Performance of Permanent Vegetable Production Systems Designed with the PermVeg Model for the Red River Delta, Vietnam

Abstract

1. Introduction

2. Materials and Methods

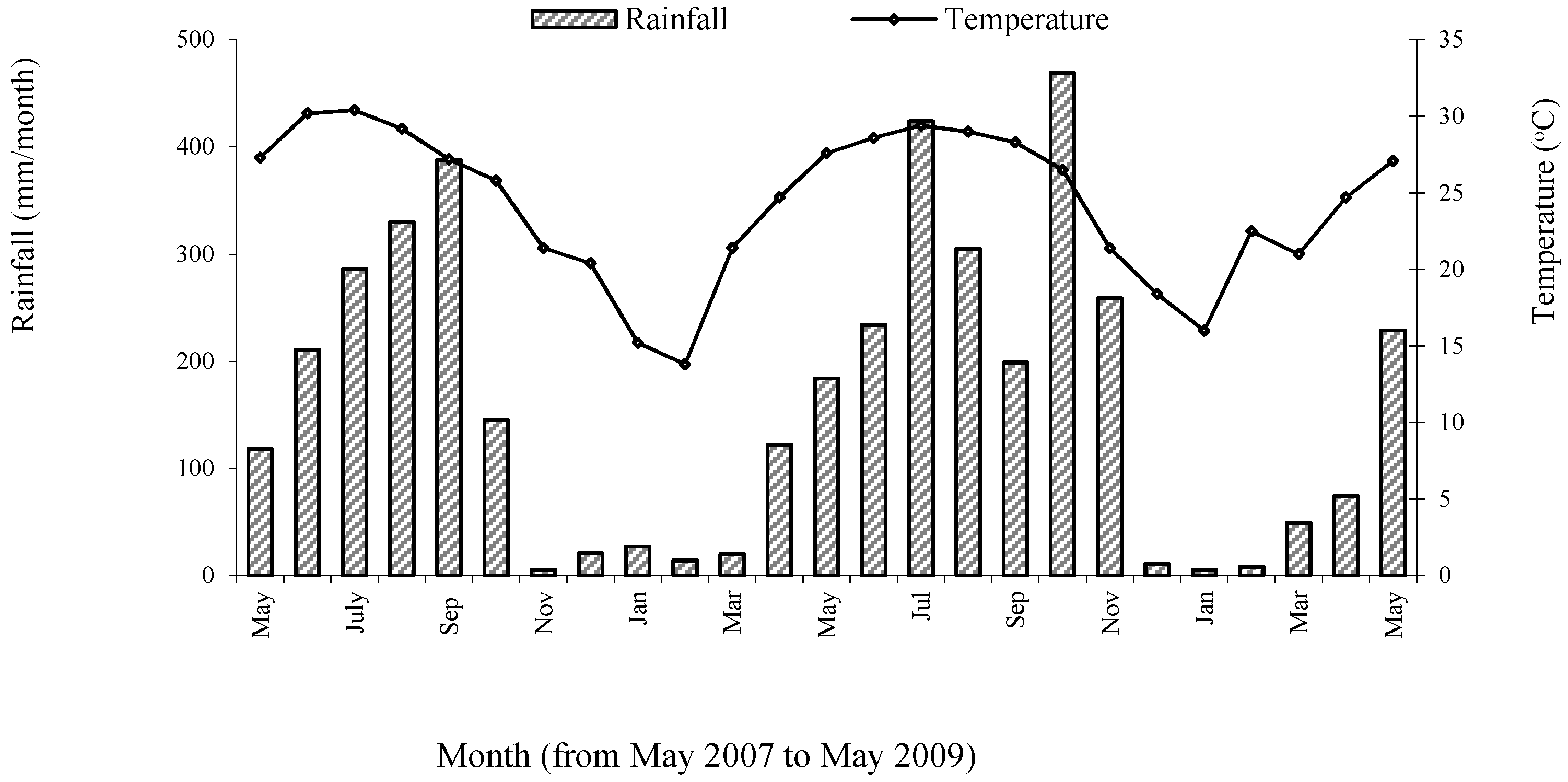

2.1. Location, Climate, and Soil of the Experimental Site

2.2. PermVeg Model and Crop Sequences

2.3. Experimental Design and Crop Production

2.4. Data Measurement and Analysis

3. Results

3.1. Crop Performance

3.2. Comparison of the Six Systems

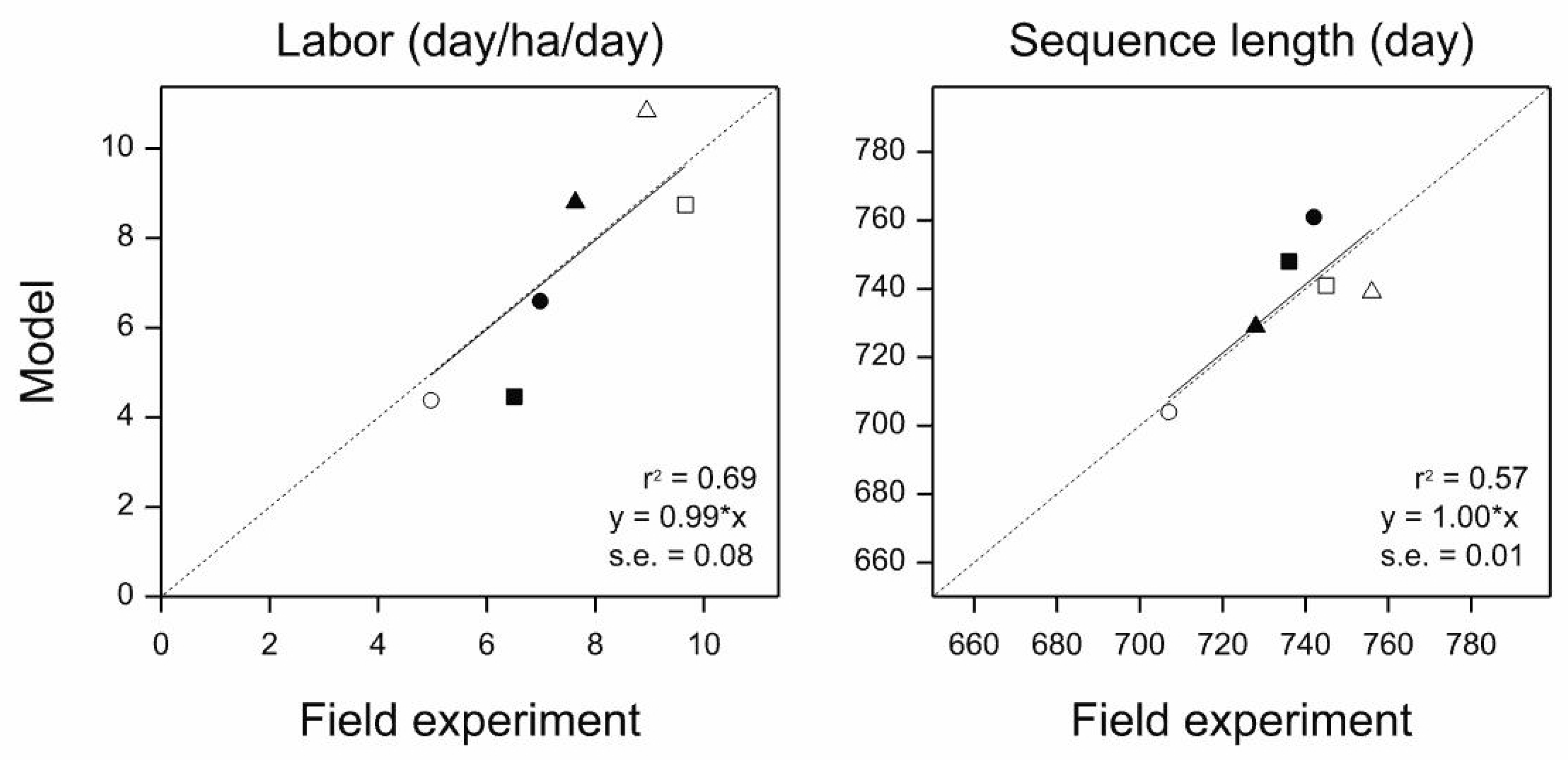

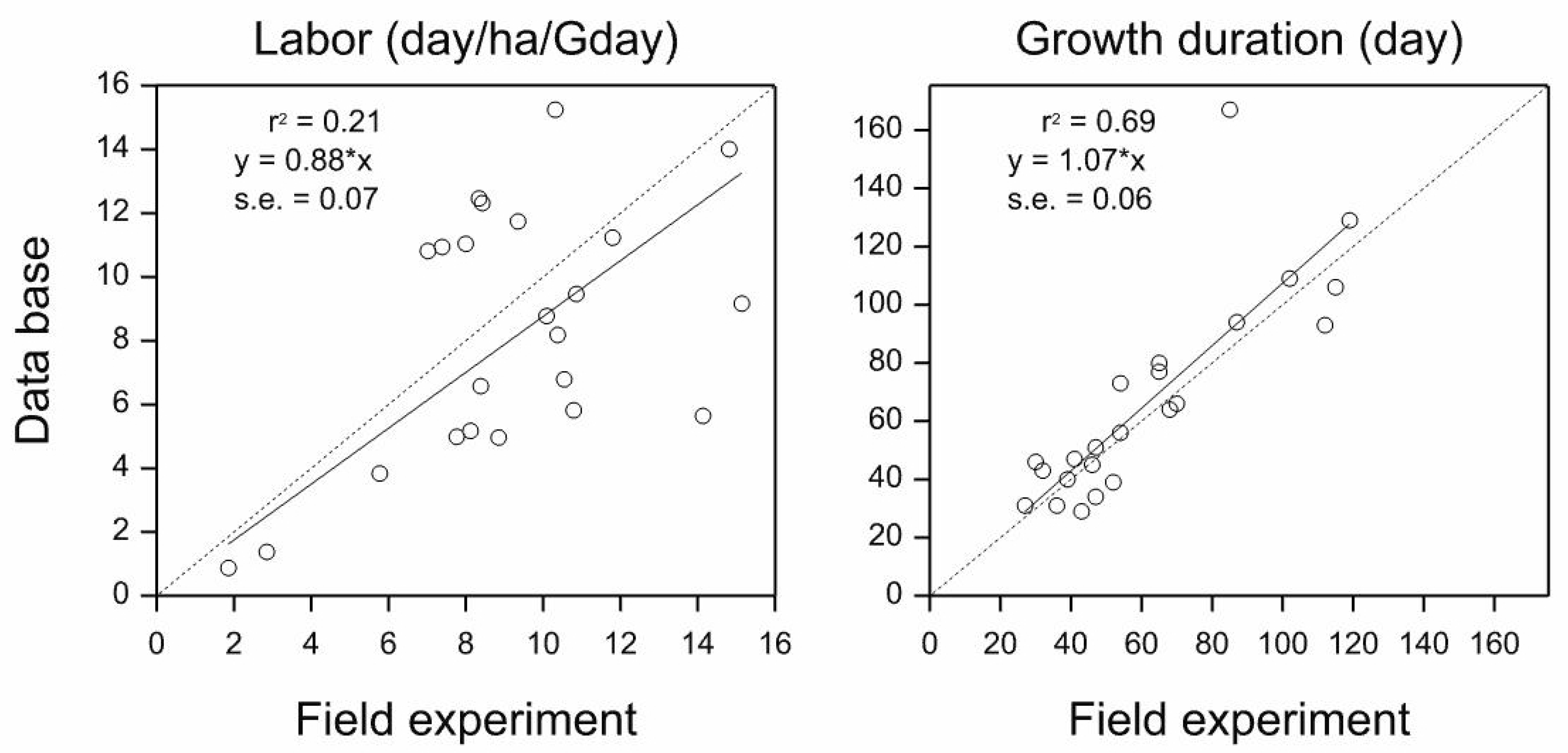

3.3. Performance of the PermVeg Model

4. Discussion

4.1. The Six Systems

4.1.1. Profitability

4.1.2. Labor

4.1.3. Pesticide

4.1.4. Biodiversity

4.1.5. Perishability

4.1.6. Traditional

4.2. The PermVeg Model

4.3. Labor

4.4. Pesticide Use

4.5. Risks in Crop Production

4.6. Marketing

4.7. Final Comments

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Johnson, G.I.; Weinberger, K.; Wu, M.-H. The vegetable sector in tropical Asia: Importance, issues and a way ahead. Acta Hort. 2009, 809, 15–34. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. FAOSTAT. Available online: http://faostat.fao.org (accessed on 1 May 2019).

- Ali, M. Horticulture revolution for the poor: Nature, challenges and opportunities. Available online: https://www.researchgate.net/profile/Mubarik_Ali/publication/254965287_Horticultural_Revolution_for_the_Poor_Nature_Challenges_and_Opportunities/links/54295dc10cf26120b7b63bfe/Horticultural-Revolution-for-the-Poor-Nature-Challenges-and-Opportunities.pdf (accessed on 1 May 2019).

- Huong, P.T.T.; Everaarts, A.P.; Neeteson, J.J.; Struik, P.C. Vegetable production in the Red River Delta of Vietnam: I. Opportunities and constraints. NJAS-Wag. J. Life Sci. 2013, 67, 27–36. [Google Scholar] [CrossRef]

- Thuy, N.T.T.; Wu, M.-H.; Lai, T.V. Northern Vietnam. In The vegetable sector in Indochina countries. Farm and household perspectives on poverty alleviation; Ali, M., Ed.; AVRDC: Tainan, Taiwan, 2002; pp. 113–153. [Google Scholar]

- An, H.B.; Vagneron, I.; Thinh, L.N.; Moustier, P.; Dam, D.D.; Nam, N.V.; Hang, L.T.; Thoai, T.Q. Spatial and institutional organization of vegetable markets in Hanoi; CIRAD, Montpellier and RIVAF: Hanoi, Vietnam, 2003. [Google Scholar]

- Everaarts, A.; Ha, N.T.T.; Hoi, P.V. Agronomy of a rice-based vegetable cultivation system in Vietnam: Constraints and recommendations for commercial market integration. Acta Hort. 2006, 699, 173–179. [Google Scholar] [CrossRef]

- Anh, D.T.; Huan, D.D.; Dat, N.S.; Chien, D.D.; Phong, L.V. Analysis of vegetable value chains in Hatay province. Available online: http://agro.gov.vn/images/2007/05/Vegetable_in_HaTay_(E).pdf (accessed on 1 May 2019).

- Anh, D.T.; Huan, D.D.; Dat, N.S.; Chien, D.D.; Phong, L.V. Analysis of vegetable value chains in Thai Binh province. Available online: http://www.sme-gtz.org.vn/Portals/0/AnPham/7-%20Analysis%20of%20safe%20vegetables%20value%20chain%20in%20Hai%20Phong-ENG.pdf (accessed on 1 May 2019).

- Huong, P.T.T.; Everaarts, A.P.; van den Berg, W.; Neeteson, J.J.; Struik, P.C. PermVeg: A model to design crop sequences for permanent vegetable production systems in Red River Delta, Vietnam. J. Agron. Crop Sci. 2014, 200, 302–316. [Google Scholar] [CrossRef]

- Dogliotti, S.; Rossing, W.A.H.; van Ittersum, M.K. ROTAT, a tool for systematically generating crop rotations. Eur. J. Agron. 2003, 19, 239–250. [Google Scholar] [CrossRef]

- Huong, P.T.T.; Everaarts, A.P.; Neeteson, J.J.; Struik, P.C. Vegetable production in the Red River Delta of Vietnam: II. Profitability, labor requirement and pesticide use. NJAS-Wag. J. Life Sci. 2013, 67, 37–46. [Google Scholar] [CrossRef]

- Everaarts, A.P.; Pham, T.T.H.; Neeteson, J.J.; Struik, P.C. Vegetable production after flooded rice improves soil properties in the Red River Delta, Vietnam. Pedosphere 2015, 25, 130–139. [Google Scholar] [CrossRef]

- Payne, R.W.; Harding, S.A.; Murray, D.A.; Soutar, D.M.; Baird, D.B.; Glaser, A.I.; Channing, I.C.; Welham, S.J.; Gilmour, A.R.; Thompson, R.; Webster, R. The guide to GenStat Release 12. Part 2: Statistics; VSN International: Hemel Hempstead, UK, 2009. [Google Scholar]

- Lu, H.; Bai, Y.; Ren, H.; Campbell, D.E. Integrated emergy, energy and economic evaluation of rice and vegetable production systems in alluvial paddy fields: Implications for agricultural policy in China. J. Environ. Manag. 2010, 91, 2727–2735. [Google Scholar] [CrossRef] [PubMed]

- Hoi, P.V.; Mol, A.P.J.; Oosterveer, P.J.M. Pesticide distribution and use in vegetable production in the Red River Delta of Vietnam. Renew. Agric. Food Syst. 2009, 24, 174–185. [Google Scholar]

- Plant Protection Department. Available online: http://www.ppd.gov.vn/index.php?language=vi&nv=laws&op=view-97-Thong-tu-so-032016TT-BNNPTNT (accessed on 1 May 2019).

- veg IMPACT NL, Wageningen University and Research. PermVeg model. Available online: www.vegimpact.com (accessed on 1 May 2019).

- Huang, J.; Qiao, F.; Zhang, L.; Rozzelle, S. Farm Pesticide, Rice Production and Human Health; Center for Chinese Agricultural Policy, Chinese Academy of Sciences: Beijing, China, 2003. [Google Scholar]

- Linh, N.V. Agricultural innovation: Multiple grounds for technology policies in the Red River Delta of Vietnam. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2001. [Google Scholar]

- Ewel, J.J. Designing agricultural systems for the humid tropics. Ann. Rev. Ecol. Syst. 1986, 17, 245–271. [Google Scholar] [CrossRef]

- Dinham, B. Growing vegetables in developing countries for local urban populations and export markets: Problems confronting small-scale producers. Pest Manag. Sci. 2003, 59, 575–582. [Google Scholar] [CrossRef] [PubMed]

- Hoi, P.V.; Mol, A.P.J.; Oosterveer, P.; van den Brink, P.J.; Huong, P.T.M. Pesticide use in Vietnamese vegetable production: A 10-year study. Int. J. Agr. Sustain. 2016, 14, 325–338. [Google Scholar] [CrossRef]

- Nguyen, T.M.; Le, N.T.T.; Havukainen, J.; Hannaway, D.B. Pesticide use in vegetable production: A survey of Vietnamese farmers’ knowledge. Plant. Protect. Sci. 2018, 54, 203–214. [Google Scholar]

- Hoi, P.V.; Mol, A.; Oosterveer, P. State governance of pesticide use and trade in Vietnam. NJAS-Wag. J. Life Sci. 2013, 67, 19–26. [Google Scholar]

- Finch, S.; Collier, R.H. Integrated pest management in field vegetable crops in northern Europe—With focus on two key pests. Crop. Prot. 2000, 19, 817–824. [Google Scholar] [CrossRef]

- Arya, L.M.; Pulver, E.L.; Genuchten, M.T.V. Economic, environmental and natural resource benefits of plastic shelters in vegetable production in a humid tropical environment. J. Sustain. Agric. 2001, 17, 123–143. [Google Scholar] [CrossRef]

- Ha, T.T.T. Sustainability of peri-urban agriculture of Hanoi: The case of vegetable production. Ph.D. Thesis, Hanoi University of Agriculture, Hanoi, Vietnam, 2008. [Google Scholar]

- Francisco, S.R.; Ali, M. Resource allocation tradeoffs in Manila’s peri-urban vegetable production systems: An application of multiple objective programming. Agric. Syst. 2006, 87, 147–168. [Google Scholar] [CrossRef]

- Moustier, P.; Figuié, M.; Loc, N.T.T.; Son, H.T. The role of coordination in the safe and organic vegetable chains supplying Hanoi. Acta Hort. 2006, 699, 297–305. [Google Scholar] [CrossRef]

- VinGroup. Vincom Retail—Vingroup. Available online: http://vingroup.net/en-us/home.aspx (accessed on 1 May 2019).

| Texture (%) | Sand | 49 |

| Silt | 42 | |

| Clay | 9 | |

| pH-H2O | 6.1 | |

| Organic carbon (%) | 1.03 | |

| N total (%) | 0.11 | |

| P total (%) | 0.04 | |

| K total (%) | 0.17 | |

| P available (mg/100g soil) | 28.0 | |

| K available (mg/100g soil) | 6.79 | |

| CEC (meq/100g soil) | 9.15 | |

| No. | Family Species | Common Name (Suitable Planting Period, Month-Month) | Sown (S)/Trans-Planted (T) | Typical Growth Duration (Days) |

|---|---|---|---|---|

| 1 | Amaranthaceae | |||

| Amaranthus tricolor | Amaranth (1-12) | S | 31 | |

| 2 | Chenopodiaceae | |||

| Spinacia oleracea | Spinach (9-2) | S | 29 | |

| 3 | Compositae | |||

| Chrysanthemum coronarium | Garland chrysanthemum (9-2) | S | 40 | |

| 4 | Cruciferae Brassica juncea var. rugosa | Wrapped heart mustard (4-8) | S | 51 |

| 5 | Brassica oleracea var. gongylodes | Kohlrabi (7-9) | T | 56 |

| 6 | Brassica oleracea var. alboglabra | Chinese kale (4-10); (11-3) | T | 47; 34 |

| 7 | Brassica rapa var. parachinensis | Green choy sum (4-8); (9-3) | S | 34; 31 |

| 8 | Brassica rapa ssp. chinensis | Green pakchoi (8-2) | T | 43 |

| 9 | Raphanus sativus | Radish (3); (8-9) | S | 46; 35 |

| 10 | Cucurbitaceae Benincasa hispida | Wax gourd (2-3); (4-6); (10); (12-1) | T | 95; 77; 93; 127 |

| 11 | Citrullus lanatus | Watermelon (2-3); (8-9) | T | 77; 64 |

| 12 | Leguminosae Pisum sativum | Snow pea (11-12) | S | 93 |

| 13 | Liliaceae Allium ampeloprasum var. porrum | Leek (3-6); (8-2) | T | 66; 61 |

| 14 | Allium cepa var. cepa | Onion (9) | T | 106 |

| 15 | Allium cepa var. ascalonicum | Shallot clove + leaves (9-1) | T (cloves) | 73 |

| 16 | Allium fistulosum | Welsh onion (1-12) | T | 39 |

| 17 | Malvaceae Corchorus olitorius | Tossa jute (2-3) | S | 167 |

| 18 | Poaceae Zea mays var. rugosa | Sweet corn (4-9) | T | 80 |

| 19 | Oryza sativa | Rice (1-2); (6-7) | T | 109; 94 |

| 20 | Solanaceae Solanum lycopersicum | Tomato (8-2) | T | 129 |

| 21 | Umbelliferae Apium graveolens | Celery (9-4) | T | 45 |

| Profitability: Welsh onion—Chinese kale—Amaranth—Watermelon—Chinese kale—Spinach—Tomato—Chinese kale—Welsh onion—Watermelon—Snow pea—Chinese kale—Amaranth |

| Labor: Sweet corn—Kohlrabi—Onion—Tomato—Wax gourd—Kohlrabi—Sweet corn—Tomato |

| Pesticide: Amaranth—Chinese kale—Welsh onion—Watermelon—Green pakchoi—Welsh onion—Spinach—Radish—Welsh onion—Tossa jute—Spinach—Welsh onion—Green choy sum—Amaranth |

| Biodiversity: Chinese kale—Tossa jute—Garland chrysanthemum—Tomato—Welsh onion—Amaranth—Watermelon—Spinach—Snow pea—Celery |

| Perishability: Wrapped heart mustard—Leek—Watermelon—Tomato—Celery—Leek—Kohlrabi—Watermelon—Tomato—Radish |

| Traditional: Rice—Chinese kale—Welsh onion—Spinach—Rice—Rice—Chinese kale—Welsh onion—Spinach—Rice |

| System | Length (Days) | Profit (kVND/ha/day) | Labor Requirement (day/ha/day) | Costs of Pesticide Use (kVND/ha/day) |

|---|---|---|---|---|

| Profitability | 741 | 561 | 8.7 | 25 |

| Labor | 748 | 333 | 4.5 | 18 |

| Pesticide | 739 | 433 | 10.8 | 10 |

| Biodiversity | 729 | 422 | 8.8 | 20 |

| Perishability | 761 | 412 | 6.6 | 21 |

| Traditional | 704 | 222 | 4.4 | 9 |

| Vegetable Production System | |||||

|---|---|---|---|---|---|

| Profitability | Labor | Pesticide | |||

| Crop | Planting Date | Crop | Planting Date | Crop | Planting Date |

| Welsh onion | 01-05-07 | Sweet corn | 01-05-07 | Amaranth | 02-05-07 |

| Chinese kale | 28-06-07 | Kohlrabi | 16-07-07 | Chinese kale | 15-06-07 |

| Amaranth | 21-08-07 | Onion | 22-09-07 | Welsh onion | 02-08-07 |

| Watermelon | 15-09-07 | Tomato | 11-03-08 | Watermelon | 20-09-07 |

| Chinese kale | 04-12-07 | Wax gourd | 07-07-08 | Green pakchoi | 15-12-07 |

| Spinach | 21-01-08 | Kohlrabi | 19-09-08 | Welsh onion | 18-01-08 |

| Tomato | 15-03-08 | Garland chrysanthemum | 15-11-08 | Spinach | 23-03-08 |

| Chinese kale | 03-07-08 | Tomato | 03-01-09 | Radish | 03-05-08 |

| Welsh onion | 28-08-08 | Welsh onion | 05-06-08 | ||

| Green choy sum | 20-10-08 | Tossa jute | 27-07-08 | ||

| Snow pea | 08-12-08 | Spinach 1 | 16-10-08 | ||

| Chinese kale | 08-04-09 | Spinach | 22-11-08 | ||

| Welsh onion | 10-01-09 | ||||

| Green choy sum | 22-03-09 | ||||

| Amaranth | 24-04-09 | ||||

| Vegetable Production System | |||||

|---|---|---|---|---|---|

| Biodiversity | Perishability | Traditional | |||

| Crop | Planting Date | Crop | Planting Date | Crop | Planting Date |

| Chinese kale | 01-05-07 | Wrapped heart mustard | 02-05-07 | Rice | 25-06-07 |

| Tossa jute | 08-06-07 | Leek | 26-06-07 | Chinese kale | 01-10-07 |

| Garland chrysanthemum | 17-09-07 | Watermelon | 31-08-07 | Welsh onion | 27-11-07 |

| Tomato | 12-11-07 | Tomato | 10-11-07 | Spinach | 19-01-08 |

| Welsh onion | 22-03-08 | Celery | 21-03-08 | Rice | 12-03-08 |

| Amaranth | 14-05-08 | Leek | 12-05-08 | Rice | 02-07-08 |

| Watermelon | 24-06-08 | Kohlrabi | 08-08-08 | Chinese kale | 06-10-08 |

| Spinach | 10-09-08 | Watermelon 1 | 18-10-08 | Shallot | 27-11-08 |

| Spinach 1 | 08-10-08 | Tomato | 15-11-08 | Rice | 16-02-09 |

| Spinach | 22-11-08 | Radish | 10-04-09 | ||

| Snow pea | 09-01-09 | ||||

| System | Profit (kVND/ha/day) | Potential Profit (kVND/ha/day) | Labor Requirement (day/ha/day) | Labor-day Income (kVND/Lday) | Potential Labor-day Income (kVND/Lday) |

|---|---|---|---|---|---|

| Profitability | 321 e | 797 c | 9.7 f | 33 bc | 83 a |

| Labor | 277 de | 877 c | 6.5 b | 42 c | 135 b |

| Pesticide | 238 cd | 763 c | 8.9 e | 27 b | 85 a |

| Biodiversity | 102 ab | 545 b | 7.6 d | 13 a | 71 a |

| Perishability | 89 a | 504 ab | 7.0 c | 13 a | 72 a |

| Traditional | 168 bc | 406 a | 5.0 a | 34 bc | 82 a |

| LSD (p = 0.05) | 71 | 132 | 0.3 | 10 | 18 |

| Significance | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 |

| System | Costs of Pesticide Use (kVND/ha/day) | Insecticide (ai) (g/ha/day) | Fungicide (ai) (g/ha/day) |

|---|---|---|---|

| Profitability | 30 | 7.3 | 32.3 |

| Labor | 39 | 26.7 | 63.0 |

| Pesticide | 29 | 5.4 | 43.3 |

| Biodiversity | 24 | 12.6 | 42.6 |

| Perishability | 38 | 18.5 | 60.0 |

| Traditional | 15 | 4.8 | 11.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huong, P.T.T.; Everaarts, A.P.; Neeteson, J.J.; Struik, P.C. Performance of Permanent Vegetable Production Systems Designed with the PermVeg Model for the Red River Delta, Vietnam. Sustainability 2019, 11, 2719. https://doi.org/10.3390/su11102719

Huong PTT, Everaarts AP, Neeteson JJ, Struik PC. Performance of Permanent Vegetable Production Systems Designed with the PermVeg Model for the Red River Delta, Vietnam. Sustainability. 2019; 11(10):2719. https://doi.org/10.3390/su11102719

Chicago/Turabian StyleHuong, Pham T.T., Arij P. Everaarts, Jacques J. Neeteson, and Paul C. Struik. 2019. "Performance of Permanent Vegetable Production Systems Designed with the PermVeg Model for the Red River Delta, Vietnam" Sustainability 11, no. 10: 2719. https://doi.org/10.3390/su11102719

APA StyleHuong, P. T. T., Everaarts, A. P., Neeteson, J. J., & Struik, P. C. (2019). Performance of Permanent Vegetable Production Systems Designed with the PermVeg Model for the Red River Delta, Vietnam. Sustainability, 11(10), 2719. https://doi.org/10.3390/su11102719