1. Introduction

Sustainability, which is regarded as a universal challenge for industrial sectors, calls for comprehensive action towards the employment of sustainable strategies [

1]. These strategies are aimed at enhancing the environmental, economic, and social factors of business processes and products to support stakeholders in making the right choices and best decisions [

2]. They promise an increase in both tangible and intangible benefits to firms due to several reasons: acceleration in the time taken for the products to reach the market, reduction of regulatory constraints, increase in consumer demands, decrease in manufacturing costs and liabilities, improvements in employee health and safety, and increase in the value-added delivery of the products to consumers [

3].

However, many manufacturers are not concerned with the sustainability aspect of their products, especially the increasing environmental impacts brought about by industrial activities. As much as 75% of the material resources used in products and their manufacturing processes are disposed in the environment as waste within a year [

4]. Furthermore, the development of industrial activities has contributed to an increase in global greenhouse gas (GHG) emissions. According to Reference [

5], 65% of GHG emissions are caused by industrial processes and the use of fossil fuels. Moreover, the quantity of generated e-waste globally was around 41.8 million tonnes in 2014 [

6]. This figure will continue to rise along with human productivity and technological innovations. Based on Reference [

7], up to 90% of the world’s e-waste is illegally traded or dumped each year.

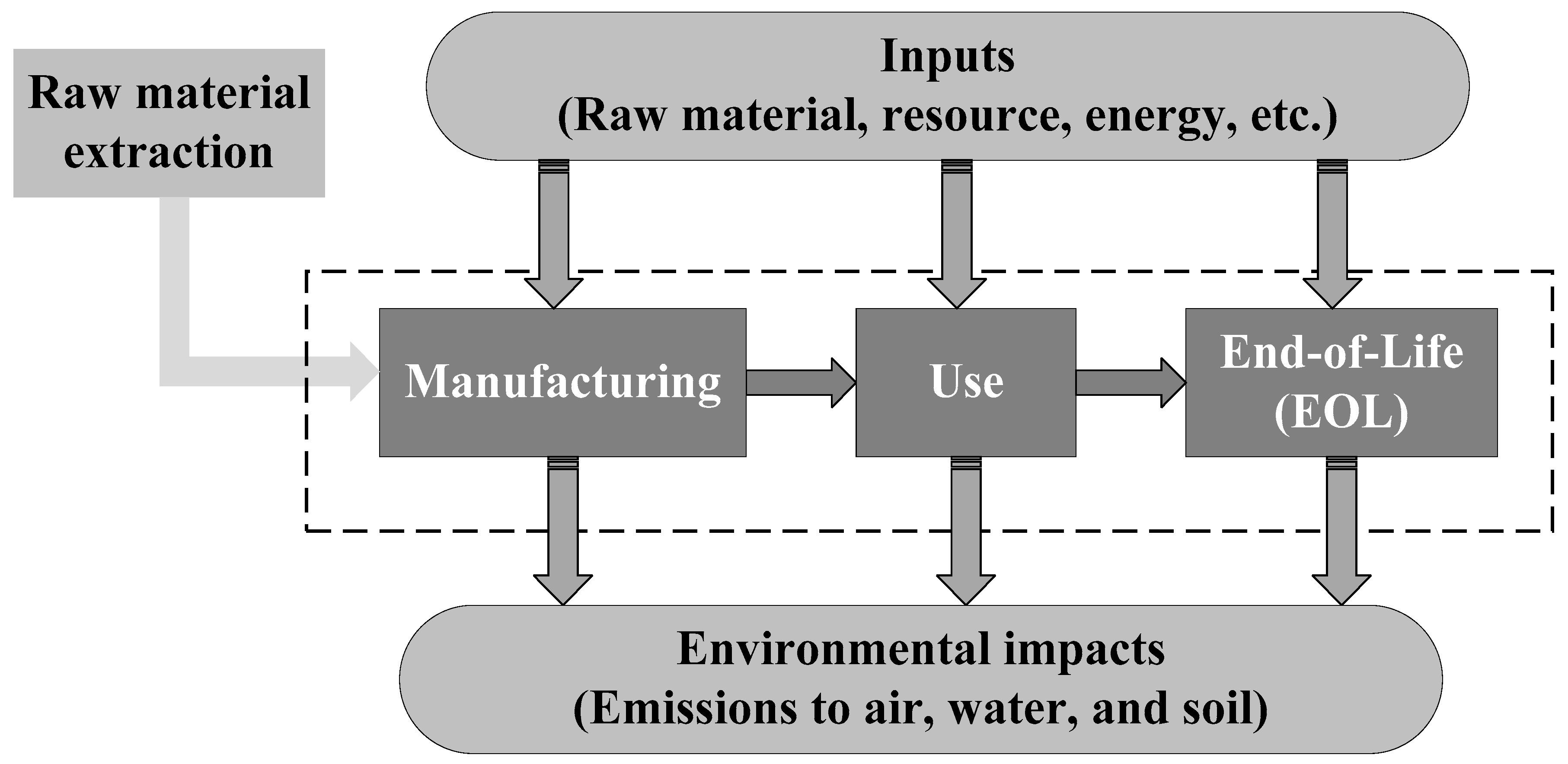

The above conditions must first be addressed by evaluating the environmental performance of products. To date, a systematic assessment tool which has the potential to deal with the problem is the Life Cycle Assessment (LCA). The LCA is a quantitative approach to evaluate the environmental impacts of products based on international standards, i.e., the International Standards Organisation (ISO) [

8]. It has been adopted by a number of corporations and non-profit organisations as a support tool to achieve several purposes, such as strategic planning, product design improvement, and marketing [

8,

9].

The LCA is a useful tool for the promotion of environmentally-conscious products. It has been studied and implemented extensively by many researchers [

10,

11,

12,

13,

14]. From the LCA results, many stakeholders will be able to identify opportunities for improvements and to determine the appropriate sustainable strategies. The LCA emphasises environmental impacts assessments which occur at all stages of the life cycle of a product, as shown in

Figure 1.

When it comes to sustainability, how a product ends its life is just as critical as how it is produced from the extraction of the raw materials, the manufacturing process, the distribution, and finally, its use. Therefore, the concept of 6Rs (Reduce, Reuse, Recycle, Recover, Redesign, and Remanufacture) was introduced to minimise the environmental burden of a product in the whole life cycle [

4]. This concept can be implemented in the early design stage, and it improves the product design, changing it from a “cradle-to-grave” to a “cradle-to-cradle” design. Its aim is to support a sustainable product design which is focused on post-use treatments.

Unfortunately, the LCA methodology still neglects the aspect of product design and development (PDD). Although PDD has an important role in maintaining the sustainable development of a product as a whole [

15,

16], the application of the LCA to PDD has not been critically addressed, and has been given little consideration in LCA researches [

17,

18]. Therefore, this paper proposed the use of LCA supported by a design efficiency evaluation to reduce the overall environmental impacts of a product. This concept is generally referred to as “eco-design”. Integrating eco-design into PDD offers several benefits to the industry and public organisations such as economic benefits, legislation fulfilment, public image improvement, and employee motivation enhancement [

19]. Eco-design must be integrated into the strategic planning and operational management to gain these advantages [

19].

The aim of this paper was to deploy the “redesign” concept based on the results of the LCA. Redesign refers to activities that are aimed at simplifying the existing design of a product to facilitate future post-use activities [

4]. Up to now, the application of the LCA results has been generally limited to improving a particular stage of a product, and the results have yet to be used to establish a more environmentally-conscious design.

In this study, a design efficiency evaluation was conducted based on the Design for Assembly (DFA) method which can also be called an assembly efficiency method [

20]. This method effectively analyses the ease of assembly and disassembly, identifies assembly problem areas, and recommends some alternative designs for simplifying the product structure. In the long term, the implementation of the DFA method can contribute to a reduction in manufacturing and assembly costs. When a product can be assembled and disassembled easily, the chances for it to be reused or recycled will increase, and further reductions in environmental impacts can be achieved.

In the rest of the paper,

Section 2 presents the literature review regarding the use of the life cycle technique and the principles for designing a product.

Section 3 explains the materials and methodology used in this study. To illustrate the methodology, a water leakage alarm (WLA) was selected as the object for a case study, which is extensively discussed in

Section 4 and

Section 5.

Section 4 explains the results of LCA study of the product, while

Section 5 presents the discussion of life cycle interpretation and design efficiency evaluation. Lastly,

Section 6 summarises the conclusions and contributions of the study, as well as recommendations for further researches.

2. Literature Review

The use of the life cycle technique to support PDD has attracted many researchers. In recent years, many studies have been undertaken to realise that objective [

21,

22,

23,

24,

25,

26,

27]. Case studies have been chosen by some researchers to present the chances for obtaining the first insight with detailed understanding into a particular field [

28]. Each case study contributes to a specific knowledge and practice. The selected object for a case study is considered to be able to illustrate the proposed methodology, and is also related to the problem of interest. For example, some researchers select electronic products as the objects for their case study in order to focus on improving the use and design of a product. On the other hand, when the problem of interest is focused on material and EOL design, some researchers tend to select polymer-based products.

As summarised in

Table 1, the review highlighted the main points which are important in developing a product design by incorporating it within the life cycle technique. Some researchers often use the life cycle technique and design principles separately. The Design for Disassembly (DFD), Design for Modularity (DFM), Design for Recycle (DFR), and Design for Environment (DFE) are among several methods that are often used to evaluate product designs. However, these approaches are still considered to be less satisfactory because a specific design principle usually only focuses on a specific problem. On the other hand, some researchers particularly use the life cycle technique to evaluate the environmental impacts of the products. The most commonly used life cycle technique is the LCA. This technique can help designers to analyse potential improvements to minimise the environmental impacts of products, establish new product designs, and compare a number of products [

29,

30]. However, this technique only focuses on the environmental aspects, while neglecting the others.

To overcome the limitations of the LCA, some researchers extended the conventional LCA. For example, the Life Cycle Reliability Assessment (LCRA) is a Bayesian model updating approach, which includes a reliability assessment for the development of new products [

31]. Also, the Life Cycle Design Assessment (LCDA) is an approach to product assessment that deals with technological changes and increasing volume using an axiomatic design theory [

32]. The Life Cycle Simulation (LCS) is also a method that was proposed to minimise environmental loads and resource consumption through simulation modelling [

33]. Even though these techniques are more advanced than the conventional LCA, researchers may face difficulties with the product architecture when it comes to improving the product design. To deal with that problem, some researchers have combined other life cycle techniques with some design principles. By integrating a specific life cycle technique and design principle, they have been able to develop a new product design with lower negative impacts across the life cycle.

Some researchers often use the LCA accompanied by the DFE. In practical terms, the DFE, coupled with a reasonable use of the LCA, is an effective tool for achieving a sustainable product design [

34]. Moreover, the DFE is also often paired with other life cycle techniques, such as the life cycle planning (LCP), life cycle design (LCD), and life cycle engineering (LCE) methods. Unlike the LCA, the LCP considers the whole life cycle of a product and fulfils customer satisfaction by establishing an eco-design product. The LCP, which is supported by a Quality Function Deployment (QFD) for the generation of customer requirements and an LCPlanner software to assess the environmental impacts [

35], is presented as a new approach for multigenerational product planning [

36]. Even though this method presents a comprehensive design concept, the software is difficult to access and the methodology has a limited environmental assessment. In addition, the Life Cycle Modelling for Design (LCMD) was also introduced by combining the LCA with a probabilistic design method to cope with the complexity of a product and various design options [

37]. Later on, a method which focused on a modular design and geometric modelling to differentiate the life cycle options was proposed by Umeda et al. [

25]. Furthermore, some researchers included other supporting methods to enhance their methodologies, such as the combination of the Fuzzy Analytic Hierarchy Process (FAHP) method and the LCD to evaluate product maintainability based on the product life cycle [

22] and the introduction of the Knowledge-based Approximate Life Cycle Assessment System (KALCAS) to improve environmental efficiency using artificial neural networks [

23]. However, the integration of specific methods is relatively complex and difficult to implement in other problems.

Since both the DFE and LCA are focused on the environmental aspect of a product, this integration method lacks the ability to capture other aspects of a product, such as operation time, cost and quality. To fill the gap in previous studies, this paper proposed a combination of the LCA technique with the DFA to improve the design of a product. This was also due to a few studies that combined the LCA and DFA to support the PDD. These methods of incorporation are expected to evaluate both the life cycle and design efficiency aspects.

Disassembly and reassembly are the most critical factors for improving the efficiency of the reuse or remanufacturing of products [

38]. The time taken for the disassembly process should be minimised using DFD guidelines, while the reassembly should refer to DFA guidelines. Mostly, a product which is designed to be easily assembled can also be easily disassembled [

39]. Kaebernick and Kara [

40] stated that the technical and economic problems of production can be reduced significantly if a product is properly designed for assembly and disassembly. DFA and DFD studies were conducted by several researchers such as Bevilacqua et al. [

9], Bogue [

41], Bras [

42], Go et al. [

43], and Kaebernick and Kara [

40]. Bevilacqua et al. [

9] discussed the Hitachi Group Eco-design Management Guidelines, which identified the environmental attributes of these requirements, such as energy efficiency, ease of disassembly and disposal, and the effects of these attributes. Bogue [

41] highlighted the importance of the DFD concept and identified the key DFD principles. Bras [

42] provided an overview of an industry, including a typical facility-level process, and discussed the qualitative design for remanufacturing guidelines, which also included the DFA and DFD. Go et al. [

43] presented a review of several disassembly methods and concluded that there was a need for an effective disassembly method in order to enhance the recovery of the products. Finally, Kaebernick and Kara [

40] discussed several disassembly processes in recycling and reusing technologies to reduce the production of new materials by bringing in used materials.

In summary, Otto and Wood [

39] divided the DFA guidelines into several categories: system design guidelines that reduce assembly, ease of handling of the required parts, ease of insertion of the parts during assembly, and ease of the actual attachment and joining methods. In this study, the implementation of these guidelines were enriched by the application of the DFA guidelines by Boothroyd et al. [

20]. The experiment on the DFA guidelines will be discussed in detail in

Section 5.

3. Materials and Methods

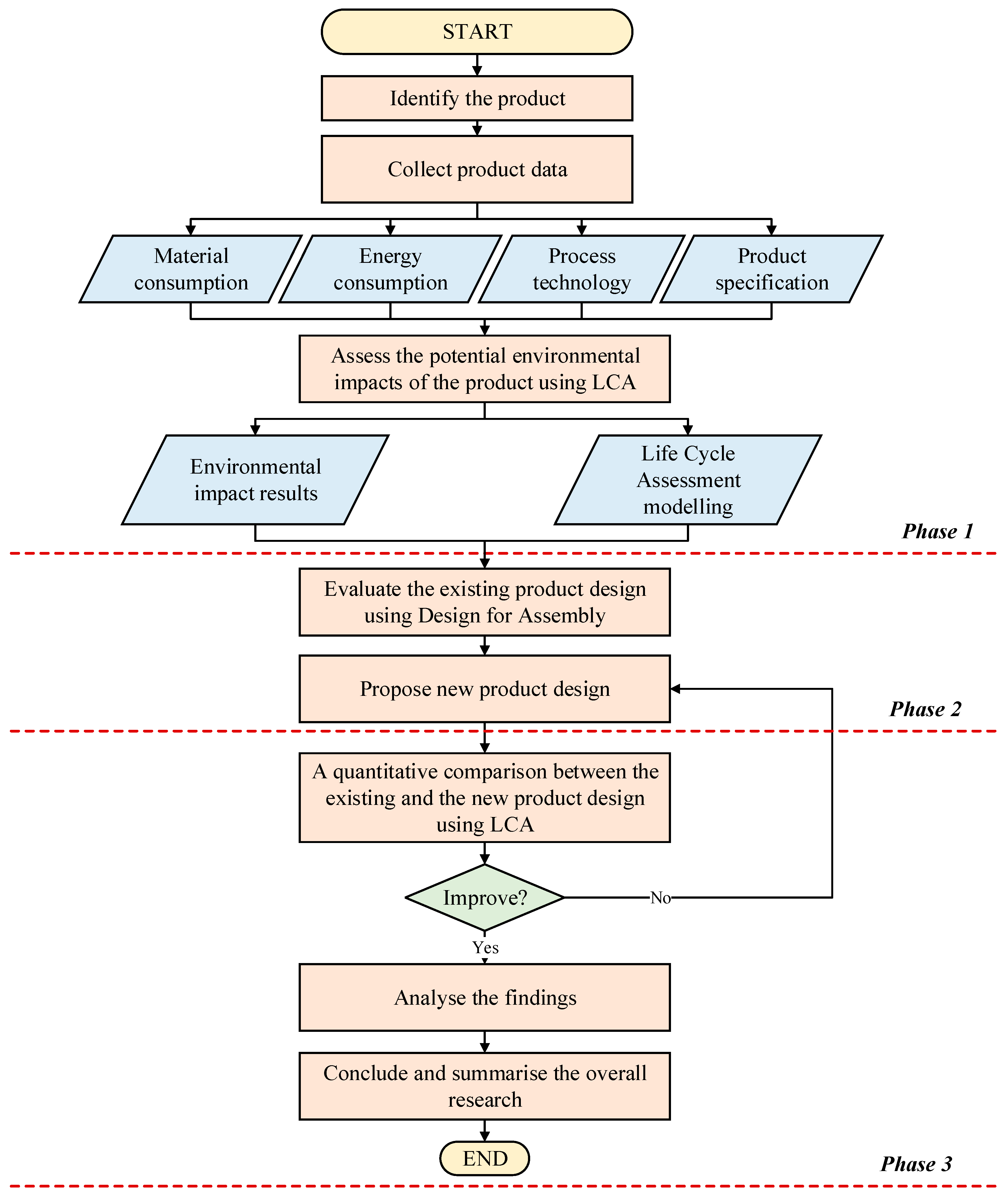

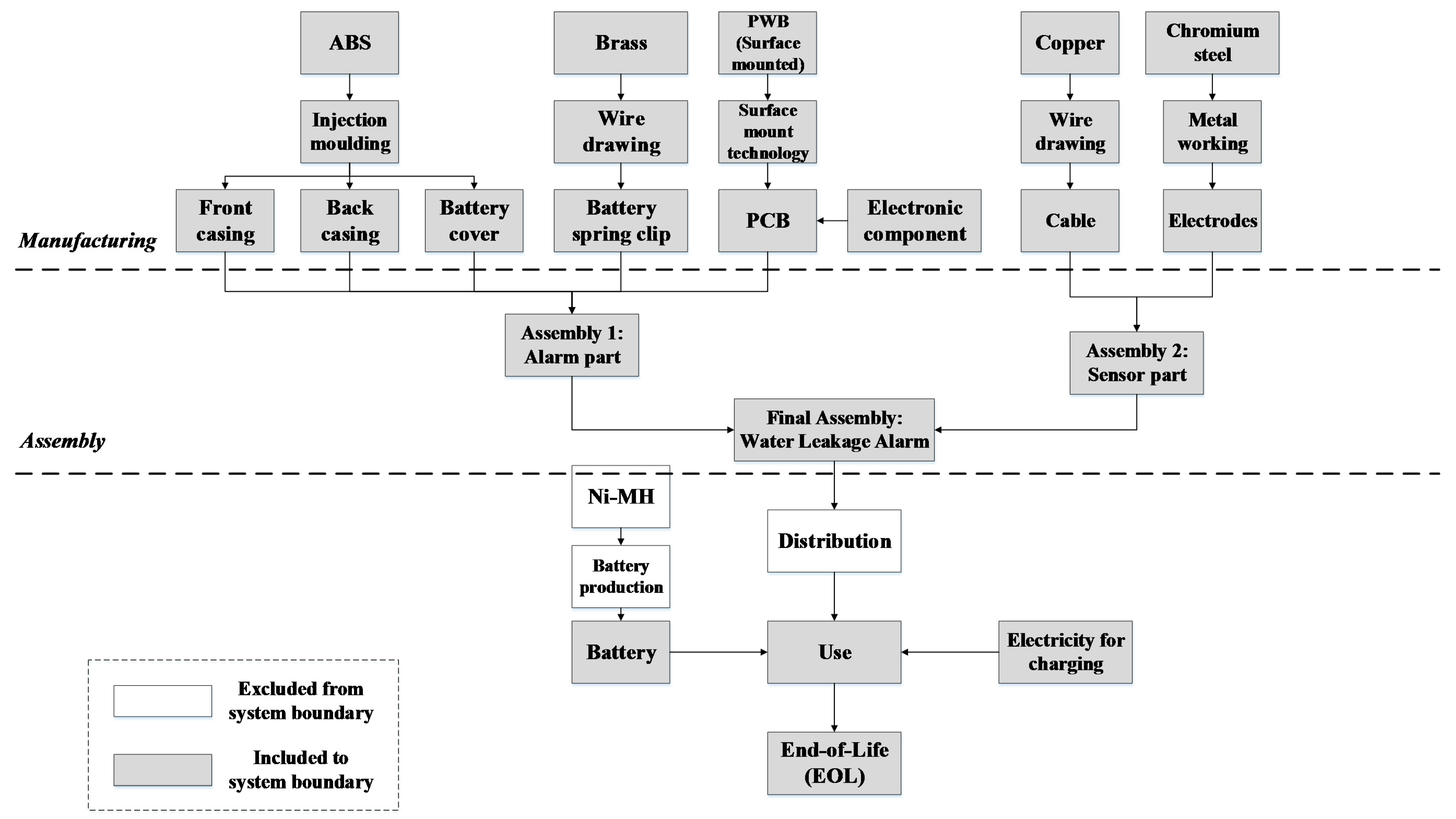

This research consists of three important phases. Each phase indicates the use of different methods or techniques which results in different outputs (see

Figure 2). Before conducting the LCA study, the first step was to identify the product system and the performance measurement. Data were collected from primary and secondary sources namely observation and literature, which includes material and energy consumption, the used process technology, and the product specification. Once data input was completed, the potential environmental impacts of the existing product were assessed according to the LCA framework.

As shown in

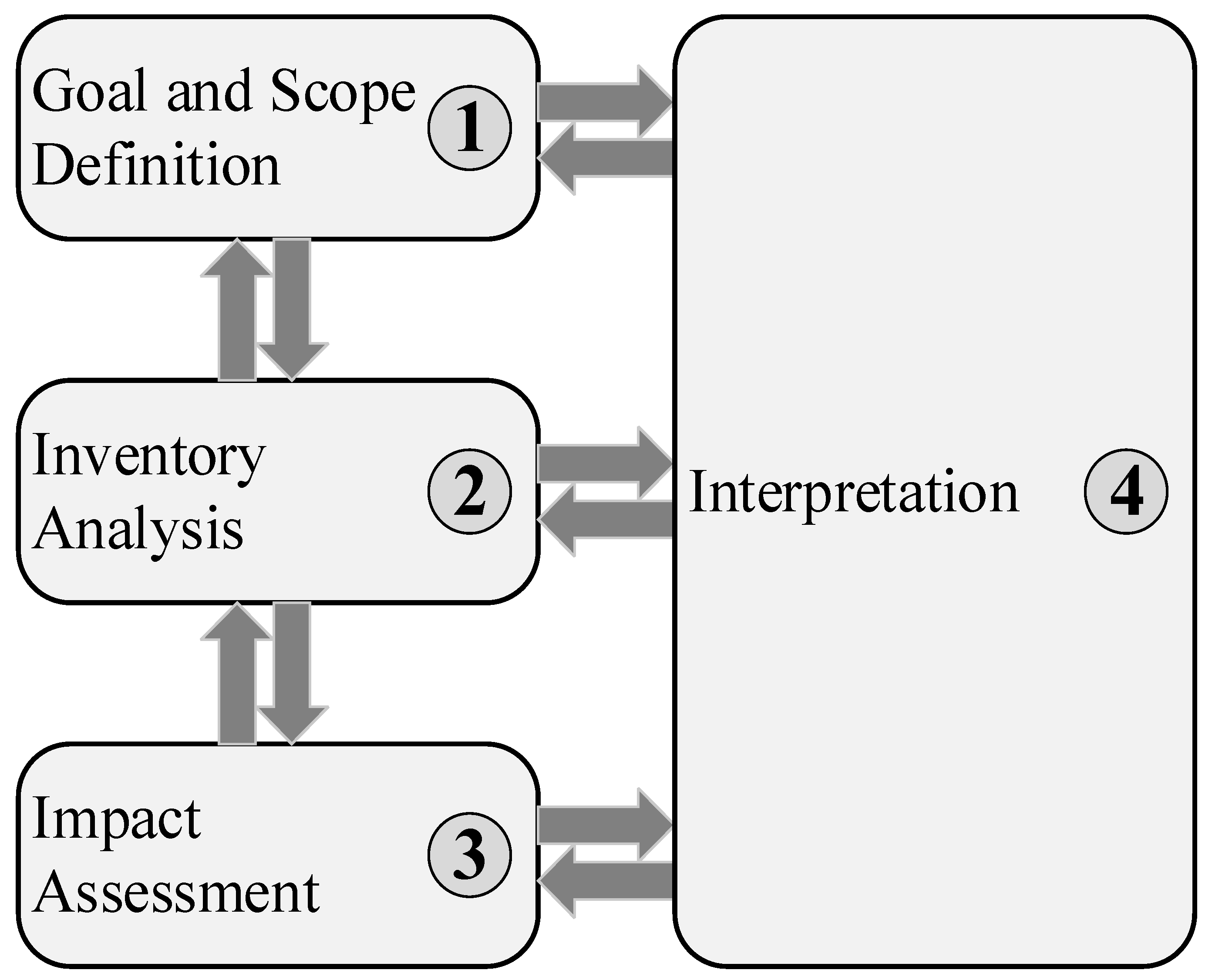

Figure 3, the LCA methodology consists of four steps, namely the definition of the goal and scope, inventory analysis or life cycle inventory (LCI), life cycle impact assessment (LCIA), and life cycle interpretation. In the goal and scope definition, the purpose and method of an LCA are defined clearly and unambiguously. It also provides an obvious description of the product system which consists of system boundaries and functional unit. The second step is LCI, which is the process of identifying and quantifying energy consumption and released emissions during the entire life cycle of a product. This phase compiles several data; such as the amount of energy, the consumption of material, and the quantity of emissions. The third step namely LCIA, is aimed at evaluating the environmental impacts of products based on LCI results within the given project scope and to determine the relative importance of each elementary flow within a given environmental problem. Finally, the last phase of LCA consists of the summary of LCI analysis and LCIA as a basis for conclusions, recommendations, and decision making in compliance with the goal and scope definition. This study used SimaPro Ph.D. version as the software to build the LCA model and to generate the results of the environmental impacts.

The second phase was to evaluate the design efficiency based on the DFA method. Since LCA only focuses on the environmental impacts of the product, this methodology usually neglects the design aspects of the product. Therefore, LCA and DFA were combined to assess both the aspects of environmental performance and product design. In redesigning the product, the guidelines from Boothroyd et al. [

20] were applied in order to establish a more environmentally-conscious product. Moreover, by implementing DFA, the cost and operation time of the new product design were expected to be reduced.

Finally, in the third phase, the existing design was compared to the new design quantitatively using LCA. From this phase, the environmental impacts of both designs can be compared and analysed to understand which design is more environmentally friendly. By combining LCA and design evaluation, a more comprehensive perspective of the product life cycle can be achieved so as to promote a sustainable product design.

The materials of the case example used in this study were identified based on a direct observation of the product in order to determine the used product materials and the processes involved, which are explained in detail in

Section 4.2. The LCA modelling process was performed using SimaPro software Ph.D. version which is integrated with the Ecoinvent database. This database contains all the inputs for making a product or service [

47].

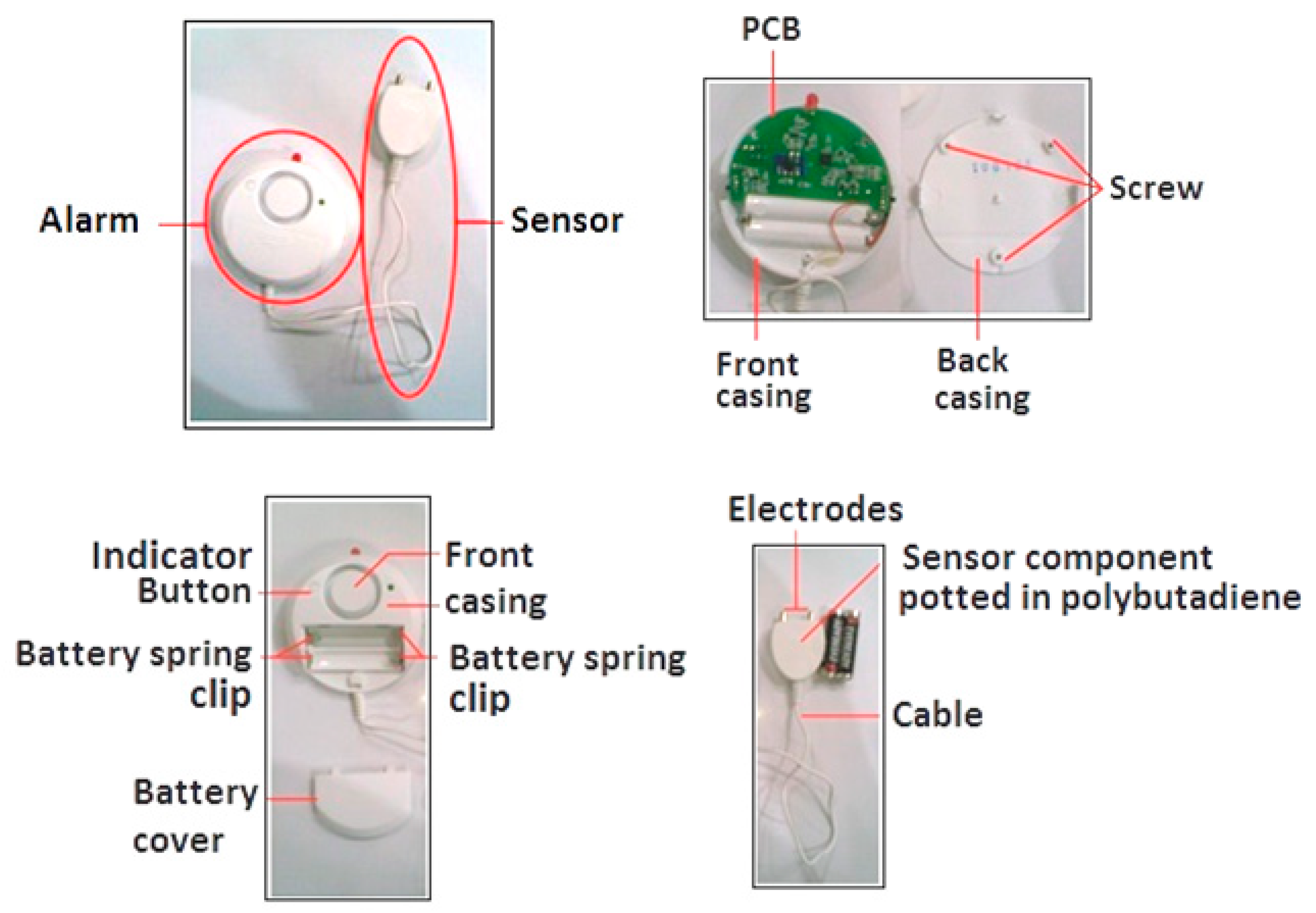

To illustrate the methodology, an electronic safety product, specifically a water leakage alarm (WLA), was chosen as the object for a case study (see

Figure 4). It consists of two main parts: an alarm and a sensor. This product functions as a detector of water leakage in bathrooms or water reservoirs. When a leak occurs, it will be detected by the sensor, which will alert the user through its sound. The alarm was selected for this study because it is frequently used in homes or public places (e.g., hotels, hospitals, etc.), and consumes electricity during its use-phase.

In this paper, the results of LCA are presented in

Section 4. Next, the DFA methodology and design improvements are discussed in detail in

Section 5. In

Section 6, several recommendations are proposed to improve the product design and to discuss the comparison between the existing product design product and the proposed new design. At the end of the paper, a general conclusion from the study and recommendations for future work are proposed.

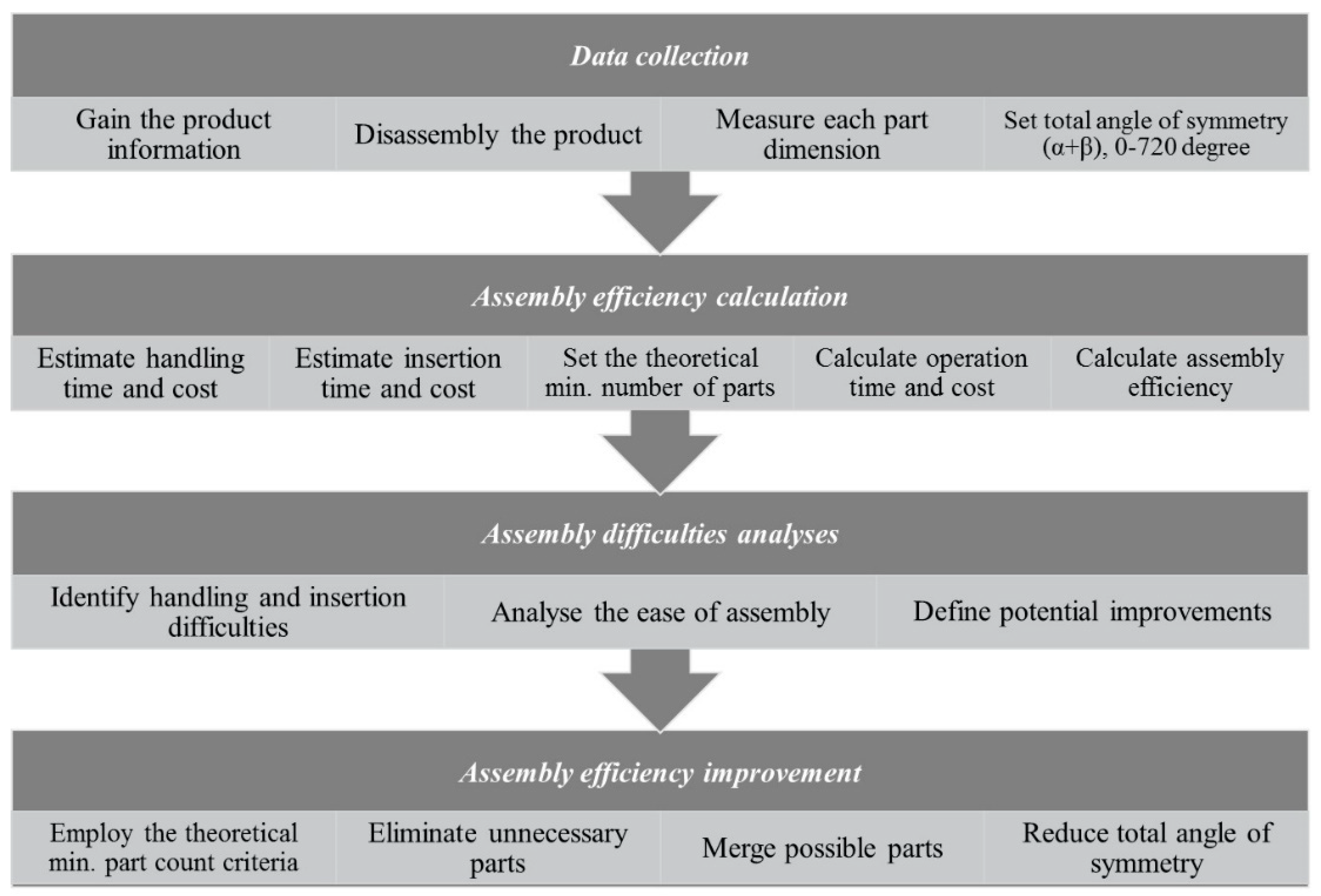

5. Results of Design Efficiency Evaluation

Design efficiency is an important aspect of a product in relation to design parameters [

53]. In the previous section, the life cycle aspect of the product was mainly discussed. Since the LCA process only captures the life cycle aspect, the improvement recommendations are still based on environmental concerns. Therefore, in this section, the design efficiency was evaluated to obtain more comprehensive improvements.

The major aim of design efficiency is to decrease the cost and lead time of a product, as well as to maintain its quality [

54]. The DFA by Boothroyd et al. [

20] was selected to ensure the consistency and completeness of the product assemblability evaluation. Usually, a product that is designed to be easily assembled can also be easily disassembled [

39]. When a product is easy to disassemble, the opportunity of the product to be recycled or reused will also increase. Even though the DFA is mainly focused on time and cost, this design tool indirectly makes a positive contribution to the environment. This is also supported by the principles of the DFA, such as to minimise the use of unnecessary parts and to reduce the use of fasteners, thereby leading to the reduced consumption of resources. As shown in

Figure 9, there are four steps to conducting a design efficiency evaluation. For the first step, as described in

Section 4.2, all the product information is collected. Then, a worksheet for calculating the design efficiency was prepared, as shown in

Table 9. The detailed calculation of design efficiency evaluation can be seen in

Appendix A,

Appendix B and

Appendix C. The next step is to analyse the ease of assembly, and finally, to improve the design efficiency based on the DFA principles. By implementing the steps of DFA evaluation, the design efficiency of the existing product was found to be 14%.

7. Conclusions

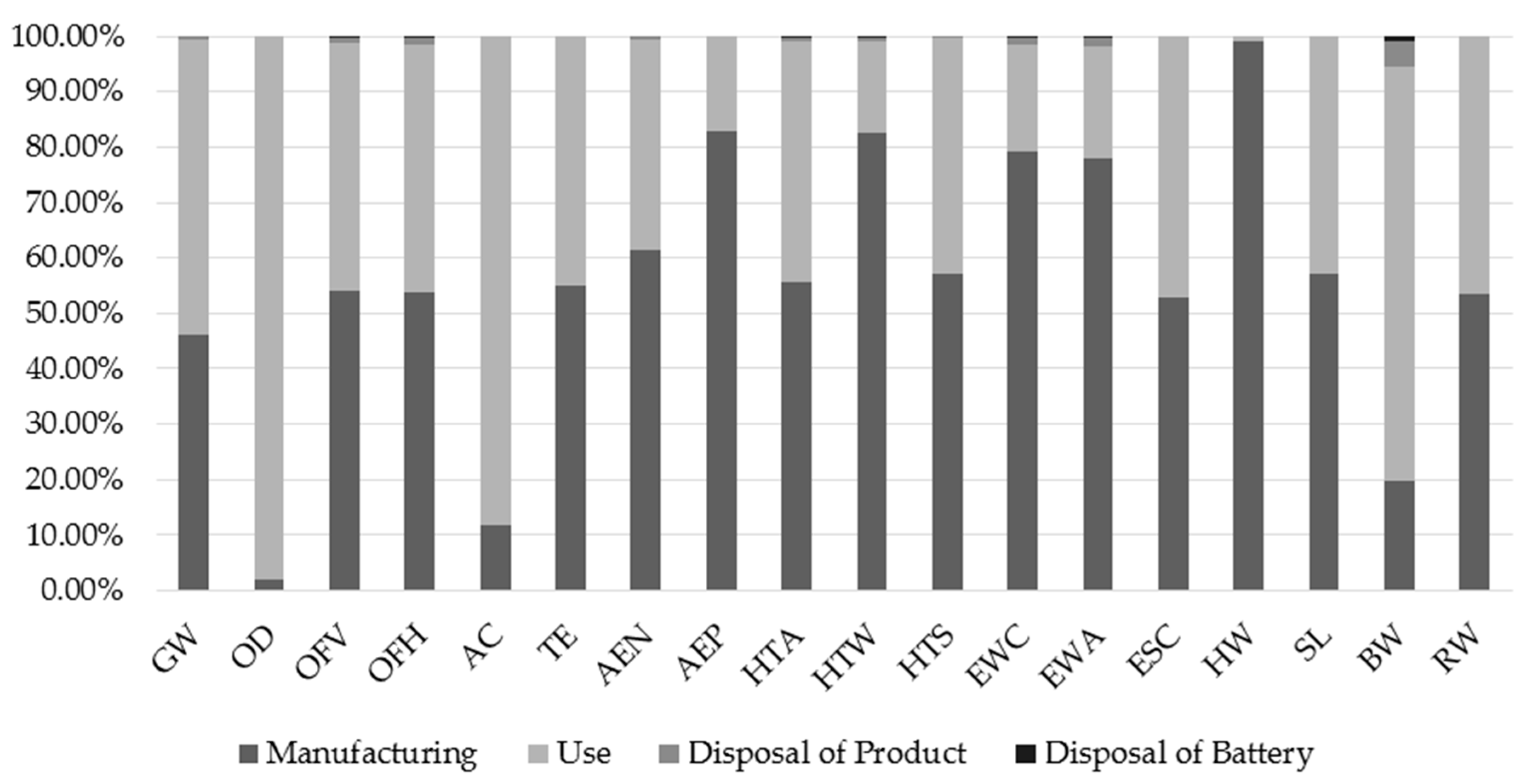

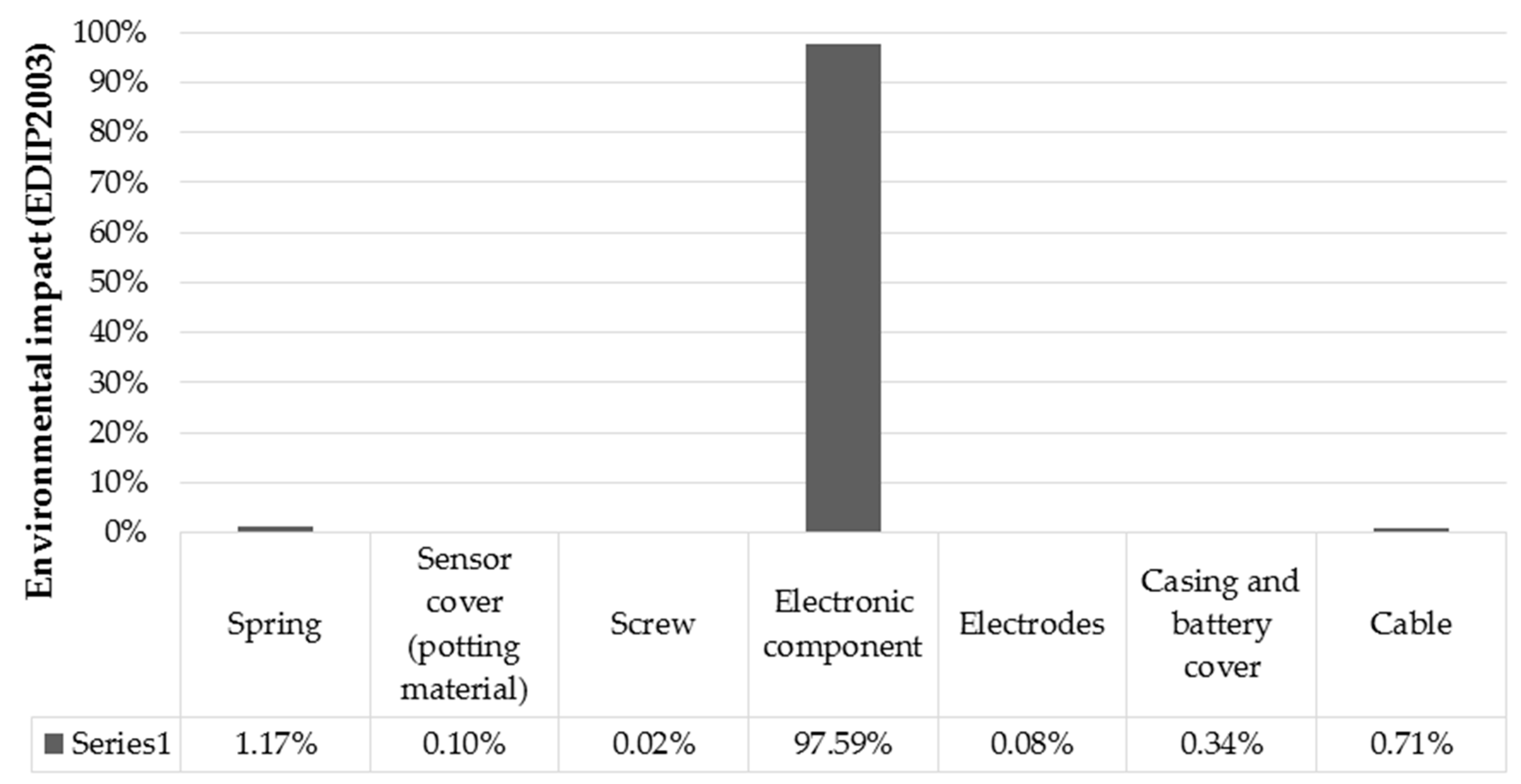

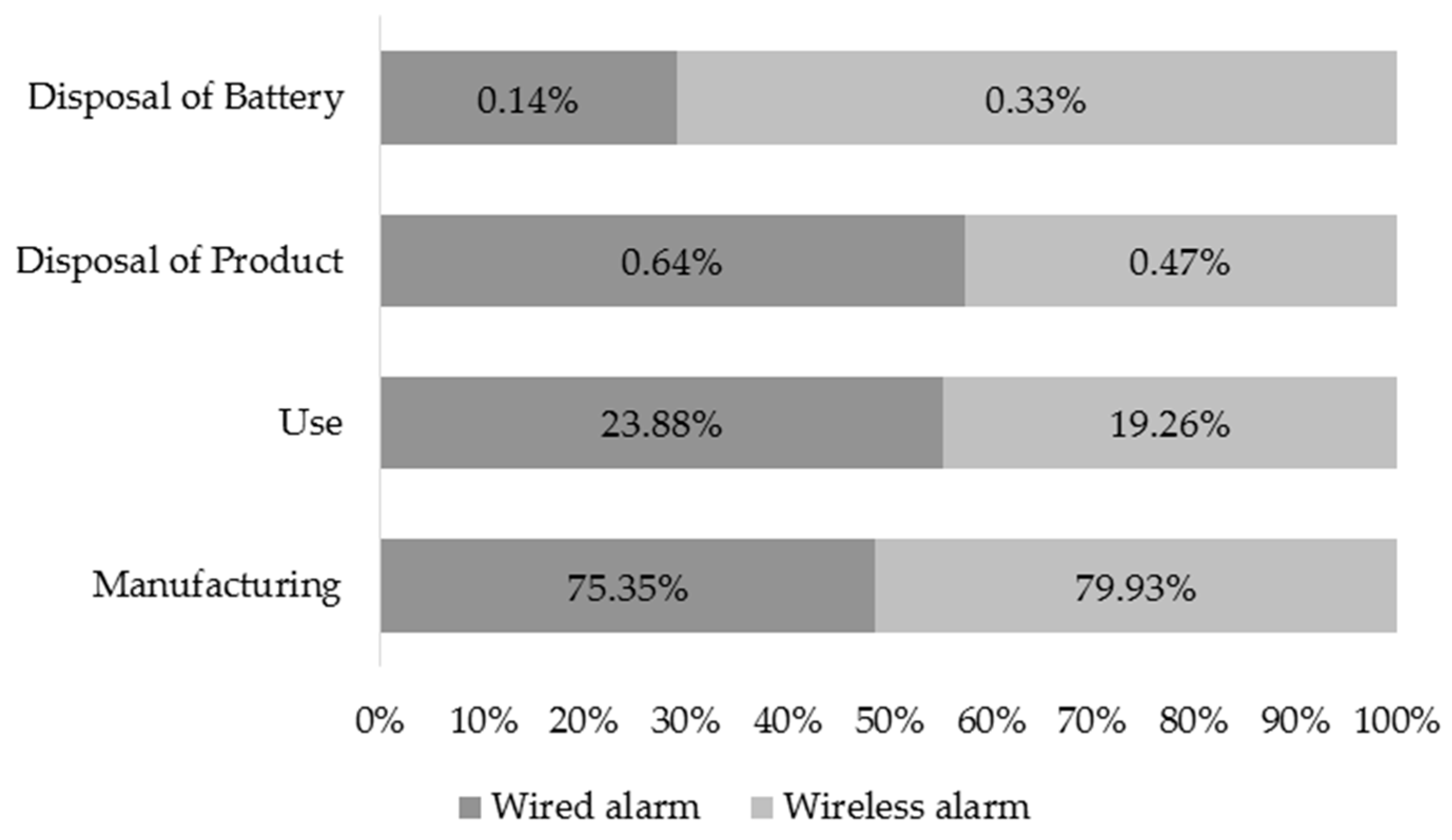

To answer the objective of this study, an LCA was performed on a water leakage alarm. It was found that 14 impact categories were dominated by the manufacturing stage, whereas the remaining categories were dominated by the use stage. On the other hand, the contributions of the WLA and battery disposal were less significant than the other categories.

Furthermore, since the purpose of this study was to integrate the LCA and DFA method, the next step was to evaluate the design efficiency of the product using the DFA guidelines. From the evaluation, the design efficiency of the existing product was found to be 14%. The two proposed improvements for redesigning the WLA were as follows: (1) To reduce the number of screws from three units to one unit, and (2) to eliminate the use of a cable and to replace it with a wireless component. The implementation of the two recommendations has improved the design efficiency by as much as 34%.

From the environmental perspective, there is not much difference between the wired alarm and wireless alarm. The wired alarm has a lower environmental impact during its manufacturing stage, however, the environmental impact is higher during its use stage. Contrarily, the production of wireless components results in higher environmental impacts than the production of general electronic components. This could be due to the complexity and limited knowledge on the production of new technology components leading to a more negative impact to the environment. However, based on the study, it was found that during the use stage, the wireless alarm requires less energy compared to the wired alarm. Generally, it can be concluded that the wired alarm has advantages in terms of the environmental impacts while the wireless alarm is superior in terms of design for assembly.

This paper contributes to the knowledge from the outlined literature review by providing insights into the development of the product design by using a life cycle technique. Moreover, this paper practically contributes towards the evaluation of environmental impacts and assembly time of the product. The combination of LCA and design evaluation provides a comprehensive perspective of the product life cycle. For further researches, more LCA studies focusing on detailed problems are required, such as PCB manufacturing, rubber recycling, and metal recycling. Also, a study on the trade-offs between the environmental and economic aspects of a wireless system could provide some useful findings for the product sustainability.