Study on the Availability of 4T-APS as a Video Monitor and Radiation Detector in Nuclear Accidents

Abstract

1. Introduction

2. Materials and Methods

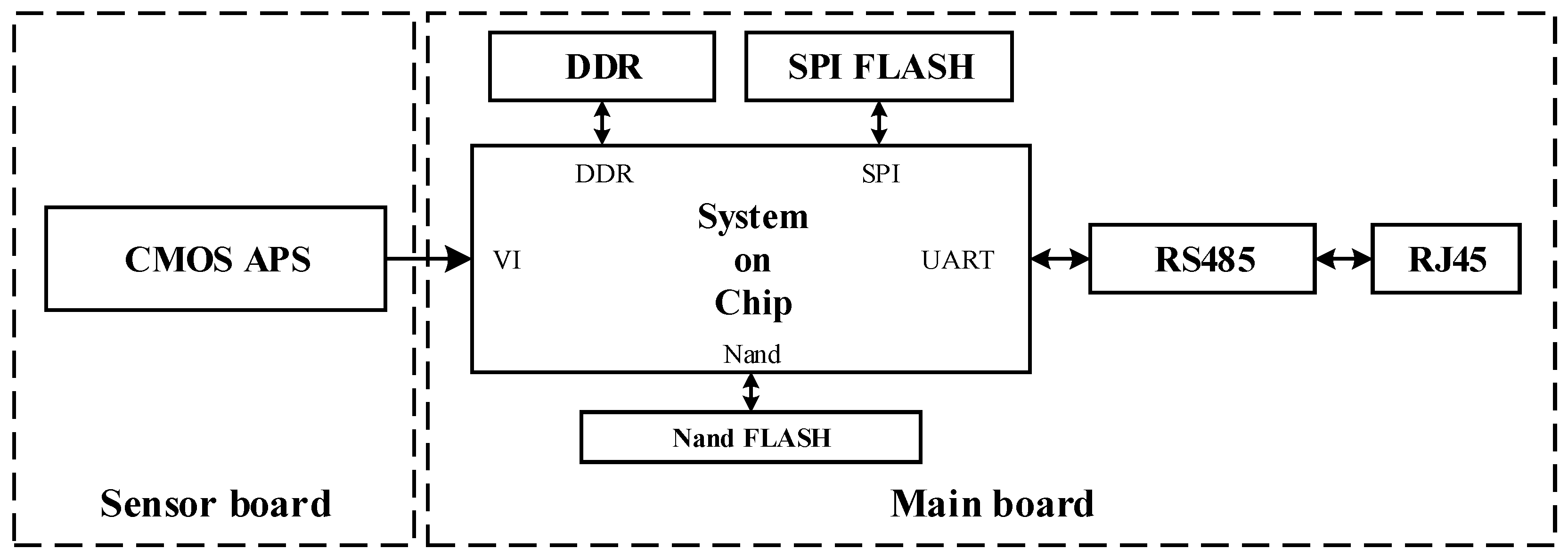

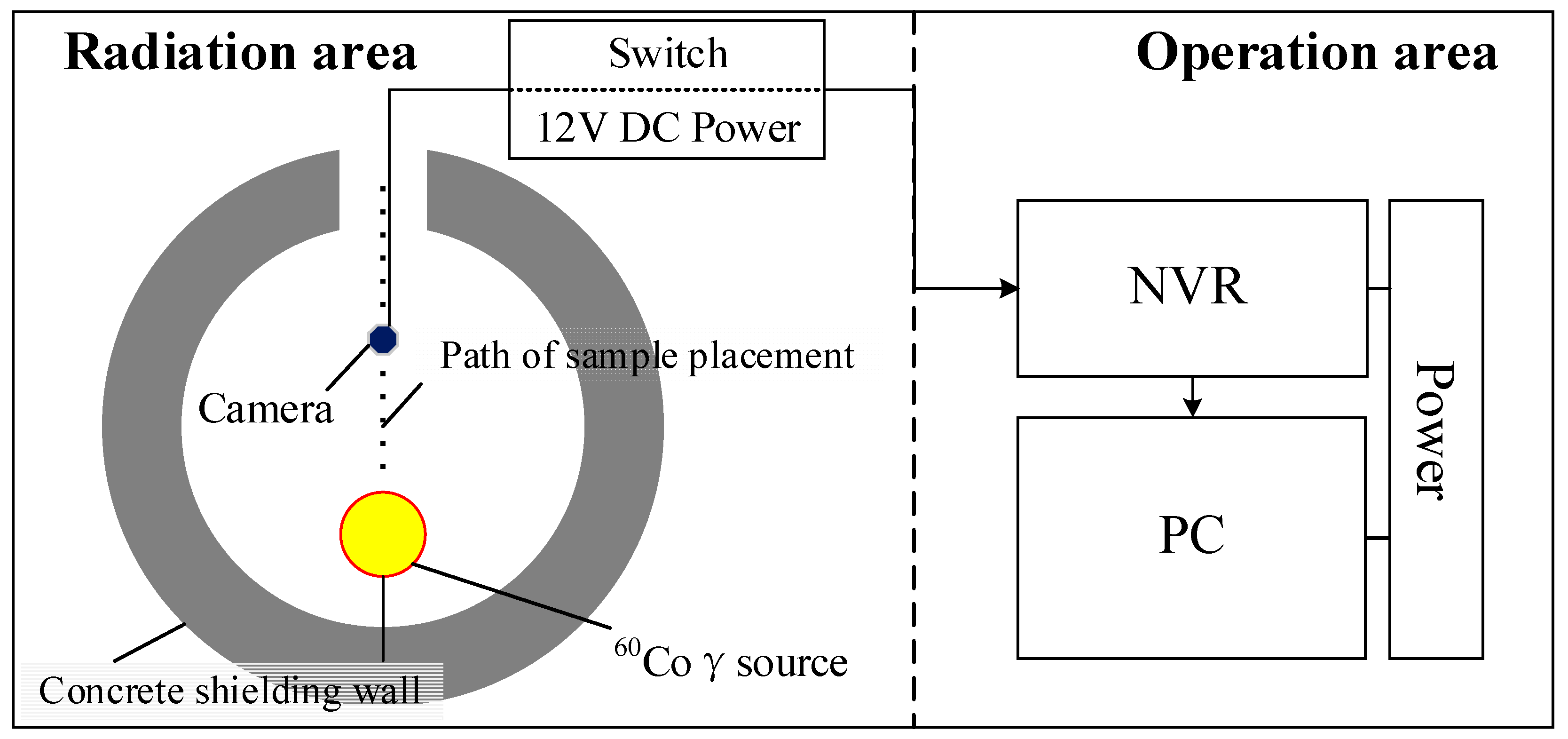

2.1. Experimental Setup

2.2. Data-Processing Methods

3. Results and Analysis

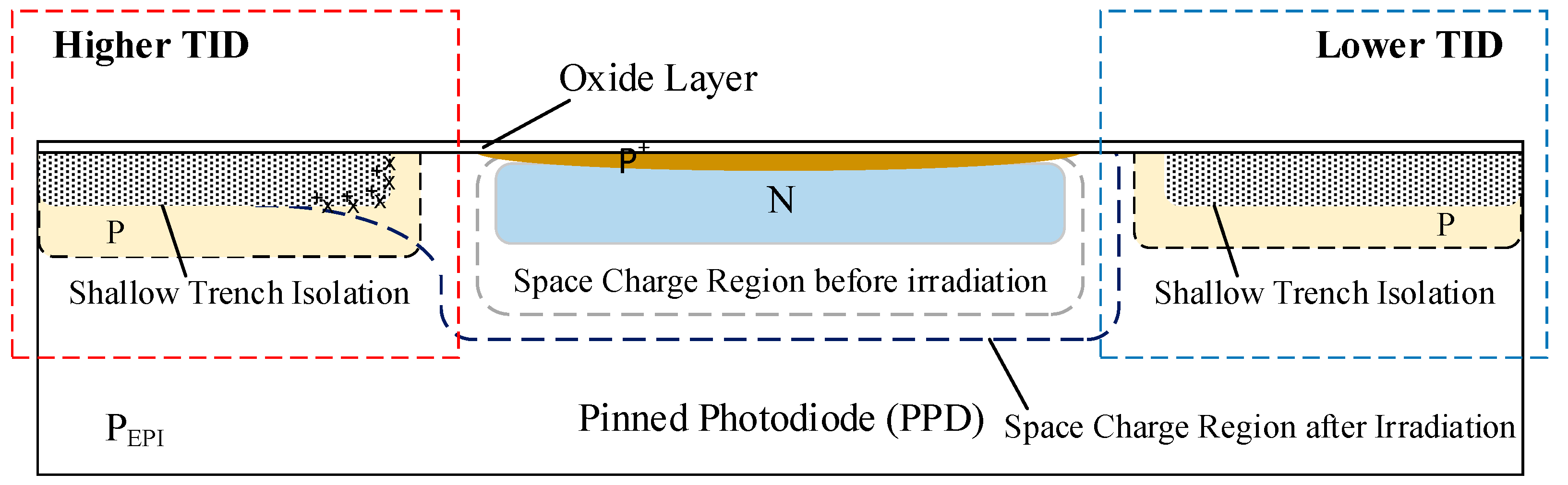

3.1. Radiation Damage

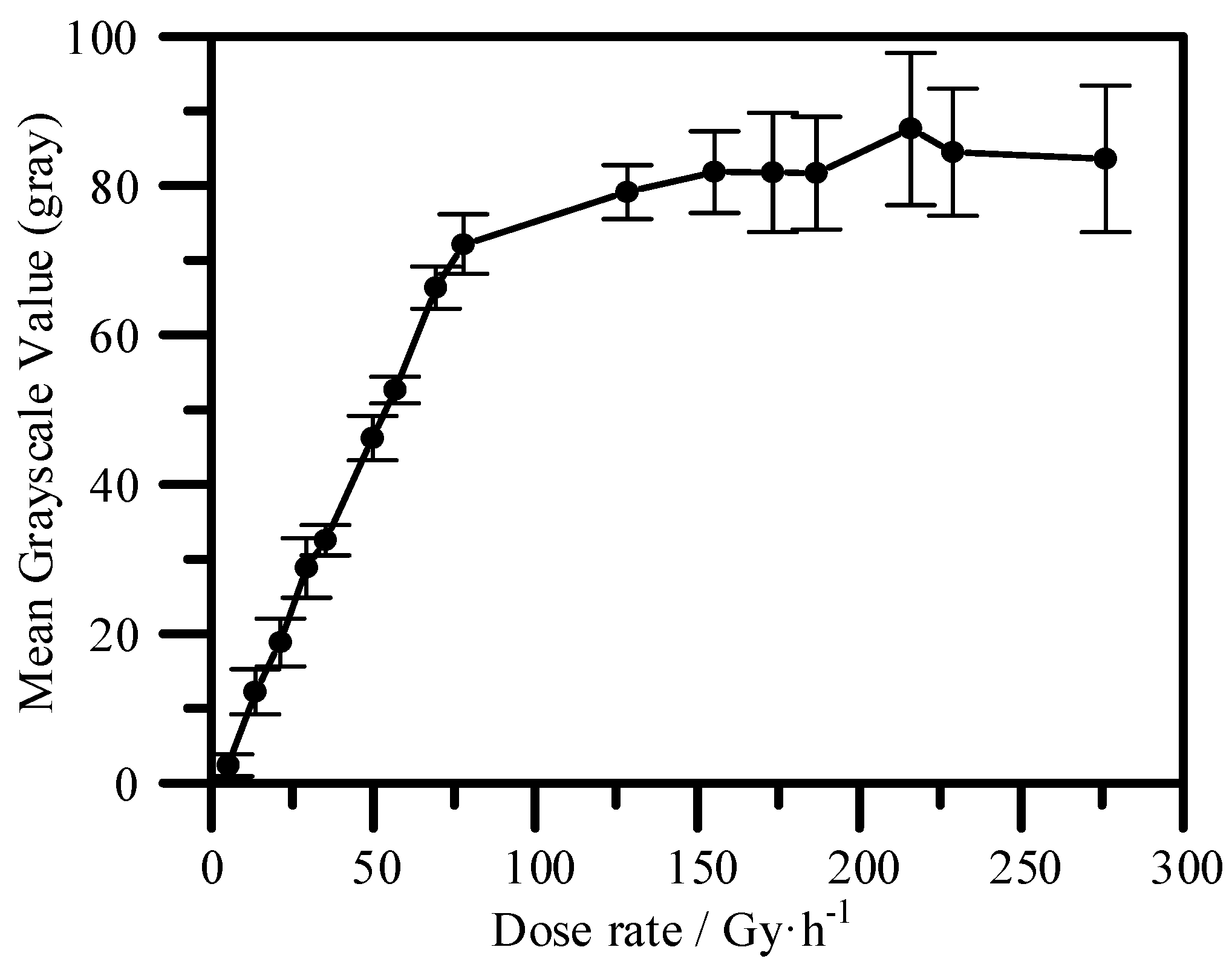

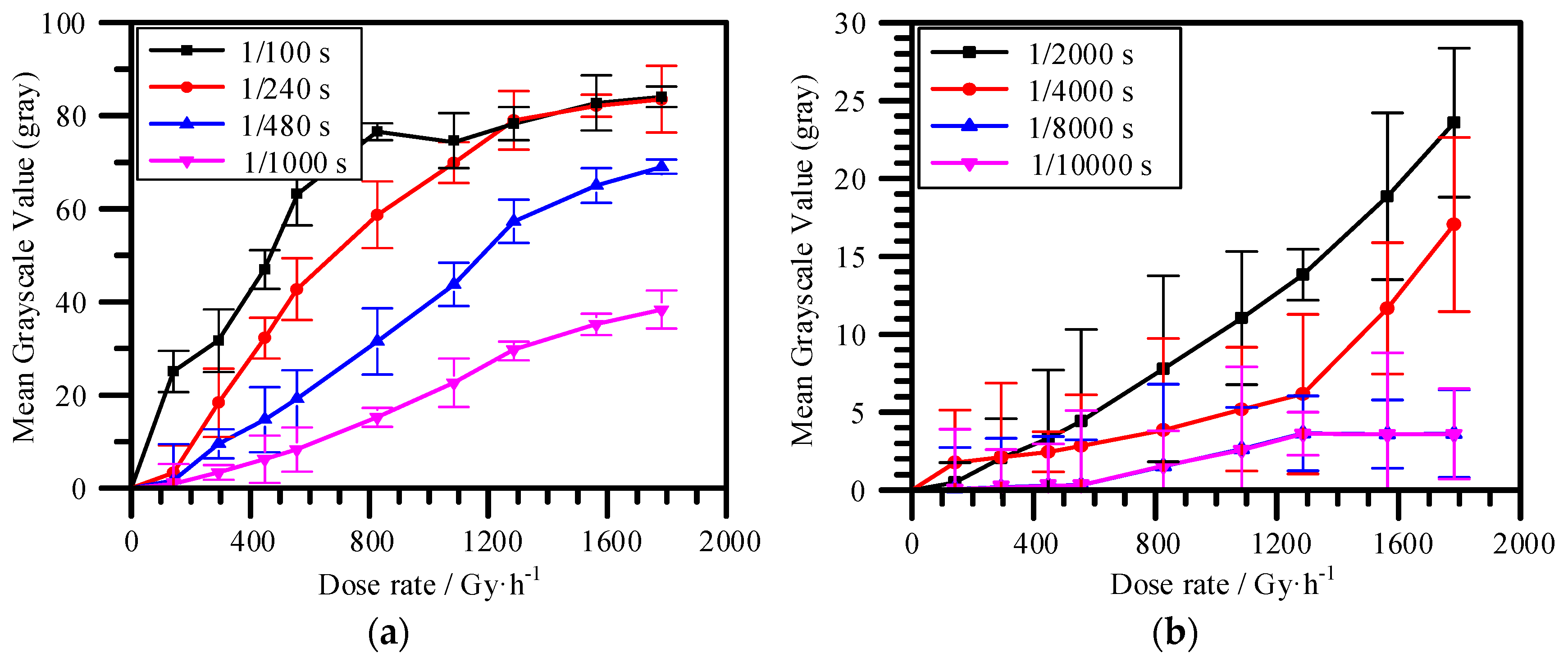

3.2. Radiation Response

4. Discussion and Application

4.1. Video Monitoring

4.2. Radiation Detection

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Goiffon, V.; Magnan, P.; Saint-Pé, O.; Bernard, F.; Rolland, G. Ionization versus displacement damage effects in proton irradiated CMOS sensors manufactured in deep submicron process. Nucl. Instrum. Methods Phys. Res. 2009, 610, 225–229. [Google Scholar] [CrossRef]

- Goiffon, V.; Virmontois, C.; Magnan, P.; Cervantes, P.; Corbière, F.; Estribeau, M.; Pinel, P. Radiation Damages in CMOS Image Sensors: Testing and Hardening Challenges Brought by Deep Sub-Micrometer CIS Processes. In Proceedings of the Sensors, Systems, and Next-Generation Satellites XIV (78261S), Toulouse, France, 13 October 2010. [Google Scholar] [CrossRef]

- Xu, S.L.; Zou, S.L.; Wu, Z.; Luo, Z.P.; Huang, Y.J.; Cai, X.M. Comparative Study on Ionizing Radiation Damage of Different Types of Image Sensor Modules. At. Energy Sci. Technol. 2016, 50, 2092–2100. [Google Scholar]

- Xu, S.L.; Zou, S.L.; Huang, Y.J. Effect of γ-ray Ionizing Radiation on CMOS Active Pixel Sensor. Chin. J. Lumin. 2017, 38, 308–315. [Google Scholar] [CrossRef]

- Fossum, E.R.; Hondongwa, D.B. A review of the pinned photodiode for CCD and CMOS image sensors. IEEE J. Electron Devices Soc. 2014, 2, 33–43. [Google Scholar] [CrossRef]

- Bagatin, M.; Gerardin, S. Ionizing Radiation Effects in Electronics: From Memories to Imagers; CRC Press: Boca Raton, FL, USA, 2015; pp. 2720–2722. ISBN 9781498722605. [Google Scholar]

- Kang, H.G.; Song, J.J.; Lee, K.; Nam, K.C.; Hong, S.J.; Kim, H.C. An investigation of medical radiation detection using CMOS image sensors in smartphones. Nucl. Instrum. Methods Phys. Res. 2016, 823, 126–134. [Google Scholar] [CrossRef]

- Sandy, T. Measurement of Gamma-Rays Using Smartphones. Open J. Appl. Sci. 2016, 6, 31–37. [Google Scholar] [CrossRef]

- Goiffon, V.; Estribeau, M.; Cervantes, P.; Molina, R.; Gaillardin, M.; Magnan, P. Influence of transfer gate design and bias on the radiation hardness of pinned photodiode CMOS image sensors. IEEE Trans. Nucl. Sci. 2014, 61, 3290–3301. [Google Scholar] [CrossRef]

- Wei, Q.Y.; Wang, Z.P.; Dai, T.T.; Yu, G. Nuclear Radiation Detection Based on Un-covered CMOS Camera under Static Scene. At. Energy Sci. Technol. 2017, 51, 175–179. [Google Scholar] [CrossRef]

- Cogliati, J.J.; Derr, K.W.; Wharton, J. Using CMOS Sensors in a Cellphone for Gamma Detection and Classification. arXiv, 2014; arXiv:1401.0766. [Google Scholar]

- Pérez, M.; Lipovetzky, J.; Haro, M.S.; Sidelnik, I.; Blostein, J.J.; Bessia, A.; Berisso, M.G. Particle detection and classification using commercial off the shelf CMOS image sensors. Nucl. Instrum. Methods Phys. Res. 2016, 827, 171–180. [Google Scholar] [CrossRef]

- Xu, S.L.; Zou, S.L.; Huang, Y.J. γ-ray Detection Using Commercial Off-The-Shelf CMOS and CCD Image Sensors. IEEE Sens. J. 2017, 17, 6599–6604. [Google Scholar] [CrossRef]

- Xu, S.L.; Zou, S.L.; Huang, Y.J.; Kuang, Y.; Guo, Z. Analysis of Photon Radiation Response Characteristics of 4T-PPD-APS. Acta Opt. Sin. 2018. Available online: http://kns.cnki.net/kcms/detail/31.1252.O4.20180116.1028.022.html (accessed on 16 January 2018).

- Xu, S.L.; Zou, S.L.; Wu, Z.; Song, L. Research on Availability of CIS Digital Module as Monitoring and Radiation Alarm Equipment under Condition of Nuclear Accidents. Nucl. Power Eng. 2017, 38, 88–94. [Google Scholar] [CrossRef]

- Goiffon, V.; Virmontois, C.; Magnan, P.; Cervantes, P.; Place, S.; Gaillardin, M.; Girard, S.; Paillet, P.; Estribeau, M.; Martin-Gonthier, P. Identification of Radiation Induced Dark Current Sources in Pinned Photodiode CMOS Image Sensors. IEEE Trans. Nucl. Sci. 2012, 59, 918–926. [Google Scholar] [CrossRef]

- Goiffon, V.; Estribeau, M.; Marcelot, O.; Cervantes, P.; Magnan, P.; Gaillardin, M.; Virmontois, C.; Martin-Gonthier, P.; Molina, R.; Corbiere, F.; et al. Radiation Effects in Pinned Photodiode CMOS Image Sensors: Pixel Performance Degradation Due to Total Ionizing Dose. IEEE Trans. Nucl. Sci. 2013, 59, 2878–2887. [Google Scholar] [CrossRef]

- Liu, Y.; Zou, S.; Kuang, Y. Effect of γ-ray Radiation and Sun Exposure on Transmittance of ZF6 Lead Glass. At. Energy Sci. Technol. 2016, 49, 2293–2298. [Google Scholar] [CrossRef]

| No. | Board Type | Dose Rate (Gy·h–1) | Operation Lifetime (h) | Dose (Gy) |

|---|---|---|---|---|

| 1 | Main board | 104.80 | 1.58 | 165.58 |

| 2 | 104.80 | 1.53 | 160.34 | |

| 3 | 113.27 | 1.68 | 190.29 | |

| 4 | 455 | 0.33 | 150.15 | |

| 5 | 1142.00 | 0.24 | 274.08 | |

| 6 | Sensor board | 409.3 | 1.22 | 499.35 |

| 7 | 409.3 | 1.2 | 491.16 | |

| 8 | 1142 | 0.45 | 513.90 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Zou, S.; Han, Y.; Qu, Y. Study on the Availability of 4T-APS as a Video Monitor and Radiation Detector in Nuclear Accidents. Sustainability 2018, 10, 2172. https://doi.org/10.3390/su10072172

Xu S, Zou S, Han Y, Qu Y. Study on the Availability of 4T-APS as a Video Monitor and Radiation Detector in Nuclear Accidents. Sustainability. 2018; 10(7):2172. https://doi.org/10.3390/su10072172

Chicago/Turabian StyleXu, Shoulong, Shuliang Zou, Yongchao Han, and Yantao Qu. 2018. "Study on the Availability of 4T-APS as a Video Monitor and Radiation Detector in Nuclear Accidents" Sustainability 10, no. 7: 2172. https://doi.org/10.3390/su10072172

APA StyleXu, S., Zou, S., Han, Y., & Qu, Y. (2018). Study on the Availability of 4T-APS as a Video Monitor and Radiation Detector in Nuclear Accidents. Sustainability, 10(7), 2172. https://doi.org/10.3390/su10072172