Mental Model Analysis of Biogas Energy Perceptions and Policy Reveals Potential Constraints in a Japanese Farm Community

Abstract

1. Introduction

2. Overview of the Biogas System in Hokkaido, Japan

3. Materials and Methods

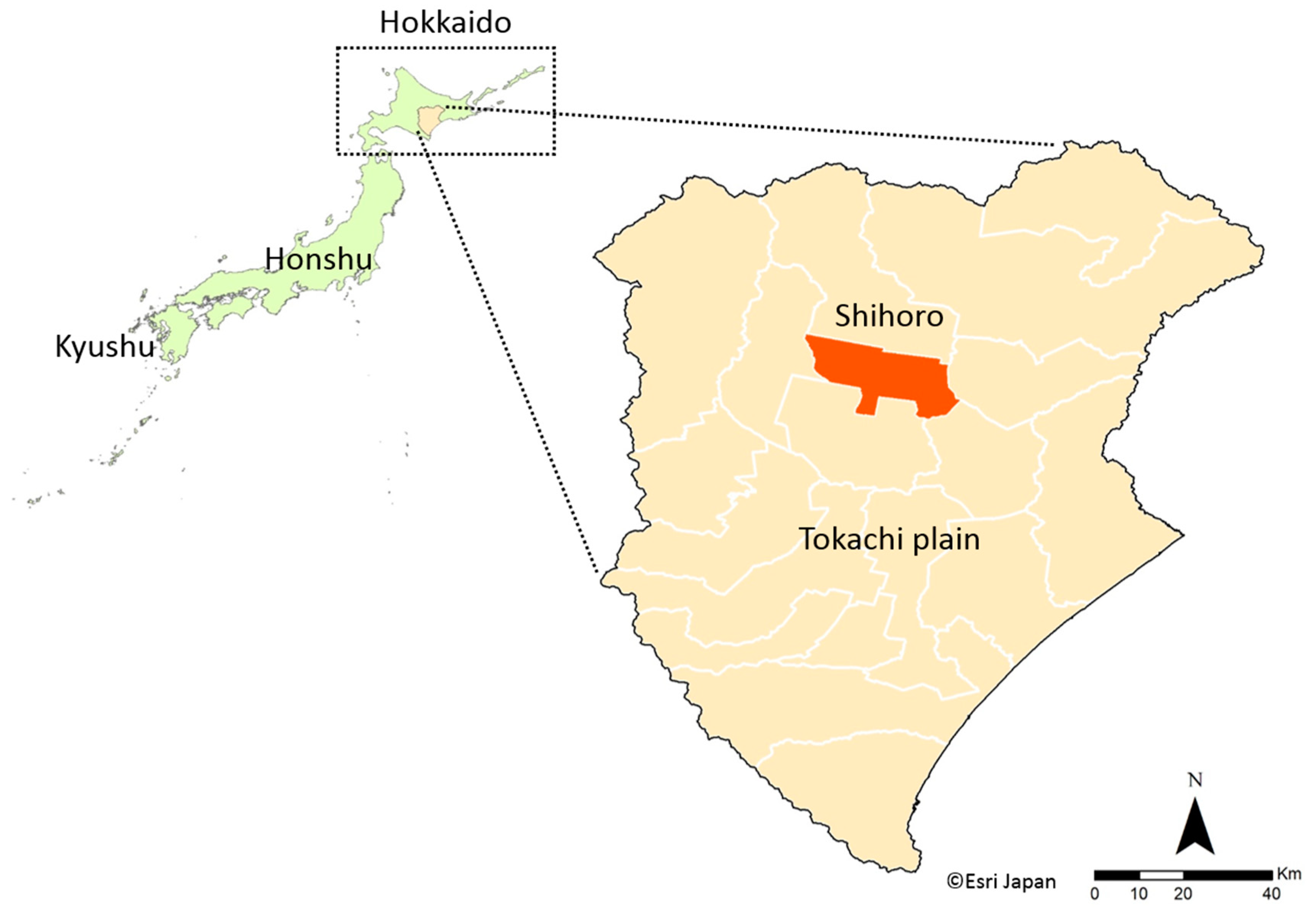

3.1. Study Site

3.2. Mental Models: The Theory and the Application

3.3. Eliciting Stakeholder Views

3.4. Data Analysis

4. Results

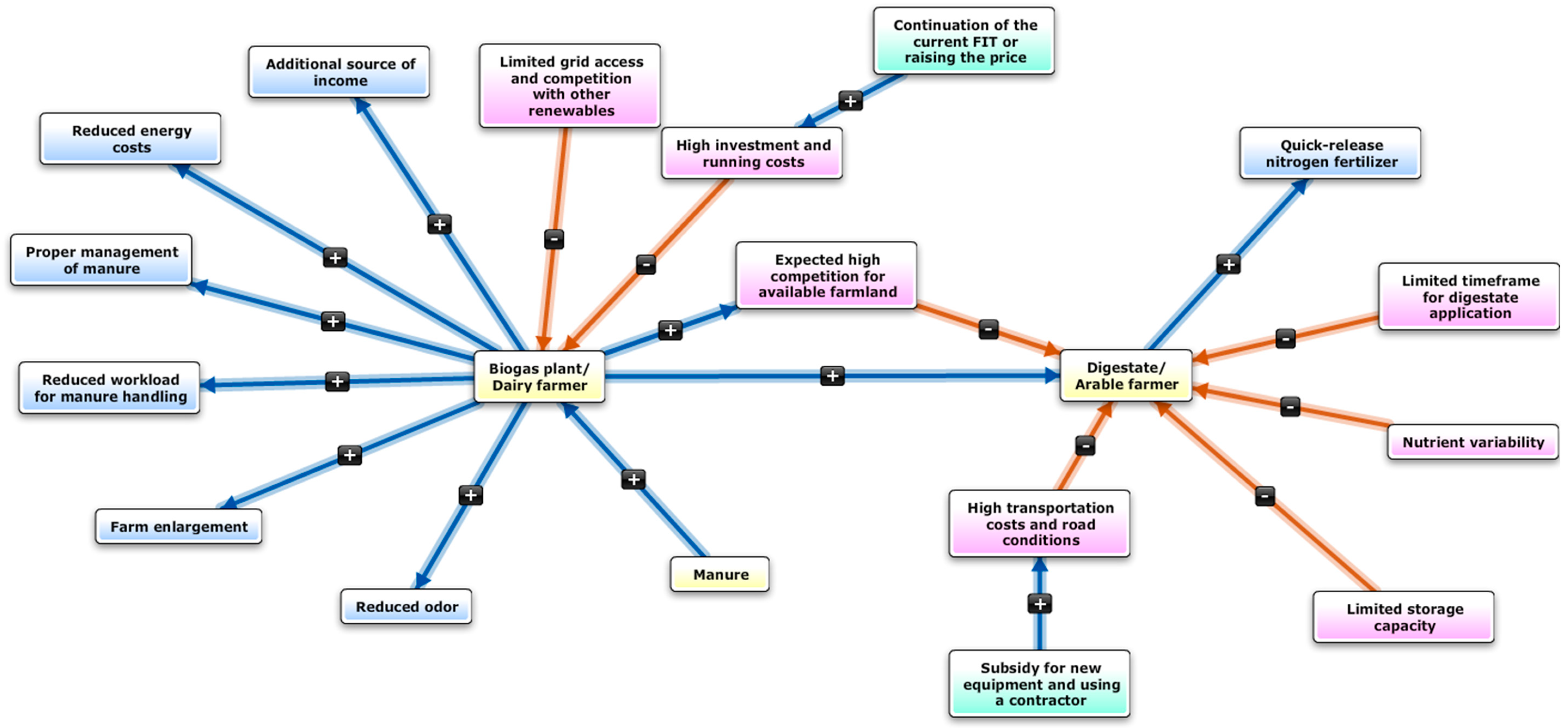

4.1. Motivations

4.2. Constraints

4.3. Actions

5. Discussion

5.1. Similarities in Perception of Biogas Systems

5.2. Differences in Perception as Potential Constraints for Further Expansion of Biogas Systems

5.3. Policy Implications for the Potential Constraints

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Holm-Nielsen, J.B.; Al Seadi, T.; Oleskowicz-Popiel, P. The future of anaerobic digestion and biogas utilization. Bioresour. Technol. 2009, 100, 5478–5484. [Google Scholar] [CrossRef] [PubMed]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Aryal, N.; Kvist, T.; Ammam, F.; Pant, D.; Ottosen, L.D.M. An overview of microbial biogas enrichment. Bioresour. Technol. 2018, 264, 359–369. [Google Scholar] [CrossRef] [PubMed]

- Huttunen, S.; Manninen, K.; Leskinen, P. Combining biogas LCA reviews with stakeholder interviews to analyse life cycle impacts at a practical level. J. Clean. Prod. 2014, 80, 5–16. [Google Scholar] [CrossRef]

- Nkoa, R. Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: A review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar] [CrossRef]

- Mol, A.P.J. Bounded Biofuels? Sustainability of Global Biogas Developments. Sociol. Rural. 2014, 54, 1–20. [Google Scholar] [CrossRef]

- Pan, S.-Y.; Du, M.A.; Huang, I.-T.; Liu, I.-H.; Chang, E.-E.; Chiang, P.-C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- Edwards, J.; Othman, M.; Burn, S. A review of policy drivers and barriers for the use of anaerobic digestion in Europe, the United States and Australia. Renew. Sustain. Energy Rev. 2015, 52, 815–828. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Callegari, A.; Lopez, M.V. European Framework for the Diffusion of Biogas Uses: Emerging Technologies, Acceptance, Incentive Strategies, and Institutional-Regulatory Support. Sustainability 2016, 8, 298. [Google Scholar] [CrossRef]

- Tranter, R.B.; Swinbank, A.; Jones, P.J.; Banks, C.J.; Salter, A.M. Assessing the potential for the uptake of on-farm anaerobic digestion for energy production in England. Energy Policy 2011, 39, 2424–2430. [Google Scholar] [CrossRef]

- Qu, W.; Tu, Q.; Bluemling, B. Which factors are effective for farmers’ biogas use?–Evidence from a large-scale survey in China. Energy Policy 2013, 63, 26–33. [Google Scholar] [CrossRef]

- Brudermann, T.; Mitterhuber, C.; Posch, A. Agricultural biogas plants—A systematic analysis of strengths, weaknesses, opportunities and threats. Energy Policy 2015, 76, 107–111. [Google Scholar] [CrossRef]

- Rupf, G.V.; Bahri, P.A.; de Boer, K.; McHenry, M.P. Barriers and opportunities of biogas dissemination in Sub-Saharan Africa and lessons learned from Rwanda, Tanzania, China, India, and Nepal. Renew. Sustain. Energy Rev. 2015, 52, 468–476. [Google Scholar] [CrossRef]

- Mwirigi, J.; Balana, B.B.; Mugisha, J.; Walekhwa, P.; Melamu, R.; Nakami, S.; Makenzi, P. Socio-economic hurdles to widespread adoption of small-scale biogas digesters in Sub-Saharan Africa: A review. Biomass Bioenergy 2014, 70, 17–25. [Google Scholar] [CrossRef]

- Lantz, M.; Svensson, M.; Björnsson, L.; Börjesson, P. The prospects for an expansion of biogas systems in Sweden—Incentives, barriers and potentials. Energy Policy 2007, 35, 1830–1843. [Google Scholar] [CrossRef]

- Bluemling, B.; Mol, A.P.J.; Tu, Q. The social organization of agricultural biogas production and use. Energy Policy 2013, 63, 10–17. [Google Scholar] [CrossRef]

- Biggs, D.; Abel, N.; Knight, A.T.; Leitch, A.; Langston, A.; Ban, N.C. The implementation crisis in conservation planning: Could “mental models” help? Conserv. Lett. 2011, 4, 169–183. [Google Scholar] [CrossRef]

- Moon, K.; Adams, V.M. Using quantitative influence diagrams to map natural resource managers’ mental models of invasive species management. Land Use Policy 2016, 50, 341–351. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; de la Fuente, C.; Campoy, M.; Carrasco, L.; Nájera, I.; Baixauli, C.; Caravaca, F.; Roldán, A.; Cegarra, J.; Bernal, M.P. Agricultural use of digestate for horticultural crop production and improvement of soil properties. Eur. J. Agron. 2012, 43, 119–128. [Google Scholar] [CrossRef]

- Bougnom, B.P.; Niederkofler, C.; Knapp, B.A.; Stimpfl, E.; Insam, H. Residues from renewable energy production: Their value for fertilizing pastures. Biomass Bioenergy 2012, 39, 290–295. [Google Scholar] [CrossRef]

- Dahlin, J.; Herbes, C.; Nelles, M. Biogas digestate marketing: Qualitative insights into the supply side. Resour. Conserv. Recycl. 2015, 104, 152–161. [Google Scholar] [CrossRef]

- Hansen, P. Becoming bovine: Mechanics and metamorphosis in Hokkaido’s animal-human-machine. J. Rural Stud. 2014, 33, 119–130. [Google Scholar] [CrossRef]

- Lybæk, R.; Asai, M. Future Pathways for Deploying Agricultural Based Biogas Plants in Denmark and Japan: A Comparative Analysis. GMSARN Int. J. 2017, 11, 129–138. [Google Scholar]

- Kuzuhara, Y. Biomass Nippon Strategy—Why “Biomass Nippon” now? Biomass Bioenergy 2005, 29, 331–335. [Google Scholar] [CrossRef]

- Matsumura, Y.; Yokoyama, S. Current situation and prospect of biomass utilization in Japan. Biomass Bioenergy 2005, 29, 304–309. [Google Scholar] [CrossRef]

- Iwasaki, M.; Takeuchi, Y.; Umetsu, K. Recent Development in Research and Technology Related to Agricultural Facilities: Livestock Manure-based Methane Fermentation Systems. J. Soc. Agr. Struct. Jpn. 2017, 48, 123–130. (In Japanese) [Google Scholar]

- METI. Feed-in Tariff Scheme in Japan. Available online: http://www.meti.go.jp/english/policy/energy_environment/renewable/pdf/summary201207.pdf (accessed on 4 January 2019).

- MAFF. Biomass Industrialization Strategy (In Japanese). Available online: http://www.maff.go.jp/j/press/shokusan/bioi/pdf/120906-02.pdf (accessed on 4 January 2019).

- Matsuda, J. Large-scaled Biogas Plant in Betsukai town. Livestock Ind. Environ. Inf. 2016, 62, 1–14. (In Japanese). Available online: https://www.leio.or.jp/pub_train/publication/tkj/tkj62/tkj62-1.pdf (accessed on 4 January 2019).

- Chen, W.-M.; Kim, H.; Yamaguchi, H. Renewable energy in eastern Asia: Renewable energy policy review and comparative SWOT analysis for promoting renewable energy in Japan, South Korea, and Taiwan. Energy Policy 2014, 74, 319–329. [Google Scholar] [CrossRef]

- Town of Shihoro. Geography, climate and population of Shioro. Available online: http://www.shihoro.jp/tem/ (accessed on 4 January 2019).

- Koga, N.; Sawamoto, T.; Tsuruta, H. Life cycle inventory-based analysis of greenhouse gas emissions from arable land farming systems in Hokkaido, northern Japan. Soil Sci. Plant Nutr. 2006, 52, 564–574. [Google Scholar] [CrossRef]

- JA Shihoro. Development of biomass projects in Shihoro (In Japanese). Available online: http://www.pref.hokkaido.lg.jp/ks/tot/biomassnetwork/H28houkokukaisiryou310.pdf (accessed on 4 January 2019).

- Hoffman, M.; Lubell, M.; Hillis, V. Linking knowledge and action through mental models of sustainable agriculture. Proc. Natl. Acad. Sci. USA 2014, 111, 13016–13021. [Google Scholar] [CrossRef]

- Jones, N.; Ross, H.; Lynam, T.; Perez, P.; Leitch, A. Mental Models: An Interdisciplinary Synthesis of Theory and Methods. Ecol. Soc. 2011, 16, 46. [Google Scholar] [CrossRef]

- Craik, K.J.W. The Nature of Explanation; Cambridge University Press: Cambridge, UK, 1967; ISBN 9780521094450. [Google Scholar]

- Wood, M.D.; Bostrom, A.; Bridges, T.; Linkov, I. Cognitive Mapping Tools: Review and Risk Management Needs. Risk Anal. 2012, 32, 1333–1348. [Google Scholar] [CrossRef] [PubMed]

- Du Toit, D.; Biggs, H.; Pollard, S. The Potential Role of Mental Model Methodologies in Multistakeholder Negotiations: Integrated Water Resources Management in South Africa. Ecol. Soc. 2011, 16, 21. [Google Scholar] [CrossRef]

- Meliadou, A.; Santoro, F.; Nader, M.R.; Dagher, M.A.; Al Indary, S.; Salloum, B.A. Prioritising coastal zone management issues through fuzzy cognitive mapping approach. J. Environ. Manag. 2012, 97, 56–68. [Google Scholar] [CrossRef] [PubMed]

- Özesmi, U.; Özesmi, S.L. Ecological models based on people’s knowledge: A multi-step fuzzy cognitive mapping approach. Ecol. Model. 2004, 176, 43–64. [Google Scholar] [CrossRef]

- Douglas, E.M.; Wheeler, S.A.; Smith, D.J.; Overton, I.C.; Gray, S.A.; Doody, T.M.; Crossman, N.D. Using mental-modelling to explore how irrigators in the Murray–Darling Basin make water-use decisions. J. Hydrol. 2016, 6, 1–12. [Google Scholar] [CrossRef]

- Jetter, A.; Schweinfort, W. Building scenarios with Fuzzy Cognitive Maps: An exploratory study of solar energy. Futures 2011, 43, 52–66. [Google Scholar] [CrossRef]

- Kermagoret, C.; Levrel, H.; Carlier, A.; Ponsero, A. Stakeholder Perceptions of Offshore Wind Power: A Fuzzy Cognitive Mapping Approach. Soc. Nat. Resour. 2016, 29, 916–931. [Google Scholar] [CrossRef]

- Konti, A.; Damigos, D. Exploring strengths and weaknesses of bioethanol production from bio-waste in Greece using Fuzzy Cognitive Maps. Energy Policy 2018, 112, 4–11. [Google Scholar] [CrossRef]

- Kontogianni, A.; Tourkolias, C.; Papageorgiou, E.I. Revealing market adaptation to a low carbon transport economy: Tales of hydrogen futures as perceived by fuzzy cognitive mapping. Int. J. Hydrogen Energy 2013, 38, 709–722. [Google Scholar] [CrossRef]

- Grenier, R.S.; Dudzinska-Przesmitzki, D. A Conceptual Model for Eliciting Mental Models Using a Composite Methodology. Hum. Resour. Dev. Rev. 2015, 14, 163–184. [Google Scholar] [CrossRef]

- Jones, N.; Ross, H.; Lynam, T.; Perez, P. Eliciting Mental Models: A Comparison of Interview Procedures in the Context of Natural Resource Management. Ecol. Soc. 2014, 19, 13. [Google Scholar] [CrossRef]

- Christen, B.; Kjeldsen, C.; Dalgaard, T.; Martin-Ortega, J. Can fuzzy cognitive mapping help in agricultural policy design and communication? Land Use Policy 2015, 45, 64–75. [Google Scholar] [CrossRef]

- Olazabal, M.; Pascual, U. Use of fuzzy cognitive maps to study urban resilience and transformation. Environ. Innov. Soc. Transit. 2016, 18, 18–40. [Google Scholar] [CrossRef]

- Vuillot, C.; Coron, N.; Calatayud, F.; Sirami, C.; Mathevet, R.; Gibon, A. Ways of farming and ways of thinking: Do farmers’ mental models of the landscape relate to their land management practices? Ecol. Soc. 2016, 21, 35. [Google Scholar] [CrossRef]

- Etienne, M.; Du Toit, D.; Pollard, S. ARDI: A Co-construction Method for Participatory Modeling in Natural Resources Management. Ecol. Soc. 2011, 16, 44. [Google Scholar] [CrossRef]

- Gray, S.; Chan, A.; Clark, D.; Jordan, R. Modeling the integration of stakeholder knowledge in social–ecological decision-making: Benefits and limitations to knowledge diversity. Ecol. Model. 2012, 229, 88–96. [Google Scholar] [CrossRef]

- Röder, M. More than food or fuel. Stakeholder perceptions of anaerobic digestion and land use; a case study from the United Kingdom. Energy Policy 2016, 97, 73–81. [Google Scholar] [CrossRef]

- Mbzibain, A.; Hocking, T.J.; Tate, G.; Ali, S. Renewable enterprises on UK farms: Assessing levels of uptake, motivations and constraints to widespread adoption. Biomass Bioenergy 2013, 49, 28–37. [Google Scholar] [CrossRef]

- Upreti, B.R.; van der Horst, D. National renewable energy policy and local opposition in the UK: The failed development of a biomass electricity plant. Biomass Bioenergy 2004, 26, 61–69. [Google Scholar] [CrossRef]

- Lybæk, R.; Kjær, T. Municipalities as facilitators, regulators and energy consumers for enhancing the dissemination of biogas technology in Denmark. Int. J. Sustain. Energy Plan. Manag. 2015, 8, 17–30. [Google Scholar]

- Hou, Y.; Velthof, G.L.; Case, S.D.C.; Oelofse, M.; Grignani, C.; Balsari, P.; Zavattaro, L.; Gioelli, F.; Bernal, M.P.; Fangueiro, D.; et al. Stakeholder perceptions of manure treatment technologies in Denmark, Italy, the Netherlands and Spain. J. Clean. Prod. 2018, 172, 1620–1630. [Google Scholar] [CrossRef]

- Case, S.D.C.; Oelofse, M.; Hou, Y.; Oenema, O.; Jensen, L.S. Farmer perceptions and use of organic waste products as fertilisers—A survey study of potential benefits and barriers. Agric. Syst. 2017, 151, 84–95. [Google Scholar] [CrossRef]

- Breetz, H.L.; Fisher-Vanden, K.; Jacobs, H.; Schary, C. Trust and Communication: Mechanisms for Increasing Farmers’ Participation in Water Quality Trading. Land Econ. 2005, 81, 170–190. [Google Scholar] [CrossRef]

- Morrison, M.; Oczkowski, E.; Greig, J. The primacy of human capital and social capital in influencing landholders’ participation in programmes designed to improve environmental outcomes. Aust. J. Agric. Resour. Econ. 2011, 55, 560–578. [Google Scholar] [CrossRef]

- Pretty, J.; Smith, D. Social Capital in Biodiversity Conservation and Management. Conserv. Biol. 2004, 18, 631–638. [Google Scholar] [CrossRef]

- Asai, M.; Moraine, M.; Ryschawy, J.; de Wit, J.; Hoshide, A.K.; Martin, G. Critical factors for crop-livestock integration beyond the farm level: A cross-analysis of worldwide case studies. Land Use Policy 2018, 73, 184–194. [Google Scholar] [CrossRef]

- Asai, M.; Langer, V.; Frederiksen, P.; Jacobsen, B.H. Livestock farmer perceptions of successful collaborative arrangements for manure exchange: A study in Denmark. Agric. Syst. 2014, 128, 55–65. [Google Scholar] [CrossRef]

- Carrosio, G. Energy production from biogas in the Italian countryside: Policies and organizational models. Energy Policy 2013, 63, 3–9. [Google Scholar] [CrossRef]

- Reise, C.; Musshoff, O.; Granoszewski, K.; Spiller, A. Which factors influence the expansion of bioenergy? An empirical study of the investment behaviours of German farmers. Ecol. Econ. 2012, 73, 133–141. [Google Scholar] [CrossRef]

- Tampio, E.; Lehtonen, E.; Kinnunen, V.; Mönkäre, T.; Ervasti, S.; Kettunen, R.; Rasi, S.; Rintala, J. A demand-based nutrient utilization approach to urban biogas plant investment based on regional crop fertilization. J. Clean. Prod. 2017, 164, 19–29. [Google Scholar] [CrossRef]

- Asai, M.; Langer, V.; Frederiksen, P. Responding to environmental regulations through collaborative arrangements: Social aspects of manure partnerships in Denmark. Livest. Sci. 2014, 167, 370–380. [Google Scholar] [CrossRef]

- ECN-QAS. European Compost Network. Available online: https://www.compostnetwork.info/ecn-qas/ (accessed on 3 December 2018).

- Dahlin, J.; Nelles, M.; Herbes, C. Biogas digestate management: Evaluating the attitudes and perceptions of German gardeners towards digestate-based soil amendments. Resour. Conserv. Recycl. 2017, 118, 27–38. [Google Scholar] [CrossRef]

- Asai, M.; Takai, H. Danish Biogas Policies and Partnerships among Prominent Actors in the Biogas Sector: Lessons Learnt from Two Newly Developed Biogas Projects. J. Agric. Policy Res. 2017, 25–47. (In Japanese) [Google Scholar]

- He, G.; Bluemling, B.; Mol, A.P.J.; Zhang, L.; Lu, Y. Comparing centralized and decentralized bio-energy systems in rural China. Energy Policy 2013, 63, 34–43. [Google Scholar] [CrossRef]

- Aryal, N.; Kvist, T. Alternative of Biogas Injection into the Danish Gas Grid System—A Study from Demand Perspective. ChemEngineering 2018, 2, 43. [Google Scholar] [CrossRef]

| Interview No. | Occupation | Age | Experiences with Biogas |

|---|---|---|---|

| 1 | Dairy farmer | 50s | Running biogas plant within a farm for 15 years. Providing digestate 12 neighbor arable farms. |

| 2 | Dairy farmer | 40s | Running biogas plant within a farm for five years. |

| 3 | Dairy farmer | 30s | Started running a biogas plant within a farm since 2016. |

| 4 | Dairy farmer | 40s | No access to biogas plant. |

| 5 | Dairy farmer | 40s | No access to biogas plant. |

| 6 | Dairy farmer | 40s | No access to biogas plant. |

| 7 | Dairy farmer | 30s | No access to biogas plant. |

| 8 | Arable farmer | 50s | Receiving digestate since 2016. |

| 9 | Arable farmer | 50s | Receiving digitate for 10 years from the neighbor biogas owner. |

| 10 | Arable farmer | 40s | Receiving digestate for 15 years. |

| 12 | Arable farmer | 40s | Receiving digestate on remote field but not on the main fields. |

| 14 | Arable farmer | 40s | Received digestate until five or six years ago, but not at this moment. |

| 11 | Arable farmer | 30s | Never received digestate. |

| 13 | Arable farmer | 30s | Never received digestate. |

| 15 | JA Shihoro officer | 50s | Coordinating biogas plant projects in the cooperative for nearly 10 years. |

| 16 | JA Shihoro officer | 30s | Working in the renewable energy division within the cooperative since 2015. |

| 17 | Engineer | 50s | Over 15 years of working experience in biogas engineering. |

| 18 | Engineer | 40s | Thirteen years of working experience in biogas engineering. |

| 19 | Municipal officer | 50s | Working on biogas development projects for six years. |

| 20 | Municipal officer | 50s | Over 15 years of experience in financial support for biogas development projects. |

| 21 | Researcher | 50s | Over 30 years of research experience in anaerobic digestion and biogas engineering. |

| 22 | Researcher/consultant | 40s | Doing a PhD study on biogas. Over 20 years of experience in consultation for the biogas sector. |

| Category | Variables | Citation Frequency | Dairy Farmers No. (% 1) | Arable Farmers No. (% 1) | Non-Farmers No. (% 1) | p2 |

|---|---|---|---|---|---|---|

| Biogas plant | Additional source of income | 12 | 5 (71) | 3 (43) | 4 (50) | NS |

| Reduced energy costs through self-provision (e.g., hot water) | 10 | 3 (43) | 3 (43) | 4 (50) | NS | |

| Utilization of available resources | 8 | 2 (29) | 3 (43) | 3 (36) | NS | |

| Reduced workload for manure handling | 7 | 2 (29) | 1 (14) | 4 (50) | NS | |

| Farm enlargement as biogas plants can handle additional amount of manure produced | 7 | 4 (57) | 1 (14) | 2 (25) | NS | |

| Proper management of manure (reduced pollution/contamination risk) | 5 | 4 (57) | 1 (14) | 2 (25) | NS | |

| Less collective manure management by using “on-farm” biogas plant | 3 | 2 (29) | 0 | 1 (13) | NS | |

| Digestate | Reduced odor from spreading digestate compared with compost | 14 | 4 (57) | 4 (57) | 6 (75) | NS |

| Reduced fertilizer costs through digestate substitution | 11 | 3 (43) | 3 (43) | 5 (63) | NS | |

| Recovery of fermentation residuals in agriculture | 6 | 1 (14) | 1 (14) | 4 (50) | NS | |

| Quick-release nitrogen fertilizer | 6 | 1 (14) | 2 (29) | 3 (38) | NS | |

| High fertilizer value for grassland | 5 | 1 (14) | 2 (29) | 2 (25) | NS | |

| Reduction of weed seeds | 4 | 2 (29) | 1 (14) | 1 (13) | NS | |

| Easy and quick to spread | 2 | 0 | 1 (14) | 1 (13) | NS | |

| Local community | Environmental benefits | 13 | 5 (71) | 4 (57) | 4 (50) | NS |

| Improved energy security | 9 | 2 (29) | 3 (43) | 4 (50) | NS | |

| Improved understanding of residents toward dairy farming | 6 | 3 (43) | 0 | 3 (38) | NS | |

| Being well-known as an “ecological town” | 4 | 0 | 1 (14) | 3 (38) | NS | |

| Creation of new jobs | 4 | 0 | 0 | 4 (50) | 0.019 | |

| Contribution to agricultural development | 3 | 1 (14) | 0 | 2 (25) | NS |

| Category | Variables | Citation Frequency | Dairy Farmers No. (% 1) | Arable Farmers No. (% 1) | Non-Farmers No. (% 1) | p2 |

|---|---|---|---|---|---|---|

| Biogas plant | High investment and running (e.g., repair) costs | 15 | 7 (100) | 3 (43) | 5 (63) | 0.081 |

| Limited grid access and competition with other renewables (solar PV) | 9 | 2 (29) | 1 (14) | 6 (75) | 0.052 | |

| Dependence of feed-in tariff on political circumstances/Lack of long-term perspective | 6 | 3 (43) | 0 | 3 (38) | NS | |

| Insufficient government support, late payment, and high competition to be supported | 5 | 1 (14) | 1 (14) | 3 (38) | NS | |

| High manure composition variability and its treatment | 4 | 3 (43) | 0 | 1 (13) | NS | |

| Unsure economic benefits | 3 | 2 (29) | 0 | 1 (13) | NS | |

| Lack of use for heat generated in particular night and summer time | 2 | 0 | 0 | 2 (25) | NS | |

| Digestate | Expected high competition for available farmland to spread digestate | 10 | 5 (71) | 3 (43) | 2 (25) | NS |

| High transportation costs and road conditions | 9 | 2 (29) | 6 (86) | 1 (13) | 0.016 | |

| Limited timeframe for digestate application (e.g., depending on weather and seasonal conditions) | 8 | 1 (14) | 6 (86) | 1 (13) | 0.005 | |

| Unclear impacts on yield/limited knowledge and practices | 6 | 1 (14) | 5 (71) | 0 | 0.005 | |

| Requirement of spreading equipment and its cause of soil compaction | 6 | 0 | 5 (71) | 1 (13) | 0.002 | |

| Preference of composted manure over liquid digestate | 6 | 2 (29) | 4 (57) | 0 | 0.039 | |

| Nutrient variability due to, for example, uncovered slurry tank and differences in feedstock | 4 | 2 (29) | 2 (29) | 0 | NS | |

| Low acceptance rate among neighbors/poor linkages and communication with suppliers | 4 | 0 | 3 (43) | 1 (13) | NS | |

| Suppliers careless about demand-side wish (e.g., spreading digestate with proper timing and amount) | 3 | 0 | 3 (43) | 0 | 0.024 | |

| Limited storage capacity | 3 | 3 (43) | 0 | 0 | 0.045 | |

| Odor from spreading digestate | 2 | 0 | 2 (29) | 0 | NS | |

| Local community | Dissemination of information about biogas system | 2 | 0 | 1 (14) | 1 (13) | NS |

| Low returns to local community | 1 | 0 | 1 (14) | 0 | NS |

| Category | Variables | Citation Frequency | Dairy Farmers No. (% 1) | Arable Farmers No. (% 1) | Non-Farmers No. (% 1) | p2 |

|---|---|---|---|---|---|---|

| Biogas plant | Establishment of the joint biogas plant to share costs | 8 | 5 (71) | 0 | 3 (38) | 0.021 |

| Continuation of the current FIT or even raising the purchase price | 7 | 3 (43) | 0 | 4 (50) | NS | |

| Subsidy for plant construction | 4 | 1 (14) | 1 (14) | 2 (25) | NS | |

| R&D for low-costs, high-productivity, and user-friendly biogas production and utilization | 3 | 0 | 0 | 3 (38) | 0.082 | |

| Improvement of power distribution/transmission environment | 3 | 0 | 0 | 3 (38) | 0.082 | |

| Digestate | Subsidy for new equipment and using a contractor to handle/spread digestate | 7 | 4 (57) | 3 (43) | 0 | 0.058 |

| Clarification of the actual merits of digestate as fertilizer | 6 | 2 (29) | 3 (43) | 1 (13) | NS | |

| Technical support to develop a crop nutrition plan including digestate use | 5 | 1 (14) | 2 (29) | 2 (25) | NS | |

| Upgrading to be more user-friendly | 4 | 0 | 4 (57) | 0 | 0.010 | |

| Providing and spreading digestate in low price or free of charge | 4 | 0 | 3 (43) | 1 (13) | NS | |

| Organizing a study group, match-making between digestate supplier and demander | 4 | 1 (14) | 2 (29) | 1 (13) | NS | |

| Supplier’s improved understanding of user’s needs (e.g., timing and amount of spread) | 2 | 0 | 2 (29) | 0 | NS | |

| Local community | Use of energy and heat in, e.g., public buildings and horticulture | 5 | 1 (14) | 0 | 4 (50) | 0.081 |

| Use the biogas plants as a tool in environmental education | 2 | 0 | 0 | 2 (25) | NS | |

| Establishment of municipal electric power systems | 2 | 0 | 0 | 2 (25) | NS | |

| Open new markets for digestate products (e.g., use digestate in organic farming) | 1 | 0 | 0 | 1 (13) | NS |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asai, M.; Hayashi, T.; Yamamoto, M. Mental Model Analysis of Biogas Energy Perceptions and Policy Reveals Potential Constraints in a Japanese Farm Community. Sustainability 2019, 11, 225. https://doi.org/10.3390/su11010225

Asai M, Hayashi T, Yamamoto M. Mental Model Analysis of Biogas Energy Perceptions and Policy Reveals Potential Constraints in a Japanese Farm Community. Sustainability. 2019; 11(1):225. https://doi.org/10.3390/su11010225

Chicago/Turabian StyleAsai, Masayasu, Takashi Hayashi, and Mitasu Yamamoto. 2019. "Mental Model Analysis of Biogas Energy Perceptions and Policy Reveals Potential Constraints in a Japanese Farm Community" Sustainability 11, no. 1: 225. https://doi.org/10.3390/su11010225

APA StyleAsai, M., Hayashi, T., & Yamamoto, M. (2019). Mental Model Analysis of Biogas Energy Perceptions and Policy Reveals Potential Constraints in a Japanese Farm Community. Sustainability, 11(1), 225. https://doi.org/10.3390/su11010225