The Role of Manufacturing in Sustainable Economic Development: A Case of Guangzhou, China

Abstract

1. Introduction

2. Literature Review: Sustainable Economic Development and Manufacturing in World Cities

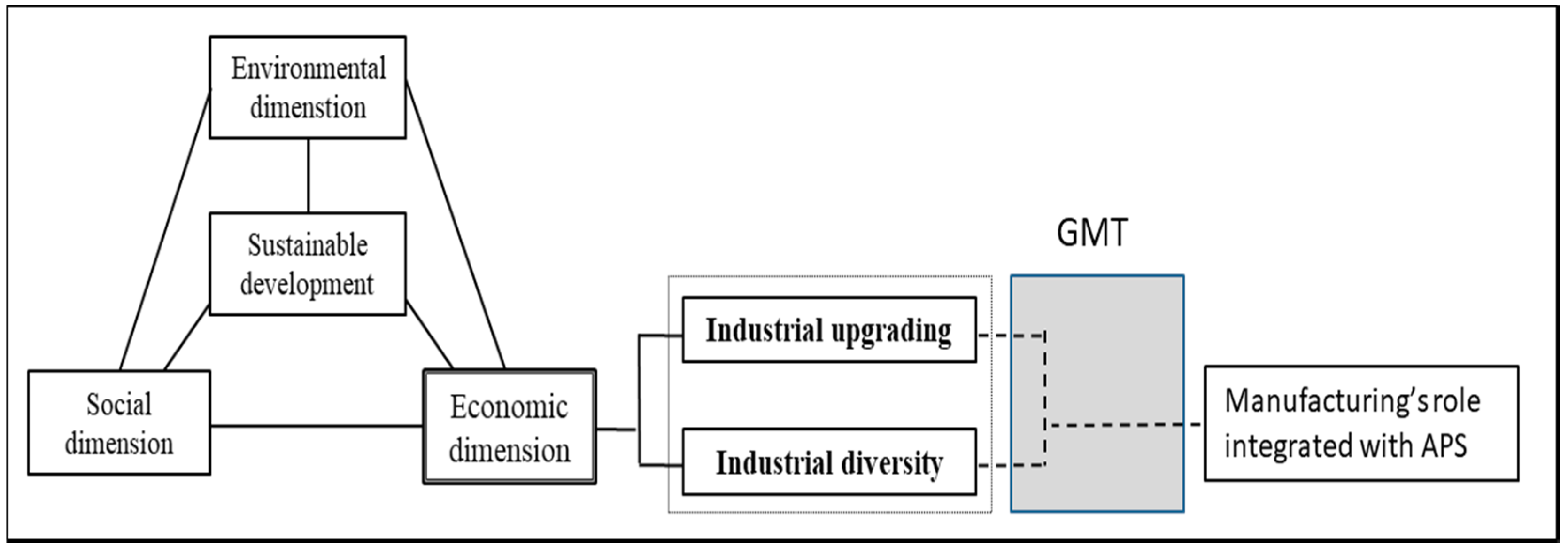

2.1. Sustainable Economic Development and Industrial Development

2.2. Manufacturing in World Cities

3. Methodology and Study Area

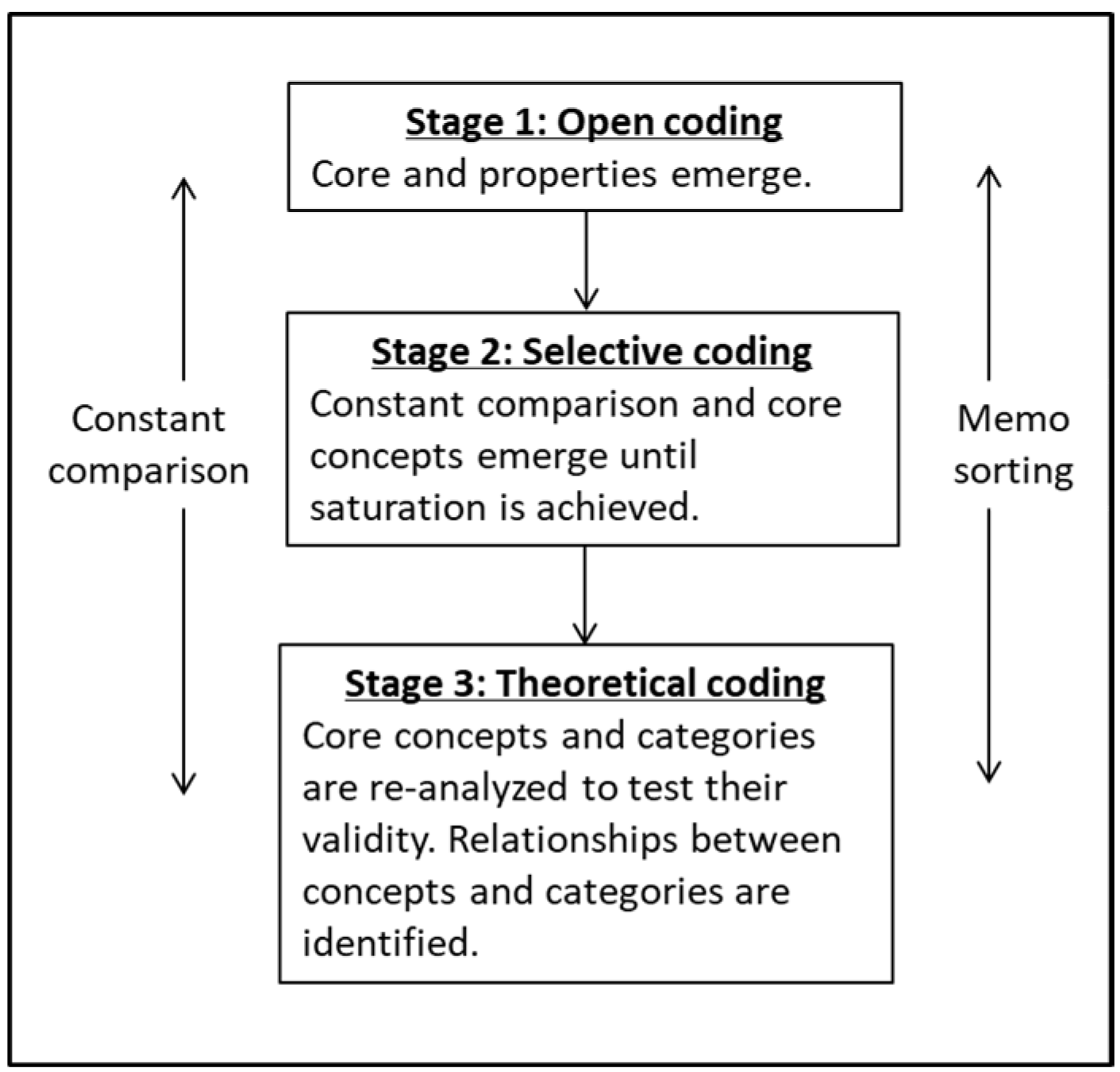

3.1. Methodology

3.1.1. GTM Data Collection

- (1)

- General information about the company: history, activities, etc.

- (2)

- Information on production: products, trends, factors diving the evolution.

- (3)

- Information on advanced producer service outsourcing: nature, partnership, goals, factors influencing cooperation, etc.

- (4)

- Information on collaboration with other industrial actors and local governments

3.1.2. GTM Data Analysis

- (1)

- Incentives for industrial interaction

- (2)

- Process of industrial interaction

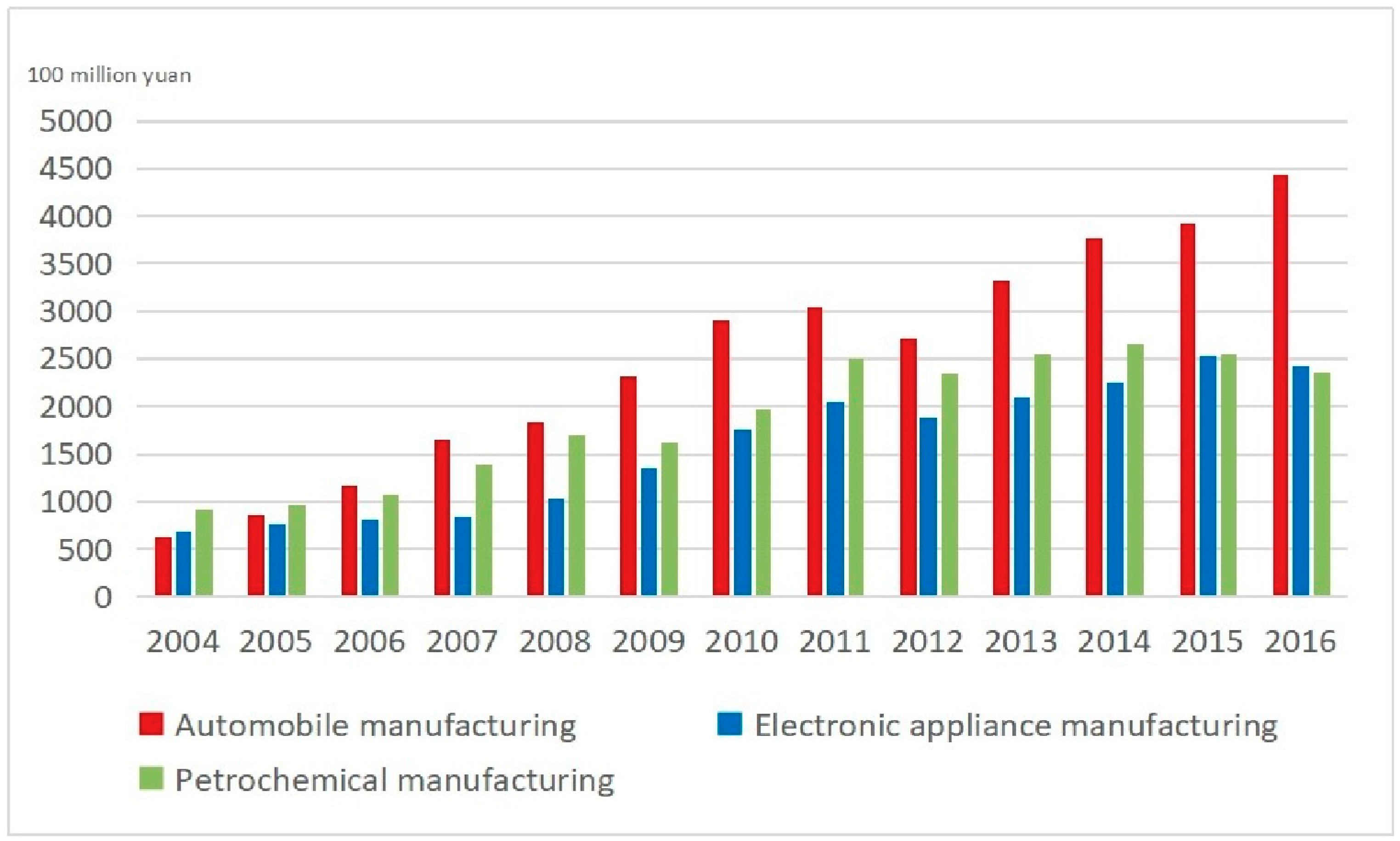

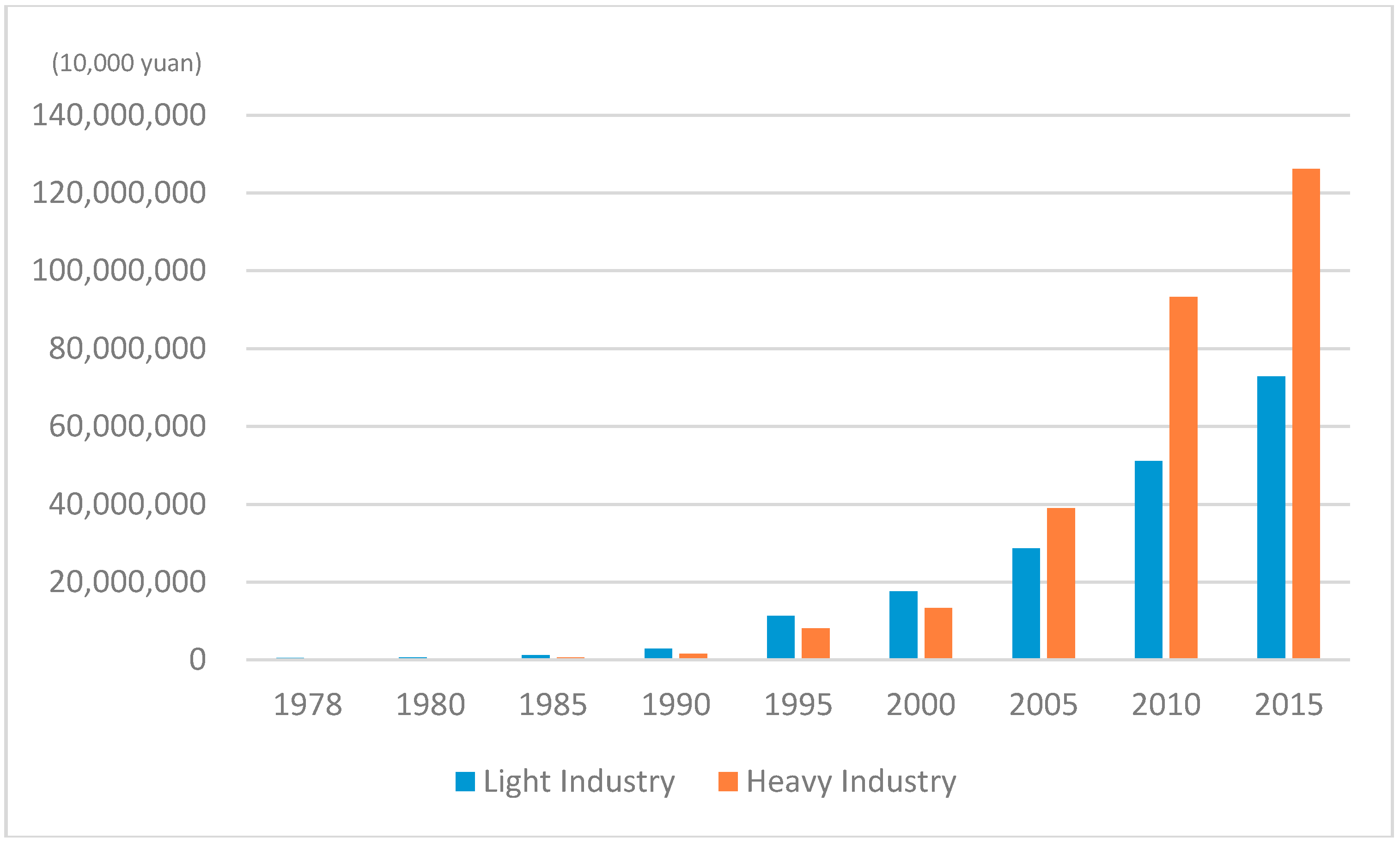

3.2. Study Area

4. Results

4.1. Mechanism for Industrial Upgrading from the Perspective of Manufacturing Development Incentive for Advanced Producer Service Development

4.2. Process of Industrial Diversity Integrated Manufacturing Development with Advanced Producer Service Development

5. Discussions and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| No. | Interview Outline for Automobile Manufacturers |

| 1 | What is your company’s status in the industry in Guangzhou? |

| 2 | What are your company’s advantageous competitions in the national and global market? |

| 3 | What’s your attitude towards the relationship between production and sustainable economic development? |

| 4 | What kinds of factors would influence the upgrading of industrial technique? Please provide two or more examples and briefly describe them. |

| 5 | What kinds of advanced producer services would you prefer to outsource? Why? Please provide two or more examples and briefly describe them. |

| 6 | Do you change your service partners? Why? Please provide two or more examples and briefly describe them. |

| 7 | What kinds of factors would influence your decision on service partners? Please provide two or more examples and briefly describe them. |

| 8 | What kinds of collaborations would you operate with other industrial actors? Any on economic sustainability? Please provide two or more examples and briefly describe them. |

| No. | Interview Outline for Advanced Producer Services |

| 1 | What is your company’s status in the industry in Guangzhou? |

| 2 | What are your company’s advantageous competitions in the national and global market? |

| 3 | What’s your attitude towards the relationship between service and sustainable economic development? |

| 4 | What kinds of factors would influence the upgrading of service technique? Please provide two or more examples and briefly describe them. |

| 5 | How would you interact with automobile manufacturers? Please provide two or more examples and briefly describe them. |

| 6 | How often would you interact with automobile manufacturers? Why? Please provide two or more examples and briefly describe them. |

| 7 | What kinds of factors would influence your service with manufactures? Please provide two or more examples and briefly describe them. |

| 8 | What kinds of collaborations would you operate with other industrial actors? Any on economic sustainability? Please provide two or more examples and briefly describe them. |

Appendix B

Appendix C

| Categories | Concepts | Codes |

|---|---|---|

| Incentive for industrial interaction | Demand for production expansion | Increase of production output |

| Increase of product sales | ||

| Expansion of assembly line | ||

| Advances in production technique | ||

| Requirement for market competition | Competitiveness for service during production | |

| Competitiveness for after-sales service | ||

| Competitiveness for production technique | ||

| Localization strategy | Multichannel integration into the local market | |

| Diversified products for various levels of consumers | ||

| Localization of spare part providers | ||

| Outsource of advanced producer services | ||

| Process of industrial interaction | Competitive selection | Scale threshold |

| Technical threshold | ||

| Cost factor | ||

| Regular evaluation | ||

| Irregular inspections | ||

| Strategic partnership | Sign long-term contracts | |

| Sign strategic cooperation memorandum | ||

| Joint research and development | ||

| Joint-venture investments | Capital investments with joint-venture services | |

| Technique investments with joint-venture services | ||

| Sole investment in subsidiary services | ||

| Proximity effect | Regular meetings held in factory | |

| Close contact | ||

| Adjacent guidance |

References

- The 17 Sustainable Development Goals (SDGs) of the 2030 Agenda for Sustainable Development; Commission on Sustainable Development: New York, NY, USA, 2016.

- Indicators of Sustainable Development: Guidelines and Methodologies; Commission on Sustainable Development: New York, NY, USA, 2001.

- Terama, E.; Milligan, B.; Jimenez-Aybar, R.; Mace, G.M.; Ekins, P. Accounting for the environment as an economic asset: Global progress and realizing the 2030 agenda for sustainable development. Sustain. Sci. 2016, 11, 945–950. [Google Scholar] [CrossRef]

- Cohen, M. A systematic review of urban sustainability assessment literature. Sustainability 2017, 9, 2048. [Google Scholar] [CrossRef]

- Strezov, V.; Evans, A.; Evans, T.J. Assessment of the economic, social and environmental dimensions of the indicators for sustainable development. Sustain. Dev. 2017, 25, 242–253. [Google Scholar] [CrossRef]

- Can, U.; Alatas, B. Big social network data and sustainable economic development. Sustainability 2017, 9, 2027. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, Y.; Ma, S.; Huang, K.; Liu, Y.; Liang, Y.; Ma, S.; Huang, K. Divergent developmental trajectories and strategic coupling in the pearl river delta: Where is a sustainable way of regional economic growth? Sustainability 2017, 9, 1782. [Google Scholar] [CrossRef]

- Bandyopadhyay, S. Evaluating sustainable economic development. Clean Technol. Environ. Policy 2017, 19, 1815–1816. [Google Scholar] [CrossRef]

- Friedmann, J. The world city hypothesis. Dev. Chang. 1986, 17, 69–83. [Google Scholar] [CrossRef]

- Friedmann, J.; Wolff, G. World city formation: An agenda for research and action. Int. J. Urban Reg. Res. 1982, 6, 309–344. [Google Scholar] [CrossRef]

- Sassen, S. Global financial centers. Foreign Aff. 1999, 78, 75–87. [Google Scholar] [CrossRef]

- Sassen, S. The Global City: New York, London, Tokyo; Princeton University Press: Princeton, NJ, USA, 2013; pp. 501–502. [Google Scholar]

- Li, Z.Y.; Dawood, S.R.S.; Zhang, X.X. An appraisal of Asia-Pacific cities as control and command centres embedded in world city network. Eng. Technol. Appl. Sci. Res. 2017, 7, 1879–1882. [Google Scholar]

- Neal, Z. Differentiating centrality and power in the world city network. Urban Stud. 2011, 48, 2733–2748. [Google Scholar] [CrossRef]

- Castells, M. Rise of the Network Society; Blackwell Publishers: Hoboken, NJ, USA, 2000; pp. 389–414. [Google Scholar]

- Liu, X.; Derudder, B.; Wu, K. Measuring polycentric urban development in China: An intercity transportation network perspective. Reg. Stud. 2016, 50, 1302–1315. [Google Scholar] [CrossRef]

- Li, Y.; Phelps, N. Megalopolis unbound: Knowledge collaboration and functional polycentricity within and beyond the Yangtze River delta region in China, 2014. Urban Stud. 2018, 55, 443–460. [Google Scholar] [CrossRef]

- Zhao, M.; Derudder, B.; Huang, J. Examining the transition processes in the Pearl River delta polycentric Mega-City region through the lens of corporate networks. Cities 2017, 60, 147–155. [Google Scholar] [CrossRef]

- Zhang, X.; Kloosterman, R.C. Connecting the “Workshop of the World”: Intra- and extra-service networks of the Pearl River delta City-Region. Reg. Stud. 2016, 50, 1069–1081. [Google Scholar] [CrossRef]

- Krätke, S. How manufacturing industries connect cities across the world: Extending research on ‘multiple globalizations’. Glob. Netw. 2014, 14, 121–147. [Google Scholar] [CrossRef]

- Martinus, K.; Tonts, M. Powering the world city system: Energy industry networks and interurban connectivity. Environ. Plan. A 2015, 47, 1502–1520. [Google Scholar] [CrossRef]

- Lin, G. Toward a post-socialist city? Economic tertiarization and urban reformation in the Guangzhou metropolis, China. Eurasian Geogr. Econ. 2004, 45, 18–44. [Google Scholar] [CrossRef]

- Jiang, H.Y.; Yang, Q.S. Analysis on the importance of manufacturing industries in the process of urban economic transition: Taking Guangzhou as an example. Econ. Geogr. 2012, 8, 012. [Google Scholar] [CrossRef]

- Dandan, D.; Chunshan, Z. Study on the characteristics of the industrial transformation of Guangzhou since 1995. Econ. Geogr. 2012, 11, 81–88. [Google Scholar] [CrossRef]

- Guangzhou Burenu of Statistics. Guangzhou Statistical Yearbook 2016; China Statistics Press: Beijing, China, 2016. (In Chinese)

- Glaser, B.G.; Strauss, A.L. The Discovery of Grounded Theroy: Strategies for Qualitative Research; Aldine: Chicago, IL, USA, 1967. [Google Scholar]

- Ness, B.; Urbel-Piirsalu, E.; Anderberg, S.; Olsson, L. Categorising tools for sustainability assessment. Ecol. Econ. 2007, 60, 498–508. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, X.; Dong, C.; Wen, S. Economic performance and emission reduction of supply chains in different power structures: Perspective of sustainable investment. Energies 2018, 11, 983. [Google Scholar] [CrossRef]

- Shi, X.; Qian, Y.; Dong, C. Economic and environmental performance of fashion supply chain: The joint effect of power structure and sustainable investment. Sustainability 2017, 9, 961. [Google Scholar] [CrossRef]

- Kesharwani, R.; Sun, Z.Y.; Dagli, C. Biofuel supply chain optimal design considering economic, environmental, and societal aspects towards sustainability. Int. J. Energy Res. 2018, 42, 2169–2198. [Google Scholar] [CrossRef]

- Stamford, L.; Greening, B.; Azapagic, A. Life cycle environmental and economic sustainability of stirling engine micro-CHP systems. Energy Technol. 2018, 6, 1119–1138. [Google Scholar] [CrossRef]

- Wang, S.S.; Li, R.R. Toward the coordinated sustainable development of urban water resource use and economic growth: An empirical analysis of Tianjin City, China. Sustainability 2018, 10, 13. [Google Scholar] [CrossRef]

- Stougie, L.; Giustozzi, N.; Van Der Kooi, H.; Stoppato, A. Environmental, economic and exergetic sustainability assessment of power generation from fossil and renewable energy sources. Int. J. Energy Res. 2018, 42, 2916–2926. [Google Scholar] [CrossRef]

- Sarker, S.; Bhuyan, M.A.H.; Rahman, M.M.; Islam, M.A.; Hossain, M.S.; Basak, S.C.; Islam, M.M. From science to action: Exploring the potentials of blue economy for enhancing economic sustainability in Bangladesh. Ocean Coast. Manag. 2018, 157, 180–192. [Google Scholar] [CrossRef]

- Lo, A.Y.; Liu, S.W. Towards sustainable consumption: A socio-economic analysis of household waste recycling outcomes in Hong Kong. J. Environ. Manag. 2018, 214, 416–425. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wang, L.; Dai, S.F. An Indicator approach to industrial sustainability assessment: The case of China’s capital economic circle. J. Clean Prod. 2018, 194, 473–482. [Google Scholar] [CrossRef]

- Rumyantsev, A.A. Research and innovation activity in the region as a driver of its sustainable economic development. Econ. Soc. Chang. Facts Trends Forecast 2018, 11, 84–99. [Google Scholar] [CrossRef]

- Luken, R.; Castellanos-Silveria, F. Industrial transformation and sustainable development in developing countries. Sustain. Dev. 2011, 19, 167–175. [Google Scholar] [CrossRef]

- Yun, J.J.; Jung, K.; Yigitcanlar, T. Open innovation of James watt and Steve jobs: Insights for sustainability of economic growth. Sustainability 2018, 10, 16. [Google Scholar] [CrossRef]

- Hameed, T.; Von Staden, P.; Kwon, K.S. Sustainable economic growth and the adaptability of a national system of innovation: A socio-cognitive explanation for South Korea’s mired technology transfer and commercialization process. Sustainability 2018, 10, 26. [Google Scholar] [CrossRef]

- Meng, B.; Chi, G.T. Evalution index system of green industry based on maximum information content. Singap. Econ. Rev. 2018, 63, 229–248. [Google Scholar] [CrossRef]

- Shao, S.A.; Luan, R.R.; Yang, Z.B.; Li, C.Y. Does directed technological change get greener: Empirical evidence from Shanghai’s industrial green development transformation. Ecol. Indic. 2016, 69, 758–770. [Google Scholar] [CrossRef]

- Liu, G.Y.; Hao, Y.; Zhou, Y.; Yang, Z.F.; Zhang, Y.; Su, M.R. China’s low-carbon industrial transformation assessment based on logarithmic mean divisia index model. Resour. Conserv. Recycl. 2016, 108, 156–170. [Google Scholar] [CrossRef]

- Fu, J.P.; Xiao, G.R.; Guo, L.L.; Wu, C.Y. Measuring the dynamic efficiency of regional industrial green transformation in China. Sustainability 2018, 10, 19. [Google Scholar] [CrossRef]

- Zhou, X.Y.; Lei, K.; Meng, W.; Khu, S.T. Industrial structural upgrading and spatial optimization based on water environment carrying capacity. J. Clean Prod. 2017, 165, 1462–1472. [Google Scholar] [CrossRef]

- Gu, J.J.; Guo, P.; Huang, G.H.; Shen, N. Optimization of the industrial structure facing sustainable development in resource-based city subjected to water resources under uncertainty. Stoch. Environ. Res. Risk Assess. 2013, 27, 659–673. [Google Scholar] [CrossRef]

- Chiang, S.-H. The effects of industrial diversification on regional unemployment in Taiwan: Is the portfolio theory applicable? Ann. Reg. Sci. 2009, 43, 947–962. [Google Scholar] [CrossRef]

- Mizuno, K.; Mizutani, F.; Nakayama, N. Industrial diversity and metropolitan unemployment rate. Ann. Reg. Sci. 2006, 40, 157–172. [Google Scholar] [CrossRef]

- Izraeli, O.; Murphy, K.J. The effect of industrial diversity on state unemployment rate and per capita income. Ann. Reg. Sci. 2003, 37, 1–14. [Google Scholar] [CrossRef]

- Malizia, E.E.; Ke, S. The influence of economic diversity on unemployment and employment stability. J. Reg. Sci. 1993, 33, 221–235. [Google Scholar] [CrossRef]

- Kort, J.R. Regional economic instability and industrial diversification in the U.S. Land Econ. 1981, 57, 596–608. [Google Scholar] [CrossRef]

- Rodgers, A. Some aspects of industrial diversification in the United States. Econ. Geogr. 1957, 33, 16–30. [Google Scholar] [CrossRef]

- Geng, Y.; Cote, R. Diversity in industrial ecosystems. Int. J. Sustain. Dev. World Ecol. 2007, 14, 329–335. [Google Scholar] [CrossRef]

- Brown, L.; Greenbaum, R.T. The role of industrial diversity in economic resilience: An empirical examination across 35 years. Urban Stud. 2017, 54, 1347–1366. [Google Scholar] [CrossRef]

- Fornahl, D.; Guenther, C. Persistence and change of regional industrial activities: The impact of diversification in the German machine tool industry. Eur. Plan. Stud. 2010, 18, 1911–1936. [Google Scholar] [CrossRef]

- Meerow, S.; Newell, J.P. Resilience and complexity a bibliometric review and prospects for industrial ecology. J. Ind. Ecol. 2015, 19, 236–251. [Google Scholar] [CrossRef]

- Siegel, P.B.; Johnson, T.G.; Alwang, J. Regional economic diversity and diversification. Growth Chang. 1995, 26, 261–284. [Google Scholar] [CrossRef]

- Ernst, D. Catching-up crisis and industrial upgrading: Evolutionary aspects of technological learning in Korea’s electronics industry. Asia Pac. J. Manag. 1998, 15, 247–283. [Google Scholar] [CrossRef]

- Chen, L.C.; Chien, S.S. Industrial Upgrading and interaction between the advanced small south and China: The case of Taiwan’s machine tool industry. Area Dev. Policy 2017, 2, 91–107. [Google Scholar] [CrossRef]

- Park, S.H.; Chan, K.S. A cross-country input-output analysis of intersectoral relationships between manufacturing and services and their employment implications. World Dev. 1989, 17, 199–212. [Google Scholar] [CrossRef]

- Hansen, N. Do producer services induce regional economic development? J. Reg. Sci. 1990, 30, 465–476. [Google Scholar] [CrossRef]

- Rodriguez, N.P.; Feagin, J.R. Urban specialization in the world-system an investigation of historical cases. Urban Aff. Rev. 1986, 22, 187–220. [Google Scholar] [CrossRef]

- Lughod, J.L.A. New York, Chicago, Los Angeles; University of Minnesota Press: Minneapolis, MN, USA, 1999. [Google Scholar]

- Hill, R.C.; Kim, J.W. Global cities and developmental states: New York, Tokyo and Seoul. Urban Stud. 2000, 37, 2167–2195. [Google Scholar] [CrossRef]

- Fujita, K.; Hill, R.C. Global toyotaism and local development. Int. J. Urban Reg. Res. 1995, 19, 7–22. [Google Scholar] [CrossRef]

- Wang, C.H. Taipei as a global city: A theoretical and empirical examination. Urban Stud. 2003, 40, 309–334. [Google Scholar] [CrossRef]

- Olds, K.; Yeung, H. Pathways to global city formation: A view from the developmental city-state of Singapore. Rev. Int. Polit. Econ. 2004, 11, 489–521. [Google Scholar] [CrossRef]

- Krätke, S. Global pharmaceutical and biotechnology firms’ linkages in the world city network. Urban Stud. 2014, 51, 1196–1213. [Google Scholar] [CrossRef]

- Chubarov, I.; Brooker, D. Multiple pathways to global city formation: A Functional approach and review of recent evidence in China. Cities 2013, 35, 181–189. [Google Scholar] [CrossRef]

- Shi, Y.; Hamnett, C. The Potential and prospect for global cities in China: In The context of the world system. Geoforum 2002, 33, 121–135. [Google Scholar] [CrossRef]

- Wu, F. The global and local dimensions of place-making: Remaking Shanghai as a world city. Urban Stud. 2000, 37, 1359–1377. [Google Scholar] [CrossRef]

- Tao, Z. Hong Kong: From an industrialised city to a centre of manufacturing-related services. Urban Stud. 2002, 39, 2345–2358. [Google Scholar] [CrossRef]

- Yusuf, S.; Wu, W. Pathways to a world city: Shanghai rising in an era of globalisation. Urban Stud. 2002, 39, 1213–1240. [Google Scholar] [CrossRef]

- Lia, Z.; Wu, F. Socioeconomic transformations in Shanghai (1990–2000): Policy impacts in global–national–local contexts. Cities 2006, 23, 250–268. [Google Scholar] [CrossRef]

- Wei, Y.D.; Yu, D.D.U.E. State policy and the globalization of Beijing: Emerging themes. Habitat Int. 2006, 30, 377–395. [Google Scholar] [CrossRef]

- Strauss, A.; Corbin, J.M. Basics of qualitative research: Grounded theory procedures and techniques. Mod. Lang. J. 2006, 77, 129. [Google Scholar] [CrossRef]

- Stumpf, T.S.; Sandstrom, J.; Swanger, N. Bridging the gap: Grounded theory method, theory development, and sustainable tourism research. J. Sustain. Tour. 2016, 24, 1691–1708. [Google Scholar] [CrossRef]

- Wuelser, G.; Pohl, C. How researchers frame scientific contributions to sustainable development: A typology based on grounded theory. Sustain. Sci. 2016, 11, 789–800. [Google Scholar] [CrossRef]

- Corbin, J.M.; Strauss, A.L. Basics of Qualitative Research: Techniques and Procedures For Developing Grounded Theory; Sage: London, UK, 1998; p. 129. [Google Scholar]

- Charmaz, K. Constructing Grounded Theory: A Practical Guide through Qualitative Analysis; Sage Publications Ltd.: London, UK, 2006. [Google Scholar]

- Charmaz, K. Constructivist grounded theory. J. Posit. Psychol. 2017, 12, 299–300. [Google Scholar] [CrossRef]

- Allen, N.; Davey, M. The value of constructivist grounded theory for built environment researchers. J. Plan. Educ. Res. 2018, 38, 222–232. [Google Scholar] [CrossRef]

- O’connor, K. Global city regions and the location of logistics activity. J. Transp. Geogr. 2010, 18, 354–362. [Google Scholar] [CrossRef]

- Taylor, P.J. Specification of the world city network. Geogr. Anal. 2001, 33, 181–194. [Google Scholar] [CrossRef]

- Charmaz, K. The legacy of anselm strauss in constructivist grounded theory. In Studies in Symbolic Interaction; Denzin, N.K., Salvo, J., Washington, M., Eds.; Emerald Group Publishing Limited: Bingley, UK, 2008; Volume 32, pp. 127–141. [Google Scholar]

- Jones, M.; Alony, I. Guiding the use of grounded theory in doctoral studies—An example from the Australian film industry. Int. J. Dr. Stud. 2011, 6, 95–114. [Google Scholar] [CrossRef]

- Xu, J.; Yeh, A.G.O. Guangzhou. Cities 2003, 20, 361–374. [Google Scholar] [CrossRef]

- Cheng, D.; Daniels, P.W. What’s so special about China’s producer services? An input–output analysis. China World Econ. 2014, 22, 103–120. [Google Scholar] [CrossRef]

- Crescenzi, R.; Pietrobelli, C.; Rabellotti, R. Regional strategic assets and the location strategies of emerging countries’ multinationals in Europe. Eur. Plan. Stud. 2016, 24, 645–667. [Google Scholar] [CrossRef]

- Fernando, L.; Evans, S. Case studies in transformation towards industrial sustainability. Int. J. Knowl. Syst. Sci. 2015, 6, 1–17. [Google Scholar] [CrossRef]

| Unit | Senior Manager | Director | Section Chief | Project Leader | Total |

|---|---|---|---|---|---|

| Manufacturers | 4 | 6 | 4 | 0 | 14 |

| Related advanced producer service | 0 | 10 | 6 | 4 | 20 |

| Industry Association | 0 | 0 | 0 | 5 | 5 |

| Government | 0 | 0 | 7 | 0 | 7 |

| Total | 4 | 16 | 17 | 9 | 46 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Xue, D.; Huang, X. The Role of Manufacturing in Sustainable Economic Development: A Case of Guangzhou, China. Sustainability 2018, 10, 3039. https://doi.org/10.3390/su10093039

Li W, Xue D, Huang X. The Role of Manufacturing in Sustainable Economic Development: A Case of Guangzhou, China. Sustainability. 2018; 10(9):3039. https://doi.org/10.3390/su10093039

Chicago/Turabian StyleLi, Wei, Desheng Xue, and Xu Huang. 2018. "The Role of Manufacturing in Sustainable Economic Development: A Case of Guangzhou, China" Sustainability 10, no. 9: 3039. https://doi.org/10.3390/su10093039

APA StyleLi, W., Xue, D., & Huang, X. (2018). The Role of Manufacturing in Sustainable Economic Development: A Case of Guangzhou, China. Sustainability, 10(9), 3039. https://doi.org/10.3390/su10093039