1. Introduction

Nitrogen (N) use in agriculture is of concern due to the dilemma of agricultural intensification to cope with the global food demand and the efforts to reduce emission of reactive N, which is one of the vital environmental challenges [

1]. To feed the growing world population, mineral N fertilizer production and application have grown ten-fold in the second half of the last century [

2]. Every kg of mineral N fertilizer application increases the global stock of reactive N which keeps partly circulating (i.e., manure recycling) in agricultural systems. Increasing use of N fertilizers causes impacts on soil, air, water, biodiversity and climate change [

3]. The application of mineral N fertilizers is the biggest source of global anthropogenic N

2O emissions [

4] which are the fastest growing source of agricultural greenhouse gas (GHG) emissions [

5]. N

2O emissions are expected to rise further and this may offset GHG mitigation efforts from other sectors [

6]. At farm level, more than half of GHG emissions generated in crop production originate from N fertilizer application [

7,

8]. Besides, production of fertilizers is an energy intensive process that is responsible for a considerable amount (0.6–1.2%) of total GHG emissions worldwide [

9] with the highest contribution from N fertilizer production [

10]. Thus, if emissions due to mineral N fertilizer production were accounted for, in addition to N

2O emissions due to application, the importance of N fertilizer in total agriculture induced GHG emissions would be even higher [

11].

Measures to tackle the N use dilemma mainly focus on how to achieve more efficient N use [

7,

12]. However, it is particularly challenging to increase N use efficiency, since reactive N is bound and cycled in various chemical pathways in agricultural soils [

3] and easily distributed by hydrologic and atmospheric transportation [

13]. Roughly half of the N added into agricultural systems in Europe is lost to the surrounding environment [

3]. Facing the high impact of N fertilizer use on the environment and especially global warming, reduction of N fertilizer seems to be an effective GHG mitigation measure. Reduction in N fertilizer related GHG emissions can be achieved by changing input management or change in cropping systems (selection of crops with lower N input). A direct reduction of N input supply into agricultural systems is an obvious mitigation measure which was suggested 20 years ago (e.g., Kroeze [

14]). Denmark implemented an N input quota system in the early 1990s setting norms for the N fertilization equal to the economic optimum N rate which was subject to further reduction up to 15% below the economic optimum [

15]. Furthermore, GHG mitigation options based on N input management were often suggested as technological approaches such as variable rate technology in precision farming [

16,

17]. While the acceptance level of such technologies still remains in a tardy progress at the global scale [

18], the returns of investments in precision farming technologies are often low [

19,

20]. One reason for the limited economic returns of precision farming practices is the flatness of profit functions around the assumed economic optimum [

21]. However, flat profit functions also provide an opportunity to reduce N input and thus associated GHG emissions, without affecting farm profitability heavily. In the same vein, McSwiney & Robertson [

22] stated that mitigation of N

2O emissions by N fertilizer reduction could be achieved without causing a strong yield penalty. Furthermore, Meyer-Aurich et al. [

23] reported that a moderate reduction of N fertilizer can be an effective measure to lower GHG emissions; and such straightforward N fertilizer reduction—without any technology investment—requires more attention as an alternative to mitigate GHG emissions in agriculture.

N fertilizer reduction has been considered from GHG mitigation point of view at different scales. For instance, Domínguez et al. [

24] evaluated the EU-wide implications of a reduction in N fertilizer input—while maintaining output constant—via eliminating assumed over-fertilization and/or achieving more balanced N fertilizer management between mineral and organic N fertilization. Mérel et al. [

25] assessed the effects of an N fertilizer tax on N mitigation at the intensive (input intensity adjustments) and extensive margins (acreage reallocation) at the regional scale. While there is information at aggregated levels in terms of to what extent and at what costs N fertilizer reduction offers GHG mitigation potentials, there is little information on cost-efficient GHG mitigation at different sites considering different yield responses to stepwise reduction of N fertilization. Such indication of GHG mitigation costs could enable comparability of GHG mitigation potentials by N fertilizer reduction among sites, since site-dependent climate and soil characteristics result in differences in crop yield potentials which in turn may lead to different GHG mitigation costs. This was already shown for GHG mitigation potentials and costs of biogas production in Brandenburg, if different feedstock are grown at sites with different yield potentials [

26].

In terms of N fertilizer, yield and GHG interactions, the first step towards understanding site-dependent GHG mitigation potentials and opportunity costs of reducing N supply would be to understand crop yield response to N fertilizer reduction. On the one hand, reduction in N fertilization abates GHG emissions—first, due to reduced energy demand for less N fertilizer production and secondly because of fewer N inputs into agricultural soils, resulting in fewer N

2O emissions. On the other hand, it can be expected that yield penalties occur, which may be a major constraint for farmers to reduce N fertilizer [

27]. The magnitude of yield penalty depends on yield response to reduced N application. Thus, cost estimation of GHG mitigation by N fertilizer reduction requires the estimation of GHG mitigation potential and thereby the economic returns of reduced N fertilization. While the former can be estimated by means of emission factors per kg N input, the latter requires the identification of production functions relating crop yield to N fertilizer application. Yield response functions can be estimated on the basis of long-term field experiments; however, such empirical data do not exist for all crops at all sites. In this context, this study aims to identify the comparative advantage of different sites (yield-zones) in Brandenburg with specific crop yield responses to N fertilizer to mitigate GHG by N fertilizer reduction. Hanff & Lau [

28] suggested yield-zone-specific N fertilizer rates but information on yield-zone-specific response to reduced N supply is not available. Therefore, we estimated yield-zone-specific response functions based on a normalization approach [

29], which enables transferring yield response to N fertilizer from sites with empirical data to the yield-zones lacking that information. The normalization approach was applied in earlier studies addressing environmental issues regarding N use in agriculture [

30,

31,

32]. For instance, Baudoux [

31] evaluated environmental and economic implications of a complete renunciation of mineral N fertilization. However, to our knowledge the comparative advantages of specific sites to mitigate GHG emissions by moderate N fertilizer reduction have not been shown yet.

In this context, our paper presents a model approach to estimate yield-zone-specific costs of GHG mitigation by mineral N fertilizer reduction. In addition, it provides a basis to analyse implications of different GHG mitigation policies on N fertilizer reduction, e.g., N fertilizer tax, incentives, or N fertilizer cap. The output of this study has potential to contribute as an aiding tool to identify cost-efficient agro-environmental policies.

2. Materials and Methods

2.1. Methodological Concept

We constructed a model which reflects yield and economic response to N fertilizer reduction in yield-zones with different yield potentials in order to identify comparative advantages for GHG mitigation. A normalization approach following Krayl [

29] was employed to transfer yield response to N fertilizer from sites with known input-output relations to yield-zones lacking that information. The workflow of the methodological approach is shown in

Scheme 1.

We applied our model to estimate winter wheat (further referred to as wheat) and winter rye (further referred to as rye) yield response to N fertilizer reduction in five yield-zones in the state of Brandenburg, Germany. Wheat and rye are dominant cereals in Brandenburg, while wheat is grown predominantly in high yield-zones, rye is grown rather in low yield-zones. Therefore, modelling both cereals with respect to GHG mitigation potentials provides representation of all possible yield-zones in the region, and, thus respective comparative advantages.

Yield response functions with respect to N fertilizer were estimated based on long-term experiments for wheat and rye (see

Section 2.2) and transferred by the normalization approach to the five yield-zones in Brandenburg (see

Section 2.3). Yield-zone-specific yield response functions were estimated to provide the base for the subsequent estimations of GHG emission response to N fertilizer reduction (see

Section 2.3). Costs of yield-zone-specific GHG mitigation were estimated combining N fertilizer reduction induced GHG mitigation (see

Section 2.4) with the economic returns (see

Section 2.5). In addition, an uncertainty analysis was executed to identify the most influential parameters on and the ranges of GHG mitigation costs by N fertilizer reduction (see

Section 2.6). Considering a constant regional demand for wheat and rye, we applied a system expansion to include possibly emerging GHG emissions by offsetting yield penalties due to N fertilizer reduction (see

Section 2.7). Furthermore, we conducted a case study on regional optimization of GHG mitigation by N fertilizer reduction in wheat and rye production in Brandenburg (see

Section 2.8).

2.2. Data

Empirical data on crop yield response to N fertilizer were taken from two long-term experiments located in north-eastern Germany (

Table 1). Data for wheat (

Triticum aestivum L.) yield response were taken from 1986 until 1999 in Dahlem [

33]; and for rye (

Secale cereal L.) yield response from 1996 until 2010 in Thyrow [

34]. The annual average precipitations were 545 mm and 495 mm and the annual average temperatures were 9.3 °C and 8.9 °C for Dahlem and Thyrow, respectively. The experiments were designed with various fertilizer treatments. For wheat, four different mineral N fertilizer application rates were used. Wheat was in rotation with barley (

Hordeum vulgare L.) and potato (

Solanum tuberosum L.) and 30 t of farmyard manure was applied on potato cultivation in the rotation triennially. For rye, three different mineral N fertilizer application rates were used; and rye was in rotation with winter barley (

Hordeum vulgare L.), oil seed rape (

Brassica napus L.), cocksfoot (

Dactylis glomerata L.) and potato. The rotation received organic fertilizer as straw after harvesting winter barley and rye.

Information on yield and N fertilizer relationships in the yield-zones were derived from Hanff & Lau [

28]. They provided input-output patterns including yield potentials and N fertilization rates for five differentiated yield-zones in Brandenburg. Yield-zones are categorized based on a soil fertility index where yield-zone-1 has the highest and yield-zone-5 has the lowest yield potential. We assumed that the data on N fertilizer can be interpreted as the recommended N fertilizer intensity to reach an expected economic optimum yield level in respective yield-zone.

Table 2 presents yield-zone-specific N fertilization rates and corresponding yield levels.

2.3. Estimation of Yield-Zone-Specific Yield Response Functions

Yield-zone-specific yield response functions were modelled in three steps: (i) estimation of yield response functions based on the empirical data; (ii) transforming them by the normalization approach and (iii) transferring the normalized yield response functions to the yield-zones in Brandenburg (

Figure 1).

Quadratic polynomial functions were estimated by ordinary least square method (Equation (1)) using the data on crop yield response to N fertilizer for wheat and rye from the considered long term field experiments (Dahlem and Thyrow). Meyer-Aurich et al. [

35] reported that quadratic functions showed the best statistical fit for wheat yield response to N fertilizer. Nonetheless, functional specification of yield response to N fertilizer does not have a strong impact on economic assessments [

36].

where

Y is yield (Mg ha

−1),

N is N fertilization rate (kg N ha

−1),

a is the quadratic coefficient,

b is the linear coefficient and

c is a constant.

We deployed the normalization approach transforming the above-mentioned crop specific polynomial function to build crop specific yield response functions for each of the five yield-zones in Brandenburg (Equation (2)).

where

i denotes yield-zone.

For the transfer of yield response functions, reference points of both sites were required and all quantities of yield and N rate were subject to be relative to these reference points. We used economic optimum N rate and corresponding yield level as reference points in the normalization approach. Economic optimum fertilizer rate maximizes profit and was found by solving the first order derivation of the yield response function. At the economic optimum N rate (

Nopt), marginal product is equal to the input-output price ratio (

PN/

PY) (Equations (3)–(5)). The economic optimum N rates and the corresponding yields (

Yopt) were calculated using coefficients of respective yield response functions for wheat and rye at fixed price ratio (5.96 € kg

−1 N/€ kg

−1 wheat; 7.80 € kg

−1 N/€ kg

−1 rye) of N fertilizer (input) and crops (output).

The coefficients of the normalized production function were derived from the coefficients of the empirically estimated yield functions

a,

b,

c (in Equation (1)) for wheat from Dahlem and rye from Thyrow; and transformed into (Equation (6)) where

Ynorm is the normalized production function with normalized N application rate (

Nnorm) and normalized coefficients

anorm, bnorm and

cnorm.

Ynorm was defined as

Y divided by

Yopt and

Nnorm was found as

N divided by

Nopt. By using these relations, Equation (1) was reformulated as:

By dividing Equation (7) by

Yopt, we re-arranged the equation and generated

Ynorm function as:

From Equation (8), we identified normalized coefficients (Equations (9)–(11)) by comparing Equation (8) with Equation (6):

Once the empirically estimated yield response functions were transformed into normalized yield response functions, they were transferred to the yield-zones of Brandenburg, where only

Nopt and

Yopt were known. We transferred the normalized yield response functions for wheat and rye to the five yield-zones in Brandenburg. Following the assumption of the normalization approach, the second-degree derivations of the normalized yield response functions at respective

Nopt points were equal (Equation (12)).

Given this assumption, we calculated the quadratic coefficient of respective yield-zone in Brandenburg as follows:

After the quadratic coefficient of the yield response function of the yield-zones was determined based on the normalization approach, we calculated the linear coefficient derived from

Nopt calculation in Equation (5):

Once quadratic (

a) and linear (

b) coefficients of the production function of each yield in Brandenburg were determined, we calculated the constant (

c) given the economic optimum N rate (

Nopt_i), the yield (

Yopt_i) at

Nopt_i and the prices of input and output based on Equation (2):

Following normalization of the yield response functions based on the empirical data and transformation of the normalized functions into five different yield-zones in Brandenburg, yield response functions for wheat and rye in each yield-zone were constructed. Consequently, yield response on adjusted N fertilization intensities could be drawn in differentiated yield-zones, so that yield-zone-specific marginal GHG mitigation costs could be identified accordingly.

2.4. Partial Budgeting of GHG Emissions of N Fertilizer

For the partial budgeting of GHG emissions, we included direct and indirect N

2O emissions due to mineral N fertilizer application and CO

2 emissions generated due to mineral N fertilizer production. Calcium ammonium nitrate (CAN) with 27% N content was chosen as the mineral N fertilizer type which is commonly used in Brandenburg. It was assumed that no manure was applied to fields of wheat and rye and above-ground crop residues were removed from fields. Change in below-ground biomass was ignored, since root biomass was expected to be only marginally affected by moderate adjustments of N fertilization.

Table 3 shows the emission factors considered in the calculation. N

2O emissions were estimated according to the Intergovernmental Panel on Climate Change (IPCC) guideline [

37].

Direct N

2O emissions considered in this study included N

2O emissions occurring due to N mineralization directly from soil where N fertilizer was applied to. Indirect emissions considered consist of N

2O emissions via volatilization, leaching and runoff of N added. N

2O emissions were converted into CO

2e according to the global warming potential (GWP) as reported in [

38]. The 100-year GWP (298) was applied for the conversion. For the GHG emissions regarding the production of N fertilizer (CAN), the average of European production technology was taken according to Bentrup & Palliere [

8]. The total emission factor (

EFTotal) including production and application of mineral N fertilizer added up to 9.91 kg CO

2e kg

−1 N. GHG emissions (

GHGi,c) of mineral N fertilization in each yield-zone (

i) were calculated according to Equation (16).

Total GHG emissions (GHGi,c; kg CO2e ha−1) of mineral N fertilization (Ni,c) were calculated for each yield-zone (i) and crop (c) using emission factors EFD (emission factor for direct N2O emissions; kg CO2e kg−1 N), EFV (emission factor for volatilization of N2O; kg CO2e kg−1 N), EFL (emission factor of leaching and runoff; kg CO2e kg−1 N) and EFP (emission factor for CAN production; kg CO2e kg−1 N).

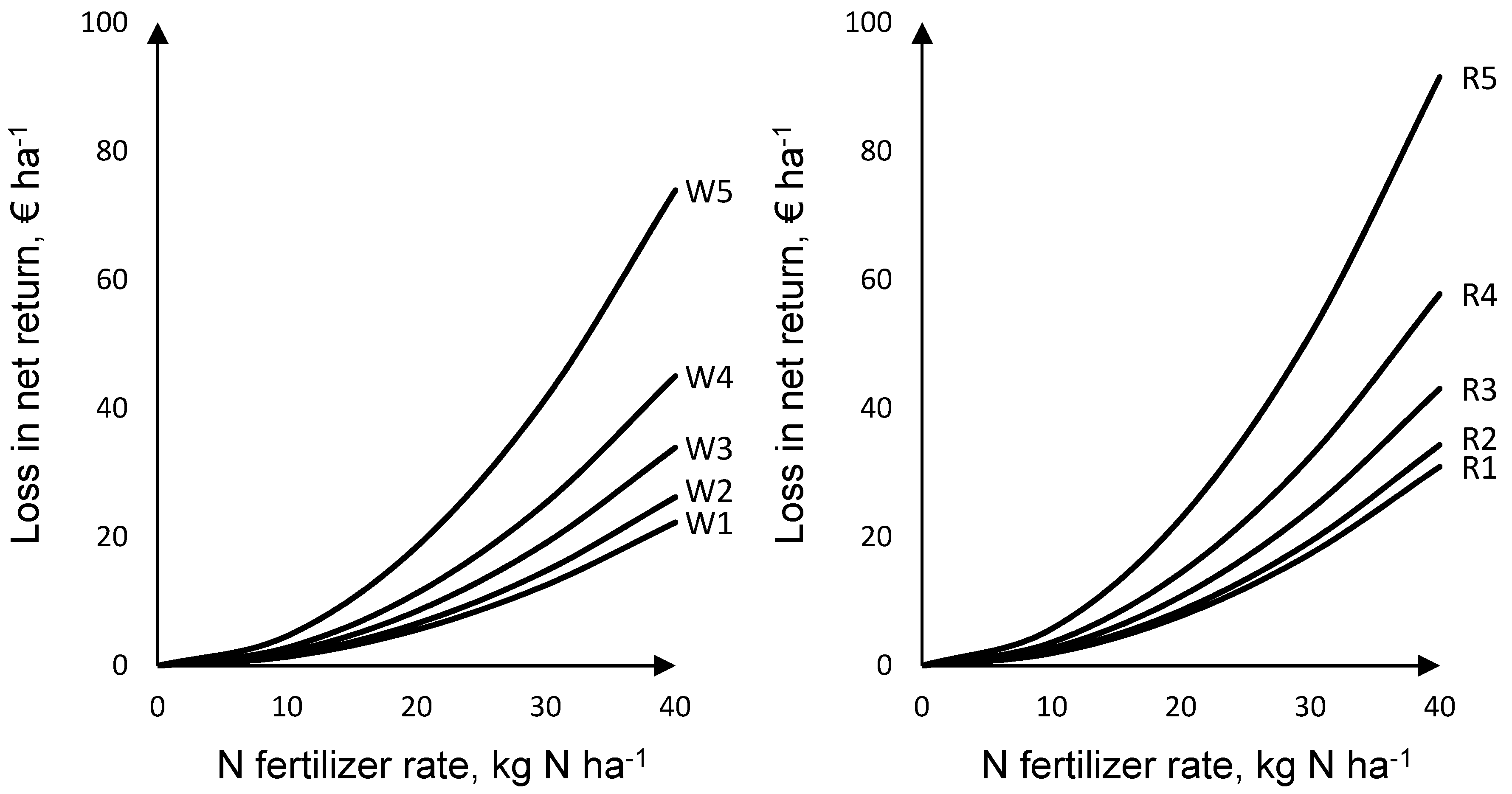

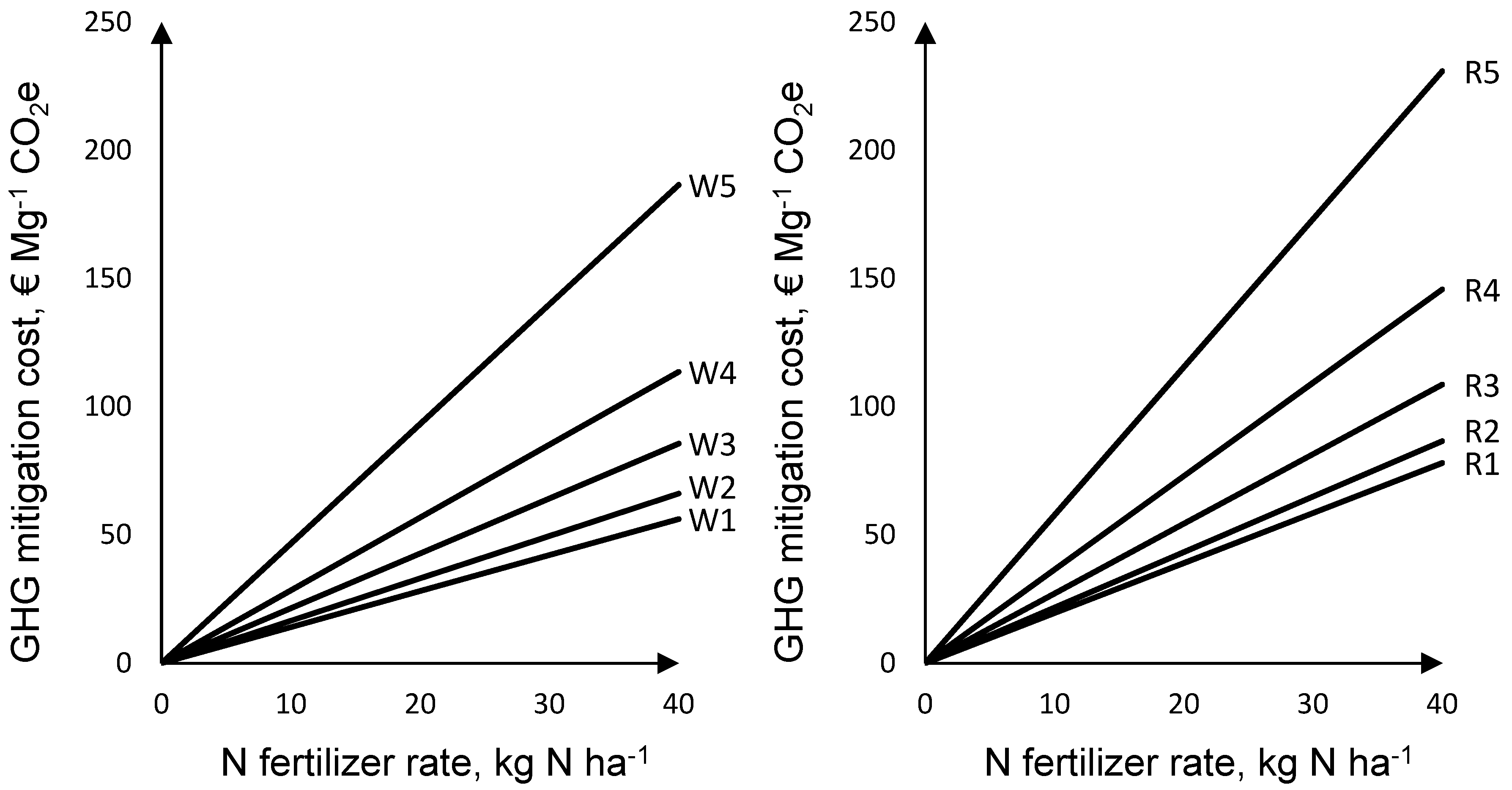

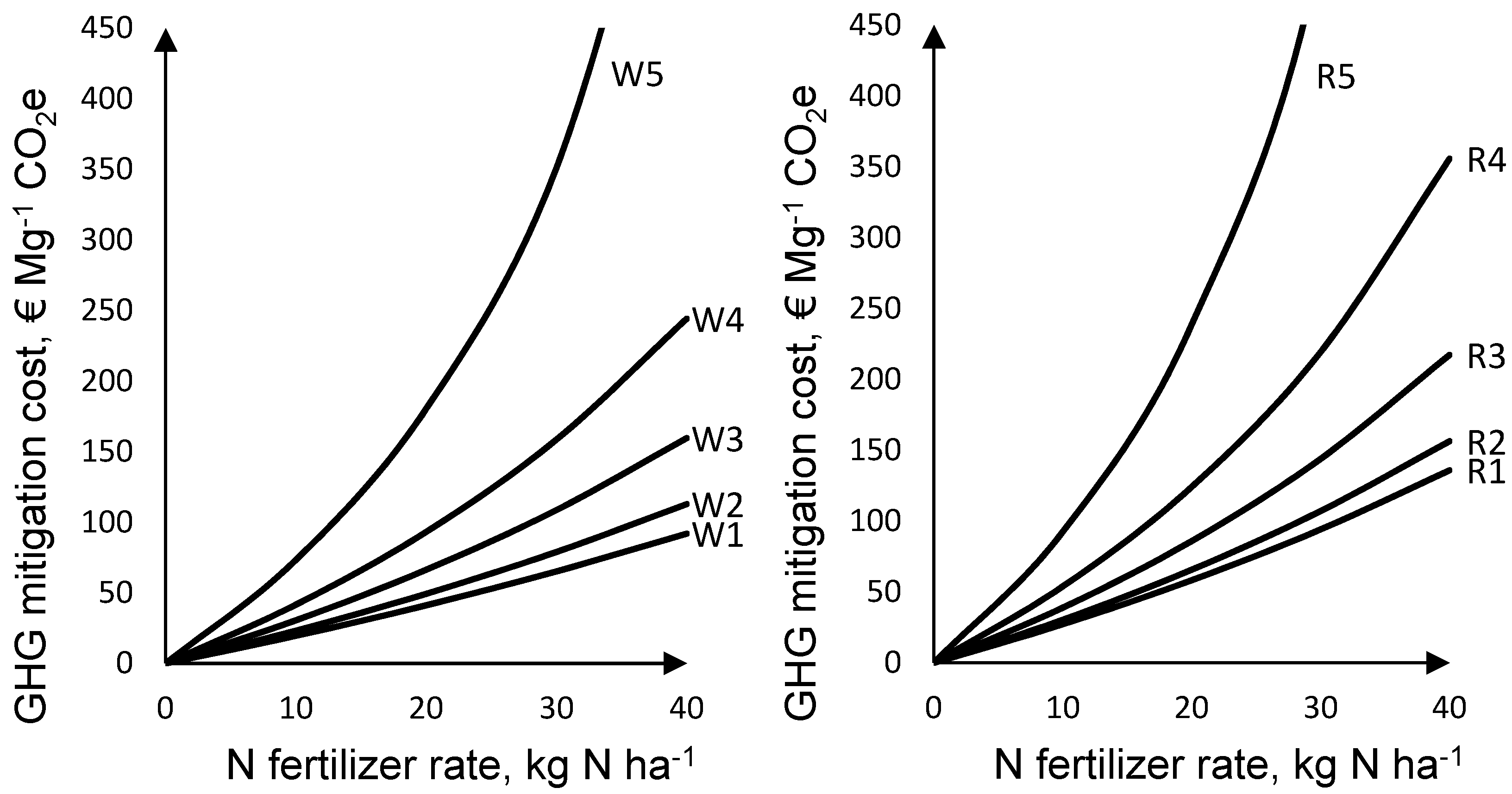

2.5. Net Return over N Fertilizer and Yield-Zone-Specific GHG Mitigation Cost Functions

In our calculation for net return, we performed a partial budgeting. N fertilizer was the only production factor that was adjusted affecting yield. Net return over N fertilizer applied (€ ha

−1) was calculated as the difference between revenue of crop sales and cost of N fertilizer applied (Equation (17)).

Table 4 presents the prices of N fertilizers and crops considered in this study.

where

NRi,c—Net return,

PY—Price of crop (€ Mg

−1),

Yi,c—Yield (Mg ha

−1),

PN—Price of N fertilizer (€ kg

−1 N),

Ni,c—N fertilizer rate (kg N ha

−1),

i—Yield-zone and

c—Crop.

Crop and yield-zone-specific GHG mitigation cost functions were estimated by coupling change in net return and change in GHG emissions when N fertilizer application was reduced (Equation (18)).

where

GHG_costi,c—Crop (

c) and yield-zone-specific (

i) cost of GHG mitigation,

NRi,c_R—Crop and yield-zone-specific net return in reference scenario (status quo),

NRi,c_A—Crop and yield-zone-specific net return in alternative scenario (N fertilizer reduction),

GHGi,c_R—Crop and yield-zone-specific greenhouse gas emissions in reference scenario (status quo) and

GHGi,c_A—Crop and yield-zone-specific GHG emissions in alternative scenario (N reduction).

2.6. Uncertainty Analysis

In order to identify the most influential parameters on and the range of GHG mitigation costs, we carried out an uncertainty analysis on cost estimation of GHG mitigation by N fertilizer reduction. We considered uncertainties of the prices of N fertilizer and crops, the emission factors related to the N transformation processes and the standard deviation of crop yields at the economic optimum. The standard deviations of crop and yield-zone-specific yields were estimated based on the assumption that the coefficient of variance for a given crop would be the same in yield-zones as well as in Dahlem and Thyrow for wheat and rye respectively. The coefficients of variance were calculated in Dahlem (wheat) and Thyrow (rye) based on the empirical data and used to estimate the standard deviation of yields in the five yield-zones in Brandenburg. A normal distribution with the respective standard deviation was modelled for each crop and yield-zone. Apart from the standard deviation of yields, all parameters were modelled in a Monte Carlo simulation with a log-triangular distribution (

Table 5), 5000 iterations were run using @Risk (Palisade Corporation Software, Ithaca, NY, USA). A multivariate regression analysis was conducted to identify the influence of uncertainty of input parameters on GHG mitigation costs. The expected value (mean) and the standard deviation of GHG mitigation costs in each yield-zone were estimated based on the simulation results.

2.7. System Expansion

A system expansion was applied for N fertilizer reduction to include GHG emissions (

EFY,c) that were assumed to be generated at a different site to offset yield penalties due to N fertilizer reduction in the considered yield-zones in Brandenburg (Equation (19)). The European Union average of GHG emissions per kg product for retail sale of wheat (409 kg CO

2e Mg

−1 product) and rye (299 kg CO

2e Mg

−1 product) were taken from ProBas database [

39].

In system expansion, total crop (

c) and yield-zone-specific (

i) GHG emissions (

GHG_sei,c; kg CO

2e ha

−1) included emissions to compensate yield penalties (

Y_pi,c; kg product ha

−1) coupled with the emission factor per kg product (

EFY,c), in addition to GHG emissions (

GHGi,c) highlighted in

Section 2.4.

2.8. Case Study

In order to simulate a comparative investigation, we conducted a case study on optimization of regional costs due to N fertilizer reduction to mitigate GHG emissions. As regional GHG mitigation goal 33.5 Gg CO

2e was set, which is equivalent to 10 kg ha

−1 on average for the given total wheat and rye production area in five yield-zones in Brandenburg. No land use change was allowed. The extension of land use of the respective crops is given in

Table 6.

We applied two strategies to reach the GHG mitigation target: Uniform reduction (the same reduction rate for both crops in all yield-zones) and smart reduction considering comparative advantages of crop- and yield-zone-specific GHG mitigation costs.

Uniform reduction implies equal amount of mineral N reduction per hectare to reach an overall reduction target. In other words, the overall reduction target was distributed to every hectare evenly independent of site qualities, crop selection and input and output prices (Equation (20)).

Nred-uni—Uniform N fertilizer reduction (kg ha−1), GHGred_target—GHG mitigation target of the region (kg CO2e), EFTotal—Total emission factor (kg CO2e kg−1 N), L—Land use (ha) for every yield-zone (i) and crop (c).

Smart reduction was defined as cost-minimizing yield-zone-specific N fertilizer reduction that considered the individual yield response to N for each crop, yield-zone, cultivated areas and input and output prices. The total reduction was achieved by considering the yield response to reduced N fertilization for wheat and rye in every yield-zone. The loss in total net return of the region was minimized as the objective function of a nonlinear optimization; while GHG mitigation induced reduction for N supply was held as constraint reflecting the mitigation goal (Equation (21)). Additionally, land use of wheat and rye in respective yield-zones were held constant.

Li,c—Land use of crop (c) in respective yield-zone (i), PY—Price of crop (€ Mg−1), Y—Yield (Mg ha−1), N—N fertilizer rate (kg N ha−1), PN—Price of N fertilizer (€ kg−1 N), Li,c_A—Land use of crop in respective yield-zone in the alternative scenario (N fertilizer reduction), Li,c_R—Land use of crop in respective yield-zone in the reference scenario.

4. Conclusions

The results indicate the feasibility of our model’s approach, which can be applied to various aspects of N fertilizer and GHG mitigation. The approach provides a modelling tool to simulate the yield and economic responses of stepwise reduction of mineral N fertilizer and assess their implications for yield-zone-specific GHG mitigation potential and costs. Our application of the model to Brandenburg implies that moderate reduction of mineral N fertilizer can mitigate GHG emissions at reasonable opportunity costs as they are in the lower-bound of wide-ranged mitigation costs across the agriculture related measures. High yield-zones show advantages over low yield-zones in terms of cost-efficient GHG mitigation. Therefore, N fertilizer reduction should be applied rather to high yield-zones as long as marginal mitigation costs do not exceed the one in the subsequent lower yield-zone. N reduction in wheat production offers GHG mitigation at lower costs with lower uncertainty compared to N fertilizer reduction in rye production. Our study assumes no change in grain quality due to moderate N fertilizer reduction. If N fertilizer reduction results in grain quality loss, GHG mitigation costs would increase due to higher income loss.

N fertilizer reduction in a given region can be optimized considering crop and yield-zone-specific yield responses (smart reduction) and, thus, the total cost-efficiency to mitigate regional GHG emissions can be improved. A total GHG mitigation target of 35.5 Gg CO2e was achievable with the smart N fertilizer reduction strategy with 19% cost savings—compared to uniform reduction—in wheat and rye production in Brandenburg. Our model can be used in further studies for policy analysis comparing different GHG mitigation strategies aiming N fertilizer reduction, e.g. incentives, N fertilizer tax, or N application cap, targeting policies to different sites with different yield potentials.