Abstract

Several studies have highlighted Combine Heat and Power (CHP) systems to be one of the proven and reliable technologies that can improve the efficiency of heat and electricity generation. The extensive adoption of this type of technology is crucial in reducing building emissions globally and in the U.K. This work uses a dynamic simulation software to evaluate the effect of CHP on the energy performance of an existing U.K. hotel and subsequently an approach to aid in the selection of optimum CHP size. The outcome of the study indicated that CHP systems in hotel buildings can provide considerable economic and environmental benefits with either maximally-sized CHP founded on the building’s base heat demand or with reduced CHP size of more than 50% smaller than the estimated maximum size. The optimum size design can be obtained through evaluation of the relationship between the main performance parameters and their variation with CHP sizes.

1. Introduction

Energy consumption and efficiency are important energy performance indicators in buildings for several stakeholders (such as energy end-users, researchers and governments) due to the continuous increase in global energy cost, depletion of available conventional energy resources and the adverse impact of global climate change and greenhouse gas emissions [1]. Research findings have highlighted the considerable proportion of building energy consumption accounting for around 40% of global energy consumption and it contribution to yearly greenhouse gas emissions, which accounts for up to 30% of global emissions [2,3]. However, compared to the other main greenhouse gas-emitting sectors, the building sector has the biggest potential of substantially reducing emissions with relatively less costly investments, especially since proven technologies that can reduce energy consumption and improve energy efficiency in both new and existing buildings are already commercially available [2].

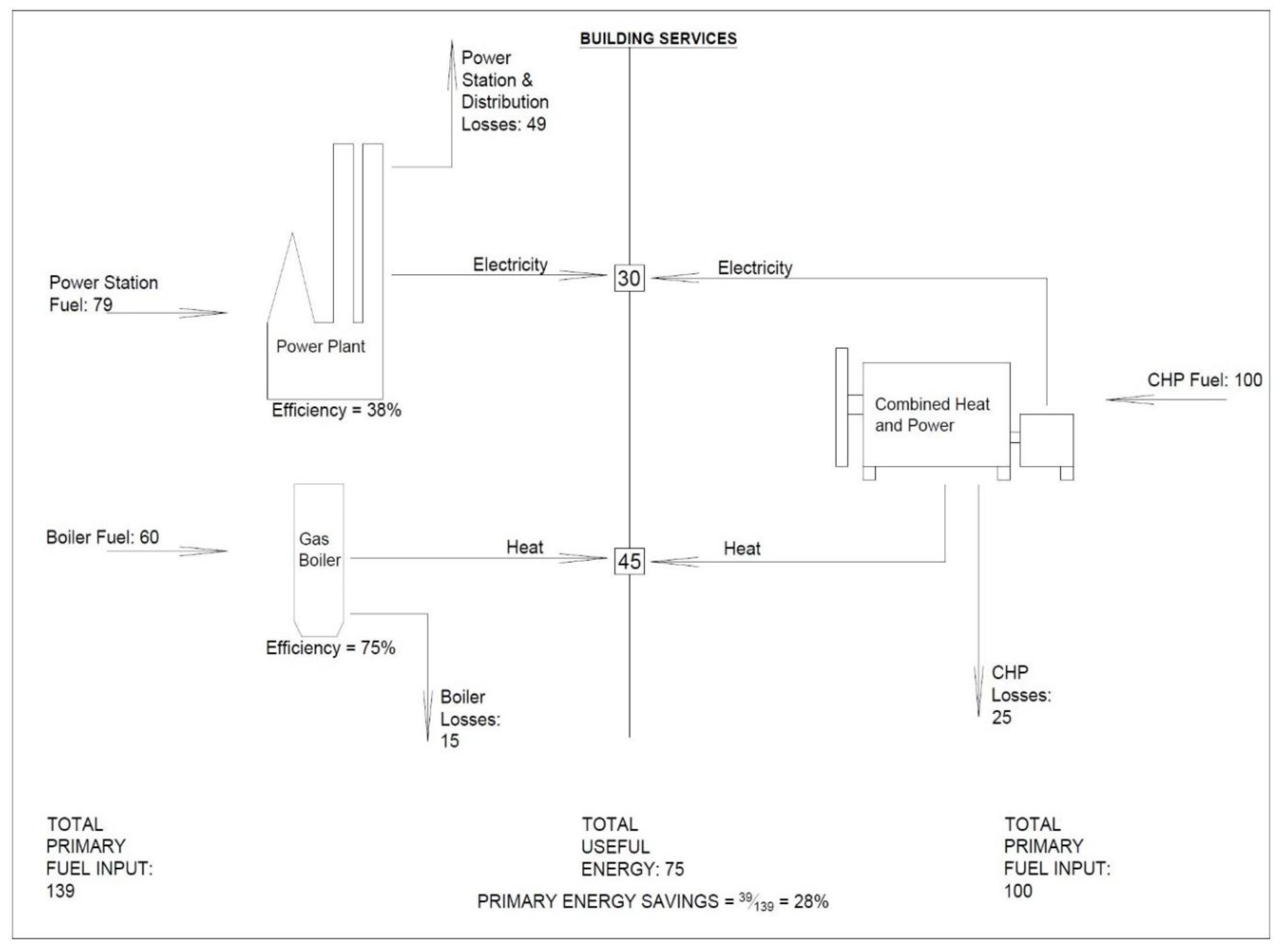

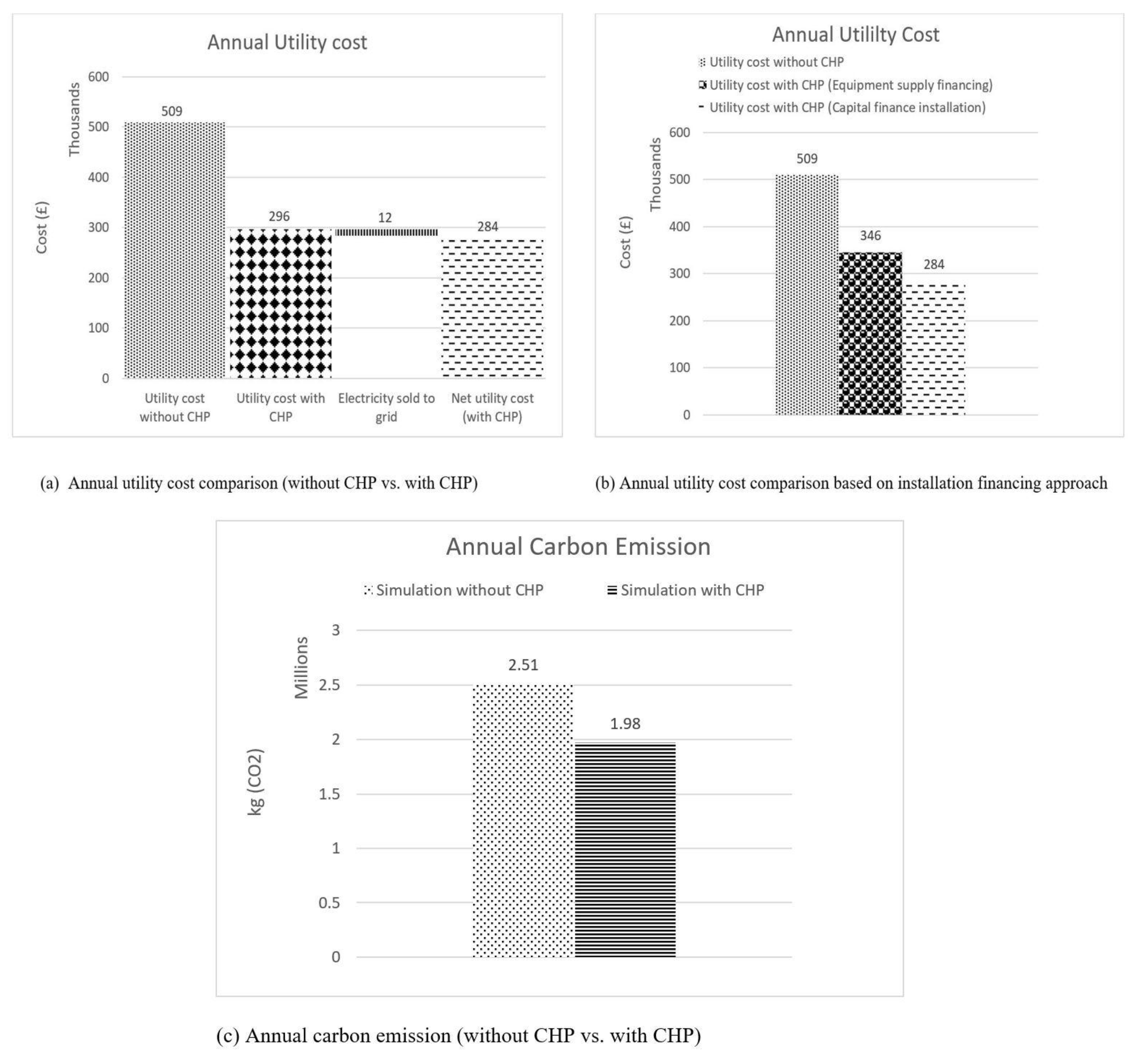

The CHP system has been highlighted by numerous studies to be one of the proven and reliable technologies that can improve the efficiency of heat and electricity generation. The extensive adoption of this type of technology is crucial in reducing building emissions in the U.K. [4], especially since recent records indicate that building emissions in the U.K. have increased in the last two years, with the trend only moderately linked to lower winter temperatures than in 2014 [5]. CHP, also known as co-generation or total energy, is the simultaneous utilization of useable heat and power from a single source fuel (such as oil, natural gas, biomass, liquefied gas) at the point of use; this offers a variety of environmental and economic benefits because of it associated primary energy savings relative to the conventional method (that is, on-site boilers and electricity power stations) [6,7,8]. To derive optimum benefit from a CHP, it is usually designed to run almost all throughout the year and to cater to the heat demand of the building as it is less expensive to transport surplus electricity than surplus heat [6]; hence, it is only viable for buildings with high and constant heat demand, such as hospitals, hotels, leisure centres and industry retail shops, among others. As a rule, CHP is economical for buildings with at least 4500 h of high and constant heat demand [7]. However, it can also be employed in buildings with lower heat demand that have high electricity and cooling demand [4,7]. Although CHP can take various forms and incorporate a variety of technologies, it is however founded on an efficient and integrated system that combines an electricity generation and heat recovery system, consequently enabling CHPs to convert between 75% and 80% of the input fuel into useful energy. Moreover, the most modern plants can offer over 90% efficiency [6]. Figure 1 shows the typical energy savings of a CHP system relative to traditional energy sources of heat and power generation in the U.K.

Figure 1.

Typical energy savings of a CHP system relative to traditional energy sources of heat and power generation in the U.K. [7].

The focus of this paper is to estimate the maximum CHP size to be retrofitted in an operational hotel building in the U.K. with the use of dynamic simulation software. Subsequently, the size is reduced to 70% of the maximum size at a rate of 10%. Critical analysis of the economic and environmental benefit of the CHP over these size ranges enables the selection of the optimum CHP size to be retrofitted. This work utilises the Hilton London Gatwick Airport hotel building as a case study. The presented objectives were employed to accomplish the study aim:

- Data collection of all essential building information including architectural plans, characteristics of the building envelope, plants/system data and actual building energy use. Inspection of the building is also done to validate collected information.

- Employing the gathered building information to develop a holistic model of the building with the energy simulation software.

- Computation of the total energy use of the building through plant/system modelling of the energy simulation software; subsequent verification of model results via comparison of the model result against the actual energy use of the hotel building.

- Introduction of the CHP into the model to evaluate the possible maximum CHP size based on the hotel’s base heating load with priority to meet Domestic Hot Water (DHW) demand, which is substantial and consistent throughout the year, hence ensuring that all the heat produced by the CHP is utilised.

- Reduction of the estimated maximum size by 10%, 20%, 30%, 40%, 50%, 60% and 70%; subsequently, critical analysis of the CHP performance over these range is employed as a basis of selection of the optimum CHP size.

Generally, in theory and practice, CHP systems in new and existing buildings are sized to match the capacity of the CHP to the base heat load of the building, to derive the most benefit [9]. However, this paper makes a contribution to existing knowledge as it presents a practical approach of assessing the optimum CHP size by critical analysis of a range of sizes; especially for large hotel buildings that tend to have considerably more heating demand compared to their electricity requirement. Moreover, this paper presents an approach of retrofit CHP sizing that is relatively more accurate as it involves dynamic whole building simulation. Therefore, the CHP is not sized based on just the annual heat demand of the building. Rather, the CHP is sized based on the results of peak heating design day from the thermal analysis simulation.

1.1. Literature Review

Evaluation of the existing literature reveals that there is a sizable amount of studies on the role of CHP in efficient energy production, the application of CHP in different types of buildings (commercial and residential), CHP operation strategies and the implementation of different hybrid cogeneration and renewable energy systems. This section presents a selection of these studies.

The works of Çakir et al. [10] and Mago and Smith [11] evaluated the potential energy efficiency and emission benefits of CHP systems in different types of buildings. Mago and Smith [11] worked on evaluating the energy performance of CHP systems in different types of commercial buildings in the United States; however, the study focused on the emission reduction benefits of the considered CHP system. The key findings of their study indicated that CHP use in the evaluated buildings always produced reduced GHG emissions of up to 21% carbon equivalent especially in commercial buildings with high thermal energy demand such as hospitals. They also claimed that it is usually beneficial to ensure that the CHP system is responsible for a high proportion of the building’s thermal demand, as this will provide improved primary energy savings, emission reduction and cost savings. Additionally, it is equally important that the thermal capacity of the chosen CHP system be close to the thermal energy requirement of the building to ensure higher efficiency of the CHP system. Çakir et al. [10] examined the contribution of CHP to the sustainability of energy using a case study gas-powered prime mover applied to a hospital building. Their study highlighted the concept of sustainability as it relates to CHP and provided a substantial review of studies that present the sustainability perspective of CHP systems even though they generally operate on fossil fuel. The sustainable aspect of cogeneration is associated with its energy efficiency and the possibility of incorporating some renewable energy conversion systems such as solar systems or heat pumps. Their results indicated that the cogeneration system improved energy efficiency, consequently resulting in in energy cost savings, reduction in GHG emissions, increased reliability of power and reduced grid congestion.

In exploring different options to improve the viability of CHP for diverse categories of buildings and developments, some studies, for instance [12,13,14,15], investigated the introduction of thermal and electric energy storage to CHP systems. Bianchi et al. [12] and Magnani et al. [15] both evaluated the performance and optimisation of CHP system integrated energy storage using residential case study buildings. The result of Bianchi et al. [12], who incorporated both thermal and electric storage technologies, demonstrated that CHP systems with aptly-sized thermal and electric storage can provide the total energy demand of the reference case study building whilst also achieving considerable primary energy savings compared to a non-CHP system reference case. The result of the work of Magnani et al. [15], which investigated the optimal design of coupling a thermal storage and absorption chiller, indicated that this tri-generation system provides significant economic and environmental benefits, especially with larger CHP size based on peak electric load. Smith et al. [13] and Wang et al. [14] evaluated the energy performance benefits of incorporating energy storage in different commercial buildings and district heating CHP-based systems, respectively. Smith et al. [13] examined CHP systems sized to operate at a constant base load with and without a heat storage system for different types of commercial buildings in the United States. Their result indicated that for all the categories of commercial buildings considered, CHP systems always provided savings in primary energy consumption and reduction in GHG emissions. Moreover, their results showed that for six of the eight building types investigated, the introduction of thermal storage delivers additional utility cost savings and reduction in GHG emissions. However, the addition of thermal storage to CHP systems is less likely to be beneficial in buildings with higher ratios of power to thermal requirements. Wang et al. [14] worked on the design and optimisation of a hybrid CHP district heating system incorporating thermal energy storage to minimise the total cost of the net procurement of heat and electricity. The core outcome of their investigation indicated that the efficiency of thermal storage systems needs to be properly considered when optimising the operation of the CHP district heating system and that the optimal operation of thermal energy storage is equally influenced by the heat demand and power price.

2. Methodology

The focus of this work is to assess the maximum and subsequently the optimum CHP size to be retrofitted in a case study hotel building, located in the southeast of the U.K. The investigation is done using of an approved energy simulation program.

The procedure used to accomplish the articulated goal with the study building can be grouped into two different phases. The initial phase entails evaluating the building’s energy behaviour by creating a holistic base model that is representative of the building envelope, plants and thermal performance of the real building. Building energy use, which is an important indicator of estimated energy performance, is verified by contrasting against the energy use data of the real building. The energy use data are obtained from onsite gas and electric meter readings. Inspection of the case study building was done to facilitate the validation of collected building information including building envelope information (e.g., walls and windows), information on building occupancy to certify that simulation assumptions are representative, building usage to confirm that zone categorisation is in conformity with that indicated on the architectural plan and Heat Ventilation and Air Conditioning (HVAC) system attributes. The concluding phase entails the incorporation of the CHP system into the model to estimate the maximum CHP size. Subsequently, the size is reduced at a rate of 10% to inform the selection of the optimum size of CHP from the succeeding critical analysis.

The whole building simulation program used to model and evaluate the energy performance for this investigation is the Environmental Design Solutions Limited (EDSL) Tas software Version 9.3.3. The program developed by EDSL, Milton Keynes, UK, is a suite of application products with the capacity to simulate the thermal behaviour of buildings and their systems [16]. Crawley et al. [16], EDSL [17] and Rotimi et al. [18] have provided a description of the capabilities of the software and its various suites such as Tas Building Designer (TBD), Tas 3D modeller and Tas systems.

2.1. Building Description

Hilton London Gatwick Airport hotel building located in Gatwick Horley is used as a case study for this investigation. The hotel structure consists of three integrated five-storey buildings with different years of construction. The central main building was constructed in 1981 with two extensions constructed to its north and south ends in 1986, and both buildings house 588 guest rooms served by the same HVAC system. An additional extension to the south was constructed in 2002, consisting of 233 rooms, served by a separate HVAC system. The hotel building is primarily a framed structure with cavity walling and double-glazed windows. The building is mostly air conditioned and sealed for noise abatement due to its proximity to the airport. The hotel has a floor area of 37,236 m2, conditioned space area of 28,257 m2 and is comprised of the main public areas including the foyer, two restaurants, meeting rooms, ballroom, gym, retail units and the back of house areas. The meeting rooms, restaurant and public areas are within the ground floor level, and Floors 1–5 of the hotel house the 821 guest bedrooms.

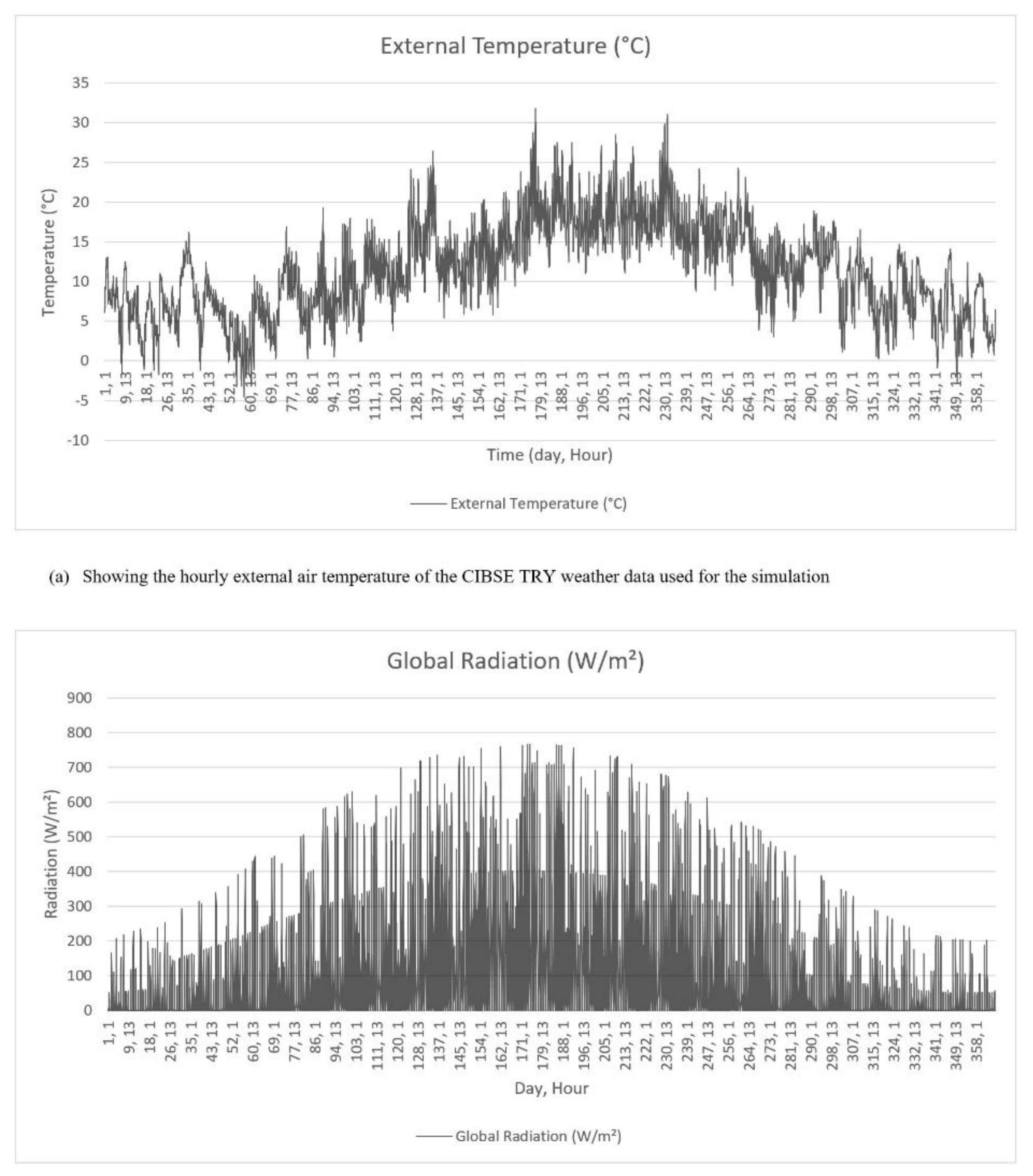

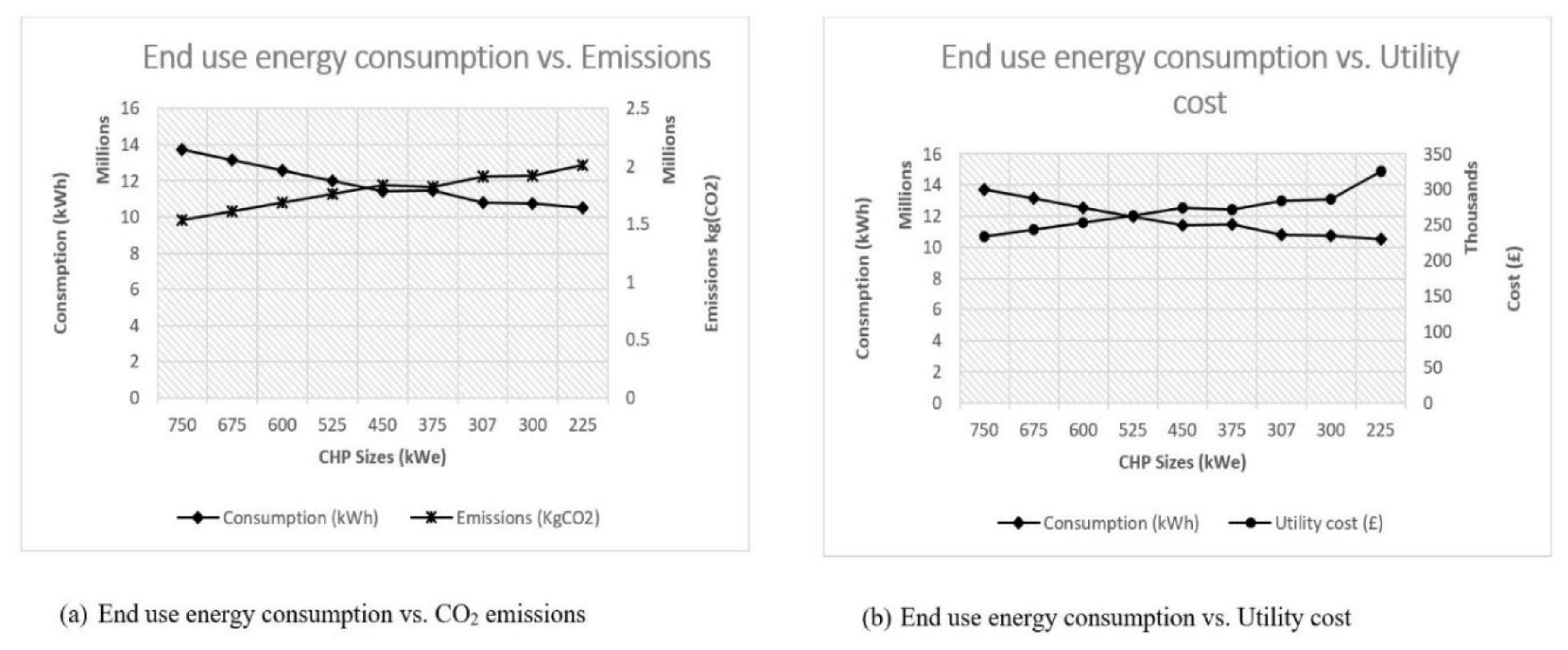

Most of the occupied spaces, comprised of the guest rooms, are served by assigned central Air Handling Units (AHUs) situated in the plant rooms. There are nineteen AHUs supplying conditioned air, and they are mainly supply units with separate extract fans. The majority of the AHUs service the main building and are supplied by two air-cooled chillers situated in the roof level plant room, while two additional smaller chillers service the newer building extension. The AHUs are also fitted with hot water heating coils fed from central gas-fired boilers (five boilers in total). The bedrooms are heated and cooled via ducted 4-pipe Fan-Coil Units (FCUs) hidden within the ceiling. Central chillers and boilers feed the cooling and hot water heating coils within the FCUs, and the central AHUs provide additional fresh air through supply air ducts to the back of individual FCUs. The nearest weather station is in central London, which is approximately 28 miles from Gatwick Horley. Hence, the weather data employed for the energy simulation modelling are the recent Chartered Institution of Building Services Engineers (CIBSE) London Test Reference Year (TRY). Latitudinal information of 51.9° north along with −0.9° east longitudinal data and UTC +0.0 time zone were inputted to facilitate the shadow calculation and orientation in the program and to register the geographical location parameters of the hotel building. Figure 2 indicates the hourly external temperature and global radiation of the weather data employed for the model.

Figure 2.

The external temperature and global solar radiation of the simulation weather data. TRY, Test Reference Year.

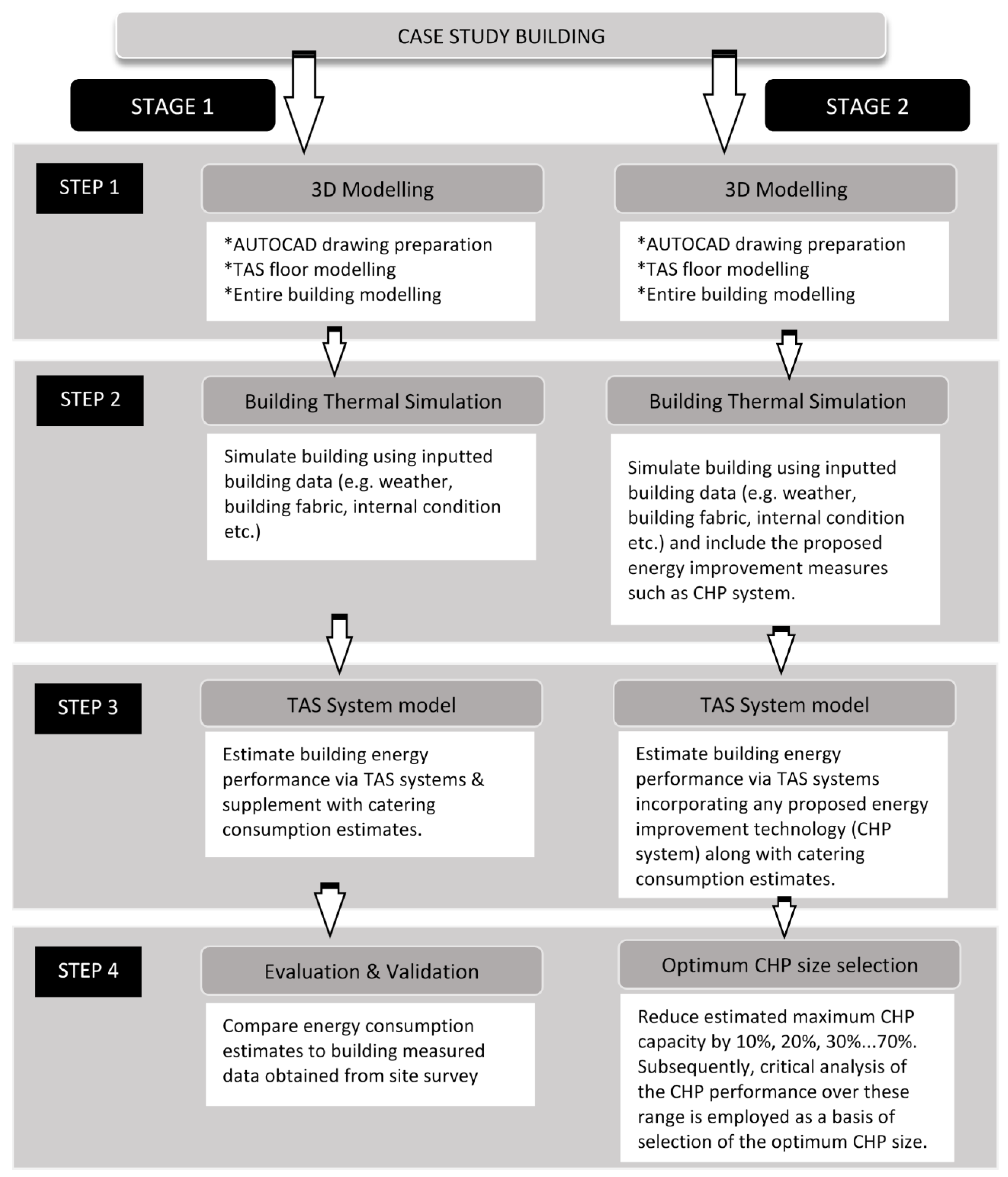

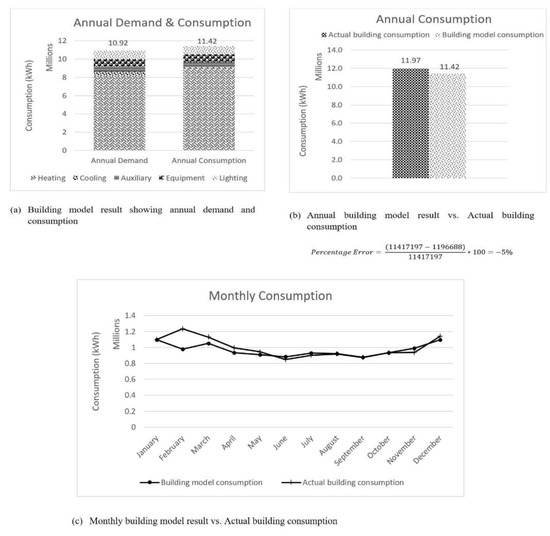

2.2. Building Modelling Process

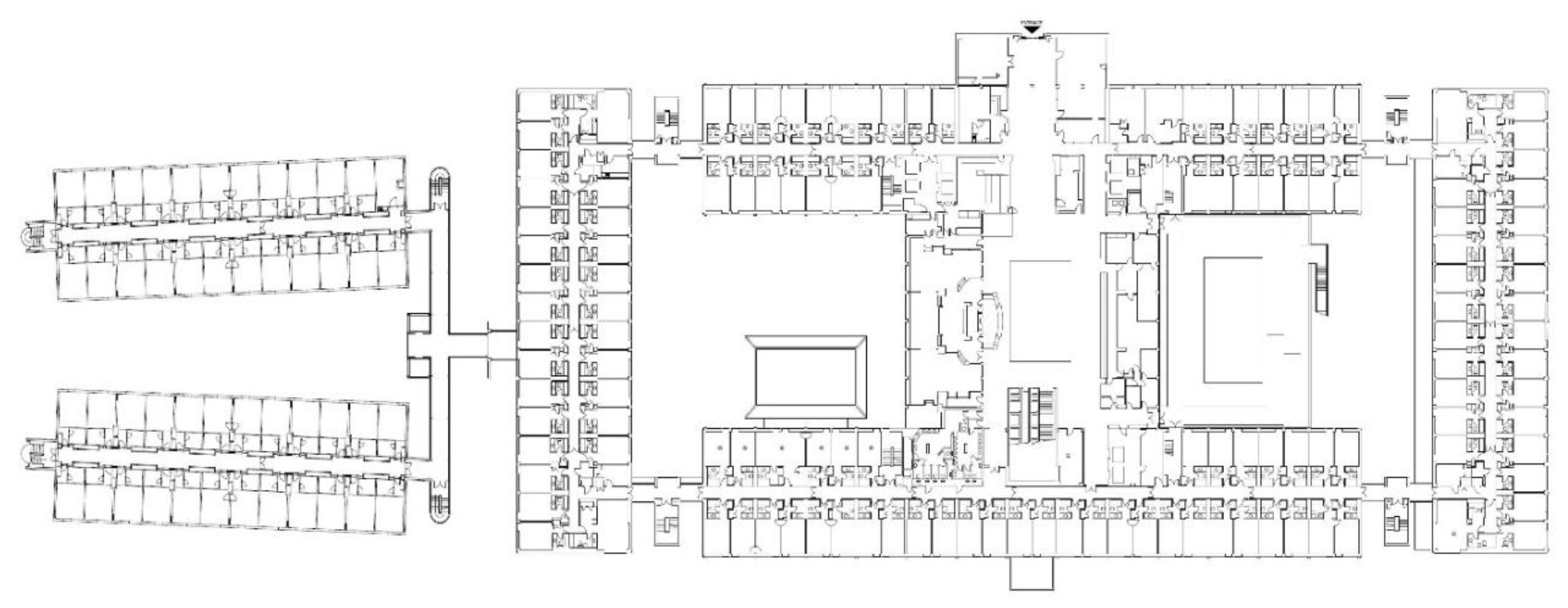

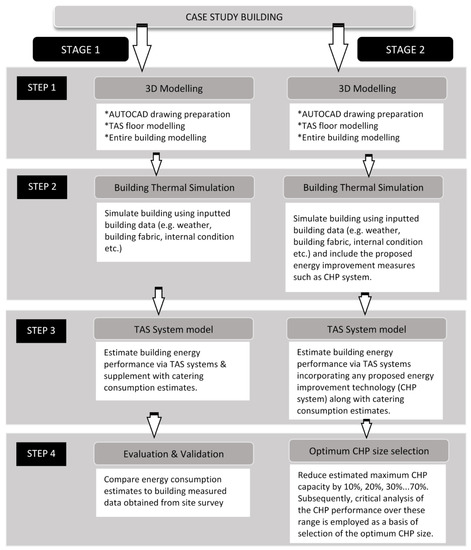

The process of modelling a building in EDSL Tas through the various applications of the package, that is the 3D modeller, thermal simulation component and plant/system modelling module, have been wholly described by [19,20]. These works provided the necessary steps to be followed including the preparation of drawings, modelling of individual building floors and flowcharts detailing each step of the distinct process of the simulation. However, a summary of the processes employed for this case study is presented in Figure 3. The floor plan used in the 3D modelling process of the building is presented in Figure 4, and Table 1 and Table 2 present the simulation parameters and assumptions of the model underpinned by the attributes of the study building.

Figure 3.

Case study method summary.

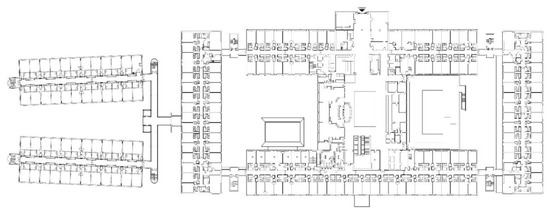

Figure 4.

Typical floor plan of the hotel building.

Table 1.

Simulation assumptions of the model underpinned by the attributes of the building.

Table 2.

Modelling and simulation parameters and assumptions.

3. Results and Discussion of Results

3.1. Base Model (without CHP)

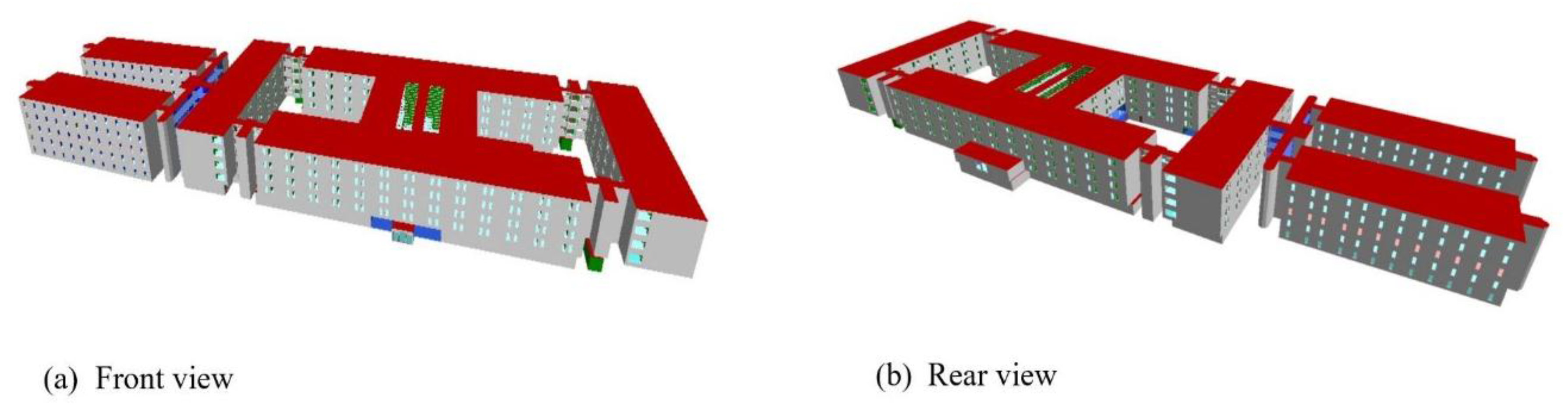

The results for and discussion of the case study hotel building are presented in this section. Figure 5 shows the 3D model of the hotel, which is the result of the 3D modelling process.

Figure 5.

3D modeller results.

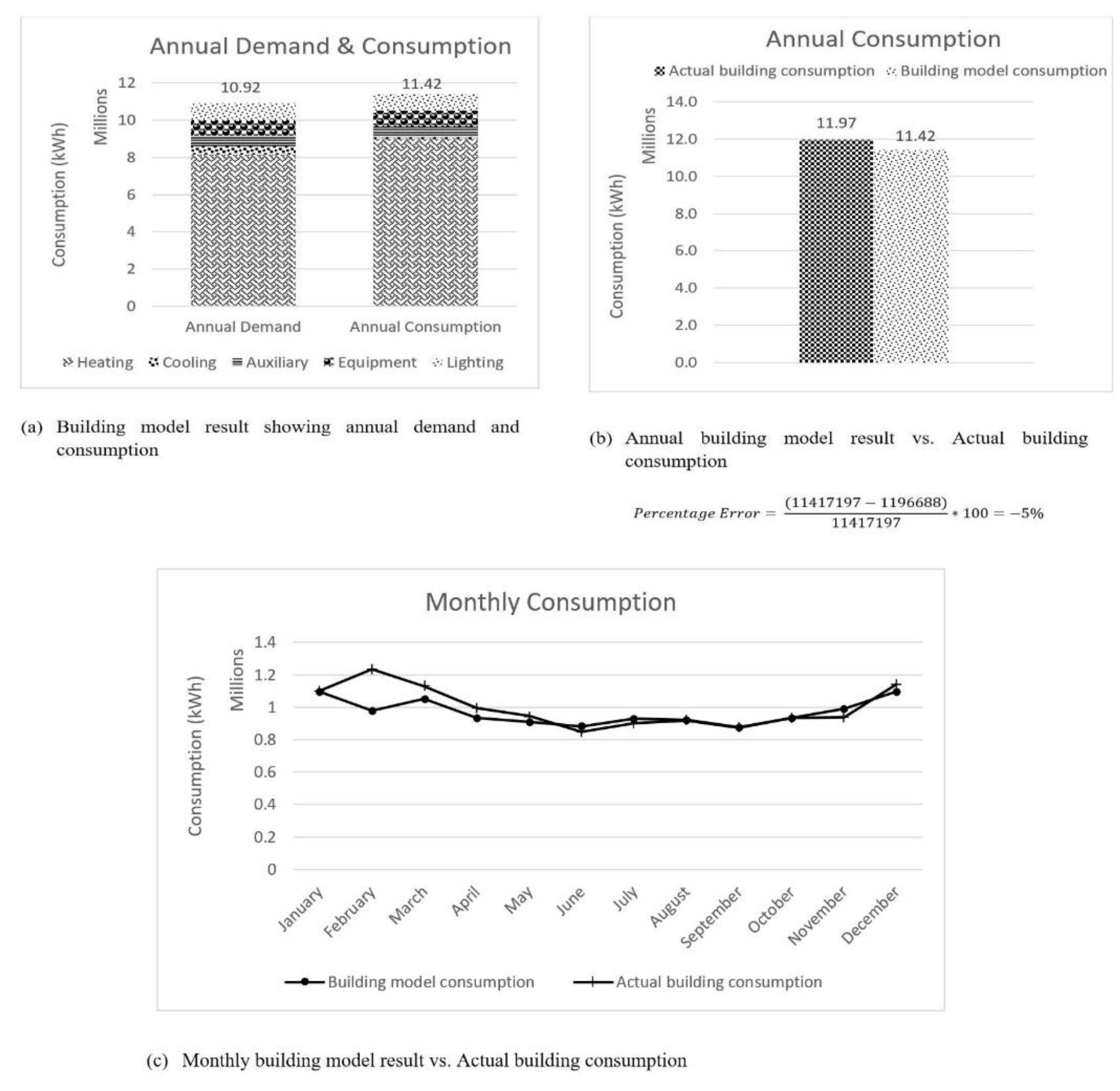

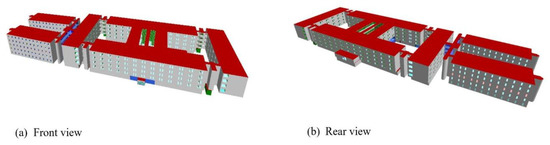

The TBD module of the program is properly populated to facilitate the simulation of the base model that is representative of the building without a CHP. Subsequently, the simulated TBD file is coupled to the systems modelling module of the program to estimate the energy performance results of the building. The performance results that are typically comprised of reports of yearly and monthly energy use and demand are presented. The energy consumption result includes heating, cooling, auxiliary, lighting and equipment energy consumption.

Figure 6a shows the yearly energy demand and consumption of the building computed via simulation of the building’s plant/systems. The figure indicates the components of energy consumption and demand estimates, consisting of heating, cooling, auxiliary, lighting and equipment. Heating includes an aggregation of space heating and Domestic Hot Water (DHW); while the energy utilised by controls, pumps and HVAC system fans is termed as the auxiliary energy. In calculating the heating and cooling demands, there is a typical allocation for small power heat gains, which is from the equipment energy use. It can be observed from Figure 6b that the predicted total energy consumption of the building simulation model is comparatively lower than that of the actual building consumption with a percentage error of −5%, indicating an underestimation. Energy simulation models cannot completely replicate the real building operation, even when the building envelope characteristics and internal condition parameters are carefully selected. The discrepancy is associated with the dynamic nature of some of the simulation input data such as weather and occupant behaviour, which are difficult to replicate; hence, errors cannot be totally eliminated. Moreover, building simulation models use typical weather data for a single year [21] like the TRY weather data used in this case study.

Figure 6.

Building energy performance result.

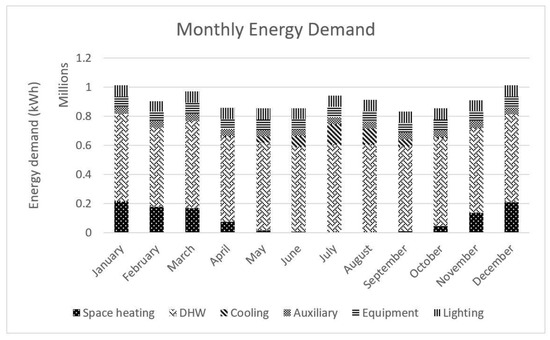

Figure 7 presents the breakdown of the monthly energy demand, which includes space heating and DHW. It also highlights the suitability of CHP for the case study building. From the figure, it can be observed that the building has high and constant heat demand throughout the year, especially DHW demand, which is up to 64% of the total energy demand even in the peak of the summer. This high and constant DHW demand, which is consistent with hotel buildings, allows the selection of the maximum size of CHP to be underpinned by the baseline heat load with priority to DHW.

Figure 7.

The breakdown of building energy demand.

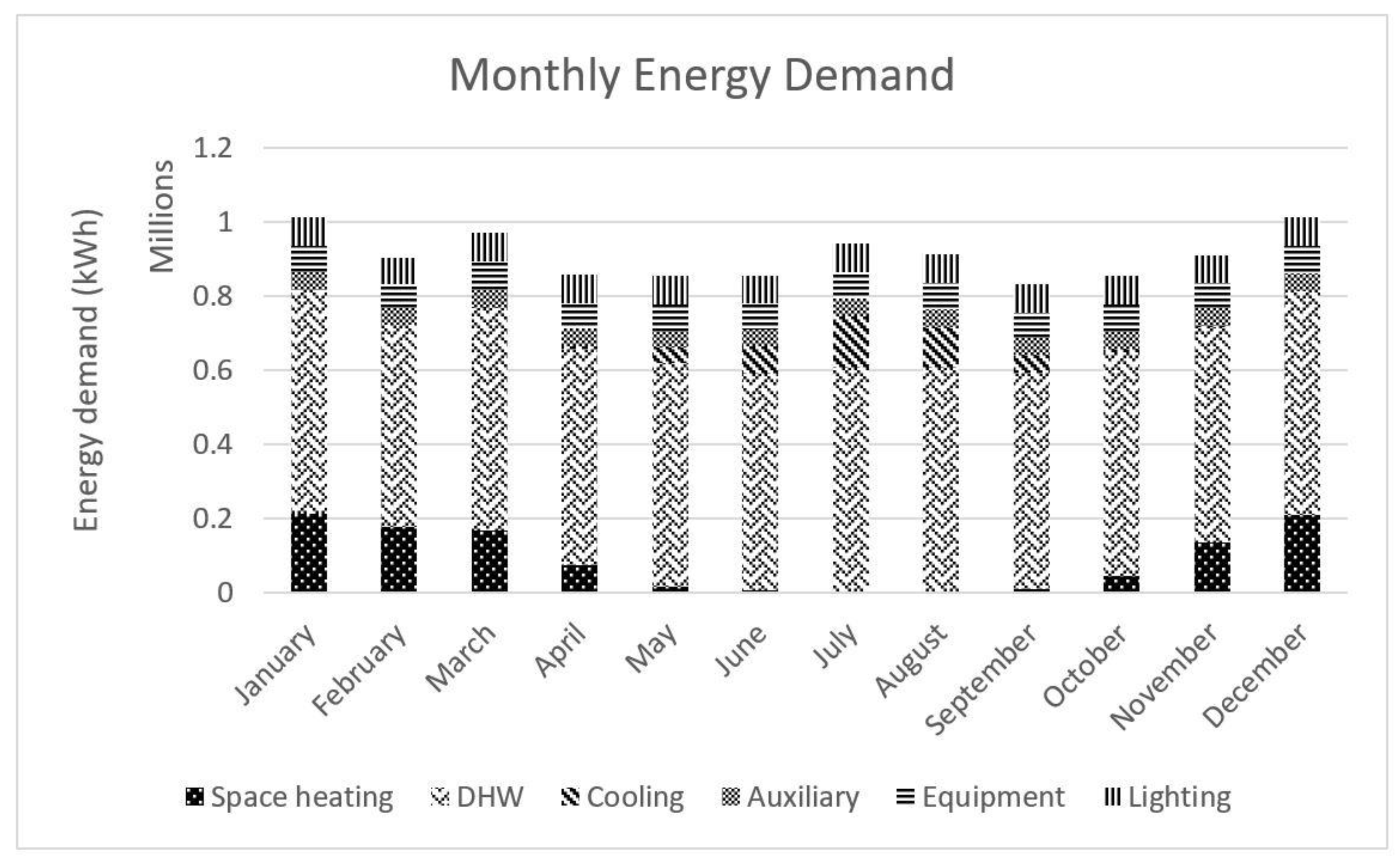

3.2. Model with Maximum Capacity of CHP

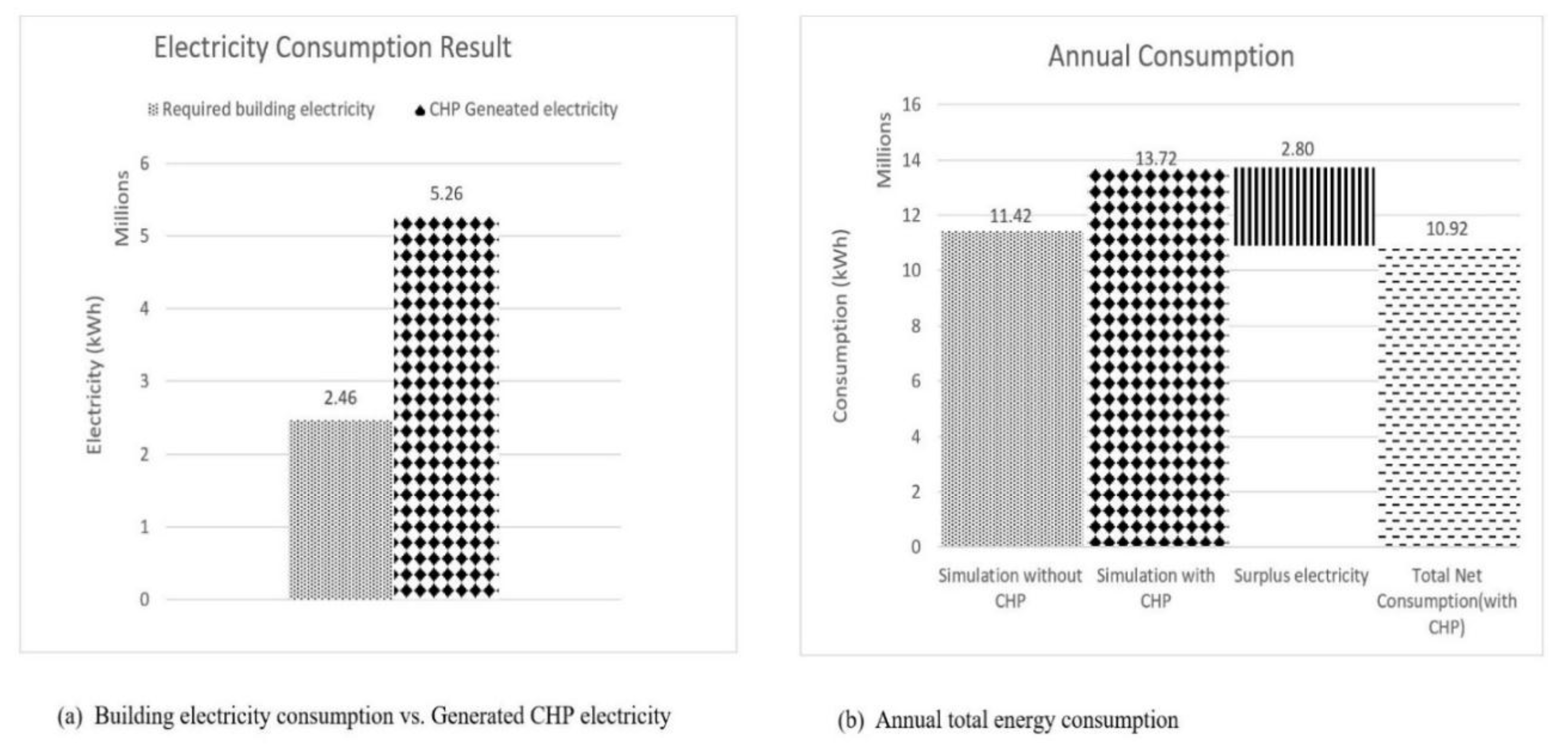

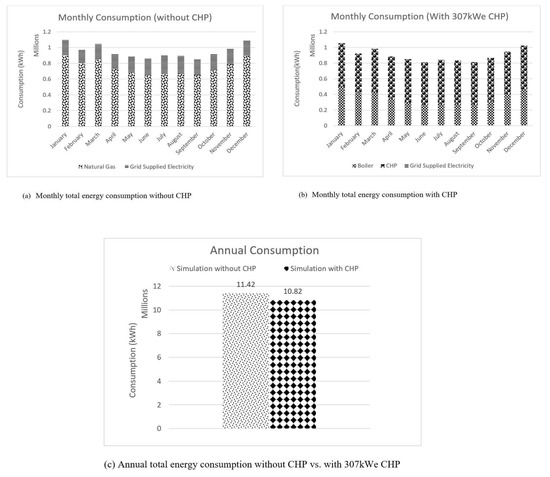

The following stage of the analysis entails the modelling of the case study building incorporating the CHP to determine the maximum size of the CHP system that is beneficial based on the base thermal energy requirement of the building. The capacity of the CHP estimated from this maximum beneficial sizing simulation is 750 kWe with a heat to power ratio of 1.2. Figure 8, Figure 9 and Figure 10 present the results of the analysis comparing the energy performance of the building without CHP against the building model with the maximum capacity of CHP.

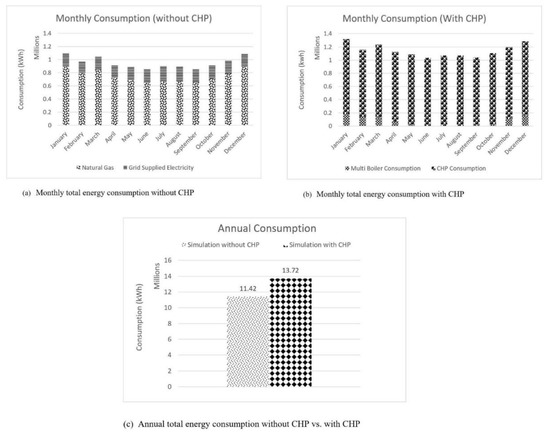

Figure 8.

Total energy consumption result (without CHP vs. with CHP).

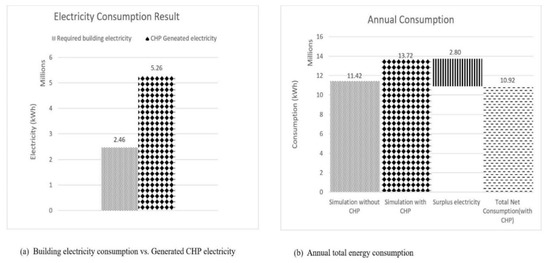

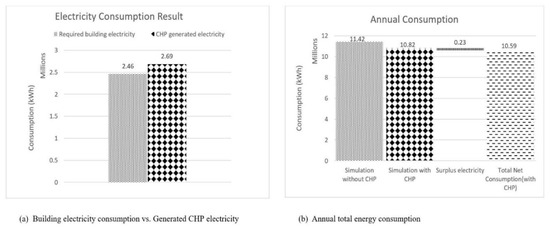

Figure 9.

Electricity generation results and total energy consumption.

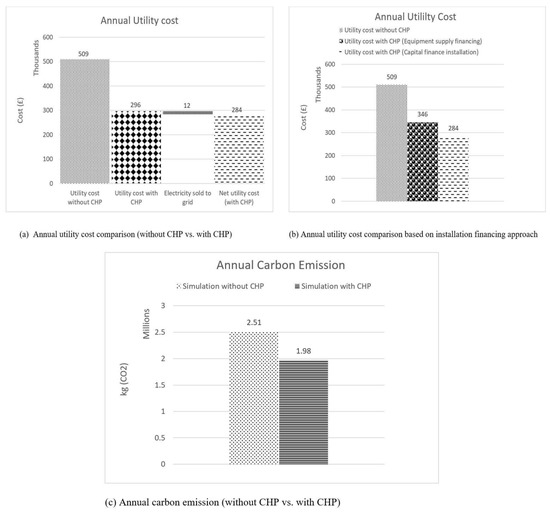

Figure 10.

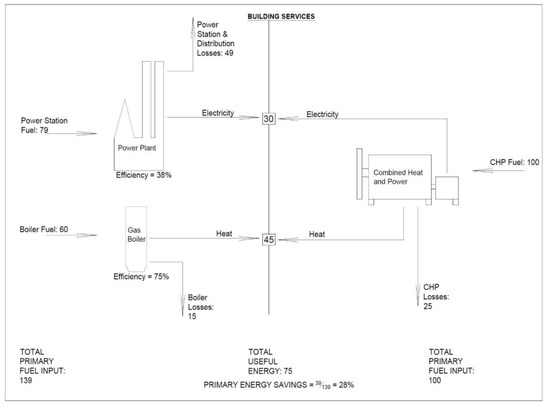

Cost and carbon emission result (without CHP vs. with CHP).

Figure 8 presents the result of the total end use energy consumption of the building without CHP compared to that with a CHP installed. From Figure 8a,b, the incorporation of the CHP resulted in the change of the fuel/energy mix of the building from natural gas and grid-supplied electricity to only natural gas. This is because the CHP produces sufficient electricity and a substantial proportion of heat to serve the building, while the deficit heat requirement is met by the boilers. In most cases, this results in the increase of the end use energy consumption of the building as more natural gas is required to run the CHP; however, the associated improved energy efficiency usually offsets the increased onsite fuel consumption [9]. From Figure 8c, an increase in annual total end use energy consumption can be observed, with the CHP model indicating a 20% increase compared to the building model without CHP.

The results of CHP electricity generation and its relation to the end use energy consumption are shown in Figure 9. From Figure 9a, the CHP generates up to 50% (2,800,317 kWh) more electricity than the electricity requirement of the building. The surplus electricity can be sold to the grid, contributing to the reduction in total energy cost. From Figure 9b, though as highlighted earlier, the end use energy consumption is higher due to the increased consumption of natural gas. However, the natural gas produces both thermal energy and electricity to be used by the building; therefore, the surplus electricity that is a positive for the site can be deducted from the total end use energy consumption of the CHP model. This energy balance gives an estimation of the total net energy consumption (with CHP) demonstrated in Figure 9b, which is even marginally lower than the total energy use of the building without CHP.

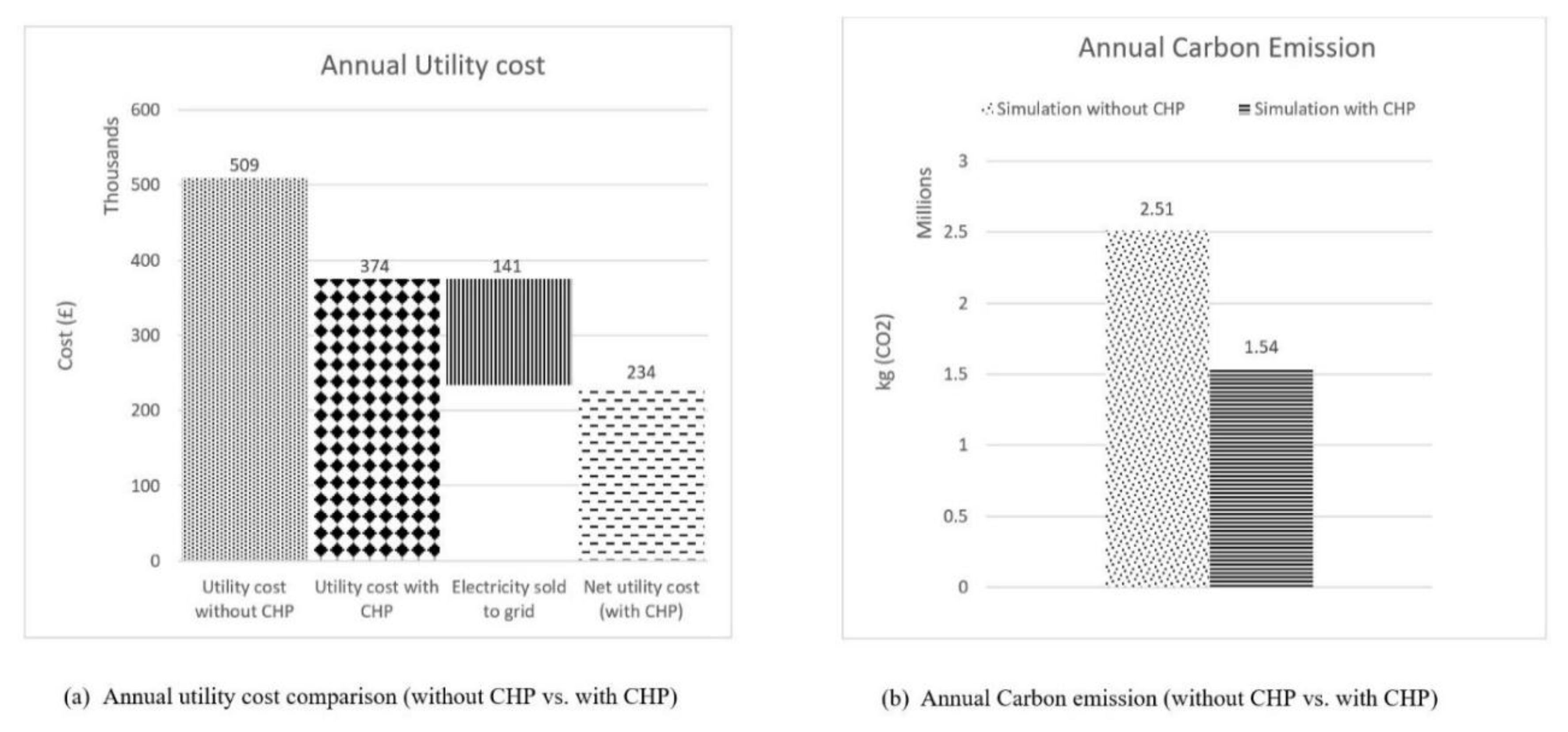

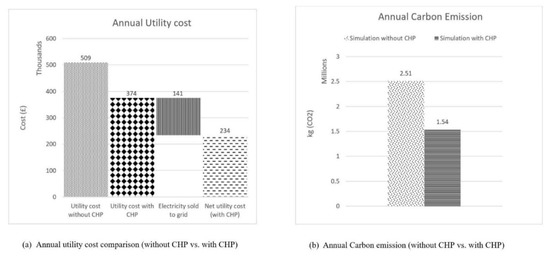

Since the benefits of the CHP system are attributed to its energy efficiency, it is useful to investigate the influence of the CHP on the carbon emissions and energy utility cost of the building. Especially as the conversion factor and unit price used for estimating the cost of energy and carbon emissions from natural gas and grid-supplied power are not the same, data for the U.K. Green House Gas (GHG) conversion factors are provided by the Department for Business, Energy & Industrial Strategy reporting spreadsheet. Hence, this analysis uses conversion factors of 0.184 for carbon emissions and 0.35156 for grid supplied power as stipulated in the spreadsheet [22]. Additionally, a natural gas price of £0.0273 per kWh and £0.108 per kWh for grid-supplied power were utilised in the utility cost calculations. The energy tariff employed in this investigation was collected from the supplied energy information of the hotel. As recommended by the Office of Gas and Electricity Market (OFGEM), a feed-in tariff rate of £0.0503 was used for the CHP surplus electricity [23]. Figure 10 presents the findings of the effect of CHP on the cost of energy and carbon emissions.

From Figure 10a, showing the annual utility cost result, the utility cost of the model with CHP was 26% lower than that without a CHP even though the end use energy consumption of the CHP model was considerably higher than that without a CHP. The reduction in cost is due to the change of the fuel source of the CHP model to gas only compared to the conventional gas and electricity energy source in the building without CHP, consequently taking advantage of the cheaper price of natural gas. Furthermore, the CHP model produces more electricity than required by the building, which can be sold back to the grid at a similar rate as grid-supplied electricity. Accounting for the sale of the surplus electricity results in up to a 54% reduction in utility cost (i.e., the net utility cost). Figure 10b illustrates the annual CO2 emissions result. It can be seen that the CHP model provides a 39% reduction in CO2 emissions relative to the model without CHP. The CO2 emissions reduction is largely due to the energy efficiency of the CHP system and its associated reduction in primary energy consumption.

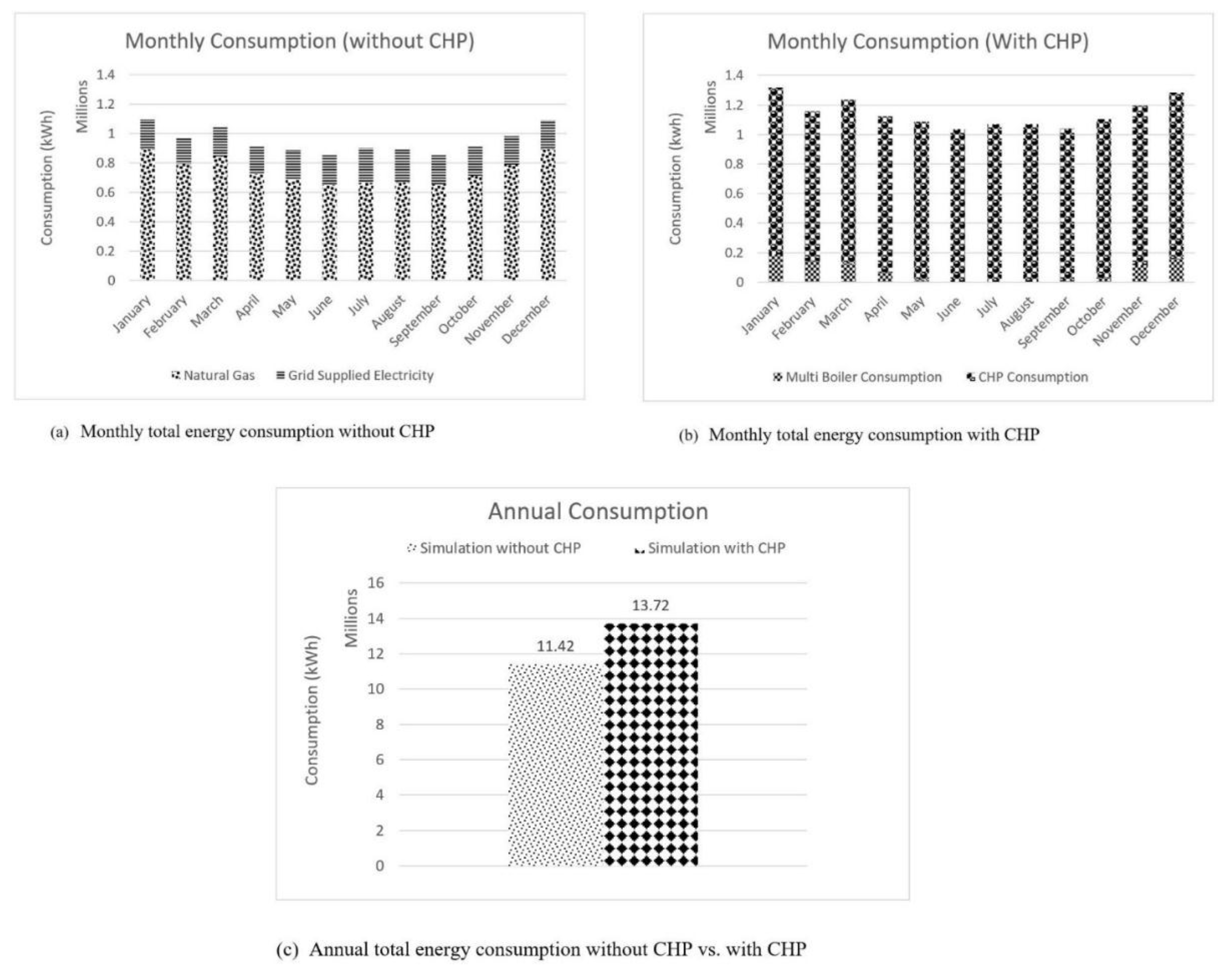

3.3. Model with CHP (307 kWe)

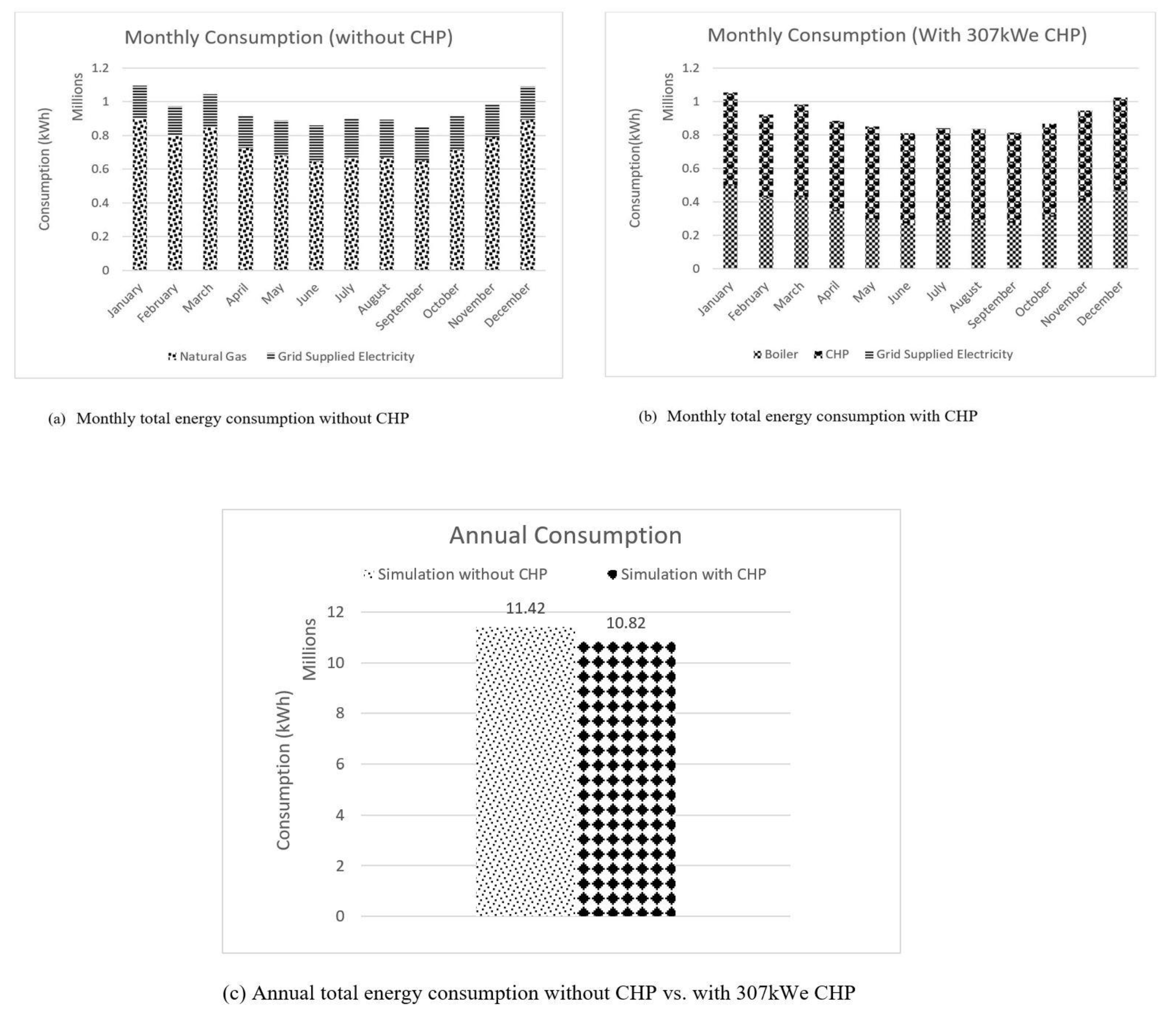

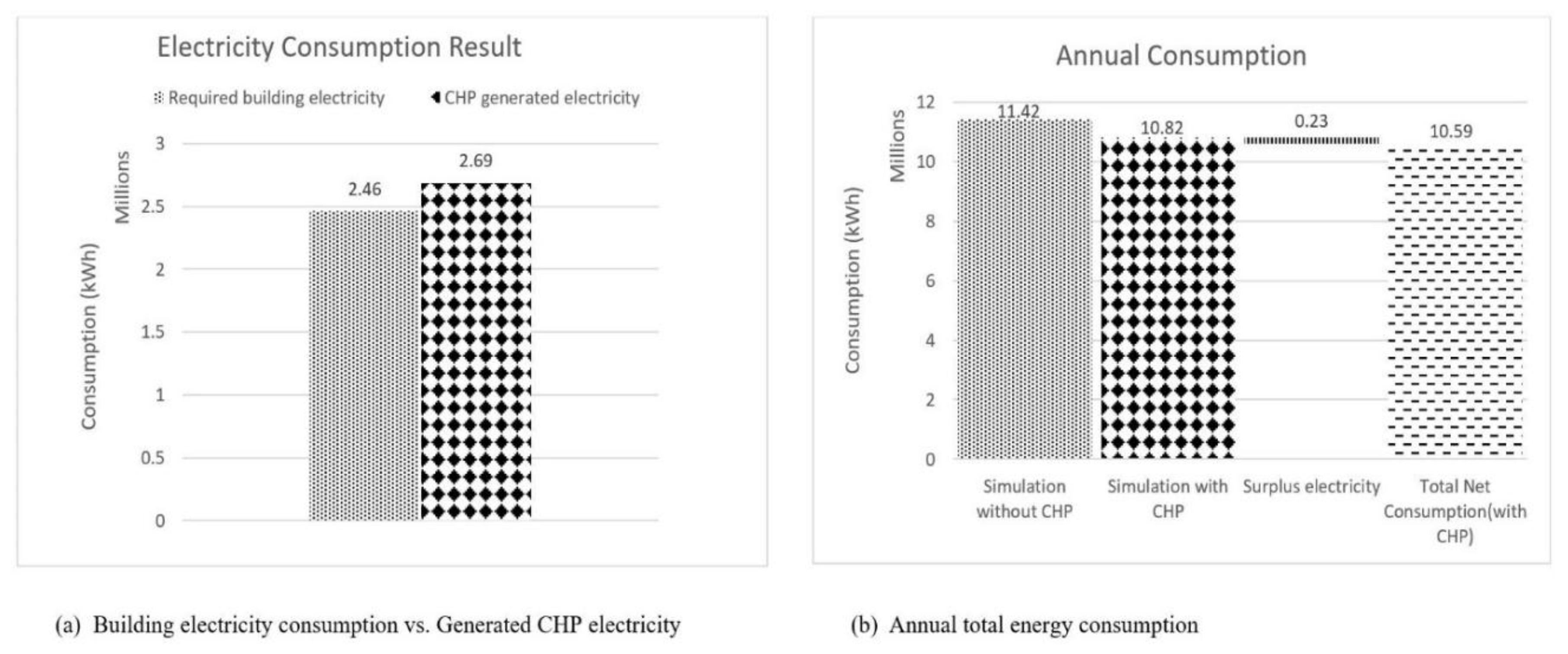

Due to the high proportion of surplus electricity produced by the CHP sized based on the thermal requirement of the building, it enables the hotel to explore reducing the size of the CHP system to match more closely the electrical demand of the building. This can lower the capital cost of the installation and reduce the complexities associated with exporting electricity whilst still providing considerable cost and environmental benefits. Therefore, the hotel management and the CHP provider have selected a 307 kWe-capacity CHP; the results of the simulation investigating the benefits of this system are presented in this section along with an approach that can be employed to aid in the selection of the optimum CHP size based on the evaluation of the key benefits of the CHP size variation analysis. Figure 11, Figure 12 and Figure 13 present the results of the analysis comparing the energy performance of the building without CHP against the building model with a 307-kWe CHP.

Figure 11.

Total energy consumption result (without CHP vs. with 307-kWe CHP).

Figure 12.

Electricity generation results and total energy consumption (307-kWe CHP).

Figure 13.

Cost and carbon emission result (without CHP vs. with 307-kWe CHP).

Similar to the model with maximum size CHP, it can be observed from Figure 11a,b that the simulation with the 307-kWe CHP resulted in the change of the fuel/energy mix of the building from natural gas and grid-supplied electricity to predominantly natural gas. This is because the CHP produces sufficient electricity to satisfy the bulk of the electricity requirement of the building, apart from the peak of the summer when a small amount of grid-supplied electricity is needed. Moreover, the CHP produces a substantial proportion of heat to serve the building, while the supplementary heat requirement is met by the boilers. In contrast to the increased energy consumption observed with the maximum size CHP, from Figure 11c, the end use energy consumption of the model with the 307-kWe CHP is 5% lower than the base model without CHP. This is due to the considerable reduction in size of the installed CHP from the maximum size of 750 kWe to 307 kWe.

Figure 12 presents the results of electricity generation and its relation to the end use energy consumption for the 307-kWe CHP model. From Figure 12a, despite the reduction in CHP size by more than 50% from 750 kWe, it can be observed that the CHP model generates sufficient electricity to satisfy the electricity requirement of the building. Moreover, surplus electricity of up to 9% is generated, which can be sold back to the grid. From Figure 12b, an energy balance can be deduced by subtracting the surplus electricity, which is an added benefit to the site from the total end use energy consumption. This gives an estimation of the total net energy consumption, which is up to 7% lower than the total end use energy consumption of the building without CHP. To further evaluate the impact of the selected 307-kWe CHP, the outcomes of the influence of the CHP on the cost of energy and carbon emissions are demonstrated in Figure 13. Installation of the selected 307-kWe CHP is to be financed by an equipment supply finance (off-balance sheet approach). Carbon Trust [7] defines this approach as a common option used to finance small packaged CHP systems, which involves making a commercial arrangement for the energy to be provided at prices that incorporate agreed discounts on the open market price. That is, the hotel pays for the natural gas and buys the CHP-generated electricity at the agreed rate. The agreed rate with the equipment supplier for the CHP-generated electricity for this case study is £0.028 per kWh of electricity. This value is used to estimate the cost savings associated with the equipment supply arrangement.

From Figure 13a illustrating the annual utility cost result, the utility cost of the model with 307 kWe CHP was approximately 42% lower than that without CHP. This cost savings is even more than the initial 26% savings recorded with the maximally-sized CHP model. However, the maximally-sized CHP model produces more surplus electricity, which makes its net savings be substantially more than that of the 307-kWe CHP model. It can also be observed from the figure that accounting for the sale of the relatively smaller surplus electricity provides a net utility cost saving of up to 44%. Figure 13b presents a comparison of the utility cost depending on the installation financing option (capital installation or equipment supply finance). It can be observed from the figure that the utility cost with the CHP installed by capital financing and the CHP installed by equipment provide a 44% and a 32% reduction in utility cost, respectively. The capital financing installation approach provides up to 12% more savings in utility cost compared to the equipment supply financing. However, it is not the selected financing approach due to the considerable technical and financial risk associated with this approach. From Figure 13c, showing the annual CO2 emissions result, the 307-kWe CHP model provides a 27% reduction in CO2 emissions relative to the model without CHP. Moreover, compared to the model with the maximum size CHP, the CO2 emission savings is only 12% lower despite the more than 50% reduction in CHP size from 750 kWe to 307 kWe. This is because the 705-kWe CHP requires considerably more natural gas to produce heat and off-grid electricity; in addition, the CO2 conversion factor for grid-supplied electricity has improved in recent times due to the increased proportion of renewable energy and the phasing out of coal power plants.

Table 3 presents the percentage difference between key simulation results without CHP in relation to simulation result with CHP.

Table 3.

Percentage difference between key simulation results without CHP in relation to simulation results with CHP.

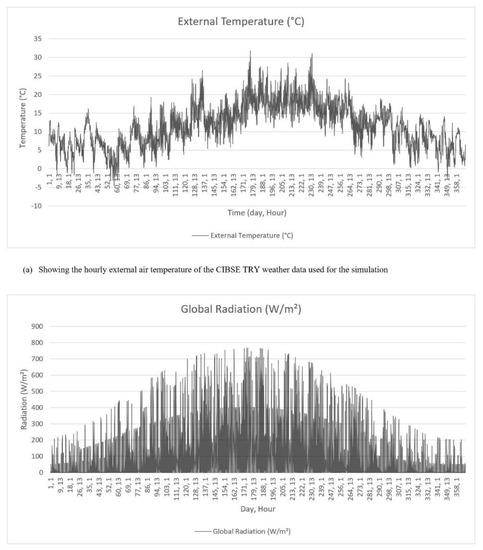

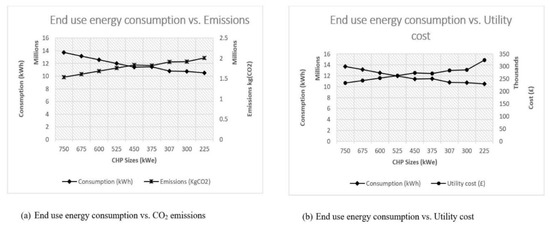

Figure 14 presents the relationship between the main performance parameters (end use energy consumption, energy cost savings and CO2 emissions) and their variation with CHP sizes. The end use energy consumption generally increases with the installation of CHP and exhibits an inversely proportional relationship with the key CHP-associated benefits (energy cost saving and CO2 emission reduction). The increase is primarily due to the change of energy source fuel mix of the building. A plot of the energy consumption and CO2 emissions or energy consumption and utility cost with the variation of CHP sizes can provide an indication of the optimum CHP size to be selected based on the equilibrium point of the variables. In Figure 14a, it can be noted that an equilibrium between energy use and CO2 emission is reached at a CHP size of 480 kWe. Furthermore, it can be noted in Figure 14b that an equilibrium between energy consumption and utility cost is reached at a CHP size of 525 kWe. Furthermore, from the equilibrium points observed in Figure 13, the optimum CHP size ranges from (525 kWe–480 kWe), which is between 30% and 36% smaller than the maximum CHP size of 750 kWe. However, selecting the optimum size of 480 kWe, which is associated with CO2 emissions is better due to its environmental benefits (reduction in primary energy consumption and GHG emissions).

Figure 14.

Showing the relationship between key energy performance parameters and variation in CHP sizes.

4. Conclusions

This paper presents a case study on the assessment of the optimum CHP size selection and the impact of CHP on the energy performance of an existing U.K. hotel. The modelling was done with the aid of a whole building energy simulation program; for validation, the predicted energy estimate of the program was compared with that of the real building consumption information prior to the simulation of the impact of the retrofitted CHP and CHP size variation analysis.

The findings of the study demonstrated that retrofit installation of CHP in the hotel, which has consistent and considerable heat demand, improves the overall energy performance of the building. The modelling of the maximum CHP capacity was built on the base of the thermal energy requirement of the building to avoid heat dumping, and the maximum CHP size of 750 kWe was obtained. The energy performance results of the maximum size CHP relative to the base model indicated that the end use energy consumption increased by 20%; however, the CHP generated 50% more electricity than the building’s requirement, which can be exported to the grid. Moreover, the utility cost was reduced by 26% compared to the model without a CHP, with a further reduction in utility cost of up to 54% resulting from the sale of the surplus electricity. Additionally, the maximum size CHP provides a 39% reduction in CO2 emissions, highlighting its environmental benefit and associated reduction in primary energy consumption.

The high proportion of surplus electricity generated allows for CHP size reduction, while still retaining the considerable economic and environmental benefit of a CHP. This can lower the capital cost of CHP installation and reduce complexities associated with exporting electricity. An approach to aid in the selection of the optimum CHP size based on the evaluation of the relationship between the main performance parameters (end use energy consumption, energy cost savings and CO2 emissions) and their variation with CHP sizes was presented in this work. The result of the analysis indicated that the optimum CHP size based on economic and environmental considerations ranges from (525 kWe–480 kWe), which is between 30% and 36% smaller than the maximum CHP size of 750 kWe.

The energy performance result of the selected 307-kWe CHP to be installed in the hotel was also presented. The result relative to the base model indicated that the end use energy consumption reduced by 5%, with the CHP-generated electricity closely matching the building’s electricity demand. Additionally, the overall utility cost was reduced by 42%, as well as a 27% reduction in CO2 emissions, highlighting its environmental benefit and associated reduction in primary energy consumption despite the over 50% reduction in CHP size from 750 kWe to 307 kWe.

Author Contributions

Conceptualization, A.B.J., A.M., P.G. and D.C. Data curation, A.R. Investigation, A.R. Supervision, A.B.J. Writing, original draft, A.R. Writing, review and editing, A.B.J., A.M., P.G. and D.C.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Babaei, T.; Abdi, H.; Lim, C.P.; Nahavandi, S. A study and a directory of energy consumption data sets of buildings. Energy Build. 2015, 94, 91–99. [Google Scholar] [CrossRef]

- UNEP-SBCI. Sustainable Buildings and Climate Initiative, Building. 2009. Available online: http://www.unep.org/sbci/AboutSBCI/Background.asp (accessed on 23 October 2017).

- Fumo, N. A review on the basics of building energy estimation. Renew. Sustain. Energy Rev. 2014, 31, 53–60. [Google Scholar] [CrossRef]

- Nock, A.; Ojiako, U.; Bektas, T.; Chipulu, M. CHP and its role in efficient energy production: a feasibility assessment model. Manag. Environ. Qual. Int. J. 2012, 23, 546–565. [Google Scholar] [CrossRef]

- Bell, M.; Gault, A.; Thompson, M. Meeting Carbon Budgets: Closing the Policy Gap: 2017 Report to Parliament. 2017. Available online: https://www.theccc.org.uk/wp-content/uploads/2017/06/2017-Report-to-Parliament-Meeting-Carbon-Budgets-Closing-the-policy-gap.pdf (accessed on 23 October 2017).

- International Energy Agency. Combined Heat and Power-Evaluating the Benefits of Greater Global Investment; IEA: Paris, France, 2008; Available online: https://www.iea.org/publications/freepublications/publication/chp_report.pdf (accessed on 9 November 2017).

- Carbon Trust. Introducing Combined Heat and Power; Technology Guide; Carbon Trust: London, UK, 2010; Available online: https://www.carbontrust.com/media/19529/ctv044_introducing_combined_heat_and_power.pdf (accessed on 16 September 2017).

- Romero Rodríguez, L.; Lissen, S.M.J.; Ramos, S.J.; Jara Roriguez, A.E.; Dominguez, A.S. Analysis of the economic feasibility and reduction of a building’s energy consumption and emissions when integrating hybrid solar thermal/PV/micro-CHP systems. Appl. Energy 2016, 165, 828–838. [Google Scholar] [CrossRef]

- Action Energy. Combined Heat and Power for Buildings; Action Energy: Sydney, Australia, 2004; Available online: http://www.cwp-ltd.com/wp-content/uploads/2012/03/UKGoodPracticeGuide.pdf (accessed on 16 September 2017).

- Çakir, U.; Çomakli, K.; Yüksel, F. The role of cogeneration systems in sustainability of energy. Energy Convers. Manag. 2012, 63, 196–202. [Google Scholar] [CrossRef]

- Mago, P.J.; Smith, A.D. Evaluation of the potential emissions reductions from the use of CHP systems in different commercial buildings. Build. Environ. 2012, 53, 74–82. [Google Scholar] [CrossRef]

- Bianchi, M.; De Pascale, A.; Melino, F. Performance analysis of an integrated CHP system with thermal and Electric Energy Storage for residential application. Appl. Energy. 2013, 112, 928–938. [Google Scholar] [CrossRef]

- Smith, A.D.; Mago, P.J.; Fumo, N. Benefits of thermal energy storage option combined with CHP system for different commercial building types. Sustain. Energy Technol. Assess. 2013, 1, 3–12. [Google Scholar] [CrossRef]

- Wang, H.; Yin, W.; Abdollahi, E.; Lahdelma, R.; Jiao, W. Modelling and optimization of CHP based district heating system with renewable energy production and energy storage. Appl. Energy 2015, 159, 401–421. [Google Scholar] [CrossRef]

- Magnani, S.; Pezzola, L.; Danti, P. Design Optimization of a Heat Thermal Storage Coupled with a Micro-CHP for a Residential Case Study. Energy Procedia 2016, 101, 830–837. [Google Scholar] [CrossRef]

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef]

- EDSL. Environmental Design Solutions Limited. 2015. Available online: http://www.edsl.net/main/Software/Designer/NVandPD.aspx (accessed on 10 October 2017).

- Rotimi, A.; Bahadori-Jahromi, A.; Mylona, A.; Godfrey, P.; Cook, D. Impact of cavity extraction fans on thermal and energy performance of existing UK hotel. Proc. Inst. Civ. Eng. Eng. Sustain. 2017. [Google Scholar] [CrossRef]

- Amoako-Attah, J.; B-Jahromi, A. Method comparison analysis of dwellings’ temperatures in the UK. Proc. Inst. Civ. Eng. Eng. Sustain. 2015, 168, 16–27. [Google Scholar] [CrossRef]

- Bahadori-Jahromi, A.; Rotimi, A.; Mylona, A.; Godfrey, P.; Cook, D. Impact of Window Films on the Overall Energy Consumption of Existing UK Hotel Buildings. Sustainability 2017, 9, 731. [Google Scholar] [CrossRef]

- Holmes, M.J.; Hacker, J.N. Climate change, thermal comfort and energy: Meeting the design challenges of the 21st century. Energy Build. 2007, 39, 802–814. [Google Scholar] [CrossRef]

- Department for Business, Energy and Industrial Strategy. UK Government Conversion Factors for Greenhouse Gas (GHG) Reporting. 2017. Available online: https://www.gov.uk/government/publications/greenhouse-gas-reporting-conversion-factors-2017 (accessed on 28 September 2017).

- Office of Gas and Electricity Markets. Feed-In Tariff (FIT) Rates. 2017. Available online: https://www.ofgem.gov.uk/environmental-programmes/fit/fit-tariff-rates (accessed on 1 December 2017).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).