A Conceptual Tool for the Implementation of the Circular Economy Emissions Reuse Closed Loops through Process Equipment

Abstract

:1. Introduction

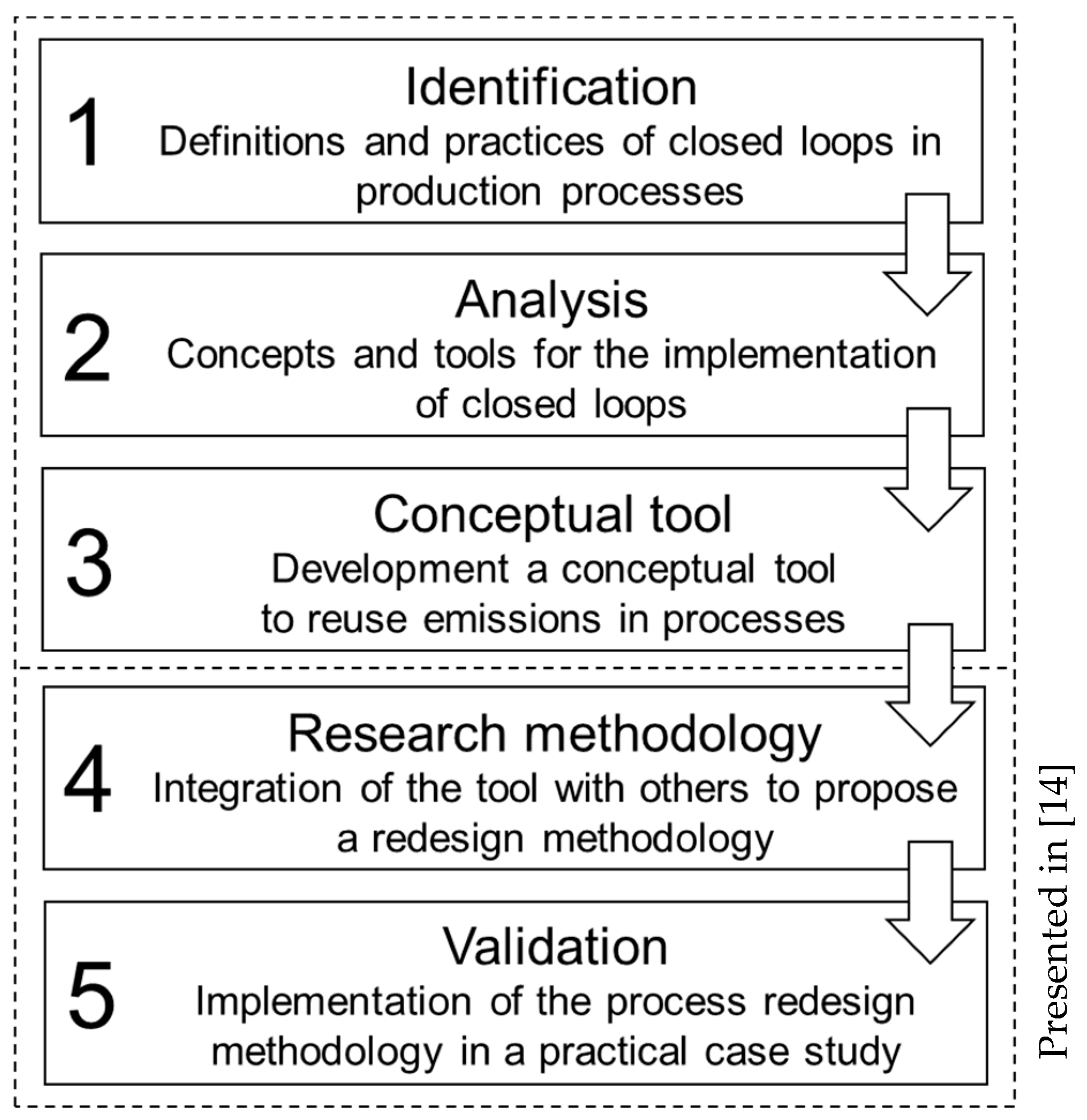

2. Methods

3. CE Emissions Reuse Closed Loops and Process Equipment Relationship

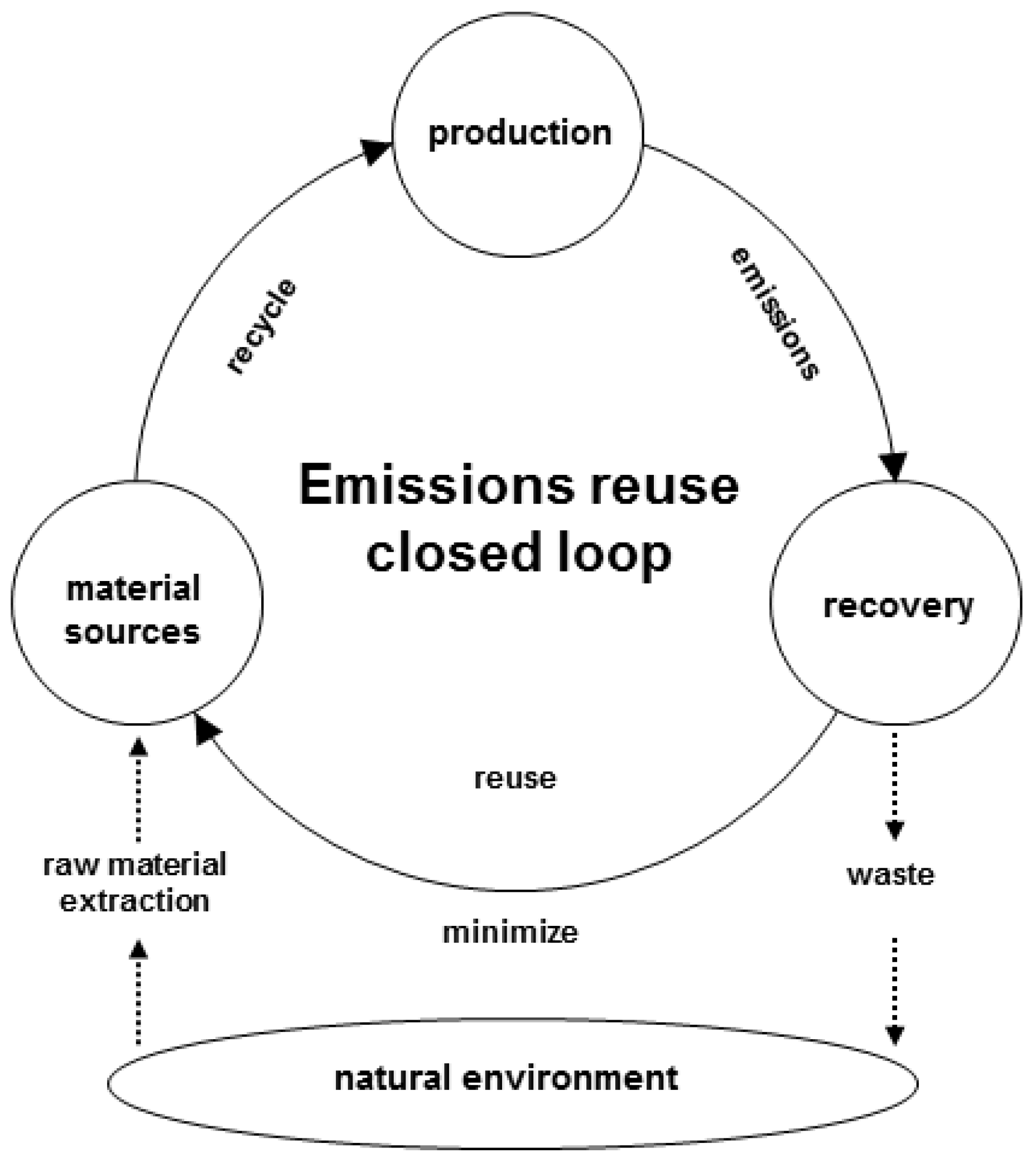

3.1. CE Closed Loops

3.2. Emissions Reuse Closed Loops in Production Processes

- (1)

- Input materials—Material substitution can reduce dramatically the input and the use of natural resources (material and energy) through the reduction or eliminating hazardous materials and the exchange of recycled resources in the production process [6].

- (2)

- Technology—Technological change include process and equipment modifications to reduce waste in production processes [25]. These may be changes in the process as an introduction of cleaner technologies or the redesign of equipment.

- (3)

- Performance of the process—Good housekeeping refers to all of the procedures in a company to reduce waste. Examples of this can be a good management practice, material handling, loss prevention, and production scheduling, as well as energy and water efficiency in the process.

- (4)

- Product—Product modification is about changing the characteristics of a product, such as its shape and material composition through eco-design [26] for the reduction of environmental impact.

- (5)

- Waste and emissions—Reuse involves the repeated use of waste and emissions (closed loop for material and energy) and recycling occurs when a process is able to utilize the waste and emissions from another production process [25].

3.3. Diachronic and Synchronic Dimensions of the Process Equipment

3.4. Summary

4. Development of the Conceptual Tool

4.1. Cleaner Production as a Base for the Conceptual Tool

4.2. Transverse Analysis of the Equipment Diachronic and Synchronic Dimensions

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Sarkis, J. Manufacturing’s Role in Corporate Environmental Sustainability Concerns for the New Millennium. Int. J. Oper. Prod. Manag. 2001, 21, 666–686. [Google Scholar] [CrossRef]

- Souza, G. Closed-Loop Supply Chains: A Critical Review, and Future Research. Decis. Sci. 2013, 44, 7–38. [Google Scholar] [CrossRef]

- ResearchGate. Available online: https://www.researchgate.net/profile/Eduardo_Zancul/publication/317179491_Cleaner_Production_Practices_Towards_Circular_Economy_Implementation_at_the_Micro-Level_An_empirical_investigation_of_a_home_appliance_manufacturer/links/5b0b0e4faca2725783ea5453/Cleaner-Production-Practices-Towards-Circular-Economy-Implementation-at-the-Micro-Level-An-empirical-investigation-of-a-home-appliance-manufacturer.pdf (accessed on 26 October 2018).

- Shahbazi, S.; Kurdve, M.; Bjelkemyr, M.; et al. Industrial Waste Management within Manufacturing: A Comparative Study of Tools, Policies, Visions and Concepts. In Proceedings of the 11th International Conference on Manufacturing Research (ICMR2013), Cranfield, UK, 19–20 September 2013; pp. 637–642. [Google Scholar]

- Zhang, H.; Kuo, T.; Lu, H. Environmentally Conscious Design and Manufacturing: A State-of-the-Art Survey. J. Manuf. Syst. 1997, 16, 352. [Google Scholar] [CrossRef]

- Curran, T.; Williams, I.D.A. Zero Waste Vision for Industrial Networks in Europe. J. Hazard. Mater. 2012, 207–208, 3–7. [Google Scholar] [CrossRef] [PubMed]

- Shan, Z.; Qin, S.; Liu, Q.; Liu, F. Key Manufacturing Technology & Equipment for Energy Saving and Emissions Reduction in Mechanical Equipment Industry. Int. J. Precis. Eng. Manuf. 2012, 13, 1095–1100. [Google Scholar] [CrossRef]

- Steelco. Available online: http://www.steelcospa.com/en/products-catalogue/medical-products/item/the-fast-cycle-concept (accessed on 4 March 2018).

- Girbau. Available online: http://www.girbau.es/productos-lavanderia/tbs-multi/TBS-Multi (accessed on 4 March 2018).

- Llorens, S. Bases Metodològiques per a Definir l’Arquitectura de Gamma de Producte d’Empreses Fabricants de Béns d’Equip Industrials. Ph.D. Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 29 July 2015. [Google Scholar]

- Ridaura, G.; Llorens-Cervera, S.; Carrillo, C.; Buj-Corral, I.; Riba-Romeva, C. Equipment Suppliers Integration to the Redesign for Emissions Reuse in Industrial Processes. Resour. Conserv. Recycl. 2018, 131, 75–85. [Google Scholar] [CrossRef]

- Kondoh, S.; Nishikiori, Y.; Umeda, Y. A Closed-Loop Manufacturing System Focusing on Reuse of Components. In Proceedings of the Fourth International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 12–14 December 2005; pp. 453–457. [Google Scholar]

- Guide, V.D.R.; Wassenhove, L.N. Closed-Loop Supply Chains: An Introduction to the Feature Issue (Part 1). Prod. Oper. Manag. 2009, 15, 345–350. [Google Scholar] [CrossRef]

- Morana, R.; Seuring, S. A Three Level Framework for Closed-Loop Supply Chain Management-Linking Society, Chain and Actor Level. Sustainability 2011, 3, 678–691. [Google Scholar] [CrossRef]

- Prendeville, S.; Sanders, C.; Sherry, J.; Costa, F. Circular Economy: Is It Enough? 2014. Available online: https://pdfs.semanticscholar.org/943c/814c3300b69a06bd411d2704ec3baa3a0892.pdf (accessed on 26 October 2018).

- European Commission. Available online: http://ec.europa.eu/environment/green-growth/tools-instruments/index_en.htm (accessed on 1 October 2018).

- ResCom. Available online: https://www.rescoms.eu/platform-and-tools (accessed on 1 October 2018).

- IISD. Available online: https://www.iisd.org/business/tools/bt_cp.aspx (accessed on 23 August 2018).

- Despeisse, M.; Ball, P.D.; Evans, S.; Levers, A. Industrial Ecology at Factory Level—A Conceptual Model. J. Clean. Prod. 2012, 31, 30–39. [Google Scholar] [CrossRef] [Green Version]

- Bilitewski, B. The Circular Economy and its Risks. Waste Manag. 2012, 32, 1–2. [Google Scholar] [CrossRef] [PubMed]

- UNIDO. Available online: http://www.unido.org/en/what-we-do/environment/resource-efficient-and-low-carbon-industrialproduction/ cp/benefits.html (accessed on 20 August 2018).

- Nilsson, L.; Persson, P.O.; Rydén, L.; Darozhka, S.; Zaliauskiene, A. Cleaner Production Technologies and Tools for Resource Efficient Production; Baltic University Press: Uppsala, Sweden, 2007; ISBN 9197552615. [Google Scholar]

- ISO (International Organization for Standardization). Environmental Management Systems—Guidelines for Incorporating Ecodesign; ISO 14006:2011: Geneva, Switzerland, 2011. [Google Scholar]

- Nowosielski, R. Sustainable technology as a basis of cleaner production. J. Achiev. 2007, 20, 527–530. [Google Scholar]

- ISO (International Organization for Standardization). Environmental Management Systems—Requirements with Guidance for Use; ISO 14001:2015: Geneva, Switzerland, 2015. [Google Scholar]

- Azapagic, A.; Millington, A.; Collett, A. A methodology for Integrating Sustainability Considerations into Process Design. Chem. Eng. Res. Des. 2006, 84, 439–452. [Google Scholar] [CrossRef]

- GOV.UK. Available online: https://www.gov.uk/guidance/best-available-techniques-environmental-permits (accessed on 1 October 2018).

- AZo Cleantech. Available online: https://www.azocleantech.com/article.aspx?ArticleID=532 (accessed on 21 August 2018).

- Adams, R.; Jeanrenaud, S.; Bessant, J.; Overy, P.; Denyer, D. Innovating for Sustainability; Routledge: London, UK, 2012; p. 107. [Google Scholar] [CrossRef]

- Cleaner Production for Process Industries. Available online: http://infohouse.p2ric.org/ref/13/12031.pdf (accessed on 26 October 2018).

- Lam, J.C.K.; Hills, P. Promoting Technological Environmental Innovations. In Green Finance and Sustainability; Luo, Z., Ed.; IGI Global: Pennsylvania, PA, USA, 2011; pp. 56–73. ISBN 1609605314. [Google Scholar]

- Hendrickson, C.; Horvath, A.; Joshi, S.; Lave, L. Economic Input-Output Models for Environmental Life-Cycle Assessment. Environ. Sci. Technol. Policy Anal. 1998, 32, 184A–191A. [Google Scholar] [CrossRef]

- Zokaei, K.; Lovins, H.; Wood, A.; Hines, P. Crating a Lean and Green Business System, Techniques for Improving Profits and Sustainability; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9781466571136. [Google Scholar]

- Fresner, J.; Jantschgi, J.; Birkel, S.; Bärnthaler, J.; Krenn, C. The theory of inventive problem solving (TRIZ) as option generation tool within cleaner production projects. J. Clean. Prod. 2010, 18, 128–136. [Google Scholar] [CrossRef]

- Riba, C.; Molina, A. Ingeniería Concurrente: Una Metodología Integradora; Edicions UPC: Barcelona, Spain, 2006; ISBN 978-84-8301-899-6. [Google Scholar]

- Kusiak, A. Concurrent Engineering: Automation, Tools and Techniques; Wiley-Interscience: New York, NY, USA, 1993. [Google Scholar]

- Zbicinski, I.; Stavenuiter, J. Product Design and Life Cycle Assessment; Baltic University Press: Uppsala, Sweden, 2006; ISBN 9197552623. [Google Scholar]

- Meyer, M.H.; Utterback, J.M. The Product Family and the Dynamics of Core Capability. MIT Sloan Manag. Rev. 1993, 34, 29–47. [Google Scholar]

- Meyer, M.H.; Lehnerd, A.P. The Power of Product Platforms: Building Value and Cost Leadership; The Free Press: New York, NY, USA, 1997. [Google Scholar]

- Miller, T.D.; Elgård, P. Designing product. In Proceedings of the 13th IPS Research Seminar, Fuglsø, Denmark, 20–21 April 1998; ISBN 87-89867-60-2. [Google Scholar]

- Robertson, D.; Ulrich, K. Platform Product Development. MIT Sloan Manag. Rev. 1998, 39, 19–31. [Google Scholar]

- Riba, C. Concurrent Design; Edicions UPC: Barcelona, Spain, 2002; ISBN 84-8301-598-6. [Google Scholar]

- Department of Taxation and Finance. Available online: https://www.tax.ny.gov/pubs_and_bulls/tg_bulletins/st/manufacturing_equipment.htm (accessed on 23 August 2018).

- Despeisse, M.; Ball, P.D.; Evans, S.; Levers, A. Industrial Ecology at Factory Level: A Prototype Methodology. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 1648–1664. [Google Scholar] [CrossRef] [Green Version]

| Equipment Life Cycle Phase | Relations between Equipment | ||

|---|---|---|---|

| Origination | Concept study | Equipment Family: Equipment of a company that share elements in their origination | |

| Design and development | |||

| Manufacturing | |||

| Destination | Use and maintenance | Equipment Portfolio: Equipment of the market (or of a company) that share elements in their destination | |

| End of life | |||

| Origination | Destination | Vision from an activity (beyond a manufacturing company) | Equipment Gamma: Equipment of the market that share elements in their origin, and destination (eventually recycling) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ridaura, G.; Llorens-Cervera, S.; Carrillo, C.; Buj-Corral, I.; Riba-Romeva, C. A Conceptual Tool for the Implementation of the Circular Economy Emissions Reuse Closed Loops through Process Equipment. Sustainability 2018, 10, 3912. https://doi.org/10.3390/su10113912

Ridaura G, Llorens-Cervera S, Carrillo C, Buj-Corral I, Riba-Romeva C. A Conceptual Tool for the Implementation of the Circular Economy Emissions Reuse Closed Loops through Process Equipment. Sustainability. 2018; 10(11):3912. https://doi.org/10.3390/su10113912

Chicago/Turabian StyleRidaura, Gregorio, Sonia Llorens-Cervera, Carmen Carrillo, Irene Buj-Corral, and Carles Riba-Romeva. 2018. "A Conceptual Tool for the Implementation of the Circular Economy Emissions Reuse Closed Loops through Process Equipment" Sustainability 10, no. 11: 3912. https://doi.org/10.3390/su10113912

APA StyleRidaura, G., Llorens-Cervera, S., Carrillo, C., Buj-Corral, I., & Riba-Romeva, C. (2018). A Conceptual Tool for the Implementation of the Circular Economy Emissions Reuse Closed Loops through Process Equipment. Sustainability, 10(11), 3912. https://doi.org/10.3390/su10113912