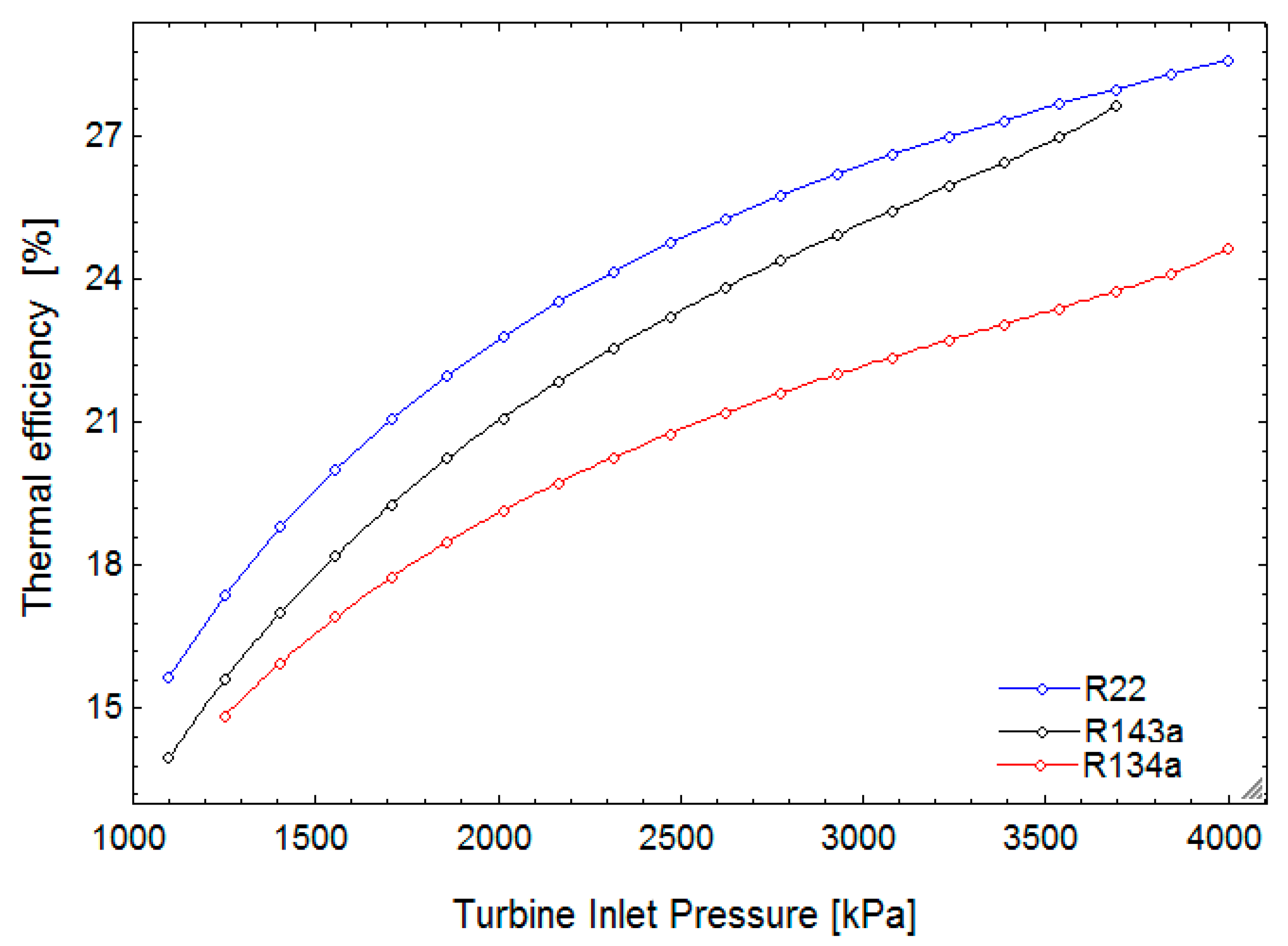

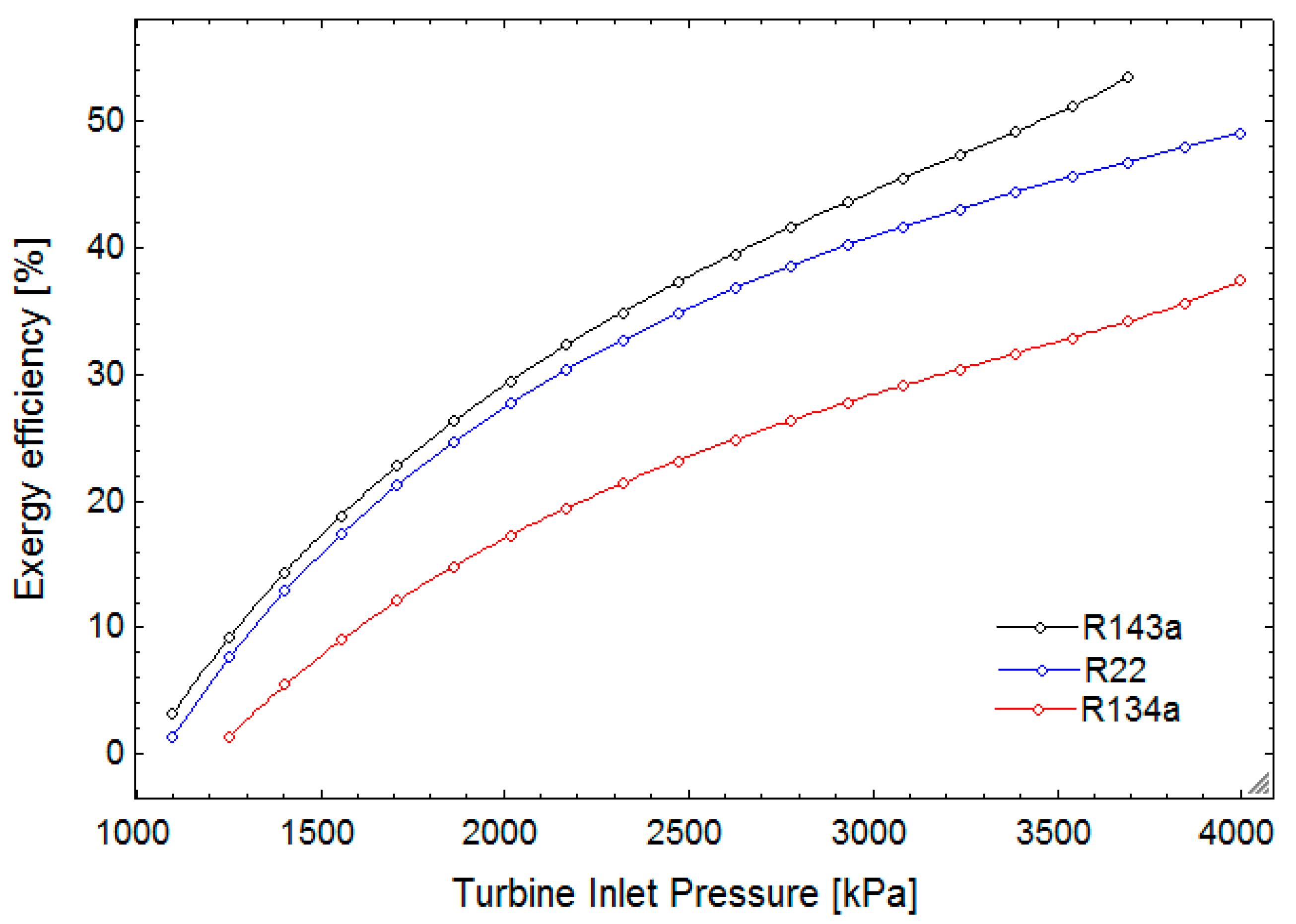

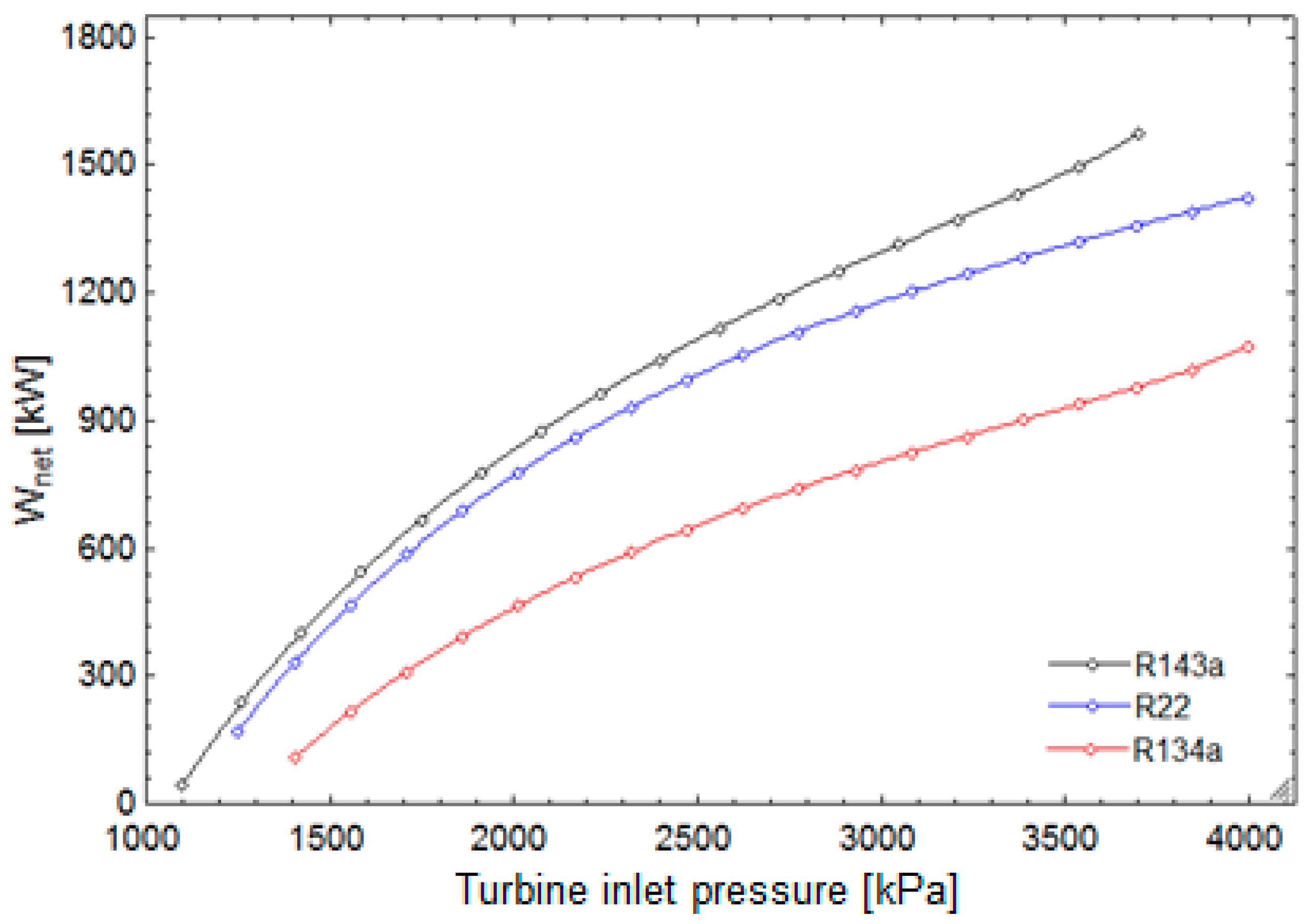

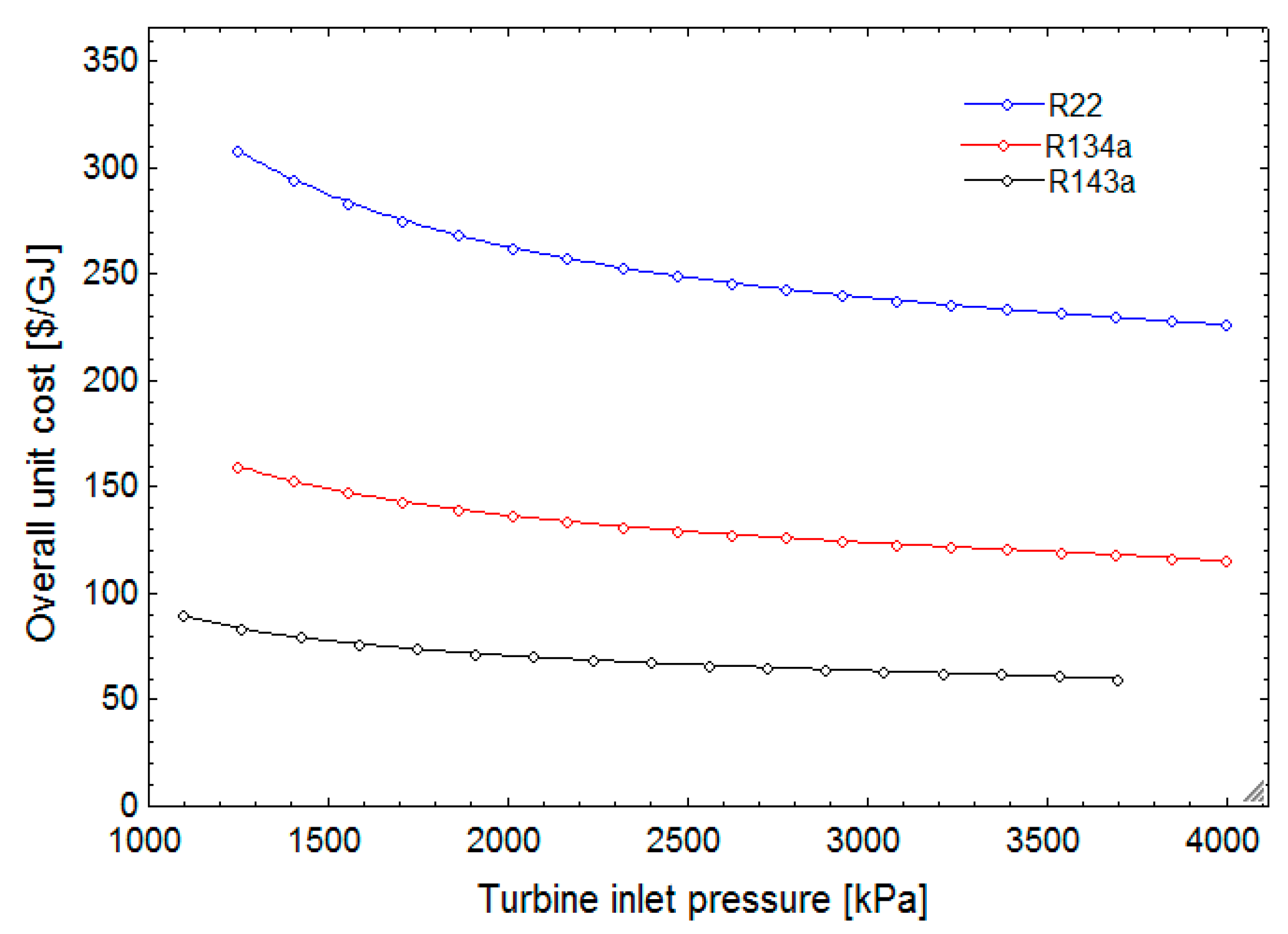

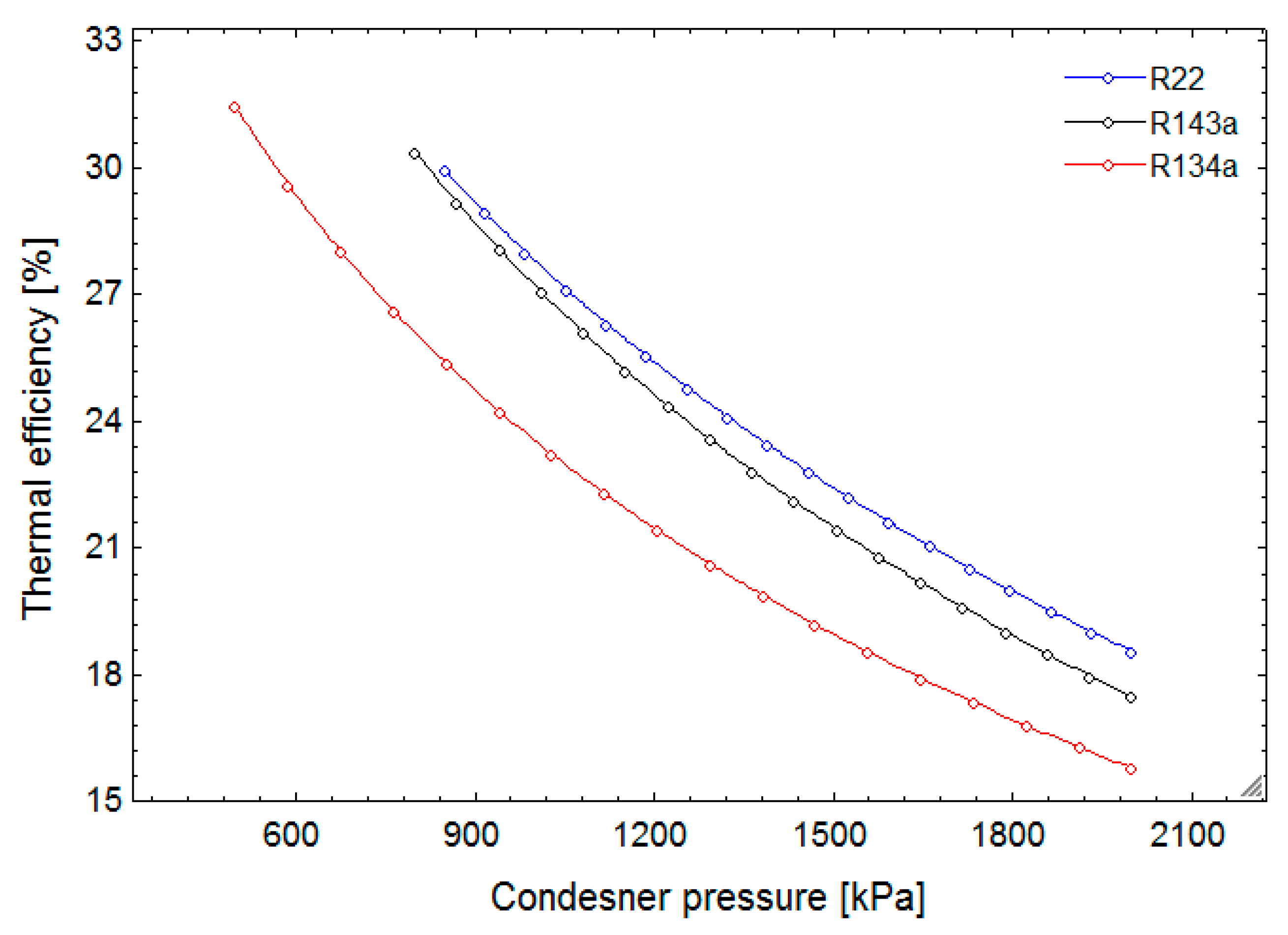

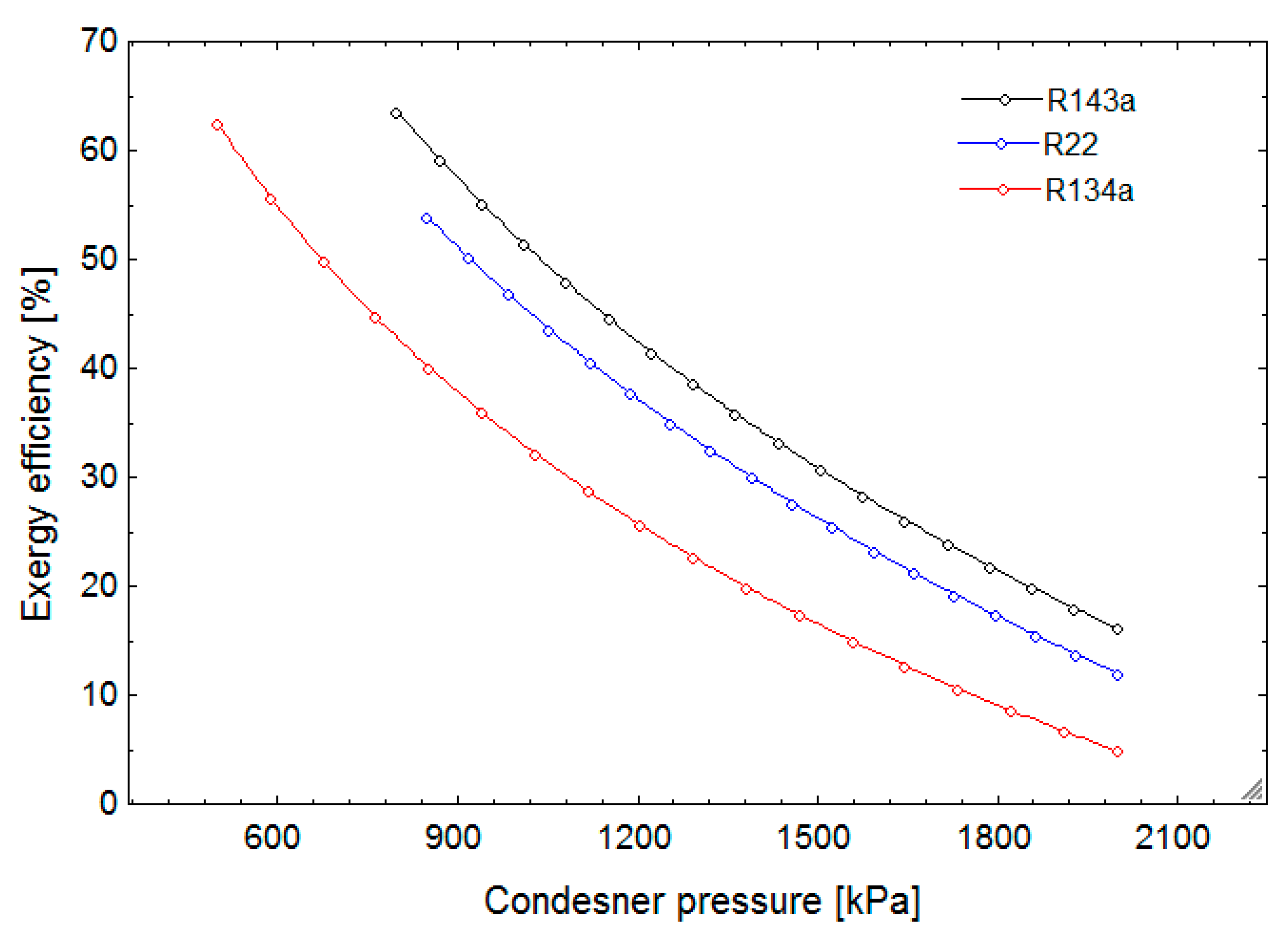

In this research, a combined cycle consisting of an ORC and a VCC using geothermal water as a low-temperature heat source is proposed and analyzed from thermodynamic and exergoeconomic viewpoints. The system generates electricity and cooling simultaneously. After determining the thermal and exergy efficiencies, a thermoeconomic analysis is performed to calculate each stream’s exergy cost, as well as total product unit cost of the system. Next, a parametric study is conducted to investigate the effects of decision parameters and various working fluids on the thermal and exergy efficiencies, as well as total product unit cost.