Electric Road Systems: Strategic Stepping Stone on the Way towards Sustainable Freight Transport?

Abstract

:1. Introduction

- What is the sustainability impact of overhead line ERS in comparison to the current fossil-powered system?

- What is the relative importance of different life-cycle phases?

- Could the introduction of ERS be a strategic stepping stone on the way towards sustainable transport?

2. Background

2.1. Electric Road Systems

- i

- Conductive power supply through overhead lines, similar to trains;

- ii

- Conductive power supply through an electric rail in the road, similar to some subways; and

- iii

- Inductive power supply without any physical contact through electric coils in the road.

2.2. Strategic Planning towards Sustainability

“In a sustainable society, nature is not subject to systematically increasing…1 …concentrations of substances extracted from the Earth’s crust;2 …concentrations of substances produced by society;3 …degradation by physical means; and, in that society…4 ...people are not subject to conditions that systematically undermine their capacity to meet their needs.”

3. Methods

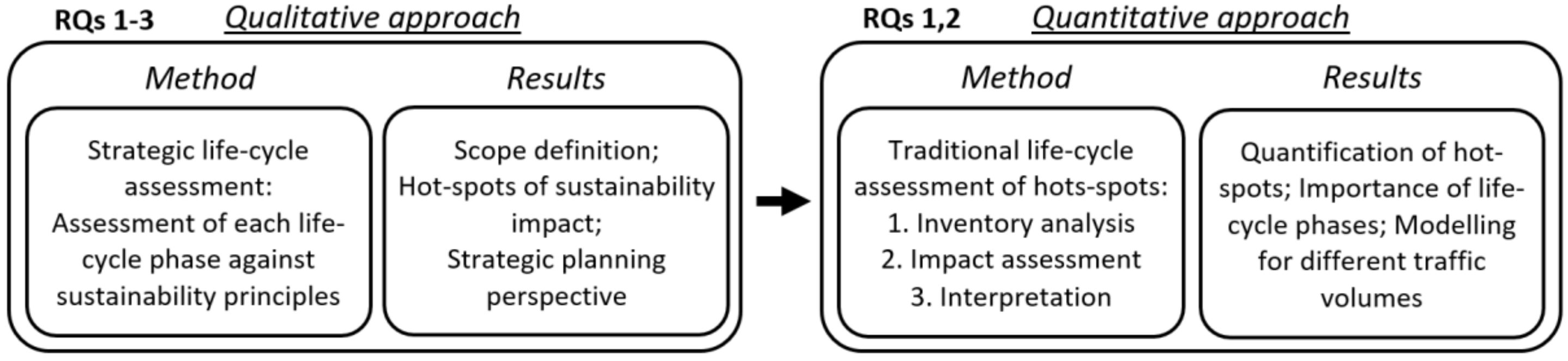

3.1. Strategic Life-Cycle Assessment

3.2. Life-Cycle Assessment

4. Results

4.1. Strategic Life-Cycle Assessment of ERS and Diesel Truck Transport

4.1.1. Assessment against Sustainability Principle 1

4.1.2. Assessment against Sustainability Principle 2

4.1.3. Assessment against Sustainability Principle 3

4.1.4. Assessment against Sustainability Principle 4

4.1.5. Requirements for Sustainable Freight Transport Systems

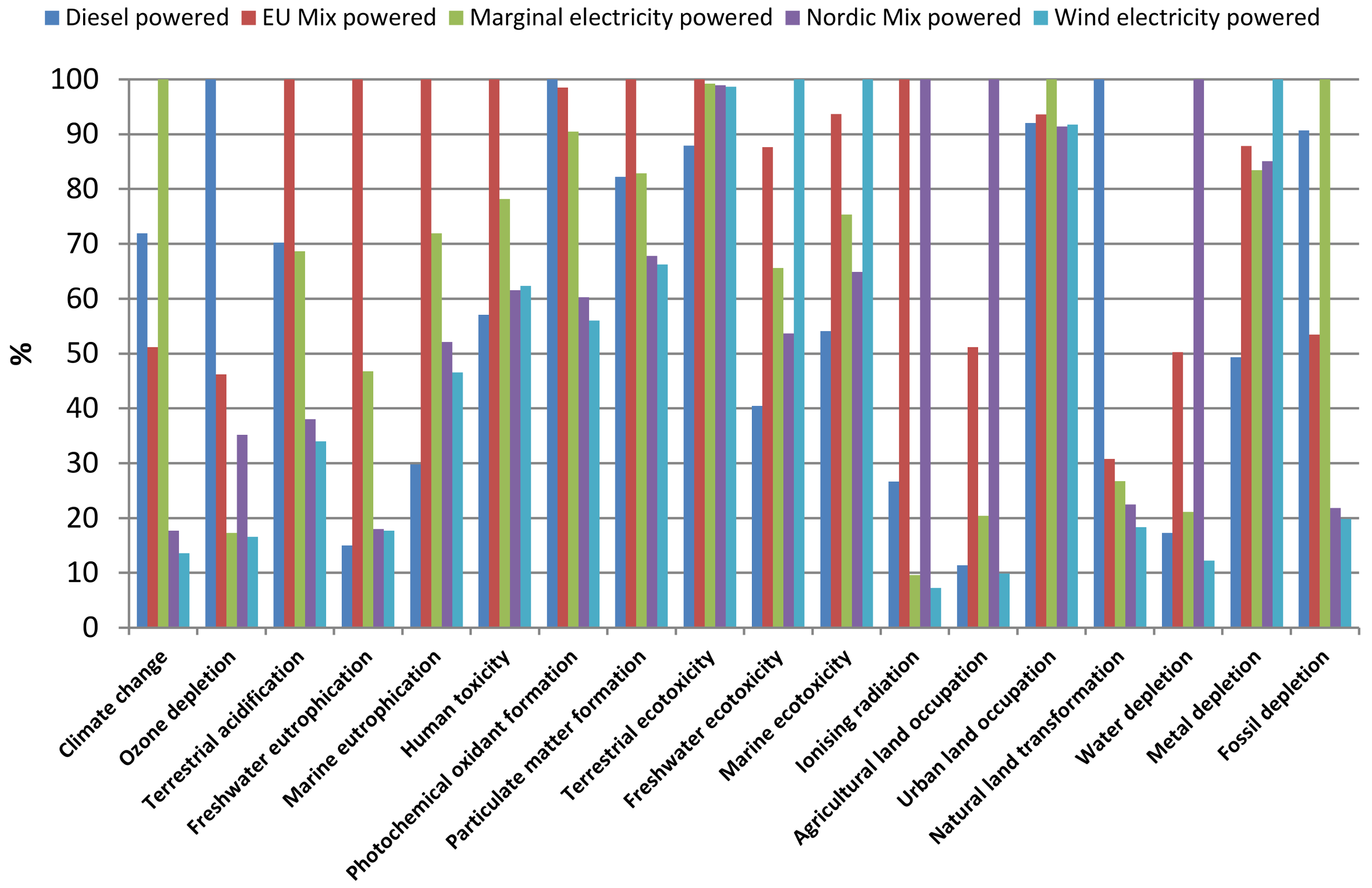

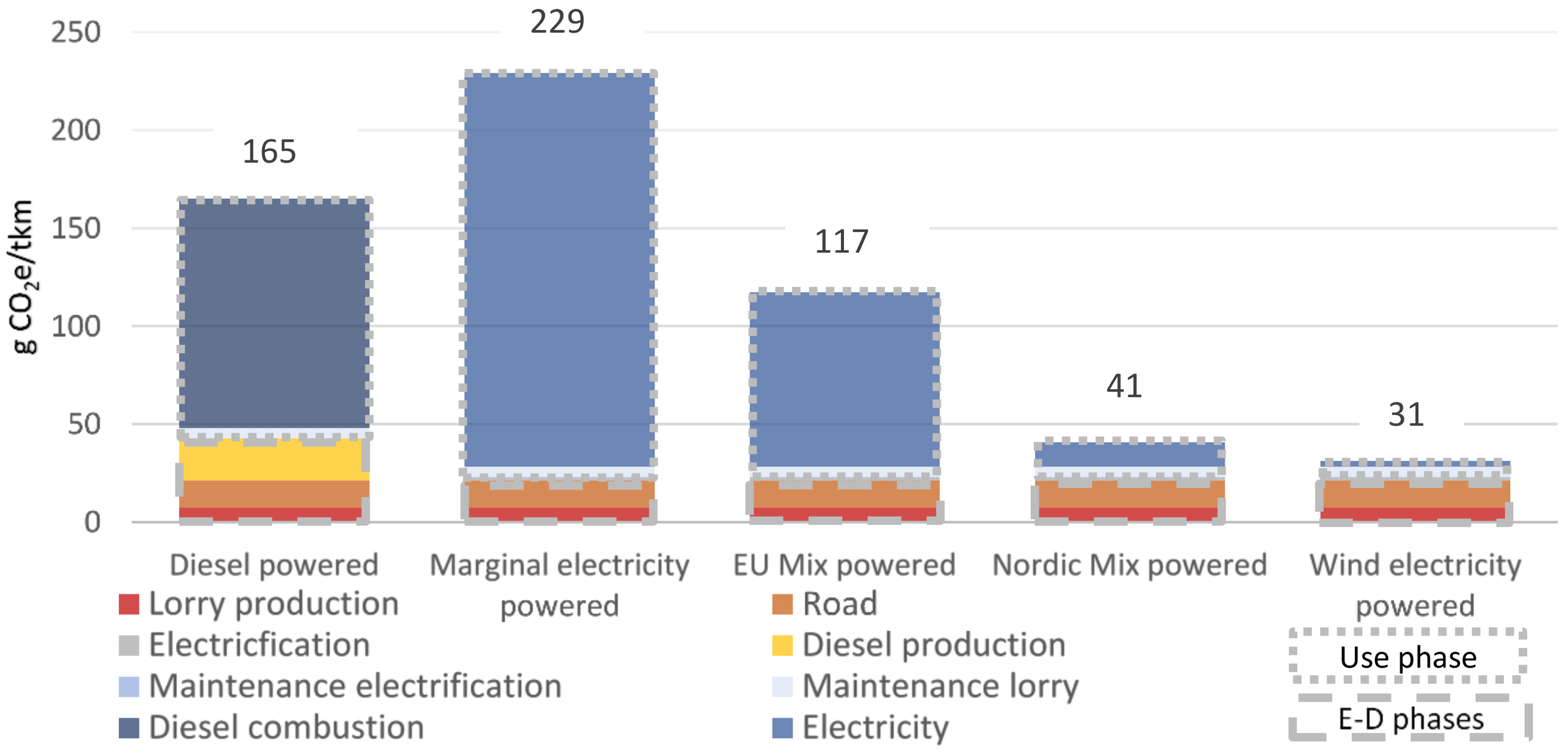

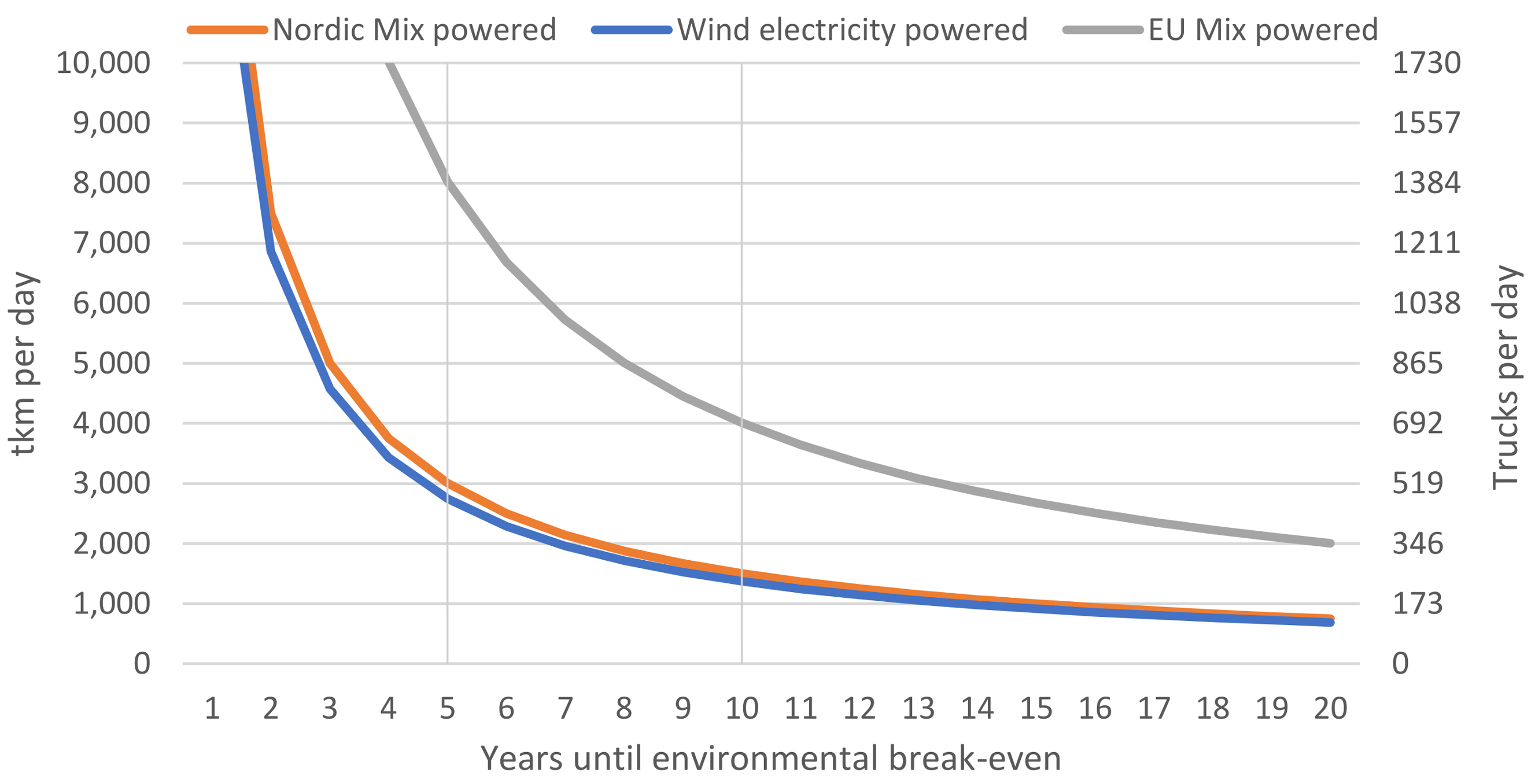

4.2. Life-Cycle Assessment of ERS and Current Fossil-Powered Truck Transport

5. Concluding Discussion

5.1. What Is the Sustainability Impact of ERS in Comparison to the Current Fossil-Powered System?

5.2. What Is the Relative Importance of Different Life-Cycle Phases?

5.3. Is the Introduction of ERS a Strategic Stepping Stone on the Way towards Sustainable Transport and What Role Could They Play in That Transition?

5.3.1. Lock-In and Threshold Effects

5.3.2. Stepping Stones towards Sustainability

5.4. Recommendations and Future Research

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nurhadi, L.; Borén, S.; Ny, H. Advancing from Efficiency to Sustainability in Swedish Medium-sized Cities: An Approach for Recommending Powertrains and Energy Carriers for Public Bus Transport Systems. Procedia Soc. Behav. Sci. 2014, 111, 586–595. [Google Scholar] [CrossRef]

- European Commission. EU Transport in Figures: Statistical Pocketbook 2015; European Commission: Luxembourg, Luxembourg, 2015. [Google Scholar]

- Teske, S.; Sawyer, S.; Schäfer, O.; Pregger, T.; Simon, S.; Naegler, T. Energy [R]evolution—A Sustainable World Energy Outlook 2015; Greenpeace International, Global Wind Energy Council, Solar Power Europe: Brussels, Belgium, 2015. [Google Scholar]

- Borén, S.; Ny, H. A Strategic Sustainability and Life Cycle Analysis of Electric Vehicles in EU today and by 2050. In Proceedings of the 18th International Conference on Sustainable Urban Transport and Environment (ICSUTE), Madrid, Spain, 24–25 March 2016; Volume 10, pp. 256–264. [Google Scholar]

- European Commission. A Strategy for Reducing Heavy Duty Vehicles’ Fuel Consumption and CO2 Emissions; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- ICCT. European Vehicle Market Statistics—Pocketbook 2014; ICCT: Berlin, Germany, 2014. [Google Scholar]

- Notter, D.A.; Gauch, M.; Widmer, R.; Wäger, P.; Stamp, A.; Zah, R.; Althaus, H.-J. Contribution of Li-ion batteries to the environmental impact of electric vehicles. Environ. Sci. Technol. 2010, 44, 6550–6556. [Google Scholar] [CrossRef] [PubMed]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Sverdrup, H.U.; Ragnarsdottir, K.V.; Koca, D. An assessment of metal supply sustainability as an input to policy: Security of supply extraction rates, stocks-in-use, recycling, and risk of scarcity. J. Clean. Prod. 2017, 140, 359–372. [Google Scholar] [CrossRef]

- Kushnir, D.; Sandén, B.A. The time dimension and lithium resource constraints for electric vehicles. Resour. Policy 2012, 37, 93–103. [Google Scholar] [CrossRef]

- Connolly, D. Economic viability of electric roads compared to oil and batteries for all forms of road transport. Energy Strateg. Rev. 2017, 18, 235–249. [Google Scholar] [CrossRef]

- Tongur, S.; Engwall, M. The business model dilemma of technology shifts. Technovation 2014, 34, 525–535. [Google Scholar] [CrossRef]

- Chen, F.; Taylor, N.; Kringos, N. Electrification of roads: Opportunities and challenges. Appl. Energy 2015, 150, 109–119. [Google Scholar] [CrossRef]

- Lennartsson, M. Elektriska Vägar, Miljöanalys (Electric Roads, Environmental Analysis). Available online: http://elvag.se/en/archive/2010-04-16/Elektriska-vagar-Miljoanalys.pdf (accessed on 7 July 2016).

- Tongur, S.; Sundelin, H. The electric road system transition from a system to a system-of-systems. In Proceedings of the Asian Conference on Energy, Power and Transportation Electrification (ACEPT), Singapore, Singapore, 25–27 October 2016; pp. 1–8. [Google Scholar]

- Sundelin, H.; Gustavsson, M.G.H.; Tongur, S. The maturity of electric road systems. In Proceedings of the International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Toulouse, France, 2–4 November 2016. [Google Scholar]

- Choi, S.Y.; Member, S.; Gu, B.W.; Member, S.; Jeong, S.Y.; Member, S.; Rim, C.T.; Member, S. Advances in Wireless Power Transfer Systems for Roadway-powered Electric Vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 18–36. [Google Scholar] [CrossRef]

- Suh, N.P.; Cho, D.H.; Rim, C.T. Design of On-Line Electric Vehicle (OLEV). In Global Product Development; Springer: Berlin/Heidelberg, Germany, 2011; pp. 3–8. [Google Scholar]

- Stamati, T.; Bauer, P. On-road charging of electric vehicles. In Proceedings of the 2013 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 16–19 June 2013; pp. 1–8. [Google Scholar]

- Sallan, J.; Villa, J.L.; Llombart, A.; Sanz, J.F. Optimal Design of ICPT Systems Applied to Electric Vehicle Battery Charge. IEEE Trans. Ind. Electron. 2009, 56, 2140–2149. [Google Scholar] [CrossRef]

- Covic, G.A.; Boys, J.T. Modern Trends in Inductive Power Transfer for Transportation Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 28–41. [Google Scholar] [CrossRef]

- Gill, J.S.; Bhavsar, P.; Chowdhury, M.; Johnson, J.; Taiber, J.; Fries, R. Infrastructure cost issues related to inductively coupled power transfer for electric vehicles. Procedia Comput. Sci. 2014, 32, 545–552. [Google Scholar] [CrossRef]

- FABRIC Test Sites. Available online: http://www.fabric-project.eu/index.php?option=com_k2&view=itemlist&layout=category&task=category&id=24&Itemid=214 (accessed on 13 February 2018).

- Viktoria Swedish ICT. Slide-in Electric Road System—Inductive Project Report; Viktoria Swedish ICT: Gothenburg, Sweden, 2014. [Google Scholar]

- Shin, J.; Shin, S.; Kim, Y.; Ahn, S.; Lee, S.; Jung, G.; Jeon, S.-J.; Cho, D.H. Design and Implementation of Shaped Magnetic Resonance Based Wireless Power Transfer System for Roadway-Powered Moving Electric Vehicles. IEEE Trans. Ind. Electron. 2014, 61, 1179–1192. [Google Scholar] [CrossRef]

- International Commission on Non-Ionizing Radiation Protection. Guidelines for Limiting Exposure to Time-Varying Electric and Magnetic Fields (1 Hz to 100 kHz). Health Phys. 2010, 99, 818–836. [Google Scholar]

- Council of Europe. Resolution 1815—The Potential Dangers of Electromagnetic Fields and Their Effect on the Environment; Council of Europe: Strasbourg, France, 2011; Volume 1815. [Google Scholar]

- Covic, G.A.; Boys, J.T. Inductive power transfer. Proc. IEEE 2013, 101, 1276–1289. [Google Scholar] [CrossRef]

- Emre, M.; Vermaat, P.; Naberezhnykh, D.; Damousuis, Y.; Theodoropoulos, T.; Cirimele, V.; Doni, A. FABRIC—Review of Existing Power Transfer. Available online: https://www.fabric-project.eu/images/Deliverables/FABRIC_D33.1_V1_20141215_Review_of_existing_solutions_PUBLIC.pdf (accessed on 7 July 2016).

- Viktoria Swedish ICT. Slide-in Electric Road System—Conductive Project Report; Viktoria Swedish ICT: Gothenburg, Sweden, 2013. [Google Scholar]

- Swedish Transport Agency First Electric Road in Sweden Inaugurated. Available online: http://www.trafikverket.se/en/startpage/about-us/news/2016/2016-06/first-electric-road-in-sweden-inaugurated/ (accessed on 13 February 2018).

- Broman, G.I.; Robèrt, K.-H. A Framework for Strategic Sustainable Development. J. Clean. Prod. 2017, 140, 17–31. [Google Scholar] [CrossRef]

- Robèrt, K.H.; Broman, G.; Waldron, D.; Ny, H.; Byggeth, S.; Cook, D.; Johansson, L.; Oldmark, J.; Basile, G.; Haraldsson, H.; et al. Strategic Leadership towards Sustainability, 6th ed.; Blekinge Institute of Technology: Karlskrona, Sweden, 2010. [Google Scholar]

- Missimer, M. Social Sustainability within the Framework for Strategic Sustainable Development; Blekinge Institute of Technology: Karlskrona, Sweden, 2015. [Google Scholar]

- Ny, H.; MacDonald, J.P.; Broman, G.; Yamamoto, R.; Robert, K.-H. Sustainability Constraints as System Boundaries: An Approach to Making Life-Cycle Management Strategic. J. Ind. Ecol. 2006, 10, 61–77. [Google Scholar] [CrossRef]

- ISO. ISO 14040:2006: Environmental Management, Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; van Zelm, R. ReCiPe 2008: A life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; Ministry of Housing, Spatial Planning and Environment (VROM): Den Haag, The Netherlands, 2013. [Google Scholar]

- Tsydenova, O.; Bengtsson, M. Chemical hazards associated with treatment of waste electrical and electronic equipment. Waste Manag. 2011, 31, 45–58. [Google Scholar] [CrossRef] [PubMed]

- Northey, S.; Mohr, S.; Mudd, G.M.; Weng, Z.; Giurco, D. Modelling future copper ore grade decline based on a detailed assessment of copper resources and mining. Resour. Conserv. Recycl. 2014, 83, 190–201. [Google Scholar] [CrossRef]

- Harmsen, J.H.M.; Roes, A.L.; Patel, M.K. The impact of copper scarcity on the efficiency of 2050 global renewable energy scenarios. Energy 2013, 50, 62–73. [Google Scholar] [CrossRef]

- Elshkaki, A. An analysis of future platinum resources, emissions and waste streams using a system dynamic model of its intentional and non-intentional flows and stocks. Resour. Policy 2013, 38, 241–251. [Google Scholar] [CrossRef]

- Blyth, W.; Gross, R.; Speirs, J.; Sorrell, S.; Nicholls, J.; Dorgan, A.; Hughes, N. Low Carbon Jobs: The Evidence for Net Job Creation from Policy Support for Energy Efficiency and Renewable Energy; UKERC: London, UK, 2014. [Google Scholar]

- Cambridge Econometrics. Employment Effects of Selected Scenarios from the Energy Roadmap 2050 Final Report for the European Commission (DG Energy); Cambridge Econometrics: Cambridge, UK, 2013. [Google Scholar]

- European Commisssion Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. 2008. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32008L0098 (accessed on 10 April 2018).

- Swedish Transport Administration. Swedish Transport Administration Climate Calculation—The Swedish Transport Administration’s Model for Calculating the Climate Change Impact and Energy Use of Infrastructure from a Life Cycle Perspective; Version: 3.0; Swedish Transport Administration: Borlänge, Sweden, 2015. [Google Scholar]

- Stripple, H.; Uppenberg, S. Life Cycle Assessment of Railways and Rail Transports; IVL Report B1943; Swedish Transport Administration: Luleå, Sweden, 2010. [Google Scholar]

- Uppenberg, S. Comparative Life Cycle Assessment for Alternative Design of Electrification for Rail Systems [in Swedish: Jämförande Livscykelanalys för Alternativ Utformning av Hjälpkraft för Spåranläggning]; Swedish Transport Administration: Luleå, Sweden, 2012. [Google Scholar]

- Ecoinvent Allocation Cut-off by Classification. Available online: http://www.ecoinvent.org/database/system-models-in-ecoinvent-3/cut-off-system-model/allocation-cut-off-by-classification.html (accessed on 7 July 2016).

- Transport and Mobility Leuven TREMOVE Economic Transport and Emissions Model v.2.7b. Available online: http://www.tmleuven.be/methode/tremove/home.htm (accessed on 7 July 2016).

- Gustafsson, M.; Blomqvist, G.; Håkansson, K.; Lindeberg, J.; Nilsson-Påledal, S. Railway Pollution—Sources, Fate and Actions. [In Swedish: Järnvägens Föroreningar- källor, Spridning och Åtgärder]; VTI: Linköping, Sweden, 2007. [Google Scholar]

- Robèrt, K.H.; Borén, S.; Ny, H.; Broman, G. A strategic approach to sustainable transport system development—Part 1: Attempting a generic community planning process model. J. Clean. Prod. 2017, 140, 53–61. [Google Scholar] [CrossRef]

- Borén, S.; Nurhadi, L.; Ny, H.; Robèrt, K.H.; Broman, G.; Trygg, L. A strategic approach to sustainable transport system development—Part 2: The case of a vision for electric vehicle systems in southeast Sweden. J. Clean. Prod. 2017, 140, 62–71. [Google Scholar] [CrossRef]

| Life-Cycle Phase | SP1 Effects of ERS-Powered Trucks | SP1 Effects of Diesel-Powered Trucks |

|---|---|---|

| Extraction | Heavy metals in components and processes. Emissions from fossil fuel usage. | Heavy metals in components and processes. Emissions from fossil fuel usage. Oil leakages, gas flaring. |

| Production | Heavy metals in components and production. Emissions from fossil fuel usage. | Heavy metals in components and production. Emissions from fossil fuel usage. |

| Distribution | Emissions from truck transports of infrastructure systems, vehicles. | Emissions from truck transports of infrastructure systems, vehicles and fuel. |

| Use | Copper emissions from catenary wire friction. Heavy metals in maintenance. Emissions from maintenance transport. | Combustion emissions. Heavy metals and fossil oil in maintenance. Emissions from maintenance transport. |

| Waste | Incomplete recycling of heavy metals and other materials related to SP1. Some cables and other components may be left in the ground and leak heavy metals. Emissions and leakages from recycling processes and landfills. | Incomplete recycling of heavy metals and other materials related to SP1. Emissions and leakages from recycling processes and landfills. |

| Life-Cycle Phase | SP2 Effects of ERS-Powered Trucks | SP2 Effects of Diesel-Powered Trucks |

|---|---|---|

| Extraction | NOX emissions from combustion. | NOX emissions from combustion. |

| Production | NOX emissions from combustion. POP and Dioxin emissions. | NOX emissions from combustion. POP and Dioxin emissions. |

| Distribution | NOX emissions from truck transports of infrastructure systems and vehicles. | NOX emissions from truck transports of infrastructure systems and vehicles. |

| Use | NOX emissions from truck transports of infrastructure systems and maintenance vehicles. Leakage of persistent chemicals from electric components. | NOX emissions from truck transports of infrastructure systems and maintenance vehicles. NOX emissions from the vehicle’s engine. Leakage of persistent chemicals from electric components. |

| Waste | Incomplete recycling of compounds related to SP2. Emissions and leakages from recycling processes and landfills. | Incomplete recycling of compounds related to SP2. Emissions and leakages from recycling processes and landfills. |

| Life-Cycle Phase | SP3 Effects of ERS-Powered Trucks | SP3 Effects of Diesel-Powered Trucks |

|---|---|---|

| Extraction | Open pit mining of metals. | Open pit mining of metals and other resources. Oil extraction. |

| Production | Contamination at refineries. | |

| Distribution | Land use for roads and power grids. | Land use for roads and pipelines. |

| Use | Land use for roads. | Land use for roads. |

| Waste | Non-recycled materials to landfills. | Non-recycled materials to landfills. |

| Life-Cycle Phase | SP4 effects of ERS-Powered Trucks | SP4 Effects of Diesel-Powered Trucks |

|---|---|---|

| Extraction | Use of scarce resources such as copper. Open pit mining causes negative health effects and forces people to move. | Use of scarce resources such as platinum. Open pit mining causes negative health effects and forces people to move. |

| Production | Negative health effects from emissions related to fossil fuel use and component production. Harmful job conditions at some places. | Negative health effects from emissions related to fossil fuel use and component production. Harmful job conditions at some places. |

| Distribution | Health effects from transport emissions. | Health effects from transport emissions. |

| Use | Health risks due to high voltage and overhead line accidents. | Negative health effects from emissions related to fossil fuel use. |

| Waste | Harmful emissions and working conditions in some countries. | Harmful emissions and working conditions in some countries. |

| Life-Cycle Phase | Requirements for Sustainable ERS |

|---|---|

| Extraction | Very limited extraction of new resources. Extraction with best available technology (BAT). Complete restauration of the site after operation. Respecting indigenous people’s rights. |

| Production | Strict application of BAT, precautionary and substitution principle. Rare substances with high accumulation potential are kept in closed loops. |

| Distribution | Only using sustainable modes of transport powered by renewable energy. |

| Use | Ensuring a safe, comfortable and effective satisfaction of people’s need for transportation *. Only renewable energy input and no emissions of critical substances from use and maintenance. |

| Waste | Optimized for following EU’s waste hierarchy [45]: prevention, reuse, recycle, recovery; except there should be no need for landfilling. Circular material flow. |

| Component | Material Use per km | Technical Life Time, Years | Reference |

|---|---|---|---|

| Overhead lines (double) | Copper: 4800 kg | 40 | Swedish Transport Administration [46], Stripple and Uppenberg [47] |

| Catenary masts | Steel: 7752 kg PE: 122 kg Fiberglass: 152 kg | 50 | Swedish Transport Administration [46], Stripple and Uppenberg [47] |

| Semi-rigid roadside barriers | Concrete: 5500 kg Steel: 16,000 kg | 20 | Swedish Transport Administration [46], Stripple and Uppenberg [47] |

| Electrical equipment, protective relay, fuses | Steel: 57 kg | 40 | Uppenberg [48] |

| Cables, AXQJ 1 kV 3×70/21 | Aluminium: 363 kg Copper: 121 kg PE: 216 kg | 40 | Uppenberg [48] |

| Distribution sheds | Steel, low-alloyed: 145 kg | 50 | Uppenberg [48] |

| Transformer 1/0,4 kV, 100 kVA | Steel: 3 kg Copper: 1 kg | 40 | Uppenberg [48] |

| Transformer 1/0,4 kV, 50 kVA | Steel: 89 kg Copper: 38 kg | 40 | Uppenberg [48] |

| Transformer 1/0,4 kV, 30 kVA | Steel: 3 kg Copper: 1 kg | 40 | Uppenberg [48] |

| Transformer 1/0,4 kV, 16 kVA | Steel: 3 kg Copper: 1 kg | 40 | Uppenberg [48] |

| Transformer 1/0,4 kV, 5 kVA | Steel: 3 kg Copper: 1 kg | 40 | Uppenberg [48] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schulte, J.; Ny, H. Electric Road Systems: Strategic Stepping Stone on the Way towards Sustainable Freight Transport? Sustainability 2018, 10, 1148. https://doi.org/10.3390/su10041148

Schulte J, Ny H. Electric Road Systems: Strategic Stepping Stone on the Way towards Sustainable Freight Transport? Sustainability. 2018; 10(4):1148. https://doi.org/10.3390/su10041148

Chicago/Turabian StyleSchulte, Jesko, and Henrik Ny. 2018. "Electric Road Systems: Strategic Stepping Stone on the Way towards Sustainable Freight Transport?" Sustainability 10, no. 4: 1148. https://doi.org/10.3390/su10041148

APA StyleSchulte, J., & Ny, H. (2018). Electric Road Systems: Strategic Stepping Stone on the Way towards Sustainable Freight Transport? Sustainability, 10(4), 1148. https://doi.org/10.3390/su10041148