Biomass-Based Innovations in Demand Driven Research and Development Projects in Africa

Abstract

:1. Introduction

- Are demand driven projects easily adoptable or upscaled?

- Does the implementation of demand-driven projects necessarily ensure the higher impact and sustainability of outcomes?

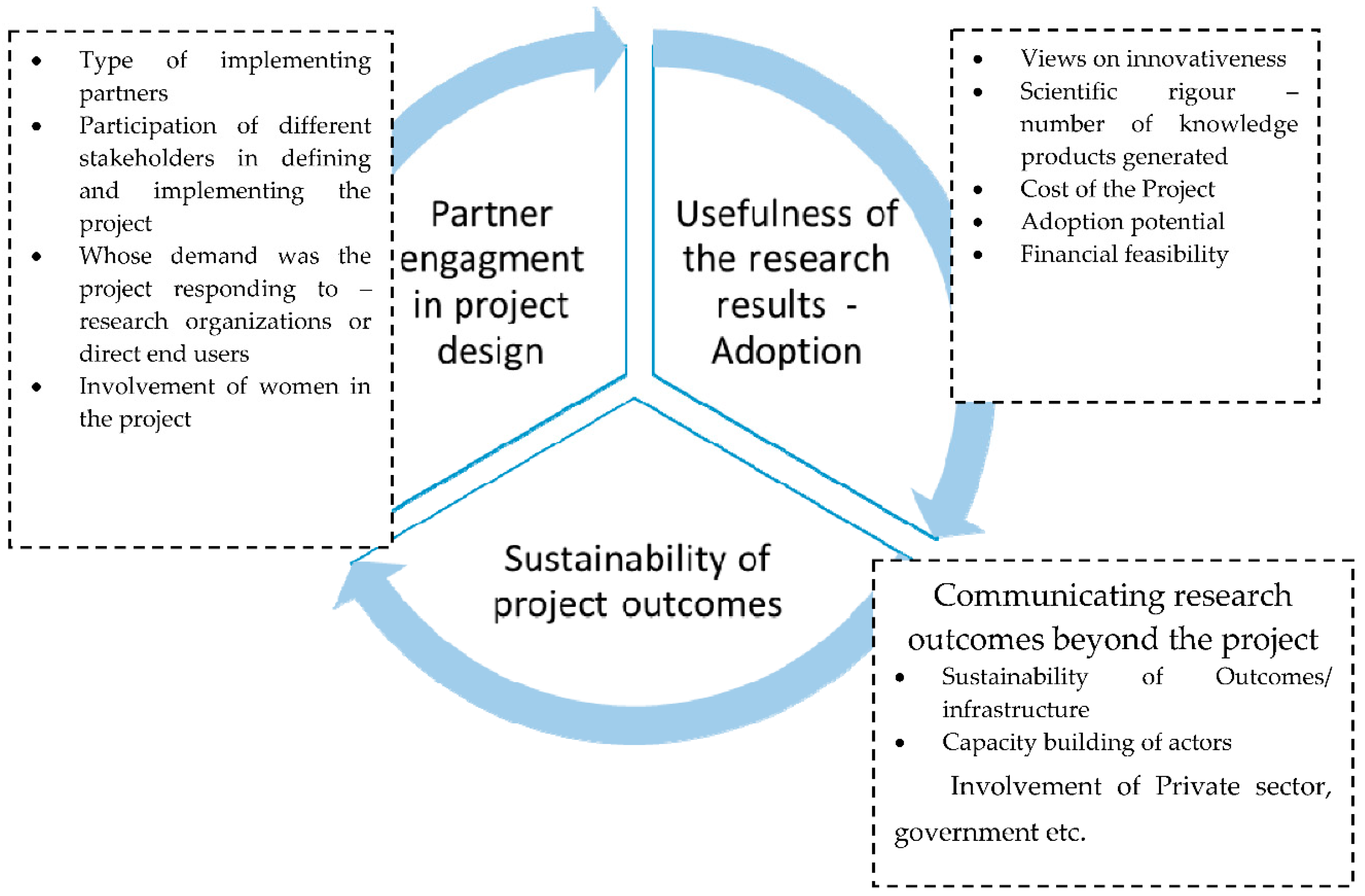

2. Materials and Methods

- Partner engagement in project design

- Quality of the research results/outputs

- Sustainability of project outcomes

3. Results

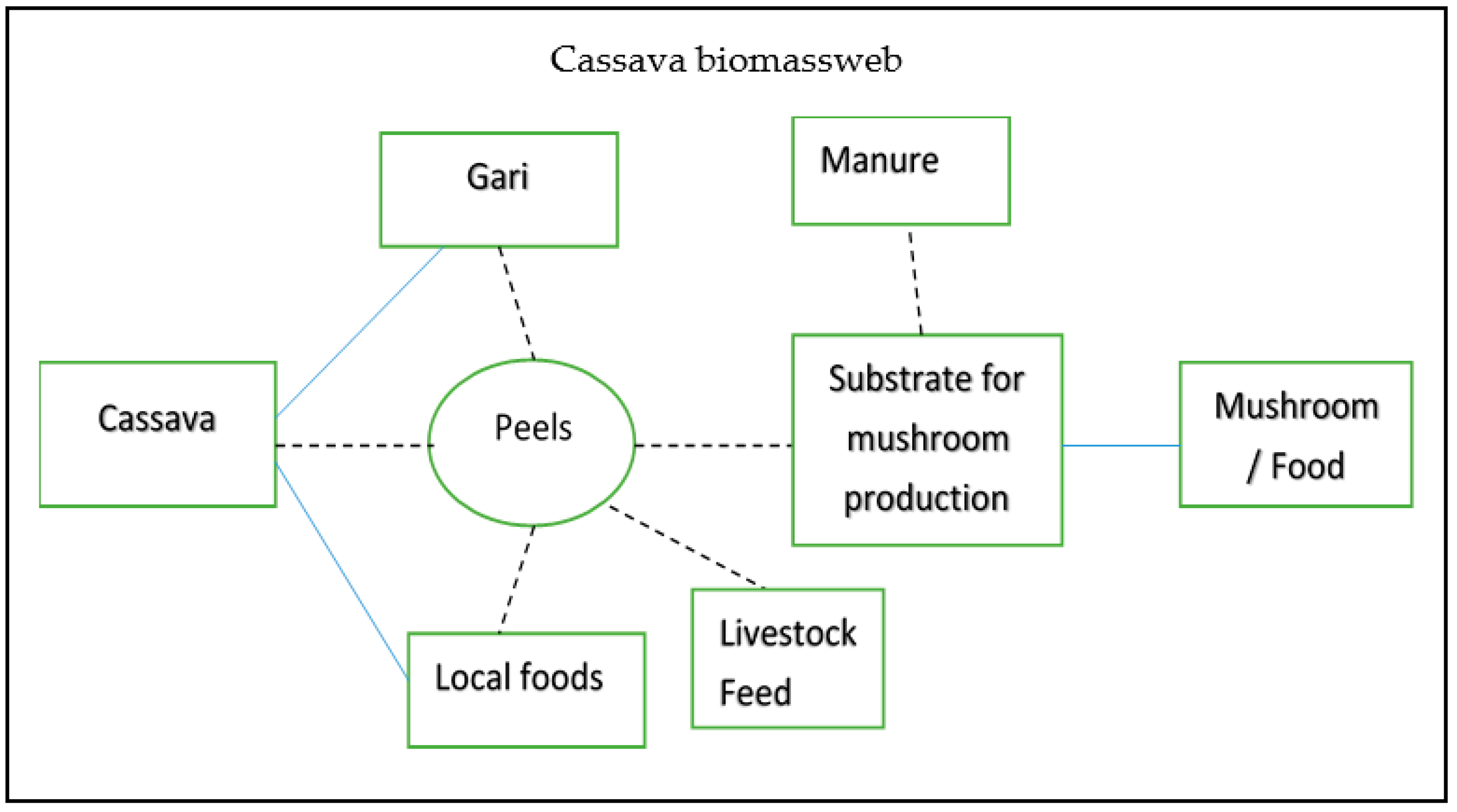

3.1. Using Cassava Peels for Mushroom Production, Ghana

3.1.1. Demand Driven Research Planning

3.1.2. Innovation in the Use of Biomass

3.1.3. Capacity Building

3.1.4. Delivery of the Project and Adoption

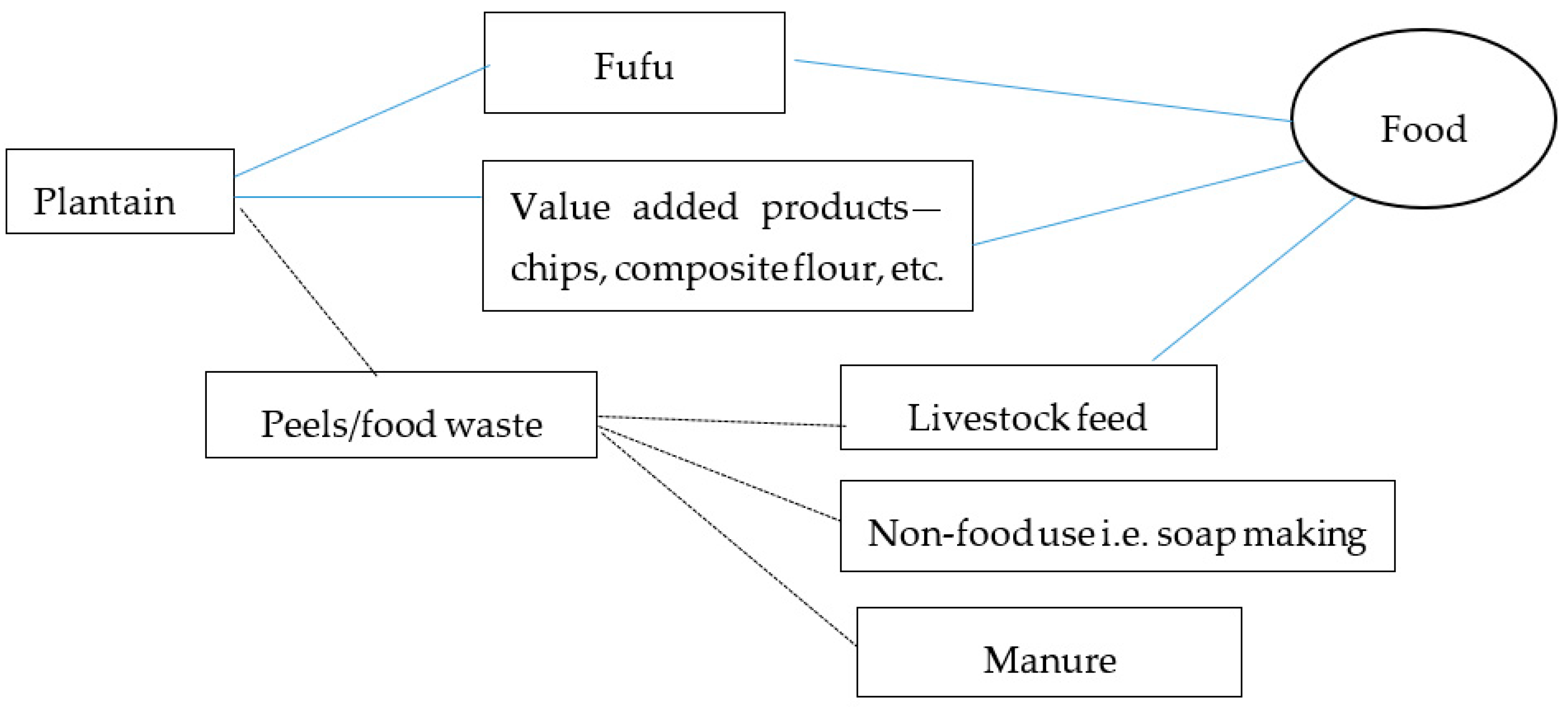

3.2. Development of Plantain Biomass into Composite Flour for Traditional Foods and Bakery Products, Ghana

3.2.1. Demand Driven Research Planning

3.2.2. Innovation in the Use of Biomass

3.2.3. Capacity Building

3.2.4. Delivery of the Project and Adoption

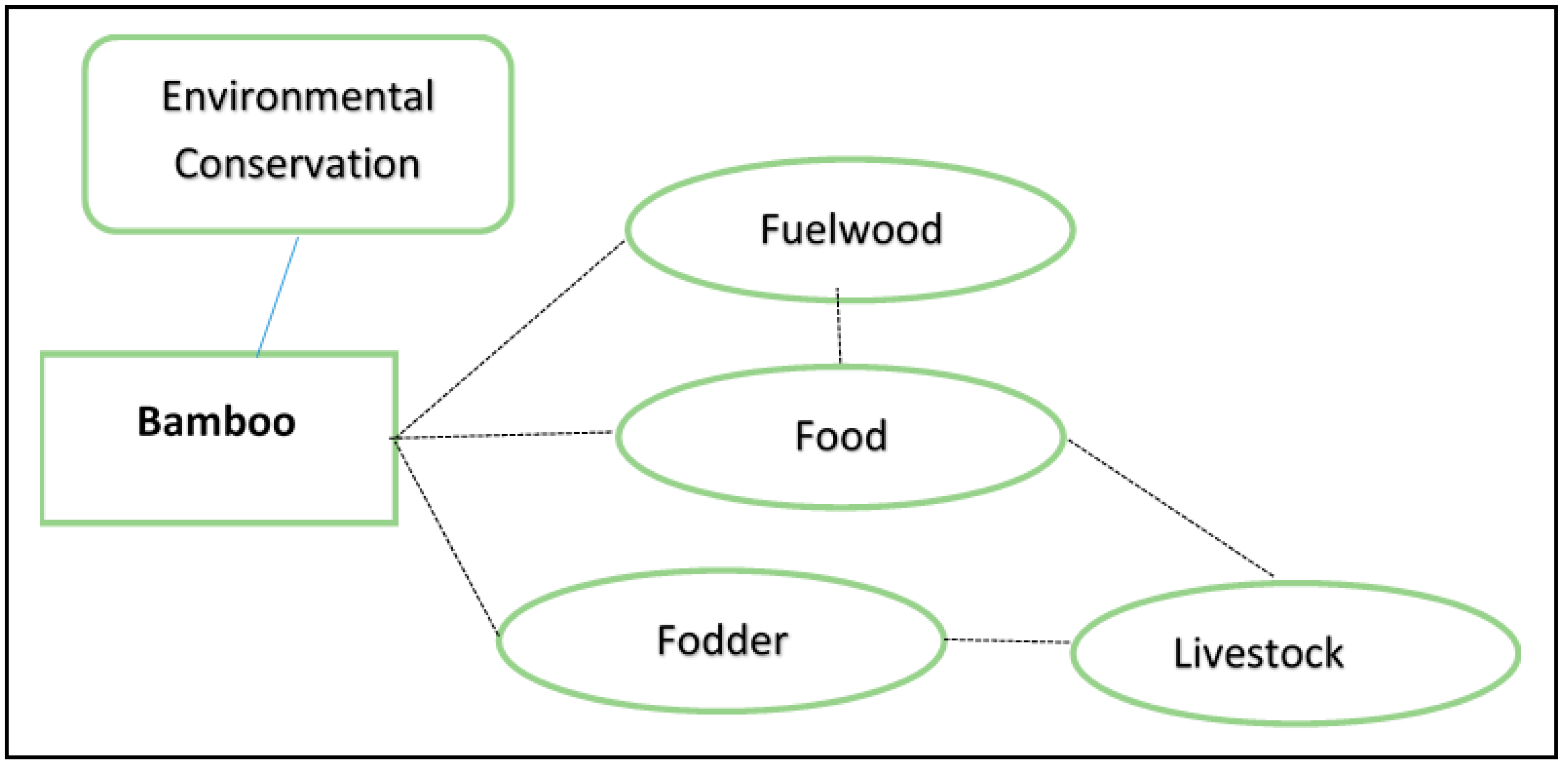

3.3. Bamboo Leaf as Fodder for Livestock Production, Ghana

3.3.1. Demand Driven Research Planning

3.3.2. Innovation in the Use of Biomass

3.3.3. Experimental Set-Up

3.3.4. Delivery of the Project and Adoption

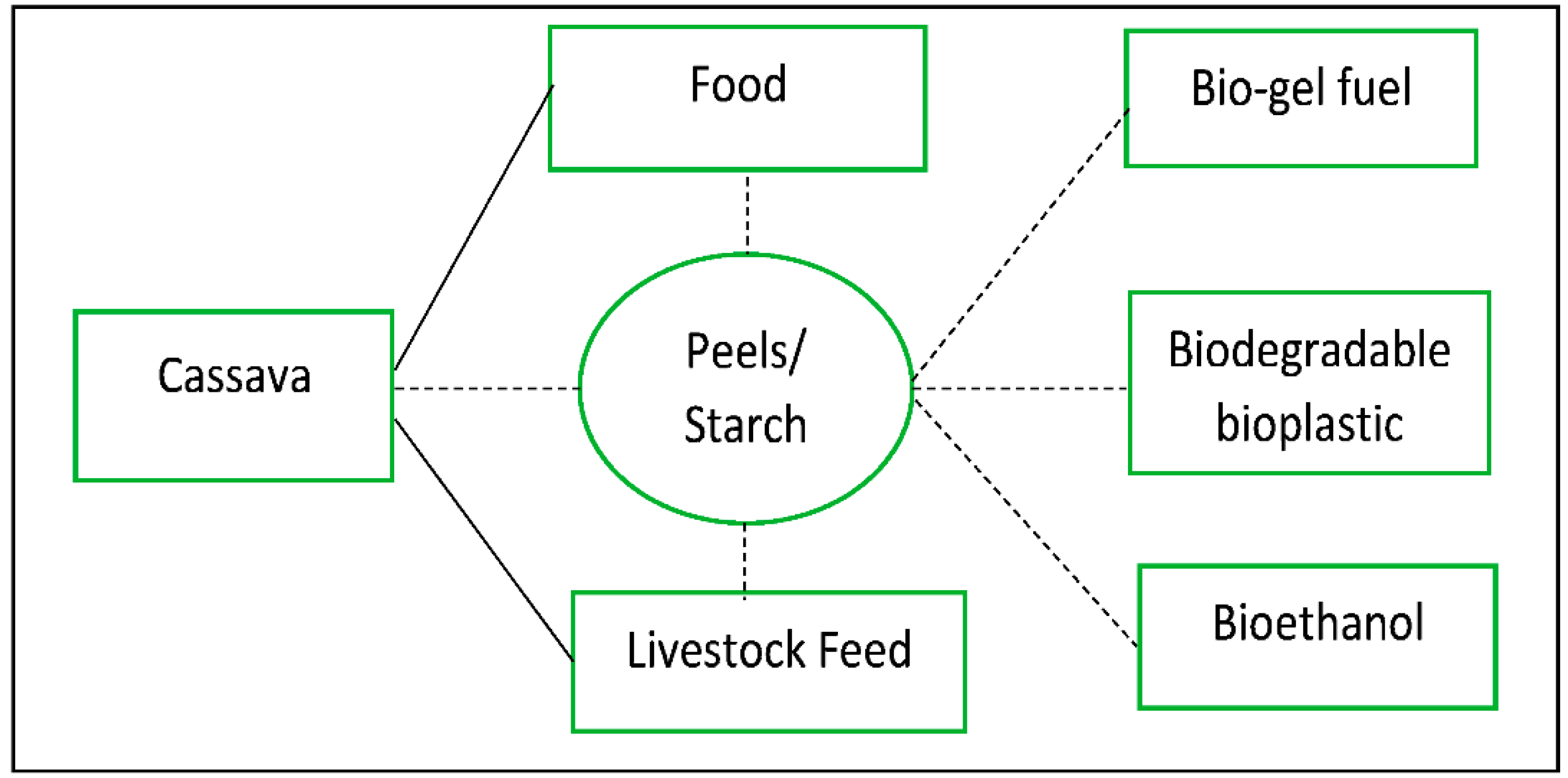

3.4. Production of Bio-Plastics and Bio-Gels from Agricultural Waste to Promote Their Biomassweb Values, Nigeria

3.4.1. Demand Driven Research Planning

3.4.2. Innovation in the Use of Biomass

3.4.3. Capacity Building

3.4.4. Delivery of the Project and Adoption/Upscaling

3.5. Mass and Energy Balance Analysis of Pneumatic Dryers for Cassava and Development of Optimization Models to Increase Competitiveness, Nigeria

3.5.1. Demand Driven Research Planning

3.5.2. Innovation in the Project

3.5.3. Capacity Building

3.5.4. Delivery of the Project and Adoption/Upscaling

3.6. Exploring Potentials of the Bamboo Sector for Employment and Food Security in Ethiopia: An Institutional Analysis of Bamboo-Based Valueweb, Ethiopia

3.6.1. Demand-Driven Research Planning

3.6.2. Innovation in the Project

3.6.3. Capacity Building

3.6.4. Delivery of the Project and Adoption/Upscaling

4. Discussion

- Innovative thinking such as in the WIAD, University of Ibadan bioplastic, and biofuel projects can lead to improved environmental conditions by reducing environmental pollution.

- Waste can be used profitably by carefully process it to reduce the environmental externalities, reduce the land area required for its disposal, and provide income.

- Extending the shelf life of perishable products and thus minimizing postharvest losses can add value and alleviate poverty.

- Bamboo has the potential to serve as an alternative feed for livestock farmers especially in the lean season when feed is scarce. This could boost meat production, increase food and nutritional security and alleviate poverty.

- Uptake of the technology such as improved design of pneumatic flash dryers by the research team from FUTA will require hands-on practical session for manufacturers on how to fabricate the improved pneumatic flash dryer model.

- Training and dissemination of research findings and output is essential to generate the desired impact and outcome of the projects.

5. Conclusions

- (1)

- Innovations around the use of biomass was led by researchers, funded by a donor who demanded on behalf of end-users to address challenges and create opportunity around the use of biomass.

- (2)

- Innovation opportunities were generated around the use of biomass in addressing challenges of postharvest losses of plantain, income generation from conversion of cassava peels into mushroom production, use of bamboo for livestock feeding in dry season and for promoting food security, production of bioplastics and bio-fuels from cassava peels, and development of improved efficient model of pneumatic flash dryers.

- (3)

- However, these innovations were not sufficiently adopted. The adoption/uptake and operationalization depended on the availability of reliable supply of biomass, technological and technical support. Adoption of the innovation around the biomass in the end depends on the end-users understanding the innovation, decision to adopt and actually adopting the innovation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Forum for Agricultural Research in Africa FARA. Science Agenda for Agriculture in Africa (S3A): “Connecting Science” to Transform Agriculture in Africa; Forum for Agricultural Research in Africa (FARA): Accra, Ghana, 2014. [Google Scholar]

- Mansuri, G.; Rao, V. Community-based and-driven development: A critical review. World Bank Res. Obs. 2004, 19, 1–39. [Google Scholar] [CrossRef]

- Kouévi, T.A.; Fatunbi, O.A. Achieving sustainable impact from development projects through multistakeholders innovation platforms: Lessons from Ghana and Rwanda. In Proceedings of the Innovation Conference—Ghana Proceedings, Accra, Ghana, 27–28 September 2016; pp. 123–131. [Google Scholar]

- Atikpo, M.; Onokpise, O.; Abazinge, M.; Louime, C.; Dzomeku, M.; Boateng, L.; Awumbilla, B. Sustainable mushroom production in Africa: A case study in Ghana. Afr. J. Biotechnol. 2007, 7, 249–253. [Google Scholar]

- Atikpo, M.; Onokpise, O.; Abazinge, A.; Awumbilla, B. Utilizing seafood waste for the production of mushrooms. In Proceedings of the Florida Academy of Sciences, Melbourne, FL, USA, 10–11 March 2006; FAS Abstracts 2006 Meeting. Agric. Sci. (AGR): AGR-10. Florida Academy of Sciences Inc.: Melbourne, FL, USA, 2006. [Google Scholar]

- Hafiz, F.; Begum, M.; Parveen, S.; Nessa, Z.; Azad, A.K.M. Study of edible Mushroom grown on Eucalyptus camaldulensis trunk and under soil of Albizzia procera. Pak. J. Nutr. 2003, 2, 279–282. [Google Scholar]

- Matila, P.; Salo-Vaananen, P.; Kanko Aro, H.; Jalava, T. Basis Composition and amino acid contents of Mushrooms cultivated in Finland. J. Agric. Food Chem. 2002, 50, 6419–6422. [Google Scholar] [CrossRef]

- Lelley, J.I.; Janben, A. Interactions between supplementation, fructification surface and productivity of the substrate of Pleurotus species. In Proceedings of the First International Conference on Mushroom Biology and Products, Hong Kong, China, 23–26 August 1993; Chang, S., Buswell, J.A., Chiu, S., Eds.; 1993; pp. 85–92. [Google Scholar]

- Tortoe, C.; Quaye, W.; Akonor, P.T.; Buckman, E.S. Improving Food Security in Africa through Increased System Productivity of Biomass-Based Value Webs; Technical Report, CSIR-FRI/FARA; FARA: Accra, Ghana, 2017. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations; Free Press: New York, NY, USA, 1995. [Google Scholar]

- Nutley, S.; Davies, H.; Walter, I. Conceptual Synthesis 1: Learning from the Diffusion of Innovations; ESRC UK Centre for Evidence Based Policy and Practise: Swindon, UK; Research Unit for Research Utilization: St Andrews, UK, 2012. [Google Scholar]

- Partey, S.I.; Kwaku, M.; Frik, O.B. Perception of Bamboo Leaf as Fodder for Livestock Production in Jeduako in the Dry Semi-Deciduous Zone of Ghana; Technical Report, INBAR/FARA; FARA: Accra, Ghana, 2017. [Google Scholar]

- Engler, B.; Schoenherr, S.; Zhong, Z.; Becker, G. Suitability of Bamboo as an Energy Resource: Analysis of Bamboo Combution Values dependent on the Culm’s Age. Int. J. For. Eng. 2012, 23, 114–121. [Google Scholar] [CrossRef]

- Partey, S.I.; Kwaku, M. Bamboo Leaves as Feed Supplement to Sheep Fed a Basal Diet of Pennisetum purpureum (Hematology and Serum Biochemical Analysis); Technical Report, INBAR/FARA; FARA: Accra, Ghana, 2018. [Google Scholar]

- Partey, S.I.; Kwaku, M. Nutritional Potential of Bamboo Leaves for Feeding Goats within the Forest Transition and Savannah Zones of Ghana and the Proximate Composition; Technical Report, INBAR/FARA; FARA: Accra, Ghana, 2018. [Google Scholar]

- Raji, A.O.; Asiru, W.B.; Abass, B.; Adefisan, O.O. Production of Bio-Plastics and Bio-Gels from Waste of Cassava, Maize and Banana to Promote Their Biomassweb Values; Technical Report, UI/IITA/FIIRO/FARA; FARA: Accra, Ghana, 2018. [Google Scholar]

- Asiru, W.B. Production of Bio-Gel and Bio-Plastic from Agricultural Wastes; Contribution to Online BiomassWeb DGroup Discussion on Demand Driven Research Projects in Africa; FARA: Accra, Ghana, 2018. [Google Scholar]

- Adegbite, S.A.; Olukunle, O.J.; Olalusi, A.P.; Adebayo, A.; Asiru, W.B.; Awoyale, W. Mass and Energy Balance Analysis of Pneumatic Dryers for Cassava and Development of Optimization Models to Increase Competiveness in Nigeria; Technical Report, FUTA/IITA/FIIRO/FARA; FARA: Accra, Ghana, 2018. [Google Scholar]

- Bamlaku, A.; Loos, T.K.; Habtamu, D.; Saurabh, G. Potential of Bamboo for Employment Creation and Food Security Enhancement in Ethiopia; Technical Report, YIELD/FARA; FARA: Accra, Ghana, 2018. [Google Scholar]

- Zenebe, M.; Adefires, W.; Temesgen, Y.; Mehari, A.; Demel, T.; Habtemariam, K. Bamboo Resources in Ethiopia: Their value chain and contribution to livelihoods. Ethno Bot. Res. Appl. 2014, 12, 511–524. [Google Scholar]

- International Network for Bamboo and Rattan (INBAR). Study on Utilization of Lowland Bamboo in Benishangul Gumus Region, Ethiopia; INBAR: Beijing, China, 2010. [Google Scholar]

- Kwapong, N.A. Bamboo for land restoration in Ghana. In FAO and INBAR 2018. Bamboo for Land Restoration; INBAR Policy Synthesis Report 4; INBAR: Beijing, China, 2018. [Google Scholar]

- FAO; INBAR. Bamboo for Land Restoration; INBAR Policy Synthesis Report 4; INBAR: Beijing, China, 2018. [Google Scholar]

- Klerks, L.; Leeuwis, C. Operationalizing Demand Driven Agricultural Research: Institutional Influences in a Public and Private System of Research Planning in the Netherlands. J. Agric. Educ. Ext. 2009, 15, 161–175. [Google Scholar] [CrossRef]

- Klerks, L.; Leeuwis, C. Institutionalizing end-user demand steering in Agriculture R & D: Farmer levy of R & D in the Netherlands. Res. Policy 2008, 37, 460–472. [Google Scholar]

| Applicant Affiliation | Title of the Project | Country | Crop |

|---|---|---|---|

| Ministry of Food and Agriculture, Accra, Ghana | Using cassava peels for mushroom cultivation | Ghana | cassava |

| Council for Scientific and Industrial Research (CSIR) Food Research Institute, Accra, Ghana | Developing biomass-based value chain of plantain and reduce post-harvest losses of plantain through the development of value added products for small scale farmers and processors in two regions in Ghana | Ghana | plantain |

| International Network for Bamboo and Rattan, Kumasi, Ghana | Exploring the potential of bamboo leave fodder for livestock production in Ghana | Ghana | bamboo |

| Department of Agricultural and Environmental Engineering, University of Ibadan, Nigeria | Production of bio-plastics and bio-gels from agricultural waste to promote their biomassweb values | Nigeria | cassava, maize, banana |

| Department of Agricultural and Environmental Engineering, Federal University of Technology, Akure, Ondo State, Nigeria | Mass and energy balance analysis of pneumatic dryers for cassava and development of optimization models to increase competitiveness | Nigeria | cassava |

| YOM Institute of Economic Development, Ethiopia | Exploring potentials of the bamboo sector for employment and food security in Ethiopia: An institutional analysis of bamboo-based valueweb | Ethiopia | bamboo |

| DDRD Project | Implementing Institution | Planning and Scope of Project How Was the Process Planned or Conceptualized? | Innovation in the Use of Biomass What Is Innovative about the Process? Number of Research Products Generated | Capacity Building/Experimental Setup How Was Training/Experimental Set Up Done? | Delivery of Project and Adoption How Was Innovation Uptake? Sustainability? |

|---|---|---|---|---|---|

| Using cassava peels for mushroom production | Ministry of Food and Agriculture, Women in Agricultural Development, (WIAD) Ghana. WIAD is a department of the Ministry of Food and Agriculture. It has National, Regional and District offices across Ghana. It is very active at local level | Researchers identified innovation and facilitated implementation of process for end users (local women and youth) | Conversion of cassava peels which are waste from processing of cassava chips into substrate for production of mushroom to improve household food security, generate income, minimize environmental degradation A manual on production of mushroom A video used in farmer training | Researchers trained beneficiaries on usage of innovative technology of using cassava peels in compost as a substrate for mushroom production. Constructing of low-cost building for mushroom with local materials. | Adoption low. A mushroom house needed to be constructed to operationalize this innovation, which comes as a cost. There is the need for more cost-effective approaches using a group based approach with access to microfinance. |

| Development of plantain biomass into composite flour for traditional foods and bakery products | Centre for Scientific and Industrial Research—Food Research Institution (CSIR-FRI), Ghana. This is an institute of the National Agricultural Research Institute. Its mandate is mainly of research. It works through other units (like WIAD) for technology outreach and adoption. | Researchers identified need to process plantain into composite flour and trained local processors and women in use of the technology. | Plantain processed into composite flour to reduce on postharvest losses and a potential subsite for wheat in bakery products. Seven knowledge products were generated, three peer reviewed articles, manuals, posters | Researchers trained beneficiaries on converting plantain biomass into composite flour, adding value to plantain products, linkage to markets. | Uptake of technology low. Hindered by the lack of access to milling machines and mechanized and solar dryer units. Locally fabricated milling machines specifically for milling of plantain should be developed and also solar drying units. Processors could access and use the facility at a fee. WIAD could mobilize the women into groups to acquire and manage the milling and drying units. |

| Bamboo leaf as fodder for livestock feeding | International Bamboo and Rattan Organization (INBAR), Ghana. INBAR is an Intergovernmental organization working in Agroforestry—focus on Bamboo and Rattan. Its regional office in West Africa is in Ghana. It works with research organizations, local NGOs and government at the frontline | Researcher led survey and experimental set-up. | Drought tolerant and fire-resistant bamboo used for feeding livestock in the dry season; inter-alley cropping to boost food production and stabilizing the soils, used as fuelwood. A peer reviewed article, a study report | Bamboo feeding trial experiment set as a completely randomized design experiment with two replications | Experimental trials show bamboo is a viable feed supplement for livestock feeding Need to supplement bamboo feed by a leguminous fodder to supply both energy, protein and minerals for the animals to meet their nutrient requirement There is the need for education and sensitization on the locals on uses of bamboo. |

| Production of bio-plastics and bio-gels from agricultural waste to promote their biomassweb values | Federal Institute of Industrial Research Oshodi (FIIRO), International Institute for Tropical Agriculture (IITA), and University of Ibadan. All three institutions are located in Nigeria | Researchers responded to the need to address the challenge of environmental pollution from plastic waste in Africa using waste from agricultural products | Development of a protocol from cassava peel starch for the production of bio-gel fuel and biodegradable plastic. Study reports and peer reviewed articles | Dissemination workshops to share findings with policy makers, manufacturers and researchers. Training of research scientist. | Scaling up bioplastic production will first needs an economic feasibility of such production using a pilot scale. There is need to set-up micro/small scale plants for bio-gel production to ensure lower cost of production and even distribution at affordable price |

| Mass and energy balance analysis of pneumatic dryers for cassava and development of optimization models to increase competitiveness | Federal University of Technology Akure (FUTA), Nigeria | Researchers identified the need to design an efficient pneumatic flash dryer to address inefficiencies in existing models. | An improved engineering design of pneumatic flash dryer was designed by the researchers to regulate the heat loss and improve on the quality of HQCF produced. The modification included the introduction of insulation for reduction of heat losses, instrumentation circuit diagram for heat control system, and an efficient two passes heat exchanger system for maximum heat utilization. Study reports and peer reviewed articles are output of the project. | Fifty fabricators and engineers from South-West Nigeria were trained on the design of the improved efficient pneumatic flash dryer. | Uptake of the technology will require hands-on practical session for manufacturers on how to fabricate the improved pneumatic flash dryer model. |

| Exploring potentials of the bamboo sector for employment and food security in Ethiopia: An institutional analysis of bamboo-based valueweb | YOM Institute of Economic Development (YIED), Ethiopia | Researcher-led survey | A study reports and peer reviewed articles are outputs of the research study. | Survey of 468 households from two major bamboo growing regional states in Ethiopia—Amhara and Benishangul Gumuz. | Need to create awareness on the diverse benefit of bamboo, improved methods of growing and extracting culms, and adoption of improved technologies. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raymond, J.; Afranaa, K.N.; Festus, N.B.; Oluwole, F. Biomass-Based Innovations in Demand Driven Research and Development Projects in Africa. Sustainability 2018, 10, 2639. https://doi.org/10.3390/su10082639

Raymond J, Afranaa KN, Festus NB, Oluwole F. Biomass-Based Innovations in Demand Driven Research and Development Projects in Africa. Sustainability. 2018; 10(8):2639. https://doi.org/10.3390/su10082639

Chicago/Turabian StyleRaymond, Jatta, Kwapong Nana Afranaa, Nero Bertrand Festus, and Fatunbi Oluwole. 2018. "Biomass-Based Innovations in Demand Driven Research and Development Projects in Africa" Sustainability 10, no. 8: 2639. https://doi.org/10.3390/su10082639

APA StyleRaymond, J., Afranaa, K. N., Festus, N. B., & Oluwole, F. (2018). Biomass-Based Innovations in Demand Driven Research and Development Projects in Africa. Sustainability, 10(8), 2639. https://doi.org/10.3390/su10082639