Where Do Our Resources Go? Indium, Neodymium, and Gold Flows Connected to the Use of Electronic Equipment in Switzerland

Abstract

1. Introduction

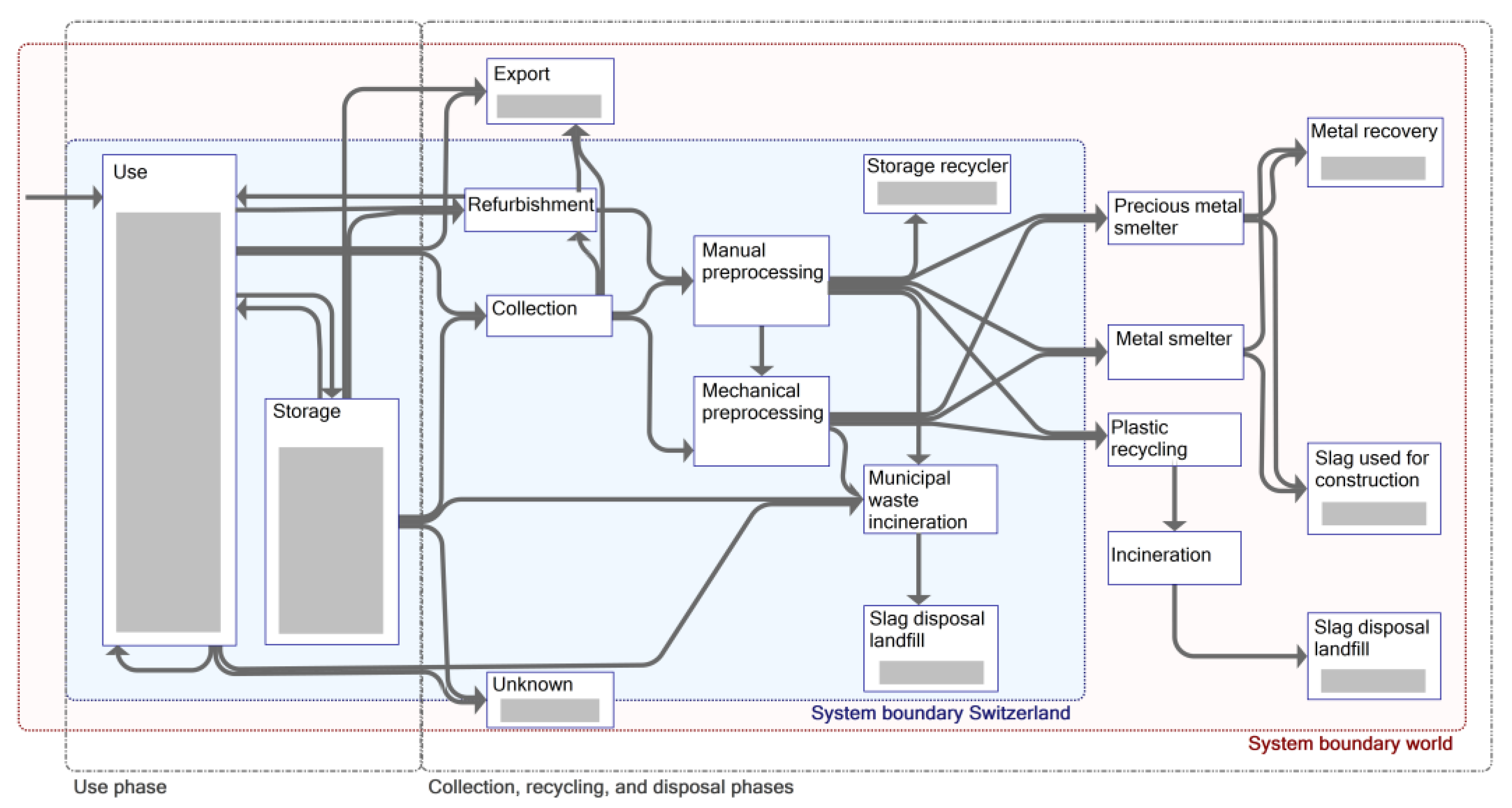

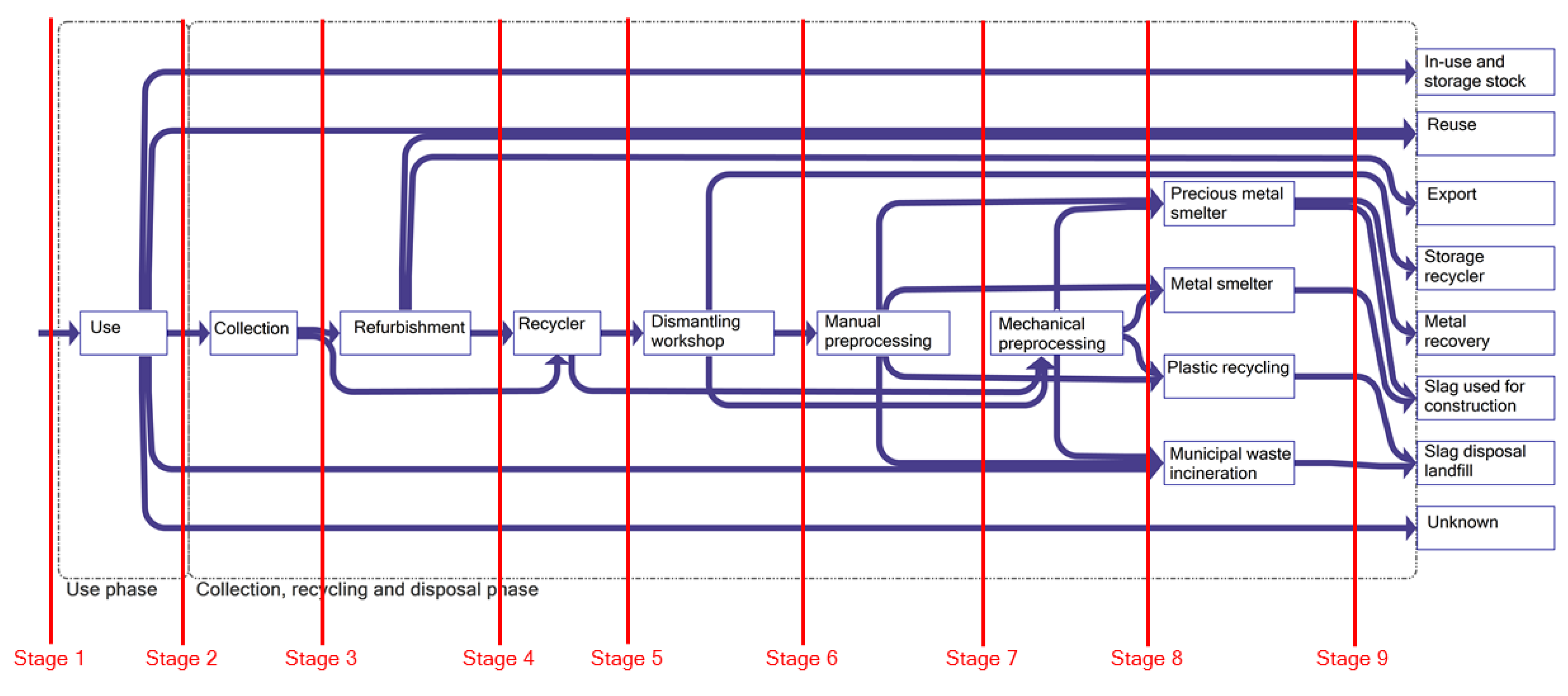

2. Materials and Methods

2.1. Overview

2.2. Design Concepts

2.2.1. Basic Principles and Modeling Approach

2.2.2. Dissipation

2.2.3. Uncertainty

2.3. Details

2.3.1. Initial Condition

2.3.2. Model Input Data

2.3.3. Model Output Data and Evaluation

2.3.4. Detailed Model Description

3. Results and Discussion

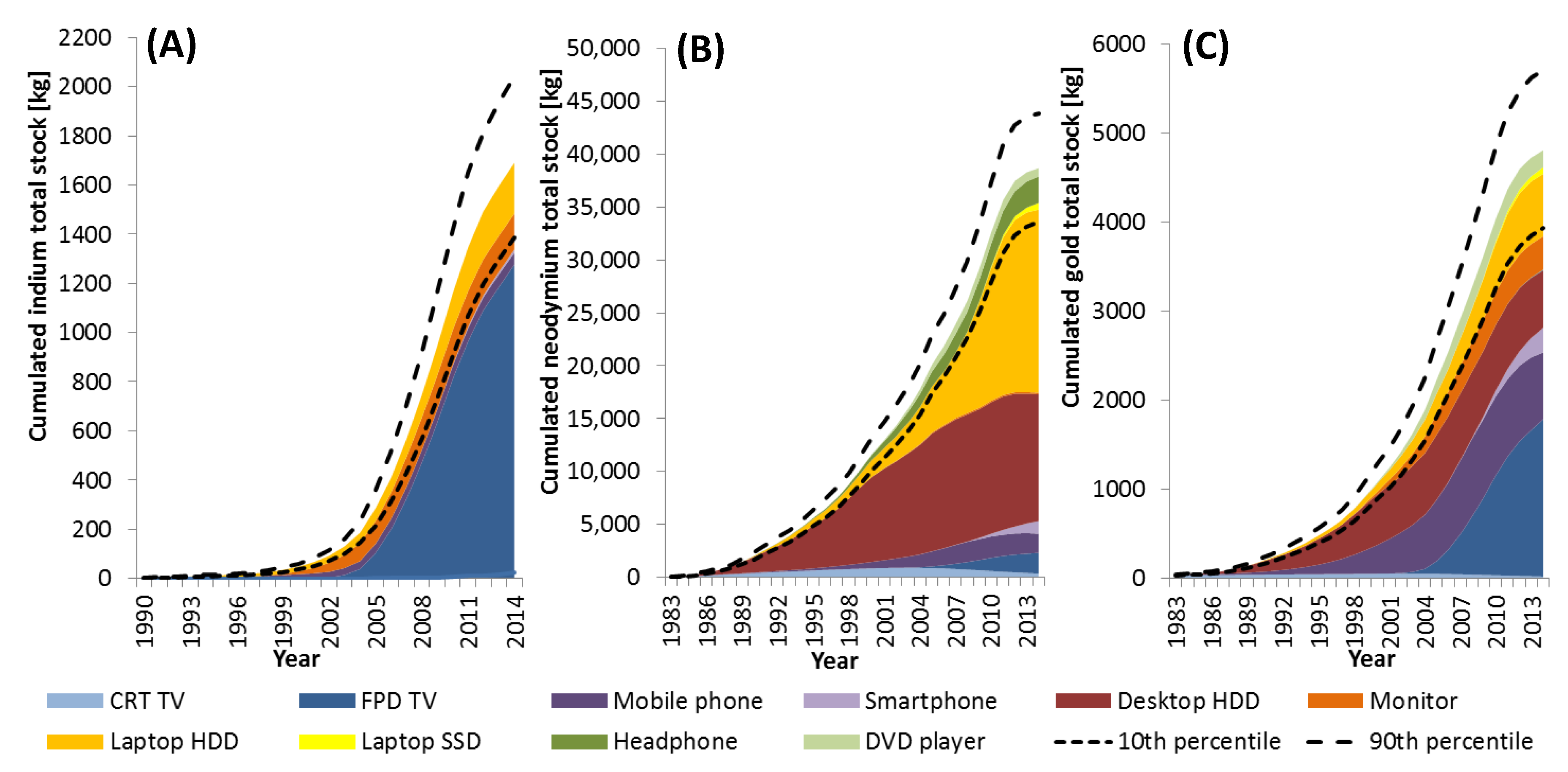

3.1. Development of Stocks

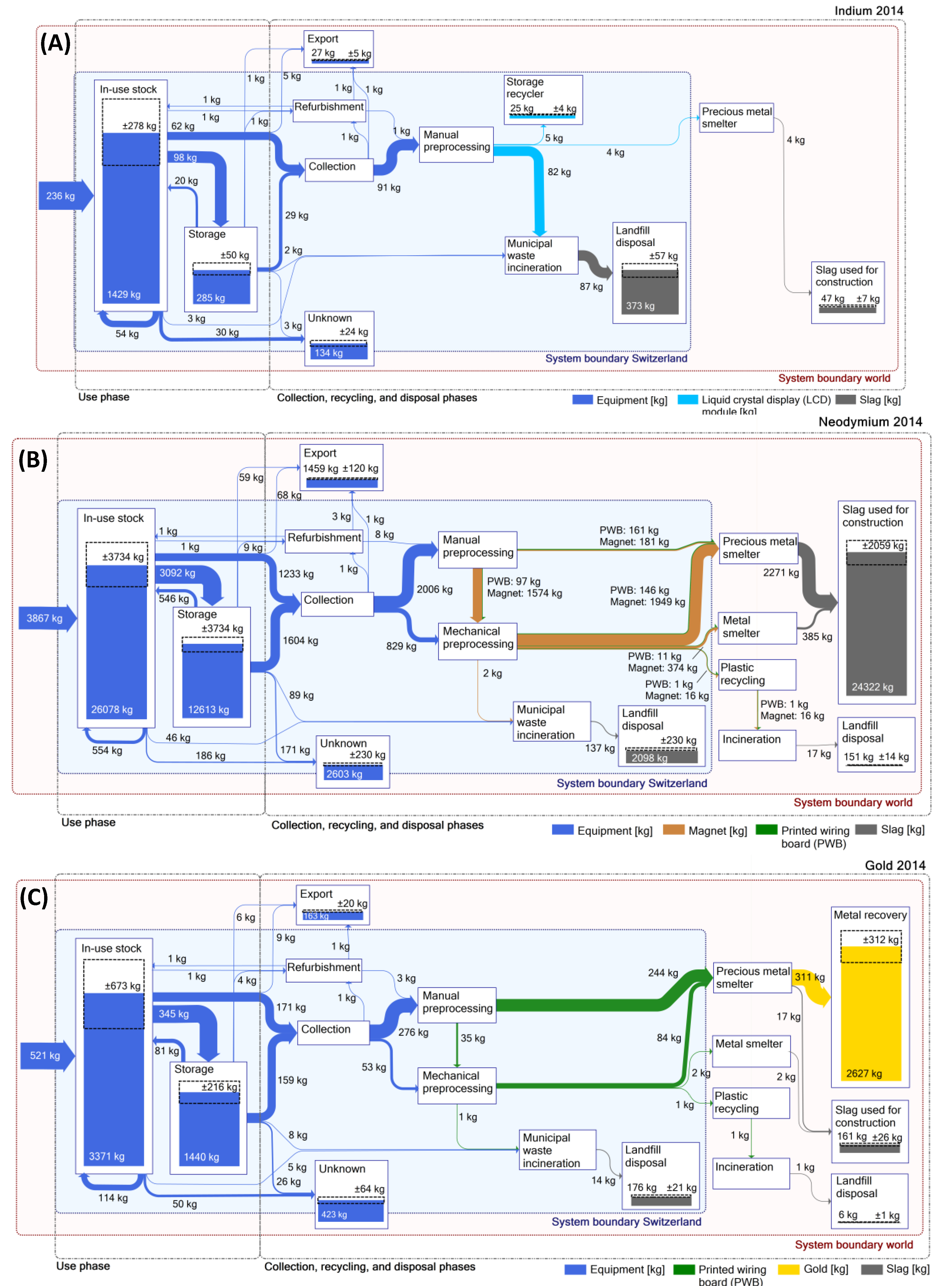

3.2. Stocks and Flows in 2014

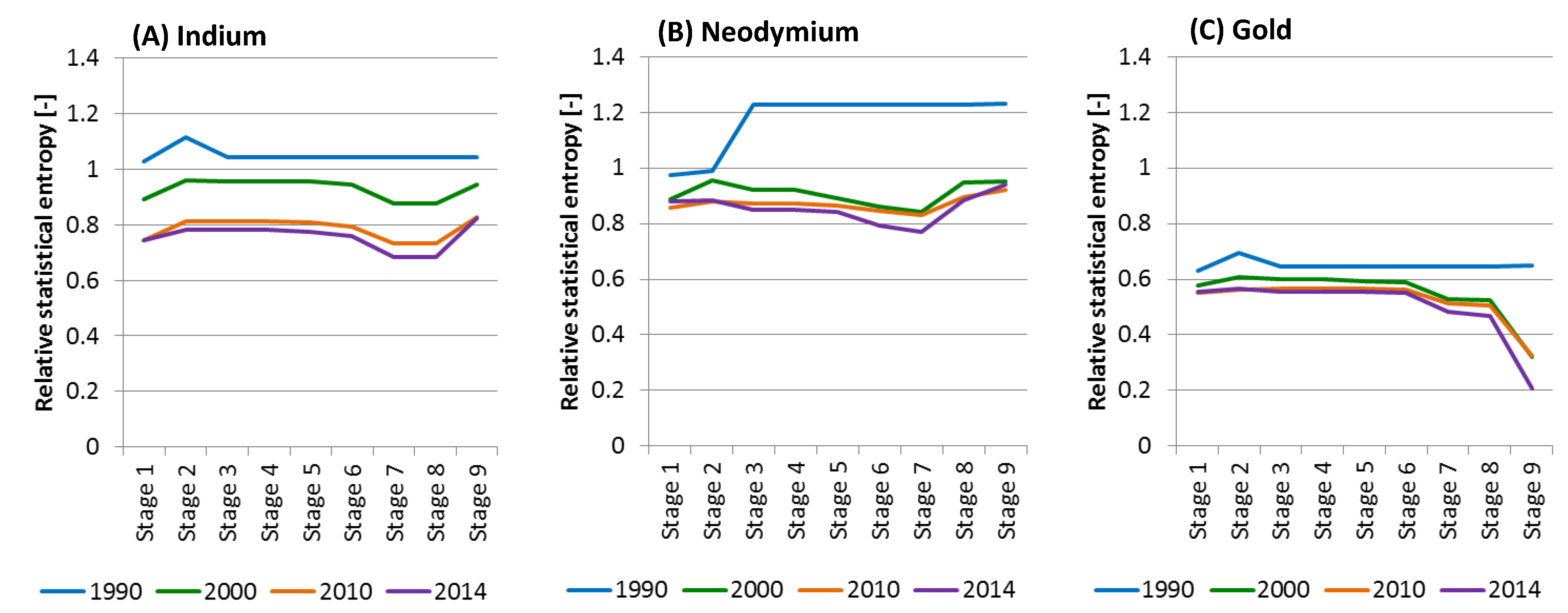

3.3. Statistical Entropy Analysis

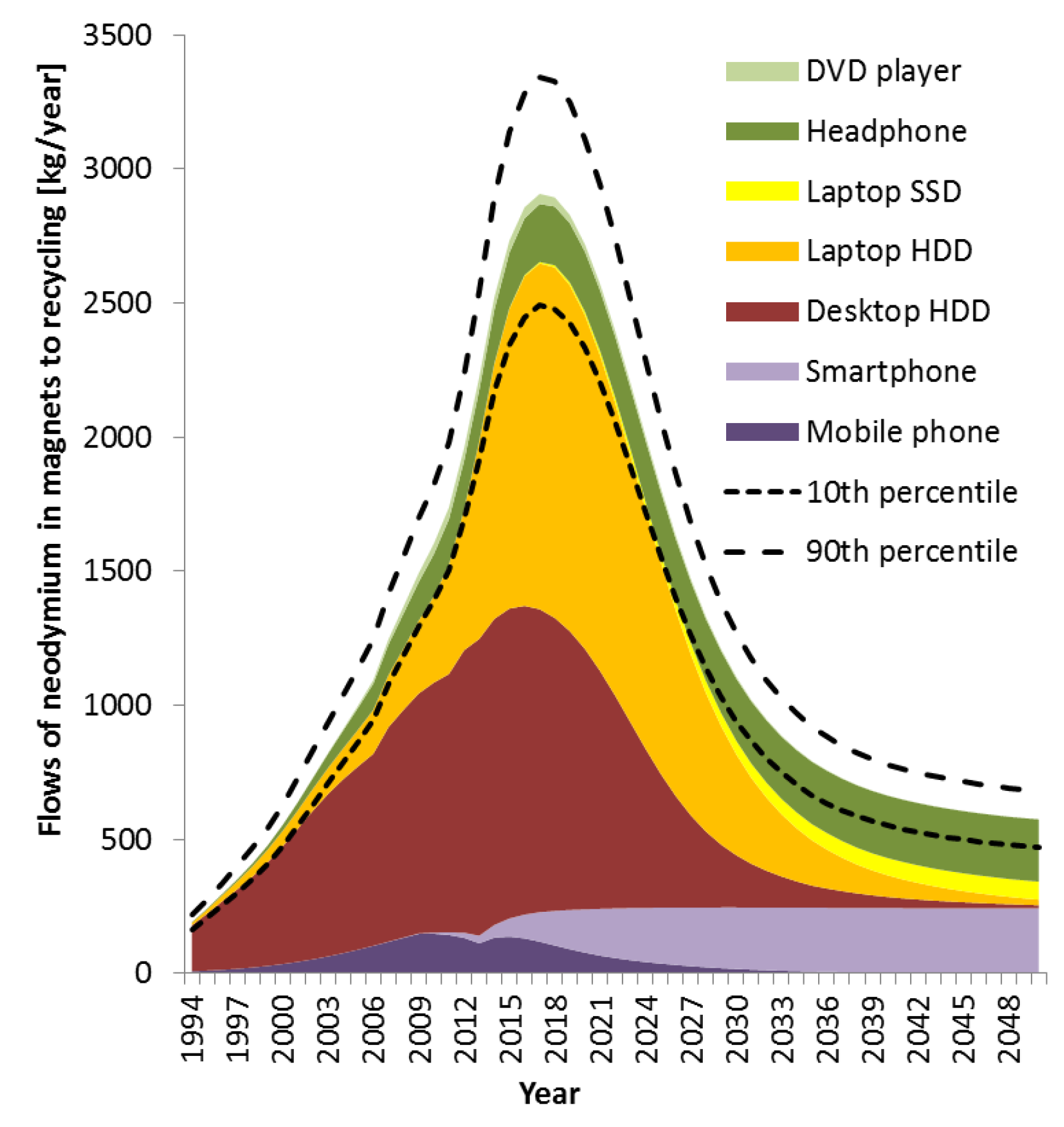

3.4. Future Developments

4. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bieser, J.C.T.; Hilty, L.M. Indirect Effects of the Digital Transformation on Environmental Sustainability: Methodological Challenges in Assessing the Greenhouse Gas Abatement Potential of ICT. Digit. Transf. Environ. Sustain. 2018, 68–53, 68–81. [Google Scholar] [CrossRef]

- Hilty, L.; Aebischer, B. ICT Innovations for Sustainability, Advances in Intelligent Systems and Computing; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-319-09227-0. [Google Scholar]

- Bieser, J.C.T.; Hilty, L.M. An approach to assess indirect environmental effects of digitalization based on a time-use perspective. 2018. accepted for publication. [Google Scholar]

- Buchert, M.; Manhart, A.; Bleher, D.; Pingel, D. Recycling Critical Raw Materials from Waste Electronic Equipment; Oeko-Institut e.V.: Breisgau, Germany, 2012. [Google Scholar]

- European Commission. Critical Raw Materials for the EU. Report of the Ad-hoc Working Group on Defining Critical Raw Materials; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- European Commission. Critical Raw Materials for the EU. Report of the Ad-hoc Working Group on Defining Critical Raw Materials; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- Buchert, M.; Schueler, D.; Bleher, D. Critical Metals for Future Sustainable Technologies and Their Recycling Potential; Öko-Institut: Freiburg, Germany, 2009. [Google Scholar]

- Streicher-Porte, M. SWICO/S.EN.S., the Swiss WEEE recycling systems and best practices from other European systems. In Proceedings of the 2006 IEEE International Symposium on Electronics and the Environment, San Francisco, CA, USA, 8–11 May 2006; pp. 281–287. [Google Scholar]

- Gerst, M.D.; Graedel, T.E. In-Use Stocks of Metals: Status and Implications. Environ. Sci. Technol. 2008, 42, 7038–7045. [Google Scholar] [CrossRef] [PubMed]

- Graedel, T.E.; Allwood, J.M.; Birat, J.-P.; Buchert, M.; Hagelüken, C.; Reck, B.K.; Sibley, S.F.; Sonnemann, G. What do we know about metal recycling rates? J. Ind. Ecol. 2011, 15, 355–366. [Google Scholar] [CrossRef]

- UNEP. Metal Recycling: Opportunities, Limits, Infrastructure, A Report of the Working Group on the Global Metal Flows to the International Resource Panel; Reuter, M.A., Hudson, C., van Schaik, A., Heiskanen, K., Meskers, C., Hagelüken, C., Eds.; UNEP: Nairobi, Kenya, 2013. [Google Scholar]

- Van Schaik, A.; Reuter, M.A. Dynamic modelling of E-waste recycling system performance based on product design. Miner. Eng. 2010, 23, 192–210. [Google Scholar] [CrossRef]

- Reuter, M.A. Limits of design for recycling and “sustainability”: A review. Waste Biomass Valorization 2011, 2, 183–208. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Lenny Koh, S.C.; Rosa, P. Recycling of WEEEs: An economic assessment of present and future e-waste streams. Renew. Sustain. Energy Rev. 2015, 51, 263–272. [Google Scholar] [CrossRef]

- Thiébaud, E.; Hilty, L.M.; Schluep, M.; Faulstich, M. Use, Storage, and Disposal of Electronic Equipment in Switzerland. Environ. Sci. Technol. 2017. [Google Scholar] [CrossRef] [PubMed]

- Schulze, R.; Buchert, M. Estimates of global REE recycling potentials from NdFeB magnet material. Resour. Conserv. Recycl. 2016, 113, 12–27. [Google Scholar] [CrossRef]

- Sprecher, B.; Kleijn, R.; Kramer, G.J. Recycling Potential of Neodymium: The Case of Computer Hard Disk Drives. Environ. Sci. Technol. 2014, 48, 9506–9513. [Google Scholar] [CrossRef] [PubMed]

- Yoshimura, A.; Daigo, I.; Matsuno, Y. Global substance flow analysis of indium. Mater. Trans. 2013, 54, 102–109. [Google Scholar] [CrossRef]

- Alonso, E.; Sherman, A.M.; Wallington, T.J.; Everson, M.P.; Field, F.R.; Roth, R.; Kirchain, R.E. Evaluating Rare Earth Element Availability: A Case with Revolutionary Demand from Clean Technologies. Environ. Sci. Technol. 2012, 46, 3406–3414. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Graedel, T.E. Global In-Use Stocks of the Rare Earth Elements: A First Estimate. Environ. Sci. Technol. 2011, 45, 4096–4101. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Graedel, T.E. Global Rare Earth In-Use Stocks in NdFeB Permanent Magnets. J. Ind. Ecol. 2011, 15, 836–843. [Google Scholar] [CrossRef]

- Zuser, A.; Rechberger, H. Considerations of resource availability in technology development strategies: The case study of photovoltaics. Resour. Conserv. Recycl. 2011, 56, 56–65. [Google Scholar] [CrossRef]

- Saurat, M.; Bringezu, S. Platinum group metal flows of europe, part II exploring the technological and institutional potential for reducing environmental impacts. J. Ind. Ecol. 2009, 13, 406–421. [Google Scholar] [CrossRef]

- Elshkaki, A.; Van Der Voet, E. The consequences of the use of platinum in new technologies on its availability and on other metals cycles. In Conservation and Recycling of Resources: A New Research; Loeffe, C.V., Ed.; Nova Publishers: Hauppauge, NY, USA, 2006; p. 245. ISBN 1-60021-125-9. [Google Scholar]

- Yamasue, E.; Nakajima, K.; Daigo, I.; Hashimoto, S.; Okumura, H.; Ishihara, K.N. Evaluation of the potential amounts of dissipated rare metals from WEEE in Japan. Mater. Trans. 2007, 48, 2353–2357. [Google Scholar] [CrossRef]

- Rechberger, H.; Graedel, T.E. The contemporary European copper cycle: Statistical entropy analysis. Ecol. Econ. 2002, 42, 59–72. [Google Scholar] [CrossRef]

- Bornhöft, N.A.; Sun, T.Y.; Hilty, L.M.; Nowack, B. A dynamic probabilistic material flow modeling method. Environ. Model. Softw. 2016, 76, 69–80. [Google Scholar] [CrossRef]

- Thiébaud, E. Critical Metals in Electronic Equipment: A Methodology to Model End-User Stocks and Flows; TU Clausthal: Clausthal-Zellerfeld, Germany, 2017. [Google Scholar]

- Licht, C.; Peiró, L.T.; Villalba, G. Global Substance Flow Analysis of Gallium, Germanium, and Indium: Quantification of Extraction, Uses, and Dissipative Losses within their Anthropogenic Cycles. J. Ind. Ecol. 2015, 19, 890–903. [Google Scholar] [CrossRef]

- Böni, H.; Wäger, P.; Thiébaud, E.; Du, X.; Figi, R.; Nagel, O.; Bunge, R.; Stäubli, A.; Spörry, A.; Wolfensberger-Malo, M.; et al. Projekt e-Recmet—Rückgewinnung von kritischen Metallen aus Elektronikschrott am Beispiel von Indium und Neodym. Schlussbericht [Project e-Recmet—Recovery of Critical Metals from e-Waste, the Example of Indium and Neodymium. FINAL Report]; Empa: St. Gallen, Switzerland, 2015. [Google Scholar]

- Wäger, P.; Widmer, R.; Restrepo, E.; Fernandes, M. Seltene Technische Metalle in Fraktionen Aus der Maschinellen Aufbereitung von WEEE; Federal Office for the Environment: Bern, Switzerland, 2014. [Google Scholar]

- Blaser, F.; Castelanelli, S.; Wäger, P.; Widmer, R. Seltene Metalle in Elektro- und Elektronikaltgeräten—Vorkommen und Rückgewinnungstechnologien; Bundesamt für Umwelt: Bern, Switzerland, 2011. [Google Scholar]

- MoE; METI. Report of the Study Group for Less Common Metal Recovery from Used Small Electric Appliances 2009 (in Japanese); Ministry of Environment; Ministry of Economy, Trade and Industry: Tokyo, Japan, 2010.

- Chancerel, P.; Meskers, C.; Hagelüken, C.; Rotter, V.S. Assessment of Precious Metal Flows During Preprocessing of Waste Electrical and Electronic Equipment. J. Ind. Ecol. 2009, 13, 791–810. [Google Scholar] [CrossRef]

- Grimm, V.; Berger, U.; DeAngelis, D.L.; Polhill, J.G.; Giske, J.; Railsback, S.F. The ODD protocol: A review and first update. Ecol. Model. 2010, 221, 2760–2768. [Google Scholar] [CrossRef]

- Grimm, V.; Berger, U.; Bastiansen, F.; Eliassen, S.; Ginot, V.; Giske, J.; Goss-Custard, J.; Grand, T.; Heinz, S.K.; Huse, G.; et al. A standard protocol for describing individual-based and agent-based models. Ecol. Model. 2006, 198, 115–126. [Google Scholar] [CrossRef]

- Müller, E.; Hilty, L.M.; Widmer, R.; Schluep, M.; Faulstich, M. Modeling Metal Stocks and Flows: A Review of Dynamic Material Flow Analysis Methods. Environ. Sci. Technol. 2014, 48, 2102–2113. [Google Scholar] [CrossRef] [PubMed]

- Gottschalk, F.; Scholz, R.W.; Nowack, B. Probabilistic material flow modeling for assessing the environmental exposure to compounds: Methodology and an application to engineered nano-TiO2 particles. Environ. Model. Softw. 2010, 25, 320–332. [Google Scholar] [CrossRef]

- Ueberschaar, M.; Schlummer, M.; Jalalpoor, D.; Kaup, N.; Rotter, V.S. Potential and Recycling Strategies for LCD Panels from WEEE. Recycling 2017, 2, 7. [Google Scholar] [CrossRef]

- Bangs, C.; Meskers, C.; Van Kerckhoven, T. Trends in electronic products—the canary in the urban mine. In Proceedings of the Electronic Goes Green 2016+, Berlin, Germany, 7–9 September 2016. [Google Scholar]

- Ueberschaar, M.; Rotter, V.S. Enabling the recycling of rare earth elements through product design and trend analyses of hard disk drives. J. Mater. Cycles Waste Manag. 2015, 17, 266–281. [Google Scholar] [CrossRef]

- Habib, K.; Schibye, P.K.; Vestbø, A.P.; Dall, O.; Wenzel, H. Material Flow Analysis of NdFeB Magnets for Denmark: A Comprehensive Waste Flow Sampling and Analysis Approach. Environ. Sci. Technol. 2014, 48, 12229–12237. [Google Scholar] [CrossRef] [PubMed]

- Sander, K.; Schilling, S.; Marscheider-Weidemann, F.; Wilts, H.; von Gries, N.; Hobohm, J. Abfallwirtschaftliche Produktverantwortung Unter Ressourcenschutzaspekten, Meilensteinbericht August 2012; Ökopol GmbH, Fraunhofer Gesellschaft ISI, TU Darmstadt, TU Hamburg-Harburg: Hamburg, Germany, 2012. [Google Scholar]

- Westphal, L.; Kuchta, K. Permanent Magnets from Small Waste Electrical and Electronic Equipment. In Proceedings of the Sardinia 2013, Sardinia, Italy, 30 September–4 October 2013. [Google Scholar]

- IUTA; fem Forschungsinstitut Edelmetalle. Metallurgische Rückgewinnung von Indium, Gallium und Germanium aus Elektronikschrott und Entwicklung Entsprechender Aufbereitungsmethoden Für Die Verwertungsindustrie; fem Forschungsinstitut Edelmetalle; Metallchemie, Schwäbisch-Gmünd; Institut Für Energie, Umwelttechnik e.V.: Schäbisch Gmünd/Duisburg, Germany, 2011. [Google Scholar]

- Oguchi, M.; Murakami, S.; Sakanakura, H.; Kida, A.; Kameya, T. A preliminary categorization of end-of-life electrical and electronic equipment as secondary metal resources. Waste Manag. 2011, 31, 2150–2160. [Google Scholar] [CrossRef] [PubMed]

- Chancerel, P. Substance Flow Analysis of the Recycling of Small Waste Electrical and Electronic Equipment; An assessment of the recovery of gold and palladium; Technische Universität Berlin, Institut für Technischen Umweltschutz, ITU-Schriftenreihe: Berlin, Germany, 2010. [Google Scholar]

- Weidema, B.P.; Wesnæs, M.S. Data quality management for life cycle inventories—An example of using data quality indicators. J. Clean. Prod. 1996, 4, 167–174. [Google Scholar] [CrossRef]

- JCGM. JCGM 100:2008. Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement (GUM); Joint Committee for Guides in Metrology: Paris, France, 2008. [Google Scholar]

- Thiébaud-Müller, E.; Hilty, L.M.; Schluep, M.; Widmer, R.; Faulstich, M. Service lifetime, storage time and disposal pathways of electronic equipment: A Swiss case study. J. Ind. Ecol. 2017, 22, 196–208. [Google Scholar] [CrossRef]

- Swisscom, AG. Personal Communication with Senior Corporate Responsibility Manager; Swisscom AG: Bern, Switzerland, 2016. [Google Scholar]

- Salt Mobile, SA. Personal Communication with Director Logistics and Retail Development; Salt Mobile SA: Renens, Switzerland, 2016. [Google Scholar]

- Media Markt Management, AG. Personal Communication with Head Business Process Management & Masterdata; Media Markt Management AG: Dietikon, Switzerland, 2016. [Google Scholar]

- Immark, AG. Personal Communication with Head Material Flow Management; Immark AG: Düren, Germany, 2016. [Google Scholar]

- RUAG Environment, AG. Personal Communication with Head Quality Management/Deputy Head of Production; RUAG Environment AG: Schattdorf, Switzerland, 2016. [Google Scholar]

- Solenthaler Recycling, AG. Personal Communication with Head Quality Management; Solenthaler Recycling AG: Gossau, Switzerland, 2016. [Google Scholar]

- Bühlmann Recycling, AG. Personal Communication with Head Environmental Officer; Bühlmann Recycling AG: Murten, Switzerland, 2016. [Google Scholar]

- Gössling-Reisemann, S. What Is Resource Consumption and How Can It Be Measured? Application of Entropy Analysis to Copper Production. J. Ind. Ecol. 2008, 12, 570–582. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Practical Handbook of Material Flow Analysis; Lewis Publishers: Boca Raton, FL, USA, 2004. [Google Scholar]

- SWICO. Swico Tätigkeitsberichte 2006–2015 (Swico Activity Reports 2006–2015); SWICO Recycling: Zürich, Switzerland, 2016. [Google Scholar]

- Swico Recycling; SENS eRecycling. Technical Regulations for the Recycling of Electrical and Electronic Equipment; Swico Recycling; SENS eRecycling: Murten, Switzerland, 2013. [Google Scholar]

- CENELEC. Collection, Logistics & Treatment Requirements for WEEE—Part 1: General Treatment Requirements; CENELEC: Brussels, Belgium, 2014. [Google Scholar]

- Habib, K.; Parajuly, K.; Wenzel, H. Tracking the Flow of Resources in Electronic Waste—The Case of End-of-Life Computer Hard Disk Drives. Environ. Sci. Technol. 2015, 49, 12441–12449. [Google Scholar] [CrossRef] [PubMed]

- Ueberschaar, M.; Geiping, J.; Zamzow, M.; Flamme, S.; Rotter, V.S. Assessment of element-specific recycling efficiency in WEEE pre-processing. Resour. Conserv. Recycl. 2017, 124, 25–41. [Google Scholar] [CrossRef]

- Commodity Trade GmbH Indium: Preis & Markt. Available online: http://www.indium-preis.de/ (accessed on 20 April 2017).

- Mineral Fund Advisory Pty. Ltd Mineralprices.com—The Global Source for Metals Pricing. Available online: http://mineralprices.com/ (accessed on 26 July 2018).

- Gold Price Limited Gold Price. Available online: http://goldprice.org/ (accessed on 20 April 2017).

- Zhang, K.; Wu, Y.; Wang, W.; Li, B.; Zhang, Y.; Zuo, T. Recycling indium from waste LCDs: A review. Resour. Conserv. Recycl. 2015, 104 Pt A, 276–290. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar] [CrossRef]

- Maât, N.; Nachbaur, V.; Lardé, R.; Juraszek, J.; Le Breton, J.-M. An Innovative Process Using Only Water and Sodium Chloride for Recovering Rare Earth Elements from Nd–Fe–B Permanent Magnets Found in the Waste of Electrical and Electronic Equipment. ACS Sustain. Chem. Eng. 2016, 4, 6455–6462. [Google Scholar] [CrossRef]

- Morf, L.S.; Gloor, R.; Haag, O.; Haupt, M.; Skutan, S.; Lorenzo, F.D.; Böni, D. Precious metals and rare earth elements in municipal solid waste—Sources and fate in a Swiss incineration plant. Waste Manag. 2013, 33, 634–644. [Google Scholar] [CrossRef] [PubMed]

- USGS. Mineral Commodities Summaries 2016; U.S. Department of the Interior; U.S. Geological Survey: Washington, DC, USA; Reston, WV, USA, 2016.

- Fishman, T.; Myers, R.J.; Rios, O.; Graedel, T.E. Implications of Emerging Vehicle Technologies on Rare Earth Supply and Demand in the United States. Resources 2018, 7, 9. [Google Scholar] [CrossRef]

- Yano, J.; Muroi, T.; Sakai, S. Rare earth element recovery potentials from end-of-life hybrid electric vehicle components in 2010–2030. J. Mater. Cycles Waste Manag. 2016, 18, 655–664. [Google Scholar] [CrossRef]

- Busch, J.; Steinberger, J.K.; Dawson, D.A.; Purnell, P.; Roelich, K. Managing Critical Materials with a Technology-Specific Stocks and Flows Model. Environ. Sci. Technol. 2013. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thiébaud, E.; Hilty, L.M.; Schluep, M.; Böni, H.W.; Faulstich, M. Where Do Our Resources Go? Indium, Neodymium, and Gold Flows Connected to the Use of Electronic Equipment in Switzerland. Sustainability 2018, 10, 2658. https://doi.org/10.3390/su10082658

Thiébaud E, Hilty LM, Schluep M, Böni HW, Faulstich M. Where Do Our Resources Go? Indium, Neodymium, and Gold Flows Connected to the Use of Electronic Equipment in Switzerland. Sustainability. 2018; 10(8):2658. https://doi.org/10.3390/su10082658

Chicago/Turabian StyleThiébaud, Esther, Lorenz M. Hilty, Mathias Schluep, Heinz W. Böni, and Martin Faulstich. 2018. "Where Do Our Resources Go? Indium, Neodymium, and Gold Flows Connected to the Use of Electronic Equipment in Switzerland" Sustainability 10, no. 8: 2658. https://doi.org/10.3390/su10082658

APA StyleThiébaud, E., Hilty, L. M., Schluep, M., Böni, H. W., & Faulstich, M. (2018). Where Do Our Resources Go? Indium, Neodymium, and Gold Flows Connected to the Use of Electronic Equipment in Switzerland. Sustainability, 10(8), 2658. https://doi.org/10.3390/su10082658