Prospective of Societal and Environmental Benefits of Piezoelectric Technology in Road Energy Harvesting

Abstract

1. Introduction

2. Existing Technologies for Road Energy Harvesting

3. The Piezoelectric Energy Harvesting System

3.1. The Concepts of the Piezoelectric Technology

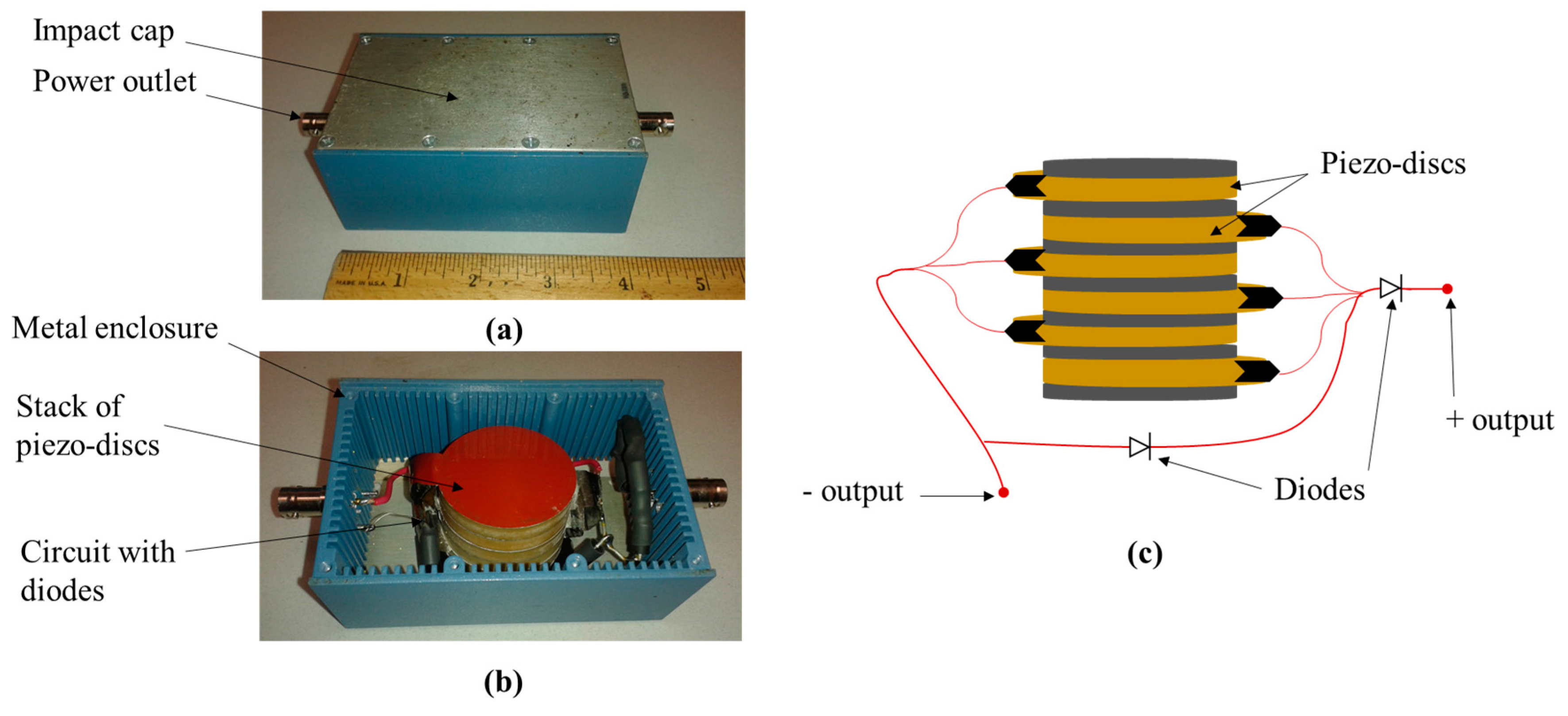

3.2. The Highway Sensing and Energy Conversion (HiSEC)

4. Benefits and Merits of the Road Energy Harvesting System

4.1. Benefits for the Society

4.1.1. Equity and Sustainability

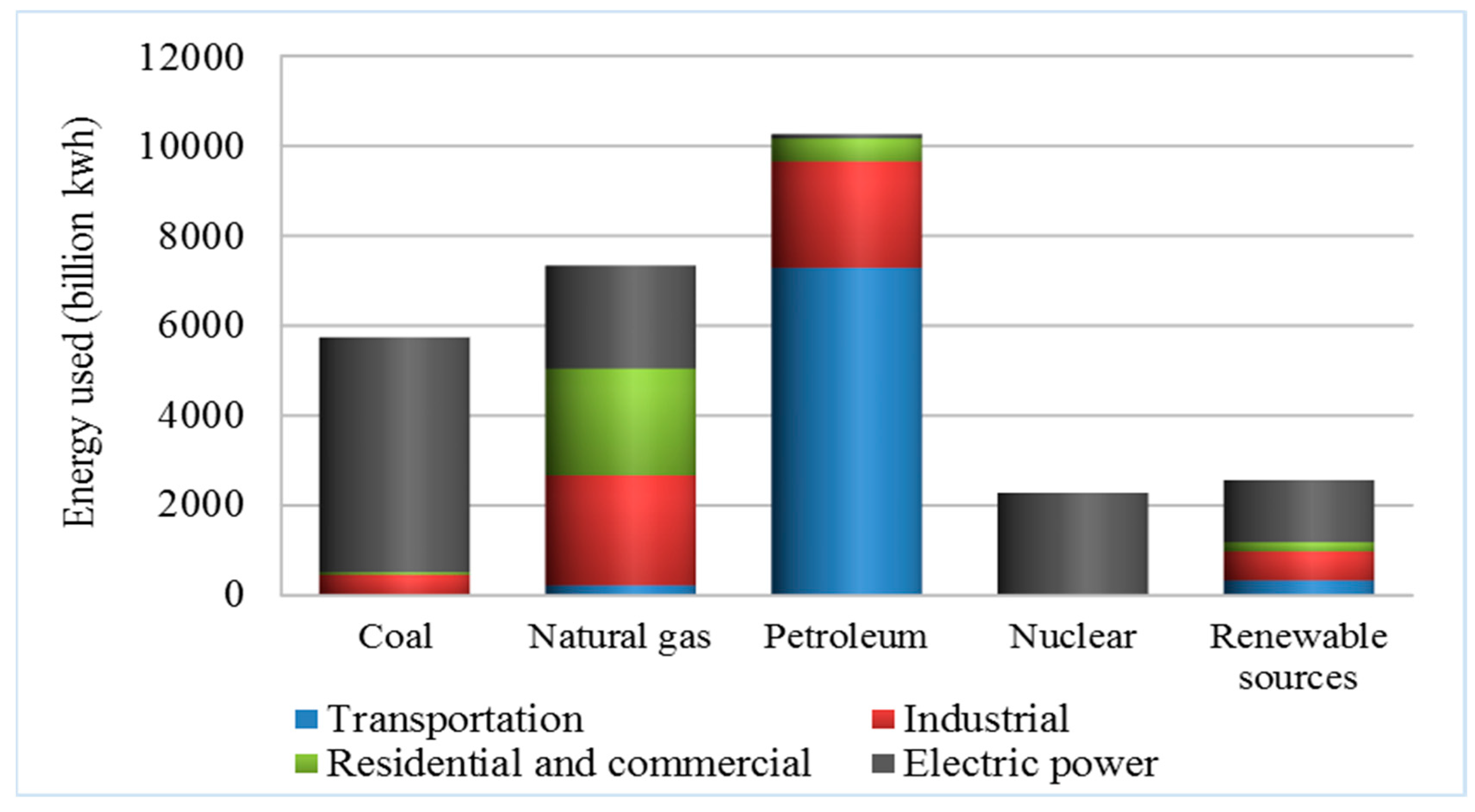

4.1.2. Energy Diversification and Source of Income for the Society

4.2. Environmental Benefits

5. Limitations and Challenges

6. Summary—Synthesis and Discussions

Acknowledgments

Author Contributions

Disclaimer

Conflicts of Interest

References

- Chang, Y.T.; Zhang, N.; Danao, D.; Zhang, N. Environmental efficiency analysis of transportation system in China: A non-radial DEA approach. Energy Policy 2013, 58, 277–283. [Google Scholar] [CrossRef]

- Litman, T. Efficient vehicles versus efficient transportation. Comparing transportation energy conservation strategies. Transp. Policy 2005, 12, 121–129. [Google Scholar] [CrossRef][Green Version]

- Worrell, E.; Bernstein, L.; Roy, J.; Price, L.; Harnisch, J. Industrial energy efficiency and climate change mitigation. Energy Effic. 2009, 2, 109–123. [Google Scholar] [CrossRef]

- Toprak, A.; Tigli, O. Piezoelectric energy harvesting: State-of-the-art and challenges. Appl. Phys. Rev. 2014, 1, 031104. [Google Scholar] [CrossRef]

- Hudak, N.S.; Amatucci, G.G. Small-scale energy harvesting through thermoelectric, vibration, and radiofrequency power conversion. J. Appl. Phys. 2008, 103, 101301. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, J.H.; Kim, J. A review of piezoelectric energy harvesting based on vibration. Int. J. Precis. Eng. Manuf. 2011, 12, 1129–1141. [Google Scholar] [CrossRef]

- Wang, H.; Jasim, A.; Chen, X. Energy harvesting technologies in roadway and bridge for different applications—A comprehensive review. Appl. Energy 2018, 212, 1083–1094. [Google Scholar] [CrossRef]

- Andriopoulou, S. A Review on Energy Harvesting from Roads. Master’s Thesis, KTH, Stockholm, Sweden, 2012; pp. 1–39. [Google Scholar]

- Cook-Chennault, K.A.; Thambi, N.; Sastry, A.M. Powering MEMS portable devices a review of non-regenerative and regenerative power supply systems with special emphasis on piezoelectric energy harvesting systems. Smart Mater. Struct. 2008, 17, 043001. [Google Scholar] [CrossRef]

- Sodano, H.A.; Inman, D.J.; Park, G. A review of power harvesting from vibration using piezoelectric materials. Shock Vib. Dig. 2004, 36, 197–206. [Google Scholar] [CrossRef]

- Bobes-Jesus, V.; Pascual-Munoz, P.; Castro-Fresno, D.; Rodriguez-Hernandez, J. Asphalt solar collectors: A literature review. Appl. Energy 2013, 102, 962–970. [Google Scholar] [CrossRef]

- Li, Z.; Zuo, L.; Luhrs, G.; Lin, L.; Qin, Y.X. Electromagnetic energy-harvesting shock absorbers: Design, modeling, and road tests. IEEE Trans. Veh. Technol. 2013, 62, 1065–1074. [Google Scholar] [CrossRef]

- Beeby, S.P.; Torah, R.N.; Tudor, M.J.; Glynne-Jones, P.; O’donnell, T.; Saha, C.R.; Roy, S. A micro electromagnetic generator for vibration energy harvesting. J. Micromech. Microeng. 2007, 17, 1257–1265. [Google Scholar] [CrossRef]

- Sazonov, E.; Li, H.; Curry, D.; Pillay, P. Self-powered sensors for monitoring of highway bridges. IEEE Sens. J. 2009, 9, 1422–1429. [Google Scholar] [CrossRef]

- Guo, L.; Lu, Q. Potentials of piezoelectric and thermoelectric technologies for harvesting energy from pavements. Renew. Sustain. Energy Rev. 2017, 72, 761–773. [Google Scholar] [CrossRef]

- Sodano, H.A.; Park, G.; Inman, D.J. Estimation of electric charge output for piezoelectric energy harvesting. Strain 2004, 40, 49–58. [Google Scholar] [CrossRef]

- Gallego-Juarez, J.A. Piezoelectric ceramics and ultrasonic transducers. J. Phys. E Sci. Instrum. 1989, 22, 804. [Google Scholar] [CrossRef]

- Mason, W.P. Piezoelectricity, its history and applications. J. Acoust. Soc. Am. 1981, 70, 1561–1566. [Google Scholar] [CrossRef]

- Kumar, B.; Kim, S.W. Energy harvesting based on semiconducting piezoelectric ZnO nanostructures. Nano Energy 2012, 1, 342–355. [Google Scholar] [CrossRef]

- Xiong, H.; Wang, L.; Wang, D.; Druta, C. Piezoelectric energy harvesting from traffic induced deformation of pavements. Int. J. Pavement Res. Technol. 2012, 5, 333–337. [Google Scholar]

- Kazmierski, T.J.; Beeby, S.P. Energy Harvesting Systems; Springer: New York, NY, USA, 2010. [Google Scholar]

- Abramovich, H.; Harash, E.; Milgrom, C.; Amit, U.; Azulay, L.E. Power harvesting apparatus, system and method. U.S. Patent No. 7,830,071; Granted: 2010-11-09, 2010. [Google Scholar]

- Garland, R. Piezoelectric Roads in California. 2013. Available online: http://large.stanford.edu/courses/2012/ph240/garland1 (accessed on 1 December 2017).

- IPCC. Climate Change 2014: Impacts, Adaptation, and Vulnerability. Part A: Global and Sectoral Aspects. Contribution of Working Group II to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Djebou, S.; Singh, V.P. Impact of climate change on the hydrologic cycle and implications for society. Environ. Soc. Psychol. 2016, 1, 9–16. [Google Scholar] [CrossRef]

- Ketcham, S.A.; Minsk, L.D.; Blackburn, R.R.; Fleege, E.J. Manual of Practice for an Effective Anti-Icing Program: A Guide for Highway Winter Maintenance Personnel; No. FHWA-RD-95-202; FHWA: Washington, DC, USA, 1996.

- Burnos, P.; Gajda, J.; Piwowar, P.; Sroka, R.; Stencel, M.; Zeglen, T. Measurements of road traffic parameters using inductive loops and piezoelectric sensors. Metrol. Meas. Syst. 2007, 14, 187–203. [Google Scholar]

- Glista, D.J.; DeVault, T.L.; DeWoody, J.A. A review of mitigation measures for reducing wildlife mortality on roadways. Landsc. Urban Plan. 2009, 91, 1–7. [Google Scholar] [CrossRef]

- Huijser, M.P.; McGowen, P.T.; Fuller, J.; Hardy, A.; Kociolek, A. Wildlife-Vehicle Collision Reduction Study: Report to Congress; No. FHWA-HRT-08-034; FHWA: Washington, DC, USA, 2007.

- Hill, D.; Tong, N. (DNV KEMA) Assessment of Piezoelectric Materials for Roadway Energy Harvesting; California Energy Commission: Sacramento, CA, USA, 2013.

- Zuo, L.; Zhang, P.S. Energy harvesting, ride comfort, and road handling of regenerative vehicle suspensions. In Proceedings of the ASME 2011 Dynamic Systems and Control Conference and Bath/ASME Symposium on Fluid Power and Motion Control, Arlington, VA, USA, 31 October–2 November 2011; American Society of Mechanical Engineers: New York, NY, USA, 2011; pp. 295–302. [Google Scholar]

- EIA, United States Energy Information Administration. Available online: http://www.eia.gov (accessed on 1 December 2015).

- EPA, United States Environmental Protection Agency. Available online: http://www.epa.gov/energy (accessed on 1 December 2015).

- Woodcock, J.; Edwards, P.; Tonne, C.; Armstrong, B.G.; Ashiru, O.; Banister, D.; Roberts, I. Public health benefits of strategies to reduce greenhouse-gas emissions: Urban land transport. Lancet 2009, 374, 1930–1943. [Google Scholar] [CrossRef]

- Berrang-Ford, L.; Ford, J.D.; Paterson, J. Are we adapting to climate change? Glob. Environ. Chang. 2011, 21, 25–33. [Google Scholar] [CrossRef]

- Maeder, M.D.; Damjanovic, D.; Setter, N. Lead free piezoelectric materials. J. Electroceram. 2004, 13, 385–392. [Google Scholar] [CrossRef]

- Zhang, J.X.; Xiang, B.; He, Q.; Seidel, J.; Zeches, R.J.; Yu, P.; Yang, S.Y.; Wang, C.H.; Chu, Y.H.; Martin, L.W.; et al. Large field-induced strains in a lead-free piezoelectric material. Nat. Nanotechnol. 2011, 6, 98–102. [Google Scholar] [CrossRef] [PubMed]

- Ibn-Mohammed, T.; Koh, S.C.L.; Reaney, I.M.; Sinclair, D.C.; Mustapha, K.B.; Acquaye, A.; Wang, D. Are lead-free piezoelectrics more environmentally friendly? MRS Commun. 2017, 7, 1–7. [Google Scholar] [CrossRef]

- Tang, L.; Yang, Y.; Soh, C.K. Toward broadband vibration-based energy harvesting. J. Intell. Mater. Syst. Struct. 2010, 21, 1867–1897. [Google Scholar] [CrossRef]

- FHWA, State Statistical Abstracts 2013. Available online: http://www.fhwa.dot.gov/policyinformation/statistics/2013/ (accessed on 2 January 2016).

- Svensson, R.; Odenberger, M.; Johnsson, F.; Strömberg, L. Transportation systems for CO2—Application to carbon capture and storage. Energy Convers. Manag. 2004, 45, 2343–2353. [Google Scholar] [CrossRef]

| Energy Source | Advantages | Disadvantages | |

|---|---|---|---|

| Non-Renewable Energy | Coal | -Relatively cheap

-Easy to store and transport -Convenient for trade | -Fossil energy

-Greenhouse gases (GHGs) emission/source of pollution -Threat for public health and environment |

| Natural gas | -Relatively cheap

-Convenient for trade | -Fossil energy

-GHGs emission/source of pollution -Threat for public health and environment | |

| Petroleum | -Relatively cheap

-Easy to store and transport -Convenient for trade -Leading energy in transportation systems | -Fossil energy

-GHGs emission/ source of pollution -Threat for public health and environment -Depleting resource | |

| Nuclear | -Cheap energy source

-Produced on demand | -Requires high technicity, high cost of installation

-High risks for the public and the environment -Social reluctance | |

| Renewable Energy | Hydro-power | -Cheap energy source

-Zero GHGs emission | -Relies on water resources availability

-Not necessarily environmental friendly/ risks of floods |

| Biomass | -Environmental friendly

-Alternative for fossil energy/reduces GHGs emission (45–65% less) -Easy to store and biodegradable | -Requires land for biomass production

-Cause of deforestation when produced at a large scale | |

| Geothermal | -Probably the cheapest in the USA

-Safe and clean, zero GHGs emissions -Environment friendly | -Risk of groundwater depletion

-Risk of harmful gases released in the air -Requires high technicity, high installation cost | |

| Solar | -Environmental friendly

-Zero GHGs emissions, safe, and clean -Adequate with climate change | -Storage problem | |

| Wind | -Environmental friendly

-Zero GHGs emissions, safe, and clean | -Storage problem | |

| Road energy (piezoelectric) | -Environmental friendly

-Zero GHGs emissions, safe and clean -Innovative technology | -Storage problem

-Lack of research efforts | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walubita, L.F.; Sohoulande Djebou, D.C.; Faruk, A.N.M.; Lee, S.I.; Dessouky, S.; Hu, X. Prospective of Societal and Environmental Benefits of Piezoelectric Technology in Road Energy Harvesting. Sustainability 2018, 10, 383. https://doi.org/10.3390/su10020383

Walubita LF, Sohoulande Djebou DC, Faruk ANM, Lee SI, Dessouky S, Hu X. Prospective of Societal and Environmental Benefits of Piezoelectric Technology in Road Energy Harvesting. Sustainability. 2018; 10(2):383. https://doi.org/10.3390/su10020383

Chicago/Turabian StyleWalubita, Lubinda F., Dagbegnon Clement Sohoulande Djebou, Abu N. M. Faruk, Sang Ick Lee, Samer Dessouky, and Xiaodi Hu. 2018. "Prospective of Societal and Environmental Benefits of Piezoelectric Technology in Road Energy Harvesting" Sustainability 10, no. 2: 383. https://doi.org/10.3390/su10020383

APA StyleWalubita, L. F., Sohoulande Djebou, D. C., Faruk, A. N. M., Lee, S. I., Dessouky, S., & Hu, X. (2018). Prospective of Societal and Environmental Benefits of Piezoelectric Technology in Road Energy Harvesting. Sustainability, 10(2), 383. https://doi.org/10.3390/su10020383