An Optimal Load Disaggregation Method Based on Power Consumption Pattern for Low Sampling Data

Abstract

1. Introduction

2. Load Signature Analysis

3. Method

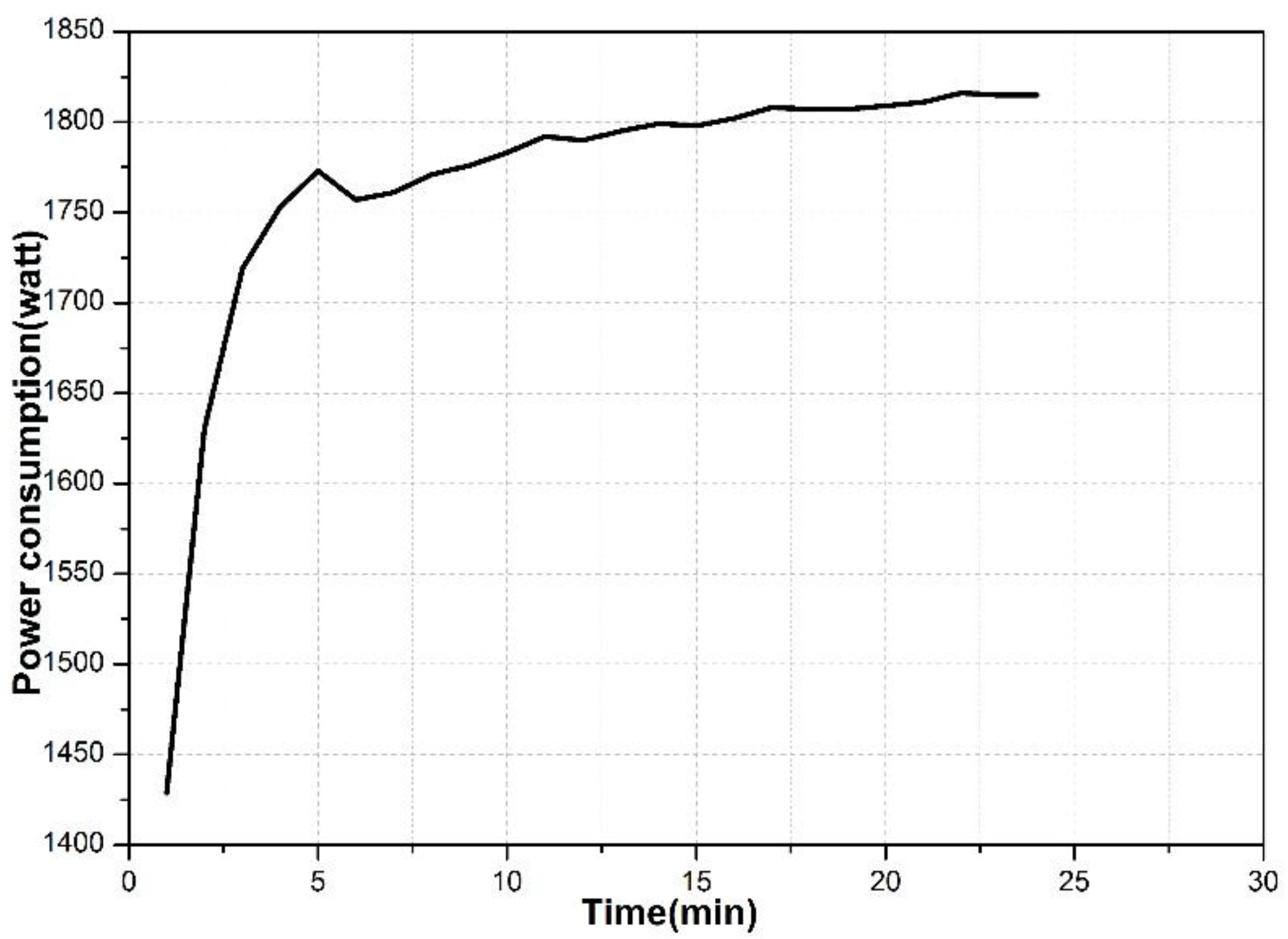

3.1. Power Consumption Pattern Characteristic Sequence of Each Appliance Extracting

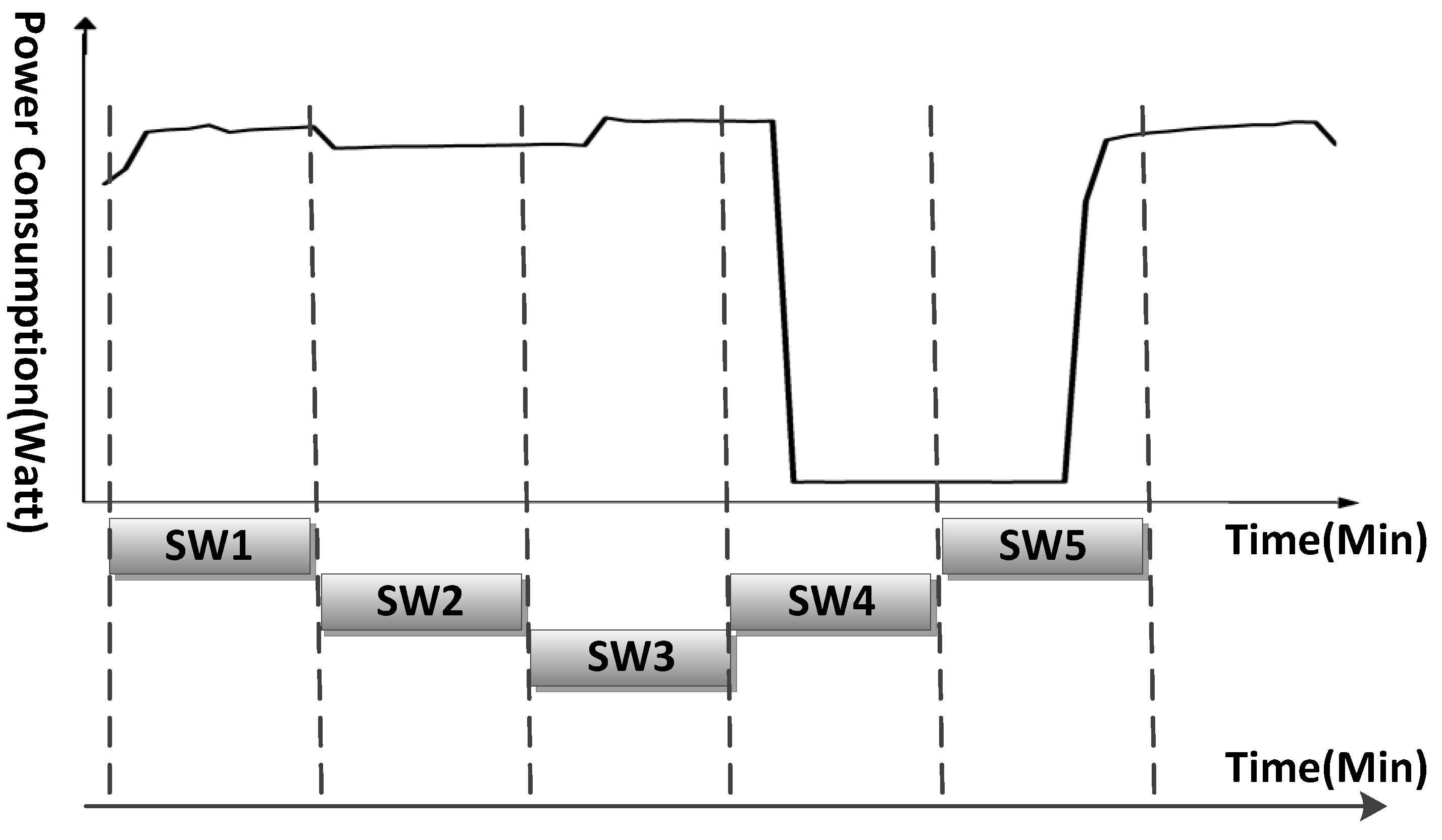

3.2. Load Disaggregation Model Based on the Signature of Appliance Power Consumption Patterns

3.2.1. Traditional Load Disaggregation Model

3.2.2. Improved Load Disaggregation Model Based on Power Consumption Pattern

3.3. Calculate the Optimal Solution Using OBSA

3.3.1. Optimized BSA

3.3.2. Calculating the Optimal Time Coefficient of Each Appliance Using OBSA

4. Validation and Comparison

4.1. Validation Data Selection and Parameter Setting

4.2. Case Validation

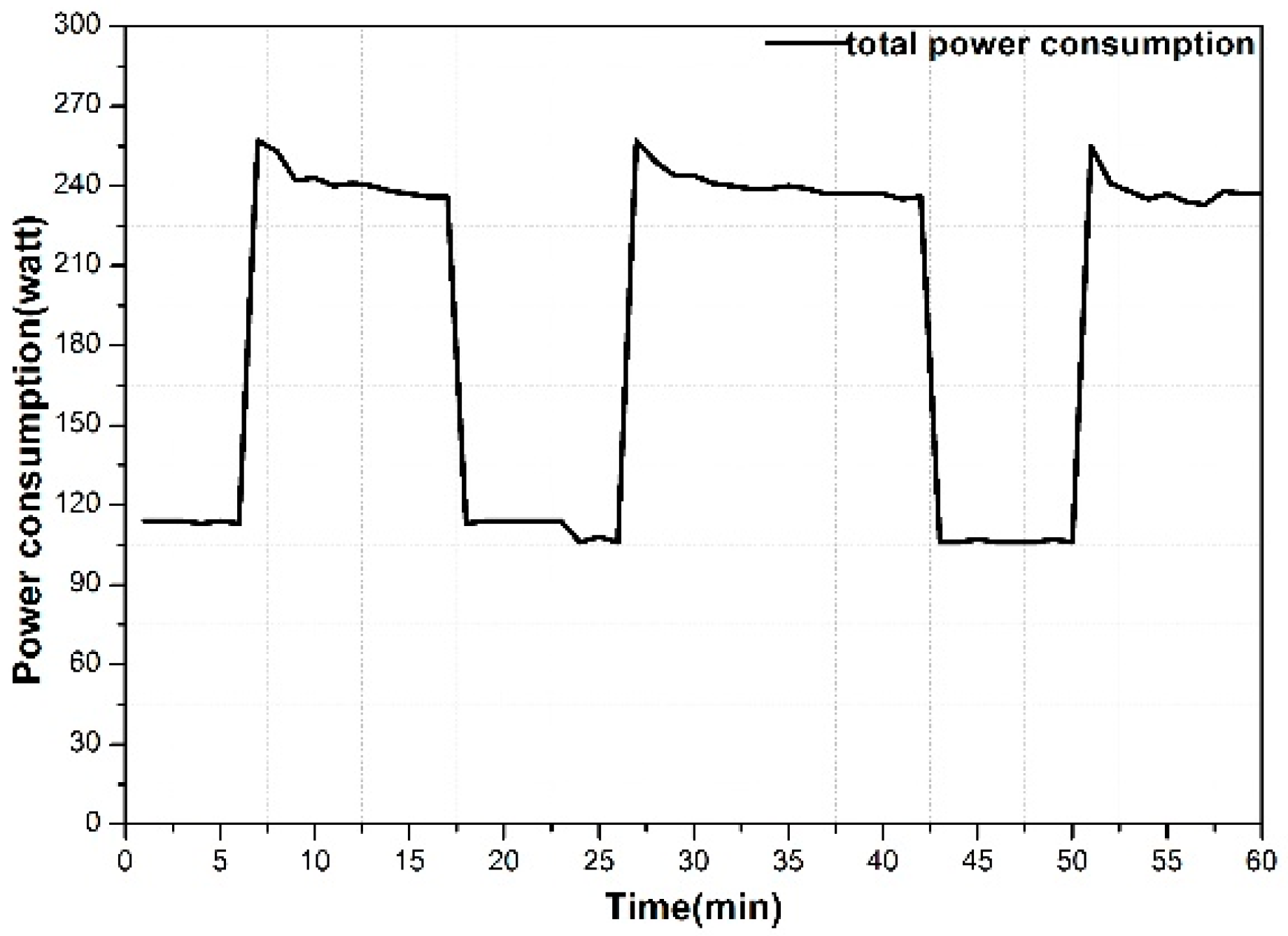

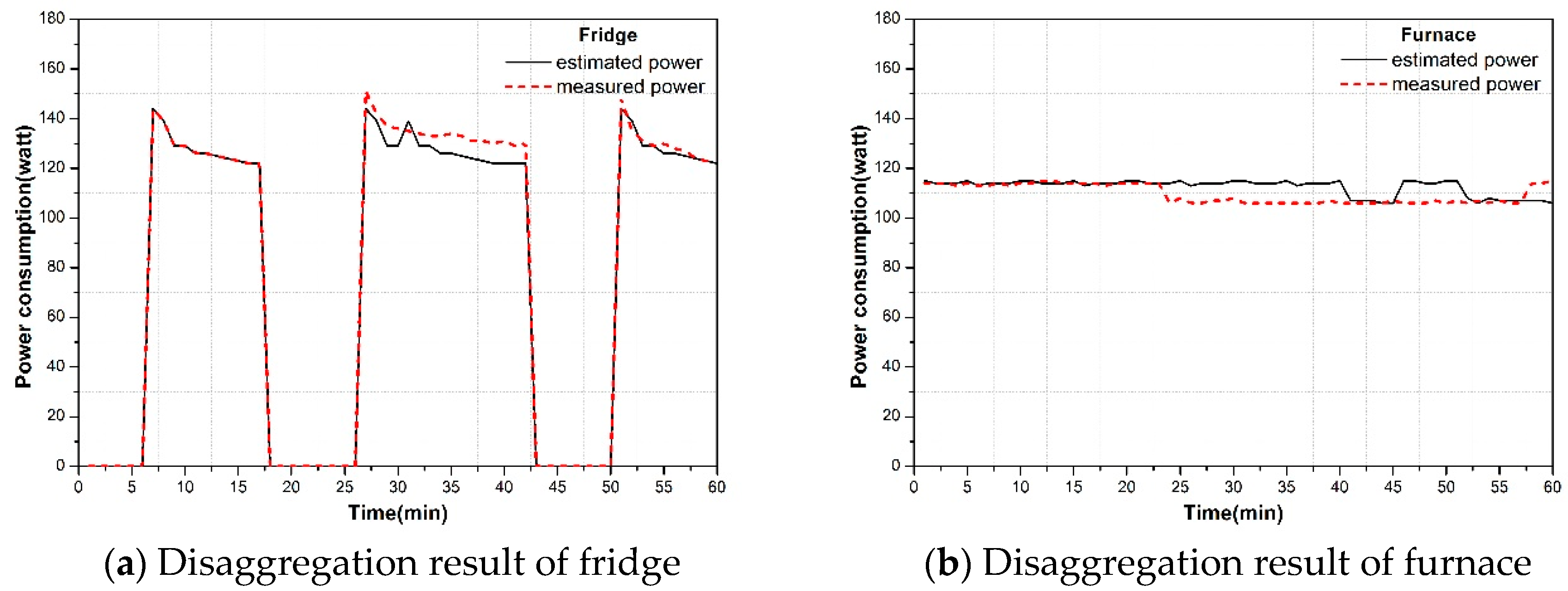

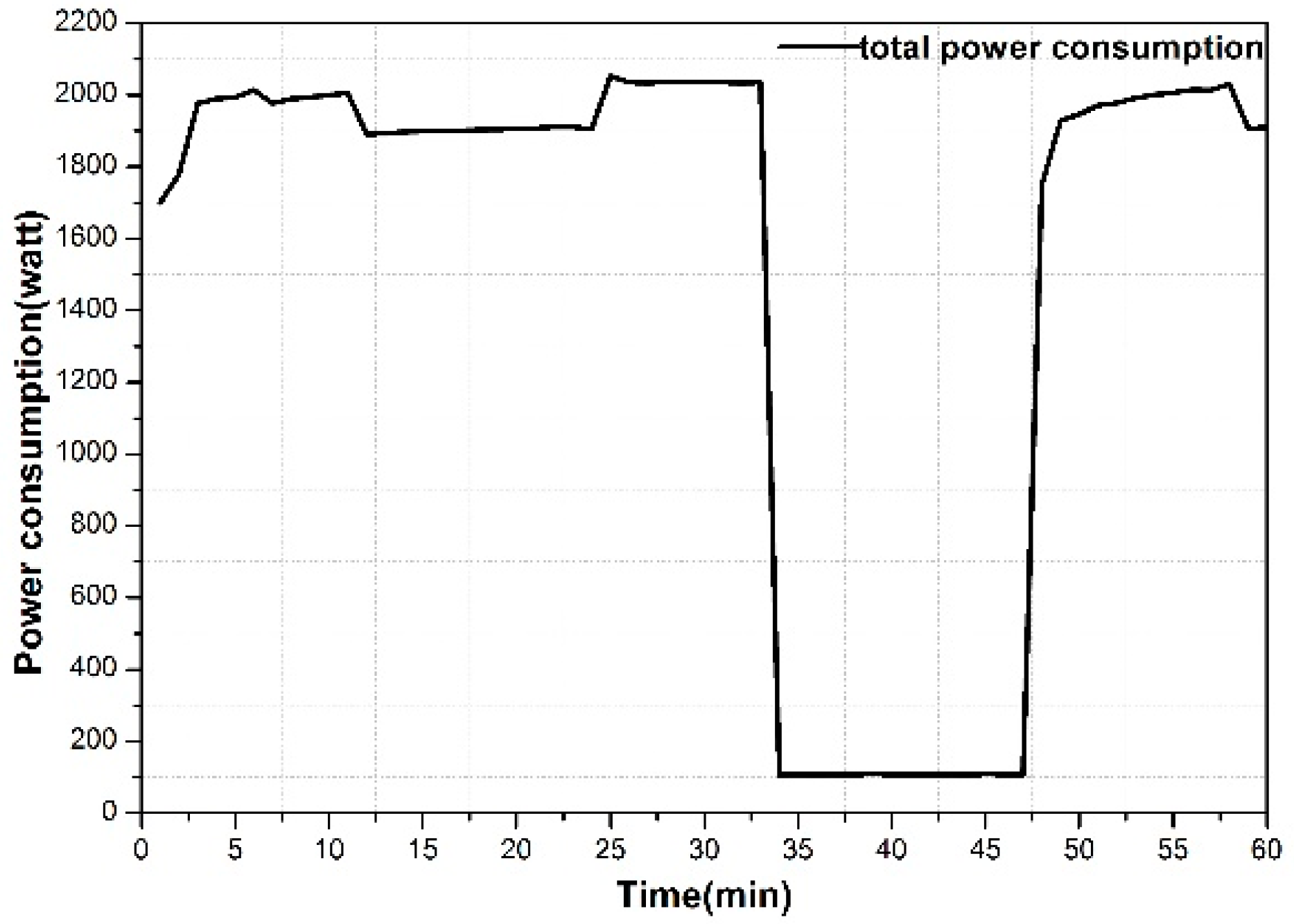

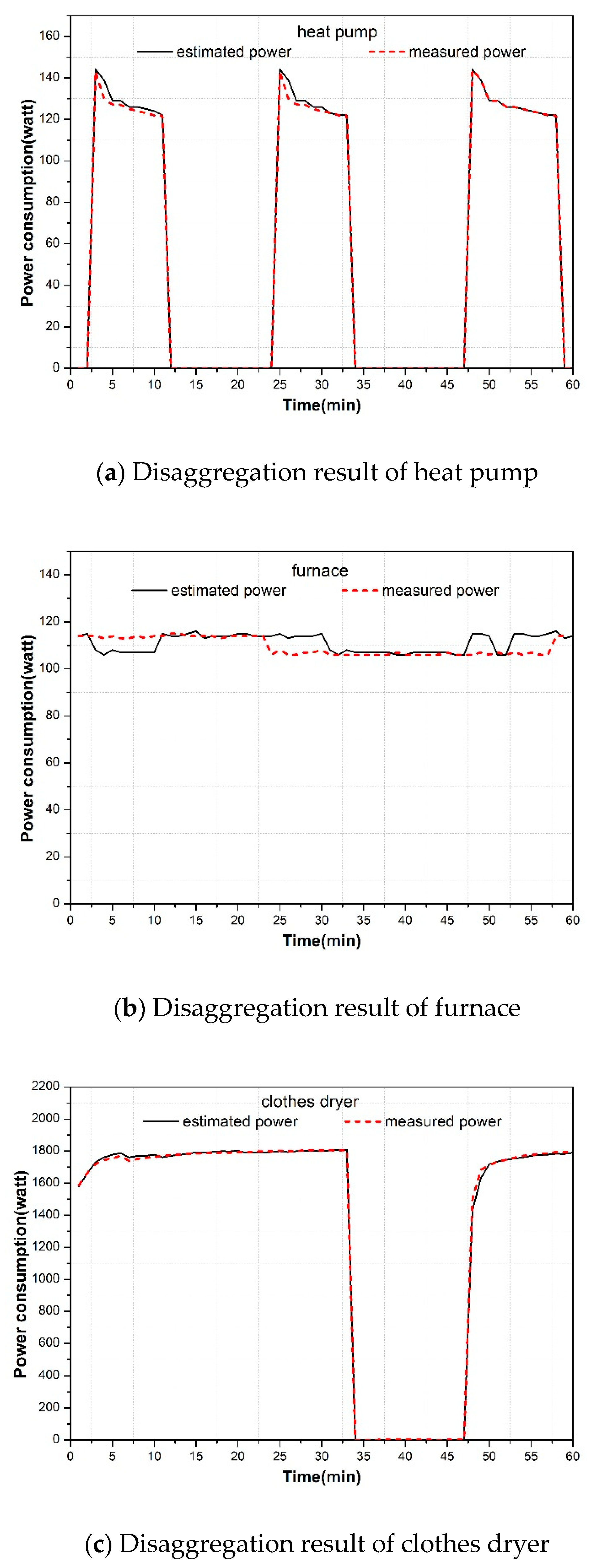

4.2.1. The Case of Two Appliances with Similar Power Consumption Operating Simultaneously

4.2.2. The Case of Power Variation Range of an Appliance During Operation Similar to Other Appliances’ Power

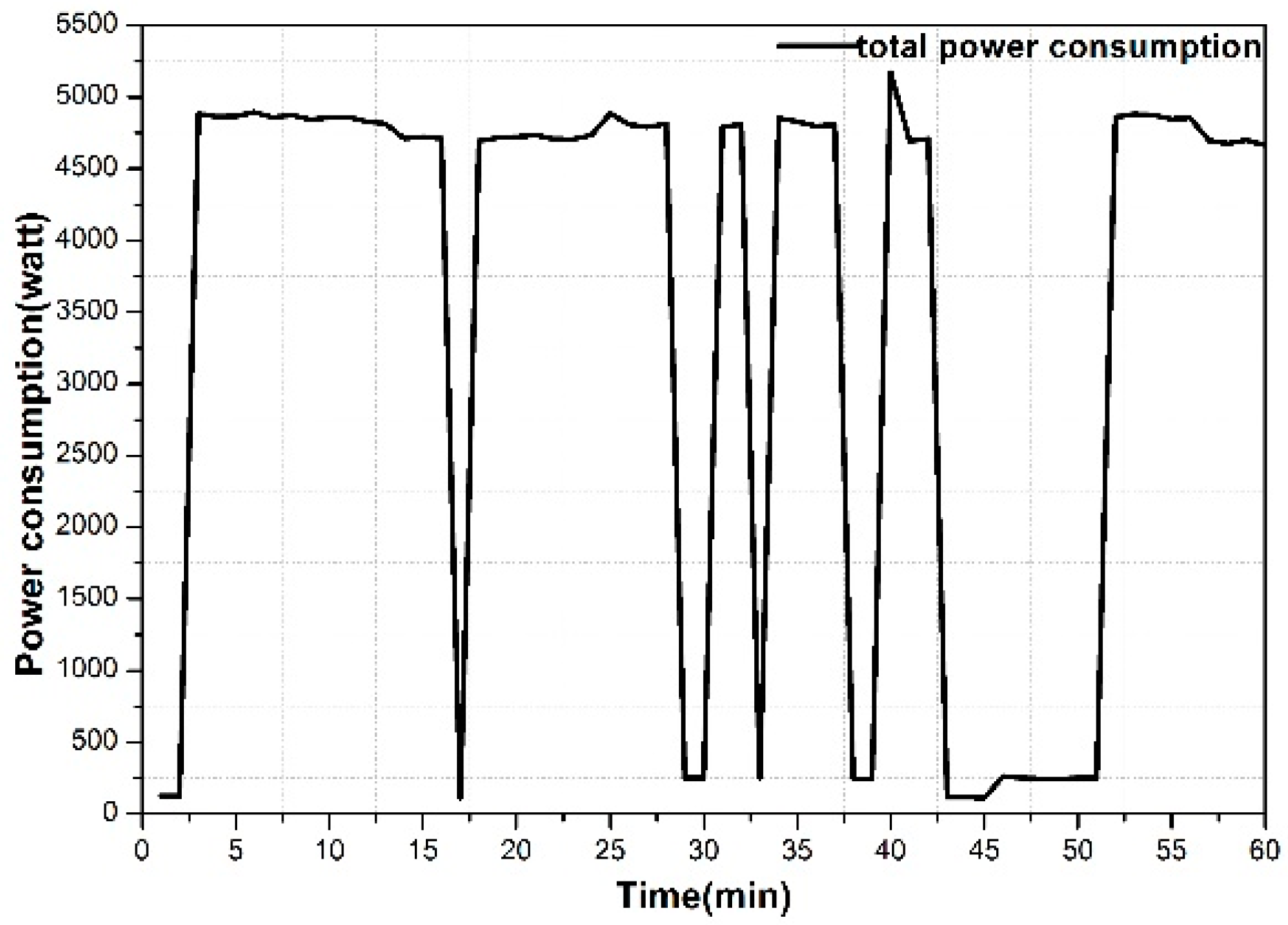

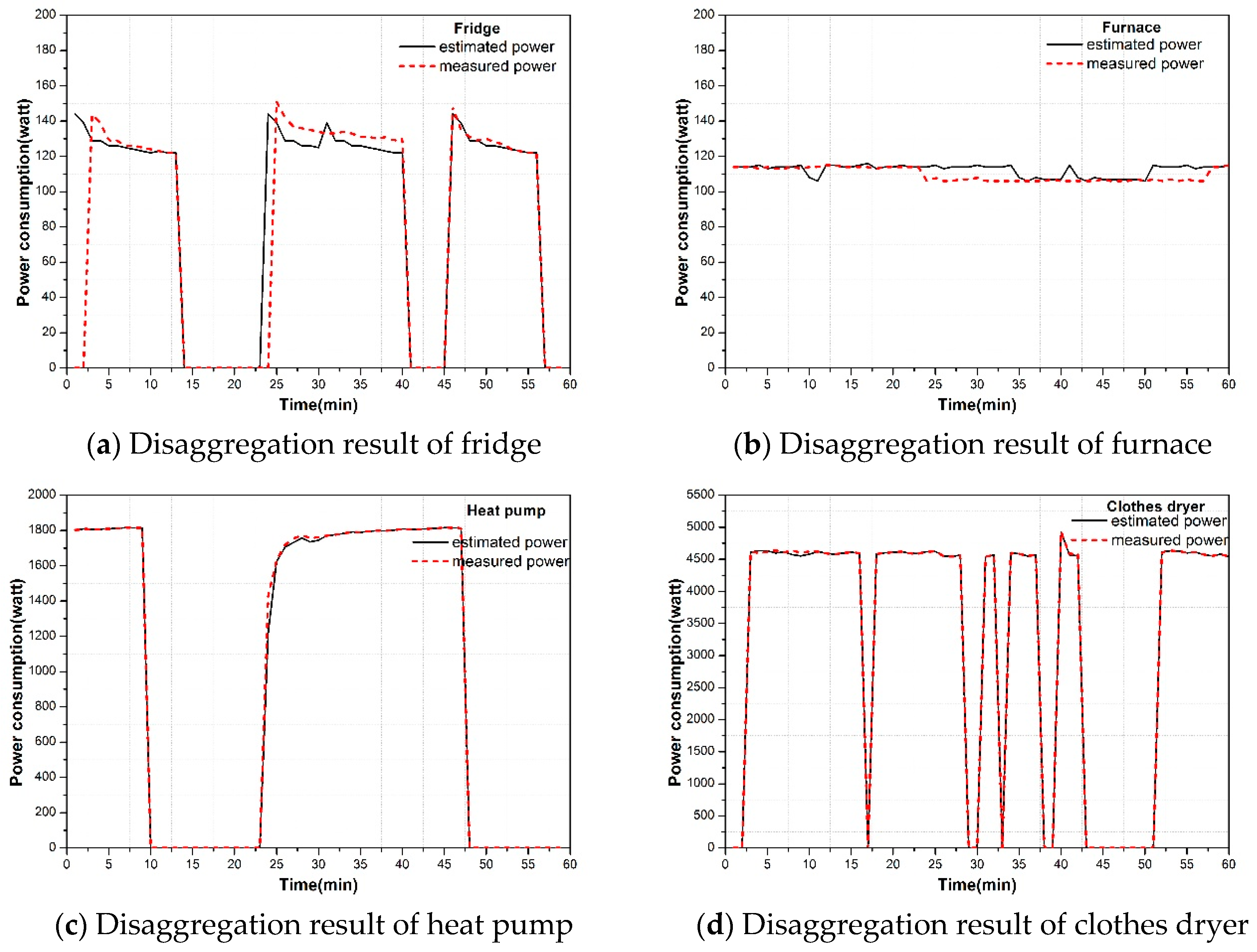

4.2.3. The Case of Four Appliances Operating Simultaneously

4.3. Load Disaggregation Performance Analysis of the Proposed Method

4.3.1. Performance Metrics

4.3.2. Load Disaggregation Performance Analysis

4.4. Performance Comparison with the Method Using PQ Features

4.5. Performance Comparison with the Method in Literature

4.6. Algorithm Robustness to Different Sampling Intervals

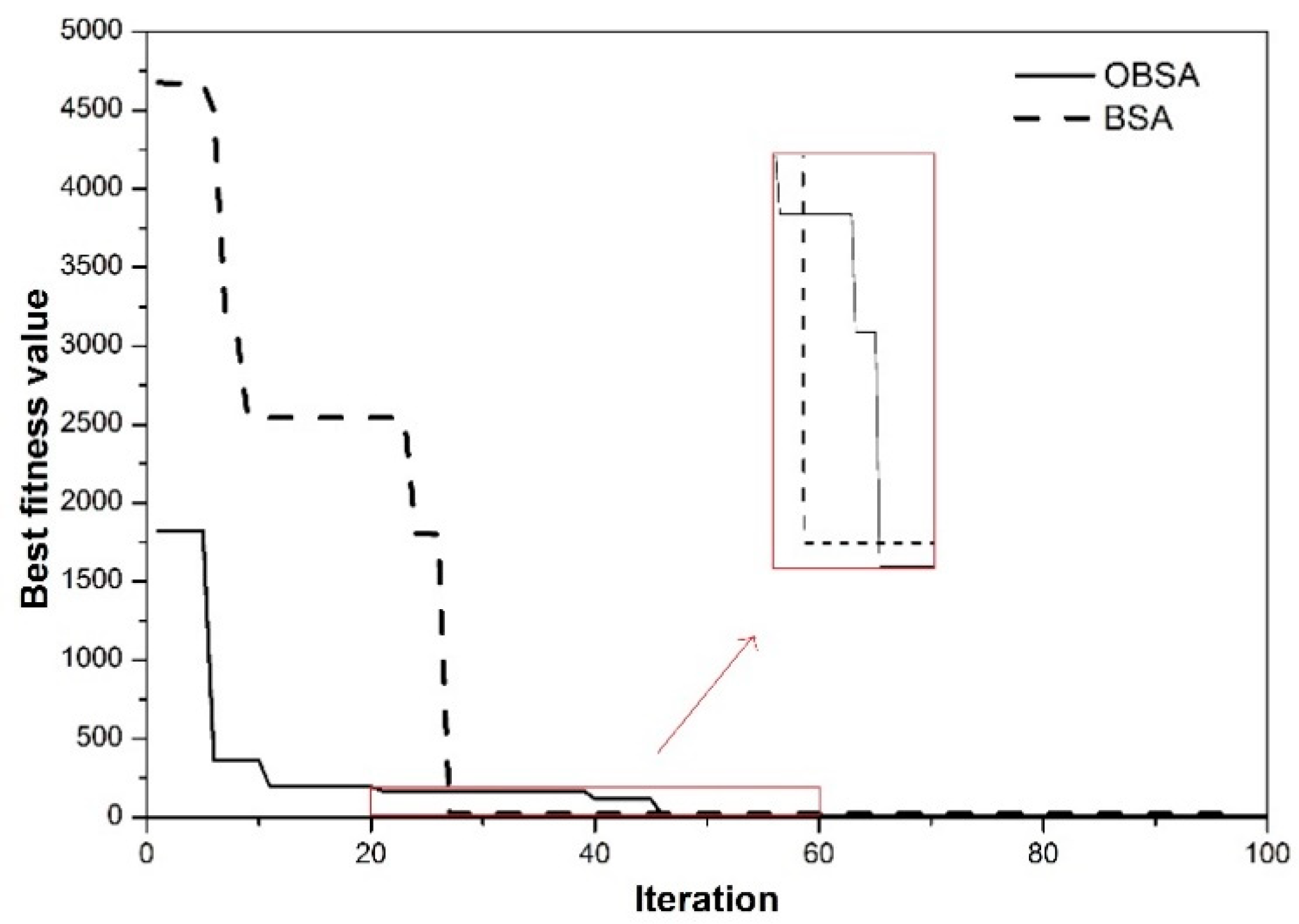

4.7. Convergence Analysis of OBSA

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Armel, K.C.; Gupta, A.; Shrimali, G.; Albert, A. Is disaggregation the holy grail of energy efficiency? The case of electricity. Energy Policy 2013, 52, 213–234. [Google Scholar] [CrossRef]

- Grueneich, D.M. The next level of energy efficiency: The five challenges ahead. Electr. J. 2015, 28, 44–56. [Google Scholar] [CrossRef]

- Yu, Y.; Luan, W. Smart grid and its implementations. Proc. CSEE 2009, 29, 1–8. [Google Scholar]

- Ehrhardt-Martinez, K.; Donnelly, K.A.; Laitner, S. Advanced Metering Initiatives and Residential Feedback Programs: A Meta-Review for Household Electricity-Saving Opportunities; American Council for an Energy-Efficient Economy: Washington, DC, USA, 2010. [Google Scholar]

- Capasso, A.; Grattieri, W.; Lamedica, R.; Prudenzi, A. A bottom-up approach to residential load modeling. IEEE Trans. Power Syst. 1994, 9, 957–964. [Google Scholar] [CrossRef]

- Kats, G.; Capital, E. Green Building Costs and Financial Benefits; Massachusetts Technology Collaborative: Westborough, MA, USA, 2003. [Google Scholar]

- Tabatabaei, S.M.; Dick, S.; Xu, W. Towards Non-Intrusive Load Monitoring via Multi-Label Classification. IEEE Trans. Smart Grid 2017, 8, 26–40. [Google Scholar] [CrossRef]

- Hart, G.W. Nonintrusive appliance load monitoring. Proc. IEEE 1992, 80, 1870–1891. [Google Scholar] [CrossRef]

- Li, R.; Wang, X.; Hu, M.; Zhou, H.; Hu, W. Application of RPROP neural network in nonintrusive load decomposition. Power Syst. Prot. Control 2016, 44, 55–61. [Google Scholar]

- Wu, X.; Qi, B.; Han, L.; Wang, Z.; Dong, C. Fast Non-intrusive Load Identification Algorithm for Resident Load Based on Template Filtering. Autom. Electr. Power Syst. 2017, 2, 021. [Google Scholar]

- Liu, B.; Luan, W.; Yu, Y. Dynamic time warping based non-intrusive load transient identification. Appl. Energy 2017, 195, 634–645. [Google Scholar] [CrossRef]

- Hassan, T.; Javed, F.; Arshad, N. An Empirical Investigation of V-I Trajectory Based Load Signatures for Non-Intrusive Load Monitoring. IEEE Trans. Smart Grid 2014, 5, 870–878. [Google Scholar] [CrossRef]

- Wang, A.L.; Chen, B.X.; Wang, C.G.; Hua, D.D. Non-intrusive load monitoring algorithm based on features of V–I trajectory. Electr. Power Syst. Res. 2018, 157, 134–144. [Google Scholar] [CrossRef]

- Fernandes, R.A.S.; Silva, I.N.D.; Oleskovicz, M. Load Profile Identification Interface for Consumer Online Monitoring Purposes in Smart Grids. IEEE Trans. Ind. Inform. 2013, 9, 1507–1517. [Google Scholar] [CrossRef]

- Aiad, M.; Peng, H.L. Non-intrusive load disaggregation with adaptive estimations of devices main power effects and two-way interactions. Energy Build. 2016, 130, 131–139. [Google Scholar] [CrossRef]

- Cominola, A.; Giuliani, M.; Piga, D.; Castelletti, A.; Rizzoli, A.E. A Hybrid Signature-based Iterative Disaggregation algorithm for Non-Intrusive Load Monitoring. Appl. Energy 2017, 185, 331–344. [Google Scholar] [CrossRef]

- Wang, H.; Yang, W. An Iterative Load Disaggregation Approach Based on Appliance Consumption Pattern. Appl. Sci. 2018, 8, 542. [Google Scholar] [CrossRef]

- Yang, C.C.; Soh, C.S.; Yap, V.V. A non-intrusive appliance load monitoring for efficient energy consumption based on Naive Bayes classifier. Sustain. Comput. Inform. Syst. 2017, 14, 34–42. [Google Scholar] [CrossRef]

- Zhou, C.; Liu, S.; Zhong, X.; Liu, P. Differential Evolution Algorithm Based Residential Load Decomposition. South. Power Syst. Technol. 2016, 10, 62–69. [Google Scholar]

- Zhao, B.; Stankovic, L.; Stankovic, V. On a Training-Less Solution for Non-Intrusive Appliance Load Monitoring Using Graph Signal Processing. IEEE Access 2016, 4, 1784–1799. [Google Scholar] [CrossRef]

- Makonin, S.; Ellert, B.; Bajic, I.V.; Popowich, F. Electricity, water, and natural gas consumption of a residential house in Canada from 2012 to 2014. Sci. Data 2016, 3, 160037. [Google Scholar] [CrossRef]

- Roy, N.; Pathak, N.; Misra, A. Fine-grained appliance usage and energy monitoring through mobile and power-line sensing. Pervasive Mob. Comput. 2016, 30, 132–150. [Google Scholar] [CrossRef]

- Das, S.; Suganthan, P.N. Differential evolution: A survey of the state-of-the-art. IEEE Trans. Evol. Comput. 2011, 15, 4–31. [Google Scholar] [CrossRef]

- Jordehi, A.R.; Jasni, J. Parameter selection in particle swarm optimization: A survey. J. Exp. Theor. Artif. Intell. 2013, 259, 527–542. [Google Scholar] [CrossRef]

- Meng, X.B.; Gao, X.Z.; Lu, L.; Liu, Y.; Zhang, H. A new bio-inspired optimisation algorithm: Bird swarm algorithm. J. Exp. Theor. Artif. Intell. 2016, 28, 673–687. [Google Scholar] [CrossRef]

- Shi, Y.; Eberhart, R. A modified particle swarm optimizer. In Advances in Natural Computation; Springer: Berlin/Heidelberg, Germany, 1998; p. 439. [Google Scholar]

- Mauch, L.; Barsim, K.S.; Yang, B. How well can HMM model load signals. In Proceedings of the 3rd International Workshop on Nilm, Vancouver, BC, Canada, 14–15 May 2016. [Google Scholar]

- Batra, N.; Kelly, J.; Parson, O.; Dutta, H.; Knottenbelt, W.; Rogers, A.; Singh, A.; Srivastava, M. NILMTK: An open source toolkit for non-intrusive load monitoring. In Proceedings of the 5th International Conference on Future Energy Systems, Cambridge, UK, 11–13 June 2014; pp. 265–276. [Google Scholar]

| SW Number | Time Coefficient | Best Fitness Value/Watt |

|---|---|---|

| 1 | [1, 1, 4, 1] | 2.45 |

| 2 | [1, 1, 14, 1] | 2.65 |

| 3 | [1, 1, 4, 1] | 13.45 |

| 4 | [1, 1, 11, 1] | 14.11 |

| 5 | [1, 1, 19, 16] | 19.05 |

| 6 | [1, 35, 10, 10] | 16.19 |

| SW Number | Time Coefficient | Best Fitness Value/Watt |

|---|---|---|

| 1 | [1, 45, 8, 9] | 38.98 |

| 2 | [1, 17, 20, 22] | 23.00 |

| 3 | [1, 58, 6, 1] | 20.17 |

| 4 | [1, 117, 18, 11] | 5.29 |

| 5 | [1, 4, 3, 14] | 78.32 |

| 6 | [1, 94, 13, 19] | 16.31 |

| SW Number | Time Coefficient | Best Fitness Value/Watt |

|---|---|---|

| 1 | [51, 124, 6, 4] | 30.61 |

| 2 | [61, 1, 18, 20] | 8.31 |

| 3 | [71, 86, 7, 1] | 79.60 |

| 4 | [81, 18, 11, 7] | 20.81 |

| 5 | [41, 28, 5, 10] | 35.03 |

| 6 | [10, 1, 15, 1] | 19.03 |

| Appliance | RMSE | Normalized RMSE/% | |

|---|---|---|---|

| Clothes dryer | 100 | 29.46 | 0.64 |

| Fridge | 94 | 19.75 | 24.83 |

| Heat pump | 100 | 31.86 | 1.12 |

| Furnace | 98.8 | 15.51 | 13.2 |

| Method | Average Accuracy/% | Calculating Time/s |

|---|---|---|

| PQ signature | 85.5 | 2.227 |

| Power consumption pattern signature | 98.2 | 1.945 |

| Appliance | Proposed Method | HSID in Literature |

|---|---|---|

| Clothes dryer | 1 | 0.76 |

| Fridge | 0.943 | 0.98 |

| Heat pump | 1 | 0.96 |

| Furnace | 0.986 | 1 |

| Security/network equipment | 0.925 | 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Yang, W.; Chen, T.; Yang, Q. An Optimal Load Disaggregation Method Based on Power Consumption Pattern for Low Sampling Data. Sustainability 2019, 11, 251. https://doi.org/10.3390/su11010251

Wang H, Yang W, Chen T, Yang Q. An Optimal Load Disaggregation Method Based on Power Consumption Pattern for Low Sampling Data. Sustainability. 2019; 11(1):251. https://doi.org/10.3390/su11010251

Chicago/Turabian StyleWang, Huijuan, Wenrong Yang, Tingyu Chen, and Qingxin Yang. 2019. "An Optimal Load Disaggregation Method Based on Power Consumption Pattern for Low Sampling Data" Sustainability 11, no. 1: 251. https://doi.org/10.3390/su11010251

APA StyleWang, H., Yang, W., Chen, T., & Yang, Q. (2019). An Optimal Load Disaggregation Method Based on Power Consumption Pattern for Low Sampling Data. Sustainability, 11(1), 251. https://doi.org/10.3390/su11010251