Risks Induced by Room Mining Goaf and Their Assessment: A Case Study in the Shenfu-Dongsheng Mining Area

Abstract

:1. Introduction

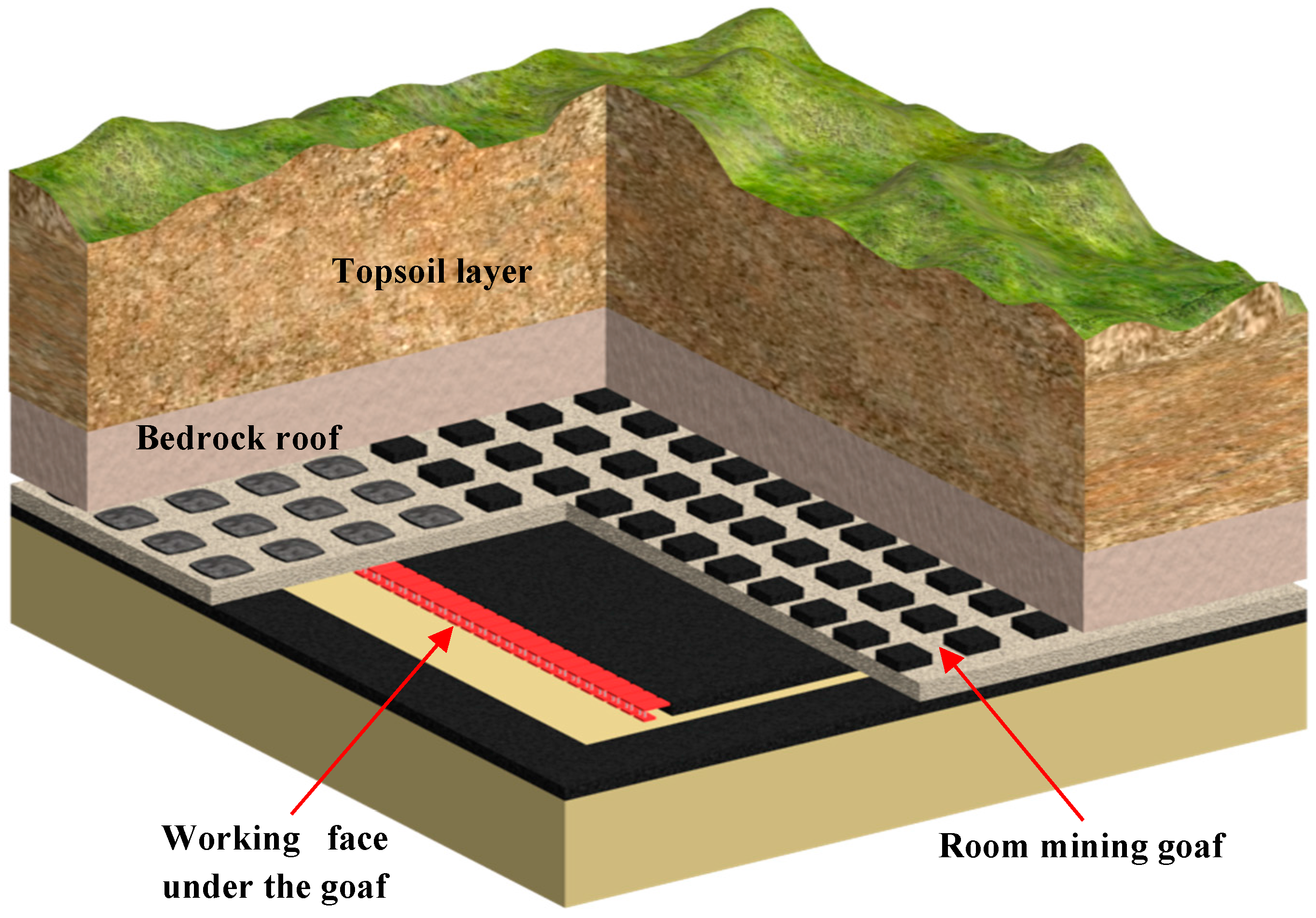

2. Characteristics of Room Mining Goaf

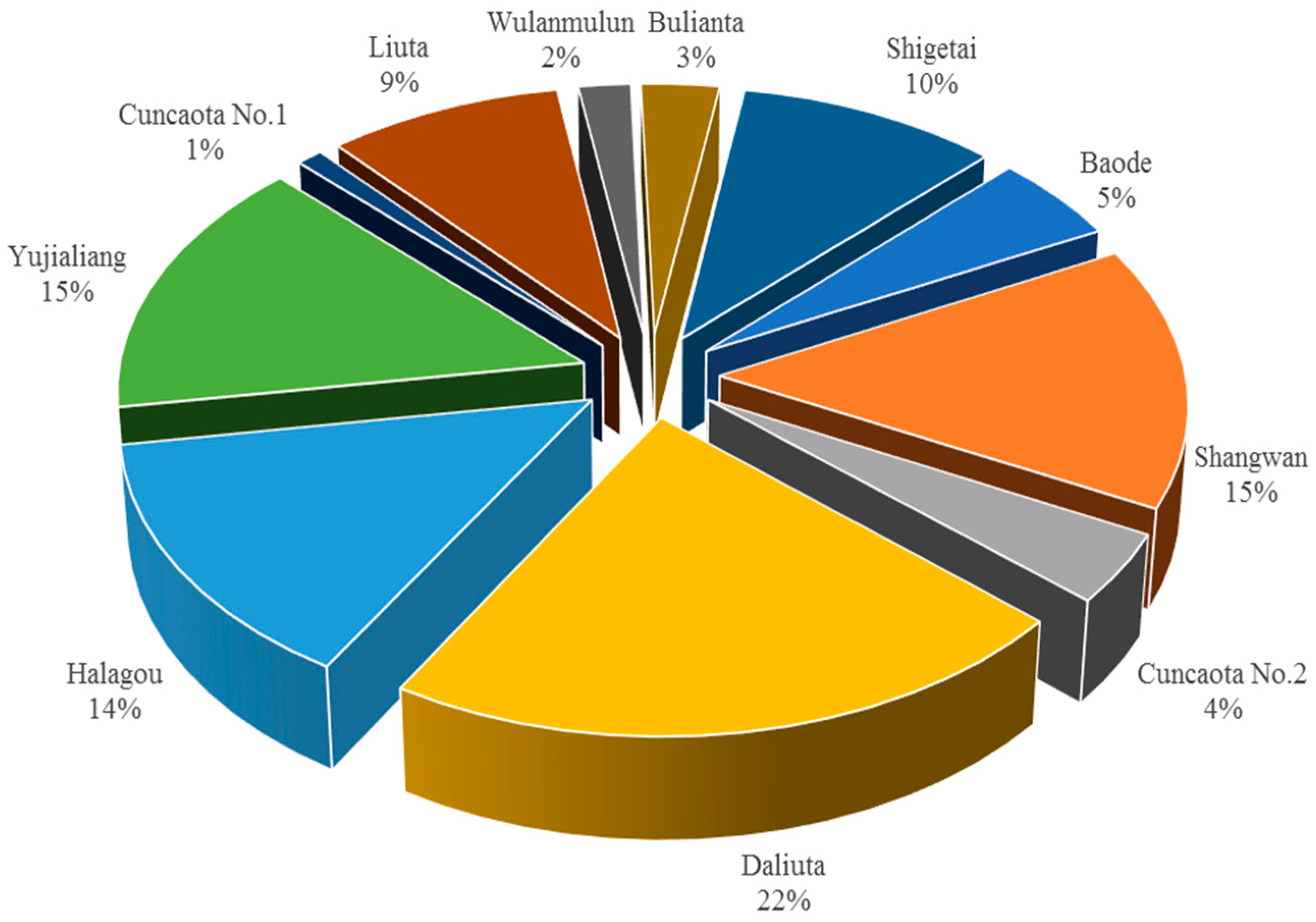

2.1. Geological Overview

2.2. Survey of the Characteristics of the Goaf

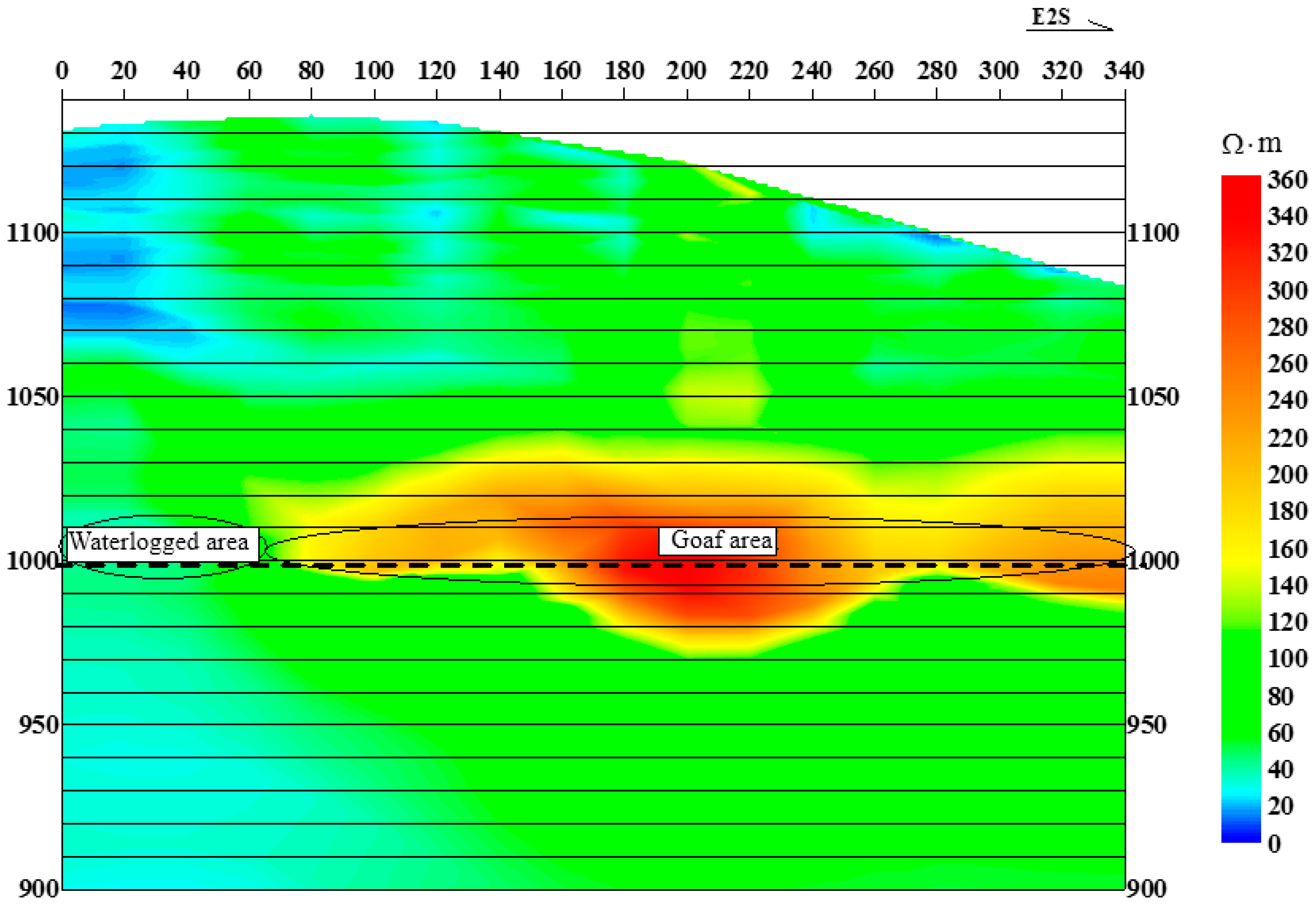

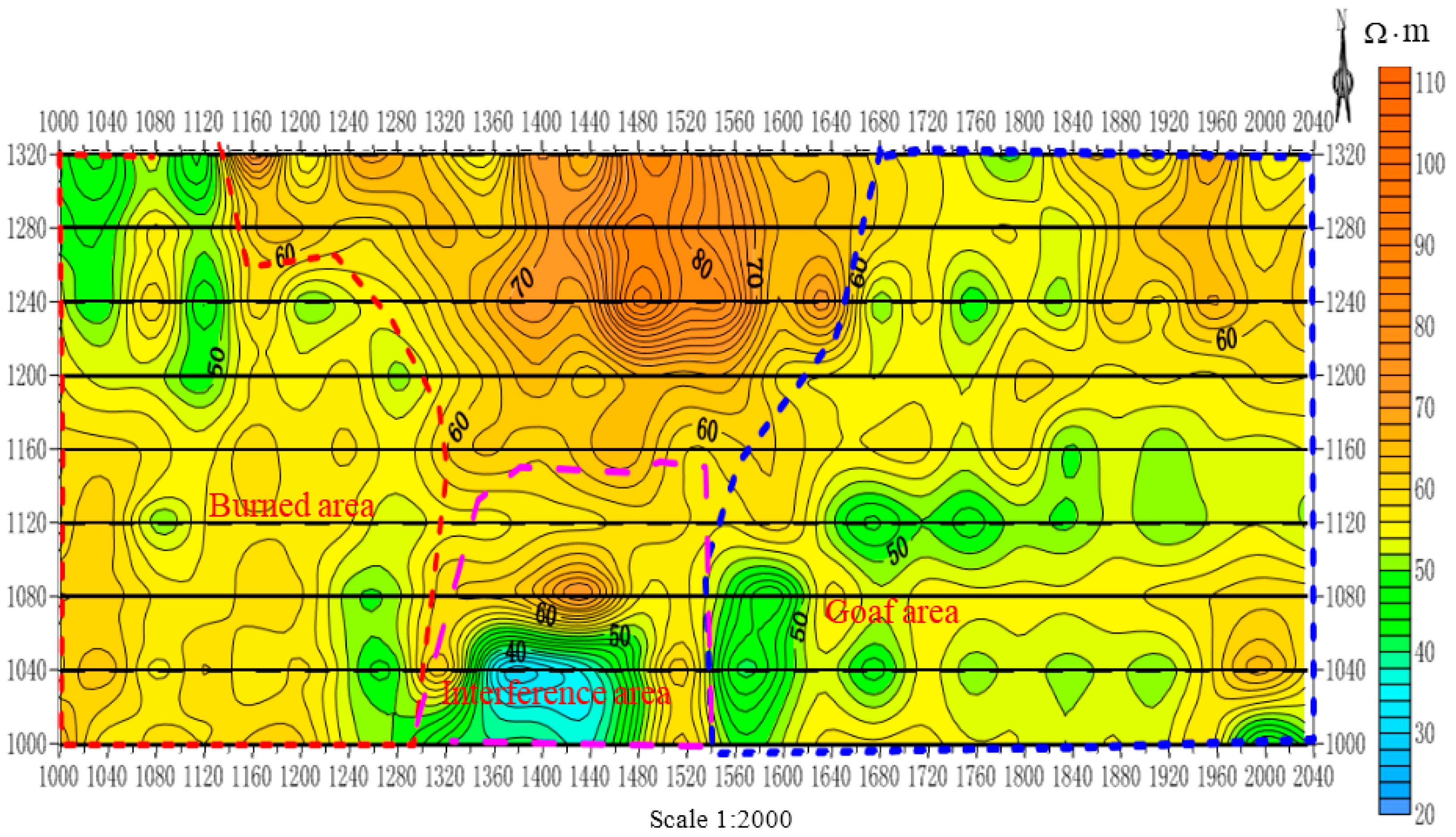

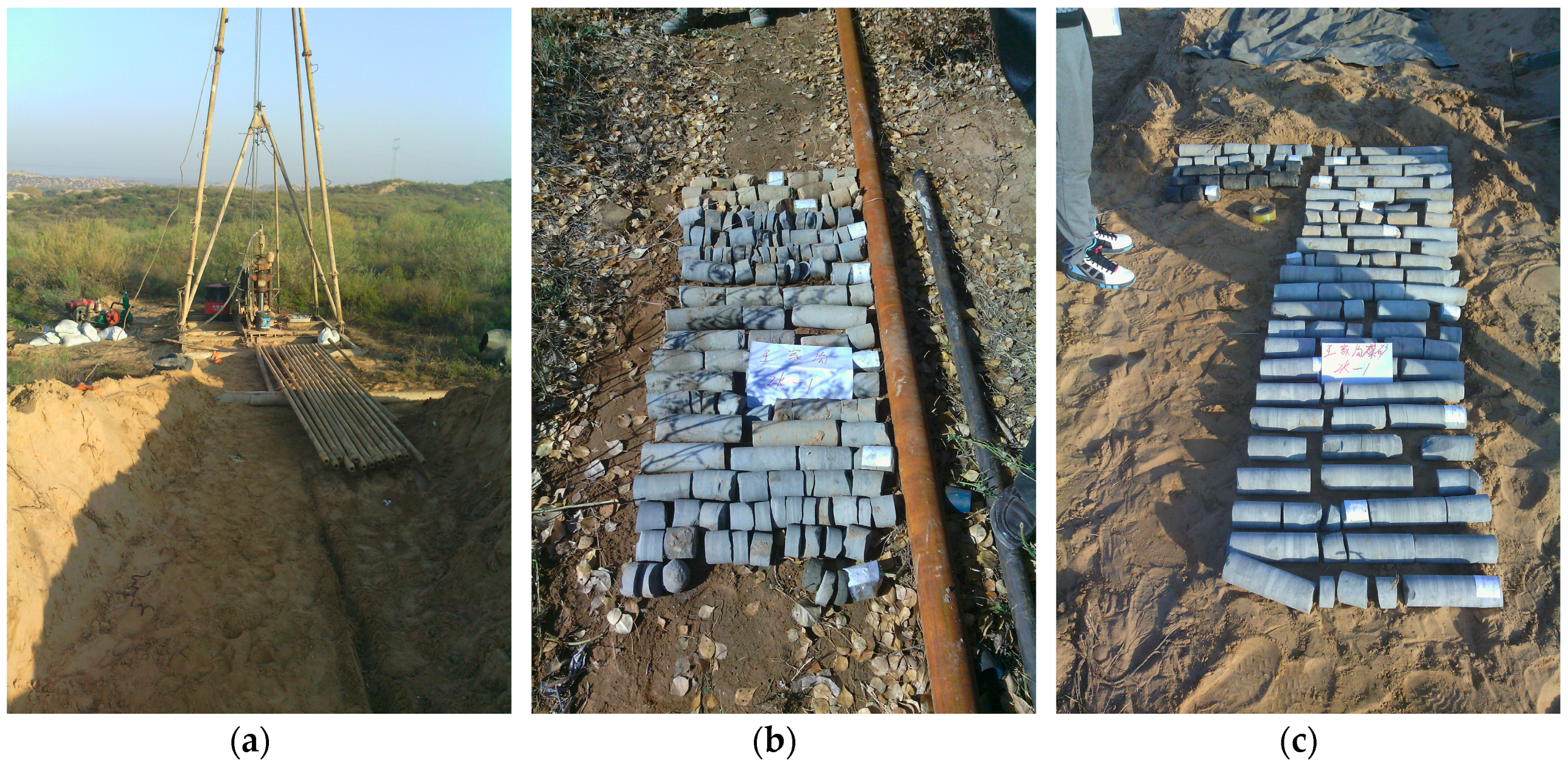

2.2.1. Introduction to the Survey Methods

2.2.2. Example of the Survey Results

3. Risks Induced by Room Mining Goaf

3.1. Common Types and Formation Mechanisms

3.1.1. Serious Waste of Coal Resources

3.1.2. Hidden Danger Caused by Accumulated Toxic and Harmful Gases

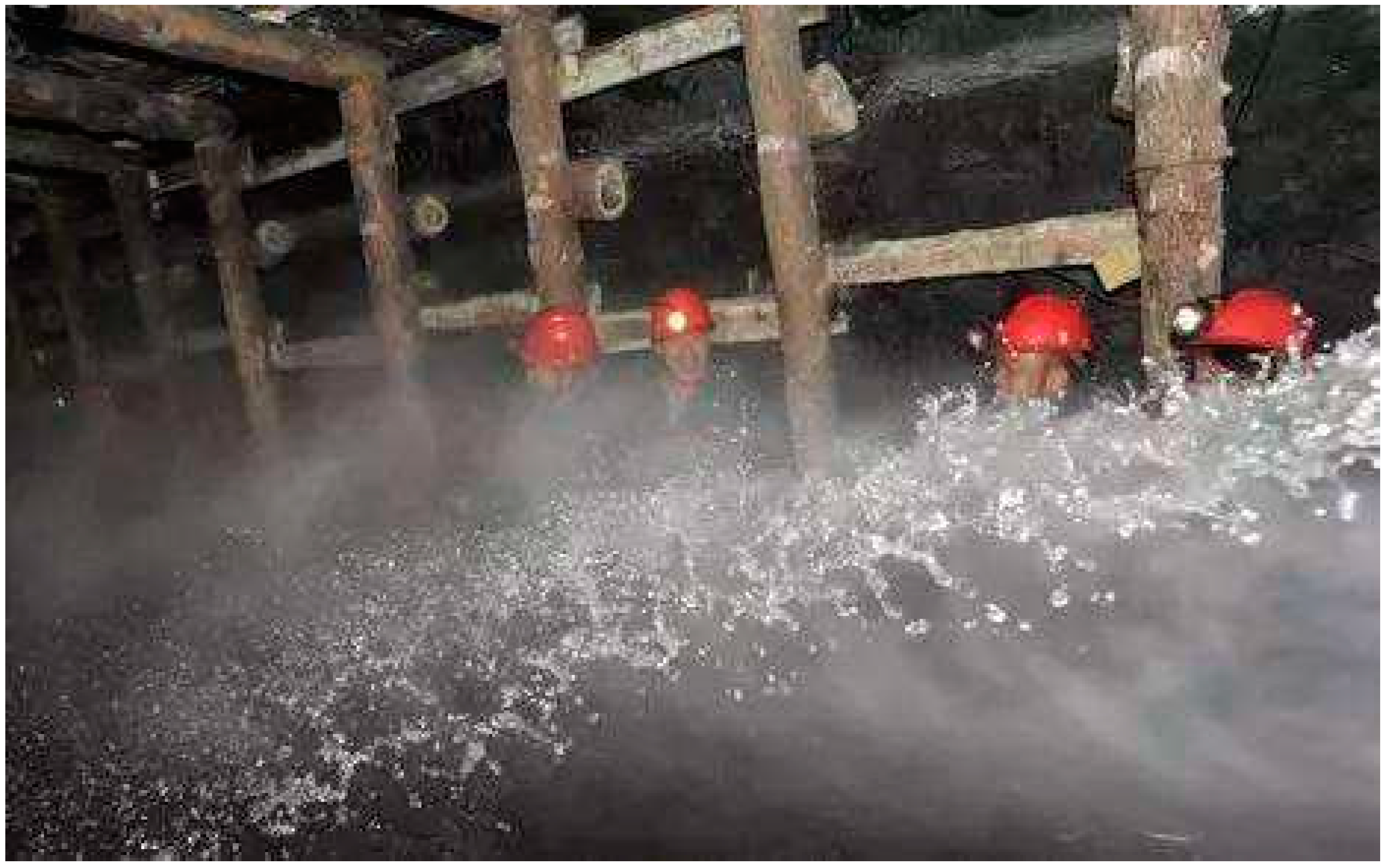

3.1.3. Water Inrush Accident Caused by Accumulated Water

3.1.4. Damage of Surface Construction Caused by Goaf Collapse

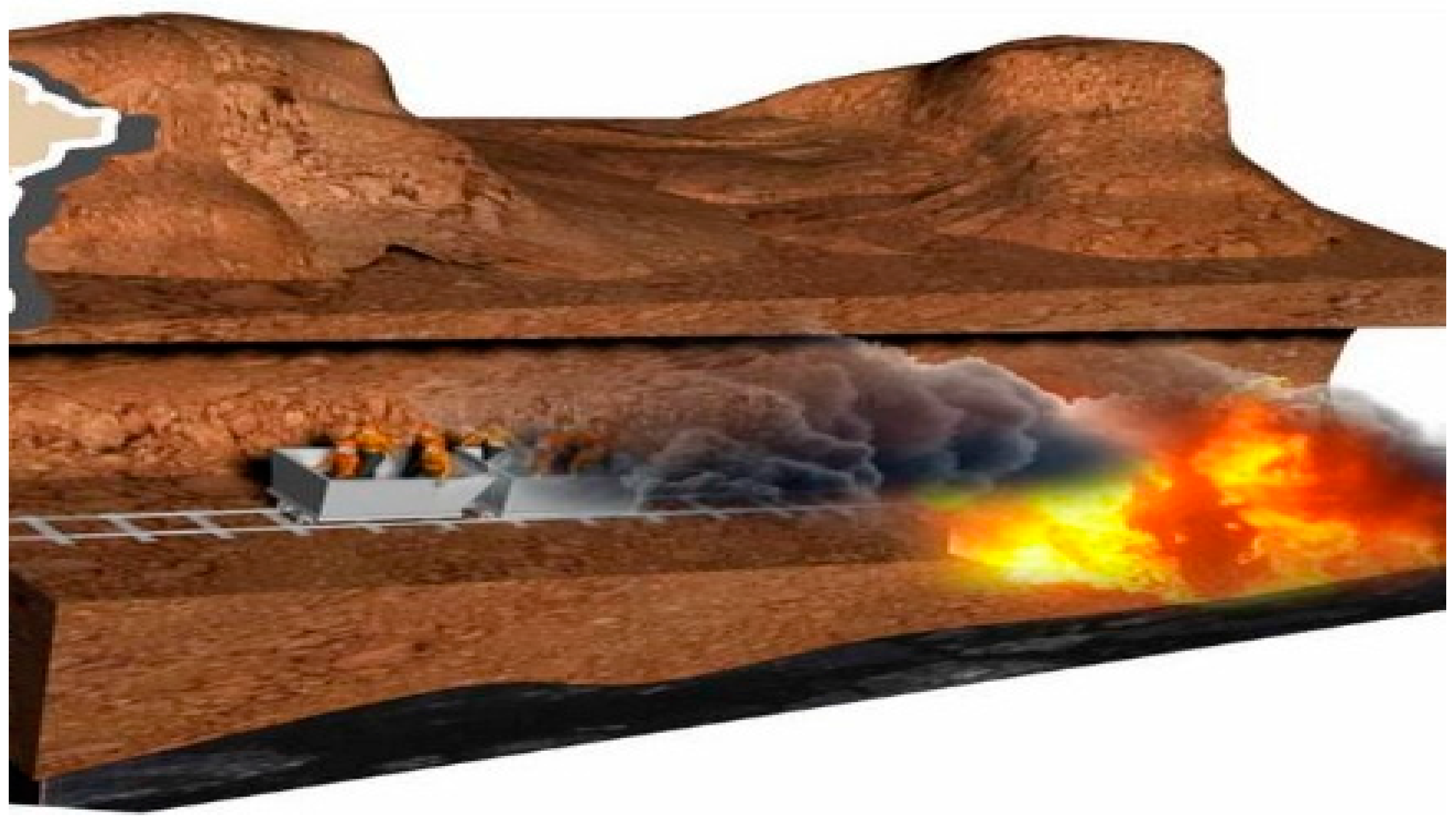

3.1.5. Spontaneous Combustion of the Coal Seam in Goaf

3.1.6. Groundwater Resource Loss Caused by the Collapse of Goaf

3.1.7. Geological Disasters Caused by Goaf Collapse

3.1.8. Power Disasters during Mining of the Coal Seam under Goaf

3.2. Comprehensive Risk Analysis

4. Risk Assessment of Room Mining Goaf

4.1. Selection of Risk Assessment Methods for Room Mining Goaf

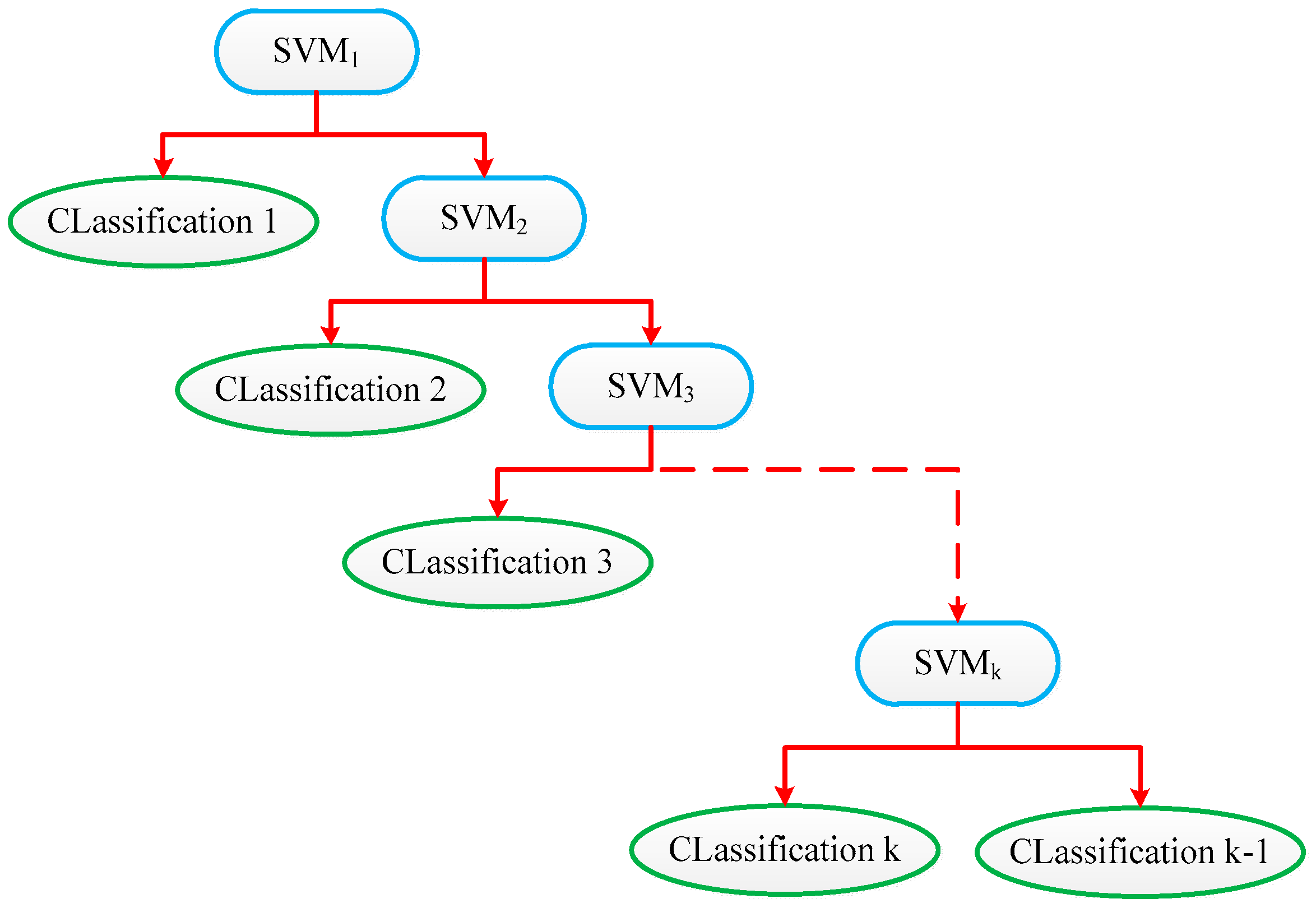

4.2. Support Vector Machine Assessment Model of Room Mining Goaf

4.2.1. Determination of Influence Factors and Classification Standard

4.2.2. Construction of the Support Vector Machine Assessment Model

4.2.3. Risk Assessment Process and Sample Training

4.3. Test of the Risk Assessment Model

5. Conclusions

- (1)

- Most of the coal seam of the Shenfu-Dongsheng mining area mined by the room mining method is buried within 150 m from the ground surface. The bedrock roof will collapse when the damaged area of the coal pillars reaches a certain extent. This will lead to the collapse of the topsoil layer and a series of serious risks.

- (2)

- Through the survey of the coal mines of the Shendong Coal Group, we found that the room mining goaf area has reached 29 million 57 thousand m2. The survey results show that there are no apparent signs of collapse in most of the goafs. Because the pillars cannot perpetually retain their stability, a sudden roof collapse and a large area of surface subsidence will occur under the influence of the increase in the surface load or the mining-disturbance-induced stress in the vicinity. These processes will cause major geological risks in the mining area.

- (3)

- The categorization of the risks induced by room mining goaf is of significance and relevant to the efforts of risk control in Chinese coal mines. Through a comprehensive analysis of the common types and formation mechanisms of disasters induced by room mining goaf, it can be seen that it can be seen that the risks are dynamic and nonlinear and the risks gradually accumulate and superimpose. The occurrence of a risk may lead to several other risks, there is a certain interaction between the risks. Surface subsidence is the most common type and often occurs when other risks occur.

- (4)

- It is advantageous to use a support vector machine, which has a prominent advantage in small-sample problems, to assess the goafs in the SDMA. The mining height, overburden structure, water accumulation characteristics, spontaneous combustion occurrence, mining disturbance, width, coal pillar state, goaf area, strength of the mining room roof and floor, and time are the main controlling factor of goaf risk. Comparing the risk assessment results with the field investigation results, it can be seen that the evaluation model has a high accuracy.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zipf, R.K. Toward Pillar Design to Prevent Collapse of Room-and-Pillar Mines. 2011. Available online: https://www.cdc.gov/niosh/mining/UserFiles/works/pdfs/tpdtp.pdf (accessed on 21 March 2017).

- Yu, Y.; Chen, S.; Deng, K.; Fan, H. Long-term stability evaluation and pillar design criterion for room-and-pillar mines. Energies 2017, 10, 1644. [Google Scholar] [CrossRef]

- Mathey, M.; van der Merwe, J.N. Critique of the South African squat coal pillar strength formula. J. S. Afr. Inst. Min. Metall. 2016, 116. [Google Scholar] [CrossRef]

- Mohan, G.M.; Sheorey, P.R.; Kushwaha, A. Numerical estimation of pillar strength in coal mines. Int. J. Rock Mech. Min. Sci. 2001, 38, 1185–1192. [Google Scholar] [CrossRef]

- Torres, V.F.N.; Da Gama, C.D.; E Silva, M.C.; Neves, P.F.; Xie, Q. Comparative stability analyses of traditional and selective room-and-pillar mining techniques for sub-horizontal tungsten veins. Int. J. Min. Metall. Mater. 2011, 18, 1–8. [Google Scholar] [CrossRef]

- Esterhuizen, G.S.; Dolinar, D.R.; Ellenberger, J.L. Pillar strength in underground stone mines in the United States. Int. J. Rock Mech. Min. Sci. 2011, 48, 42–50. [Google Scholar] [CrossRef]

- Kostecki, T.; Spearing, A.J.S. Influence of backfill on coal pillar strength and floor bearing capacity in weak floor conditions in the Illinois Basin. Int. J. Rock Mech. Min. Sci. 2015, 76, 55–67. [Google Scholar] [CrossRef]

- Salmi, E.F.; Nazem, M.; Karakus, M. The effect of rock mass gradual deterioration on the mechanism of post-mining subsidence over shallow abandoned coal mines. Int. J. Rock Mech. Min. Sci. 2017, 91, 59–71. [Google Scholar] [CrossRef]

- Poulsen, B.A.; Shen, B. Subsidence risk assessment of decommissioned bord-and-pillar collieries. Int. J. Rock Mech. Min. Sci. 2013, 60, 312–320. [Google Scholar] [CrossRef]

- Dehghan, S.; Shahriar, K.; Maarefvand, P.; Goshtasbi, K. 3-D numerical modelling of Domino failure of hard rock pillars in Fetr6 Chromite Mine, Iran, and comparison with empirical methods. J. Cent. South Univ. 2013, 20, 541–549. [Google Scholar] [CrossRef]

- Sherizadeh, T.; Kulatilake, P.H.S.W. Assessment of roof stability in a room and pillar coal mine in the U.S. using three-dimensional distinct element method. Tunn. Undergr. Sp. Technol. 2016, 59, 24–37. [Google Scholar] [CrossRef]

- Castellanza, R.; Gerolymatou, E.; Nova, R. An attempt to predict the failure time of abandoned mine pillars. Rock Mech. Rock Eng. 2008, 41, 377–401. [Google Scholar] [CrossRef]

- Sahu, P.; Lokhande, R.D. An investigation of sinkhole subsidence and its preventive measures in underground coal mining. Procedia Earth Planet. Sci. 2015, 11, 63–75. [Google Scholar] [CrossRef]

- Li, C.; Xu, J.; Wang, Z.; Qin, S. Domino instability effect of surrounding rock-coal pillars in a room-and-pillar gob. Int. J. Min. Sci. Technol. 2013, 23, 913–918. [Google Scholar] [CrossRef]

- Ghasemi, E.; Shahriar, K.; Sharifzadeh, M.; Hashemolhosseini, H. Quantifying the uncertainty of pillar safety factor by Monte Carlo simulation—A case study. Arch. Min. Sci. 2010, 55, 623–635. [Google Scholar]

- Clarke, B.G.; Welford, M.; Hughes, D.B. The Threat of Abandoned Mines on the Stability of Urban Areas. 2006. Available online: http://iaeg2006.geolsoc.org.uk/cd/papers/iaeg_379.pdf (accessed on 18 November 2016).

- Zhang, J.; Huang, P.; Zhang, Q.; Li, M.; Chen, Z. Stability and control of room mining coal pillars—Taking room mining coal pillars of solid backfill recovery as an example. J. Cent. South Univ. 2017, 24, 1121–1132. [Google Scholar] [CrossRef]

- Ghasemi, E.; Ataei, M.; Shahriar, K. Prediction of global stability in room and pillar coal mines. Nat. Hazards 2014, 72, 405–422. [Google Scholar] [CrossRef]

- Sun, H.; Cheng, M.; Su, C.; Li, H.; Zhao, G.; Su, M.; Li, S.; Zhang, B.; Zhang, L.; Li, K. Characterization of shallow karst using electrical resistivity imaging in a limestone mining area. Environ. Earth Sci. 2017, 76, 767. [Google Scholar] [CrossRef]

- Gui, H.; Lin, M. Types of water hazards in China coalmines and regional characteristics. Nat. Hazards 2016, 84, 1501–1512. [Google Scholar] [CrossRef]

- Yang, L.; Lu, H.; Zhang, X.; Sheng, W. Application research of multiclass support vector machines in coal mine safety evaluation. J. Saf. Sci. Technol. 2012, 4, 111–115. (In Chinese) [Google Scholar]

| Shangwan | Cuncaota No. 2 | Daliuta | Halagou | Yujialiang | Cuncaota No. 1 | Liuta | Wulan Mulun | Bulianta | Shigetai | Baode | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 426.75 | 125.50 | 642.49 | 413.40 | 423.30 | 24.79 | 258.11 | 72.00 | 88.86 | 292.35 | 138.15 | 2905.70 |

| Risk Type | Causes | Scope of Influence |

|---|---|---|

| Waste of Coal Resources | The retention of a large number of coal pillars. | The sustainability of the ecological environment. |

| Water Inrush | The new excavation space is directly connected with the old space or is connected through the fissures. | Underground operation personnel as well as equipment and facilities in some areas or the whole mine. |

| Spontaneous Combustion | The fissures in the goaf communicate with the surface, and the heat of the oxidation reaction in the goaf cannot be diffused in time | Underground operation personnel as well as equipment and facilities in some areas or the whole mine. |

| Impact waves | The gas in the goaf is compressed because a large area of the roof of the goaf suddenly collapses. | Underground operation personnel as well as equipment and facilities in some areas or the whole mine. |

| Rock burst | The existence of the goaf intensifies the stress concentration. | Underground operation personnel as well as equipment and facilities in some areas. |

| Mine earthquake | The composite effect of mechanical shock, impact waves and rock burst caused by the sudden collapse of a large area of the roof. | Surface and underground operation personnel as well as equipment and facilities in the whole mine. |

| Air leakage into goaf | Fresh air flows into the goaf. | Underground operation personnel in some areas. |

| Emission of toxic and harmful gases | The toxic and harmful gases diffuse to the surface or underground mining spaces through fissures. | Underground operation personnel; residents or livestock, etc. |

| Surface subsidence | The roof of the goaf (suddenly) collapses, and the collapse develops to the surface. | Surface construction (residential, highway, high pressure line tower, signal tower, etc.). |

| Crushing of the airtight wall | The roof of the goaf suddenly collapses, and the resistance of the airtight wall is poor. | Underground operation personnel as well as equipment and facilities in some areas. |

| Water level lowering and water shortages | The water of the aquifer flows into the goaf through the connection. | Water use in underground work and water for surrounding residents. |

| Landslide | The collapse of the goaf has developed to the surface. | Mountains and slopes. |

| Factor Number | Impact Factor | Factor Sets | Unit | Details of the Influencing Factors |

|---|---|---|---|---|

| F1 | Mining height | [1, 7] | m | Actual mining height. |

| F2 | Overburden structure | [0, 1] | Dimensionless | The characteristics of the coal seam. |

| F3 | Water accumulation | [0, 50,000] | m3 | Volume of water accumulated in the goaf. |

| F4 | Spontaneous combustion | [0, 1] | Dimensionless | The state of spontaneous combustion of the coal pillars in the goaf. |

| F5 | Mining disturbance | [0, 1] | Dimensionless | Mining disturbance to the goaf caused by work on the nearby coal seam. |

| F6 | Width | [0.5, 2] | Dimensionless | The ratio of the width of the room to the width of the coal pillar. |

| F7 | Coal pillar state | [0, 6] | m | The width of the elastic core area of the coal pillar. |

| F8 | Goaf area | [0, 2.5] | km2 | Area of room mining goaf joined together. |

| F9 | Roof and floor | [0, 1] | MPa | The influence of the strengths of the roof and floor on the stability of the coal pillar. |

| F10 | Time | [0, 15] | year | The time that the goaf has existed. |

| Coal Mine Name | Grade | Classification Standard |

|---|---|---|

| Shibadun | I | Two mine earthquakes occurred in 2012 |

| Changxing | I | A 2.8 magnitude mine earthquake occurred in 2011 |

| Jinniu | I | A 2.1 magnitude mine earthquake occurred in 2012 |

| Shaqu | I | A 3.0 magnitude mine earthquake occurred in 2011 |

| Bandingliang | II | The ratio of the subsidence area to the goaf area is 10% |

| Dashata | II | The ratio of the subsidence area to the goaf area is 14% |

| Sujiata | II | The ratio of the subsidence area to the goaf area is 28% |

| Xiaosuangou | II | The ratio of the subsidence area to the goaf area is 16% |

| Yubojie | III | No surface subsidence and no mine earthquake |

| Yujialiang | III | No surface subsidence and no mine earthquake |

| Zhugaita | III | No surface subsidence and no mine earthquake |

| Qianliang | III | No surface subsidence and no mine earthquake |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 |

|---|---|---|---|---|---|---|---|---|---|

| 4.2 | 0.1 | 0 | 0.1 | 0.1 | 0.625 | 4 | 1.21 | 0.9 | 2005 |

| 0.53 | 0.10 | 0.00 | 0.10 | 0.10 | 0.08 | 0.67 | 0.48 | 0.90 | 0.56 |

| Coal Mine Name | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | Target Status |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Shibadun | 0.92 | 0.90 | 0.80 | 0.5 | 0.50 | 0.33 | 0.33 | 0.568 | 0.5 | 0.69 | I |

| Changxing | 0.42 | 0.90 | 0.40 | 0.1 | 0.50 | 0.43 | 0.50 | 0.884 | 0.5 | 0.81 | I |

| Jinniu | 0.42 | 0.90 | 0.60 | 0.5 | 0.50 | 0.25 | 0.50 | 0.544 | 0.5 | 0.88 | I |

| Shaqu | 0.37 | 0.50 | 0.00 | 0.5 | 0.50 | 0.50 | 0.33 | 0.168 | 0.5 | 0.88 | I |

| Bandingliang | 0.77 | 0.90 | 0.10 | 0.1 | 0.10 | 1.00 | 0.50 | 0.316 | 0.5 | 0.63 | II |

| Dashata | 0.81 | 0.10 | 0.00 | 0.1 | 0.50 | 0.56 | 0.50 | 0.636 | 0.9 | 0.56 | II |

| Sujiata | 0.41 | 0.10 | 0.00 | 0.1 | 0.50 | 0.56 | 0.50 | 0.196 | 0.5 | 0.69 | II |

| Xiaosuangou | 0.62 | 0.50 | 0.00 | 0.1 | 0.50 | 0.33 | 0.50 | 0.132 | 0.5 | 0.56 | II |

| Yubojie | 0.18 | 0.10 | 0.00 | 0.1 | 0.50 | 0.33 | 0.33 | 0.068 | 0.9 | 0.63 | II |

| Yujialiang | 0.60 | 0.10 | 0.00 | 0.1 | 0.90 | 0.33 | 0.67 | 0.964 | 0.9 | 0.50 | III |

| Zhugaita | 0.23 | 0.10 | 0.00 | 0.1 | 0.50 | 0.20 | 0.50 | 0.128 | 0.9 | 0.88 | III |

| Qianliang | 0.25 | 0.50 | 0.00 | 0.1 | 0.90 | 0.24 | 0.50 | 0.804 | 0.5 | 0.44 | III |

| Shibadun | 0.32 | 0.10 | 0.00 | 0.1 | 0.50 | 0.11 | 0.50 | 0.364 | 0.9 | 0.50 | III |

| Coal Mine Name | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | Target Status |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dabeimao | 0.47 | 0.90 | 0.00 | 0.50 | 0.50 | 0.08 | 0.83 | 1.00 | 0.90 | 0.44 | III |

| Tengwei | 0.20 | 0.50 | 0.00 | 0.50 | 0.90 | 0.33 | 0.33 | 0.50 | 0.10 | 0.50 | II |

| Sujiahao | 0.77 | 0.10 | 0.00 | 0.50 | 0.50 | 0.33 | 0.50 | 0.67 | 0.50 | 0.63 | I |

| Cunyi 3114 area | 0.42 | 0.90 | 0.00 | 0.10 | 0.10 | 0.08 | 1.00 | 1.00 | 0.90 | 0.56 | III |

| Cunyi 301 area | 0.27 | 0.50 | 0.04 | 0.50 | 0.50 | 0.33 | 0.50 | 0.50 | 0.50 | 0.63 | II |

| Hexi | 0.32 | 0.10 | 0.00 | 0.10 | 0.90 | 0.17 | 0.67 | 1.00 | 0.90 | 0.81 | III |

| Zhaojialiang | 0.53 | 0.50 | 0.00 | 0.10 | 0.10 | 0.08 | 0.67 | 1.00 | 0.90 | 0.56 | III |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, H.; Lin, H.; Jiang, Y.; Wang, Y.; Liu, J.; Wang, P. Risks Induced by Room Mining Goaf and Their Assessment: A Case Study in the Shenfu-Dongsheng Mining Area. Sustainability 2018, 10, 631. https://doi.org/10.3390/su10030631

Luan H, Lin H, Jiang Y, Wang Y, Liu J, Wang P. Risks Induced by Room Mining Goaf and Their Assessment: A Case Study in the Shenfu-Dongsheng Mining Area. Sustainability. 2018; 10(3):631. https://doi.org/10.3390/su10030631

Chicago/Turabian StyleLuan, Hengjie, Huili Lin, Yujing Jiang, Yahua Wang, Jiankang Liu, and Pu Wang. 2018. "Risks Induced by Room Mining Goaf and Their Assessment: A Case Study in the Shenfu-Dongsheng Mining Area" Sustainability 10, no. 3: 631. https://doi.org/10.3390/su10030631

APA StyleLuan, H., Lin, H., Jiang, Y., Wang, Y., Liu, J., & Wang, P. (2018). Risks Induced by Room Mining Goaf and Their Assessment: A Case Study in the Shenfu-Dongsheng Mining Area. Sustainability, 10(3), 631. https://doi.org/10.3390/su10030631