1. Introduction

Green operations in manufacturing are being studied with the purpose of improving the use of resources. Advances have been realized in machining processes to improve their environmental characteristics while maintaining or increasing their efficiency. Because machining processes are most commonly used in industry, great efforts are being made to find a suitable combination of efficiency and sustainability [

1,

2]. In this sense, dry and cooling air machining are options to avoid the use of lubricants, which have a harmful impact on the environment and are chemical exposition risks to operators. Shokrani et al. [

3], in their literature review, identified various procedures used in machining by cooling air and highlighted composites, among others, as materials that are challenging to machine. Boswell [

4] found that cooling air is an efficient mechanism for metal cutting, with improvements in the quality of steel workpieces and the tool life after turning. Nor-Khairusshima [

5] determined that the delamination factor improved after the milling of carbon fiber reinforced plastics at −10 °C and high cutting speeds. Lee and Lee [

6] had similar realizations during the grinding of steels at −20 °C: a low temperature decreased the forces and tool wear. Su et al. [

7] found that cooling air at −20 °C improved the results of steel milling regarding the dry machining, both in forces and tool life. Liu and Chou [

8], using alloys of aluminum, concluded that cooling effects decrease with increasing cutting speed and feed rate. As is seen, the decreased temperature provides improved outcomes. In more radical approaches, with greater reductions in temperature, improved results were also found. Yuan et al. [

9] determined that cryogenic machining with the use of cooling air requires lower cutting forces to mill metallic alloys (TiAl6V4), and achieves lower surface roughness and higher tool life than with other procedures, such as wet, dry or MQL machining. Sun et al. [

10] analyzed dry machining and machining with compressed air and cryogenic compressed air at −196 °C in a titanium alloy, and found that the thrust and cutting forces in turning operations were lower when using compressed air.

The selection of the tool also has an important influence on the results of forces [

11], torques [

12], and energy or power [

13]. The coating of tools, which is another factor to analyze, can influence the process variables. The tapping operation is as common as it is complex in the industry, particularly when the result is an internal thread in through or blind holes for later use in assembly processes. Two important variables for tapping control are the axial force and cutting torque [

14], as well as the required power as a green operation criterion [

15], because this power is responsible for the energy consumption during the cutting process, and consequently emissions are generated during the process. Similar combinations of variables, including power, can be found in the literature, e.g., in the turning [

16,

17]. Uzun and Korkut [

18] studied the tapping process in a titanium alloy under cryogenic conditions, and found that the torque was lower in a cryogenically-treated tool than in coated and uncoated tools. In tapping operations, increasing the cutting speed can increase or decrease the thrust forces [

19]. The forces and torques are higher than in flooding or MQL conditions [

20]. Moreover, the values of these variables are important, because they contribute to the consumption of energy during the holes’ machining [

21], and thus low values of force, torque, and power contribute to lower energy consumption and to the sustainability of the process.

Polyamide PA66 and reinforced polyamide with glass fiber, PA66-GF30, are materials widely used in the industry. Research on polyamide’s machinability [

22] has found that the addition of glass fiber influences the tool performance, and that the specific cutting force is much higher in unreinforced polyamide. Campos et al. [

23] determined that an increase of spindle speeds generates an increase of cutting temperatures, which affects the responses in drilling operations. Quadrini et al. [

24] found that in drilling operations in PA66-GF30, the thrust forces are strongly dependent on the cutting conditions, and that these forces never increase with increasing cutting speed and feed rate. Similar considerations were realized by Domingo et al. [

25], and could be extended to torques. Although tapping operations are performed frequently in polyamide, with or without reinforcement, the material’s response to tapping has not previously been studied.

Previous studies have identified cooling air machining as an environmentally-conscious technique. Some studies have focused on the effect of cooling air in dry machining, but they are devoted to the turning of steel, [

4] or the milling of carbon fiber reinforced plastic [

5] or steel [

7]. In addition, specific and accurate predictive models have been developed for tapping processes [

26], and the influence of new factors requires new experimental data. Thus, we analyze the outcomes regarding the axial or thrust force, cutting torque, and required power under various cutting conditions in tapping operations of PA66 and PA66-GF30, and under various environments in dry conditions with compressed cooling air at several temperatures. The objective is to find the more adequate temperatures, cutting speed, and tools, using multi-response surface methodology.

3. Results and Discussion

The outcomes of the experimental test can be seen in

Table 4. These results have been previously analyzed to assess which model to adopt. A third-order model was found to be the most convenient. The mixed-level factorial analysis is a screening design with resolution V, so the factors to consider as maximum are A

3, A, B, C, A

2, A

2B, A

2C, AB, ABC, AC, and BC. In ANOVA, some factors have been eliminated to find a fitted model. In the regression equations, or the equations of the fitted models, the values of the variables are specified in their original units.

3.1. Factors Affecting Thrust Force, Torque, Power, and Regression Models

3.1.1. Unreinforced Polyamide PA66

As shown in

Table 5,

Table 6 and

Table 7, the ANOVA study, which explains the variability of a variable for each effect, indicates that there are significant factors. For thrust forces (see

Table 5), four main factors (A

2, A, B, and C) and two interactions (AB and A

2C) at a 95% confidence level are associated with

p-values of less than 0.05. The most influential factors are A

2, C, and A; the environment as second-order factor (A

2) is responsible of 27.25% of the variability, while C and A represent variability close to 25% and 23%, respectively. The residual values represent only 0.01%. The strong dependency of the force regarding A and A

2 confirms the importance of analyzing the tool temperature in the tapping and its influence.

The torque, T_PA66, has three significant factors: A

2B, B, and C (see

Table 6). In this particular case, the coating had an influence of 39.31%, an A

2B of 30.67%, and a cutting speed of 17.04%; thus, these factors had the most influence on the torque. The influence of residual values fell to 4.06%.

For the power, P_PA66, there are four significant factors: A

2B, B, BC, and C (see

Table 7). As expected, the most influential factor was B (42.25%), due to the dependence of power on speed. Note that the residual values only represented 1.11%. In this sense, the interaction was between environment and speed and between speed and coating, and the importance of coating can be appreciated; this finding implies a satisfactory choice of coating in the experimental test.

The ANOM study identified significant differences between the means of all levels of each factor for variables F_PA66, T_PA66, and P_PA66, at a 95% confidence level. This could indicate that the levels have been chosen appropriately, and that there is no particularly sensitive level affecting the results, so the following analysis is necessary.

A regression model was developed for thrust forces, torque and power. With respect to thrust forces of PA66, initially, a third-order model provides an R

2 value of 99.99% and an adj-R

2 value of 99.86, which implies that this model can be considered acceptable. Close values of R

2 and adj-R

2 indicate that the significant terms are included in the model [

31]. Therefore, this thrust force model in terms of multiple regression can be considered adequate, because adj-R

2 is between 0.8 and 1 [

31].

The torque analysis provides an R2 value of 95.94% and adj-R2 of 88.84%. To achieve a more closely fitted model, it was necessary to eliminate several factors, such as A2C, ABC, and AC.

In power, the R2 statistic indicates that the model as fitted explains 98.89% of the variability in P_PA66. The adj-R2 statistic, which is more suitable for comparing models with different numbers of independent variables, is 96.94%. The regression model shows accurate capability for the third-order approach. The environment temperature (°C) can be a determinant factor in the results obtained in F, T and P.

The equations of the fitted model are:

3.1.2. Reinforced Polyamide PA66-GF30

In the ANOVA study, for axial forces (see

Table 8), a second-order main factor A

2 and three interactions (AC, BC, and ABC) are significant, because the

p-value is less than 0.05 at the 95% confidence level. BC was the most influential factor (34.37%). To achieve an acceptable value for adj-R

2, several factors were eliminated: A

3, A

2B, A

2C, AB, and B. Thus, R

2 was 91.40%, adj-R

2 was 81.09%, and adj-R

2 was close to 80%, so it can be considered suitable in machining processes [

36].

Table 9 describes the ANOVA results for torques; at a confidence level of 95%, there are two significant factors, A and A

2, and a significant interaction ABC. Note that the effect of environment was very strong (54.8%). The residuals values achieved 7.77%. To achieve adequate R

2 and adj-R

2, the factors A

3, A

2C, AB, BC, and C had been eliminated. For the other factors, R

2 took a value of 92.23%, and adj-R

2 was 83%.

With respect to the power,

Table 10 shows the results of the ANOVA study. Factors A

3 and A

2C had been eliminated to achieve a major correlation. Two main factors (A and B) and three interactions (AB, AC, and ABC) have a significant effect on the results. The influence of cutting speed was higher, at 22.17% over the total. Regarding the power, its strong dependency on cutting speed was shown as a factor through interactions with the environment, as well as with the environment and coating. Therefore, the effect on power depends on variations of speed, together with the environment for each coating. Note that A

2 was not a significant factor in this case. The coating affected only the interactions of the first and second order. Note that the residual represents only the 0.31%. The adjustment provided an R

2 of 99.68% and an adj-R

2 of 98.23%.

On the same manner as in the PA66 material, for PA66-GF30, the ANOM study identified significant differences between the means of all the levels of each factor for the variables F, T, and P, at a 95% confidence level. The same considerations above could be taken into account.

The equations of the fitted model of the force, torque, and power are:

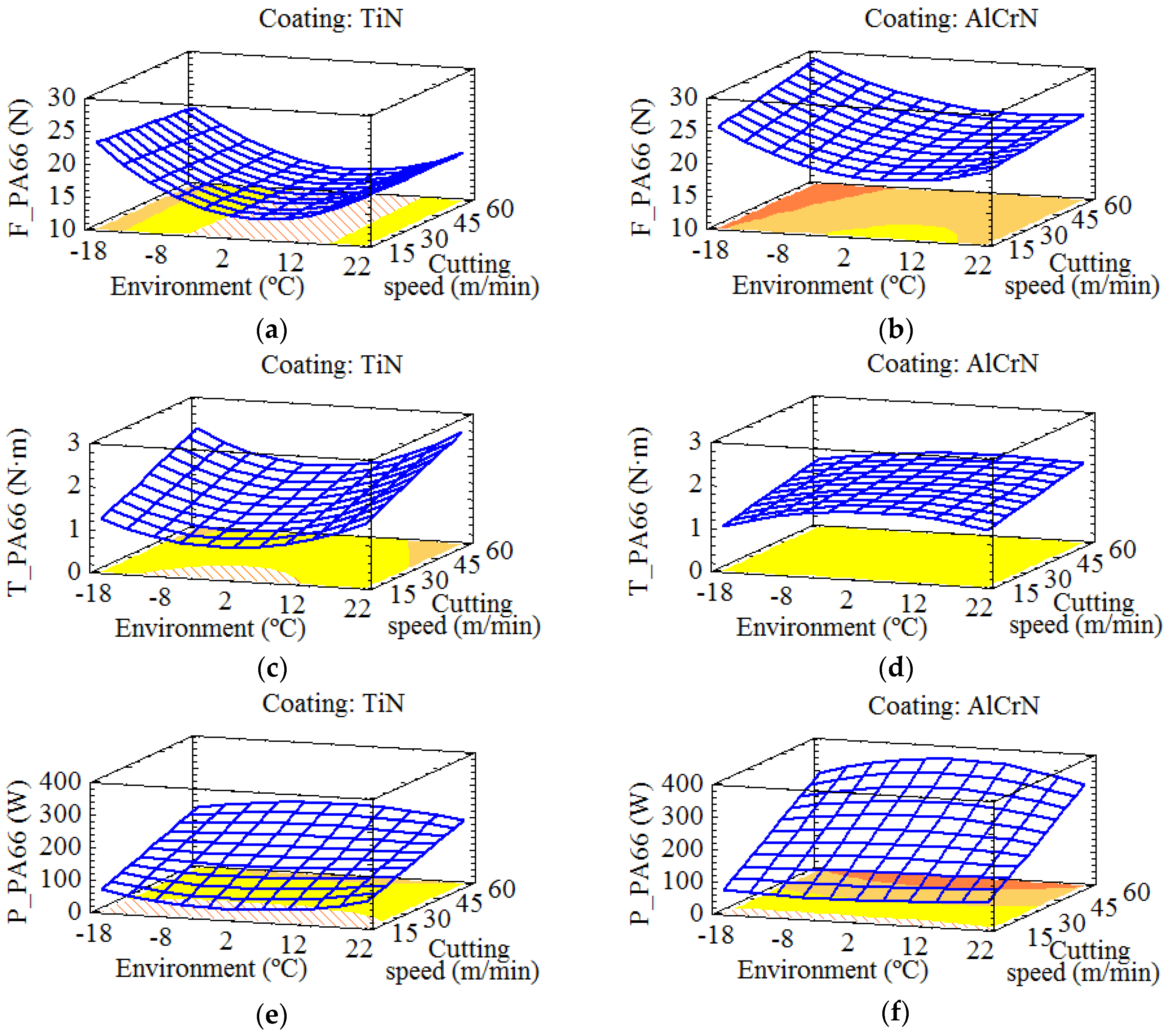

3.2. Response Surfaces

Figure 3 shows the estimated response surface in the variables

F,

T and

P in tapping operations of PA66. The effect of the coating is unambiguous, as is seen in

Figure 3a–f. At environmental temperature, the thrust forces practically do not vary (

Figure 3a,b), but the effect of the cutting speed is greater when the temperature drops. The coating has a determining effect on the torque; the cooling air gives a minimum at temperatures close to 0 °C with TiN (

Figure 3c), while it has almost no influence with the use of AlCrN (

Figure 3). With regards to power, the cooling effect is similar with both coatings, although with a greater influence on cutting speed when using AlCrN (

Figure 3e,f).

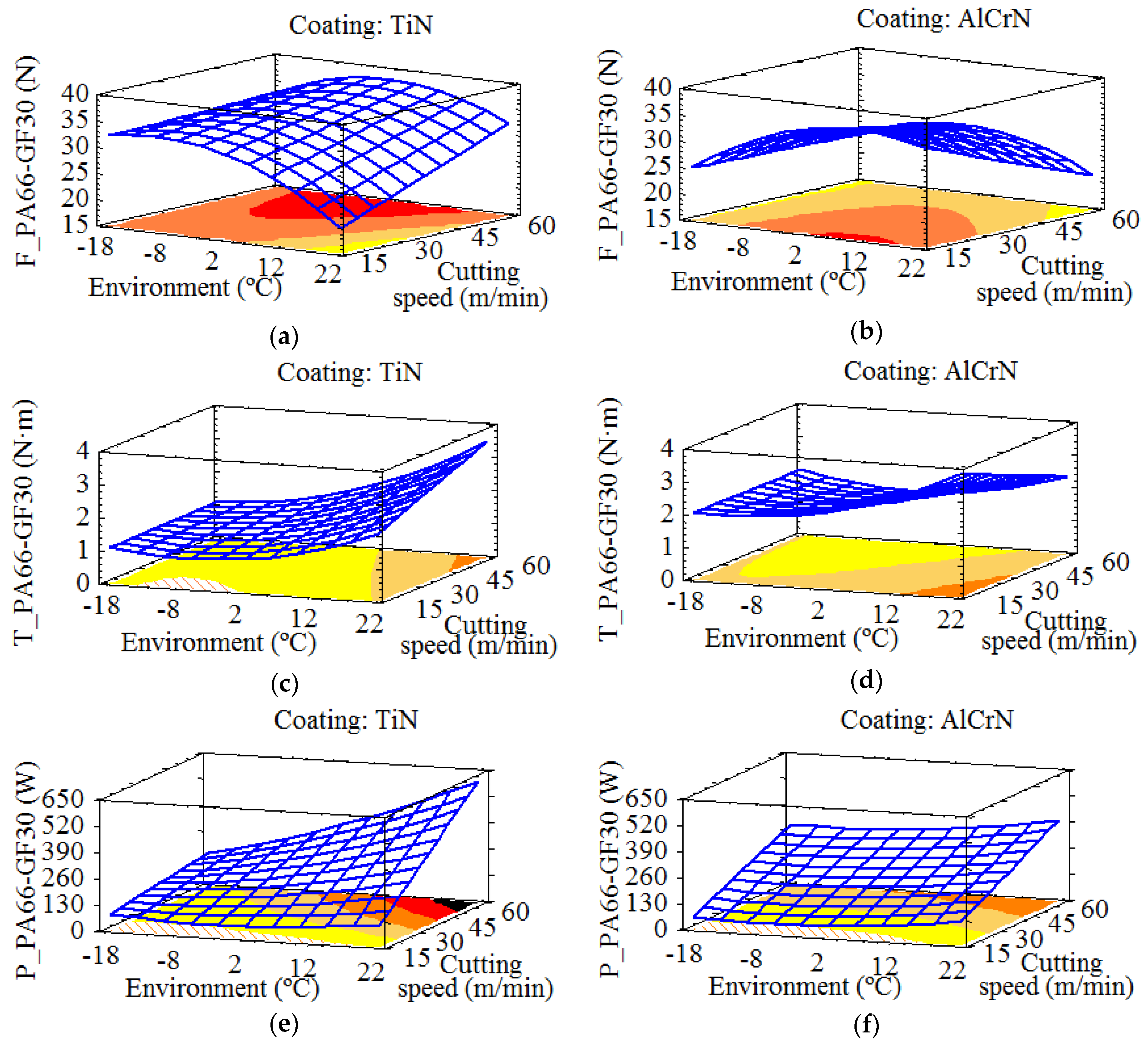

For PA66-GF30,

Figure 4 shows the estimated response surface. These results indicate dissimilar behavior with each tool, as was expected. For high speeds, the effect of the AlCrN coating was milder. With tool T1, the thrust force increased with increasing cutting speed (

Figure 4a). However, for tool T2, the thrust force decreased when the speed is increased (

Figure 4b); this phenomenon is common in other materials, such as steel [

19].

For each coating, in general, a reduction of torques (

Figure 4c,d) and power (

Figure 4e,f) could be achieved when the environmental temperature was lower, although with a strong influence of speed. This can explain the effect of the interaction ABC.

In the range of cutting conditions, with the tapping operations of the PA66-GF30 material, a coating of AlCrN resulted in a decrease in the thrust forces when the cutting speed was increased.

3.3. Multi-Response Optimization

The goals of optimizing the response are to minimize all variables and identify each one’s optimal value. In

Table 11, the optimal values of each variable can be observed. First, for PA66, the importance of TiN coating can be observed; this is the coating that provides the optimal result for the three variables. However, with respect to the environment and cutting speed, several contradictions are found, as shown in

Figure 3.

The optimal values for F, T, and P can be obtained with different cutting and environmental conditions; only the coating is maintained in PA66. Thus, to achieve a global solution, multi-response optimization is conducted for F, T, and P and for PA66 and PA66-GF30.

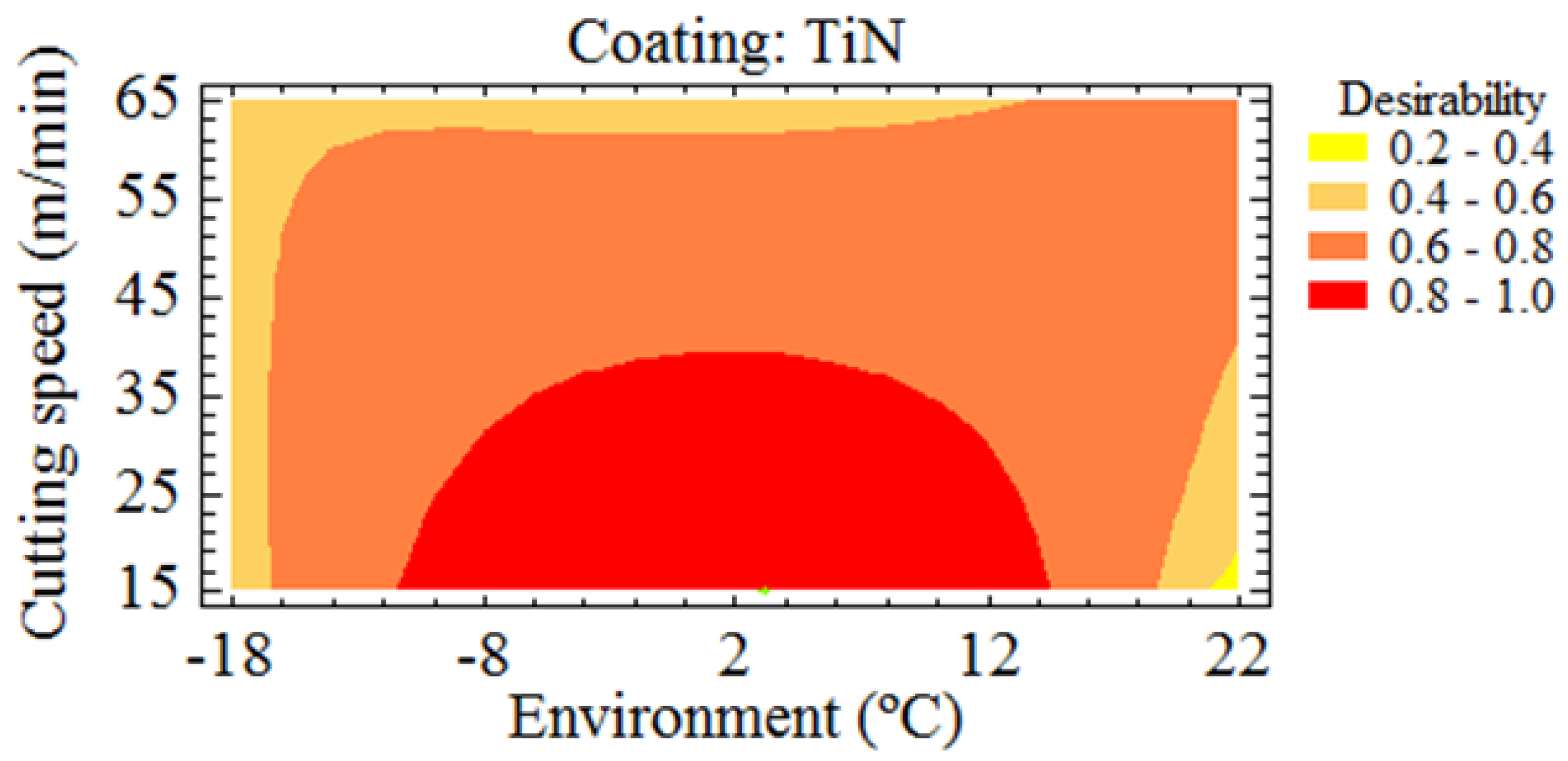

3.3.1. Multi-Response Optimization for PA66

This procedure helps determine the combination of experimental factors that simultaneously optimize several responses by minimizing

F,

T and

P, and by maximizing a desirability function. The values of weights (

t) are 1 for all variables, and the importance or impact (

ri) is 3 for all variables in the two materials, as well as in the range analyzed that corresponds to the value, identified in

Table 4. The current goal for each of the responses (variables) is to minimize the force, torque, and power. As shown in

Figure 3, the cutting conditions that provide the minimal force, torque, and power for PA66 are different; only the TiN coating is recommended for the three variables. The temperatures are practically equal in

T and

P, as is the cutting speed in

F and

P (despite the strong dependence of the power on the torque). The multiple performance gives a common optimization, according to the combination of factor levels that maximize the overall optimal desirability over the indicated region. The evolution of the desirability function is shown in

Figure 5.

Finally, this optimum can be found using cooling air at temperatures near 3 °C (3.15 °C), a cutting speed of 15 m/min, and a TiN coating. Consequently, the cooling air has a positive influence, although it is not necessary to achieve temperatures under zero. The TiN coating is the reference, as expected, because it is the better coating in the sub-optimization; a possible explanation is that although TiN is less lubricous than AlCrN, and has a higher coefficient of friction than AlCrN [

29], the required forces are low and the friction has no affect. The optimal responses for F_PA66, T_PA66, and P_PA66 are 12.26 N, 1 N·m, and 30.9 W, respectively. The optimal value of desirability (

D) is 0.99.

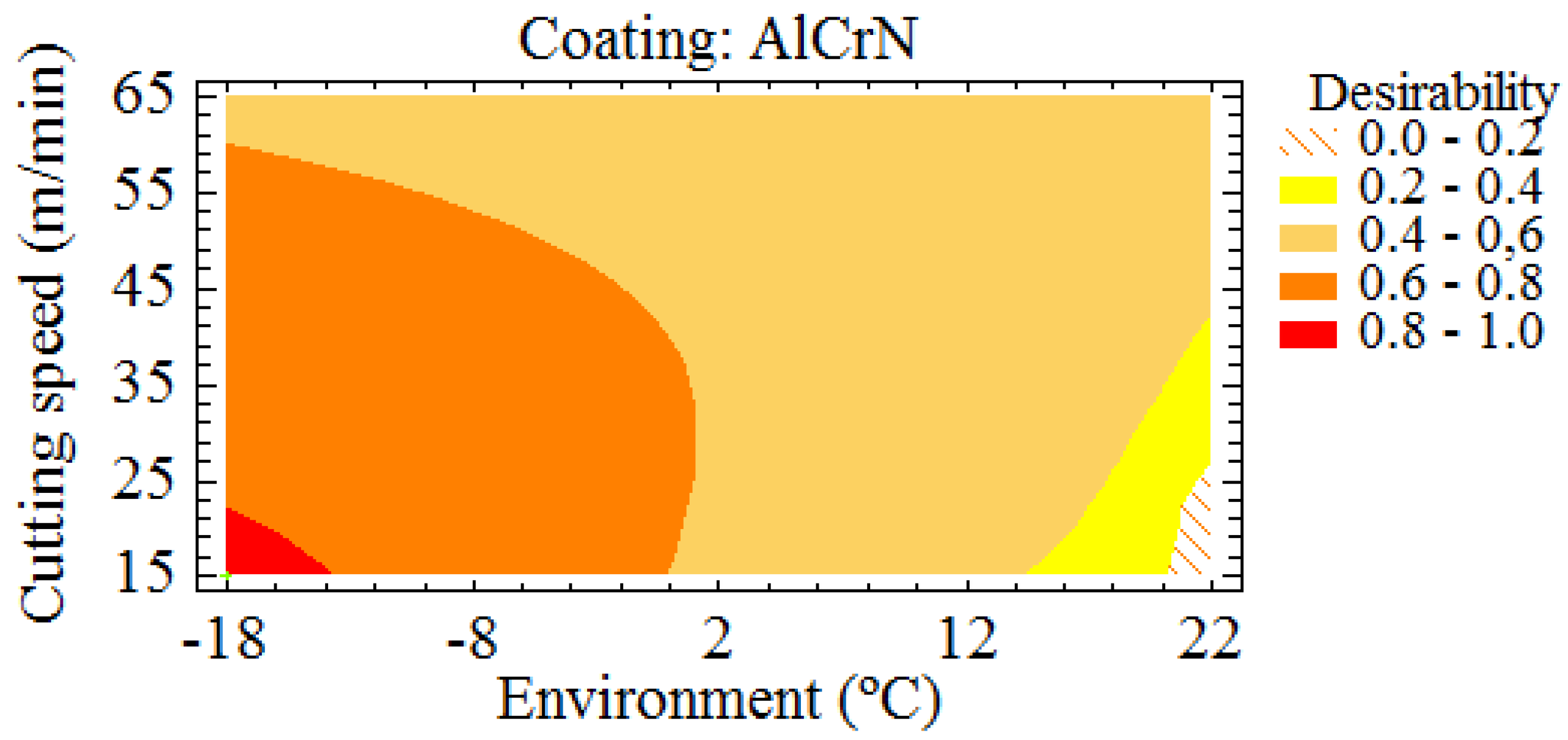

3.3.2. Multi-Response Optimization for PA66-GF30

With respect to PA66-GF30, the optimization of each variable does not allow all variables to be optimized, because the values of parameters are different for each variable, as observed in

Table 11.

Thus, the multi-response optimization allows the optimal combination of cutting conditions to obtain the optimal desirability. The cooling is effective, and the minimal temperature achieved (−18 °C) allows a strong desirability value. The low cutting speed (15 m/min) can be explained by its high influence on the power; the AlCrN coating is better for achieving the maximal desirability, which is notable because this coating has favorable properties for use in dry machining [

28]. This coating is more lubricous than TiN [

29]—AlCrN is dense and has few microvoids and microdroplets, which provides a uniform structure [

37]. This uniform structure can benefit the machining process in a composite material such as PA66-GF30.

Figure 6 shows the contours of the estimated response surface for the AlCrN coating.

The optimal response is 24.94 N for F_PA66-GF30, 1.45 N·m for T_PA66-GF30, and 63.45 W for P_PA66-GF30. The optimal value of desirability (D) is 0.83, which is lower than that for PA66, while the values of F, T, and P are higher than in unreinforced polyamide.

4. Conclusions

A study based on machining through cooling air has been conducted, with the purpose of finding greener operation processes. These processes were performed on tapping operations in dry conditions and with two materials, PA66 and PA66-GF30. The experimental results were treated statistically by an ANOVA study, regression models, and multi-response optimization. In PA66, the environment is an influence factor, and the cooling of the tool affects the results of F, T, and P. Similar considerations can be realized for PA66-GF30, due to the influence of the first-order, second-order, or interaction effect of the “environment” factor.

A multi-response surface optimization shows that the optimum value can be found in environments close to 3 °C for PA66, while the optimum for PA66-GF30 is found at the minimal temperature studied (−18 °C). Thus, cooling air can be considered an adequate procedure for tapping operations to increase the sustainability of the manufacturing processes.

In future work, the influence of other geometries and the coating should be explored with regards to tapping operations in polyamide and reinforced polyamide, along with the effect of lower temperatures in the machining, particularly with PA66-GF30. In both materials, it can be of interest to seek other conditions that achieve a desirable result.