Markov-Chain Simulation-Based Analysis of Human Resource Structure: How Staff Deployment and Staffing Affect Sustainable Human Resource Strategy

Abstract

1. Introduction

2. Literature Review

2.1. Human Resources in Production and Logistics

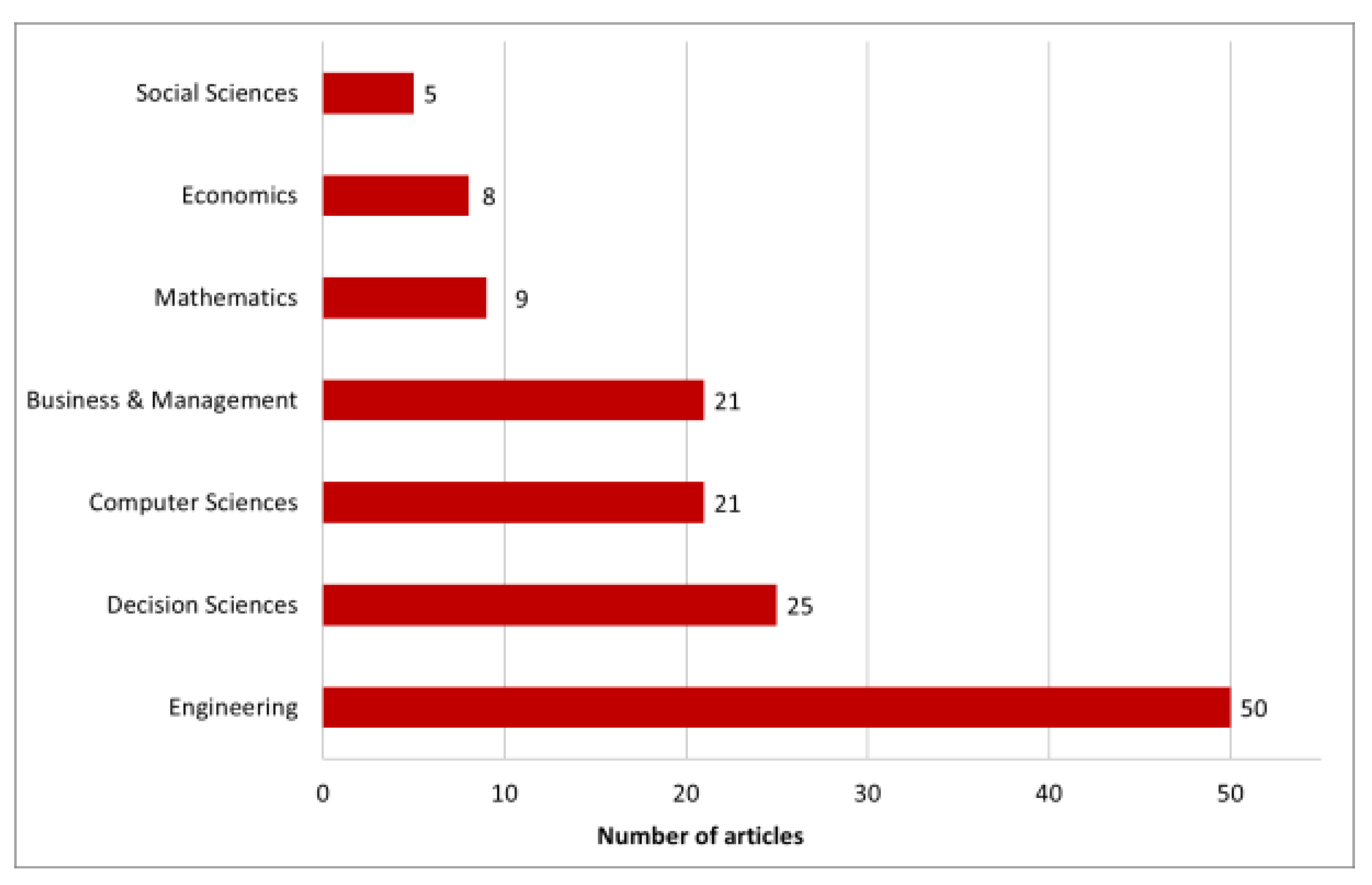

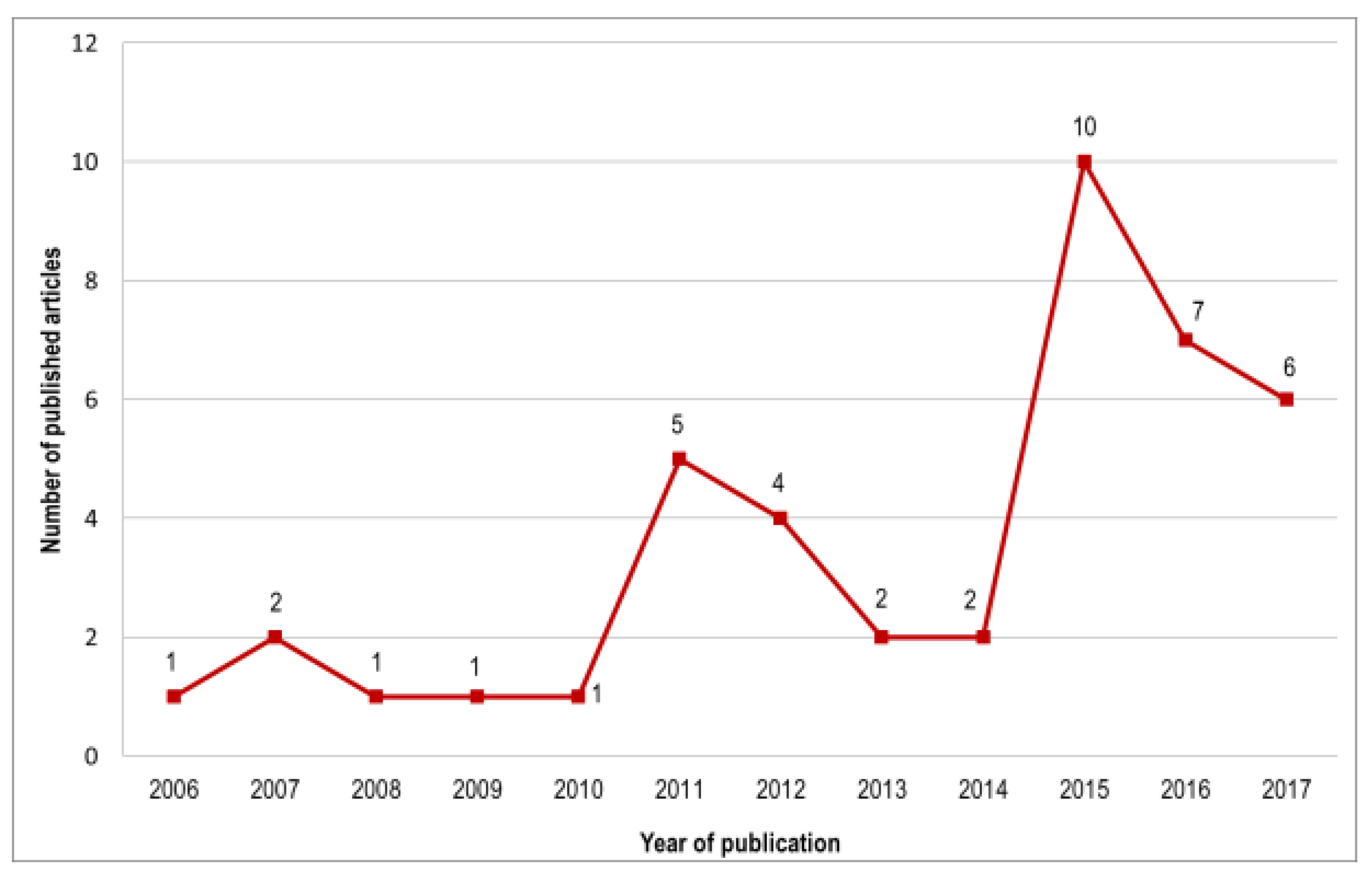

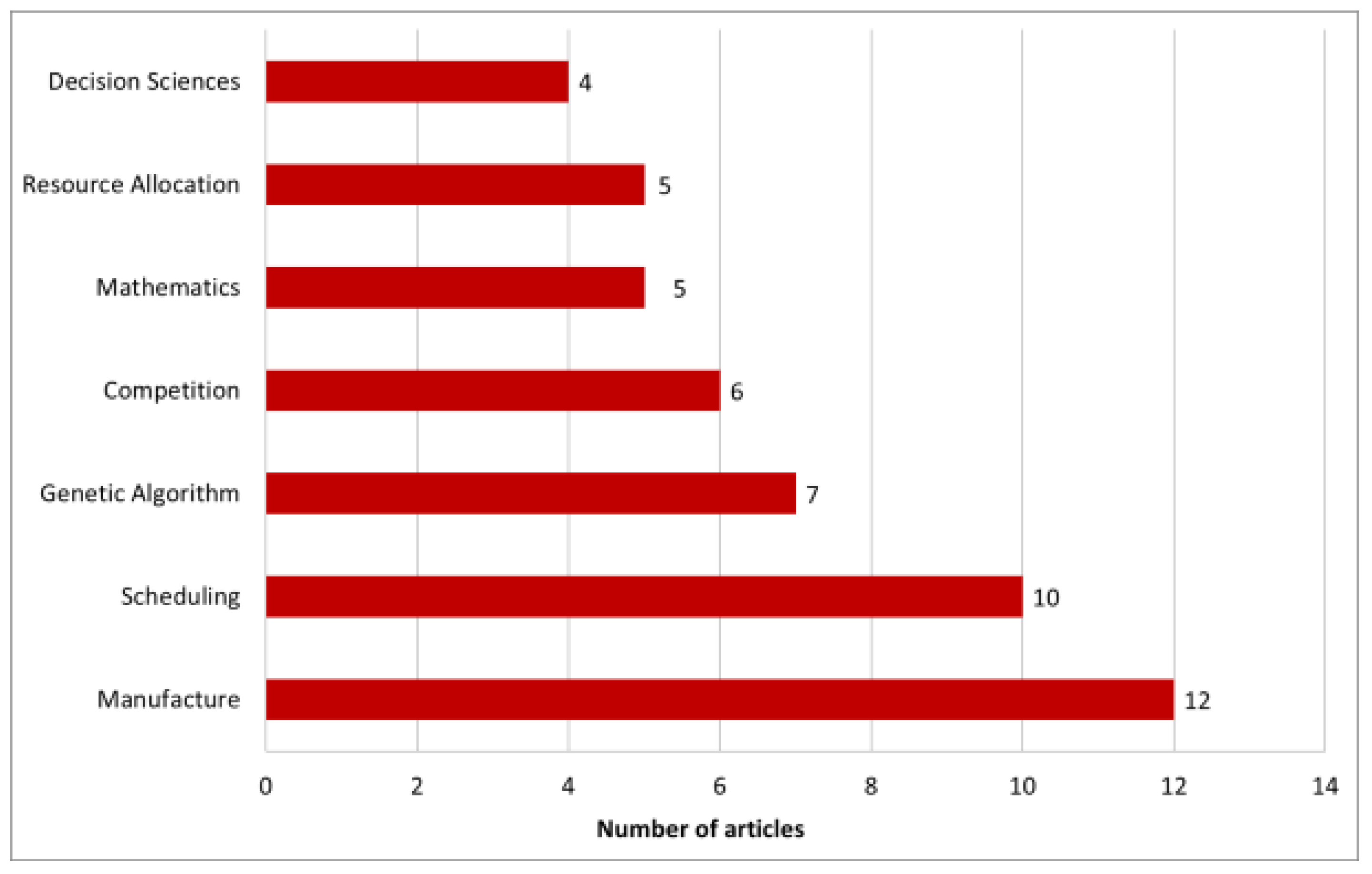

2.2. State of the Art in Human Resource Research

2.3. Markov-Chain Modelling

2.4. Consequences of Literature Review

3. Materials and Methods

4. Results

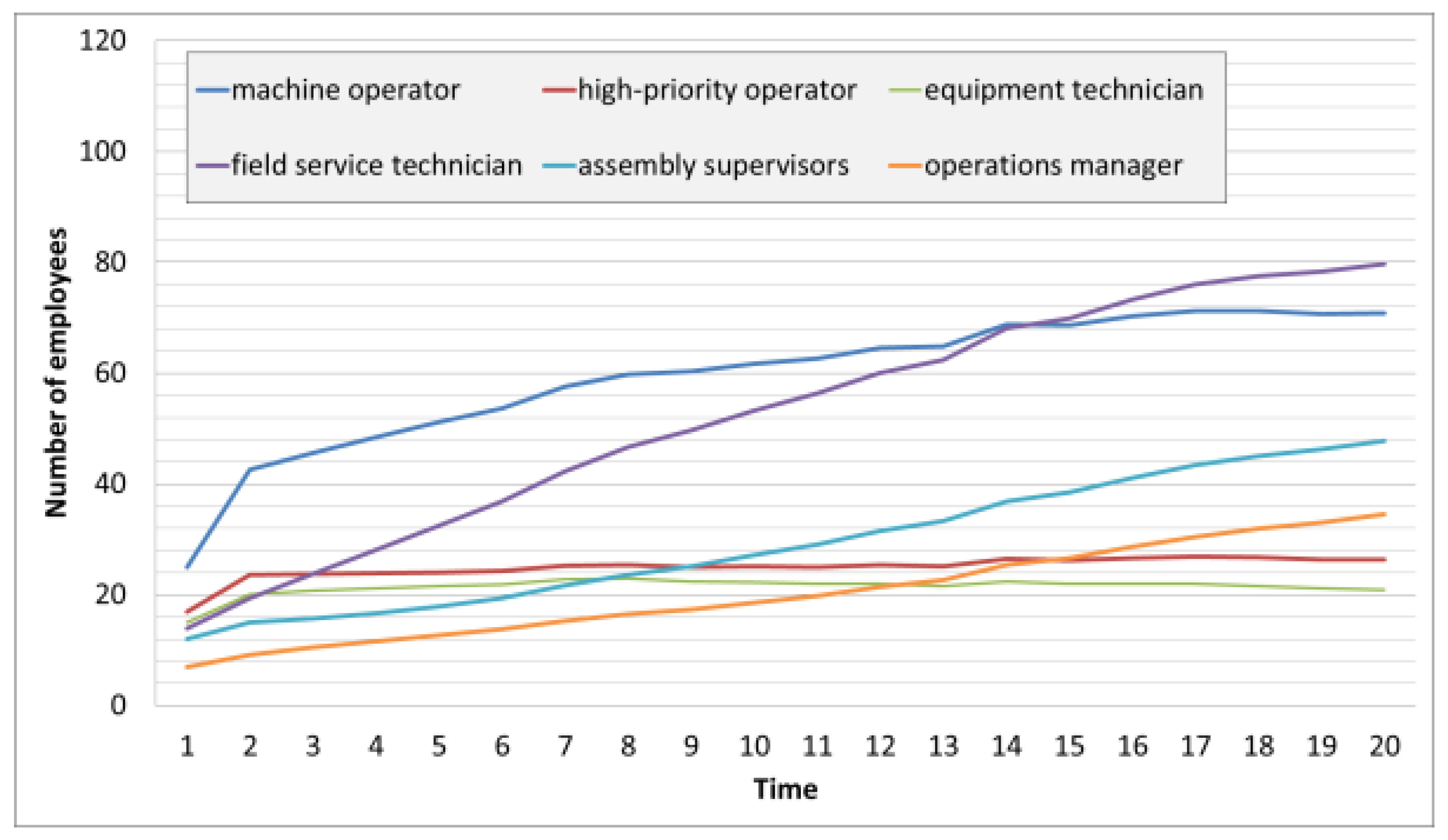

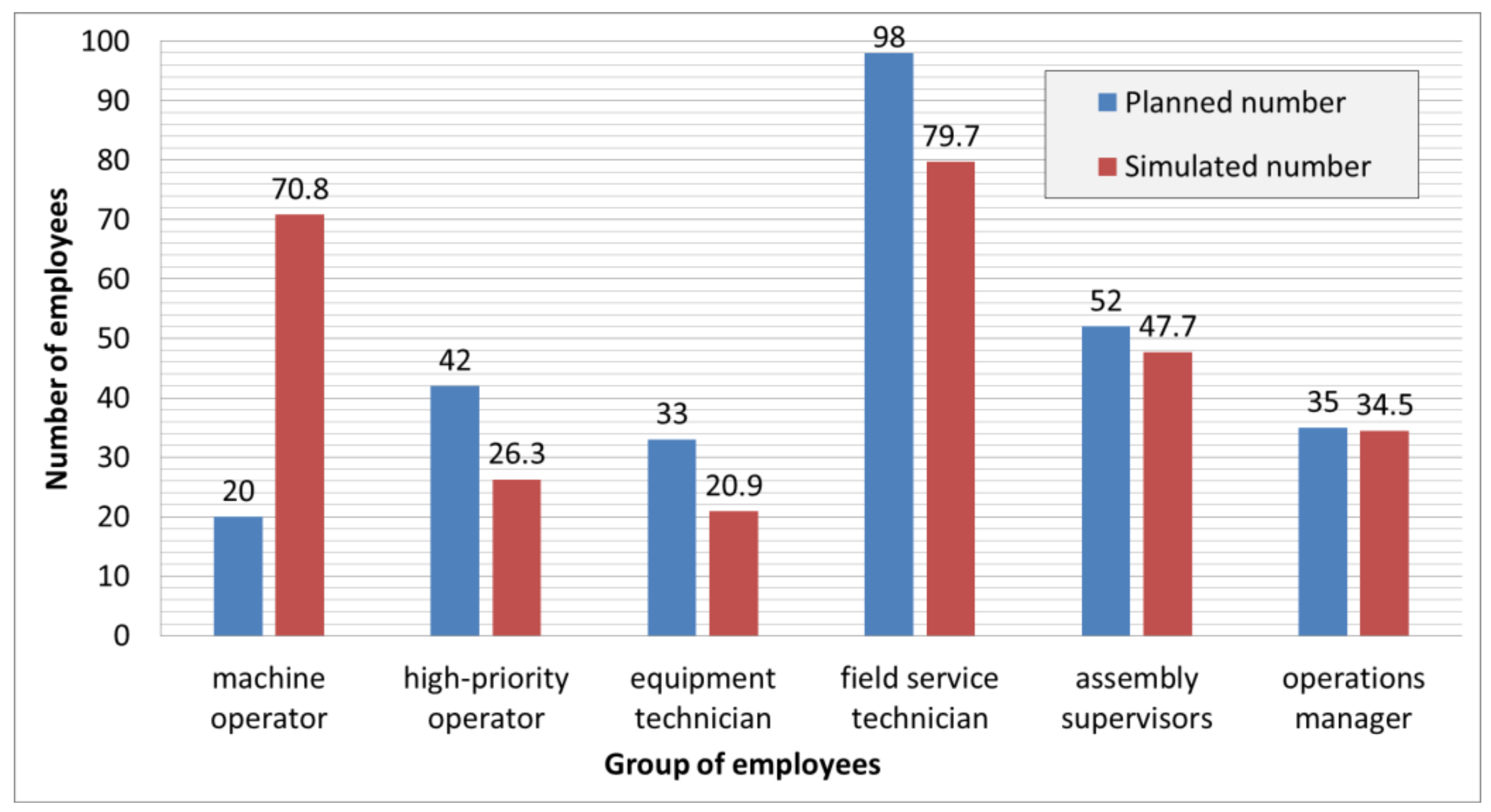

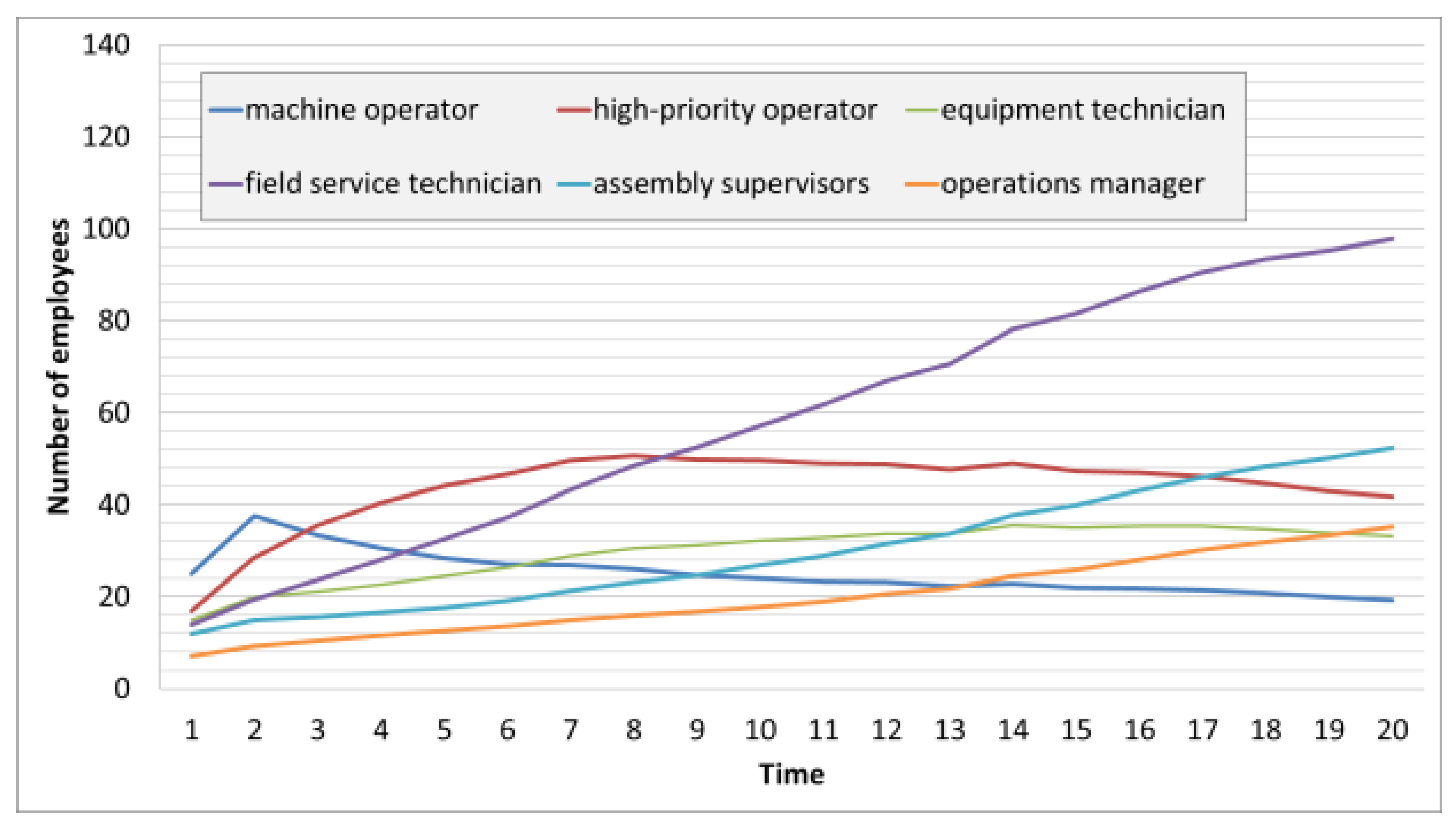

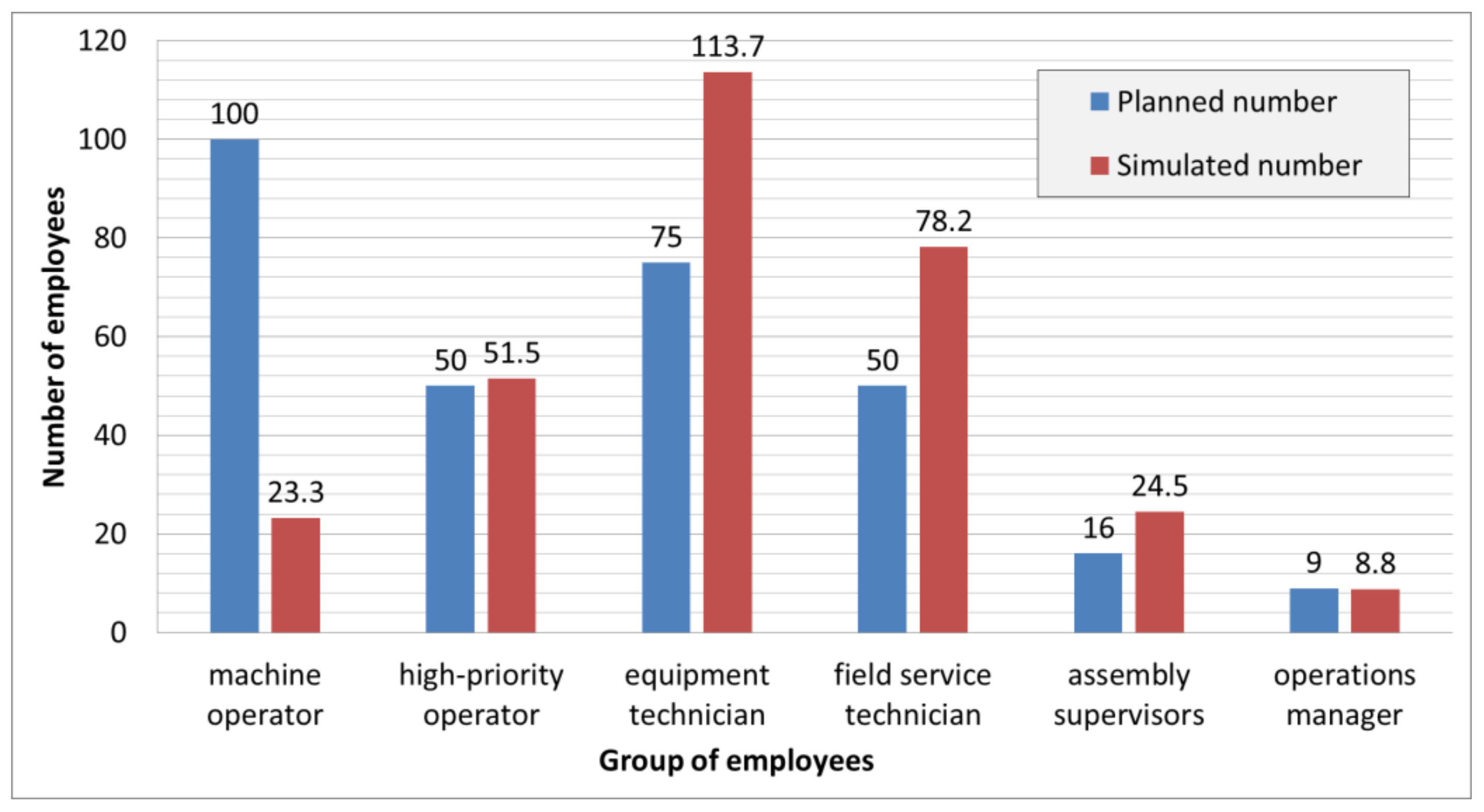

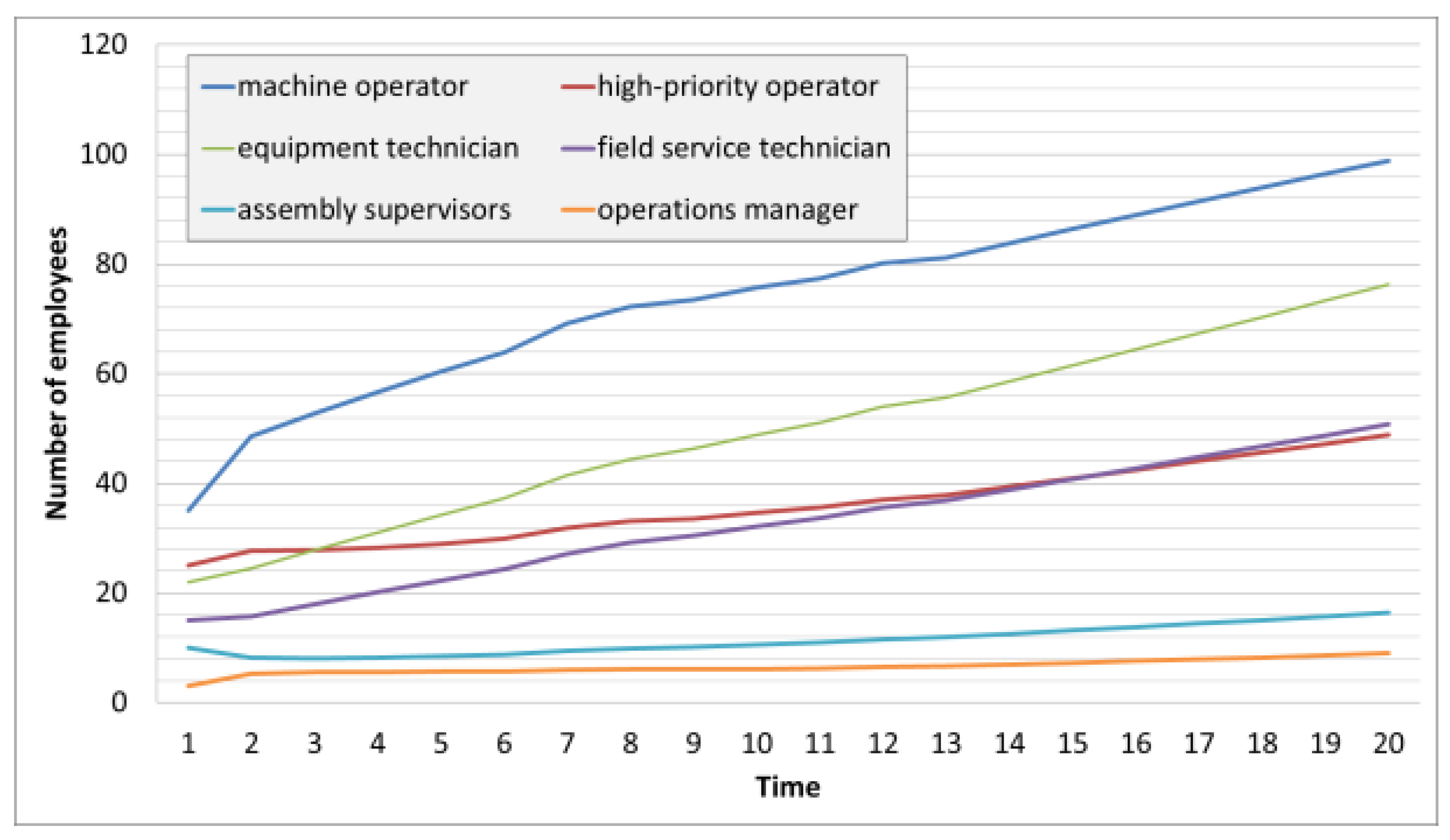

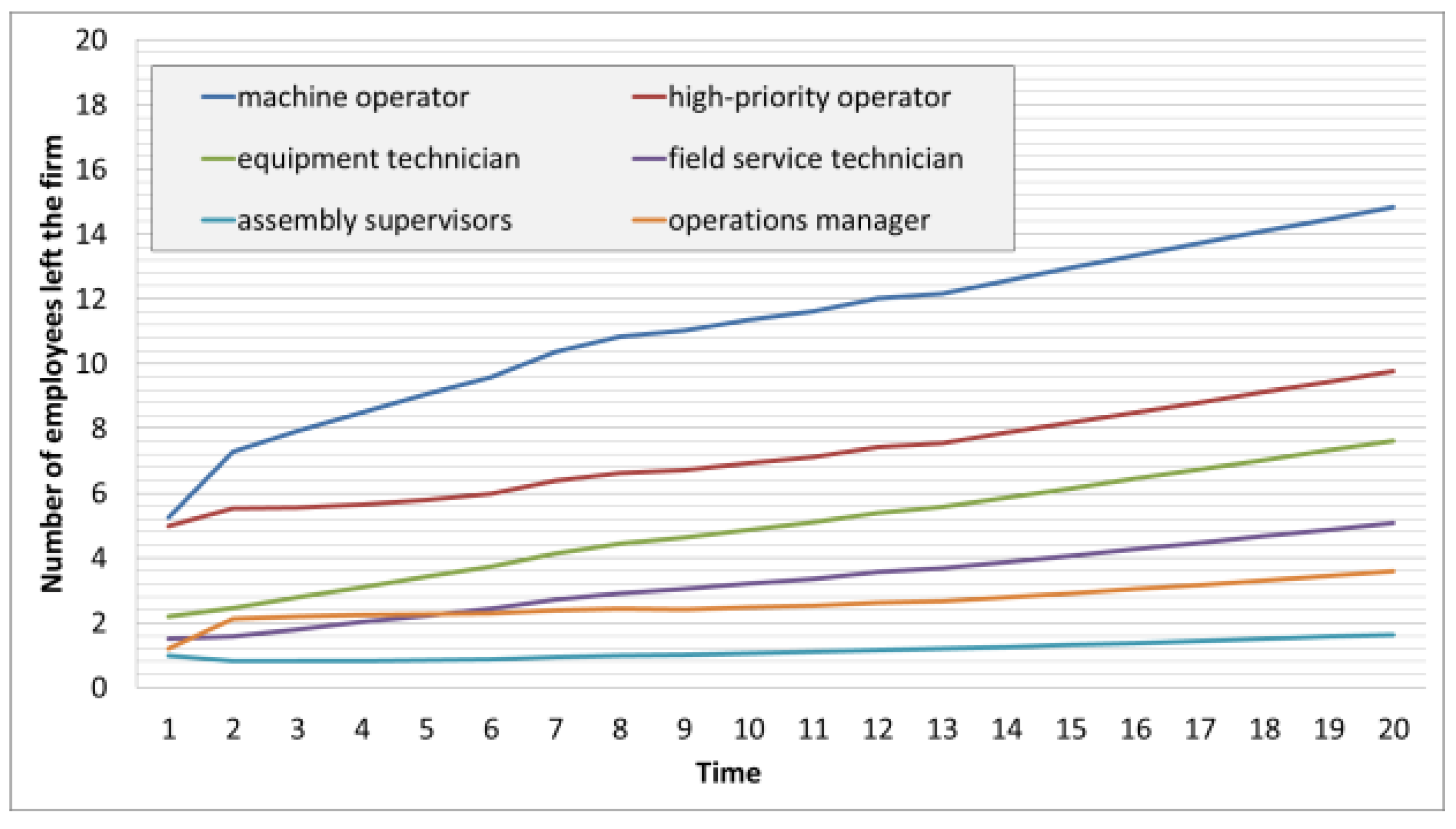

4.1. Scenario 1: Superdiagonal Promotion Matrix with Dynamic Recruitment Rate

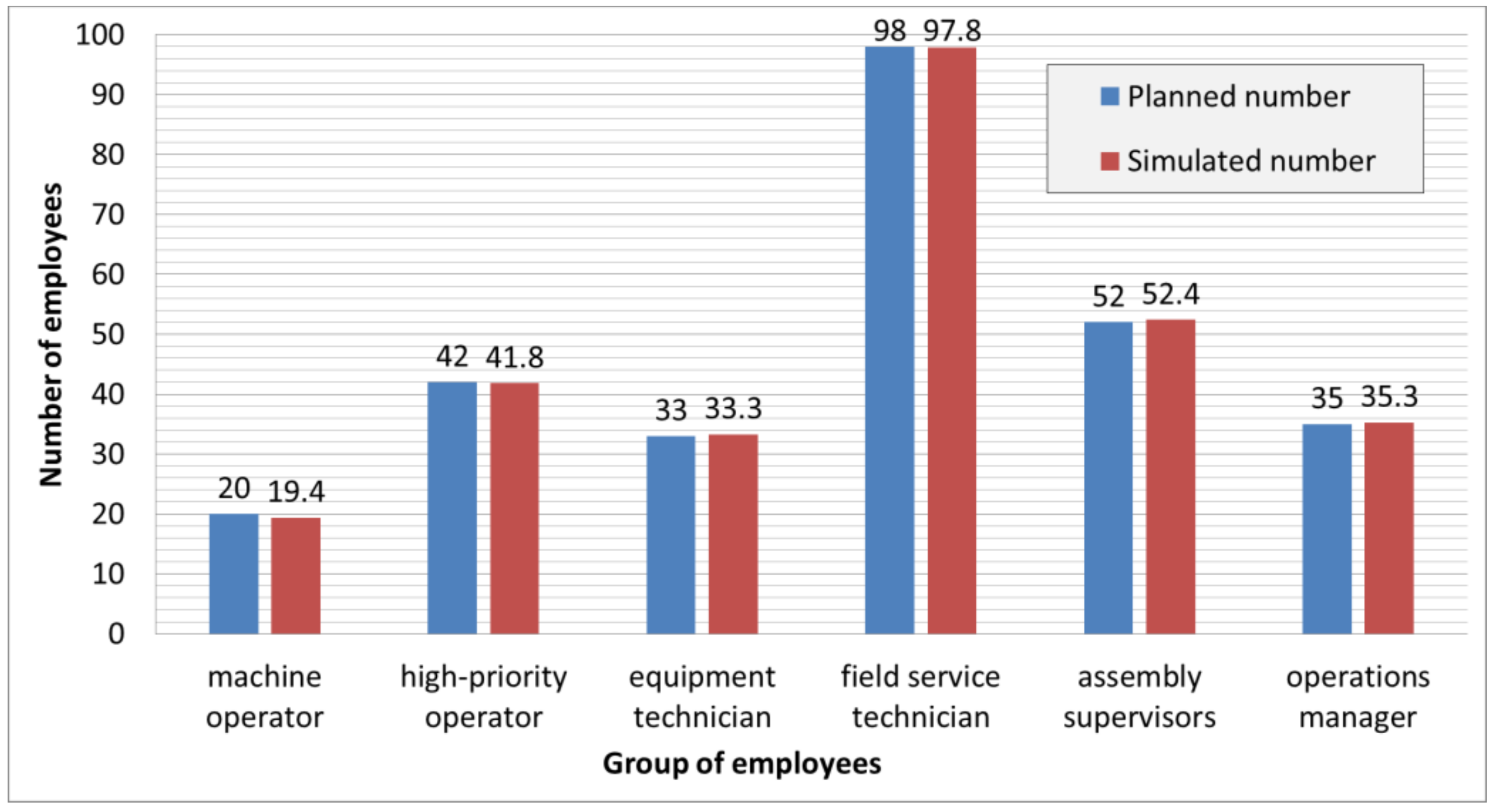

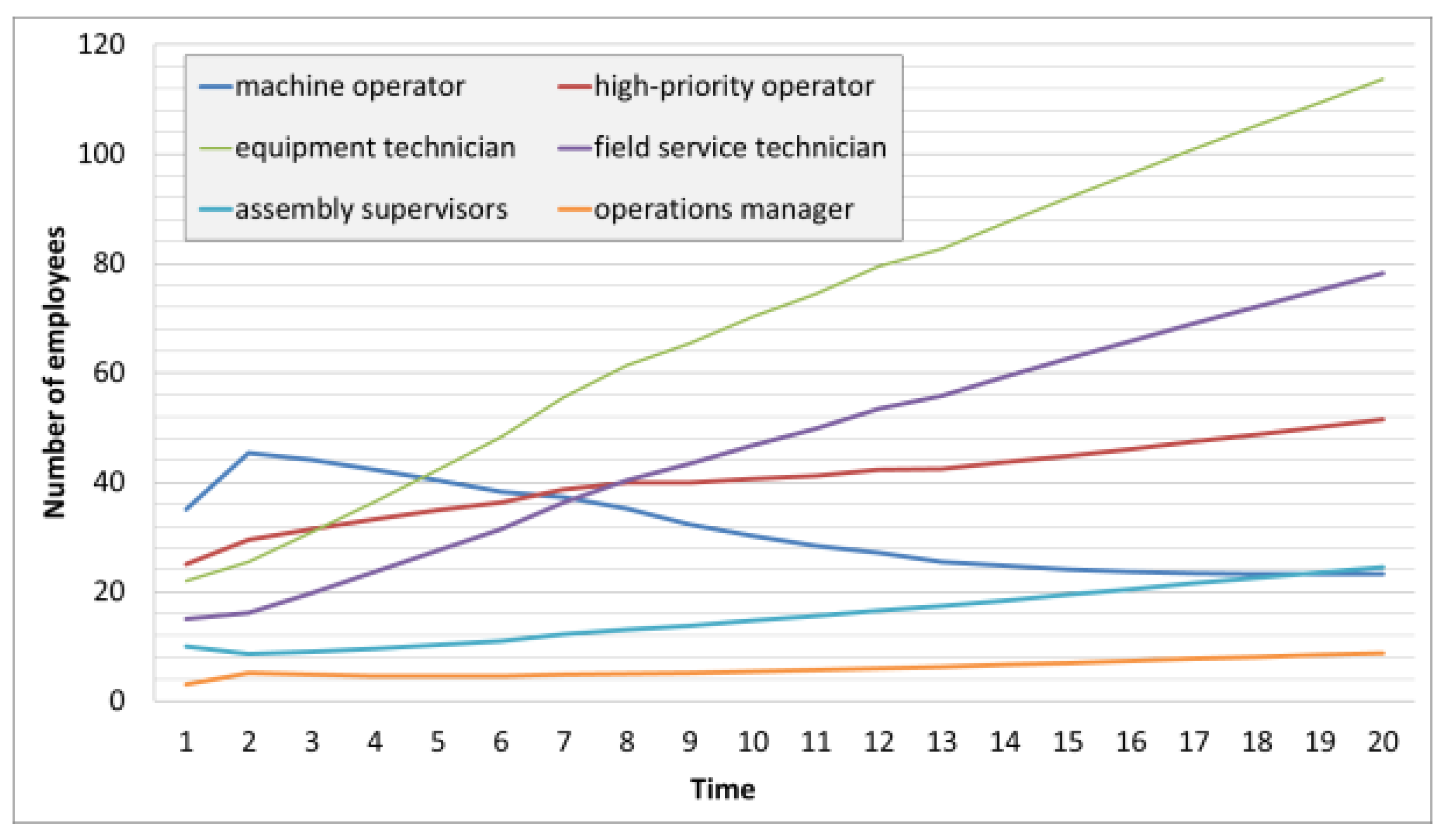

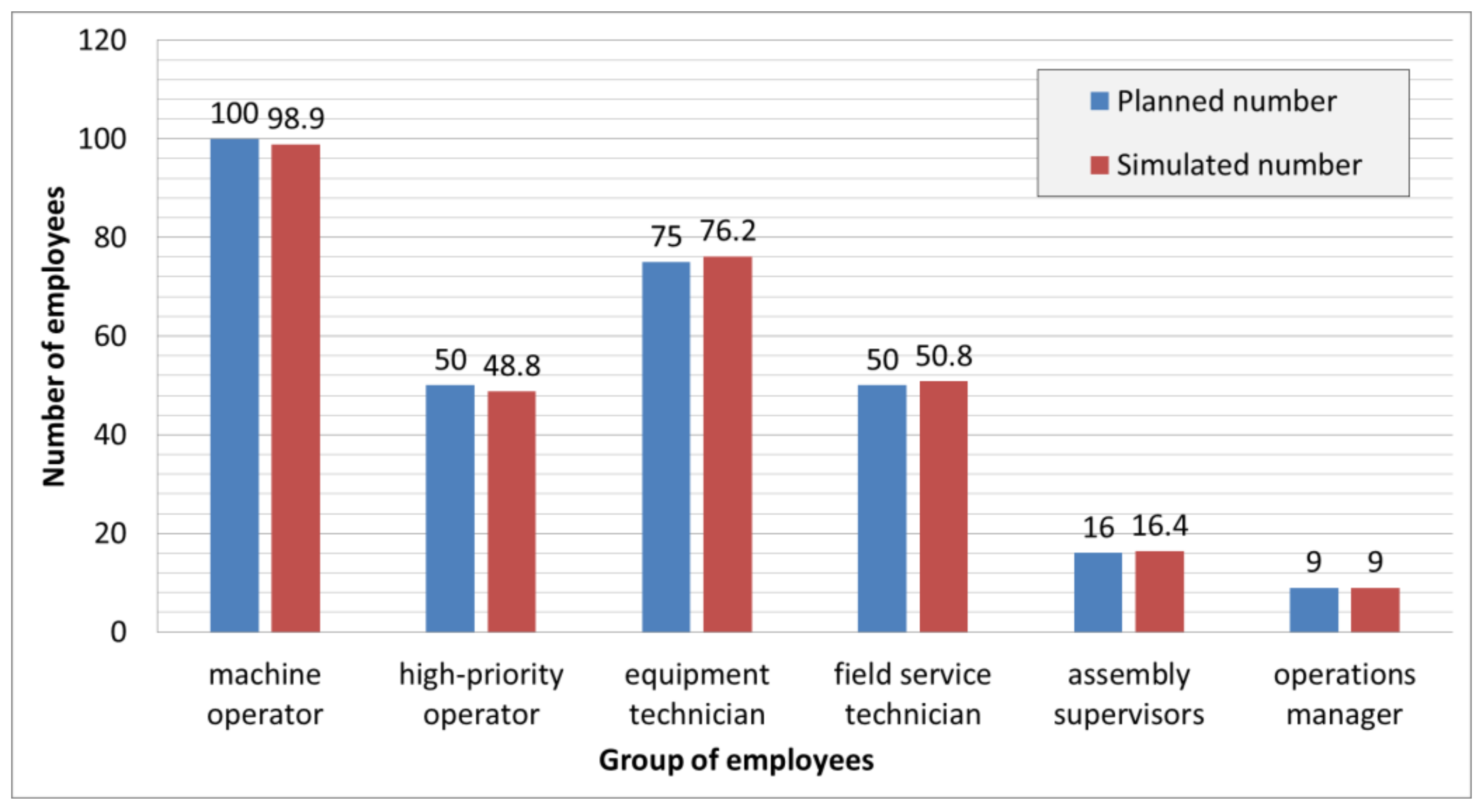

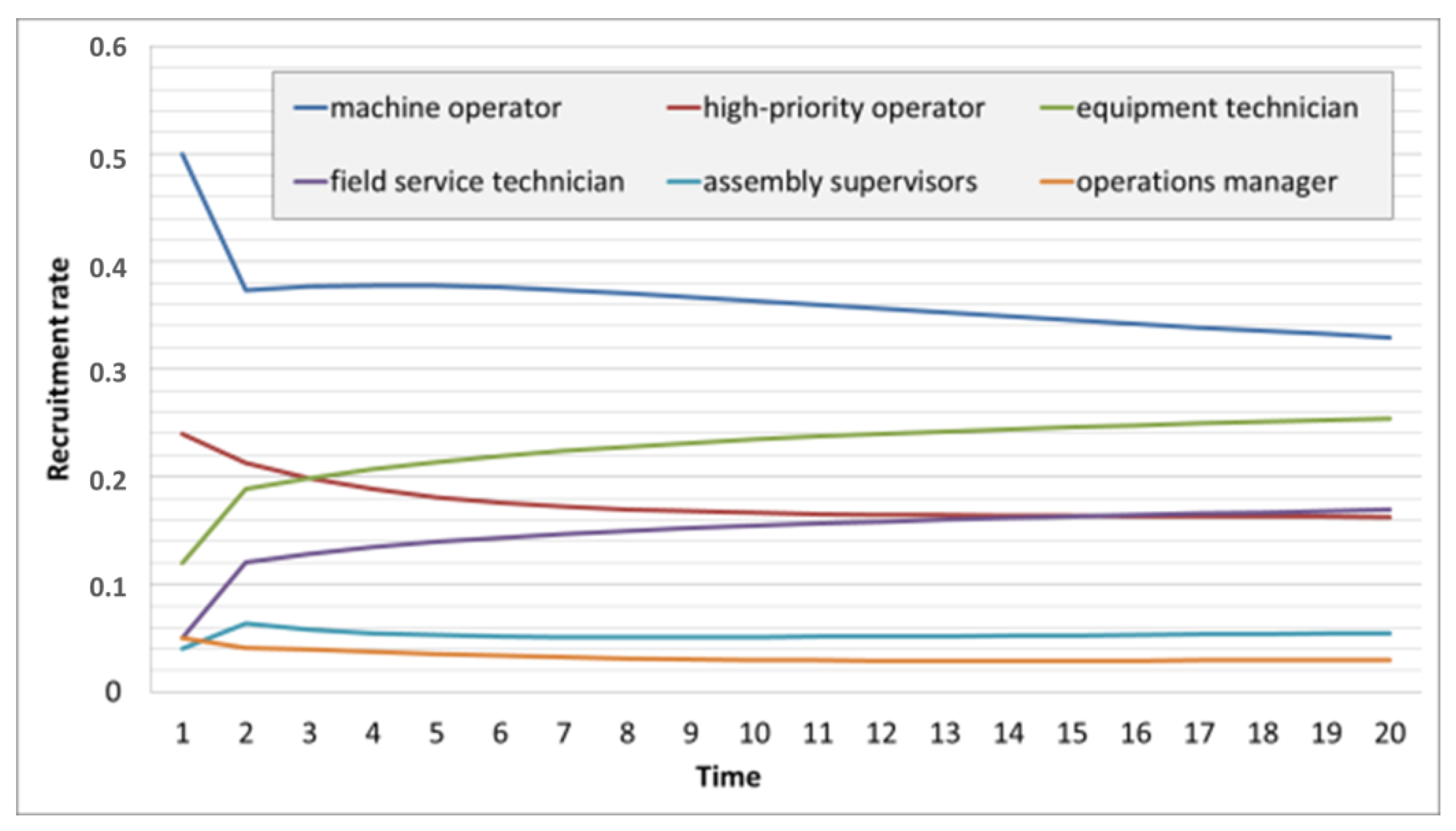

4.2. Scenario 2: Promotion Matrix with Sub- and Superdiagonal Elements with Dynamic Recruitment Rate

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Houdek, P.; Koblovský, P. Behavioural economics of organization: Employees and managers. Ekon. Manag. 2017, 20, 4–15. [Google Scholar] [CrossRef]

- Ibrahim, O.; Nossei, A. A Combined AHP and Source of Power Schemes for Prioritising Requirements Applied on a Human Resources. MATEC Web Conf. 2016, 76, 04016. [Google Scholar] [CrossRef]

- Mazur, B. Sustainable human resource management in theory and practice. Econ. Manag. 2014, 1, 158–170. [Google Scholar] [CrossRef]

- Lage, M.; Filho, G. Variations of the Kanban system: Literature review and classification. Int. J. Prod. Econ. 2010, 125, 13–21. [Google Scholar] [CrossRef]

- Fiorini, P.C.; Jabbour, C.J.C. Information systems and sustainable supply chain management towards a more sustainable society: Where we are and where we are going. Int. J. Inform. Manag. 2017, 37, 241–249. [Google Scholar] [CrossRef]

- Dean, B.V.; Yu, Y.-M.; Schniederjans, M.J. A goal programming approach to production planning for flexible manufacturing systems. J. Eng. Technol. Manag. 1990, 6, 207–220. [Google Scholar] [CrossRef]

- Delgoshaei, A.; Ali, A. An applicable method for scheduling temporary and skilled-workers in dynamic cellular manufacturing systems using hybrid ant colony optimization and tabu search algorithms. J. Ind. Prod. Eng. 2017, 34, 425–449. [Google Scholar] [CrossRef]

- Jong, W.-R.; Lai, P.-J. The navigation process of mould-manufacturing scheduling optimisation by applying genetic algorithm. Int. J. Comput. Integr. Manuf. 2015, 28, 1331–1349. [Google Scholar] [CrossRef]

- Ko, H.J.; Evans, G.W. A genetic algorithm-based heuristic for the dynamic integrated forward/reverse logistics network for 3PLs. Comput. Oper. Res. 2007, 34, 346–366. [Google Scholar] [CrossRef]

- Campos Ciro, G.; Dugardin, F.; Yalaoui, F.; Kelly, R. Open shop scheduling problem with a multi-skills resource constraint: A genetic algorithm and an ant colony optimisation approach. Int. J. Prod. Res. 2016, 54, 4854–4881. [Google Scholar] [CrossRef]

- Xiang, W.; Yin, J.; Lim, G. An ant colony optimization approach for solving an operating room surgery scheduling problem. Comput. Ind. Eng. 2015, 85, 335–345. [Google Scholar] [CrossRef]

- Delgoshaei, A.; Ariffin, M.K.A.; Ali, A. A multi-period scheduling method for trading-off between skilled-workers allocation and outsource service usage in dynamic CMS. Int. J. Prod. Res. 2017, 55, 997–1039. [Google Scholar] [CrossRef]

- Brusco, M.J. A bicriterion algorithm for the allocation of cross-trained workers based on operational and human resource objectives. Eur. J. Oper. Res. 2015, 247, 46–59. [Google Scholar] [CrossRef]

- Ferjani, A.; Ammar, A.; Pierreval, H.; Elkosantini, S. A simulation-optimization based heuristic for the online assignment of multi-skilled workers subjected to fatigue in manufacturing systems. Comput. Ind. Eng. 2017, 112, 663–674. [Google Scholar] [CrossRef]

- Pramanik, S.; Jana, D.K.; Maiti, M. Bi-criteria solid transportation problem with substitutable and damageable items in disaster response operations on fuzzy rough environment. Soc. Econ. Plan. Sci. 2016, 55, 1–13. [Google Scholar] [CrossRef]

- Karande, P.; Chakraborty, S. A fuzzy-MOORA approach for ERP system selection. Decis. Sci. Lett. 2012, 1, 11–22. [Google Scholar] [CrossRef]

- Liao, M.-S.; Lin, S.-C.; Liang, G.-S.; Chen, C.-Y. Improving the management and operational success of the third party logistics industry in Taiwan: Application of fuzzy quality function deployment. J. Test. Eval. 2015, 43, 201–211. [Google Scholar] [CrossRef]

- Addo-Tenkorang, R.; Helo, P.T.; Kantola, J. Concurrent enterprise: A conceptual framework for enterprise supply-chain network activities. Enterp. Inf. Syst. 2017, 11, 474–511. [Google Scholar] [CrossRef]

- Pathak, S.; Mondal, S.S. A fuzzy optimization model to the aggregate production/distribution planning decision in a multi-item supply chain network. Int. J. Manag. Eng. Manag. 2012, 7, 163–173. [Google Scholar] [CrossRef]

- Lewczuk, K. The concept of genetic programming in organizing internal transport processes. Arch. Transp. 2015, 34, 61–74. [Google Scholar] [CrossRef][Green Version]

- Stajniak, M.; Guszczak, B. Analysis of logistics processes according to BPMN Methodology. Adv. Eng. Res. 2011, 537–549. [Google Scholar] [CrossRef]

- Kramer, R.; Maculan, N.; Subramanian, A.; Vidal, T. A speed and departure time optimization algorithm for the pollution-routing problem. Eur. J. Oper. Res. 2015, 247, 782–787. [Google Scholar] [CrossRef]

- Koltai, T.; Tatay, V.; Kalló, N. Application of the results of simple assembly line balancing models in practice: The case of a bicycle manufacturer. Int. J. Comput. Integr. Manuf. 2014, 27, 887–898. [Google Scholar] [CrossRef]

- Jamshidi, R.; Seyyed Esfahani, M.M. Human resources scheduling to improve the product quality according to exhaustion limit. TOP 2013, 22, 1028–1041. [Google Scholar] [CrossRef]

- Kolisch, R.; Heimerl, C. An efficient metaheuristic for integrated scheduling and staffing IT projects based on a generalized minimum cost flow network. Nav. Res. Log. 2012, 59, 111–127. [Google Scholar] [CrossRef]

- Chen, J.; Lee, C.-Y. General multiprocessor task scheduling. Nav. Res. Logist. 1999, 46, 72–74. [Google Scholar] [CrossRef]

- Wang, W.; Huang, X.; Xie, J. Study on optimizing resources configuration of value activity network of manufacturing clusters. Kybernetes 2012, 41, 953–962. [Google Scholar] [CrossRef]

- Paquet, M.; Martel, A.; Montreuil, B. A manufacturing network design model based on processor and worker capabilities. Int. J. Prod. Res. 2008, 46, 2009–2030. [Google Scholar] [CrossRef]

- Forrai, M.K.; Kulcsár, G. A new scheduling software for supporting automotive component manufacturing. Lect. Notes Eng. 2017, F12, 257–274. [Google Scholar] [CrossRef]

- Forrai, M.K.; Kulcsár, G. Modelling and Solving an Extended Parallel Resource Scheduling Problem in the Automotive Industry. Acta Politech. Hung. 2017, 14, 27–46. [Google Scholar]

- Di Francesco, M.; Manca, A.; Zanda, S.; Zuddas, P. Planning and optimising manpower management in a transshipment container terminal. Eur. J. Ind. Eng. 2016, 10, 777–793. [Google Scholar] [CrossRef]

- Fang, L.; Li, X.; Li, A. Analysis of the symbiotic relationship between managers and staff with an application for coal mine safety management. Int. J. Eng. Res. Afr. 2015, 16, 156–165. [Google Scholar] [CrossRef]

- Jong, W.-R.; Lai, P.-J.; Lo, C.-W. Applying ant colony system algorithm in the navigation process for plastic injection mould manufacturing scheduling optimization. Int. J. Prod. Res. 2014, 52, 2530–2549. [Google Scholar] [CrossRef]

- Calciolari, S.; Ferrari, D.; Ortiz, L.G.; Meneguzzo, M. Organizing healthcare in remote rural areas: Comparing experiences of service delivery re-design. Int. J. Healthc. Manag. 2016, 9, 190–200. [Google Scholar] [CrossRef]

- Huang, L.; Zhao, W.; Xie, G.; Xie, H.; Yi, Q. Evaluating and optimizing city E-commerce competitiveness based on FA-CA Model: A case from 32 cities in China. Revista de la Facultad de Ingenieria 2017, 32, 298–308. [Google Scholar]

- Lee, K.K.; Shan, R.M.Y.; Leung, H.C.H.; Li, J.W.H. Competency enhancement model of physical infrastructure and asset management in compliance with PAS-55 for Hong Kong automotive manufacturing engineers. Lect. Notes Mech. Eng. 2015, 19, 729–737. [Google Scholar] [CrossRef]

- Lebreton, B.G.M.; Van Wassenhove, L.N.; Bloemen, R.R. Worldwide sourcing planning at Solutia’s glass interlayer products division. Int. J. Prod. Res. 2010, 48, 801–819. [Google Scholar] [CrossRef]

- Labuttis, J. Ergonomics as Element of Process and Production Optimization. Procedia Manuf. 2015, 3, 4168–4172. [Google Scholar] [CrossRef]

- Shibin, K.T.; Gunasekaran, A.; Papadopoulos, T.; Childe, S.J.; Dubey, R.; Singh, T. Energy sustainability in operations: An optimization study. Int. J. Adv. Manuf. Technol. 2016, 86, 2873–2884. [Google Scholar] [CrossRef][Green Version]

- Ardeleanu, M.P. Corporate environmental sustainability. Qual. Access Success 2011, 12, 347–351. [Google Scholar]

- Huber, V.L.; Brown, K.A. Human resource issues in cellular manufacturing: A sociotechnical analysis. J. Oper. Manag. 1991, 10, 138–159. [Google Scholar] [CrossRef]

- Boon, B.H.; Sierksma, G. Team formation: Matching quality supply and quality demand. Eur. J. Oper. Res. 2003, 148, 277–292. [Google Scholar] [CrossRef]

- Lai, X.; Xie, M.; Tan, K.-C. QFD optimization using linear physical programming. Eng. Optim. 2006, 38, 593–607. [Google Scholar] [CrossRef]

- Marksberry, P.; Parsley, D. Managing the IE (Industrial Engineering) mindset: A quantitative investigation of Toyota’s practical thinking shared among employees. J. Ind. Eng. Manag. 2011, 4, 771–779. [Google Scholar] [CrossRef]

- Tamošiūnas, A. The integrative management model for restructuring small and medium-sized enterprises. Ekon. Manag. 2017, 20, 36–51. [Google Scholar] [CrossRef]

- Bányai, Á. How to support purchasing with ERP systems as integrator of novel logistic tools? Adv. Log. Syst. 2013, 7, 7–12. [Google Scholar]

- Dröge, C.; Jayaram, J.; Vickery, S.K. The ability to minimize the timing of new product development and introduction: An examination of antecedent factors in the North American automobile supplier industry. J. Prod. Innov. Manag. 2000, 17, 24–40. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Y.; Sun, L. Study of integrated management mechanism and implement ways in reengineering product innovation process of manufacturing enterprises. Chin. J. Mech. Eng. 2000, 13, 127–132. [Google Scholar] [CrossRef]

- Chen, F.; Sekiyama, K.; Huang, J.; Sun, B.; Sasaki, H.; Fukuda, T. An assembly strategy scheduling method for human and robot coordinated cell manufacturing. Int. J. Intell. Comput. Cybern. 2011, 4, 487–510. [Google Scholar] [CrossRef]

- Cai, Y.; Huo, Y.-Z. Simulation and optimization of container terminal logistics system: An overview. J. Syst. Simul. 2009, 21, 2119–2124. [Google Scholar]

- Bányai, Á.; Illés, B.; Schenk, F. Supply chain design of manufacturing processes with blending technologies. Solid State Phenom. 2017, 261, 509–515. [Google Scholar] [CrossRef]

- Sandrea, M.; Boscán, M. The value chain in the clothing sector. Rev. Venez. Gerenc. 2004, 9, 336–353. [Google Scholar]

- Korponai, J.; Bányai, Á.; Illés, B. The effect of the safety stock on the occurrence probability of the stock shortage. Manag. Prod. Eng. Rev. 2017, 8, 69–77. [Google Scholar] [CrossRef]

- Manley, K.; Martin, A.; Jackson, C.; Wright, T. A realist synthesis of effective continuing professional development (CPD): A case study of healthcare practitioners’ CPD. Nurs. Educ. Today. 2018, 69, 134–141. [Google Scholar] [CrossRef] [PubMed]

- Anwar, C.M. Linkages between personality and knowledge sharing behaviour in workplace: Mediating role of affective states. Ekon. Manag. 2017, 20, 102–115. [Google Scholar] [CrossRef]

- Firlej, K.; Żmija, D. The specificity of knowledge management in the food industry in Poland. Ekon. Manag. 2017, 20, 83–97. [Google Scholar] [CrossRef]

- Jin, Z.; Xu, G.; Li, Y.; Liu, P. A novel cloud data center resource scheduling optimization model based on KPCA and Markov chain. Rev. Tec. Fac. Ing. Univ. 2016, 39, 87–95. [Google Scholar] [CrossRef]

- Im, C.-H.; Kim, H.-K.; Jung, H.-K. Electromagnetic topology optimization using large-step Markov chain method with novel local optimization algorithm. Int. J. Appl. Electromagn. 2003, 18, 259–267. [Google Scholar]

- Arts, J.; Van Vuuren, M.; Kiesmüller, G. Efficient optimization of the dual-index policy using Markov chains. IIE Trans. 2011, 43, 604–620. [Google Scholar] [CrossRef]

- Sragovich, V.G. Optimization with constraints on finite homogeneous Markov chains. Sov. J. Comput. Syst. Sci. 1985, 23, 96–102. [Google Scholar]

- Cheng, K.; Zhang, K.-J. Potentials based optimization with embedded Markov chain for stochastic constrained system. Nonlinear Dyn. 2012, 67, 1067–1073. [Google Scholar] [CrossRef]

- Svoboda, M. Stochastic model of short-term prediction of stock prices and its profitability in the Czech Stock Market. Ekon. Manag. 2016, 19, 188–200. [Google Scholar] [CrossRef]

- Clempner, J.B.; Poznyak, A.S. Multiobjective Markov chains optimization problem with strong Pareto frontier: Principles of decision making. Expert Syst. Appl. 2017, 68, 123–135. [Google Scholar] [CrossRef]

- Cao, X.-R. Optimization of average rewards of time nonhomogeneous Markov chains. IEEE Trans. Autom. Control 2015, 60, 1841–1856. [Google Scholar] [CrossRef]

- Cao, X.-R. State classification of time-nonhomogeneous Markov chains and average reward optimization of multi-chains. IEEE Trans. Autom. Control 2016, 61, 3001–3015. [Google Scholar] [CrossRef]

- Koutras, V.P.; Platis, A.N.; Gravvanis, G.A. On the optimization of free resources using non-homogeneous Markov chain software rejuvenation model. Reliab. Eng. Syst. Saf. 2007, 92, 1724–1732. [Google Scholar] [CrossRef]

- Campos-Náñez, E.; Patek, S.D. Dynamically identifying regenerative cycles in simulation-based optimization algorithms for Markov chains. IEEE Trans. Autom. Control 2004, 49, 1022–1025. [Google Scholar] [CrossRef]

- Meyn, S. Algorithms for optimization and stabilization of controlled Markov chains. Sadhana Acad. Proc. Eng. Sci. 1999, 24, 339–367. [Google Scholar] [CrossRef]

- Lecchini-Visintini, A.; Lygeros, J.; MacIejowski, J.M. Stochastic optimization on continuous domains with finite-time guarantees by Markov chain monte carlo methods. IEEE Trans. Autom. Control 2010, 55, 2858–2863. [Google Scholar] [CrossRef]

- Milito, R.A.; Cruz, J.B. An optimization-oriented approach to the adaptive control of Markov chains. IEEE Trans. Autom. Control 1987, 32, 754–762. [Google Scholar] [CrossRef][Green Version]

- Kaedi, M.; Ghasem-Aghaee, N.; Ahn, C.W. Biasing the transition of Bayesian optimization algorithm between Markov chain states in dynamic environments. Inf. Sci. 2016, 334–335, 44–64. [Google Scholar] [CrossRef]

- Xu, G.; Wu, Z.-H.; Jiang, M.-Z. Premature convergence of standard particle swarm optimisation algorithm based on Markov chain analysis. Int. J. Wirel. Mob. Comput. 2015, 9, 377–382. [Google Scholar] [CrossRef]

- Stewart, B.D.; Webster, D.B.; Ahmad, S.; Matson, J.O. Mathematical models for developing a flexible workforce. Int. J. Prod. Econ. 1994, 36, 243–254. [Google Scholar] [CrossRef]

- Caple, D. Impact of New Technology on Job Design, Skill Profiling and Assessing the Physical, Cognitive and Psychosocial Impacts on the Workforce. Adv. Intell. Syst. 2019, 821, 87–91. [Google Scholar] [CrossRef]

- Developing HR Strategy: 8 Steps towards Delivering a Successful HR Strategy. Available online: https://www.personneltoday.com/hr/developing-hr-strategy-8-steps-towards-delivering-a-successful-hr-strategy/ (accessed on 9 October 2018).

- Thiefels, J. Five Pillars of Successful HR Strategy. Available online: https://www.achievers.com/blog/2018/01/5-pillars-successful-hr-strategy/ (accessed on 29 September 2018).

- Mark, C.C. Fuzzy Logic vs. Probability. Available online: http://goodmath.scientopia.org/2011/02/02/fuzzy-logic-vs-probability/ (accessed on 8 October 2018).

- Gubán, Á.; Kása, R.; Gubán, M. The theory of perception driven process logistification. In Proceedings of the 18th International Working Seminar of Production Economics, Innsbruck, Austria, 24–28 February 2014; Grubbström, R.W., Hinterhuber, H.H., Eds.; University Innsbruck: Innsbruck, Austria, 2014; pp. 1–12. [Google Scholar]

| Operator | Technician | Supervisor | Line Manager | Unchallenged by the Work | Lack of Recognition | Financial Reasons | |

|---|---|---|---|---|---|---|---|

| Operator | 0.80 | 0.15 | 0.00 | 0.00 | 0.02 | 0.01 | 0.02 |

| Technician | 0.00 | 0.85 | 0.12 | 0.00 | 0.01 | 0.01 | 0.01 |

| Supervisor | 0.00 | 0.00 | 0.80 | 0.05 | 0.02 | 0.03 | 0.10 |

| Line Manager | 0.00 | 0.00 | 0.00 | 0.80 | 0.04 | 0.05 | 0.11 |

| Operator | Technician | Supervisor | Line Manager | |

|---|---|---|---|---|

| 1 | 0.60 | 0.25 | 0.10 | 0.05 |

| 2 | 0.62 | 0.23 | 0.11 | 0.04 |

| ... | 0.65 | 0.20 | 0.10 | 0.05 |

| n | 0.70 | 0.18 | 0.08 | 0.04 |

| E | 1 | 2 | 3 | 4 | 5 | 6 | R | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 25 | 17 | 15 | 14 | 12 | 7 | 1 | 0.4 | 0.2 | 0.15 | 0.1 | 0.1 | 0.05 |

| 2 | 42.6 | 23.6 | 20.1 | 19.4 | 15 | 9.22 | 2 | 0.33 | 0.18 | 0.15 | 0.15 | 0.12 | 0.07 |

| 3 | 45.6 | 23.7 | 20.7 | 23.7 | 15.7 | 10.5 | 3 | 0.33 | 0.17 | 0.15 | 0.17 | 0.11 | 0.08 |

| 4 | 48.5 | 23.9 | 21.2 | 28.1 | 16.7 | 11.7 | 4 | 0.32 | 0.16 | 0.14 | 0.19 | 0.11 | 0.08 |

| 5 | 51.2 | 24.1 | 21.6 | 32.5 | 17.9 | 12.7 | 5 | 0.32 | 0.15 | 0.14 | 0.2 | 0.11 | 0.08 |

| 6 | 53.7 | 24.3 | 21.9 | 36.9 | 19.4 | 13.8 | 6 | 0.32 | 0.14 | 0.13 | 0.22 | 0.11 | 0.08 |

| 7 | 57.6 | 25.2 | 22.8 | 42.4 | 21.7 | 15.3 | 7 | 0.31 | 0.14 | 0.12 | 0.23 | 0.12 | 0.08 |

| 8 | 59.8 | 25.4 | 22.9 | 46.7 | 23.7 | 16.5 | 8 | 0.31 | 0.13 | 0.12 | 0.24 | 0.12 | 0.08 |

| 9 | 60.4 | 25 | 22.4 | 49.7 | 25.2 | 17.4 | 9 | 0.3 | 0.13 | 0.11 | 0.25 | 0.13 | 0.09 |

| 10 | 61.7 | 25.1 | 22.2 | 53.2 | 27.1 | 18.6 | 10 | 0.3 | 0.12 | 0.11 | 0.26 | 0.13 | 0.09 |

| 11 | 62.7 | 25 | 22 | 56.4 | 29.1 | 19.9 | 11 | 0.29 | 0.12 | 0.1 | 0.26 | 0.14 | 0.09 |

| 12 | 64.5 | 25.4 | 22 | 60.1 | 31.5 | 21.5 | 12 | 0.29 | 0.11 | 0.1 | 0.27 | 0.14 | 0.1 |

| 13 | 64.8 | 25.2 | 21.6 | 62.4 | 33.3 | 22.7 | 13 | 0.28 | 0.11 | 0.09 | 0.27 | 0.14 | 0.1 |

| 14 | 68.8 | 26.5 | 22.4 | 68.1 | 36.9 | 25.3 | 14 | 0.28 | 0.11 | 0.09 | 0.27 | 0.15 | 0.1 |

| 15 | 68.7 | 26.2 | 21.9 | 69.9 | 38.6 | 26.7 | 15 | 0.27 | 0.1 | 0.09 | 0.28 | 0.15 | 0.11 |

| 16 | 70.3 | 26.6 | 22 | 73.3 | 41.1 | 28.6 | 16 | 0.27 | 0.1 | 0.08 | 0.28 | 0.16 | 0.11 |

| 17 | 71.3 | 26.9 | 22 | 76 | 43.4 | 30.5 | 17 | 0.26 | 0.1 | 0.08 | 0.28 | 0.16 | 0.11 |

| 18 | 71.3 | 26.7 | 21.6 | 77.5 | 45 | 31.9 | 18 | 0.26 | 0.1 | 0.08 | 0.28 | 0.16 | 0.12 |

| 19 | 70.8 | 26.4 | 21.2 | 78.3 | 46.2 | 33.1 | 19 | 0.26 | 0.1 | 0.08 | 0.28 | 0.17 | 0.12 |

| 20 | 70.8 | 26.3 | 20.9 | 79.7 | 47.7 | 34.5 | 20 | 0.25 | 0.09 | 0.07 | 0.28 | 0.17 | 0.12 |

| E | 1 | 2 | 3 | 4 | 5 | 6 | R | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 35 | 25 | 22 | 15 | 10 | 3 | 1 | 0.5 | 0.24 | 0.12 | 0.05 | 0.04 | 0.05 |

| 2 | 45.4 | 29.5 | 25.5 | 16.1 | 8.55 | 5.09 | 2 | 0.35 | 0.23 | 0.196 | 0.124 | 0.066 | 0.039 |

| 3 | 44.1 | 31.5 | 30.8 | 19.8 | 9.01 | 4.8 | 3 | 0.31 | 0.23 | 0.22 | 0.141 | 0.064 | 0.034 |

| 4 | 42.4 | 33.3 | 36.5 | 23.6 | 9.57 | 4.63 | 4 | 0.28 | 0.22 | 0.243 | 0.157 | 0.064 | 0.031 |

| 5 | 40.4 | 34.9 | 42.4 | 27.5 | 10.2 | 4.58 | 5 | 0.25 | 0.22 | 0.265 | 0.172 | 0.064 | 0.029 |

| 6 | 38.3 | 36.4 | 48.2 | 31.5 | 11 | 4.62 | 6 | 0.23 | 0.21 | 0.284 | 0.185 | 0.065 | 0.027 |

| 7 | 37.3 | 38.7 | 55.5 | 36.4 | 12.2 | 4.88 | 7 | 0.2 | 0.21 | 0.3 | 0.197 | 0.066 | 0.026 |

| 8 | 35.2 | 39.9 | 61.3 | 40.4 | 13.1 | 5.07 | 8 | 0.18 | 0.2 | 0.315 | 0.207 | 0.067 | 0.026 |

| 9 | 32.3 | 40 | 65.4 | 43.3 | 13.8 | 5.18 | 9 | 0.16 | 0.2 | 0.327 | 0.217 | 0.069 | 0.026 |

| 10 | 30.2 | 40.7 | 70.2 | 46.8 | 14.7 | 5.42 | 10 | 0.15 | 0.2 | 0.338 | 0.225 | 0.071 | 0.026 |

| 11 | 28.3 | 41.2 | 74.5 | 49.8 | 15.5 | 5.66 | 11 | 0.13 | 0.19 | 0.346 | 0.232 | 0.072 | 0.026 |

| 12 | 27.1 | 42.3 | 79.5 | 53.5 | 16.6 | 6.01 | 12 | 0.12 | 0.19 | 0.353 | 0.238 | 0.074 | 0.027 |

| 13 | 25.5 | 42.5 | 82.6 | 55.8 | 17.3 | 6.23 | 13 | 0.11 | 0.18 | 0.359 | 0.243 | 0.075 | 0.027 |

| 14 | 24.7 | 43.7 | 87.4 | 59.2 | 18.4 | 6.6 | 14 | 0.1 | 0.18 | 0.364 | 0.247 | 0.077 | 0.027 |

| 15 | 24.1 | 44.9 | 92 | 62.6 | 19.4 | 6.97 | 15 | 0.1 | 0.18 | 0.368 | 0.25 | 0.078 | 0.028 |

| 16 | 23.7 | 46.1 | 96.5 | 65.9 | 20.5 | 7.35 | 16 | 0.09 | 0.18 | 0.371 | 0.253 | 0.079 | 0.028 |

| 17 | 23.4 | 47.4 | 101 | 69 | 21.5 | 7.72 | 17 | 0.09 | 0.18 | 0.374 | 0.256 | 0.08 | 0.029 |

| 18 | 23.2 | 48.7 | 105 | 72.2 | 22.5 | 8.09 | 18 | 0.08 | 0.17 | 0.376 | 0.258 | 0.08 | 0.029 |

| 19 | 23.2 | 50.1 | 109 | 75.2 | 23.5 | 8.46 | 19 | 0.08 | 0.17 | 0.377 | 0.259 | 0.081 | 0.029 |

| 20 | 23.3 | 51.5 | 114 | 78.2 | 24.5 | 8.82 | 20 | 0.08 | 0.17 | 0.379 | 0.261 | 0.082 | 0.029 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bányai, T.; Landschützer, C.; Bányai, Á. Markov-Chain Simulation-Based Analysis of Human Resource Structure: How Staff Deployment and Staffing Affect Sustainable Human Resource Strategy. Sustainability 2018, 10, 3692. https://doi.org/10.3390/su10103692

Bányai T, Landschützer C, Bányai Á. Markov-Chain Simulation-Based Analysis of Human Resource Structure: How Staff Deployment and Staffing Affect Sustainable Human Resource Strategy. Sustainability. 2018; 10(10):3692. https://doi.org/10.3390/su10103692

Chicago/Turabian StyleBányai, Tamás, Christian Landschützer, and Ágota Bányai. 2018. "Markov-Chain Simulation-Based Analysis of Human Resource Structure: How Staff Deployment and Staffing Affect Sustainable Human Resource Strategy" Sustainability 10, no. 10: 3692. https://doi.org/10.3390/su10103692

APA StyleBányai, T., Landschützer, C., & Bányai, Á. (2018). Markov-Chain Simulation-Based Analysis of Human Resource Structure: How Staff Deployment and Staffing Affect Sustainable Human Resource Strategy. Sustainability, 10(10), 3692. https://doi.org/10.3390/su10103692