Properties of Fired Bricks Incorporating TFT-LCD Waste Glass Powder with Reservoir Sediments

Abstract

1. Introduction

2. Experimental Details

2.1. Materials and Test Items

2.2. Experimental Program

2.3. Laboratory-Scale Firing Test

2.4. Test Methods and Data Analysis

3. Results and Discussion

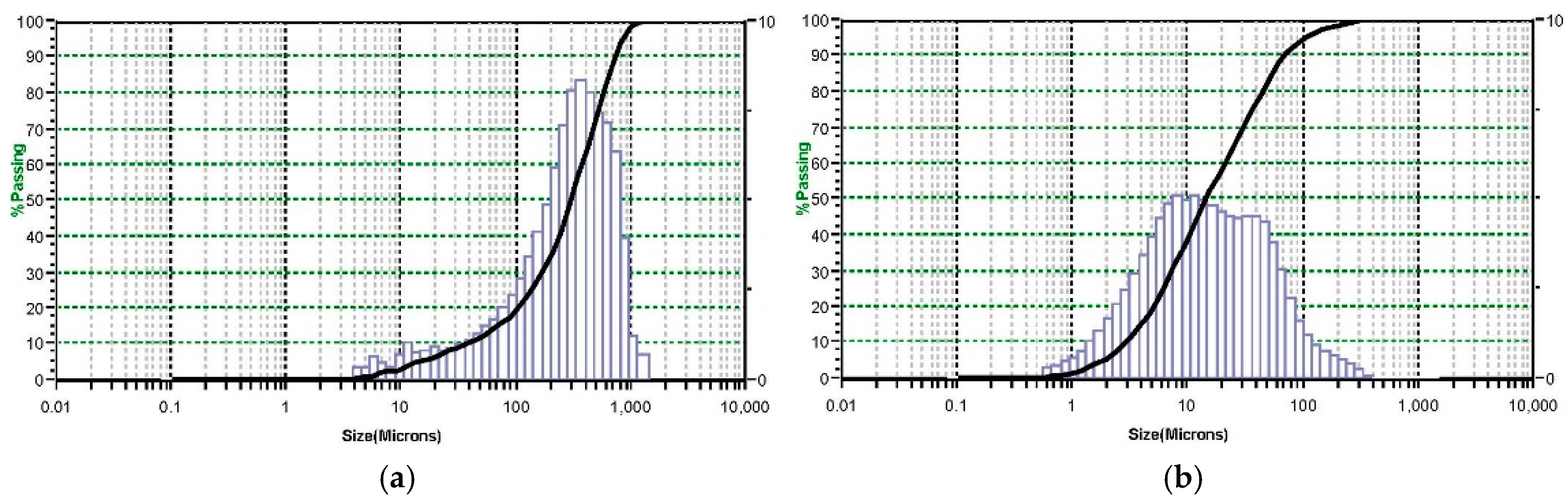

3.1. Physical Properties and Chemical Composition Analysis of Raw Materials

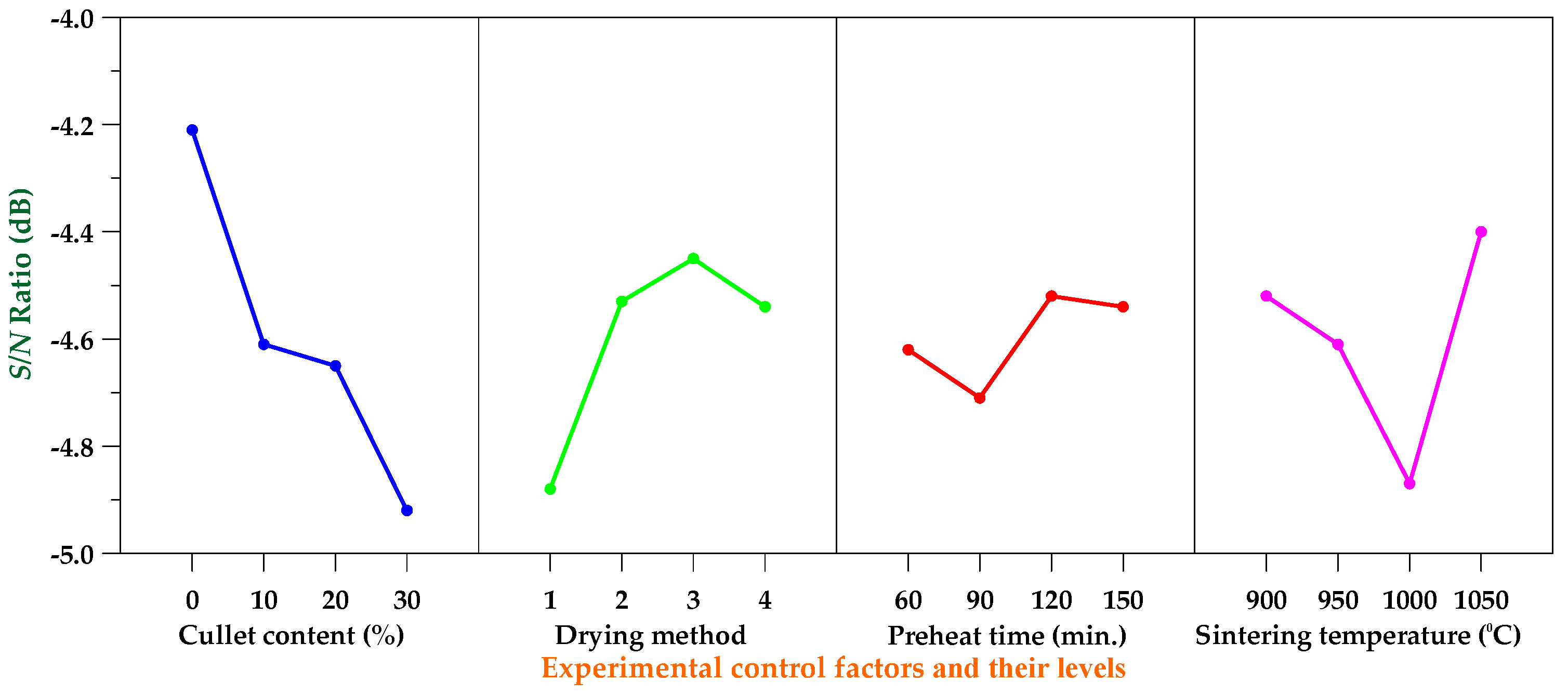

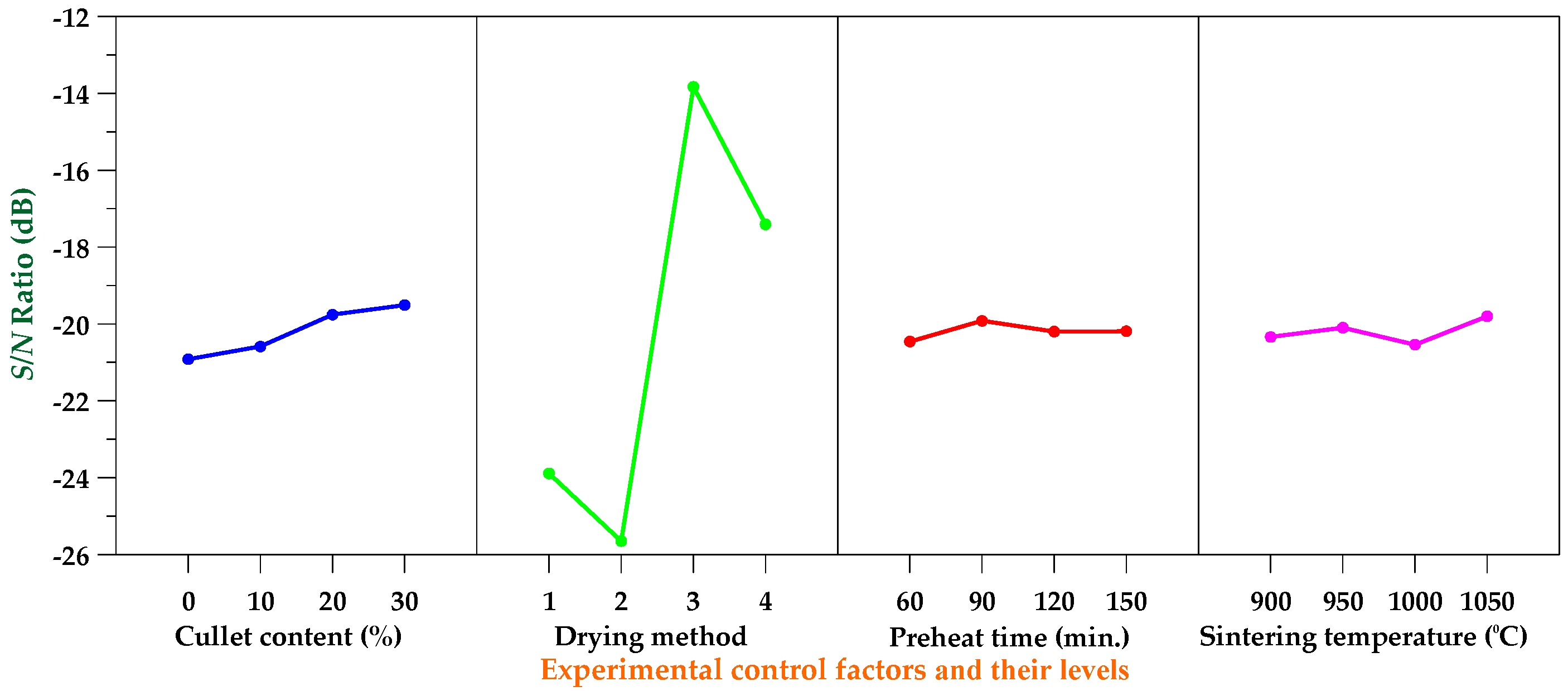

3.2. Density

3.3. Water Absorption

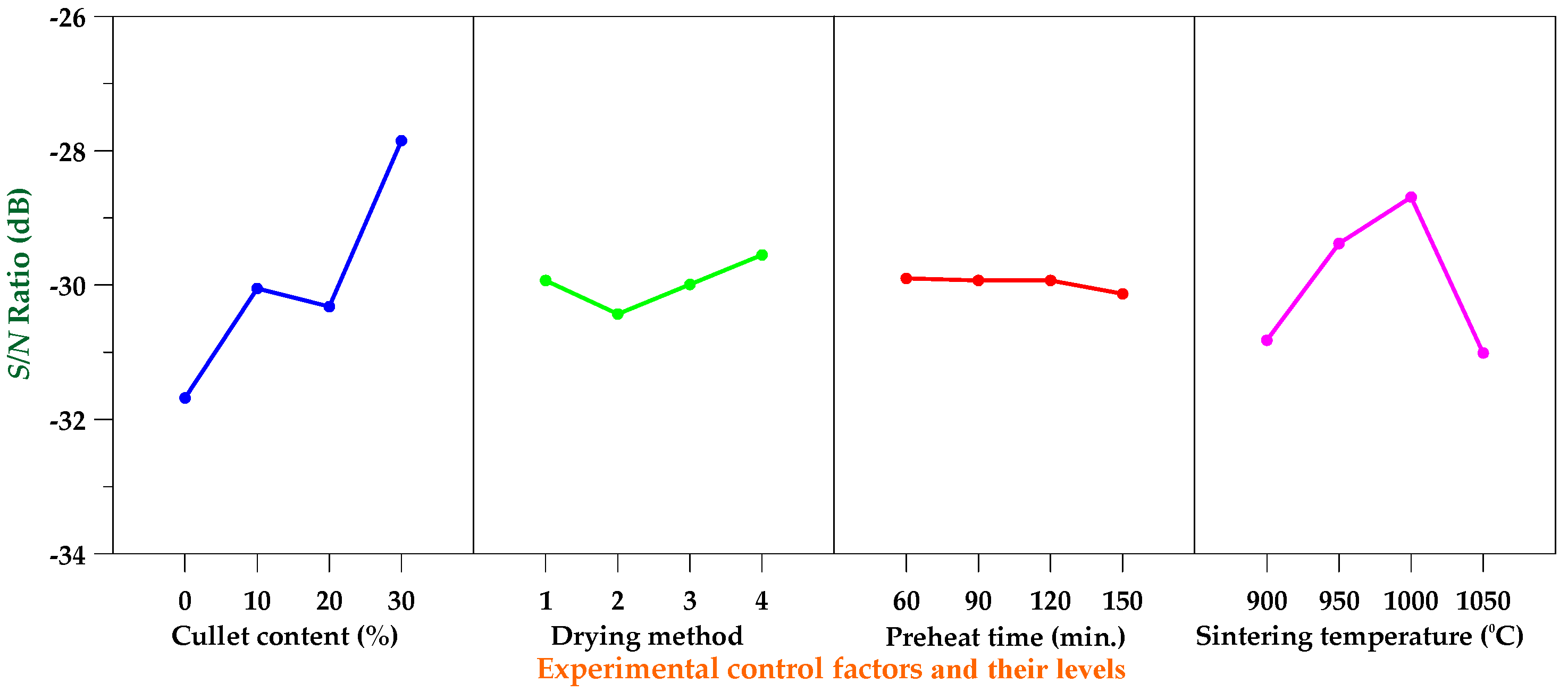

3.4. Shrinkage Ratio

3.5. Loss on Ignition

3.6. Porosity

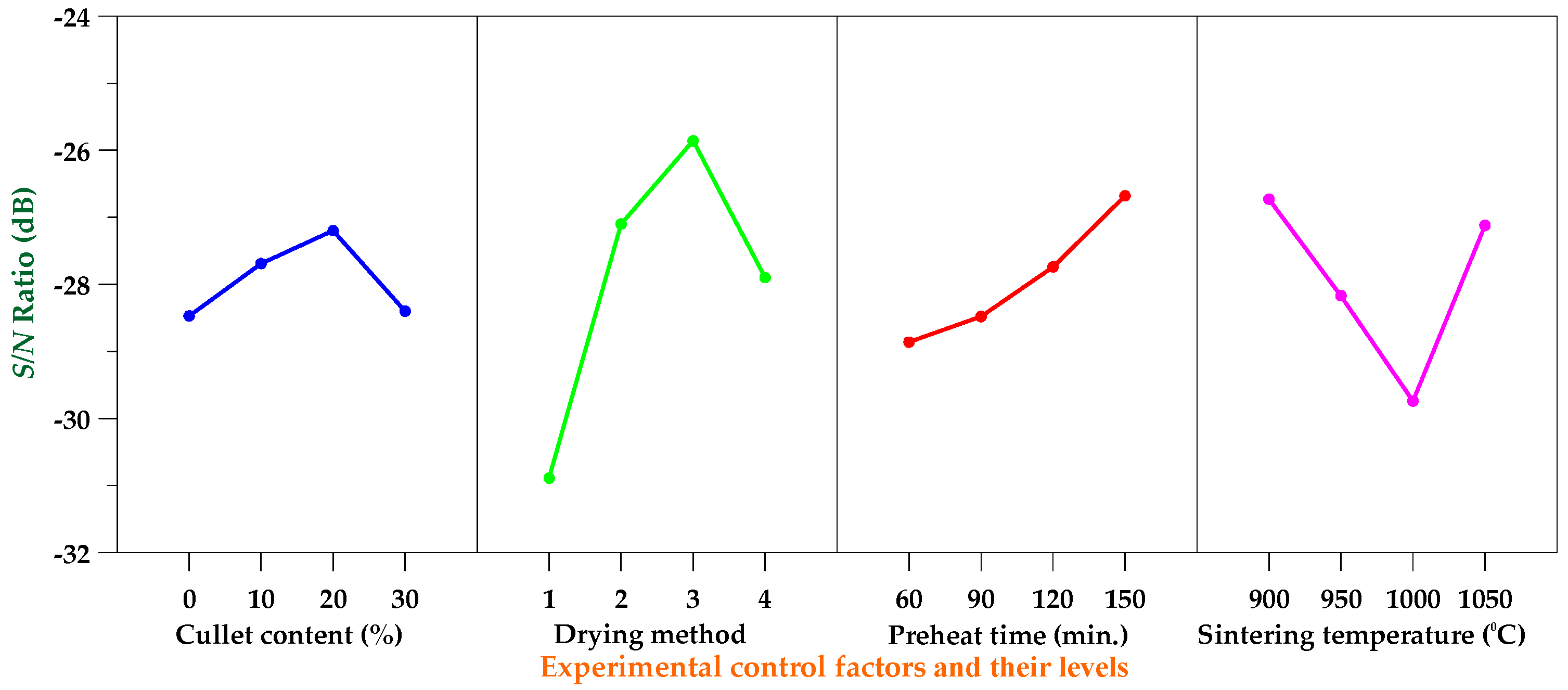

3.7. Compressive Strength

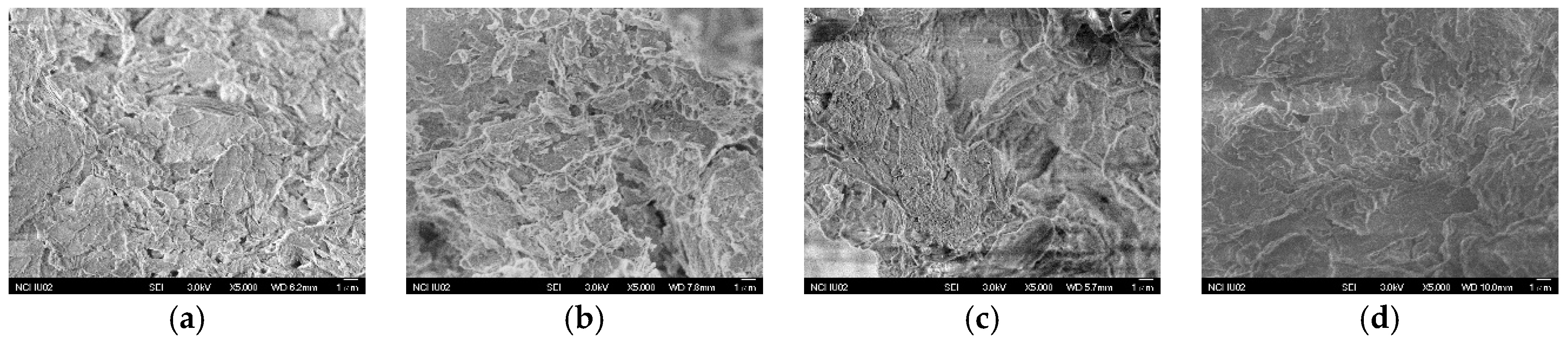

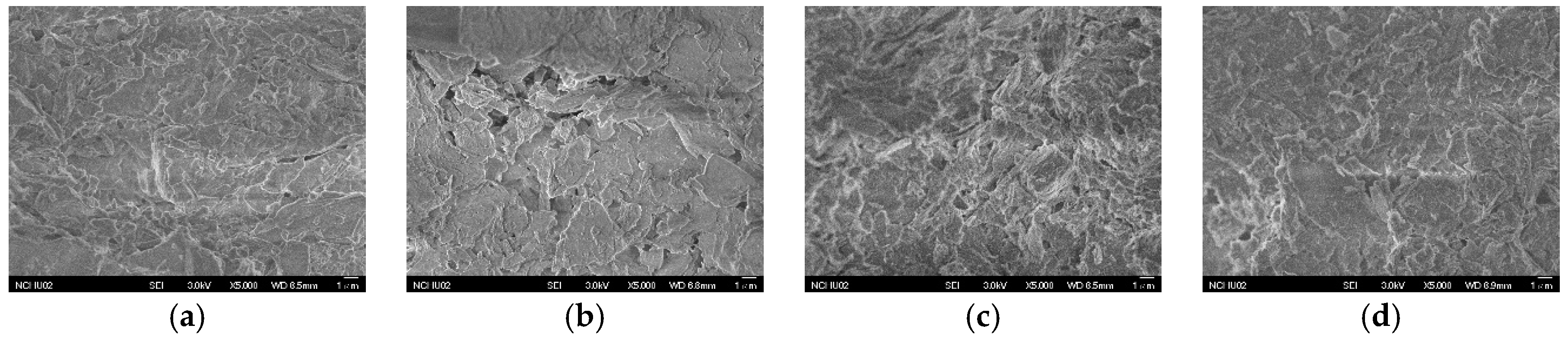

3.8. Microscopic Analysis of Bricks

3.9. Performance of Fired Bricks in Tunnel Kiln

4. Conclusions

- Increasing content of TFT-LCD waste glass decreased the water absorption and increased the compressive strength of the fired bricks.

- The sintering temperature was the most significant factor in controlling the compressive strength of the fired bricks.

- The water absorption and compressive strength of the fired bricks in the tunnel kiln were in line with the requirements of CNS 382 for first-class bricks.

- The use of TFT-LCD waste glass and reservoir sediments to manufacture bricks will entail a cost reduction for the bricks because government subsidies will be available in Taiwan. Therefore, the cost per brick can be reduced by at least 40%.

Funding

Acknowledgments

Conflicts of Interest

References

- Somayaji, S. Civil Engineering Materials; Prentice Hall: Upper Siddle River, NJ, USA, 2001. [Google Scholar]

- Letelier, V.; Ortega, J.M.; Muñoz, P.; Tarela, E.; Moriconi, G. Influence of waste brick powder in the mechanical properties of recycled aggregate concrete. Sustainability 2018, 10, 1037. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M. Houses based on wood as an ecological and sustainable housing alternative—Case study. Sustainability 2018, 10, 1502. [Google Scholar] [CrossRef]

- Wu, F.; Li, L.H.; Han, S.Y. Social sustainability and redevelopment of urban villages in China: A case study of Guangzhou. Sustainability 2018, 10, 2116. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Antucheviciene, J.; Vilutiene, T.; Adeli, H. Sustainable decision-making in civil engineering, construction and building technology. Sustainability 2018, 10, 14. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Alqedra, M.A.; Mo, K.H.; Sumesh, M. Evaluation of industrial by-products as sustainable pozzolanic materials in recycled aggregate concrete. Sustainability 2017, 9, 767. [Google Scholar] [CrossRef]

- Fernandes, F.M.; Lourenço, P.B.; Castro, F.M. Ancient clay bricks: Manufacture and properties. In Materials, Technologies and Practice in Historic Heritage Structures; Springer Science & Business Media: Berlin, Germany, 2010; pp. 29–48. [Google Scholar]

- Shakir, A.A.; Mohammed, A.A. Manufacturing of bricks in the past, in the present and in the future: A state of the art review. Int. J. Adv. Appl. Sci. 2013, 2, 145–156. [Google Scholar] [CrossRef]

- Harrison, T.W. Full Scale Operational Trials Involving the Use of Recycled Glass Additions to Clay Bricks Fired through a Tunnel Kiln; The Waste & Resources Action Programme: Banbury, UK, 2005; ISBN 1-84405-219-2. [Google Scholar]

- Smith, A.S. To Demonstrate Commercial Viability of Incorporating Ground Glass in Bricks With Reduced Emissions and Energy Savings; WRAP R&D Report GLA2-018; WRAP: Banbury, UK, 2004; ISBN 1-84405-101-3. [Google Scholar]

- Smith, A.S. Glass Addition Trials: York Handmade Bricks Co Ltd.; The Waste & Resources Action Programme: Banbury, UK, 2005; ISBN 1-84405-203-6. [Google Scholar]

- Rahman, M.E.; Ong, P.J.; Nabinejad, O.; Islam, S.; Khandoker, N.A.N.; Pakrashi, V.; Shorowordi, K.M. Utilization of blended waste materials in bricks. Technologies 2018, 6, 20. [Google Scholar] [CrossRef]

- Rahman, M.E.; Boon, A.; Muntohar, A.S.; Tanim, M.N.H.; Pakrashi, V. Performance of bricks incorporating palm oil fuel ash. J. Clean. Prod. 2014, 78, 195–201. [Google Scholar] [CrossRef]

- Muntohar, A.S.; Rahman, M.E. Lightweight masonry block from oil palm kernel shell. Constr. Build. Mater. 2014, 54, 477–484. [Google Scholar] [CrossRef]

- Ean, L.W.; Marlinda, A.M.; Bashar, S.M.; Tang, C.W.; Muhammad, T.T. Experimental study on compressive strength of sediment brick masonry. AIP Conf. Proc. 2018, 1930, 020017. [Google Scholar] [CrossRef]

- Kirby, R. Potential Energy Savings from the Use of Recycled Glass in Brick Manufacturing; Center for Environmental Economic Development: Arcata, CA, USA, 2006. [Google Scholar]

- British Standards Institute. PAS 102. Specification for Processed Glass for Selected Secondary End Markets; British Standards Institute: London, UK, 2004; ISBN 0-580-42588-1. [Google Scholar]

- Bernd, W.; Carl, F.S. Utilization of sewage sludge ash in the brick and tile industry. Water Sci. Technol. 1997, 36, 251–258. [Google Scholar]

- Nagaharu, O.; Shiro, T. Full scale application of manufacturing bricks from sewage. Wat. Sci. Technol. 1997, 36, 243–250. [Google Scholar]

- Leshina, V.A.; Pivnev, A.L. Ceramic wall material using glass waste. Glass Ceram. 2002, 59, 356–358. [Google Scholar] [CrossRef]

- Safiuddin, M.; Jumaat, M.Z.; Salam, M.A.; Islam, M.S.; Hashim, R. Utilization of solid wastes in construction materials. Int. J. Phys. Sci. 2010, 5, 1952–1963. [Google Scholar]

- Demir, I. Reuse of waste glass in building brick production. Waste Manag. Res. 2009, 27, 572–577. [Google Scholar] [CrossRef] [PubMed]

- Algin, H.M.; Turgut, P. Cotton and limestone powder wastes as brick material. Constr. Build. Mater. 2008, 22, 1074–1080. [Google Scholar] [CrossRef]

- Chidiac, S.E.; Federico, L.M. Effects of waste glass additions on the properties and durability of fired clay brick. Can. J. Civil Eng. 2007, 34, 1458–1466. [Google Scholar] [CrossRef]

- Dondi, M.; Guarini, G.; Raimondo, M.; Zanelli, C. Recycling of PC and TV glass in clay bricks and roof tiles. Waste Manag. 2009, 29, 1945–1951. [Google Scholar] [CrossRef] [PubMed]

- Lin, K.L. The effect of heating temperature of thin film transistor-liquid crystal display (TFT-LCD) optical waste glass as a partial substitute partial for clay in eco-brick. J. Clean. Prod. 2007, 15, 1755–1759. [Google Scholar] [CrossRef]

- Dalkılıçn, N.; Nabikoğlu, A. Traditional manufacturing of clay brick used in the historical buildings of Diyarbakir (Turkey). Front. Arch. Res. 2017, 6, 346–359. [Google Scholar] [CrossRef]

- Hegazy, B.E.D.E.; Fouad, H.A.; Hassanain, A.M. Incorporation of water sludge, silica fume, and rice husk ash in brick making. Adv. Environ. Res. 2012, 1, 83–96. [Google Scholar] [CrossRef]

- Loryuenyong, V.; Panyachai, T.; Kaewsimork, K.; Siritai, C. Effects of recycled glass substitution on the physical and mechanical properties of clay bricks. Waste Manag. 2009, 29, 2717–2721. [Google Scholar] [CrossRef] [PubMed]

- Salim, R.W.; Ndambuki, J.M.; Adedokun, D.A. Improving the bearing strength of sandy loam soil compressed earth block bricks using sugercane bagasse ash. Sustainability 2014, 6, 3686–3696. [Google Scholar] [CrossRef]

- Taguchi, G. Introduction to Quality Engineering: Designing Quality into Products and Processes; Asian Productivity Organization: Tokyo, Japan, 1987. [Google Scholar]

- Roy, R.K. A Primer on the Taguchi Method; Van Nostrand Reinhold: New York, NY, USA, 1990. [Google Scholar]

- Roy, R.K. Design of Experiments Using the Taguchi Approach; John Wiley & Sons Inc.: New York, NY, USA, 2001. [Google Scholar]

- Taguchi, G.; Chowdhury, S.; Wu, Y. Taguchi’s Quality Engineering Handbook; John Wiley & Sons Inc.: New York, NY, USA, 2005. [Google Scholar]

- CNS 1127. Method of Test for General Type of Bricks for Buildings; Bureau of Standards, Metrology & Inspection, M.O.E.A., R.O.C.: Taipei, Taiwan, 1959. [Google Scholar]

- ASTM C67/C67M-18. Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Neville, A.M. Properties of Concrete; Longman: Harlow, Essex, UK, 1994. [Google Scholar]

- Chen, H.J.; Chang, S.N.; Tang, C.W. Application of the Taguchi Method for Optimizing the Process Parameters of Producing Lightweight Aggregates by Incorporating Tile Grinding Sludge with Reservoir Sediments. Materials 2017, 10, 1294. [Google Scholar] [CrossRef] [PubMed]

- Ardeshir, A.; Farnood Ahmadi, P. A synopsis about production of brick from lightweight and waste material—A review. Mat. Civil. Eng. 2016, 1, 143–163. [Google Scholar]

- Peña, P.P.; Lozano, M.A.G.; Pulido, A.R.; Castro, R.H.L.; Jurado, Z.V.Q.; Medina, J.C.P.; Vázquez, M.E.P.; Torres, A.V. Effect of crushed glass cullet sizes on physical and mechanical properties of red clay bricks. Adv. Mater. Sci. Eng. 2016. [Google Scholar] [CrossRef]

- CNS 382. Bricks for Buildings; Bureau of Standards, Metrology & Inspection, M.O.E.A., R.O.C.: Taipei, Taiwan, 1978. [Google Scholar]

- Tay, J.H.; Goh, A.T.C. Engineering properties of incinerator reside. J. Environ. Eng. 1991, 117, 224–235. [Google Scholar] [CrossRef]

| Parameter (Experimental Control Factor) | Levels of Parameter | Performance Parameter | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Cullet Content, A (%) | 0 | 10 | 20 | 30 | Density (g/cm3) Water Absorption (%) Shrinkage Ratio (%) Loss on Ignition (%) Porosity (%) Compressive Strength (MPa) |

| Drying Method (DM), B | DM1 | DM2 | DM3 | DM4 | |

| Preheat Time, C (min) | 60 | 90 | 120 | 150 | |

| Sintering Temperature, D (°C) | 900 | 950 | 1000 | 1050 | |

| Error, E | - | - | - | - | |

| Experiment Number | Parameter (Level) | ||||

|---|---|---|---|---|---|

| A | B | C | D | E | |

| G1 | 0 (1) * | DM1 (1) | 60 (1) | 900 (1) | |

| G2 | 0 (1) | DM2 (2) | 90 (2) | 950 (2) | |

| G3 | 0 (1) | DM3 (3) | 120 (3) | 1000 (3) | |

| G4 | 0 (1) | DM4 (4) | 150 (4) | 1050 (4) | |

| G5 | 10 (2) | DM1 (1) | 90 (2) | 1000 (3) | |

| G6 | 10 (2) | DM2 (2) | 60 (1) | 1050 (4) | |

| G7 | 10 (2) | DM3 (3) | 150 (4) | 900 (1) | |

| G8 | 10 (2) | DM4 (4) | 120 (3) | 950 (2) | |

| G9 | 20 (3) | DM1 (1) | 120 (3) | 1050 (4) | |

| G10 | 20 (3) | DM2 (2) | 150 (4) | 1000 (3) | |

| G11 | 20 (3) | DM3 (3) | 60 (1) | 950 (2) | |

| G12 | 20 (3) | DM4 (4) | 90 (2) | 900 (1) | |

| G13 | 30 (4) | DM1 (1) | 150 (4) | 950 (2) | |

| G14 | 30 (4) | DM2 (2) | 120 (3) | 900 (1) | |

| G15 | 30 (4) | DM3 (3) | 90 (2) | 1050 (4) | |

| G16 | 30 (4) | DM4 (4) | 60 (1) | 1000 (3) | |

| Experiment Number | Drying Method | Moisture Content of Green Brick Embryos (%) | Moisture Content of Dry Brick Embryos (%) |

|---|---|---|---|

| G1 | DM1 | 18.0 | 11.6 |

| G5 | 18.0 | 11.1 | |

| G9 | 18.0 | 10.3 | |

| G13 | 18.0 | 10.4 | |

| G2 | DM2 | 18.0 | 14.9 |

| G6 | 18.0 | 14.8 | |

| G10 | 18.0 | 14.2 | |

| G14 | 18.0 | 14.3 | |

| G3 | DM3 | 18.0 | 0.0 |

| G7 | 18.0 | 0.0 | |

| G11 | 18.0 | 0.0 | |

| G15 | 18.0 | 0.0 | |

| G4 | DM4 | 18.0 | 1.1 |

| G8 | 18.0 | 1.6 | |

| G12 | 18.0 | 2.4 | |

| G16 | 18.0 | 3.3 |

| Sample Type | Specific Gravity | Plasticity Index (PI) | Average Particle Size (μm) | Maximum Particle Size (μm) | Minimum Particle Size (μm) |

|---|---|---|---|---|---|

| Reservoir Sediments | 2.49 | 14 | 30.34 | 418.6 | 0.688 |

| TFT-LCD Waste Glass | 2.3 | N.P. | 357 | 1408 | 4.62 |

| Sample | Chemical Compositions (wt %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | OS | LOI | Total | |

| Reservoir Sediments | 58.4 | 23.8 | 5.9 | 3.6 | 2.6 | 4.2 | 1.5 | - | 3.9 | 100 |

| TFT-LCD Waste Glass | 85.4 | 5.6 | 0.2 | - | 2.5 | - | 6.3 | - | 0.04 | 100 |

| Experiment Number | Experimental Results | S/N Ratio (dB) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ρ (g/cm3) | Wa (%) | Sr (%) | LOI (%) | VV (%) | fc’ (MPa) | ρ | Wa | Sr | LOI | VV | fc’ | |

| G1 | 1.67 | 29.0 | 34.4 | 17.4 | 42.7 | 3.31 | −4.45 | −29.25 | −30.73 | −24.81 | −32.61 | 10.40 |

| G2 | 1.60 | 27.4 | 22.9 | 20.6 | 40.5 | 4.03 | −4.08 | −28.76 | −27.20 | −26.28 | −32.15 | 12.11 |

| G3 | 1.66 | 18.9 | 28.3 | 5.6 | 28.4 | 6.93 | −4.40 | −25.53 | −29.04 | −14.96 | −29.07 | 16.81 |

| G4 | 1.57 | 30.3 | 22.2 | 7.6 | 44.1 | 5.05 | −3.92 | −29.63 | −26.93 | −17.62 | −32.89 | 14.07 |

| G5 | 1.84 | 18.5 | 47.6 | 16.3 | 28.6 | 9.50 | −5.30 | −25.34 | −33.55 | −24.24 | −29.13 | 19.55 |

| G6 | 1.68 | 21.0 | 25.1 | 19.9 | 32.2 | 12.09 | −4.51 | −26.44 | −27.99 | −25.98 | −30.16 | 21.65 |

| G7 | 1.61 | 25.0 | 12.5 | 5.4 | 38.6 | 3.34 | −4.14 | −27.96 | −21.94 | −14.65 | −31.73 | 10.47 |

| G8 | 1.68 | 18.6 | 23.1 | 7.5 | 28.8 | 7.38 | −4.51 | −25.39 | −27.27 | −17.50 | −29.19 | 17.36 |

| G9 | 1.67 | 25.8 | 24.9 | 14.7 | 39.5 | 14.11 | −4.45 | −28.23 | −27.92 | −23.35 | −31.93 | 22.99 |

| G10 | 1.74 | 19.2 | 21.1 | 18.5 | 31.1 | 11.05 | −4.81 | −25.67 | −26.49 | −25.34 | −29.86 | 20.87 |

| G11 | 1.69 | 20.4 | 22.0 | 4.7 | 32.0 | 5.95 | −4.56 | −26.19 | −26.85 | −13.44 | −30.10 | 15.49 |

| G12 | 1.73 | 18.5 | 23.8 | 7.0 | 29.5 | 4.19 | −4.76 | −25.34 | −27.53 | −16.90 | −29.40 | 12.44 |

| G13 | 1.84 | 12.5 | 37.0 | 14.4 | 20.1 | 6.05 | −5.30 | −21.94 | −31.36 | −23.17 | −26.06 | 15.64 |

| G14 | 1.72 | 18.8 | 21.7 | 17.8 | 30.0 | 3.78 | −4.71 | −25.48 | −26.73 | −25.01 | −29.54 | 11.55 |

| G15 | 1.72 | 17.7 | 19.1 | 4.1 | 28.4 | 14.70 | −4.71 | −24.96 | −25.62 | −12.26 | −29.07 | 23.35 |

| G16 | 1.77 | 13.7 | 31.2 | 7.6 | 21.7 | 10.49 | −4.96 | −22.73 | −29.88 | −17.62 | −26.73 | 20.42 |

| Parameter | Mean S/N Ratio (η, Unit: dB) | Delta (Max η − Min η) | Rank | |||

|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Level 4 | |||

| Cullet Content, A (%) | −4.21 | −4.61 | −4.65 | −4.92 | 0.71 | 1 |

| Drying Method, B | −4.88 | −4.53 | −4.45 | −4.54 | 0.43 | 3 |

| Preheat Time, C (min) | −4.62 | −4.71 | −4.52 | −4.54 | 0.19 | 5 |

| Sintering Temperature, D (°C) | −4.52 | −4.61 | −4.87 | −4.40 | 0.47 | 2 |

| Error, E | −4.62 | −4.41 | −4.74 | −4.62 | 0.33 | 4 |

| Parameter | Sum of Square (SSZ) | Degree of Freedom | Variance (MSZ) | F Value (FZ) | F0.05;3,3 | Percentage Contribution (PZ) | Note |

|---|---|---|---|---|---|---|---|

| Cullet Content, A (%) | 1.01 | 3 | 0.34 | 10.88 | 9.28 | 40.97 | Significant |

| Drying Method, B | 0.43 | 3 | 0.14 | 4.61 | 9.28 | 14.96 | |

| Preheat Time, C (min) | 0.09 | 3 | 0.03 | 1.00 | 9.28 | 20.73 | |

| Sintering Temperature, D (°C) | 0.48 | 3 | 0.16 | 5.15 | 9.28 | 17.21 | |

| Error, E | 0.23 | 3 | 0.08 | 2.48 | 9.28 | 6.13 | |

| All Other | 0.09 | 3 | 0.03 | ||||

| Total | 2.24 | 15 | 0.75 | 100 |

| Parameter | Mean S/N Ratio (η, Unit: dB) | Delta (Max η − Min η) | Rank | |||

|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Level 4 | |||

| Cullet Content, A (%) | −28.29 | −26.28 | −26.36 | −23.78 | 4.51 | 1 |

| Drying Method, B | −26.19 | −26.59 | −26.16 | −25.77 | 0.82 | 4 |

| Preheat Time, C (min) | −26.15 | −26.10 | −26.16 | −26.30 | 0.20 | 5 |

| Sintering Temperature, D (°C) | −27.01 | −25.57 | −24.82 | −27.32 | 2.50 | 2 |

| Error, E | −26.32 | −26.92 | −24.81 | −26.66 | 2.11 | 3 |

| Parameter | Sum of Square (SSZ) | Degree of Freedom | Variance (MSZ) | F Value (FZ) | F0.05;3,3 | Percentage Contribution (PZ) | Note |

|---|---|---|---|---|---|---|---|

| Cullet Content, A (%) | 41.05 | 3 | 13.68 | 481.07 | 9.28 | 58.57 | Significant |

| Drying Method, B | 1.32 | 3 | 0.44 | 15.51 | 9.28 | 1.77 | |

| Preheat Time, C (min) | 0.09 | 3 | 0.03 | 1.00 | 9.28 | 0.61 | |

| Sintering Temperature, D (°C) | 16.82 | 3 | 5.61 | 197.13 | 9.28 | 23.93 | Significant |

| Error, E | 10.66 | 3 | 3.55 | 124.94 | 9.28 | 15.12 | Sub-significant |

| All Other | 0.09 | 3 | 0.03 | ||||

| Total | 69.94 | 15 | 23.31 | 100.00 |

| Parameter | Mean S/N Ratio (η, Unit: dB) | Delta (Max η − Min η) | Rank | |||

|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Level 4 | |||

| Cullet Content, A (%) | −28.47 | −27.69 | −27.20 | −28.40 | 1.27 | 5 |

| Drying Method, B | −30.89 | −27.10 | −25.86 | −27.90 | 5.03 | 1 |

| Preheat Time, C (min) | −28.86 | −28.48 | −27.74 | −26.68 | 2.18 | 4 |

| Sintering Temperature, D (°C) | −26.73 | −28.17 | −29.74 | −27.12 | 3.01 | 2 |

| Error, E | −27.53 | −26.74 | −28.98 | −28.51 | 2.24 | 3 |

| Parameter | Sum of Square (SSZ) | Degree of Freedom | Variance (MSZ) | F Value (FZ) | F0.05;3,3 | Percentage Contribution (PZ) | Note |

|---|---|---|---|---|---|---|---|

| Cullet Content, A (%) | 4.44 | 3 | 1.48 | 1.00 | 9.28 | 0.00 | |

| Drying Method, B | 54.99 | 3 | 18.33 | 12.40 | 9.28 | 48.44 | Significant |

| Preheat Time, C (min) | 11.08 | 3 | 3.69 | 2.50 | 9.28 | 27.63 | |

| Sintering Temperature, D (°C) | 21.71 | 3 | 7.24 | 4.89 | 9.28 | 16.55 | |

| Error, E | 12.14 | 3 | 4.05 | 2.74 | 9.28 | 7.38 | |

| All Other | 4.44 | 3 | 1.48 | ||||

| Total | 104.35 | 15 | 34.78 | 100.00 |

| Parameter | Mean S/N Ratio (η, Unit: dB) | Delta (Max η − Min η) | Rank | |||

|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Level 4 | |||

| Cullet Content, A (%) | −20.92 | −20.59 | −19.76 | −19.51 | 1.41 | 2 |

| Drying Method, B | −23.89 | −25.65 | −13.83 | −17.41 | 11.82 | 1 |

| Preheat Time, C (min) | −20.46 | −19.92 | −20.20 | −20.19 | 0.54 | 4 |

| Sintering Temperature, D (°C) | −20.34 | −20.10 | −20.54 | −19.80 | 0.74 | 3 |

| Error, E | −19.98 | −20.47 | −20.25 | −20.08 | 0.49 | 5 |

| Parameter | Sum of Square (SSZ) | Degree of Freedom | Variance (MSZ) | F Value (FZ) | F0.05;3,3 | Percentage Contribution (PZ) | Note |

|---|---|---|---|---|---|---|---|

| Cullet Content, A (%) | 5.35 | 3 | 1.78 | 9.48 | 9.28 | 1.28 | Sub-significant |

| Drying Method, B | 367.01 | 3 | 122.34 | 650.91 | 9.28 | 97.79 | Significant |

| Preheat Time, C (min) | 0.59 | 3 | 0.20 | 1.04 | 9.28 | 0.76 | |

| Sintering Temperature, D (°C) | 1.23 | 3 | 0.41 | 2.19 | 9.28 | 0.18 | |

| Error, E | 0.56 | 3 | 0.19 | 1.00 | 9.28 | 0.00 | |

| All Other | 0.56 | 3 | 0.19 | ||||

| Total | 374.74 | 15 | 124.91 | 100.00 |

| Parameter | Mean S/N Ratio (η, Unit: dB) | Delta (Max η − Min η) | Rank | |||

|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Level 4 | |||

| Cullet Content, A (%) | −31.68 | −30.05 | −30.32 | −27.85 | 3.83 | 1 |

| Drying Method, B | −29.93 | −30.43 | −29.99 | −29.55 | 0.88 | 4 |

| Preheat Time, C (min) | −29.90 | −29.93 | −29.93 | −30.13 | 0.23 | 5 |

| Sintering Temperature, D (°C) | −30.82 | −29.38 | −28.69 | −31.01 | 2.32 | 2 |

| Error, E | −30.18 | −30.64 | −28.67 | −30.42 | 1.97 | 3 |

| Parameter | Sum of Square (SSZ) | Degree of Freedom | Variance (MSZ) | F Value (FZ) | F0.05;3,3 | Percentage Contribution (PZ) | Note |

|---|---|---|---|---|---|---|---|

| Cullet Content, A (%) | 30.16 | 3 | 10.05 | 217.13 | 9.28 | 53.16 | Significant |

| Drying Method, B | 1.54 | 3 | 0.51 | 11.10 | 9.28 | 2.48 | |

| Preheat Time, C (min) | 0.14 | 3 | 0.05 | 1.00 | 9.28 | 1.23 | |

| Sintering Temperature, D (°C) | 15.14 | 3 | 5.05 | 109.00 | 9.28 | 26.57 | Significant |

| Error, E | 9.49 | 3 | 3.16 | 68.32 | 9.28 | 16.56 | Sub-significant |

| All Other | 0.14 | 3 | 0.05 | ||||

| Total | 56.48 | 15 | 18.83 | 100.00 |

| Parameter | Mean S/N Ratio (η, Unit: dB) | Delta (Max η − Min η) | Rank | |||

|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Level 4 | |||

| Cullet Content, A (%) | 13.35 | 17.26 | 17.95 | 17.74 | 4.60 | 2 |

| Drying Method, B | 17.14 | 16.54 | 16.53 | 16.07 | 1.07 | 5 |

| Preheat Time, C (min) | 16.99 | 16.86 | 17.18 | 15.26 | 1.92 | 4 |

| Sintering Temperature, D (°C) | 11.22 | 15.15 | 19.41 | 20.51 | 9.29 | 1 |

| Error, E | 17.99 | 16.50 | 16.64 | 15.17 | 2.82 | 3 |

| Parameter | Sum of Square (SSZ) | Degree of Freedom | Variance (MSZ) | F Value (FZ) | F0.05;3,3 | Percentage Contribution (PZ) | Note |

|---|---|---|---|---|---|---|---|

| Cullet Content, A (%) | 56.53 | 3 | 18.84 | 24.36 | 9.28 | 17.98 | Significant |

| Drying Method, B | 2.32 | 3 | 0.77 | 1.00 | 9.28 | 0.00 | |

| Preheat Time, C (min) | 9.38 | 3 | 3.13 | 4.04 | 9.28 | 6.19 | |

| Sintering Temperature, D (°C) | 217.24 | 3 | 72.41 | 93.61 | 9.28 | 71.28 | Significant |

| Error, E | 16.03 | 3 | 5.34 | 6.91 | 9.28 | 4.55 | |

| All Other | 2.32 | 3 | 0.77 | ||||

| Total | 301.50 | 15 | 100.50 | 100.00 |

| Experiment Number | Parameter | |||

|---|---|---|---|---|

| Cullet Content, A (%) | Drying Method, B | Preheat Time, C (min) | Sintering Temperature, D (°C) | |

| P1 | 30 | DM4 | 90 | 1000 |

| P2 | 20 | DM1 | 120 | 1050 |

| Experiment Number | Finished Brick Features | |||

|---|---|---|---|---|

| Density (g/cm3) | Water Absorption (%) | Compressive Strength (MPa) | Rupture Modulus (MPa) | |

| P1 | 2.21 | 12.9 | 35.2 | 0.62 |

| P2 | 2.24 | 14.5 | 48.2 | 0.68 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, C.-W. Properties of Fired Bricks Incorporating TFT-LCD Waste Glass Powder with Reservoir Sediments. Sustainability 2018, 10, 2503. https://doi.org/10.3390/su10072503

Tang C-W. Properties of Fired Bricks Incorporating TFT-LCD Waste Glass Powder with Reservoir Sediments. Sustainability. 2018; 10(7):2503. https://doi.org/10.3390/su10072503

Chicago/Turabian StyleTang, Chao-Wei. 2018. "Properties of Fired Bricks Incorporating TFT-LCD Waste Glass Powder with Reservoir Sediments" Sustainability 10, no. 7: 2503. https://doi.org/10.3390/su10072503

APA StyleTang, C.-W. (2018). Properties of Fired Bricks Incorporating TFT-LCD Waste Glass Powder with Reservoir Sediments. Sustainability, 10(7), 2503. https://doi.org/10.3390/su10072503