Environmental Efficiency of Organic and Conventional Cotton in Benin

Abstract

1. Introduction

2. Literature Review of the Cotton Sector

3. Materials and Methods

3.1. Study Area and Sampling

3.2. Analytical Framework of Environmental Efficiency

- (1)

- It is homogenous:

- (2)

- It is non-decreasing in desirable outputs:

- (3)

- It is non-increasing in undesirable outputs:

- (4)

- It is non-increasing in input:

3.3. Empirical Model

- Cotton yield (kg per hectare) of producer i

- Amount of cottonseed (kg per hectare)

- Amount of chemical fertilizer (NPK and urea) (kg per hectare)

- Amount of organic fertilizer (kg per hectare)

- Amount of synthetic pesticides or organic pesticides (liter per hectare)

- Amount of labor (man hour per hectare)

- Amount of GHGs emitted (kg CO2e per hectare)

3.3.1. Production Elasticity

3.3.2. Shadow Price of Undesirable Output

3.3.3. Estimation of the Undesirable Output

3.4. Data Collection

4. Results

4.1. Socio-economics Characteristics of Producer

4.2. Farm Characteristics

4.3. Environmental Efficiency and Shadow Price of Cotton Farming

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mondelaers, K.; Aertsens, J.; Van Huylenbroeck, G. Meta-analysis of the differences in environmental impacts between organic and conventional farming. Br. Food J. 2009, 111, 1098–1119. [Google Scholar] [CrossRef]

- Relyea, R. The impact of insecticides and herbicides on the biodiversity and productivity of aquatic communities. Ecol. Appl. 2005, 15, 618–627. [Google Scholar] [CrossRef]

- Trang, N.; Khai, H.; Tu, H.; Hong, N. Environmental efficiency of transformed farming systems: A case study of change from sugarcane to shrimp in the vietnamese mekong delta. For. Res. Eng. Int. J. 2018, 2, 54–60. [Google Scholar]

- Seufert, V.; Ramankutty, N.; Foley, J. Comparing the yields of organic and conventional agriculture. Nature 2012, 485, 229–232. [Google Scholar] [CrossRef] [PubMed]

- IFOAM, (International Federation of Organic Agriculture Movements). Resource Efficiency and Organic Frming: Facing Up to the Challenge; IFOAM EU Group: Belgium, Brussel, 2011. [Google Scholar]

- Marchand, S.; Guo, H. The environmental efficiency of non-certified organic farming in China: A case study of paddy rice production. China Econ. Rev. 2014, 31, 201–2016. [Google Scholar] [CrossRef]

- Reganold, J.P.; Wachter, J.M. Organic agriculture in the twenty-first century. Nat. Plants 2016, 2, 15221. [Google Scholar] [CrossRef]

- Aldanondo-Ochoa, A.; Casasnovas-Olivia, V.L.; Arandia-Miura, A. Environmental efficiency and the impact of regulation in dryland organic vine production. Land Use Policy 2014, 36, 275–284. [Google Scholar] [CrossRef]

- Ba, A.; Barbier, B. Economic and Environmental Performances of Organic Farming System Compared to Conventional Farming System: A Case Farm Model to Simulate the Horticultural Sector of the Niayes Region in Senegal. J. Hortic. 2015, 2, 1–10. [Google Scholar] [CrossRef]

- Tongwane, M.; Moeletsi, M. A review of greenhouse gas emissions from the agriculture sector in Africa. Agric. Syst. 2018, 166, 124–134. [Google Scholar] [CrossRef]

- FAO (Food and Agriculture Organisation). Organic Agriculture and Climate Change Mitigation: A Report of the Round Table on Organic Agriculture and Climate Change; Food and Agriculture Organization of the United Nations (FAO), Natural Resources Management and Environment Department: Rome, Italy, 2011. [Google Scholar]

- Ba, M. Analysis of Agricultural Commodities Value Chains and Greenhouse Gas Emission in Rice and Maize in West Africa: Impact on Food Security. Agric. Sci. 2016, 7, 457–468. [Google Scholar] [CrossRef][Green Version]

- Njuki, E.; Bravo-Ureta, B.; Mukherjee, D. The Good and the Bad: Environmental Ef ciency in Northeastern U.S. Dairy Farm. Agric. Resour. Econ. Rev. 2016, 45, 22–43. [Google Scholar] [CrossRef]

- ICAC (International Cotton Advisory Committee). Measuring Sustainability in Cotton Farming Systems Towards a Guidance Framework; International Cotton Advisory Committee: Washington, DC, USA, 2015.

- Kpadé, P.C. Adaptation de la Coordination et Nouvelles Contradictions entre Acteurs du système coton au Bénin face à la Libéralisation Économique. Thèse de Doctorat, Université de Bourgogne, Science Économique, Dijon, France, 2011. [Google Scholar]

- PASCiB (Plateforme des Acteurs de la Société Civile du Bénin). La Filière coton au Bénin: Regard et Analyses Prospectives de la Société Civile; PASCiB: Cotonou, Bénin, 2013. [Google Scholar]

- MAEP (Ministère de l’Agriculture de l’Elevage et de la Pêche). Plan Stratégique de Relance du Secteur Agricole (PSRSA) au Bénin; MAEP: Cotonou, Bénin, 2000. [Google Scholar]

- Bonou-zin, D.C.R.; Allali, K.; Tovignan, D.S.; Yabi, A.J.; Houessionon, P. Drivers of Farmers’ Perception of the Environmental Externalities of Cotton Production Practices in Benin: A Tobit Analysis. J. Agric. Environ. Sci. 2019, 7, 120–130. [Google Scholar] [CrossRef]

- Sodjinou, E.; Glin, L.C.; Nicolay, G.; Tovignan, S.; Hinvi, J. Socioeconomic determinants of organic cotton adoption in Benin, West Africa. Agric. Food Econ. 2015, 3, 1–22. [Google Scholar] [CrossRef]

- Honfoga, B.G. Diagnosing soil degradation and fertilizer use relationship for sustainable cotton production in Benin. Cogent Environ. Sci. 2018, 4, 1422366. [Google Scholar] [CrossRef]

- Kumbhakar, S.; Orea, L.; Tsionas, E.; Rodriguez-Alavez, A. Do we estimate an input or an output distance function? An application of the mixture approach to European railways. J. Product. Anal. 2007, 27, 87–100. [Google Scholar] [CrossRef]

- Cuesta, R.; Lovell, C.; Zofio, J. Environmental efficiency measurement with Translog distance functions: A parametric approach. Ecol. Econ. 2009, 68, 2232–2242. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Lovell, C.; Pasurka, C. Multilateral productivity comparisons when some outputs are undesirable: A nonparametric approach. Rev. Econ. Stat. 1989, 78, 90–98. [Google Scholar] [CrossRef]

- Chung, Y.; Färe, R.; Grosskopf, S. Productivity and undesirable outputs: A directional distance function approach. J. Environ. Manag. 1997, 51, 229–240. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Noh, D.-W.; Weber, W. Characteristics of a polluting technology: Theory and practice. J. Econom. 2005, 126, 469–492. [Google Scholar] [CrossRef]

- Sodjinou, E. Poultry-Based Intervention as Tool for Poverty Reduction and Gender Empowerment: Empirical Evidence from Benin. Ph.D. Thesis, Institute of Food and Resource Economics, Faculty of Life Sciences, University of Copenhagen, Copenhagen, Denmark, 2011. [Google Scholar]

- Färe, R.; Primont, D. Multi-Output Production and Duality: Theory and Applications; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1995. [Google Scholar]

- Fare, R.; Grosskopf, S.; Lovell, C.A.; Yaisawarng, S. Derivation of Shadow Prices for Undesirable Outputs: A Distance Function Approach. Rev. Econ. Stat. 1993, 75, 374–380. [Google Scholar] [CrossRef]

- Kumbhakar, S.; Wang, H.-J.; Horncastle, A. A Practitioner’s Guide to Stochastic Frontier Analysis Using Stata; Cambridge University Press: New York, NY, USA, 2015. [Google Scholar]

- Kumbhakar, S.; Ghosh, S.; Mucguckin, J.T. A generalized production frontier approach for estimating determinants of inefficiency in U.S. dairy farm. J. Bus. Econ. Stat. 1991, 9, 279–286. [Google Scholar]

- Battese, G.; Coelli, T. A model for technical inefficiency effect in a stochastic frontier production function for panel data. Empir. Econ. 1995, 20, 325–332. [Google Scholar] [CrossRef]

- Alamu, B.A.; Nuppenau, E.-A.; Boland, H. Technical Efficiency of Farming Systems across Agro-ecological Zones in Ethiopia: An Application of Stochastic Frontier Analysis. 2009. Available online: http://www.csae.ox.ac.uk/conferences/2009-EDiA/papers/030-Alemu.pdf (accessed on 11 March 2019).

- Ndambiri, H.K.; Ritho, C.; Mbogoh, S.; Ng’ang’a, S.I.; Muiruri, E.J.; Nyangweso, P.; Cherotwo, F.H. Analysis of Farmers’ Perceptions of the Effects of Climate Change in Kenya: The Case of Kyuso District. J. Environ. Earth Sci. 2012, 2, 74–81. [Google Scholar]

- Rahman, S. Environmental impacts of modern agricultural technology diffusion in Bangladesh: An analysis of farmers’ perceptions and their determinants. J. Environ. Manag. 2003, 68, 183–191. [Google Scholar] [CrossRef]

- Dyer, J.; Desjardins, R. Carbon dioxide emissions associated with the manufacturing of tractors and farm machinery in Canada. Biosyst. Eng. 2006, 93, 107–118. [Google Scholar] [CrossRef]

- Kramer, K.; Moll, H.; Nonhebel, S. Total greenhouse gas emissions related to the Dutch crop production system. Agric. Ecosyst. Environ. 1999, 72, 9–16. [Google Scholar] [CrossRef]

- Macedo, I.; Seabra, J.; Silva, J. Greenhouse gases emissions in the production and use of ethanol from sugarcane in Brazil: The 2005/2006 averages and a prediction for 2020. Biomass Bioenergy 2008, 32, 582–595. [Google Scholar] [CrossRef]

- Xiaomei, L.; Kotelko, M. An integrated manure utilization system (imus): Its social and environmental benefits. Lecture No.: AG056. In Proceedings of the 3rd International Methane and Nitrous Oxide Mitigation Conference, Beijing, China, 17–21 November 2003. [Google Scholar]

- IPCC, (Intergouvernemental Panel on Climate Change). IPCC Guidelines for National Greenhouse Gas Inventories Prepared by the National Greenhouse Gas Inventories; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Institute for Global Environmental Strategies: Tokyo, Japan, 2006. [Google Scholar]

- Audsley, E.; Stacey, K.; Parsons, D.; Williams, A. Estimation of the Greenhouse Gas Emissions from Agricultural Pesticide Manufacture and Use; Prepared for Crop Protection Association; Cranfield University: Silsoe, UK, 2009. [Google Scholar]

- IPCC, (Intergouvernemental Panel on Climate Change). Climate Change 2007: Synthesis Report. Contribution of Working Groups I, II and III to the Fourth Assessment; Pachauri, R.K., Reisinger, A., Eds.; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2007. [Google Scholar]

- Kodde, D.; Palm, F. Wald criteria for jointly testing equality and inequality restriction. Econometrica 1986, 50, 1243–1248. [Google Scholar] [CrossRef]

- Jouzi, Z.; Azadi, H.; Taheri, F.; Zarafshani, K.; Gebrehiwot, K.; Van Passel, S.; Lebailly, P. Organic Farming and Small-Scale Farmers: Main Opportunities and Challenges. Ecol. Econ. 2017, 132, 144–154. [Google Scholar] [CrossRef]

- Dal Ferro, N.; Zanin, G.; Borin, M. Crop yield and energy use in organic and conventional farming: A case study in north-east Italy. Eur. J. Agron. 2017, 86, 37–47. [Google Scholar] [CrossRef]

- Kirchmann, H.; Bergström, L.; Kätterer, T.; Andrén, O.; Andersson, R. Can organic crop production feed the world. In Organic Crop Production—Ambitions and Limitations; Kirchmann, H., Bergström, L., Eds.; Springer: Doordrecht, The Netherlands, 2008; pp. 39–72. [Google Scholar]

- Omotayo, O.E.; Chukwuka, K.S. Soil fertility restoration techniques in Sub- Saharan Africa using organic resources. Review. Afr. J. Agric. Res. 2009, 4, 144–150. [Google Scholar]

- Amouzou, K.; Naab, J.; Lamers, J.; Becker, M. Productivity and nutrient use efficiency of maize, sorghum, and cotton in the West African Dry Savanna. J. Plant Nutr. Soil Sci. 2018, 181, 261–274. [Google Scholar] [CrossRef]

- Serra, T.; Goodwin, B. The efficiency of Spanish arable crop organic farms, a local maximum likelihood approach. J. Produat. Anal. 2009, 31, 113–124. [Google Scholar] [CrossRef]

- Tan, S.; Heerink, N.; Kuyvenhoven, A.; Qu, F. Impact of land fragmentation on rice producers’ technical efficiency. NJAS Wagening. J. Life Sci. 2010, 57, 117–123. [Google Scholar] [CrossRef]

- Kroupova, Z.; Cechura, L.; Havlikova, M.; Halova, P.; Maly, M. Shadow prices of greenhouse gas emissions: An application to the Czech dairy production. Agric. Econ. Czech 2018, 64, 291–300. [Google Scholar]

- Kantelhardt, J.; Eckstein, K.; Hoffmann, H. Assessing programs for the provision of agri-environmental services—An efficiency analysis realized in Southern Germany. In Proceedings of the Conference of the International Association of Agricultural Economists (IAAE), Beijing, China, 16–22 August 2009; p. 13. [Google Scholar]

| Variables | Type | Modality | Sign |

|---|---|---|---|

| Age | Continuous | + | |

| Gender | Binary | 0 = Female, 1 = Male | + |

| Year of schooling | Continuous | + | |

| Experience in cotton production | Continuous | + | |

| Contact with extension services | Binary | 0 = No, 1 = Yes | + |

| Access to agricultural credit | Binary | 0 = No, 1 = Yes | + |

| Access to information on environmental effects of cotton practices | Binary | 0 = No, 1 = Yes | + |

| Training on agricultural practices | Binary | 0 = No, 1 = Yes | + |

| Soil fertility level assessment | Binary | 0 = Poor, 1 = Fertile | + |

| Input | Unit | g/Unit | (kg/Unit) | Source | ||

|---|---|---|---|---|---|---|

| CO2 | N2O | CH4 | CO2e | |||

| Machinery | Mj | 71 | - | - | 0.071 | [35] |

| Diesel fuel | l | 3560 | 0.7 | 5.2 | 3.8862 | [36] |

| Gasoline | l | 3393 | 3.393 | [37] | ||

| Organic fertilizer | kg | 126 | - | - | 0.126 | [38] |

| N | kg | 3970 | 3.97 | [37] | ||

| P | kg | 1000 | 0.02 | 1.8 | 1.3 | [37] |

| K | kg | 700 | 0.01 | 1 | 0.710 | [37] |

| N_urea | kg | 1595.6 | 1.5956 | [39] * | ||

| Direct emission (N) | kg | 15.7 | 0.3768 | [39] * | ||

| Volatilization (N) | kg | 1.96 | 0.0470 | [39] * | ||

| Runoff (N) | kg | 3.53 | 0.0847 | [39] * | ||

| Herbicide | 2960 | 29.6 | [40] | |||

| Insecticide | kg | 2139 | - | - | 21.39 | [40] |

| Potential | kg | 1 | 24 | 310 | [41] | |

| Socio-economics Characteristics | Organic | Conventional | Total | Statistic Test |

|---|---|---|---|---|

| Age of producer | 42.16 (10.76) | 44.14 (12.12) | 43.14 (11.48) | 1.63 * |

| Formal education | 2.45 (4.19) | 3.96 (4.82) | 3.19 (4.57) | 3.15 *** |

| Experience in cotton production | 12.36 (9.42) | 18.7 (9.9) | 15.48 (10.15) | 6.18 *** |

| Gender of producer (% male) | 75 | 99.4 | 87 | 46.94 *** |

| Access to Credit (%) | 3.9 | 30.9 | 17.2 | 45.34 *** |

| soil fertility (%) | 32.6 | 22.2 | 27.3 | 4.78 ** |

| Contact with extension agent (%) | 28.3 | 20.6 | 24.5 | 2.88 * |

| Access to information on the environmental effect of cotton practices (%) | 41.7 | 17.8 | 29.6 | 40.44 *** |

| Training on agricultural practice (%) | 14.4 | 9.1 | 11.8 | 2.39 |

| Inputs | Organic | Conventional | Total | t-Student |

|---|---|---|---|---|

| cotton area (Hectare) | 1.29 (1.06) | 8.52 (10.06) | 4.85 (7.96) | 9.57 *** |

| Seed (kg/ha) | 29.75 (11.29) | 29.23 (10.80) | 29.49 (11.04) | 0.44 |

| chemical fertilizer (kg/ha) | 0 | 211.55 (71.29) | 104.29 (117.12) | 39.81 *** |

| organic fertilizer (kg/ha) | 2227.55 (3977.71) | 465.94 (1134.71) | 1359.15 (3067.77) | 5.64 *** |

| chemical pesticides (l/ha) | 0 | 8.19 (4.08) | 8.19 (4.04) | 3.5 *** |

| organic pesticide (l/ha) | 21.54 (50.24) | 0 | 21.54 (36.46) | 3.5 *** |

| human labor (man hour/ha) | 777.40 (929.05) | 887.90 (1128.08) | 831.87 (1031.99) | 1 |

| cotton yield (kg/ha) | 924.27 (326.30) | 1230.47 (297.79) | 1075.21 (347.75) | 9.22 *** |

| GHG (kg CO2e/ha) | 462.65 (580.74) | 882.06 (357.98) | 669.40 (526.89) | 8.16 *** |

| Variables | Coefficients | t-Test | p Value |

|---|---|---|---|

| Seed | 0.950 (0.770) | 1.23 | 0.218 |

| Chemical fertilizer | −1.196 (0.149) *** | −8.01 | 0.000 |

| Organic fertilizer | −0.244 (0.080) *** | −3.03 | 0.002 |

| Pesticide | 0.379 (0.223) * | 1.70 | 0.089 |

| Labor | −0.666 (0.217) *** | −3.06 | 0.002 |

| GHGs | 0.891 (0.315) *** | 2.83 | 0.005 |

| Seed2 | −0.350 (0.180) ** | −1.94 | 0.052 |

| Chemical fertilizer 2 | −0.191 (0.029) *** | −6.49 | 0.000 |

| Organic fertilizer 2 | −0.042 (0.006) *** | −7.10 | 0.000 |

| Pesticide 2 | 0.015 (0.021) | 0.69 | 0.493 |

| Labor 2 | −0.016 (0.019) | −0.79 | 0.431 |

| GHGs 2 | −0.068 (0.025) *** | −2.70 | 0.007 |

| Seed * Chemical fertilizer | 0.020 (0.021) | 0.97 | 0.330 |

| Seed * Organic fertilizer | 0.004 (0.012) | 0.30 | 0.761 |

| Seed * Pesticide | 0.087 (0.041) ** | 2.14 | 0.032 |

| Seed * Main d’œuvre | 0.050 (0.041) | 1.23 | 0.220 |

| Seed * GES | −0.029 (0.048) | −0.61 | 0.539 |

| Chemical fertilizer *Engrais organique | −0.006 (0.002) ** | −2.49 | 0.013 |

| Chemical fertilizer * Pesticide | 0.005 (0.012) | 0.46 | 0.648 |

| Chemical fertilizer * Labor | −0.002 (0.008) | −0.22 | 0.827 |

| Chemical fertilizer * GES | 0.117 (0.013) *** | 9.18 | 0.000 |

| Organic fertilizer * Pesticide | 0.004 (0.007) | 0.52 | 0.601 |

| Organic fertilizer * Labor | −0.005 (0.005) | −1.03 | 0.302 |

| Organic fertilizer * GES | 0.029 (0.007) *** | 4.26 | 0.000 |

| Pesticide * Labor | −0.024 (0.018) | −1.37 | 0.170 |

| Pesticide * GES | −0.043 (0.015) *** | −2.88 | 0.004 |

| Labor * GES | 0.049 (0.015) *** | 3.23 | 0.001 |

| Constant | 1.091 (2.460) | 0.44 | 0.657 |

| Sigmau_2 | 0.075 (0.014) *** | 5.31 | |

| Sigmav_2 | 0.017 (0.003) *** | 4.44 | |

| LR test | 16.69 *** | ||

| Inefficiency factors | Marginal effect | ||

| Age | 0.026 (0.012) ** | 2.23 | 0.003 |

| Year of schooling | 0.023 (0.024) | 0.97 | 0.003 |

| Gender of cotton farmer (Male) | −0.208 (0.313) | −0.66 | −0.023 |

| Contact with extension services | −0.440 (0.243) * | −1.81 | −0.049 |

| Access to agricultural credit | −0.854 (0.319) *** | −2.67 | −0.09 |

| Training on agricultural practice | 0.251 (0.313) | −0.80 | −0.028 |

| Access to information on environmental effect of cotton practices | −0.445 (0.158) *** | −2.27 | −0.049 |

| Soil fertility | −1.863 (0.821) | −2.81 | −0.207 |

| Experience in cotton production | −0.028 (0.01) ** | −1.99 | −0.003 |

| constant | −0.161 (1.019) | −0.16 |

| Input Elasticity | Organic | Conventional | Total | t-Test |

|---|---|---|---|---|

| Seed | −0.079 (0.149) | −0.012 (0.127) | −0.463 (0.142) | 4.49 *** |

| Chemical fertilizer | −0.488 (0.003) | |||

| Organic fertilizer | −0.114 (0.106) | 0.022 (0.124) | −0.468 (0.1341) | 11.13 *** |

| Pesticides (Bio) | 0.075 (0.047) | 0.019 (0.031) | 0.048 (0.048) | −13.11 ** |

| Human labor | −0.021 (0.030) | 0.062 (0.030) | 0.083 (0.0735 | 16.65 *** |

| GHGs | 0.314 (0.091) | 0.769 (0.10) | 0.538 (0.247) | 44.72 *** |

| Farm Type | Organic | Conventional | Total |

|---|---|---|---|

| Small | 84.64 (6.24) | 113.94 (8.20) | 110.03 (12.93) |

| Medium | 74.47 (17.78) | 115.18 (8.28) | 93.77 (24.75) |

| Large | 69.02 (14.90) | 111.53 (8.83) | 90.28 (24.73) |

| Total | 74.10 (17.51) | 114.76 (8.34) | 94.14 (24.57) |

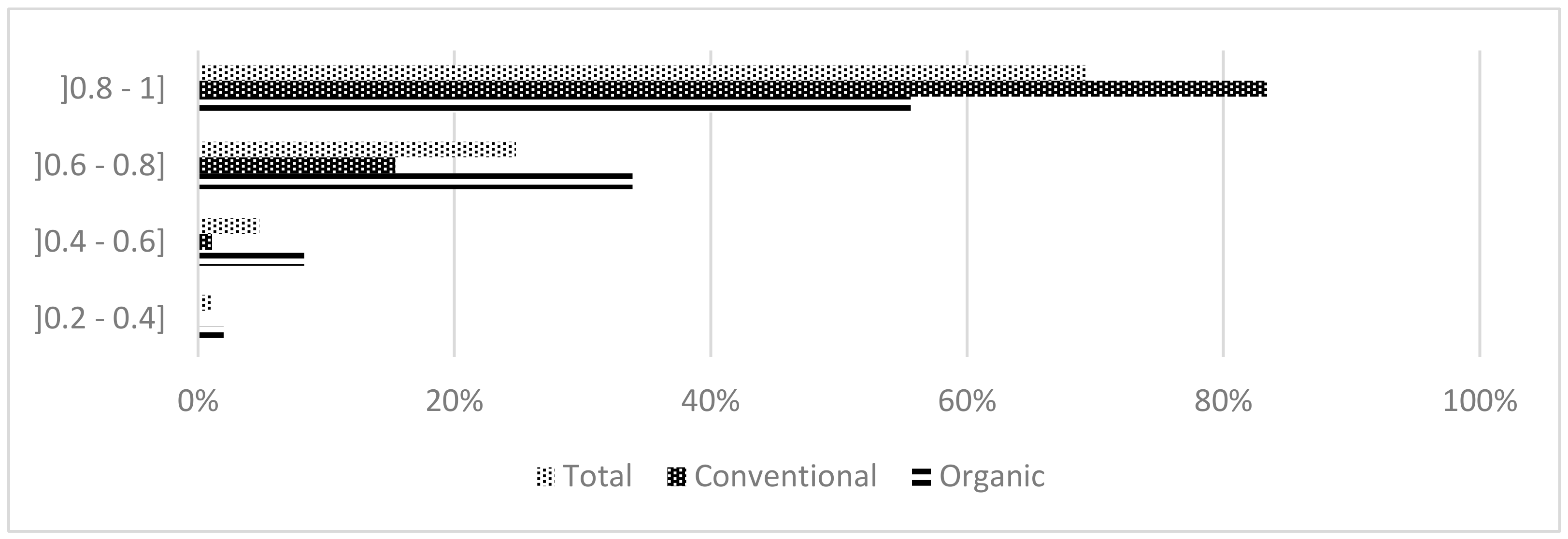

| Efficiency Index | Organic | Conventional | Total | t-Test |

|---|---|---|---|---|

| Inefficiency | 0.263 (0.207) | 0.164 (0.088) | 0.214 (0.197) | −5.79 *** |

| Environemental efficiency | 0.786 (0.137) | 0.854 (0.068) | 0.819 (0.114) | 17.24 *** |

| Farm Size | Organic | Conventional | Total |

|---|---|---|---|

| Small | 0.66 (0.32) | 0.80 (0.11) | 0.78 (0.14) |

| Medium | 0.79 (0.13) | 0.85 (0.06) | 0.82 (0.11) |

| Large | 0.72 (0.16) | 0.88 (0.04) | 0.80 (0.13) |

| Total | 0.78 (0.14) | 0.85 (0.06) | 0.81 (0.11) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonou-zin, R.D.C.; Allali, K.; Fadlaoui, A. Environmental Efficiency of Organic and Conventional Cotton in Benin. Sustainability 2019, 11, 3044. https://doi.org/10.3390/su11113044

Bonou-zin RDC, Allali K, Fadlaoui A. Environmental Efficiency of Organic and Conventional Cotton in Benin. Sustainability. 2019; 11(11):3044. https://doi.org/10.3390/su11113044

Chicago/Turabian StyleBonou-zin, Régina D.C., Khalil Allali, and Aziz Fadlaoui. 2019. "Environmental Efficiency of Organic and Conventional Cotton in Benin" Sustainability 11, no. 11: 3044. https://doi.org/10.3390/su11113044

APA StyleBonou-zin, R. D. C., Allali, K., & Fadlaoui, A. (2019). Environmental Efficiency of Organic and Conventional Cotton in Benin. Sustainability, 11(11), 3044. https://doi.org/10.3390/su11113044