Bio-Pellet Fuel from Oil Palm Empty Fruit Bunches (EFB): Using European Standards for Quality Testing

Abstract

:1. Introduction

Potential Uses of Empty Fruit Bunches (EFBs)

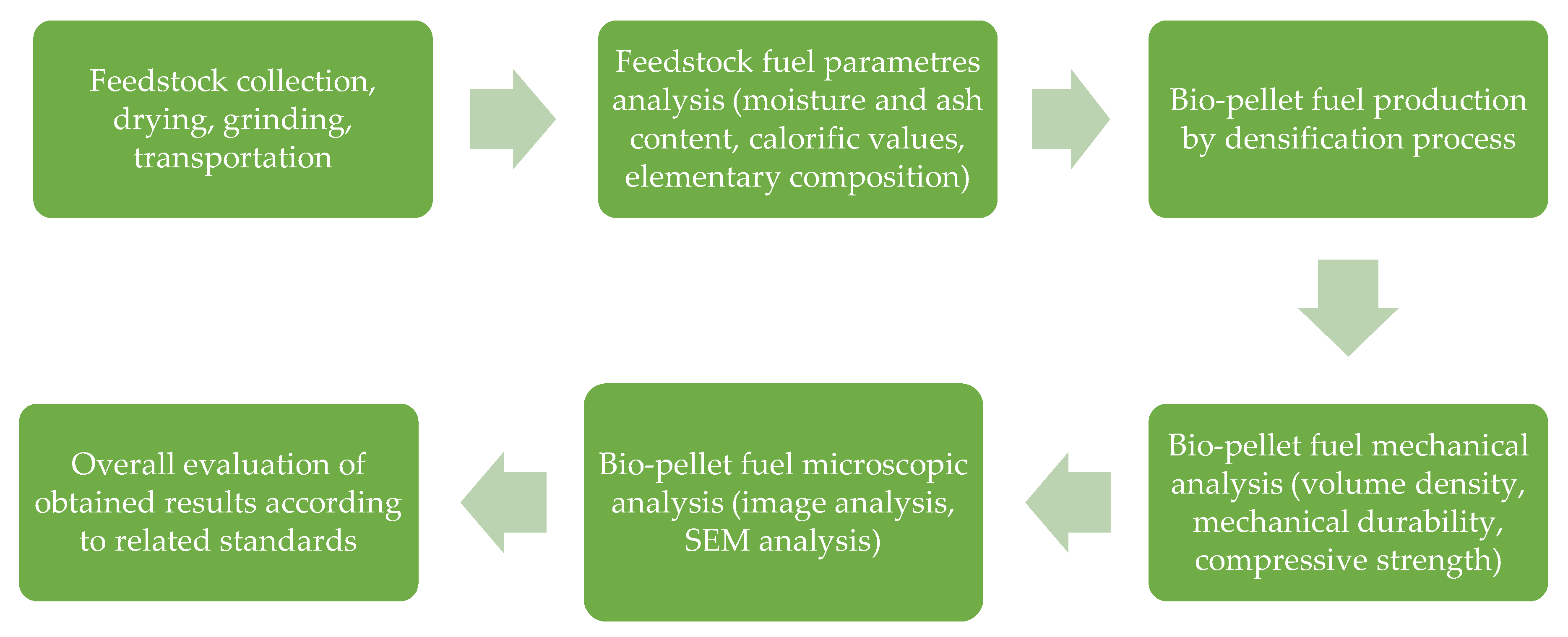

2. Materials and Methods

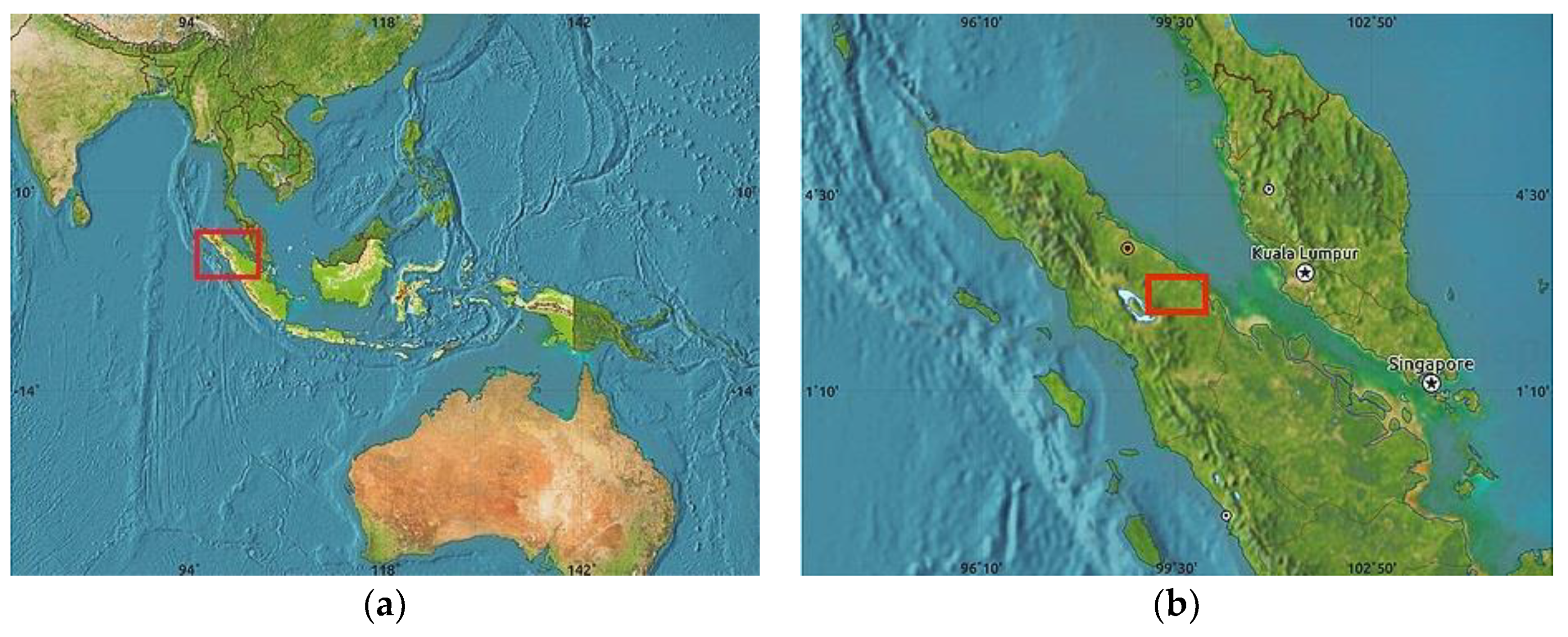

2.1. Materials and Samples

2.2. Fuel Parameter Analysis

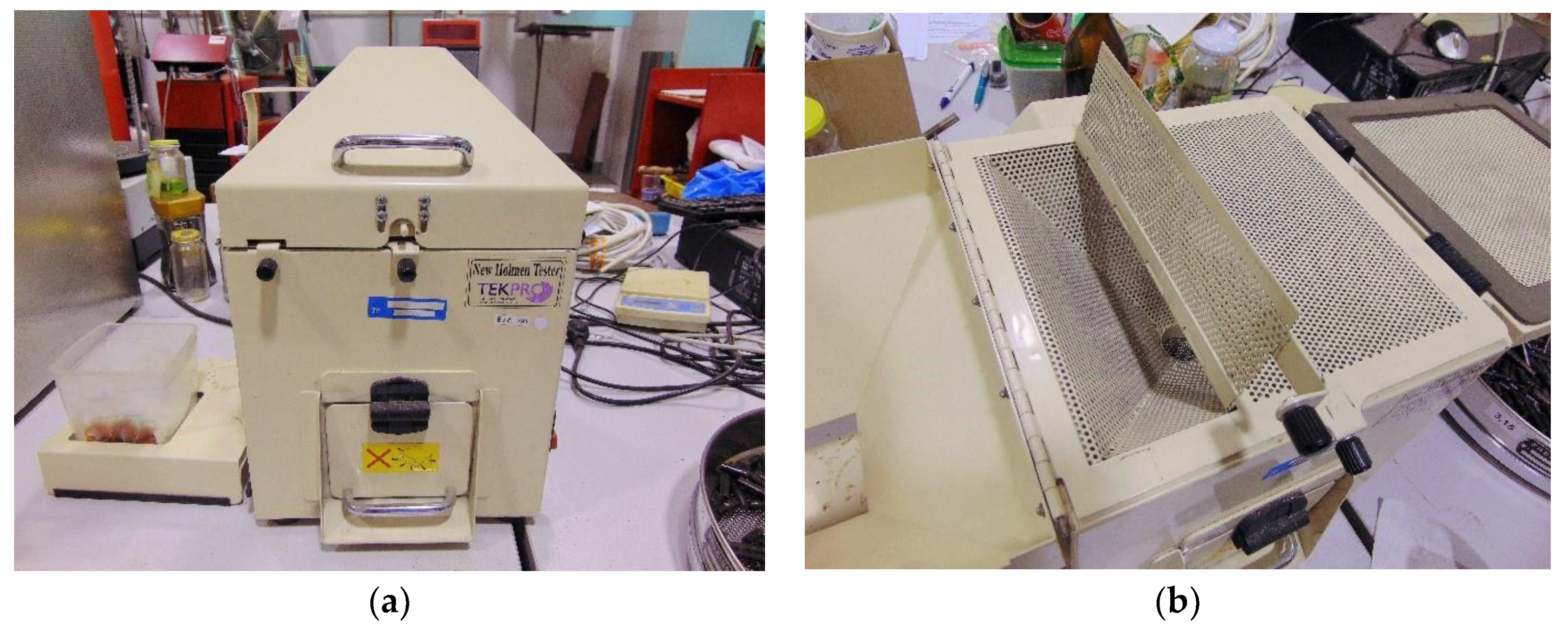

2.3. Mechanical Analysis

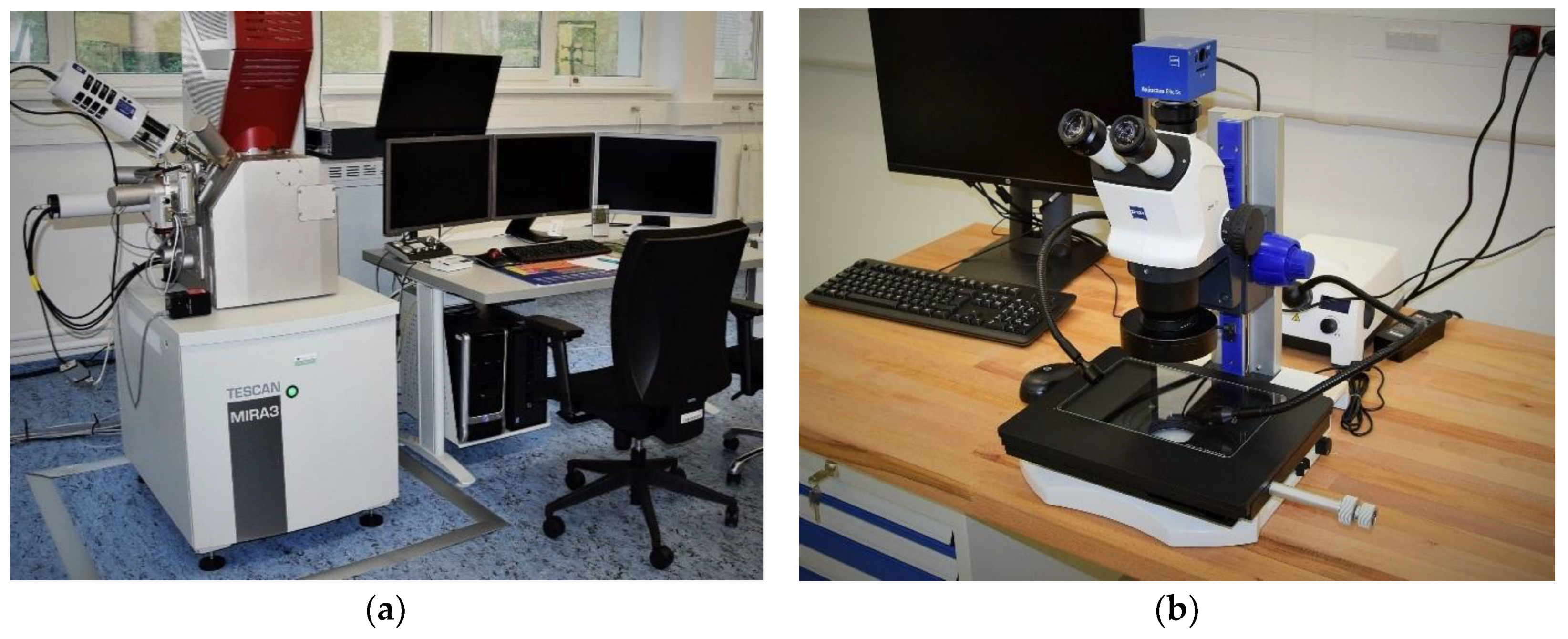

2.4. Microscope Analysis

2.5. Statistical Analysis

3. Results and Discussion

3.1. Fuel Parameter Analysis

3.2. Mechanical Analysis

3.3. Microscopic Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclatures

| Ac | ash content (%) |

| AR | abrasion (%) |

| BD | bulk density (kg·m3) |

| C | carbon (%) |

| DU | mechanical durability (%) |

| F | amount of fines (%) |

| Fmax | maximal loading force (N) |

| GCV | gross calorific value (MJ∙kg−1) |

| H | hydrogen (%) |

| L | length (mm) |

| m | samples mass (kg) |

| m1 | weight of empty container (kg) |

| m2 | weight of filled container (kg) |

| mA | mass of sieved pellets after the tumbling treatment (g) |

| Mc | moisture content (%) |

| mE | mass of pre-sieved pellets before the tumbling treatment (g) |

| mF | mass amount of fines (g) |

| mS | mass amount of samples (g) |

| N | nitrogen (%) |

| NCV | net calorific value (MJ∙kg−1) |

| S | sulphur (%) |

| V | samples volume (m3) |

| Vc | container volume (m3) |

| vp | pressing speed (mm∙min−1) |

| ρ | volume density (kg·m3) |

| σ | compressive strength (-) |

| σc | compressive strength in cleft (N∙mm−1) |

| σp | compressive strength in simple pressure (MPa) |

References

- Abdul Khalil, H.P.S.; Siti, M.A.; Ridzuan, R.; Kamarudin, H.; Khairul, A. Chemical composition, morphological characteristics, and cell wall structure of Malaysian oil palm fibers. Polym. Plast. Technol. Eng. 2008, 47, 273–280. [Google Scholar] [CrossRef]

- Mayes, S. The Oil Palm, 4th ed.; Corley, R.H.V., Tinker, P.B., Eds.; Blackwell Science: Oxford, UK, 2004; Volume xxviii, p. 562. [Google Scholar]

- Millennium Ecosystem Assessment (MEA). Ecosystems and Human Well-Being: Biodiversity Synthesis; World Resources Institute: Washington, DC, USA, 2005; Available online: https://www.millenniumassessment.org/documents/document.354.aspx.pdf (accessed on 25 September 2018).

- Fitzherbert, E.B.; Struebig, M.J.; Morel, A.; Danielsen, F.; Brühl, C.A.; Donald, P.F.; Phalan, B. How will oil palm expansion affect biodiversity? Oil palm and biodiversity. Trends Ecol. Evol. 2008, 23, 529–588. [Google Scholar] [CrossRef] [PubMed]

- Mahlia, T.M.I.; Abdulmuin, M.Z.; Alamsyah, T.M.I.; Mukhlishien, D. An alternative energy source from palm wastes industry for Malaysia and Indonesia. Energy Convers. Manag. 2001, 42, 2109–2118. [Google Scholar] [CrossRef]

- Shinoj, S.; Visvanathanb, R.; Panigrahic, S.; Kochubabua, M. Oil palm fiber (OPF) and its composites: A review. Ind. Crop. Prod. 2011, 33, 7–22. [Google Scholar] [CrossRef]

- Hasamudin, W.; Soom, R.M. Road Making Using Oil Palm Fiber. Malaysian Palm Oil Board Information Series; Malaysian Palm Oil Board, Ministry of Primary Industries: Kuala Lumpur, Malaysia, 2002; p. 171. ISSN 1511-7871. Available online: http://palmoilis.mpob.gov.my/publications/TOT/tt171.pdf (accessed on 20 September 2018).

- Food and Agriculture Organization of the United Nations (FAO). FAOSTAT. Data. Crops. Available online: http://www.fao.org/faostat/en/?#data/QC (accessed on 25 September 2018).

- Roslan, A.; Kamarudin, M.F.; Nordin, A.B.A.; Simeh, M.A. A study on the Malaysian oil palm biomass sector—Supply and perception of palm oil millers. Oil Palm Ind. Econ. J. 2011, 11, 28–41. [Google Scholar]

- Malaysian Palm Oil Board (MPOB) [Online]. Statistics. Area and Sectoral Status. Kelana Jaya: Economics & Industry Development Division. Available online: http://bepi.mpob.gov.my/index.php/en/statistics/production/186-production-2018.html (accessed on 22 August 2018).

- Abdullah, N.; Gerhauser, H.; Sulaiman, F. Fast pyrolysis of empty fruit bunches. Fuel 2010, 89, 2166–2169. [Google Scholar] [CrossRef]

- Omar, R.; Idris, A.; Yunus, R.; Khalid, K.; Aida Isma, M.I. Characterization of empty fruit bunch for microwave-assisted pyrolysis. Fuel 2011, 90, 1536–1544. [Google Scholar] [CrossRef]

- Palamaea, S.; Dechatiwongse, P.; Choorita, W.; Chistid, Y.; Prasertsan, P. Cellulose and hemicellulose recovery from oil palm empty fruit bunch (EFB) fibers and production of sugars from the fibers. Carbohydr. Polym. 2017, 155, 491–497. [Google Scholar] [CrossRef] [PubMed]

- Sulaiman, F.; Abdullah, N.; Gerhauser, H.; Shariff, A. An outlook of Malaysian energy, oil palm industry and its utilization of wastes as useful resources. Biomass Bioenergy 2011, 35, 3775–3786. [Google Scholar] [CrossRef]

- Chiew, Y.L.; Iwata, T.; Shimada, S. System analysis for effective use of palm oil waste as energy resources. Biomass Bioenergy 2011, 35, 2925–2935. [Google Scholar] [CrossRef]

- Chiew, Y.L.; Shimada, S. Current state and environmental impact assessment for utilizing oil palm empty fruit bunches for fuel, fiber and fertilizer—A case study of Malaysia. Biomass Bioenergy 2013, 51, 109–124. [Google Scholar] [CrossRef]

- Nasrin, A.B.; Ma, A.N.; Choo, Y.M.; Mohamad, S.; Rohaya, M.H.; Azali, A.; Zainal, Z. Oil Palm Biomass as Potential Substitution Raw Materials for Commercial Biomass Briquettes Production. Am. J. Appl. Sci. 2008, 5, 179–183. [Google Scholar] [CrossRef]

- Nyakuma, B.B.; Ahmad, A.; Johari, A. Analysis of the Pyrolytic Fuel Properties of Empty Fruit Bunch Briquettes. J. Appl. Sci. 2012, 12, 2527–2533. [Google Scholar] [CrossRef]

- Lam, P.S.; Lam, P.Y.; Sokhansanj, S.; Lim, C.J.; Bi, X.T.; Stephen, J.D.; Pribowo, A.; Mabee, W.E. Steam explosion of oil palm residues for the production of durable pellets. Appl. Energy 2015, 141, 160–166. [Google Scholar] [CrossRef] [Green Version]

- Zaini, I.N.; Novianti, S.; Nurdiawati, A.; Irhamna, A.R.; Aziz, M.; Yoshikawa, K. Investigation of the physical characteristics of washed hydrochar pellets made from empty fruit bunch. Fuel Process. Technol. 2017, 160, 109–120. [Google Scholar] [CrossRef]

- Nyakuma, B.B.; Mazangi, M.; Tuan Abdullah, T.A.; Johari, A.; Ahmad, A.; Oladokun, O. Gasification of Empty Fruit Bunch Briquettes in a Fixed Bed Tubular Reactor for Hydrogen Production. Appl. Mech. Mater. 2014, 699, 534–539. [Google Scholar] [CrossRef]

- ISO 16559 (2014): Solid Biofuels—Terminology, Definitions and Descriptions; ISO: Geneva, Switzerland, 2014.

- ISO 17225-6 (2014): Solid Biofuels—Fuel Specifications and Classes—Part 6: Graded Non-Woody Pellets; ISO: Geneva, Switzerland, 2014.

- ISO 17225-1 (2014): Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements; ISO: Geneva, Switzerland, 2014.

- Maphill. 2018. Available online: http://www.maphill.com/ (accessed on 22 August 2018).

- ISO 17829 (2015): Solid Biofuels—Determination of Length and Diameter of Pellets; ISO: Geneva, Switzerland, 2015.

- ISO 18134-1 (2015): Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 1: Total Moisture—Reference Method; ISO: Geneva, Switzerland, 2015.

- ISO 18134-2 (2017): Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method; ISO: Geneva, Switzerland, 2017.

- ISO 18122 (2015): Solid Biofuels—Determination of Ash Content; ISO: Geneva, Switzerland, 2015.

- ISO 18125 (2017): Solid Biofuels—Determination of Calorific Value; ISO: Geneva, Switzerland, 2017.

- ISO 1928 (2009): Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimetric Method and Calculation of NCV; ISO: Geneva, Switzerland, 2009.

- ISO 16948 (2015): Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen; ISO: Geneva, Switzerland, 2015.

- ISO 16994 (2016): Solid Biofuels—Determination of Total Content of Sulfur and Chlorine; ISO: Geneva, Switzerland, 2016.

- ISO 18135 (2017): Solid Biofuels—Sampling; ISO: Geneva, Switzerland, 2017.

- ISO 14780 (2017): Solid Biofuels—Sample Preparation; ISO: Geneva, Switzerland, 2017.

- ISO 18846 (2016): Solid Biofuels—Determination of Fines Content in Quantities of Pellets; ISO: Geneva, Switzerland, 2016.

- ISO 3310-2 (2013): Test Sieves—Technical Requirements and Testing—Part 2: Test Sieves of Perforated Metal Plate; ISO: Geneva, Switzerland, 2013.

- ISO 17828 (2015): Solid Biofuels—Determination of Bulk Density; ISO: Geneva, Switzerland, 2015.

- EN ISO 18847 (2016): Solid Biofuels—Determination of Particle Density of Pellets and Briquettes; ISO: Geneva, Switzerland, 2016.

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Effects of operating parameters on maize COB briquette quality. Biomass Bioenergy 2018, 112, 61–72. [Google Scholar] [CrossRef]

- Seifi, M.R. The moisture content effect on some Physical and Mechanical Properties of Corn. J. Agric. Sci. 2010, 2, 125–134. [Google Scholar] [CrossRef]

- Altuntaş, E.; Yıldız, M. Effect of Moisture Content on Some Physical and Mechanical Properties of Faba Bean (Vicia faba L.) Grains. J. Food Eng. 2007, 78, 174–183. [Google Scholar] [CrossRef]

- Yahya, A.; Hamdan, K.; Ishola, T.A.; Suryanto, H. Physical and Mechanical Properties of Jatropha curcas L. Fruits from Different Planting Densities. J. Appl. Sci. 2013, 13, 1004–1012. [Google Scholar] [CrossRef]

- ISO 17831-1 (2015): Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets; ISO: Geneva, Switzerland, 2015.

- ÖNORM M 7135 (2003): Compressed Wood or Compressed Bark in Natural State, Pellets and Briquettes. Requirements and Test Specifications; ISO: Geneva, Switzerland, 2003.

- Rubio, B.; Izquierdo, M.T.; Segura, E. Effect of binder addition on the mechanical and physicochemical properties of low rank coal char briquettes. Carbon 1999, 37, 1833–1841. [Google Scholar] [CrossRef]

- ISO 7500-1 (2018): Metallic Materials—Calibration and Verification of Static Uniaxial Testing Machines—Part 1: Tension/Compression Testing Machines—Calibration and Verification of the Force-Measuring System; ISO: Geneva, Switzerland, 2018.

- García-Maraver, A.; Popov, V.; Zamorano, M. A review of European standards for pellet quality. Renew. Energy 2011, 36, 3537–3540. [Google Scholar] [CrossRef]

- Mohamed, A.R.; Lee, K.T. Energy for sustainable development in Malaysia: Energy policy and alternative energy. Energy Policy 2006, 34, 2388–2397. [Google Scholar] [CrossRef]

- Vijaya, S.; Chow, M.C.; Ma, A.N. Energy Database of the Oil Palm. MPOB Palm Oil. Eng. Bull. 2004, 70, 15–22. [Google Scholar]

- Nurdiawati, A.; Novianti, S.; Zaini, I.N.; Sumida, H.; Yoshikawa, K. Production of low-potassium solid fuel from empty fruit bunches (EFB) by employing hydrothermal treatment and water washing proces. J. Jpn. Inst. Energy 2015, 94, 775–780. [Google Scholar] [CrossRef]

- Harun, N.Y.; Parvez, A.M.; Afzal, M.T. Process and Energy Analysis of Pelleting Agricultural and Woody Biomass Blends. Sustainability 2018, 10, 1770. [Google Scholar] [CrossRef]

- Uemura, Y.; Omar, W.N.; Tsutsui, T.; Yusup, S.B. Torrefaction of oil palm wastes. Fuel 2011, 90, 2585–2591. [Google Scholar] [CrossRef]

- Rahman, N.A.; Atan, M.F.; Low, C.M.; Baini, R.; Che Mat, N.F.; Salleh, S.F. Study on the Potential of Pelletisation of Empty Fruit Bunch with Sago as Binding Agent for Power Generation. Eur. Int. J. Sci. Technol. 2013, 2, 111–118. [Google Scholar]

- Erlich, C.; Fransson, T.H. Downdraft gasification of pellets made of wood, palm-oil residues respektive bagasse: Experimental study. Appl. Energy 2011, 88, 899–908. [Google Scholar] [CrossRef]

- Gravalos, I.; Xyradakis, P.; Kateris, D.; Gialamas, T.; Bartzialis, D.; Giannoulis, K. An Experimental Determination of Gross Calorific Value of Different Agroforestry Species and Bio-Based Industry Residues. Nat. Resour. 2016, 7, 57–68. [Google Scholar] [CrossRef]

- Miranda, T.; Montero, I.; Sepúlveda, F.J.; Arranz, J.I.; Rojas, C.V.; Nogales, S. A Review of Pellets from Different Sources. Materials 2015, 8, 1413–1427. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Núñez, C.A.F.; Jochum, J.; Vargas, F.E.S. Characterization and feasibility of biomass fuel pellets made of Colombian timber, coconut and oil palm residues regarding European standards. Environ. Biotechnol. 2012, 8, 67–76. [Google Scholar]

- Talero, G.F.; Rincon, S.L.; Gonzalez, A. Use of Colombian Oil Palm Wastes for Pellets Production: Reduction of the Process Energy Consumption by Modifying Moisture Content. In Proceedings of the 6th International Conference on Engineering for Waste and Biomass Valorisation, Albi, France, 23–26 May 2016. [Google Scholar]

- De Santoli, L.; Mancini, F.; Nastasi, B.; Piergrossi, V. Building integrated bioenergy production (BIBP): Economic sustainability analysis of Bari airport CHP (combined heat and power) upgrade fueled with bioenergy from short chain. Renew. Energy 2015, 81, 499–508. [Google Scholar] [CrossRef]

| Year | Harvested Area | Yield | Production |

|---|---|---|---|

| (ha) | (hg·ha−1) | (t) | |

| 2016 | 8,150,000 | 171,721 | 139,952,542 |

| 2015 | 8,630,000 | 172,731 | 149,066,849 |

| 2014 | 9,333,482 | 171,571 | 160,135,795 |

| Biomass | Length | Diameter | Weight |

|---|---|---|---|

| (mm) | (mm) | (g) | |

| Oil palm EFB | 30.61 ± 6.10 | 8.71 ± 0.22 | 2.63 ± 0.55 |

| Parameter | ISO Standard | Equipment |

|---|---|---|

| Moisture content Mc (%) | ISO 18134-1 (2015): Solid biofuels—Determination of moisture content—Oven dry method—Part 1: Total moisture—Reference method [27] | Thermogravimetric analyser LECO, Type TGA 701 (Saint Joseph, MO, USA) |

| ISO 18134-2 (2017): Solid biofuels—Determination of moisture content—Oven dry method—Part 2: Total moisture—Simplified method [28] | ||

| Ash content Ac (%) | ISO 18122 (2015): Solid biofuels—Determination of ash content [29] | |

| Gross calorific value GCV (MJ∙kg−1) | ISO 18125 (2017): Solid biofuels—Determination of calorific value [30] | Isoperibol calorimeter LECO, Type AC 600 (Saint Joseph, MO, USA) |

| Net calorific value NCV (MJ∙kg−1) | ISO 1928 (2010): Solid mineral fuels—Determination of gross calorific value by the bomb calorimetric method and calculation of NCV [31] | |

| Carbon C, Nitrogen N, Hydrogen H (%) | ISO 16948 (2015): Solid biofuels—Determination of total content of carbon, hydrogen and nitrogen [32] | Laboratory equipment LECO, Type CHN628+S (Saint Joseph, MO, USA) |

| Sulphur S (%) | ISO 16994 (2016): Solid biofuels—Determination of total content of sulfur and chlorine [33] |

| Parameter | ISO Standard | Equipment |

|---|---|---|

| Amount of fines F (%) | ISO 18846 (2016): Solid biofuels—Determination of fines content in quantities of pellets [36] ISO 3310-2 (2013): Test sieves—Technical requirements and testing—Part 2: Test sieves of perforated metal plate [37] | Metal sieve with 3.15 mm diameter round hole |

| Bulk density BD (kg∙m−3) | ISO 17828 (2015): Solid biofuels—Determination of bulk density [38] | Stainless steel measuring container |

| Volume density ρ (kg∙m−3) | EN ISO 18847 (2016): Solid biofuels—Determination of particle density of pellets and briquettes [39] | Digital measuring instruments Kern |

| Compressive strength σ (-) | [40,41,42,43] | Universal hydraulic machine Labortech, Type MP Test 5.050 (Opava, Czech Republic) |

| Mechanical durability DU (%) | ISO 17831-1 (2015): Solid biofuels—Determination of mechanical durability of pellets and briquettes—Part 1: Pellets [44] | Pellettester PT 500 (Prague, Czech Republic) |

| ÖNORM M 7135 (2003): Compressed wood or compressed bark in natural state, pellets and briquettes. Requirements and test specifications [45] | Lingo-tester Tekpro Limited, type New Holmen Tester (Norfolk, UK) |

| Indicator | Result | Standard | |

|---|---|---|---|

| in w. b. | in d. b. | ||

| Mc (%) | 7.07 | - | ≤15 [27,28] |

| Ac (%) | 9.41 | 10.12 | ≤10 [29] |

| GCV (MJ∙kg−1) | 16.32 | 17.56 | - |

| NCV (MJ∙kg−1) | 15.06 | 16.39 | ≥14.5 [30] |

| C (%) | 42.54 | 45.78 | - |

| H (%) | 5.80 | 5.39 | - |

| N (%) | 0.75 | 0.81 | ≤2.0 [32] |

| S (%) | 0.13 | 0.14 | ≤0.3 [33] |

| O (%) | - | 37.76 | - |

| Indicator | Result | Reference |

|---|---|---|

| Ac (%) | 7.55 | [17] |

| 7.30 | [5] | |

| 4.70 | [17] | |

| 4.56 | [18] | |

| 5.47 | [19] | |

| 4.90 | [51] | |

| Wood biomass * Ac (%) | <1% | [52] |

| NCV (MJ∙kg−1) | 16.64 | [17] |

| 15.82 | [53] | |

| 17.00 | [54] | |

| 18.05 | [55] | |

| 17.57 | [18] | |

| 18.54 | [19] | |

| Wood biomass * NCV (MJ∙kg−1) | 19.15–19.75 | [52] |

| Indicator | Reference | ||||

|---|---|---|---|---|---|

| C | H | N | S | O | |

| 48.80 | 6.30 | 0.20 | 0.20 | 36.70 | [5] |

| 45.14 | 6.05 | 0.54 | 0.20 | 48.08 | [21] |

| 47.20 | 6.00 | 0.60 | 0.12 | 38.20 | [55] |

| 42.99 | 6.19 | 0.64 | 0.08 | 50.11 | [17] |

| 45.53 | 5.89 | 0.45 | - | 43.40 | [53] |

| C | H | N | S | O | GCV | NCV |

|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | (%) | (MJ∙kg−1) | (MJ∙kg−1) |

| 50.94 | 5.99 | 0.90 | 0.16 | 42.01 | 19.54 | 18.24 |

| Indicator | Result | Standard |

|---|---|---|

| F (%) | 0.40 | ≤3.0 [36] |

| BD (kg∙m−3) | 758.12 | - |

| ρ (kg∙m−3) | 1440.01 ± 79.25 | ≥600 [38] |

| σp (MPa) | 10.83 ± 2.94 | - |

| σc (N·mm−1) | 60.46 ± 9.61 | - |

| Related Standard | Required DU | Observed DU |

|---|---|---|

| (%) | (%) | |

| ISO 17831-1 (2015) [44] | ≥96.0 | 97.4 |

| ÖNORM M 7135 (2000) [45] | <2.3 | 0.6 |

| Indicator | Result | Reference |

|---|---|---|

| F (%) | 0.35 | [54] |

| BD (kg∙m−3) | 580.00 | [55] |

| 582.45 | [17] | |

| 441.60 | [53] | |

| ρ (kg∙m−3) | 607.00 | [54] |

| 980.00 | [51] | |

| 1040.00 | [55] | |

| 1140.00 | [19] | |

| 1245.00 | [17] | |

| 1023.00 | [59] | |

| DU (%) | 87.89 | [51] |

| 96.45 | [17] | |

| 93.13 | [60] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brunerová, A.; Müller, M.; Šleger, V.; Ambarita, H.; Valášek, P. Bio-Pellet Fuel from Oil Palm Empty Fruit Bunches (EFB): Using European Standards for Quality Testing. Sustainability 2018, 10, 4443. https://doi.org/10.3390/su10124443

Brunerová A, Müller M, Šleger V, Ambarita H, Valášek P. Bio-Pellet Fuel from Oil Palm Empty Fruit Bunches (EFB): Using European Standards for Quality Testing. Sustainability. 2018; 10(12):4443. https://doi.org/10.3390/su10124443

Chicago/Turabian StyleBrunerová, Anna, Miroslav Müller, Vladimír Šleger, Himsar Ambarita, and Petr Valášek. 2018. "Bio-Pellet Fuel from Oil Palm Empty Fruit Bunches (EFB): Using European Standards for Quality Testing" Sustainability 10, no. 12: 4443. https://doi.org/10.3390/su10124443

APA StyleBrunerová, A., Müller, M., Šleger, V., Ambarita, H., & Valášek, P. (2018). Bio-Pellet Fuel from Oil Palm Empty Fruit Bunches (EFB): Using European Standards for Quality Testing. Sustainability, 10(12), 4443. https://doi.org/10.3390/su10124443