Abstract

With the rising atmospheric CO2, crops will assimilate more carbon. Yields will increase in terms of carbohydrates while diluting the content of protein and minerals in compound pig feed, calling for an altered formulation with more protein and less carbohydrate crops to maintain its nutritional value. Using crop response data from CO2 exposures in a linear modeling of feed formulation, we apply a consequential life cycle assessment (cLCA) to model all of the environmental impacts and socio-economic consequences that altered crop yields and chemical composition at elevated CO2 levels have on feed formulation, targeting altered amino acid contents rather than overall protein. An atmospheric CO2 of 550 µmole mole−1 gives rise to a 6% smaller demand for land use for pig feed production. However, feed produced at this CO2 must include 23% more soymeal and 5% less wheat than at present in order to keep its nutritional value. This counteracts the yield benefit. The monetized environmental cost of producing pig feed, where sunflower and soy contribute the most, equals the direct feed price in both scenarios. If external costs were internalized, honoring the Rio Declaration, feed prices would double. In contrast, the future composition of pig feed will increase the direct price by only 0.8%, while the external cost decreases by only 0.3%.

1. Introduction

During this century, the rising atmospheric carbon dioxide concentration (CO2) is expected to increase crop yields due to increased carbon assimilation, for example in wheat grains, by 10% [1]. On the other hand, the higher carbon uptake causes increased starch content, and consequently also a dilution of the relative protein and mineral content in food and feed crops [2]. Additional consequences of future atmospheric CO2 include altered patterns of temperature and precipitation, which together with regional changes, e.g., ozone pollution and nitrogen (N) fertilization, will further modify plant growth and its chemical composition.

The animal feed market, which currently absorbs approximately 45%, 58%, and 80% of the world cereal, maize, and soy, respectively [3], is likely to be affected by such changes in crop yield and composition. In fact, since the composition of animal feed for intensive livestock production is carefully optimized in order to meet both the applying legislation and the nutritional requirements in a cost-effective manner, any change in both the chemical composition and the yield of feed crops will affect the future formulation of the feed.

Although the environmental consequences of the forecasted future increases in meat (and thus feed) demand have been overly studied (e.g., references [4,5,6]), there are no studies, to the authors’ knowledge, that have attempted to address the environmental impacts related to the changes that a higher CO2 would induce to the feed market. From an environmental perspective, a (CO2-induced) higher crop yield would contribute to reduce both the land use and the land-use changes that are associated with increased demand for animal feed. On the other hand, lower protein content would trigger an increased need for protein-rich crops such as soybeans, which in turns would involve an increased land-use change, the environmental impact of which may be considerable (e.g., references [7,8,9]). Yet, it is not clear which effect would dominate over the other. Further, a change in protein content has to be addressed with regards to the specific amino acids affected, as a change in some non-essential amino acids (e.g., proline) is rather useless for the overall feed composition.

Focusing on the effects of elevated CO2 alone, this study endeavors to assess the environmental consequences, the associated environmental cost, and the direct price of compound pig feed based on the yield and chemical composition of crops grown at the “present” atmospheric CO2 (taken at 380 µmole CO2 mole−1 dry air) and at a “future” CO2 (550 µmole mole−1 dry air by 2050 [10]). From this point onwards, the former will be referred to as “present feed”, and the latter will be referred to as “future feed”, with the understanding that these are both compound feeds. Further, the socio-economic consequences are, in this study, represented by the sum of the direct price and the cost of environmental impacts (so-called shadow price) of producing compound pig feed. Compound feed means multi-component animal feed produced at a competitive price to satisfy all of the nutritional and technical needs in terms of carbohydrates, protein, oils, fiber, enzymes, vitamins, etc.

2. Materials and Methods

2.1. Life Cycle Assessment (LCA) Model

Consequential life cycle assessment (cLCA, e.g., references [11,12]) modeling was used to assess the environmental burdens of producing one extra tonne (the functional unit) of pig feed produced today (present CO2 scenario) and in a future with 550 µmole CO2 mole−1 (future CO2 scenario).

The life cycle impact assessment was carried out using the stepwise method, which allows for the full monetarization of environmental impacts (expressed in €2003). This method combines characterization models from IMPACT2002 + v2.1 and EDIP2003 and is further described in reference [13]. The assessment was facilitated with the LCA software Simapro® 7.3.3. Translating all of the environmental impact into monetized costs enables the selection and presentation of the most important environmental impact categories causing the socio-economic impacts of compound pig feed (other impact categories are presented in Supplementary). Biogenic carbon (C), including soil C changes and C sequestration by feed crops, was included in all of the calculations in order to allow for a transparent carbon balance, as described by reference [14].

Background LCA data were taken from the Ecoinvent v.2.2 database [15], while foreground data were essentially related to the cultivation, yield, and chemical composition of the crops used in feed formulation. These are described in Section 2.4 and Supplementary. The geographical scope considered for the foreground system was Denmark, i.e., the pig feed was considered to be manufactured for the Danish market. The Danish example is taken as representative for most industrialized countries in a temperate climate.

2.2. LCA System Boundary

All of the processes affected by the production of one tonne of pig feed, i.e., from crop cultivation to harvest, and up to the mixing of the feed, were included within the LCA system boundary. Direct as well as indirect land-use changes were also included in the study (Section 2.4). As the focus of the study is on the production of the feed itself, processes downstream from the feed production (e.g., consumption by the animals) were excluded, as these were outside of the study’s scope.

Based on the cLCA principles, system expansion was performed for all of the feed ingredients affected by the considered change of atmospheric CO2.

2.3. Feed Formulation and Life Cycle Inventory (LCI)

2.3.1. Formulation of Present and Future Pig Feed

To apply a market-based approach, the commercial feed formulation software Bestmix® [16] was used to establish both the present and future feed formulation for piglets, sows, and slaughter pigs (a feed mix consisting of 20% piglet feed, 20% sow feed, and 60% fattening pig feed was considered, because this is what is used in a normal pig life cycle). Through optimization algorithms, Bestmix® formulated the best compromise between profitability, nutritional value, and animal health, while ensuring that the Danish and European legal requirements of the feed were met. This procedure allowed determining the exact ingredient proportions constituting the present and future pig feed.

One important input to Bestmix® is the chemical composition of crop ingredients, in terms of starch, protein, amino acids, macronutrients, and micronutrients. Another important input parameter to Bestmix® is the price of feed ingredients. However, as the aim of this study is primarily to investigate the consequences of altered crop composition, and since no reliable estimate is available on future crop prices, the prices of crop ingredients under a high CO2 future were taken to be equal to the present prices.

The chemical composition of all of the crop ingredients, when grown under today’s atmospheric CO2, was established based on the Danish Pig Research Centre feed ingredients database [17]. Data on the yield and chemical composition of the crop ingredients grown at 550 µmole CO2 mole−1 was established based on data from growth experiments with increased CO2 exposure taken from the scientific literature. Reliable data was only found for the four main crop ingredients (Table 1): namely wheat, barley, soy, and rape, which together make up 89% of the present pig feed by dry weight (Table 2).

Table 1.

Chemical composition and yield of wheat, barley, soy, and rape at the present (380 µmole mole−1) and future (550 µmole mole−1) atmospheric CO2 concentrations.

Table 2.

Ingredients in Danish pig feed for piglets, sows, and slaughter pigs, and their weighted average, produced at the present (380 µmole mole−1) and future (550 µmole mole−1) atmospheric CO2 concentrations. Amino acids produced by fermentation include lysine, threonine, and tryptophan. Dl-methionine is chemically synthesized.

Since there is a large variability reported in the literature for plant responses to elevated CO2, the following principles for selection of the best data were adopted. Results from Free Air Carbon Dioxide Exposure (FACE) systems were assumed to provide the most reliable data, since they represent the most realistic growing conditions, although FACE responses are typically smaller than for other exposure systems, see e.g., references [18,19]. When FACE data were not available, data from open-top chambers (OTC), from outdoor closed-top chambers (CTC), or from climate chambers were used, in that order of ranking. As crops respond differently to elevated atmospheric CO2 with different climatic or other abiotic or biotic conditions, exposure experiments that were performed near to where the feed ingredients that were considered in this study were grown were preferred over other studies. Even with the same exposure technique, all of the studies give different results for each year, and with each plant species, it varies with the studied cultivar. Under these conditions, either the best available reference was applied for each species and chemical component, or data from meta studies were applied. When data for future chemical content was not found for a given component (e.g., amino acids), the future content was presumed to be the same as today. The chosen data sources are summarized in Table 1.

2.3.2. Life Cycle Inventory (LCI) Data for Crop and Non-Crop Ingredients

Crop Ingredients

The LCI of crops grown in Denmark (wheat and barley) was based on a recent Danish consequential LCI dataset [14], which comprises all of the processes involved during the cultivation stage, up to harvest. This includes the tillage activities, liming, seed propagation, plant protection, fertilization, sowing, harvest, and transport from farm to field. A sandy soil has been considered for both crops, as well as precipitations of 964 mm y−1 and removal (harvest) of the straw. LCI data from the Ecoinvent (v.2.2) database were used to model the cultivation of imported soybean (Brazil), rapeseed (Germany), sunflower (Spain), and palm oil (Malaysia). Other important foreground data for crop ingredients are thoroughly described in the appendices.

Industrial Amino Acids

As shown in Table 2, two types of industrial amino acids are included in the assessed pig feed: industrial amino acids produced by fermentation (lysine, threonine, and tryptophan) and industrial amino acids produced synthetically (dl-methionine). Based on reference [19], a generic recipe was considered for 1 kg of amino acids produced by fermentation; 1 kg of sugar (from sugar beet), 0.5 kg of maize starch, 0.5 kg of wheat starch, 0.3 kg of liquid ammonia, and 36 MJ of process energy at the plant. In this study, the recipe was supplemented with 0.053 kg of sulfuric acid per kg amino acid, and 4.6 g of phosphorous based on data from the Danish lysine supplier (see Supplementary). Under Danish production conditions, the energy consumption was estimated at only 18 MJ, which was supplied as electricity (50%) and natural gas (50%). On the basis of reference [20], it was assumed that the production of 1 kg of dl-methionine required 0.43 kg of propylene, 0.27 kg of hydrogen sulfide, 0.39 kg of methanol, 0.21 kg of hydrogen cyanide, and 7.4 MJ of process energy at the plant, which was supplied by electricity (50%) and natural gas (50%).

Enzymes

No specific LCI data were found for the added enzymes (phytase, xylanase). Instead, published LCA data for phytase (i.e., characterization results for global warming, acidification, nutrient enrichment, photochemical ozone formation, land use, phosphorus consumption, and energy consumption) were used for both types of enzymes [21].

Other Ingredients

In the absence of LCI data for the vitamins added to the compound pig feed, these ingredients were calculated as for enzymes. LCI data for limestone meal (CaCO3), monocalcium phosphate (MCP), phosphoric acid, and sodium chloride (NaCl) were taken from the Ecoinvent (v.2.2) database. LCI data for fish meal were taken from the LCA food database (“industrial fish, ex harbor”, as available in Simapro 7.3.3).

2.4. Land-Use Changes (LUC)

In order to quantify the environmental consequences of land-use changes, three main steps are required: (i) determining the total land area undergoing conversion to cropland; (ii) identifying which land types (i.e., biomes) are converted; and (iii) determining the changes in carbon flows from these conversions. Direct and indirect land-use change (LUC) have been extensively studied over the past decade for all of the major global ecosystems [8,22,23,24,25]. LUC also impacts biogeochemical cycling [26,27] and biodiversity [28], but these aspects have not yet been sufficiently quantified, and can therefore not be included in the present analyses.

2.4.1. Land Conversion: Determination of the Area and Geographical Location (Steps i and ii)

In this study, a deterministic explorative approach based on crop yields (Table 1), carbohydrate content, lysine content, and historical market trends has been used in order to determine the above-mentioned steps (i) and (ii). This is further described below. As a starting point, the LUC involved in this study may be classified in two distinct categories: (a) those triggered by the displacement of carbohydrates crops, and (b) those triggered by the displacement of oil crops.

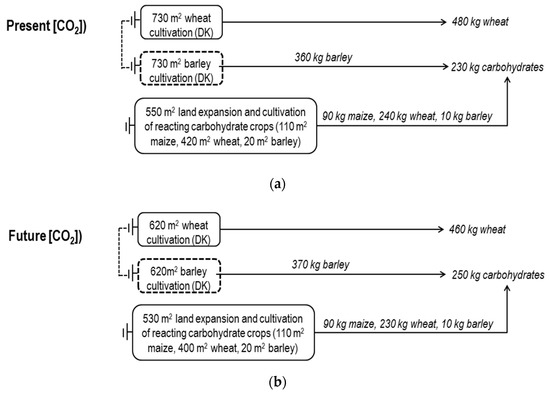

The former represents the LUC resulting from the cultivation of crops whose increased demand (as a result of producing one extra tonne of Danish pig feed) involves the displacement of a carbohydrate crop. This can be illustrated by the case of wheat (Figure 1). As shown in Figure 1, an extra demand of one tonne of Danish pig feed induces a need for an additional 480 kg of wheat (present feed) and 460 kg of wheat (future scenario). These figures were determined from Bestmix® data, as presented in Table 2.

Figure 1.

Consequential life cycle assessment (LCA) model for wheat grown (a) at the present CO2 and (b) at the future CO2. Dotted lines indicate avoided flows. All of the flows are related to the functional unit, i.e., 1 tonne of compound Danish pig feed.

In a country such as Denmark, where 65% of the total land is used for cropland, and where policies have been adopted in order to double the forested area (nowadays representing ca. 13% of the total land [29]), very limited conversion from forest or similar nature types is realistic. Most likely, the land that is needed to grow this extra wheat will be taken from actual Danish cropland, which means that one crop cultivated today will be displaced. Such a displaced crop is, in cLCA, referred to as the marginal crop. In this study, the marginal crop was assumed to be spring barley (a carbohydrate crop), based on references [30,31]. The environmental consequences of cultivating wheat instead of spring barley represent, in this case, the so-called direct land-use changes (dLUC). Indirect land-use changes (ILUC), on the other hand, represent the environmental consequences that are related to how this missing supply of Danish spring barley will be supplied on the world market. Such increased crop production may stem from increased yield, which is also referred to as intensification, or from land conversion to cropland, which is also referred to as agricultural land expansion. As illustrated in Figure 1, and as in many ILUC or LCA studies (e.g., references [32,33,34,35]), this study includes the environmental impacts of the latter only.

Similar to wheat, an increased demand for land in Europe in order to cultivate the barley, rapeseed meal, and sunflower meal (Table 2) resulting from an extra demand of Danish pig feed was considered to take place at the expense of spring barley. The process flow diagrams for these crops are illustrated in Supplementary.

An extra demand for soybean meal, rapeseed meal, sunflower meal, and palm oil also implies an interaction with the vegetable oil market (category “b” above). For the latter, this interaction is straightforward. For the three former, the interaction is indirect and happens as oil is co-produced with the desired meal. This can be illustrated with the case of soybean meal (Figure S3 in Supplementary). Increased soybean meal production involves increased soy oil co-production, causing a decrease in palm oil production (palm oil being identified as the marginal oil, on the basis of the references [30,31]), and consequently also a decrease in the co-produced palm meal (a source of both protein and carbohydrates), inducing, somewhere in the world, an increase in the production of a marginal protein and carbohydrate feed crop. Since the production of a marginal protein interacts with the oil market again, a loop system is thus created, and this loop should be stopped at the point where the consequences are so small (or the uncertainties so large) that any further expansion of the boundaries would yield no significant information for decision support [36]. Such flows are illustrated in Supplementary for all of the crops interacting with the oil market. A substitution ratio of 1:1 was assumed, i.e., that 1 t of a given vegetable oil would replace 1 t of the marginal oil (palm oil), since it is the long-term effect of the demand that should be guiding for decisions in LCA [37]. In other words, the supply of goods and services was assumed to be fully elastic, and accordingly, short-term effects are not captured.

For LCA models of soy, rape, and sunflower that all involve the displacement of palm meal as a result of the above-described oil loop, soybean meal was identified as the reacting marginal protein [30,31]. Being the market covering the greatest share of the worldwide increase in soybean production [38], soybean from South America (Argentina and Brazil) was identified as the market reacting to an extra demand for soybean meal. Based on a similar logic, palm fruit cultivation from Southeast Asia was identified as the one reacting to an extra demand.

When applying a deterministic approach to land-use changes in LCAs, it has been a common practice to determine the amount of marginal protein crop (here soybean meal) reacting to a decrease in palm meal production on the basis of the protein content of these meals, e.g., references [23,31,39]. However, it is the composition of the protein in terms of amino acids, or rather in terms of the limiting amino acids, that matters for feed. The most important limiting amino acid in pig feed is lysine. Therefore, the reacting amount of soybean meal has been identified on the basis of the lysine content of the meals (Supplementary).

For fermentation-based amino acids, which are produced from of a mix of different crops (Supplementary), the same principles as described above were applied. For each crop system, all of the details of the inventory data that were used for determining the area and geographical location of the land converted are presented in Supplementary. Further, it has been considered, on the basis of reference [34], that only 80% of the new soy and carbohydrates demand is supplied through land expansion, while this was 70% for palm oil. The remaining production must be supplied by the intensification of existing areas (the various types of intensification pathways and the extent to which each is driven by crop prices is discussed in reference [40]. As previously highlighted, the environmental impacts of such intensification were not included in this study. With input-driven intensification, the reduced environmental impact associated with increased crop yield is countered by the environmental impact of an increased use of fertilizers, pesticides, and machinery, among others.

2.4.2. Environmental Consequences of Land Conversion

The dLUC consequences, in terms of changed C and N flows, of cultivating a given crop in Europe instead of spring barley have been included and modeled on the basis of the data from reference [14].

In order to quantify the releases of carbon due to the land converted to cultivate soybean, palm fruit, or the reacting carbohydrate mix, the soil and vegetation carbon data from the Woods Hole Research Centre, as published in reference [8], was used. This allowed the calculation of the CO2 emitted during land conversion (i.e., step (iii) referred to in the first sentence of Section 2.4), where the following has been considered:

- 25% of the carbon in the soil is released as CO2 for all types of land-use conversion, except when forests are converted to grassland, where 0% is released;

- 100% of the carbon in vegetation is released as CO2 for all of the forest types as well as for tropical grassland conversions, while 0% is released for the remaining biome types (e.g., shrub land, non-tropical grassland, chaparral).

The results of this calculation are shown in Supplementary; flows were annualized (distributed equally) over 20 years, which is in line with most LUC calculations used by European policy makers [41]. A similar procedure has also been applied by reference [35].

2.5. Direct Cost

Based on today’s market prices for all of the ingredients (as available in Bestmix®), the price of one tonne compound pig feed for the present and future atmospheric CO2 were calculated.

3. Results and Discussion

3.1. Changes in Crops’ Chemical Composition and in the Compound Feed Formulation

Table 1 shows the established present and future chemical composition of wheat, barley, soymeal, and rape meal used as input to Bestmix® [16]. The optimization performed in Bestmix® determined that one tonne of compound pig feed produced under the future relative to the present atmospheric CO2 will contain 5.1% less wheat, 23% more soy, unchanged amounts of barley, rape, and sunflower, 18% more beet molasses, 65% more hemoglobin meal, 16% less amino acids produced by fermentation (lysine, threonine, tryptophan), and varying amounts of other minor ingredients (Table 2). The results in Table 2 thus support the hypothesis that pig feed based on wheat, barley, and rape grown in Northern Europe under higher CO2 will need a higher supplement of protein as well as less carbohydrate ingredients. Table 2 also highlights that both present and future feed consist of at least 46% wheat, 25% barley, 9% soy meal, 7% rape meal, and 4% sunflower seeds; these five ingredients making up approximately 93% of the feed.

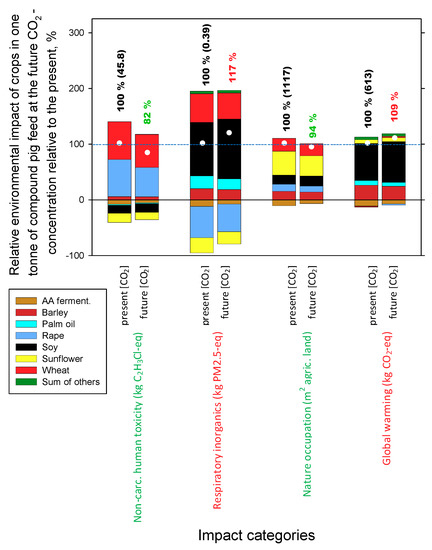

3.2. Environmental Impact

Characterized LCA results are presented in Figure 2, with a focus on the four socio-economically most important impact categories, which were identified through normalization (Section 3.4); human toxicity in terms of non-carcinogenic organics and respiratory inorganics (PM2.5); nature occupation; and global warming. The results for all of the other evaluated impact categories are given in Supplementary (Figures S8 and S9).

Figure 2.

Relative environmental impacts of producing one tonne of compound pig feed under future and current CO2 for the socio-economically four most important impact categories. The dots represent the net value of the environmental impact, i.e., the positive minus the negative values. Eq: equivalents; PM2.5: ultrafine particles; AA ferment.: amino acids produced for feed by fermentation processes (lysine, threonine, tryptophan).

The environmental impact of producing one extra tonne of compound pig feed was expected to decrease in the high CO2 future due to the higher yields (and thus lower land use) caused by the higher CO2 uptake from the atmosphere. However, even though the yield increases were found to be large, e.g., 10% for wheat and 28% for rape, the net land use did not decrease to the same extent. The net reduction in land use per tonne of pig feed was found to be around 6%. Unexpectedly, this did not lead to a net fall in greenhouse gas emissions per tonne of feed; on the contrary, it increased by 9% for crops grown at the future CO2 (explained in detail in Supplementary, Figure S10). This is essentially due to the change in feed composition, where considerably more soybean meal, which involves the conversion of biomes with relatively high C stock, is required under a high CO2. This is reflected in Table 2 and Figure 2.

However, the biggest differences are found for the impact categories of respiratory inorganics (fine particles) and non-carcinogenic human toxicity (17% increase and 18% decrease, respectively). Again, these differences between the present and future CO2 scenarios can be explained by the change in the feed’s chemical composition, especially the increased need for soy meal and decreased need for wheat at elevated atmospheric CO2.

Nearly all of the impacts are due to the crop-based ingredients, i.e., the sum of others (non-crop ingredients) is infinitesimal (reflected in Figure 3 discussed in Section 3.4). For non-carcinogenic human toxicity, rape and wheat are the biggest contributors (caused by rape and wheat cultivation, but the effect of wheat will be greatly reduced by the displaced barley; Figure 1). For respiratory inorganics, soy and wheat are the major contributors (caused by soy and wheat cultivation, but the effect of wheat will be greatly reduced by the displaced barley, and that of soy will be somewhat reduced by soy oil displacing palm oil; see Figure S3 in Supplementary), while rape contributes negatively (mainly due to displaced palm oil; Figure S4). Regarding natural occupation, all of the main crop ingredients contribute, and sunflower the most (due to the low yield of sunflower cultivation and the displaced barley; Figure S5). For global warming, soy is the biggest overall contributor (71% of its contribution is caused by indirect land-use change, 19% by soy oil displacing palm oil; Figure S3), followed by barley. These observations emphasize that each crop ingredient in compound pig feed contributes differently to the various environmental impacts of the feed based on their content, and that ILUC is important in the calculation of the overall GWP (Global Warming Potential) of feed production, second only to crop and displaced crop cultivation. Cultivation of the main crops (photosynthetic carbon uptake) as well as the reacting carbohydrate crop cultivation all contribute negatively to the GWP impact (Supplementary, Figure S10).

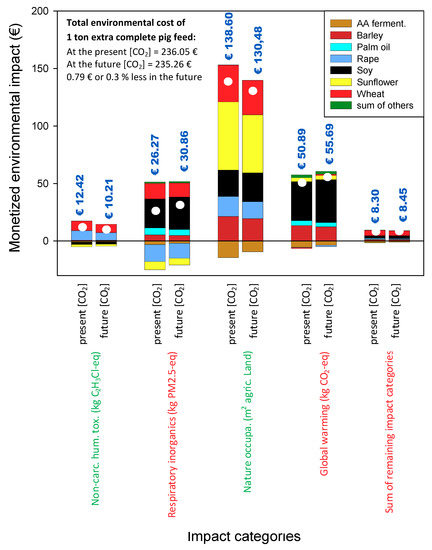

Figure 3.

Breakdown of the monetized environmental impact results per ingredient. The white dots represent the net value of the environmental impact, i.e., the positive minus the negative values. Eq: equivalents; PM2.5: ultrafine particles; AA ferment.: amino acids produced by fermentation (lysine, threonine, tryptophan).

Amino acids produced by fermentation contribute negatively to each of the main impact categories. This is because sugar production (one of the substrates in the fermentation process producing amino acids) gives rise to by-products (molasses and pulp), which can substitute the use of marginal carbohydrates for animal feed. The saved carbohydrates production (and the land-use changes it generated) had a greater negative impact than the positive impact from the consumed sugar substrate (see Figure S7a in Supplementary). Yet, these effects are of course highly dependent upon the data quality that is used to model them. As three crop ingredients are used to produce these amino acids (Figure S7a–c in Supplementary), and as each of these crops involve at least three co-products, a considerable degree of uncertainty is introduced in the model, as a result of the numerous assumptions involved regarding the displacement effects (i.e., system expansion).

3.3. Direct Cost

Data for direct market prices of all of the ingredients were added up for each pig growth stage (Table 3). Based on the present prices of commodities and the altered content of future feed, an increase in the direct costs for future pig feed was estimated at €1.92 per tonne of pig feed, which represents an increase of only 0.8% on top of the current price of €250.39 per tonne.

Table 3.

Differences in direct costs for present and future compound pig feed, on the basis of today’s prices.

These results indicate that the direct price of future pig feed will not increase significantly due to elevated atmospheric CO2. However, it may, very well increase due to other circumstances, e.g., increasing prices on land, energy, fertilizers and pesticides, transport, manufacture, and increased demand. If the demand for protein in animal feed continues to rise, the price of soy is likely to go up, and soy in European pig feed may be replaced with other protein sources combined with an increased application of industrial amino acids. However, all of these circumstances are impossible to foresee in any detail, and are not directly related to the rising atmospheric CO2.

3.4. External Environmental Cost

In the future, the external cost that is associated with the environmental impact of growing crops may be included in the actual cost of food and feed according to “the polluter pays principle” [40], significantly increasing the current price for compound pig feed. This in itself makes calculations of external cost of pig feed production relevant.

Figure 3 shows the monetized environmental impact using the stepwise normalization methodology [13] for the four most important impact categories, and the sum of 12 other categories. As indicated in Figure 3 (and further detailed in Figure S11 and S12 in Supplementary), the cost of the overall environmental externalities of one tonne of pig feed is estimated at €236.05 for the present CO2, and at €235.26 for the future CO2, i.e., €0.79 or 0.3% less than feed produced today. These results indicate that elevated CO2 will not increase the external environmental costs of pig feed.

As highlighted in Table 3 and Figure 3, the external socio-economic costs of producing compound pig feed are in the same order of magnitude as the direct costs of pig feed. In fact, internalizing the environmental externalities of producing pig feed nearly doubles the present (direct) cost of pig feed, which is a vast price increase if the Rio Declaration is to be taken seriously [48].

Figure 3 (as Figure 2 and the extended Figures S9–S12 in Supplementary) highlights soy as a main contributor to most of the environmental impact categories, whereas for natural occupation, sunflower is the major contributor. Figure 3 also highlights the important contribution of the natural occupation category, when environmental impacts are translated into a common monetized environmental impact, which explains why the overall high environmental cost of sunflower is associated with a low yield. Per tonne of pig feed, soy has the largest environmental impact in monetary terms, followed by sunflower (Table 4). However, relative to their content in pig feed, sunflower has an 11-times higher (specific) impact and soy has a seven-times higher (specific) impact compared with wheat, barley, or rape (Table 4).

Table 4.

The relative importance of crops in one tonne of feed at the present CO2 in terms of monetized environmental impact. Due to the negative environmental impact that amino acids and some crops have for various impact categories, the sum of the crop impact percentages surpasses 100%.

In the context of a worldwide growing population with growing food and energy needs (e.g., reference [49]), alternative strategies to minimize the amount of land that is used for food, feed, or bioenergy are urgent. The main ingredients in compound pig feed could just as well be consumed directly by humans. A pig consumes 2.5 times its weight gain in terms of pig feed before only part of the pig ends up as food for humans (bones, head, and entrails are wasted). In a world with a growing population and with about 800 million people starving, a more plant-based diet would make sense, in terms of increasing food production, increasing the availability of bioenergy, and reducing the environmental impact of global agriculture.

According to Table 4, future pig feed recipes ought to consider a reduced use of sunflower and soy as protein crops. Whether rape or non-crop ingredients (e.g., industrial amino acids, insect-based protein) would be a better environmental choice could be the object of future investigations. However, since the value of protein in animal feed relies on the amino acid composition, it is important to consider balancing the overall amino acid composition of the pig feed to suit the needs of pigs. In this sense, industrial amino acids have a clear advantage, although economically it may not be the best solution measured in the present commodity prices (as in this study). On the other hand, if and when the cost of environmental impacts is included in the price of pig feed, it may likely be an advantage to include more industrial amino acids in the feed.

An alternative or supplement to the above-mentioned solutions could be to include genetically modified grain crops. These crops would need not only to contain more protein—which may in itself be useless—but rather, they should contain more of the limiting amino acids for the better digestibility of the protein in the feed.

3.5. Limits and Uncertainties

One limit of this study is that it focused only on the effect of elevated CO2 to represent the future conditions under which pig feed will be produced. In fact, higher atmospheric CO2 is not the only global change to determine the yield and the chemical composition of crops in the future. With elevated CO2 follows elevated temperature and altered patterns of precipitation (10). Typically, crop yields respond positively to both elevated CO2 and moderate (1–3 °C) temperature increases, but negatively to high (i.e., above 3 °C) temperature increases [47,50]. Moreover, the response depends on the plant species, water availability, humidity, wind, soil type, etc.

Furthermore, it has been highlighted that the current and anticipated elevated concentration of ground-level ozone may likely decrease plant productivity [51]; and contrary to elevated CO2, ozone increases grain protein concentration [51].

Thus, the results of this study are not to be seen as representative of the future state of global climate and meteorological conditions (data for this is as yet unavailable), but rather as an illustration of the cascading consequences that any change in crop yield and composition (which is in this case triggered by an increase in atmospheric CO2) can have for pig feed formulation. As for any LCA, the results of this study are closely linked to the quality of the inventory data and assumptions taken. For example, no changes in amino acid composition were considered for barley and soy as a result of elevated CO2, because no data or reliable estimations could be found. Further, the overall changes in yield and chemical composition considered (Table 1) are based on the best state-of-knowledge, as available FACE experiments results are still scarce. Thus, this study would considerably benefit from a greater availability of such data. Nevertheless, the study provides a solid framework for assessing the consequences of a changed crop composition due to the effect that elevated atmospheric CO2 would have on pig feed, which has not, to authors’ knowledge, been available so far.

Another limit is that the changes in manure composition resulting from a change in feed composition have not been taken into account. Feed containing less protein from cereals, which are difficult to digest, and more easily digestible protein from e.g., soy or rapeseed meal, involves a better digestion, and thus a reduction in excreted N. This could have consequences for the subsequent use of the manure as a fertilizer, as it would involve a reduced potential for the emission of N flows (e.g., ammonia, nitrous oxide, nitrate losses). Based on Table 2, these induced changes in manure composition would likely have induced additional benefits for the future pig feed, which comprises significantly more soymeal and less wheat.

One of the most important sources of uncertainty probably lies in the estimation of the environmental consequences generated by land-use changes. As clearly emphasized in several publications, e.g., references [52,53,54], the estimation of land-use changes, particularly ILUC, involves multiple sources of uncertainty. In the explorative deterministic approach used in this study, one main source of uncertainty lies in the choice of the market that would react to a changed demand for the different crop ingredients presented in Table 2, i.e., the choice of the marginal crops and their geographical location. Further, as expressed by e.g., reference [52] there is also uncertainty related to the actual C stock in the biomes converted. On the other hand, the strength of the approach used in this study lies in its transparency. In fact, the assumptions used in the deterministic model can be easily changed to reflect different possible futures with regard to how the land market could develop. However, such assessment is beyond the scope of this study. Nevertheless, it should be highlighted that although the actual magnitude of environmental impacts related to land-use changes is uncertain, the potentiality of adverse effects arising from it is hardly subject to dispute [25,53].

Finally, we draw the attention to the work by Dijkman et al. [55], where the environmental impact of barley cultivation under current and future climatic conditions is analyzed using aLCA. Dijkman et al. [55] found that a predicted decrease in barley yields under future climate conditions is the main driver for increased impacts. An increased impact was not substantiated by the present study based on cLCA and including all of the ingredients of compound pig feed.

4. Conclusions

The main findings and highlights of this study can be summarized as follows:

- A methodological framework was developed in order to assess the cascading environmental consequences that a change in crop yield and chemical composition (triggered by an increase in atmospheric CO2) can have for pig feed formulation, including land-use change consequences.

- The positive environmental effect of elevated CO2 on crop yield (carbohydrates) was counterbalanced by a need for increased soy content in pig feed, and the land-use that consequences this generated. Therefore, the net effects are close to zero.

- The four most important environmental impact categories in pig feed production under current and future atmospheric CO2, as determined by the stepwise normalization methodology, were human toxicity in terms of non-carcinogenic toxicity and respiratory inorganics, natural occupation, and global warming.

- The monetized environmental impact (shadow price) of compound pig feed produced today (€236.05 per tonne) was found to be of the same order of magnitude as the direct price of compound pig feed (€250.39 per tonne). Internalizing the cost of environmental impacts would nearly double the price of pig feed if the Rio Declaration was to be honored.

- Since the protein crops (soy, rape, and sunflower) account for about 60% of the overall environmental impact of pig feed, it is important to optimize their content in a future with expected growing demands for food and bioenergy (and thus for land). In this context, it is important to optimize the protein content in the feed based on the limiting amino acids in each crop rather than on total protein.

Supplementary Materials

The following are available online at http://www.mdpi.com/2071-1050/10/9/3184/s1. References [56,57,58,59,60,61,62,63,64] are cited in the supplementary materials.

Author Contributions

Conceptualization: H.S.; Methodology, software, formal analyses and investigation: H.S., L.H., T.H.; Original Draft Preparation and visualization: H.S. and L.H.; Project Administration: H.S. and H.W.; Funding Acquisition, H.W.

Funding

This research was funded by the Danish Food Research Programme 2009 for supporting this project through grant number 3304-FVFP-09-B-004: “Development of genetically modified cereals adapted to the increased CO2 levels of the future”.

Acknowledgments

The authors thank DLG for participating with Bestmix® analyses performed by Torben Hinrichsen.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Högy, P.; Wieser, H.; Köhler, P.; Schwadorf, K.; Breuer, J.; Franzaring, J.; Muntefering, R.; Fangmeier, A. Effects of elevated CO2 on grain yield and quality of wheat: Results from a 3-year free-air CO2 enrichment experiment. Plant Biol. 2009, 11, 60–69. [Google Scholar] [CrossRef]

- Smith, M.R.; Myers, S.S. Impact of anthropogenic CO2 emissions on global human nutrition. Nat. Clim. Chang. 2018, 8, 834–839. [Google Scholar] [CrossRef]

- International Grain Council. Grain Marked Report. 2018, pp. 1–8. Available online: http://www.igc.int/downloads/gmrsummary/gmrsumme.pdf (accessed on 14 August 2018).

- Steinfeld, H.; Gerber, P.; Wasssenaar, T.; Castel, V.; Rosales, M.; de Haan, C. Livestock’s Long Shadow; Environmental Issues and Options; FAO: Rome, Italy, 2006; pp. 1–390. [Google Scholar]

- Nellemann, C.; MacDevette, M.; Manders, T.; Eickhout, B.; Svihus, B.; Prins, A.G.; Kaltennorn, B.P. The Environmental Food Crisis–the Environment’s Role in Averting Future Food Crisis. A UNEP Rapid Response Assessment. United Nations Environment Programme, GRID-Arendal. 2009. Available online: http://www.grida.no/publications/rr/food-crisis/ (accessed on 14 August 2018).

- Meul, M.; Ginneberge, C.; Van Middelaar, C.E.; de Boer, I.J.M.; Fremaut, D.; Haesaert, G. Carbon footprint of five pig diets using three land use change accounting methods. Livest. Sci. 2012, 149, 215–223. [Google Scholar] [CrossRef]

- Hamelin, L.; Naroznova, I.; Wenzel, H. Environmental consequences of different carbon alternatives for increased manure-based biogas. Appl. Energy 2014, 114, 774–782. [Google Scholar] [CrossRef]

- Searchinger, T.; Heimlich, R.; Houghton, R.A.; Dong, F.; Elobeid, A.; Fabiosa, J.; Tokgoz, S.; Hayes, D.; Yu, T.-H. Use of U.S. Croplands for Biofuels Increases Greenhouse Gases through Emissions from Land Use Change. Science 2008, 319, 1238–1240. [Google Scholar] [CrossRef] [PubMed]

- Gibbs, H.K.; Johnston, M.; Foley, J.A.; Holloway, T.; Monfreda, C.; Ramankutty, N.; Zaks, D. Carbon payback times for crop-based biofuel expansion in the tropics: The effects of changing yield and technology. Environ. Res. Lett. 2008, 3, 1–10. [Google Scholar] [CrossRef]

- IPCC, Climate Change 2014. Synthesis Report. 2015. Available online: https://www.ipcc.ch/pdf/assessment-report/ar5/syr/SYR_AR5_FINAL_full_wcover.pdf (accessed on 14 August 2018).

- Weidema, B.P.; Ekvall, T.; Heijungs, R. Guidelines for Applications of Deepened and Broadened LCA. Deliverable D18 of Work Package 5 of the CALCAC Project. 2009, pp. 1–49. Available online: https://www.leidenuniv.nl/cml/ssp/publications/calcas_report_d18.pdf (accessed on 14 August 2018).

- Earles, J.M.; Halog, A. Consequential life cycle assessment: A review. Int. J. LCA 2011, 16, 445–453. [Google Scholar] [CrossRef]

- Weidema, B.P. Using the budget constraint to monetarise impact assessment results. Ecol. Econ. 2008, 68, 1591–1598. [Google Scholar] [CrossRef]

- Hamelin, L.; Jørgensen, U.; Petersen, B.M.; Olesen, J.E.; Wenzel, H. Modelling the carbon and nitrogen balances of direct land use changes from energy crops in Denmark: A consequential life cycle inventory. GCB Bioenergy 2012, 4, 889–907. [Google Scholar] [CrossRef]

- Ecoinvent Centre. 2013. Available online: http://www.ecoinvent.org/database/ecoinvent-version-2/ (accessed on 14 August 2018).

- Adifo. Bestmix Software. 2011. Available online: https://www.adifo.com/products/bestmix-feed-formulation (accessed on 14 August 2018).

- VSP, Videncenter for Svineproduktion, 2012. Fodermiddeldatabase (Feed Database). Available online: https://www.lf.dk/aktuelt/nyheder/2015/april/ny-organisation-i-seges-videncenter-for-svineproduktion#.W05DYtL7SUk (accessed on 14 August 2018).

- Ainsworth, E.A.; Leakey, A.D.B.; Ort, D.R.; Long, S.P. FACE-ing the facts: Inconsistencies and interdependence among field, chamber and modelling studies of elevated [CO2] impacts on crop yield and food supply. New Phytol. 2008, 179, 5–9. [Google Scholar] [CrossRef] [PubMed]

- Högy, P.; Fangmeier, A. Review: Effects of elevated atmospheric CO2 on grain quality of wheat. J. Cereal Sci. 2008, 48, 580–591. [Google Scholar] [CrossRef]

- Mosnier, E.; van der Werf, H.M.G.; Boissy, J.; Dourmad, J.-Y. Evaluation of the environmental implications of the incorporation of feed-use amino acids in the manufacturing of pig and broiler feeds using Life Cycle Assessment. Animal 2011, 5, 1972–1983. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, P.H.; Wenzel, H. Environmental assessment of Ronozyme® P5000 CT phytase as an alternative to inorganic phosphate supplementation to pig feed used in intensive pig production. Int. J. LCA 2007, 12, 514–520. [Google Scholar] [CrossRef]

- Schmidt, J.H.; Weidema, B.P.; Brandão, M. A framework for modelling indirect land use changes in Life Cycle Assessment. J. Clean. Prod. 2015, 99, 230–238. [Google Scholar] [CrossRef]

- Tonini, D.; Hamelin, L.; Astrup, T.F. Environmental implications of the use of agro-industrial residues for biorefineries: Application of a deterministic model for indirect land-use changes. GCB Bioenergy 2016, 8, 690–706. [Google Scholar] [CrossRef]

- JRC. World Atlas of Desertification. 2018. Available online: https://wad.jrc.ec.europa.eu/ (accessed on 14 August 2018).

- Marelli, L.; Mulligan, D.; Edwards, R.; Critical Issues in Estimating ILUC Emissions. Critical Issues in Estimating ILUC Emissions. JRC Scientific and Technical Reports. Outcomes of an Expert Consultation 9–10 November 2010, Ispra, Italy. 2011, pp. 1–64, EUR 24816EN-2011. Available online: http://publications.jrc.ec.europa.eu/repository/bitstream/111111111/22908/2/reqno_jrc64429_cirtical%20issues%20in%20estimating%20iluc%20emissions%20print%20version.pdf (accessed on 14 August 2018).

- Verchot, L.V.; Davidson, E.A.; Cattânio, J.H.; Ackerman, I.L.; Erickson, H.E.; Keller, M. Land use change and biogeochemical controls of nitrogen oxide emissions from soils in eastern Amazonia. Glob. Biogeochem. Cycles 1999, 13, 31–46. [Google Scholar] [CrossRef]

- Wolosin, M.; Harris, N. Ending Tropical Deforestation: A Stock-Take of Progress and Challenges. Tropical Forests and Climate Change: The Latest Science. 2018. World Resources Institute, Working Paper. Available online: https://wriorg.s3.amazonaws.com/s3fs-public/ending-tropical-deforestation-tropical-forests-climate-change.pdf (accessed on 14 August 2018).

- De Lima, R.F.; Dallimer, M.; Atkinson, P.W.; Barlow, J. Biodiversity and land-use change: Understanding the complex responses of an endemic-rich bird assemblage. Divers. Distrib. 2013, 19, 411–422. [Google Scholar] [CrossRef]

- Nielsen, O.-K.; Mikkelsen, M.H.; Hoffmann, L.; Gyldenkærne, S.; Winther, M.; Nielsen, M.; Fauser, P.; Thomsen, M.; Plejdrup, M.S.; Albrektsen, R.; et al. Denmark’s National Inventory Report 2011-Emission Inventories 1990–2009-Submitted under the United Nations Framework Convention on Climate Change and the Kyoto Protocol; NERI Technical Report 827; The National Environmental Research Institute, Aarhus University: Aarhus, Denmark, 2011; pp. 1–1199. Available online: http://www2.dmu.dk/pub/fr827.pdf (accessed on 14 August 2018).

- Schmidt, J.H. Life Cycle Assessment of Rapeseed Oil and Palm Oil. Ph.D. Thesis, Department of Development and Planning, Aalborg University, Aalborg, Denmark, 15 June 2007. [Google Scholar]

- Dalgaard, R.; Schmidt, J.; Halberg, N.; Christensen, P.; Thrane, M.; Pengue, W.A. LCA of soybean meal. Int. J. LCA 2008, 13, 240–254. [Google Scholar] [CrossRef]

- Edwards, R.; Mulligan, D.; Marelli, L. Indirect Land Use Change from Increased Biofuels Demand. Comparison of Models and Results for Marginal Biofuels Production from Different Feedstocks. (No. EUR 24485). European Commission Joint Research Centre. 2010. Available online: https://www.energy.eu/publications/Indirect-Land-Use-Change-from-increased-Biofuels-Demand.pdf (accessed on 14 August 2018).

- Hertel, T.W.; Golub, A.A.; Jones, A.D.; O’Hare, M.; Plevin, R.J.; Kammen, D.M. Effects of US Maize Ethanol on Global Land Use and Greenhouse Gas Emissions: Estimating Market-mediated Responses. Bioscience 2010, 60, 223–231. [Google Scholar] [CrossRef]

- Laborde, D. Assessing the Land Use Change Consequences of European Biofuel Policies. ATLASS Consortium, 2011. Available online: http://trade.ec.europa.eu/doclib/docs/2011/october/tradoc_148289.pdf (accessed on 14 August 2018).

- Tonini, D.; Hamelin, L.; Wenzel, H.; Astrup, T. Bioenergy Production from Perennial Energy Crops: A Consequential LCA of 12 Bioenergy Scenarios including Land Use Changes. Environ. Sci. Technol. 2012, 46, 13521–13530. [Google Scholar] [CrossRef] [PubMed]

- Ekvall, T.; Weidema, B. System Boundaries and Input Data in Consequential Life Cycle Inventory Analysis. Int. J. LCA 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. The Ecoinvent Database: Overview and Methodology, Data Quality Guideline for the Ecoinvent Database Version 3. 2017. Available online: https://lca-net.com/publications/show/overview-methodology-data-quality-guideline-ecoinvent-database-version-3/ (accessed on 14 August 2018).

- FAOSTAT. 2011. Available online: http://www.fao.org/faostat/en/#data (accessed on 14 August 2018).

- De Vries, J.W.; Vinken, T.M.W.J.; Hamelin, L.; De Boer, I.M.J. Comparing environmental consequences of anaerobic mono- and co-digestion alternatives for pig manure to produce bio-energy—A life cycle perspective. Bioresour. Technol. 2012, 125, 239–248. [Google Scholar] [CrossRef] [PubMed]

- Hamelin, L. Carbon Management and Environmental Consequences of Agricultural Biomass in a Danish Renewable Energy Strategy. Ph.D. Thesis, University of Southern Denmark, Odense, Denmark, February 2013. [Google Scholar]

- Edwards, R.; Padella, M.; Vorkapic, V.; Marelli, L. Historical Deforestation Due to Expansion of Crop Demand: Implications for Biofuels. 2014. Available online: http://publications.jrc.ec.europa.eu/repository/handle/JRC83819 (accessed on 14 August 2018).

- Erbs, M.; Manderscheit, R.; Jansen, G.; Seddig, S.; Pacholski, A.; Weigel, H.-J. Effects of free-air CO2 enrichment and nitrogen supply on grain quality parameters and elemental composition of wheat and barley grown in a crop rotation. Agric. Ecosyst. Environ. 2010, 136, 59–68. [Google Scholar] [CrossRef]

- Högy, P.; Franzaring, J.; Schwadorf, K.; Breuer, J.; Schütze, W.; Fangmeier, A. Effects of free-air CO2 enrichment on energy traits and seed quality of oilseed rape. Agric. Ecosyst. Environ. 2010, 139, 239–344. [Google Scholar] [CrossRef]

- Taub, D.R.; Miller, B.; Allen, H. Effects of elevated CO2 on the protein concentration of food crops: A meta-analysis. Glob. Chang. Biol. 2008, 14, 65–575. [Google Scholar] [CrossRef]

- Fangmeier, A.; Chrost, B.; Högy, P.; Krupinska, K. CO2 enrichment enhances flag leaf senescence in barley due to greater grain nitrogen sink capacity. Environ. Exp. Bot. 2000, 44, 151–164. [Google Scholar] [CrossRef]

- Morgan, P.B.; Bollero, G.A.; Nelson, R.L.; Dohleman, F.G.; Long, S.P. Smaller than predicted increase in aboveground net primary production and yield of field-grown soybean under fully open-air [CO2] elevation. Glob. Chang. Biol. 2005, 11, 1856–1865. [Google Scholar] [CrossRef]

- Clausen, S.K.; Frenck, G.; Linden, L.G.; Mikkelsen, T.N.; Lunde, C.; Jørgensen, R.B. Effects of single and multifactor treatment with elevated temperature, CO2 and ozone on oilseed rape and barley. J. Agron. Crop Sci. 2011, 197, 442–453. [Google Scholar] [CrossRef]

- Rio Declaration. 1992. Rio Declaration on Environment and Development. Principle 16. Available online: https://www.jus.uio.no/lm/environmental.development.rio.declaration.1992/16.html (accessed on 14 August 2018).

- Nonhebel, S. Global food supply and the impacts of increased biofuels. Energy 2012, 37, 115–121. [Google Scholar] [CrossRef]

- Qaderi, M.M.; Reid, D.M. Crop Responses to Elevate Carbon Dioxide and Temperature; Singh, S.N., Ed.; Chapter 1 in: Climatic Change and Crops, Environmental Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1–17. [Google Scholar]

- Booker, F.; Muntifering, R.; McGrath, M.; Burkey, K.; Decoteau, D.; Fiscus, E.; Manning, W.; Krupa, S.; Chappelka, A.; Grantz, D. The ozone component of global change: Potential effects on agricultural and horticultural plant yield, product quality and interactions with invasive species. J. Integr. Plant Biol. 2009, 51, 337–351. [Google Scholar] [CrossRef] [PubMed]

- Plevin, R.J.; O’Hara, M.; Jones, A.D.; Torn, M.S.; Gibbs, H.K. Greenhouse Gas Emissions from Biofuels’ Indirect Land Use Change Are Uncertain but May Be Much Greater than Previously Estimated. Environ. Sci. Technol. 2010, 44, 8015–8021. [Google Scholar] [CrossRef] [PubMed]

- Khanna, M.; Crago, C.L. Measuring Indirect Land Use Change with Biofuels: Implications for Policy. Annu. Rev. Resour. Econ. 2012, 4, 161–184. [Google Scholar] [CrossRef]

- Sanchez, S.T.; Woods, J.; Akhurst, M.; Brander, M.; O’Hara, M.; Dawson, T.P.; Edwards, R.; Liska, A.J.; Malpas, R. Accounting for indirect land-use change in the life cycle assessment of biofuel supply chains. J. R. Soc. Interface 2012, 9, 1105–1119. [Google Scholar] [CrossRef] [PubMed]

- Dijkman, T.J.; Birkved, M.; Saxe, H.; Wenzel, H. Environmental impacts of barley cultivation under current and future climatic conditions. J. Clean. Prod. 2017, 140, 644–653. [Google Scholar] [CrossRef]

- Kløverpris, J. Consequential Life Cycle Inventory Modelling of Land Use Induced by Crop Consumption. Ph.D. Thesis, DTU Management Engineering, Lyngby, Denmark, November 2008. Updated Version 2010. Available online: http://orbit.dtu.dk/en/publications/consequential-life-cycle-inventory-modelling-of-land-use-induced-by-crop-consumption%286457fc93-c53a-4beb-83ff-015c8047b682%29.html (accessed on 14 August 2018).

- Jungbluth, N.; Dinkel, F.; Doka, G.; Chudacoff, M.; Dauriat, A.; Gnansounou, E.; Sutter, J.; Spielmann, M.; Kljun, N.; Keller, M. Life Cycle Inventory of Bioenergy. Data v2.0. Ecoinvent Report no. 17. Swiss Centre for Life Cycle Inventories. A Joint Initiative of the ETH Domain and Swiss Federal Offices, Ulster, Switzerland. Available online: https://www.researchgate.net/profile/Niels_Jungbluth/publication/230725648_Life_Cycle_Inventories_of_Bioenergy_ecoinvent_report_No_17/links/0c96051b76e2fb8dce000000/Life-Cycle-Inventories-of-Bioenergy-ecoinvent-report-No-17.pdf (accessed on 14 August 2018).

- Schmidt, J.H.; Christensen, P.; Christensen, T.S. Assessing the land use implications of biodiesel use from an LCA perspective. J. Land Use Sci. 2009, 4, 35–52. [Google Scholar] [CrossRef]

- Nemecek, T.; Kägi, T. Life Cycle Inventory of Agricultural Production Systems. Data ver. 2.0. Ecoinvent Report no. 15. Agroscope Reckenholz-Tänikon Research Station ART, Zürich and Dübendorf, Switzerland. Available online: https://db.ecoinvent.org/reports/15_Agriculture.pdf (accessed on 14 August 2018).

- Miyagi, K.-M.; Kinugasa, T.; Hikosaka, K.; Hirose, T. Elevated CO2 concentration, nitrogen use, and seed production in annual plants. Glob. Chang. Biol. 2007, 13, 2161–2170. [Google Scholar] [CrossRef]

- Buckley, T.N. The role of stomatal acclimation in modelling tree adaptation to high CO2. J. Exp. Bot. 2008, 59, 1951–1961. [Google Scholar] [CrossRef] [PubMed]

- Attavanich, W.; McCarl, B.A. The effect of climate change, CO2 fertilization, and crop production technology on crop yields and its economic implications on market outcomes and welfare distribution. In Proceedings of the Agricultural & Applied Economics Association’s 2001 AAEA & NAREA Joint Annual Meeting, Pittsburgh, PA, USA, 24–26 July 2011. [Google Scholar]

- Sprague, G.F.; Duncan, W.G.; Kommedahl, T.; BeMiller, J.N. Corn. In AccessScience, ®McGraw-Hill Companies. 2008. Available online: https://www.accessscience.com/content/corn/162600 (accessed on 14 August 2018).

- Cederberg, C.; Flysjö, A. Environmental Assessment of Future Pig Farming Systems–Quantification of Three Scenarios from the FOOD 21 Synthesis Work. SIK Rapport nr. 723. SIK, Sweden. 2004. Available online: http://www.vaxteko.nu/html/sll/institutet_livsm_bioteknik/sik-rapport/SIK723/SIK723.PDF (accessed on 14 August 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).