1. Introduction

With emerging environmental issues and growing pressure owing to scarcity of resources, waste disposal has become a major issue for sustainable development of economies all over the world. To solve this problem, governments in many countries have introduced various environmental regulations and policies and have set up relevant management systems to improve environmental conditions and ensure energy savings. Extended Producer Responsibility (EPR), proposed by Thomas Lindhquist in 1988, is one of the major and most popular environmental principles in waste management and environmental protection. In this research, EPR is defined as an environmental principle that guides manufacturing enterprises in assuming responsibilities of recycling and final disposal of their used and waste products, thus helping solve environmental pollution problems. It focuses on utilizing reusable materials and components by incorporating modular design and capturing residual values from recycling products [

1]. In recent years, EPR has become a global hot issue in the research fields of management, environmental science, sociology, and law. As a management principle arising from increasing severe pollution and scarce resources, EPR has been applied and promoted by several countries and regions as the basic standard of environmental policy. In 1991, the Packaging Act in Germany was the first to clearly highlight the EPR principle in their law. Several developed countries and regions have also passed environmental legislations to establish a waste product recycling management system based on EPR. Developing countries (such as India and Malaysia) have also planned to introduce EPR in the field of product waste management. As the world’s largest producer of solid waste, China is facing tremendous pressure regarding the environment and resources, and economic development problems caused by environmental pollution [

1]. Organizations’ performance is measured based on the different levels of effective output to achieve its goals. It reflects the organization’s measurement of and feedback on the degree of achievement and efficiency of the target under certain resources, conditions, and environments. An increasing number of manufacturing enterprises have begun to use EPR to improve eco-efficiency to satisfy the growing environmental requirements expected in the market. The effective implementation of EPR not only improves the environmental benefits of enterprises’ products, but also enhances the enterprises’ social image, which in turn boosts international competitiveness and influence.

The issue of the performance of EPR practices has always been a bone of contention in the academic field. Based on existing research, the performance of EPR practices is reflected in the following three aspects: economic benefit, environmental benefit, and social benefit. The main topics of research in this field are studying the effectiveness and the gap between theory and practice of EPR, evaluating the economic/environmental/social benefits generated by EPR legislation and mechanisms, and scientifically verifying the effectiveness of EPR practices. Achillas (2010), Cahill et al. (2011) and Dubois (2012) have studied EPR practices and their performance [

2,

3,

4]. According to their research, the methods of EPR practices mainly include voluntary participation, legal enforcement, economic stimulation, protocol implementation, or a combination of these methods. The benefits to enterprises by EPR practices may include: economic benefits (affecting the design of products and packaging, enhancing the competitive advantage of enterprises, and improving the management of materials), environmental benefits (reducing landfill and incineration, reducing the use of raw materials, reducing waste gas and waste water) and social benefits (improving the relationships between enterprises and communities, changing people’s lifestyles, and changing the social production modes) [

5].

Green supply chain management is a modern management model that considers environmental impacts and resource efficiency throughout supply chains. It focuses on inter-organizational efforts in managing supply chain processes to reduce the adverse environmental impacts of material purchasing, production, and used products distribution. In the era of global sustainable development, the cooperation of stakeholders in the supply chain system receives increasing attention. The improvement of the sustainability of the whole supply chain system has become a key factor in the obtaining of core competitive advantages for enterprises. Circular economy and sustainable development are issues at the level of the supply chain system and cannot be solved by a single enterprise. Only with the cooperation of stakeholders in the upstream and downstream of the supply chain can the enterprise and the entire industry achieve sustainable development. Source governance is an inevitable part of EPR practices, which includes R&D and the acquisition of green and environmentally-friendly raw materials from upstream suppliers, which may have an impact on the performance of EPR practices. Due to the responsibility of recycling and the corresponding costs when implementing EPR mechanisms, enterprises are motivated to pay more attention to the greenness of the components they purchase, to maximize their reuse value, and reduce the use of components with high pollution, thus reducing environmental governance costs and gain more profits [

6,

7].

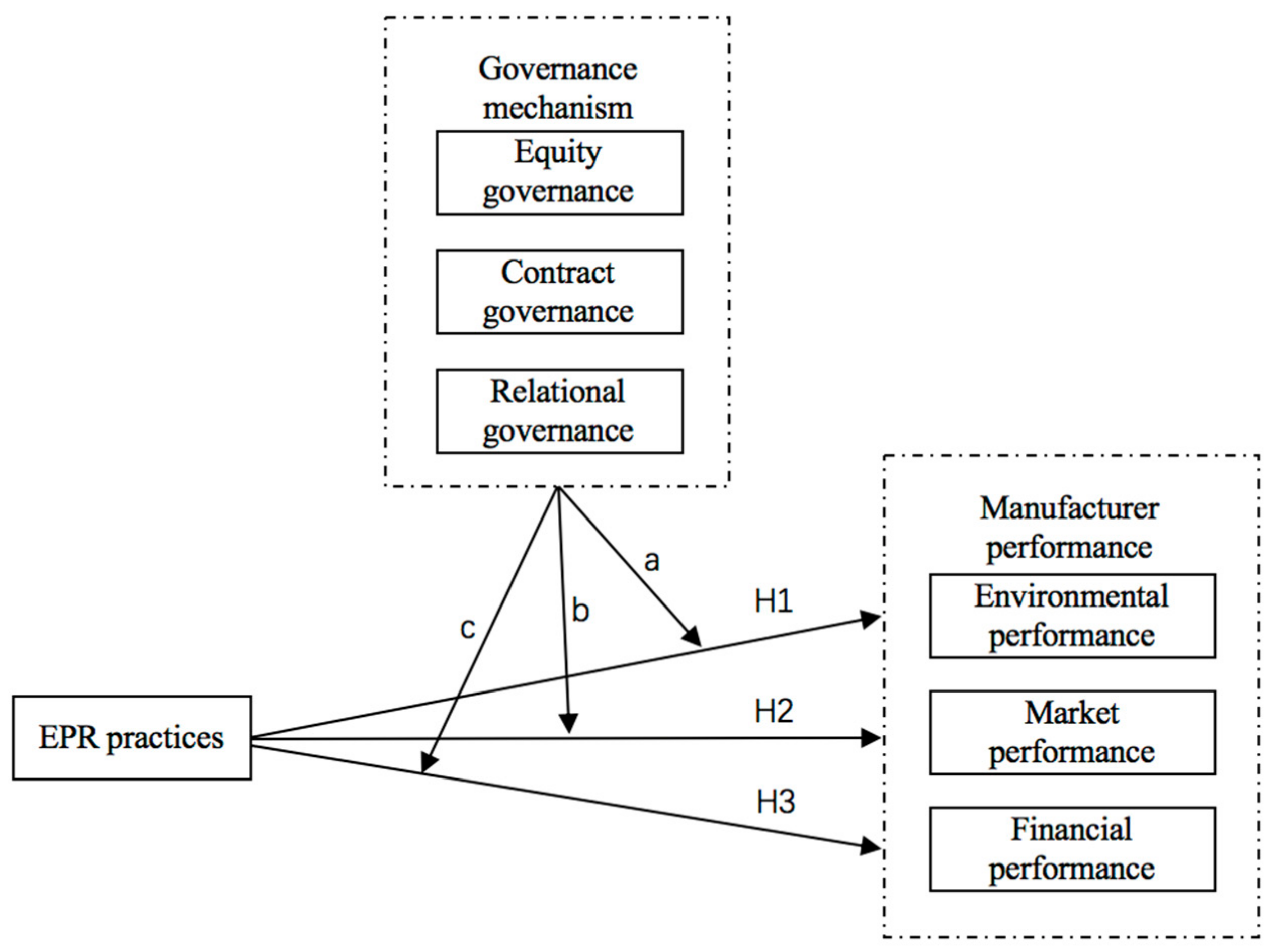

From the perspective of green supply chain, this study takes the performance of EPR system as the main research object, introduces three kinds of supplier governance mechanisms, including contract governance, relational governance and equity governance, and systematically studies the relationship between manufacturers’ EPR practices and operation performance, as well as the governance effects of three governance mechanisms on the performance of EPR practices. This study aims to provide decision support and strategic suggestions for enterprises’ EPR practices and supply chain governance.

2. Literature Review and Research Hypothesis

2.1. EPR Practices and Enterprise Performance

As a widely-used management principle in environment management, EPR has always been paid attention to by the academic and industry. Under EPR mechanism, the manufacturers’ environmental responsibility is extended to the post-stage of product consumption, focusing on the retirement phase of the product, which includes product eco-design, manufacturing, distribution, retail and other stages of processing issues. EPR helps to further constrain and motivate the environmental behavior of producers in the entire product life cycle. Subramanian et al. (2009) believe that EPR practices can reduce the environmental impact of enterprises and improve enterprise performance [

8]. Li and Brenda (2013) study the recycling issue of waste electrical and electronic equipment around the world, focusing on the implementation gaps of EPR in developed and developing countries [

9]. Then they analyze the impact of collaborations between importers and exporters in different regions on the establishment of EPR from the perspective of stakeholders. Meanwhile, they also point out that EPR is a good solution, which can effectively promote the establishment of internationally common EPR standards, improve the social performance of government and enterprises, and achieve effective compensation for environmental performance losses. Jacobs and Subramanian (2012) discuss the responsibility sharing of product recycling on the level of supply chain, emphasizing that each participant in the supply chain should be responsible for product recycling [

10]. By establishing a two-stage supply chain model, which consists of a supplier and a manufacturer, they analyze the impact of the product recovery responsibility sharing on the economic and environment in both integrated and decentralized supply chain, and prove that the responsibility sharing of product recycling can increase the profit of the entire supply chain in the decentralized supply chain. In addition, they also verify the improvements of economic and environmental performance by responsibility sharing in terms of consumer surplus, environment externality, raw material extraction, product consumption, and sale of non-recyclable products. In addition, Ren et al. (2006) and Lai et al. (2012) propose that EPR practices can help enterprises improve their environmental performance and reduce environmental pollution [

5,

11]. Based on the above research, we propose the following hypotheses:

Hypothesis 1 (H1). EPR practices has a positive impact on manufacturers’ environmental performance.

EPR practices can be regarded as a form of corporate social responsibility. Consumer preference and enterprises’ green advertisement can play an important role in the enterprises’ products market expansion. On one hand, under the concept of product lifecycle and EPR mechanism, the green level and corporate image of enterprises can be improved significantly. The advantages of enterprises in social responsibility and corporate image play a positive role in their competition with other enterprises in the same industry. Meanwhile, global green barriers provide a certain market advantage for enterprises with higher green levels, thus gaining more opportunities in international market expansion and improving their negotiation ability and market position in international trade [

12]. On the other hand, consumers’ environmental preferences can also promote the expansion of the product market to a certain extent. Specifically, consumers prefer products with higher green level when facing products with similar price and performance [

8,

13]. In addition, under the EPR mechanism, manufacturers provide services such as free recycling, trade-in and acquisition, which offer convenience for consumers to dispose of waste products. The reuse of waste components also shortens the lead time of products and components, thus increasing the demand for products and expanding the market [

14]. Therefore, the hypotheses are proposed as follows:

Hypothesis 2 (H2). EPR practices has a positive impact on manufacturers’ market performance.

Undertaking EPR can encourage manufacturers to improve product design, reduce the amount of material used in the product to a certain extent, and improve the environmental protection of parts to reduce processing costs. Specifically, when the enterprises do not have to bear the responsibility for the end-of-life treatment of the product, they will pay less attention to the environmental effects of the product in the waste phase due to certain externalities, and do not deliberately use materials and components that are not harmful to the environment. However, when the enterprises implement EPR practices, they have the responsibility to eliminate the environmental hazards of the products in the waste phase and bear the cost of the treatment. Therefore, the manufacturers will gradually pay attention to environmental factors in the selection of product materials. In the academic field, the existing researches have explored the relationship between EPR practices and enterprise financial performance, which indicate that EPR practices contribute to improving the financial performance of enterprises. The reason is that under the implementation of EPR, manufacturers bear the responsibility of waste products for a full life cycle, and the economic value of waste products can increase the income of the enterprises, thus improving their financial performance [

5,

11,

15,

16]. In addition, Hindo and Arndt (2006) argue that the implementation of EPR can not only reduce the operating costs of the enterprises, but also reduce the risk of lawbreaking [

17].

Hypothesis 3 (H3). EPR practices has a positive impact on manufacturers’ financial performance.

2.2. Governance Mechanism and Enterprise Performance

From the perspective of green supply chain, suppliers’ behavior plays an important role in enterprises, and the suppliers’ governance mechanism will also have an impact on their operational performance. Thus, we opened the black box of the governance mechanism, and analyzed the relationship between these governance mechanisms and enterprise performance, and finally proposed relevant assumptions.

The supplier governance mechanism and its governance effects are typical research problems in the field of supplier management research [

18,

19,

20,

21]. Enterprises may improve their operational performance through supplier governance mechanisms. The selection problem of supplier management mechanisms has been studied by many scholars in the context of procurement and supply management [

22,

23]. Aubert, Patry & Rivard (2005) and Earl (1996) propose that parallel researches on different governance mechanisms and their performance issues should be conducted, thus making choices about governance mechanisms. In this research, we explore three different types of supplier governance mechanisms (contract governance, relational governance, and equity governance) and their impacts on enterprise performance [

24,

25].

The equity governance mechanism means that the manufacturers increase the control and decision power of the suppliers’ decision-making by investing in a certain share of the suppliers, thereby realizing the management and control of the suppliers. Killing (1988) divides the equity-based cooperative governance model into a traditional joint venture and minority equity investment [

26]. The former refers to the model in which two (or more) parties achieve governance through the establishment of independent new enterprise forms; the latter refers to the way that two (or more) parties do not form independent new enterprises, but one party obtains a minority shareholding from another and achieves governance over it through investment. An equity-based cooperation is similar to a bureaucracy company, and can promote information exchange and knowledge-sharing more effectively, thus offering higher coordination efficiency [

27]. The equity governance mechanism has the following characteristics. Firstly, the formal governance institutions in equity-based cooperation can serve as a formal communication channel to ensure the effective flow of information. Secondly, besides the top management team of enterprises, the equity-based cooperation also has an independent management organization to deal with daily problems, which can guarantee the effective resolution of cooperation conflicts. Finally, equity-based cooperation can promote the establishment practices of information communication and knowledge sharing more effectively and improve coordination efficiency [

28]. Based on the research and conclusions above, we propose the following hypotheses:

Hypothesis 4 (H4). Equity governance has a positive moderating effect on the relationship between EPR practices and manufacturer performance.

Hypothesis 4a (H4a). Equity governance has a positive moderating effect on the relationship between EPR practices and manufacturers’ environmental performance.

Hypothesis 4b (H4b). Equity governance has a positive moderating effect on the relationship between EPR practices and manufacturers’ market performance.

Hypothesis 4 (H4c). Equity governance has a positive moderating effect on the relationship between EPR practices and manufacturers’ financial performance.

Contract governance mechanism is another important governance mechanism in enterprise management. Pisano (1989) introduces the contractual cooperative governance model, and indicates that the equity-based and contract-based cooperative governance model are two typical cooperative governance models [

29]. Under the contract governance mechanism, manufacturers establish clear responsibilities and requirements with suppliers to achieve management on suppliers and therefore affect their own performance. Managing suppliers through clear contracts is a form of arm’s length contract [

22]. Meanwhile, manufacturers put forward clear requests for suppliers and supervise them. Such a governance mechanism is conducted to realize governance objectives (reducing the default risk from supplier), and has certain advantages in supplier management risk control [

30,

31]. When the requirements are clear, it will also require a certain amount of supervision costs [

32]. Based on the above research and conclusions, we anticipate that:

Hypothesis 5 (H5). Contract governance has a positive moderating effect on the relationship between EPR practices and manufacturer performance.

Hypothesis 5a (H5a). Contract governance has a positive moderating effect on the relationship between EPR practices and manufacturers’ environmental performance.

Hypothesis 5b (H5b). Contract governance has a positive moderating effect on the relationship between EPR practices and manufacturers’ market performance.

Hypothesis 5c (H5c). Contract governance has a positive moderating effect on the relationship between EPR practices and manufacturers’ financial performance.

Under relational governance mechanism, which is operated based on trust, the manufacturers control their suppliers’ behavior indirectly through long-term cooperation with them as an invisible constraint mechanism. The relational governance mechanism is achieved by the cooperative relationship between enterprises, which emphasizes the quality of relationship. In the long-term cooperation between manufacturers and suppliers, the relationships of two parties have largely reduced moral hazard and other issues. At the same time, the coordination of resource and profit avoids the problem of the stronger party getting too much profit and the weaker party finding it difficult to do so. Under the relational governance mechanism, manufacturers will also take efforts to improve the suppliers’ technology and capacity through investment or other ways, because manufacturers can also benefit from the improvement and development of suppliers, so as to achieve a win-win in a long-term cooperation. Hart & Moore (1988) and Spencer (2005) argue that under the relational governance mechanism, suppliers should strive to meet the requirements of the buyer as they obtain a certain investment from them [

33,

34,

35,

36,

37]. In the existing literature, Dyer & Singh (1998), Cannon, Achrol & Gundlach (2000) interpret governance mechanism from a relational perspective [

38,

39]. Bolton & Dewatripont (2005) believe that relational governance is a long-term process that requires gradual adjustments in long-term cooperation to achieve risk and benefit sharing, and achieve governance goals [

40]. In terms of the impact of relational governance mechanisms on performance, Dyer & Singh (1998), McIvor (2009), and Heric & Singh (2010) propose that relational governance can effectively improve performance [

38,

41,

42]. Grossman & Hart (1986) conclude that under the relational governance mechanism, the buyer will get more benefits (e.g., performance increase) through resource sharing [

43]. According to the research and conclusions above, we propose that:

Hypothesis 6 (H6). Relational governance has a positive moderating effect on the relationship between EPR practices and manufacturer performance.

Hypothesis 6 (H6a). Relational governance has a positive moderating effect on the relationship between EPR practices and manufacturers’ environmental performance.

Hypothesis 6 (H6b). Relational governance has a positive moderating effect on the relationship between EPR practices and manufacturers’ market performance.

Hypothesis 6 (H6c). Relational governance has a positive moderating effect on the relationship between EPR practices and manufacturers’ financial performance.

Hence, we propose the following research framework in

Figure 1.

3. Research Methods

The methodology of this research is as follows: (1) propose research hypotheses; (2) data collection; (3) variable measurement; (4) measurement development; (5) reliability (including EFA and Cronbach α) and validity test (CFA); (6) SEM test (including main effect analysis and moderating effect analysis).

3.1. Sample Data

In this research, we collected sample survey data from electronics enterprises in October 2016. The questionnaire is divided into three parts: (1) basic information about the enterprises, such as the property, the scale and the main business scope; (2) relevant measurement items on EPR practices and supplier governance mechanism; (3) measurement items on implementation performance. A total of 150 questionnaires were distributed, and 132 were collected. Since only the third part of the data is involved in this paper, we deleted 15 invalid samples, and finally obtained 117 samples to validate the proposed model and assumptions.

Table 1 shows the distribution of valid survey samples in terms of the property, scale, and annual income of the enterprises. In terms of enterprise property, state-owned enterprises (SOEs) account for 35.9%, private enterprises (PEs) for 25.6%, foreign-owned enterprises (FOEs) for 19.7%, and Sino-foreign joint ventures (SFJVs), Taiwan, Hong Kong and Macao enterprises (T&H&MEs) and other types of enterprises for 18.8%. The samples involve all types of enterprises and distribute uniformly. In terms of enterprise scale, small enterprises with fewer than 300 employees account for 27.4%, medium-sized enterprises with 300 to 2000 employees for 32.4%, and large enterprises with more than 2000 employees for 40.2%.

3.2. Measurement Development

The second and third parts of the questionnaire cover related questions on enterprises EPR practices, supplier governance mechanisms, and enterprise performance. Based on the findings of existing literature in

Section 2, we conducted interviews with executives of Chinese electronics manufacturing enterprises through a pre-study to ensure the validity of the questionnaire and implemented an exploratory qualitative study to measure EPR implementation and corporate performance of electronic manufacturing enterprises (environmental performance, market performance and financial performance) and governance mechanisms (equity governance, contract governance and relational governance). During the interview, we explored the specific EPR practices of the company, including the enterprises’ specific practices and issues of waste electronic products recycling, resource utilization, and collaborative innovation.

Based on the findings of the relevant literature and interviews, we formulated the specific content of the measurement. Specifically, enterprise performance includes financial performance, market performance and environmental performance; supplier governance mechanism includes contract governance mechanism, relational governance mechanism and equity governance mechanism. The questionnaire uses a five-point Likert Scale with dimensions 1~5 to indicate the degree of agreement of each item from strongly disagree to totally agree.

The variables involved in this part of the questionnaire are as follows: (1) EPR practices. The independent variable of this study is the enterprises EPR practices. We adapted the scale used in Lai et al. (2014) to make a sub-measurement of the behavior of the enterprises’ EPR practices [

1]. It includes seven questions. (2) Enterprise performance. This study focuses on three aspects of enterprise performance: financial, environmental and market performance. In this study, financial performance generally assesses cost saving and revenue increase of the manufacturers due to EPR practices implementation. Environmental performance investigates the improvement of the environment and the reduction of pollution based on environmental policies, objectives and indicators of EPR practices’ implementation. Market performance evaluates improvements in lead time, market position, sales opportunity, and corporate image in the marketplace. We have a relatively mature scale to measure the above three enterprise performances. Specifically, we selected a scale suggested by Autry et al. (2001), Ayres et al. (1997) and Lai et al. (2012) to measure financial performance, a scale by Lai et al. (2012) to measure environmental performance, and a scale by Venkatraman and Ramanujam (1986) to measure market performance [

11,

44,

45,

46]. (3) Supplier governance mechanism. We explored three kinds of supplier governance mechanisms in this study: contract governance, relational governance and equity governance, and empirically studied the choice of the three supplier governance mechanisms and their impact on enterprise performance. The maturity scales of existing research were used to measure the above three governance mechanisms in this paper. In particular, the scale of contract governance was derived from Cannon and Perreault (1999), measuring contract governance implemented by enterprises from three perspectives [

39]. We integrated the measurement scales for relational supplier governance mechanisms in Anderson & Narus (1990) into the scale of relational governance [

47]. The scale of equity governance comes from Pisano (1989) and was divided into two items according to the characteristics of the equity governance mechanism, which is convenient and simple for enterprises to respond to [

29]. With regard to the measurement of this research, we also discussed with managers in the electronics industry of China before formally collecting the questionnaire data. Based on the above, the measurement scale is summarized in

Appendix A.

3.3. Reliability and Validity

This study uses structural equation modeling (SEM) to verify hypothesis. SEM is widely used by scholars in sociology, management, psychology and economics. As a multivariate statistical analysis method, it can not only measure and test latent variables, but also estimate the causality model between independent variables and dependent variables. The main feature of this method is that it can replace multiple regression, path analysis, factor analysis, covariance analysis and other methods to deal with the measurement and analysis of variables in the model. In the parameter estimation of the structural model, the error generated by the measurement is included in the analysis process, so that the concept of measurement reliability can be integrated into the analysis of the causal model. Therefore, SEM is suitable for this study.

Reliability refers to the stability and consistency of the results of the test or scale. The greater the reliability of the scale, the smaller the standard error. Reliability can be defined as the ratio of the true score’s variance to the observed score’s variance. For the Likert scale used in this study, the commonly used reliability test standards are Cronbach α coefficient and half-fold reliability. The higher the reliability of a scale, the more stable the scale. The Cronbach α is a reliability test standard commonly used in the field of social science research. It is not only a function of internal consistency, but also a function of the degree of interrelationship between test questions. It can evaluate the consistency between items within a construct.

In this study, we used SPSS 22.0 to conduct Exploratory Factor Analysis (EFA) with the maximum variance varimax rotation method for data rotation. According to the results of EFA, the items EP6 and EP7 were deleted because their factor loadings were less than 0.5. After that, we conducted factor analysis on the data again. The results show that KMO = 0.855, greater than 0.7, which means that it is suitable for factor analysis. The chi-square value of Bartlett’s test is 1626.902, the degree of freedom is 300, and the p-value is 0.000, reaching a significant level of 0.05. The null hypothesis can be rejected, that is, we reject the hypothesis that the net correlation matrix between variables is not a unit matrix. The results of factor analysis show that the factor loading of all items are greater than 0.5, and others are less than 0.5. In addition, we also verified the cross-loading of the items, and we found that the items of each factors have higher loading values on their own factor than other factors. Therefore, the factor attribution in this study is clear. At last, the scale is suitable for factor analysis and validated for all the items.

We then calculated the Cronbach α of five principal components separately to further test the reliability of the scale. According to the results, the Cronbach α of EPR practices (EP1~EP5) was 0.892, the Cronbach α of market performance (M1~M4) was 0.831, the Cronbach α of financial performance (F1~F4) was 0.857, the Cronbach α of environmental performance (EN1~EN3) was 0.812, the Cronbach α of relational governance (R1~R4) was 0.776, the Cronbach α of contract governance (C1~C3) was 0.824, and the Cronbach α of equity governance (E1~E2) was 0.887, all of which are higher than the minimum acceptable value (0.7) for Cronbach α. Therefore, all the seven constructs in this questionnaire have good reliability.

Validity refers to the degree to which a concept or theory is measured by the attitude scale. We used Amos 20.0 to conduct Confirmatory Factor Analysis (CFA) to verify the validity of the survey data in this study, and the method used is Maximum Likelihood Estimation (MLE) method for CFA. The results of MLE show that χ2/df value was 1.231. According to Hair’s judgment standard, the χ2/df value should be between 1 and 3; the smaller the better. Moreover, we chose Fit Index (FI), which is less affected by the sample scale, to verify the validity of the model due to the relatively small sample scale. The results show that RMSEA (Root Mean Square Error Approximation) = 0.058, which is less than the standard value of 0.08. The Comparative Fit Index CFI = 0.960, Incremental Fit Index IFI = 0.961, and the Tuck-Lewis Index TLI = 0.953, are all greater than the standard value of 0.9. Accordingly, the fit degree of the measurement model in this study is good.

4. Results

This study establishes a Structural Equation Model (SEM) to test the hypotheses proposed above. The model is divided into two parts: main effect and moderating effect. The former includes the impact of EPR practices and governance mechanism on enterprise performance, while the latter includes the moderating effect of governance mechanism on the relationship between EPR and enterprise performance. The main effect and the moderating effect are tested by Amos 22.0 and SPSS 20.0 separately.

4.1. Main Effect Analysis

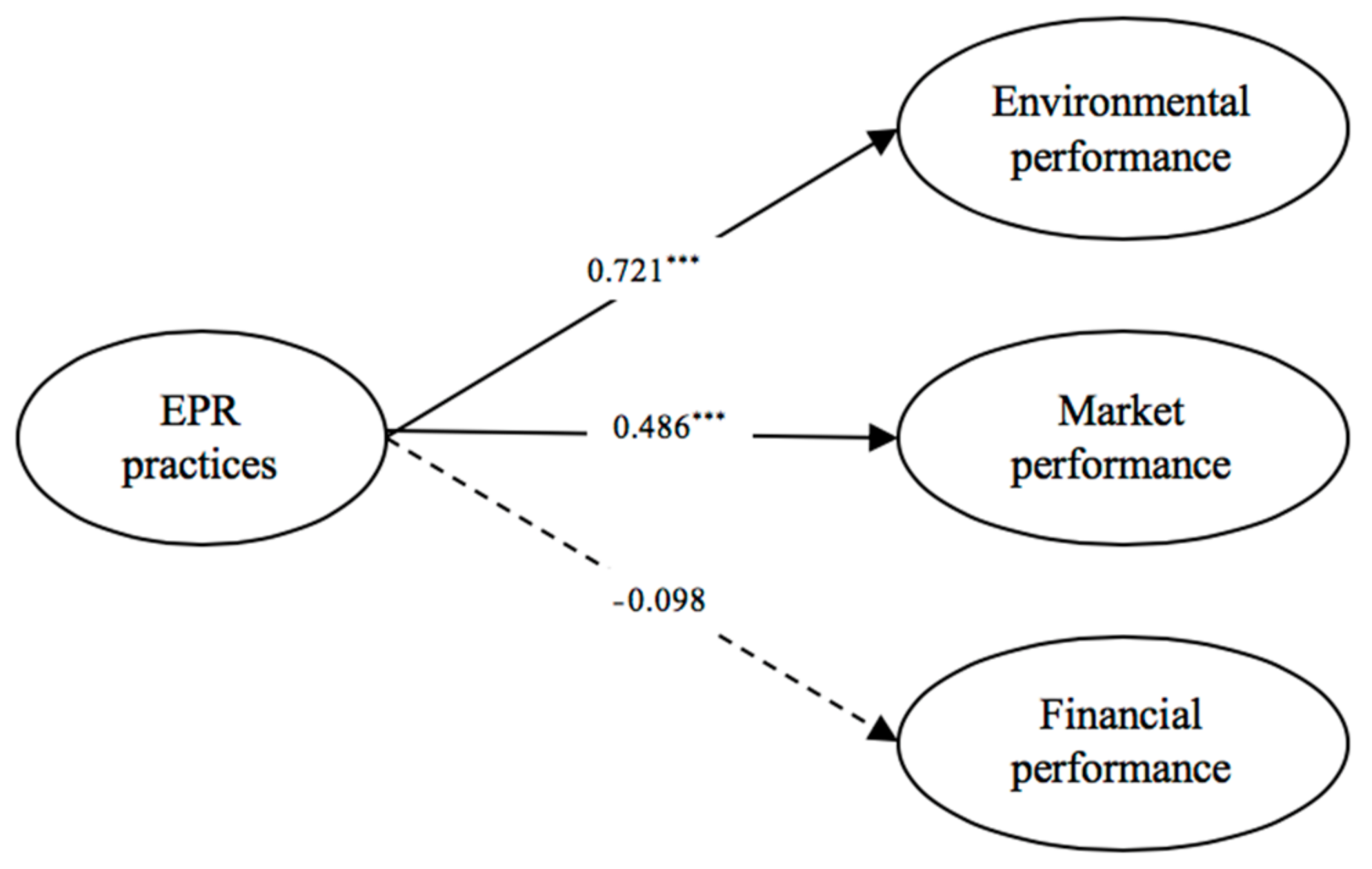

The hypotheses proposed above are verified by SEM, which is a common statistics research tool for confirmatory analysis. Specifically, in the SEM method, the hypothetical theoretical framework should be firstly established; statistical data is collected to verify whether this theoretical hypothesis can be supported. From the perspective of research methodology, SEM is good at solving problems that cannot be directly observed and explored as latent variables, which are reflected by variables or indicators that can be directly measured, thus establishing the relationship between latent variables. The reliability and validity of measures must be ideal enough to ensure the reliability of the SEM. This study uses Amos 22.0 to test the main effect of the SEM and verify the hypothesis by model fitting, path coefficient, and its significance. The estimations of the SEM are shown as

Figure 2.

Then we tested the fitting results by Amos. According to the fitting index standard, χ2/df value is 1.239, RMSEA = 0.045, RMR = 0.5, CFI = 0.974, TLI = 0.969, IFI = 0.975, GFI = 0.888, SRMR = 0.048, PGFI = 0.659, PNFI = 0.742. Among them, except for the GFI value of 0.888, which is slightly lower than the ideal value of 0.9, all other fitting indexes reach the ideal level. Therefore, the fitting is overall ideal.

The results of

Table 2 show that: First, the standardized path coefficient between EPR practices and environmental performance is 0.721, the

t-value is 6.736, which is significant at the level of 0.001. Based on the above data, there is a significant positive relationship between EPR practices and environmental performance. That is, the higher EPR practices degree of the enterprises, the better the environmental performance. Thus, H1 is verified. Second, the standardized path coefficient between EPR practices and market performance is 0.486, the

t-value is 5.478, which is significant at the level of 0.001. Thus, there is a significant positive relationship between EPR practices and market performance. That is, the higher the enterprises’ EPR practices degree, the better the market performance. H2 is also verified. Finally, the standardized path coefficient between EPR practices and financial performance is 0.098, and the

t-value is −0.962. The result is not significant, that is, enterprises EPR practices does not bring direct economic benefits. Therefore, H3 is not verified.

4.2. Moderating Effect Analysis

To verify Hypotheses 4–6, we conducted the hierarchical regression analysis (HRA) to test the moderating effect of governance mechanisms. According to the common method of moderating effect, we set the interaction items of the moderators and independent variables as new variables in the regression equation, then judged the existence of moderating effect by the significance of the regression coefficient of these interaction items. Before the hierarchical regression analysis, we first normalized each variable data to reduce the collinearity problem.

4.2.1. Moderating Effect of Governance Mechanism on the Relationship between EPR Behavior and Enterprise Environmental Performance

Taking environmental effect as the dependent variable, and taking EPR practices and various governance mechanisms (contract governance, relational governance, equity governance) and their corresponding interaction items as independent variables, this study performed a hierarchical regression to analyze the moderating effect of the model. The results are shown in

Table 3.

According to the results of model 1 and 2 in

Table 3, on the dimension of enterprise environmental performance, only the interaction items between contract governance mechanism and EPR practices has a significant effect on the environmental performance. The other two governance mechanisms (relational governance mechanism and equity governance mechanism) have no significant moderating effect. The results show that the contract governance mechanism can significantly positively moderate enterprise environmental performance when EPR is implemented by the enterprises. However, the relational governance mechanism and the equity governance mechanism have no positive moderating effect on enterprise environmental performance. Therefore, H4 is partially verified.

4.2.2. Moderating Effect of Governance Mechanism on the Relationship between EPR Behavior and Enterprise Market Performance

Taking market effect as the dependent variable, EPR practices and various governance mechanisms (contract governance, relational governance, and equity governance) and their corresponding interaction items as independent variables, we performed a hierarchical regression analysis on this model. According to the results of model 3 and 4 in

Table 3, on the dimension of market performance of EPR practices, all the interaction items of three governance mechanisms (contract governance mechanism, relational governance mechanism and equity governance mechanism) and EPR practices show significant effects on enterprise environmental performance. The results show that all three governance mechanisms can significantly positively adjust enterprise environmental performance when EPR is implemented by the enterprises, which is beneficial for market expansion. Thus, H5 is partially verified.

4.2.3. Moderating Effect of Governance Mechanism on the Relationship between EPR Behavior and Enterprise Financial Performance

Taking enterprise financial performance as the dependent variable, and taking EPR practices and various governance mechanisms and their corresponding interaction items as independent variables, we conducted a hierarchically regression analysis to test this model. According to the results of model 5 and 6 in

Table 3, on the dimension of enterprise financial performance, only the interaction item between equity governance mechanism and EPR practices has a significant effect on financial performance. The other two governance mechanisms (contract governance mechanism and relational governance mechanism) have no significant moderating effect. The results show that the equity governance mechanism has a significant positive moderating effect on enterprise financial performance and improve the manufacturers’ profits when EPR is implemented by the enterprises. However, the other two governance mechanisms have no positive moderating effect on enterprise financial performance. Therefore, H6 is partially verified.

In summary, the results of three hypotheses for the effects of independent variables (EPR practices) on dependent variables (environmental performance, market performance and financial performance) are shown in

Table 4. In terms of moderating effects of governance mechanisms, the obtained results indicate that all of these three governance mechanism has a significant positive moderating effect on enterprise market performance (H4b, H5b, H6b are supported), the contract governance mechanism has a significant positive moderating effect on the environmental performance (H5a is supported), while the relational and equity governance mechanism does not have a significant positive moderating effect on environmental performance (H4a, H6a are not supported). None of the three governance mechanisms have an impact on enterprise financial performance (H4c, H5c, H6c are not supported).

5. Discussion

According to the results above, the manufacturer’s EPR practices can significantly improve their environmental performance and market performance. At the same time, manufacturers can adjust their operation performance according to the choice of supplier governance mechanism, which is chosen based on the operation objectives of the enterprises. To be specific, if the enterprises want to obtain better environmental performance and improve their social image, they should choose the contract governance mechanism to explicitly stipulate the responsibility and obligation of the supplier. In addition, three governance mechanisms can improve the market performance of enterprises in EPR practices. The findings of this study provide implications and theory contribution to the enterprise EPR practices and suppliers’ choice of governance mechanisms.

On one hand, we explored the impact of EPR practices on enterprise performance. First, from the perspective of EPR practices performance, manufacturers’ EPR practices can improve environmental performance of enterprises and effectively reduce the negative impact of their production operations on the environment. The conclusions obtained are consistent with existing research. For example, EPR practices is efficient in reducing the environmental impact of enterprise operations, which has been verified by many scholars in the model research of a closed-loop supply chain [

8,

10]. In the field of empirical research, some scholars have also explored EPR practices and environmental effects and verified their positive correlations [

11]. Second, manufacturers can improve the market performance in the implementation of EPR, expand the market significantly, and help the promotion of products in the international market. The EPR practices of enterprises are an embodiment of corporate social responsibility and can enhance enterprise image to a certain extent. At the same time, enterprises that implement EPR will also promote the environmental protection of products and improve the degree of reusability and environmental protection of products. All the improvements above have a positive impact on consumers’ choices in purchasing behavior, increase consumers’ preference for products and the enterprises’ corresponding market performance [

8,

13]. EPR practices can also help enterprises to overcome green barriers in international trade, thus enabling them to gain more opportunities in international market expansion, improve negotiation and market position in international trade, and improve their product market performance [

12]. Third, we also find that EPR practices cannot bring direct economic benefits, which is different from the conclusion of Lai et al. (2012) who found that EPR practices are positively related to enterprises’ financial performance. The difference may be caused by the characteristics of the investigated sample [

11]. In the questionnaire of this study, we selected enterprises from the electronics industry in China as research samples. More remarkably, the characteristics of reverse logistics in the electronics industry include larger environmental hazards, higher processing costs and larger quantities, with a strong dependence on the reverse logistics and waste product processing technology of the enterprises. Barnett and Salomon (2006) propose that the relationship between the implementation of enterprises’ social responsibility and financial performance is related to various factors such as community, environment and manpower, and financial performance is constantly changing with time [

15]. Specifically, the implementation of enterprises’ social responsibility will reduce the financial performance in the short term, and as time changes, enterprise financial performance will gradually increase in the long term. This study provides theoretical support for our research conclusion to a certain extent. Moreover, we tried to verify the obtained conclusions in our research with relevant practitioners in the electronics industry of China, and received positive response from the perspective of enterprises’ actual operation. Some employees of relevant enterprises said that the development of EPR systems in the electronic industry in China is still immature, and the reverse logistics and closed-loop supply chain system and technology of enterprises are still in early stages. Therefore, it is difficult to achieve short-term profit through EPR practices.

On the other hand, we explored the relationship between governance mechanisms and enterprise performance. First, in the case of EPR practices, the contract governance mechanism for suppliers has a significant positive moderating effect on manufacturers’ environmental performance and market performance. That is, when cooperating with the supplier in the form of specific contract, manufacturers would explicitly stipulate the environmental protection nature of supplier, which helps to improve the manufacturer’s own environmental performance and market performance, and reduces the impact of enterprises’ production and operation on the environment. Moreover, it will further expand the product market and increase products sales. When the manufacturers implement EPR, the lack of contract management for suppliers may lead to reducing the environmental requirements for their products and production, thus affecting manufacturers’ performance to some extent. Therefore, in order to ensure its own environmental performance and market performance from the perspective of supplier management, enterprises should explicitly stipulate the relevant environmental protection and product design of suppliers, and regularly supervise them to avoid the moral hazard of suppliers, thus improving the manufacturer’s operations and reducing its environmental performance and market performance. When the manufacturers use a relational governance mechanism or an equity governance mechanism in supplier management during the implementation of EPR, both relational governance mechanism and equity governance mechanism have a significant positive moderating effect on their market performance. That is, they help manufacturers expand the product market and scale, increasing product sales and trade scope. However, they cannot influence manufacturers’ environmental performance. Second, in the case of manufacturers implementing EPR, on the one hand, enterprises can implement a relational governance mechanism by establishing long-term cooperative management with suppliers, thus to adjust the enterprise market performance and increase the product sales. Manufacturers can also choose to directly hold all or some of the equity of their suppliers and increase their decision-making power, thus positively moderating market performance.

6. Contribution and Future Research

From the perspective of supply chain governance, this paper introduces three types of supplier governance mechanisms—contract governance, relationship governance, and equity governance—and explores the influences on manufacturers’ performances. Based on the survey data of electronics enterprises in China as the research object, this paper finds that manufacturers’ EPR practices can significantly improve their environmental performance and market performance. At the same time, manufacturers can adjust their operation performance according to the choice of supplier governance mechanism, which is chosen based on the operation objectives of the enterprises. To be specific, if the enterprises tend to obtain better environmental performance and improve their social image, they should choose the contract governance mechanism to explicitly stipulate the responsibility and obligation of the supplier. In addition, three governance mechanisms can improve the market performance of enterprises in EPR practices.

However, there are several limitations to our research. First, this study selects electronics enterprises in China as research samples, because EPR is implemented more widely in the electronics industry than other sectors. However, it cannot represent the universal rules of EPR implementation. In future studies, we could collect questionnaire data from other industries (automobile, packaging, etc.), and obtain different conclusions and diverse managerial insights. Second, this research is carried out in China, which may reflect key conclusions applicable to most developing countries. In order to fully understand the impact of EPR practices on enterprise performance, we could conduct more research in developed countries, and compare the conclusions. In addition, in this research, supplier governance mechanisms are considered as a moderation variable to study the relationship between EPR implementation and enterprise performance. In future research, more moderation variables, such as government and consumer factors, could be studied and verified, which could provide valuable decision support for governments and policy makers.