Investigating the Relationship between Construction Supply Chain Integration and Sustainable Use of Material: Evidence from China

Abstract

:1. Introduction

2. Literature Review and Hypothesis Development

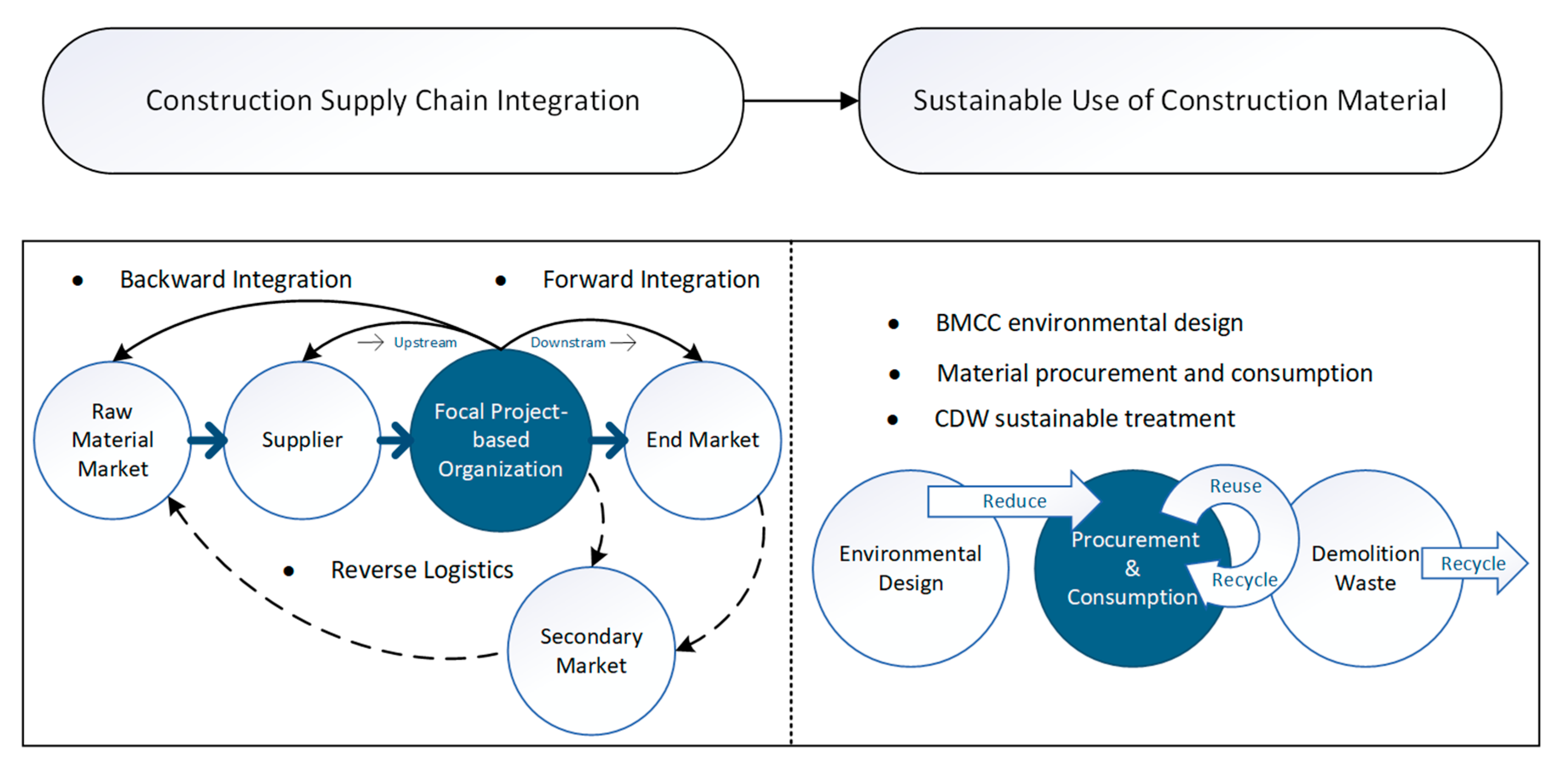

2.1. Construction Supply Chain Integration (CSCI)

2.2. Sustainable Use of Construction Material (SUCM)

3. Hypothesis Development

- Hypothesis 1 (H1).High degree of the construction supply chain integration is likely to improve sustainable use of construction materials.

- Hypothesis 2 (H2).High degree of the backward integration is likely to enhance construction supply chain integration.

- Hypothesis 3 (H3).High degree of the forward integration is likely to enhance construction supply chain integration.

- Hypothesis 4 (H4).High degree of the reverse logistics application is likely to enhance construction supply chain integration.

- Hypothesis 5 (H5).The sustainable use of construction material is positively associated with BMCC environmental design.

- Hypothesis 6 (H6).The sustainable use of construction material is positively associated with material procurement and consumption.

- Hypothesis 7 (H7).The sustainable use of construction material is positively associated with C&D waste sustainable treatment.

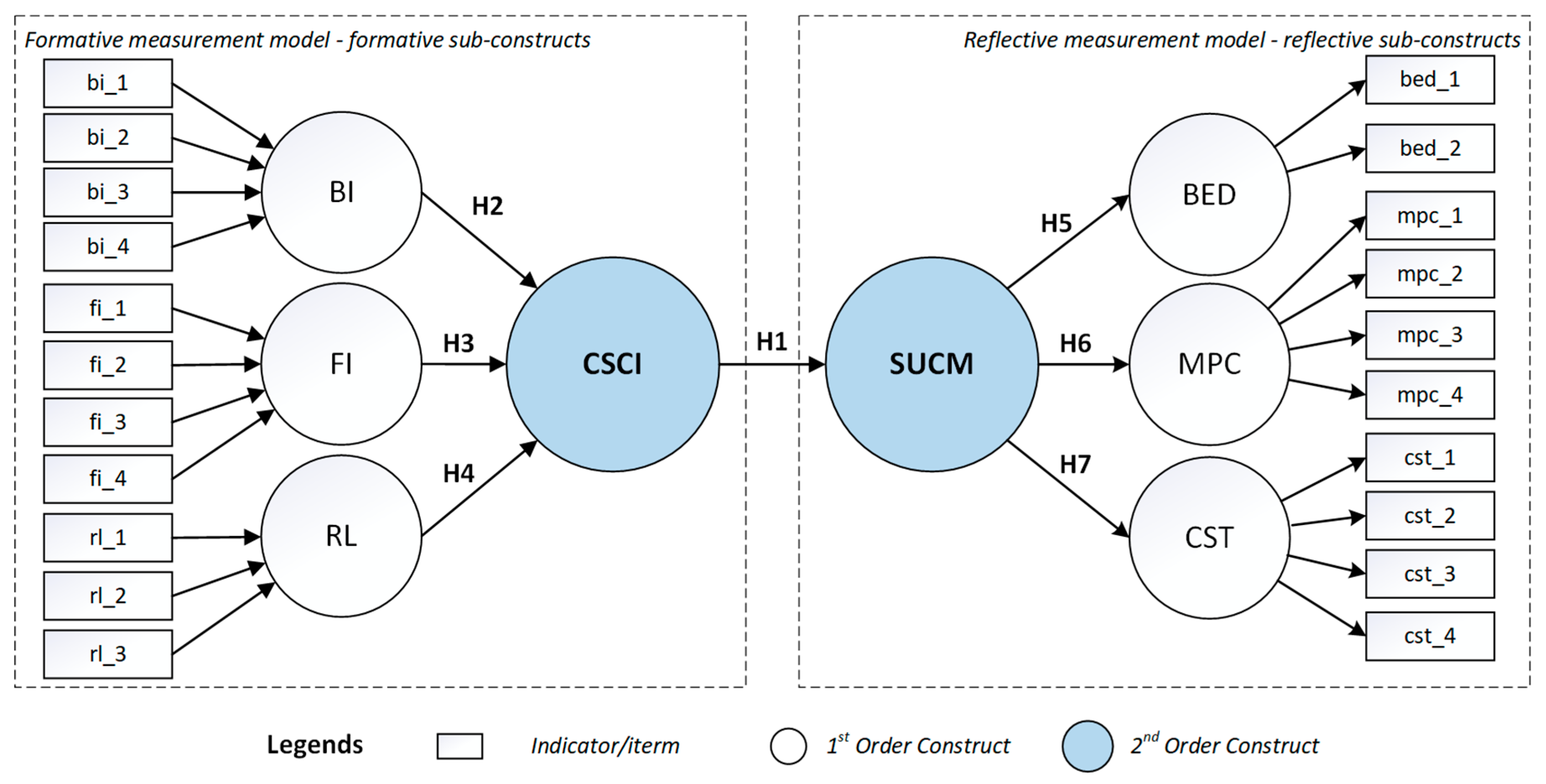

4. Method

- Initial questionnaire design: a questionnaire with 25 questions was designed for data collection according to the literature. In the questionnaire, the first three questions were designed to exclude invalid data provided by respondents without sufficient expertise.

- Interview for questionnaire improvement: the content was validated by interviewing five project managers with over five years of experience from three owner organizations and two contractors. They were invited to modify items in the scale that were unclear or incorrectly expressed.

- Pre-test for questionnaire improvement: a pre-test with 39 valid samples was conducted.

- Formal questionnaire survey: After the interview for questionnaire improvement and pre-test, two questions about CSCI in the questionnaire were substantially modified and combined into one question. Consequently, in the initial research model, observable variables bi_2 and bi_3 were altered into one observable variable as off-site process monitoring, as shown in Table 4. The modified questionnaire includes 24 questions. A formal questionnaire survey was conducted to collect a larger sample.

- Interviews were carried out alongside the model evaluation.

5. Results

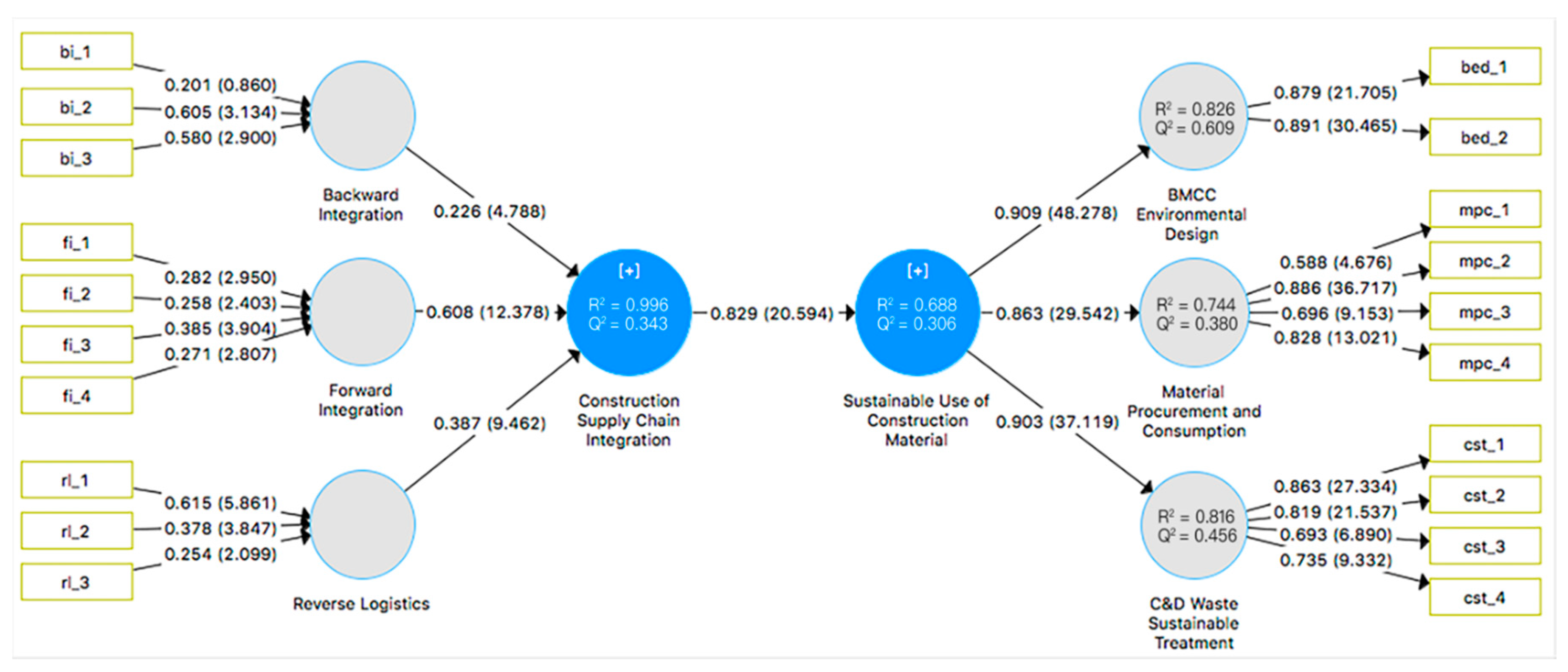

5.1. Measurement Model Evaluation

5.2. Structural Model Evaluation

6. Discussion and Implications

6.1. Stakeholder-Driven Integration and Sustainability

6.2. Supply Chain Integration for Early Environmental Design

6.3. C&D Waste Treatment and Reverse Logistics

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Khasreen, M.M.; Banfill, P.F.G.G.; Menzies, G.F. Life-cycle assessment and the environmental impact of buildings: A review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef] [Green Version]

- Tam, V.W.Y. Comparing the implementation of concrete recycling in the Australian and Japanese construction industries. J. Clean. Prod. 2009, 17, 688–702. [Google Scholar] [CrossRef]

- Durdyev, S.; Zavadskas, E.K.; Thurnell, D.; Banaitis, A.; Ihtiyar, A. Sustainable construction industry in Cambodia: Awareness, drivers and barriers. Sustainability 2018, 10, 1–19. [Google Scholar] [CrossRef]

- Serpell, A.; Kort, J.; Vera, S. Awareness, actions, drivers and barriers of sustainable construction in Chile. Technol. Econ. Dev. Econ. 2013, 19, 272–288. [Google Scholar] [CrossRef]

- Peng, C. Calculation of a building’s life cycle carbon emissions based on Ecotect and building information modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A. Policy trends for the sustainability assessment of construction materials: A review. Sustain. Cities Soc. 2017, 35, 280–288. [Google Scholar] [CrossRef]

- Gan, X.; Zuo, J.; Ye, K.; Skitmore, M.; Xiong, B. Why sustainable construction? Why not? An owner’s perspective. Habitat Int. 2015, 47, 61–68. [Google Scholar] [CrossRef]

- Li, H.; Zhang, X.; Ng, S.T.; Skitmore, M. Quantifying stakeholder influence in decision/evaluations relating to sustainable construction in China—A Delphi approach. J. Clean. Prod. 2018, 173, 160–170. [Google Scholar] [CrossRef]

- Wang, T.; Wang, J.; Wu, P.; Wang, J.; He, Q.; Wang, X. Estimating the environmental costs and benefits of demolition waste using life cycle assessment and willingness-to-pay: A case study in Shenzhen. J. Clean. Prod. 2018. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, B. Research on the life-cycle CO2emission of China’s construction sector. Energy Build. 2016, 112, 244–255. [Google Scholar] [CrossRef]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, S. A Hierarchical Framework of Barriers to Green Supply Chain Management in the Construction Sector. J. Sustain. Dev. 2012, 5, 15–27. [Google Scholar] [CrossRef]

- Bankvall, L.; Bygballe, L.E.; Dubois, A.; Jahre, M. Interdependence in supply chains and projects in construction. Supply Chain Manag. Int. J. 2010, 15, 385–393. [Google Scholar] [CrossRef]

- Kache, F.; Seuring, S. Linking collaboration and integration to risk and performance in supply chains via a review of literature reviews. Supply Chain Manag. Int. J. 2014, 19, 664–682. [Google Scholar] [CrossRef]

- Childerhouse, P.; Lewis, J.; Naim, M.; Towill, D.R. Re-engineering a construction supply chain: A material flow control approach. Supply Chain Manag. Int. J. 2003, 8, 395–406. [Google Scholar] [CrossRef]

- Dubois, A.; Gadde, L.-E. The construction industry as a loosely coupled system: Implications for productivity and innovation. Constr. Manag. Econ. 2002, 20, 621–631. [Google Scholar] [CrossRef]

- Chileshe, N.; Rameezdeen, R.; Hosseini, M.R.; Lehmann, S. Barriers to implementing reverse logistics in South Australian construction organisations. Supply Chain Manag. Int. J. 2015, 20, 179–204. [Google Scholar] [CrossRef]

- Bentler, P.M. Multivariate analysis with latent variables: causal modeling. Ann. Rev. Psychol. 1980, 31, 419–456. [Google Scholar] [CrossRef]

- Bagozzi, R.P.; Yi, Y. On the evaluation of structural equation models. J. Acad. Mark. Sci. 1988, 16, 74–94. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a Silver Bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Chin, W.W.; Peterson, R.A.; Brown, S.P. Structural Equation Modeling in Marketing: Some Practical Reminders. J. Mark. Theory Pract. 2008, 16, 287–298. [Google Scholar] [CrossRef]

- Dijkstra, T.K. Latent Variables and Indices: Herman Wold’s Basic Design and Partial Least Squares. In Handbook of Partial Least Squares; Springer: Heidelberg, Germany, 2010; pp. 23–46. ISBN1 978-3-540-32825-4. ISBN2 978-3-540-32827-8. [Google Scholar]

- Cerchione, S.; Cerchione, R.; Singh, R.; Centobelli, P.; Shabani, A. Food cold chain management: From a structured literature review to a conceptual framework and research agenda. Int. J. Logist. Manag. 2018, 29, 792–821. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008. [Google Scholar] [CrossRef]

- Harrigan, K.R. Matching vertical integration strategies to competitive conditions. Strateg. Manag. J. 1986, 7, 535–555. [Google Scholar] [CrossRef]

- Vickery, S.K.; Jayaram, J.; Droge, C.; Calantone, R. The effects of an integrative supply chain strategy on customer service and financial performance: An analysis of direct versus indirect relationships. J. Oper. Manag. 2003, 21, 523–539. [Google Scholar] [CrossRef]

- Hill, C.W.L.; Jones, G.R.; Schilling, M.A. Strategic Management: Theory: An Integrated Approach; Cengage Learning: Boston, MA, USA, 2014; ISBN 10-1285184491. [Google Scholar]

- David, F.R. Strategic Management: Concepts and Cases; Peaeson/Prentice Hall: Upper Saddle River, NJ, USA, 2011; ISBN 0136120989. [Google Scholar]

- Koolwijk, J.S.J.; Van Oel, C.J.; Wamelink, J.W.F.; Vrijhoef, R. Collaboration and Integration in Project-Based Supply Chains in the Construction Industry. J. Manag. Eng. 2018, 34, 4018001. [Google Scholar] [CrossRef]

- Doran, D.; Giannakis, M. An examination of a modular supply chain: a construction sector perspective. Supply Chain Manag. Int. J. 2011, 16, 260–270. [Google Scholar] [CrossRef]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Marquez, A.C.; Bianchi, C.; Gupta, J.N.D. Operational and financial effectiveness of e-collaboration tools in supply chain integration. Eur. J. Oper. Res. 2004, 159, 348–363. [Google Scholar] [CrossRef]

- Rosenzweig, E.D.; Roth, A.V.; Dean, J.W. The influence of an integration strategy on competitive capabilities and business performance: An exploratory study of consumer products manufacturers. J. Oper. Manag. 2003, 21, 437–456. [Google Scholar] [CrossRef]

- Zhao, X.; Huo, B.; Selen, W.; Yeung, J.H.Y. The impact of internal integration and relationship commitment on external integration. J. Oper. Manag. 2011, 29, 17–32. [Google Scholar] [CrossRef]

- Rai, A.; Patnayakuni, R.; Seth, N. Firm Performance Impacts of Digitally Enabled Supply Chain Integration Capabilities. MIS Q. 2006, 30, 225. [Google Scholar] [CrossRef] [Green Version]

- Ataseven, C.; Nair, A. Assessment of supply chain integration and performance relationships: A meta-analytic investigation of the literature. Int. J. Prod. Econ. 2017, 185, 252–265. [Google Scholar] [CrossRef]

- Prajogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- Mentzer, J.T.; Keebler, J.S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Lin, Y.T.; Parlaktürk, A.K.; Swaminathan, J.M. Vertical integration under competition: Forward, backward, or no Integration? Prod. Oper. Manag. 2014, 23, 19–35. [Google Scholar] [CrossRef]

- Vrijhoef, R.; Koskela, L. The four roles of supply chain management in construction. Eur. J. Purch. Supply Manag. 2000, 6, 169–178. [Google Scholar] [CrossRef] [Green Version]

- Sacks, R. What constitutes good production flow in construction? Constr. Manag. Econ. 2016, 34, 641–656. [Google Scholar] [CrossRef]

- Love, P.E.D.; Edwards, D.J. A seamless supply chain management model for construction. Supply Chain Manag. Int. J. 2004, 9, 43–56. [Google Scholar] [CrossRef]

- Segerstedt, A.; Olofsson, T. Supply chains in the construction industry. Supply Chain Manag. Int. J. 2010, 15, 347–353. [Google Scholar] [CrossRef]

- Chen, A. China’s urban housing: privatization and market integration. In Urbanization and Social Welfare in China; Routledge: Abingdon, UK, 2018; pp. 77–100. [Google Scholar]

- Chiu, R.L.H. Planning, land and affordable housing in Hong Kong. Hous. Stud. 2007, 22, 63–81. [Google Scholar] [CrossRef]

- OHern, M.S.; Rindfleisch, A. Customer Co-Creation. In Review of Marketing Research; Emerald Group Publishing Limited: Bingley, UK, 2010; pp. 84–106. ISBN 978-0-7656-2127-6. [Google Scholar]

- Hosseini, M.R.; Rameezdeen, R.; Chileshe, N.; Lehmann, S. Reverse logistics in the construction industry. Waste Manag. Res. 2015, 33, 499–514. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Klein, S.; Frazier, G.L.; Roth, V.J. A Transaction Cost Analysis Model of Channel Integration in International Markets. J. Mark. Res. 1990. [Google Scholar] [CrossRef]

- Kuhlman, T.; Farrington, J. What is sustainability? Sustainability 2010, 2, 3436–3448. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Seco, A.; Omer, J.; Marcelino, S.; Espuelas, S.; Prieto, E. Sustainable unfired bricks manufacturing from construction and demolition wastes. Constr. Build. Mater. 2018, 167, 154–165. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Shen, L.Y.; Hao, J.L.; Wing, V.; Tam, Y.; Yao, H. A checklist for assessing sustainability performance of construction projects. J. Civ. Eng. Manag. 2007, 13, 273–281. [Google Scholar] [CrossRef]

- Harris, D.J. A quantitative approach to the assessment of the environmental impact of building materials. PERGAMON Build. Environ. 1999, 34, 75–758. [Google Scholar] [CrossRef]

- Edum-Fotwe, F.T.; Price, A.D.F. A social ontology for appraising sustainability of construction projects and developments. Int. J. Proj. Manag. 2009, 27, 313–322. [Google Scholar] [CrossRef]

- Berardi, U. Sustainability assessment in the construction sector: Rating systems and rated buildings. Sustain. Dev. 2012, 20, 411–424. [Google Scholar] [CrossRef]

- Gilbert Silvius, A.J.; Kampinga, M.; Paniagua, S.; Mooi, H. Considering sustainability in project management decision making; An investigation using Q-methodology. Int. J. Proj. Manag. 2017, 35, 1133–1150. [Google Scholar] [CrossRef]

- Vazquez, E.; Rola, S.; Martins, D.; Alves, L.; Freitas, M.; Rosa, L.P. Sustainability in civil construction: Application of an environmental certification process (leed) during the construction phase of a hospital enterprise-rio de janeiro/Brazil. Int. J. Sustain. Dev. Plan. 2013, 8, 1–19. [Google Scholar] [CrossRef]

- Gámez-García, D.C.; Gómez-Soberón, J.M.; Corral-Higuera, R.; Saldaña-Márquez, H.; Gómez-Soberón, M.C.; Arredondo-Rea, S.P. A cradle to handover life cycle assessment of external walls: Choice of materials and prognosis of elements. Sustainability 2018, 10, 2748. [Google Scholar] [CrossRef]

- Allen, I.E.; Seaman, C.A. Likert scales and data analyses. Qual. Prog. 2007, 40, 64. [Google Scholar]

- Ringle, C.M.; Wende, S.; Will, A. SmartPLS (Release 2.0 M3). University of Hamburg, Hamburg, 2005. Available online: http://www.smartpls.de (accessed on 15 August 2018).

- Ringle, C.M.; Sarstedt, M.; Straub, D. A critical look at the use of PLS-SEM in MIS Quarterly. MIS Q. 2012, 36, iii–xiv. [Google Scholar] [CrossRef]

- Bagozzi, R.P.; Yi, Y. Specification, evaluation, and interpretation of structural equation models. J. Acad. Mark. Sci. 2012, 40, 8–34. [Google Scholar] [CrossRef]

- Ringle, C.M.; Sarstedt, M.; Mitchell, R.; Gudergan, S.P. Partial least squares structural equation modeling in HRM research. Int. J. Hum. Resour. Manag. 2018, 5192, 1–27. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Comrey, A.L. A First Course in Factor Analysis; Psychology Press: London, UK, 1993; ISBN 1317844076. [Google Scholar]

- Hair, J.F.; Sarstedt, M.; Hopkins, L.; Kuppelwieser, V.G. Partial least squares structural equation modeling (PLS-SEM): An emerging tool in business research. Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Routledge: Abingdon, UK, 1988. [Google Scholar]

- Chin, W.W. How to write up and report PLS analyses. In Handbook of Partial Least Squares; Springer: Berlin, German, 2010; pp. 655–690. [Google Scholar]

- Lenferink, S.; Tillema, T.; Arts, J. The potential of a life-cycle approach for improving road infrastructure planning in the Netherlands. In Colloquium Vervoersplanologisch Speurwerk; CVS: Santpoort, The Netherlands, 2008. [Google Scholar]

- Álvarez-Gil, M.J.; Berrone, P.; Husillos, F.J.; Lado, N. Reverse logistics, stakeholders’ influence, organizational slack, and managers’ posture. J. Bus. Res. 2007. [Google Scholar] [CrossRef] [Green Version]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Butt, A.; Naaranoja, M.; Savolainen, J. Project change stakeholder communication. Int. J. Proj. Manag. 2016. [Google Scholar] [CrossRef]

- Baiden, B.K.; Price, A.D.F.; Dainty, A.R.J. The extent of team integration within construction projects. Int. J. Proj. Manag. 2006. [Google Scholar] [CrossRef]

- Gosling, J.; Naim, M.M. Engineer-to-order supply chain management: A literature review and research agenda. Int. J. Prod. Econ. 2009, 122, 741–754. [Google Scholar] [CrossRef]

- Simpson, D. Use of supply relationships to recycle secondary materials. Int. J. Prod. Res. 2010. [Google Scholar] [CrossRef]

| Code | Form/Item | Reference |

|---|---|---|

| BI | Backward integration | [16,41] |

| bi_1 | Source control | |

| bi_2 | Bring influence to the off-site process | |

| bi_3 | Off-site process monitoring | |

| bi_4 | Transfer partial on-site activities into off-site, e.g., prefabrication | |

| FI | Forward integration | [47,49] |

| fi_1 | Acceptance of ideas proposed by clients or end-users | |

| fi_2 | Improvement based on ideas from clients or end-users | |

| fi_3 | Joint decision-making | |

| fi_4 | Joint decision-driven implementation | |

| RL | Reverse logistics | [18,48] |

| rl_1 | Purchase permit of recycled materials | |

| rl_2 | Recycle C&D waste to the secondary market | |

| rl_3 | Recycle C&D waste to the raw material market |

| Code | Factor | References | Sum | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | M | |||

| BED | BMCC environmental design | ||||||||||||||

| bed_1 | Alternative of non-renewable resources | × | × | × | × | × | × | × | × | × | × | × | × | 12 | |

| bed_2 | Environmental targets early setting | × | × | × | × | × | × | × | × | × | × | × | 11 | ||

| MPC | Material procurement and consumption | ||||||||||||||

| mpc_1 | Accurate quantity estimation | × | × | × | × | × | × | × | × | 8 | |||||

| mpc_2 | Adoption of sustainable/green material | × | × | × | × | × | × | × | × | × | × | × | × | 12 | |

| mpc_3 | Green procurement (e.g., GPP) | × | × | × | × | × | × | × | × | × | × | × | 11 | ||

| mpc_4 | Material using strategies | × | × | × | × | × | × | × | × | × | × | × | 11 | ||

| CST | C&D waste sustainable treatment | ||||||||||||||

| cst_1 | Recycling technology | × | × | × | × | × | × | × | × | × | × | × | 11 | ||

| cst_2 | Re-use of site-recycled BMCC | × | × | × | × | × | × | × | × | × | × | 10 | |||

| cst_3 | Approval of qualified recycled BMCC | × | × | × | × | × | 5 | ||||||||

| cst_4 | Raw material extraction from demolition | × | × | × | × | × | × | × | × | 8 | |||||

| Construct | Code | Definition | |

|---|---|---|---|

| Second Order | Construction supply chain integration | CSCI | The degree to which a focal construction organization has integrated its upstream and downstream and reverse logistics partners along the supply chain. |

| First Order | Backward integration | BI | The degree to which a focal construction organization takes measures with its upstream partners to guarantee and manage production, transportation, and construction activities. |

| Forward integration | FI | The degree to which a focal construction organization takes measures with its downstream partners to access end-markets. | |

| Reverse logistics | RL | The extent of the material circulation from the point of consumption, i.e., construction sites to the point of origin, i.e., material markets and salvaged buildings. | |

| Second Order | Sustainable use of construction material | SUCM | The extent of improving the efficient use of construction materials, minimizing waste generation, and creating channels to transform waste into the material resource. |

| First Order | BMCC environmental design | BED | The extent of source control and materials optimization through design, to set up environmental targets and find alternatives to non-renewable resources. |

| Material procurement and consumption | MPC | The extent of process control and material using regulation, including accurate material quantity estimation, green procurement, and appropriate material use strategies. | |

| C&D waste sustainable treatment | CST | The extent of re-using and recycling construction and demolition waste with corresponding regulations, standards, and technologies. |

| Code | Item | Interviewee | Sum | Adjustment | ||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||||

| BI | Backward integration | |||||||

| bi_1 | Source control | × | × | × | × | 4 | ||

| bi_2 | Bring influence to the off-site process | 0 | Delete | |||||

| bi_3 | Off-site process monitoring | × | × | × | × | × | 5 | renumbered as bi_2 |

| bi_4 | Transfer partial on-site activities into off-site, e.g., prefabrication | × | × | × | × | × | 5 | renumbered as bi_3 |

| FI | Forward integration | |||||||

| fi_1 | Acceptance of ideas proposed by clients or end-users | × | × | × | × | 4 | ||

| fi_2 | Improvement based on ideas from clients or end-users | × | × | × | × | × | 5 | |

| fi_3 | Joint decision-making | × | × | × | × | 4 | ||

| fi_4 | Joint decision-driven implementation | × | × | × | × | 4 | ||

| RL | Reverse logistics | |||||||

| rl_1 | Purchase permit of recycled materials | × | × | × | × | 4 | ||

| rl_2 | Recycle C&D waste to the secondary market | × | × | × | × | 4 | ||

| rl_3 | Recycle C&D waste to the raw material market | × | × | × | × | × | 5 | |

| Personal Attribute | Categorization | Number of Respondents | Percentage (%) |

|---|---|---|---|

| Organization type | Contractor | 25 | 32.89 |

| Owner | 32 | 42.11 | |

| Material Supplier | 4 | 5.27 | |

| Consulting | 6 | 7.89 | |

| Designer | 9 | 11.84 | |

| Investment scale (RMB, the Chinese currency) | <1 million | 4 | 5.26 |

| 1 million–10 million | 7 | 9.21 | |

| 10 million–100 million | 8 | 10.53 | |

| 100 million–1000 million | 26 | 34.21 | |

| 1000 million–10,000 million | 24 | 31.58 | |

| >10,000 million | 7 | 9.21 |

| Construct | Indicator | Absolute Indicator Contribution | Significance of Weight | Multicollinearity | |||

|---|---|---|---|---|---|---|---|

| Weight | Mean | Std Dev | t-Value | Significance | VIF | ||

| BI | bi_1 | 0.201 | 0.177 | 0.239 | 0.839 | - | 1.195 |

| bi_2 | 0.605 | 0.580 | 0.192 | 3.156 | p < 0.01 | 1.207 | |

| bi_3 | 0.580 | 0.554 | 0.199 | 2.919 | p < 0.01 | 1.042 | |

| FI | fi_1 | 0.282 | 0.281 | 0.095 | 2.959 | p < 0.01 | 1.847 |

| fi_2 | 0.258 | 0.248 | 0.107 | 2.406 | p < 0.05 | 2.338 | |

| fi_3 | 0.385 | 0.395 | 0.098 | 3.913 | p < 0.001 | 2.350 | |

| fi_4 | 0.271 | 0.266 | 0.095 | 2.861 | p < 0.01 | 1.669 | |

| RL | rl_1 | 0.615 | 0.609 | 0.105 | 5.866 | p < 0.001 | 1.317 |

| rl_2 | 0.378 | 0.374 | 0.098 | 3.866 | p < 0.001 | 1.382 | |

| rl_3 | 0.254 | 0.256 | 0.119 | 2.135 | p < 0.05 | 1.379 | |

| CSCI | bi_1 | 0.066 | 0.064 | 0.036 | 1.814 | p < 0.10 | 1.384 |

| bi_2 | 0.120 | 0.116 | 0.032 | 3.771 | p < 0.001 | 1.430 | |

| bi_3 | 0.119 | 0.116 | 0.027 | 4.476 | p < 0.001 | 1.217 | |

| fi_1 | 0.185 | 0.183 | 0.020 | 9.132 | p < 0.001 | 2.200 | |

| fi_2 | 0.187 | 0.185 | 0.021 | 9.043 | p < 0.001 | 2.835 | |

| fi_3 | 0.199 | 0.197 | 0.020 | 10.046 | p < 0.001 | 2.781 | |

| fi_4 | 0.164 | 0.160 | 0.021 | 7.742 | p < 0.001 | 1.921 | |

| rl_1 | 0.191 | 0.189 | 0.020 | 9.672 | p < 0.001 | 1.739 | |

| rl_2 | 0.164 | 0.162 | 0.020 | 8.176 | p < 0.001 | 1.967 | |

| rl_3 | 0.148 | 0.148 | 0.025 | 5.923 | p < 0.001 | 1.739 | |

| Construct | Indicator | Indicator Reliability | Internal Consistency Reliability | Convergent Validity | |||

|---|---|---|---|---|---|---|---|

| Loading | t-Value | Significance | Cronbach’s α | CR | AVE | ||

| BED | bed_1 | 0.879 | 21.059 | p < 0.001 | 0.723 | 0.878 | 0.783 |

| bed_2 | 0.891 | 29.857 | p < 0.001 | ||||

| MPC | mpc_1 | 0.588 | 4.657 | p < 0.001 | 0.746 | 0.841 | 0.575 |

| mpc_2 | 0.886 | 35.494 | p < 0.001 | ||||

| mpc_3 | 0.696 | 9.017 | p < 0.001 | ||||

| mpc_4 | 0.828 | 13.256 | p < 0.001 | ||||

| CST | cst_1 | 0.863 | 27.089 | p < 0.001 | 0.784 | 0.861 | 0.609 |

| cst_2 | 0.819 | 22.001 | p < 0.001 | ||||

| cst_3 | 0.693 | 6.964 | p < 0.001 | ||||

| cst_4 | 0.735 | 9.152 | p < 0.001 | ||||

| SUCM | bed_1 | 0.785 | 15.543 | p < 0.001 | 0.882 | 0.905 | 0.495 |

| bed_2 | 0.823 | 25.192 | p < 0.001 | ||||

| mpc_1 | 0.490 | 3.548 | p < 0.001 | ||||

| mpc_2 | 0.759 | 13.123 | p < 0.001 | ||||

| mpc_3 | 0.723 | 11.763 | p < 0.001 | ||||

| mpc_4 | 0.585 | 6.098 | p < 0.001 | ||||

| cst_1 | 0.798 | 15.121 | p < 0.001 | ||||

| cst_2 | 0.765 | 13.053 | p < 0.001 | ||||

| cst_3 | 0.551 | 5.185 | p < 0.001 | ||||

| cst_4 | 0.674 | 7.677 | p < 0.001 | ||||

| Indicator | BI | FI | RL | BED | MPC | CST |

|---|---|---|---|---|---|---|

| bi_1 | 0.528 | 0.205 | 0.117 | 0.027 | 0.270 | 0.141 |

| bi_2 | 0.789 | 0.255 | 0.343 | 0.346 | 0.281 | 0.416 |

| bi_3 | 0.720 | 0.211 | 0.345 | 0.433 | 0.409 | 0.346 |

| fi_1 | 0.267 | 0.808 | 0.428 | 0.546 | 0.680 | 0.430 |

| fi_2 | 0.277 | 0.855 | 0.459 | 0.544 | 0.532 | 0.476 |

| fi_3 | 0.251 | 0.893 | 0.546 | 0.525 | 0.580 | 0.519 |

| fi_4 | 0.275 | 0.770 | 0.414 | 0.468 | 0.450 | 0.377 |

| rl_1 | 0.352 | 0.541 | 0.880 | 0.513 | 0.551 | 0.591 |

| rl_2 | 0.321 | 0.398 | 0.754 | 0.596 | 0.345 | 0.623 |

| rl_3 | 0.367 | 0.306 | 0.686 | 0.515 | 0.426 | 0.507 |

| bed_1 | 0.288 | 0.552 | 0.644 | 0.879 | 0.543 | 0.718 |

| bed_2 | 0.530 | 0.550 | 0.546 | 0.891 | 0.685 | 0.673 |

| mpc_1 | 0.308 | 0.405 | 0.388 | 0.369 | 0.588 | 0.332 |

| mpc_2 | 0.403 | 0.669 | 0.568 | 0.619 | 0.886 | 0.516 |

| mpc_3 | 0.382 | 0.369 | 0.424 | 0.615 | 0.696 | 0.628 |

| mpc_4 | 0.283 | 0.582 | 0.338 | 0.444 | 0.828 | 0.287 |

| cst_1 | 0.337 | 0.470 | 0.548 | 0.763 | 0.508 | 0.863 |

| cst_2 | 0.429 | 0.458 | 0.580 | 0.653 | 0.555 | 0.819 |

| cst_3 | 0.244 | 0.329 | 0.495 | 0.440 | 0.303 | 0.693 |

| cst_4 | 0.478 | 0.430 | 0.654 | 0.549 | 0.485 | 0.735 |

| AVE | BI | FI | RL | BED | MPC | CST | |

|---|---|---|---|---|---|---|---|

| BI | N.A. | N.A. | |||||

| FI | N.A. | 0.318 | N.A. | ||||

| RL | N.A. | 0.431 | 0.561 | N.A. | |||

| BED | 0.783 | 0.465 | 0.623 | 0.671 | 0.885 * | ||

| MPC | 0.575 | 0.461 | 0.674 | 0.577 | 0.695 | 0.758 * | |

| CST | 0.609 | 0.480 | 0.546 | 0.727 | 0.785 | 0.604 | 0.780 * |

| Path | Path Coefficient | The Significance of Path Coefficient | Coefficient of Determination | Cross-Validated Redundancy | ||||

|---|---|---|---|---|---|---|---|---|

| β | Mean | Std Dev | t-Value | Significance | R2 | f2 | Q2 | |

| BI → CSCI | 0.226 | 0.218 | 0.047 | 4.753 | p < 0.001 | 0.996 | 9.941 | 0.343 |

| FI → CSCI | 0.608 | 0.596 | 0.049 | 12.325 | p < 0.001 | 60.780 | ||

| RL → CSCI | 0.387 | 0.381 | 0.040 | 9.592 | p < 0.001 | 22.261 | ||

| CSCI → SUCM | 0.829 | 0.832 | 0.041 | 20.131 | p < 0.001 | 0.688 | 2.200 | 0.306 |

| SUCM → BED | 0.909 | 0.912 | 0.019 | 48.122 | p < 0.001 | 0.826 | 4.735 | 0.609 |

| SUCM → MPC | 0.863 | 0.867 | 0.030 | 28.780 | p < 0.001 | 0.744 | 2.908 | 0.380 |

| SUCM → CST | 0.903 | 0.904 | 0.024 | 38.371 | p < 0.001 | 0.816 | 4.421 | 0.456 |

| Path | Hypothesis | Construct Order | Result |

|---|---|---|---|

| CSCI → SUCM | H1 | 2 → 2 | Supported |

| BI → CSCI | H2 | 1 → 2 | Loosely supported * |

| FI → CSCI | H3 | 1 → 2 | Supported |

| RL → CSCI | H4 | 1 → 2 | Supported |

| SUCM → BED | H5 | 2 → 1 | Supported |

| SUCM → MPC | H6 | 2 → 1 | Loosely supported * |

| SUCM → CST | H7 | 2 → 1 | Supported |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, N.; Liu, Y.; Mao, C.; König, M. Investigating the Relationship between Construction Supply Chain Integration and Sustainable Use of Material: Evidence from China. Sustainability 2018, 10, 3581. https://doi.org/10.3390/su10103581

Zeng N, Liu Y, Mao C, König M. Investigating the Relationship between Construction Supply Chain Integration and Sustainable Use of Material: Evidence from China. Sustainability. 2018; 10(10):3581. https://doi.org/10.3390/su10103581

Chicago/Turabian StyleZeng, Ningshuang, Yan Liu, Chao Mao, and Markus König. 2018. "Investigating the Relationship between Construction Supply Chain Integration and Sustainable Use of Material: Evidence from China" Sustainability 10, no. 10: 3581. https://doi.org/10.3390/su10103581

APA StyleZeng, N., Liu, Y., Mao, C., & König, M. (2018). Investigating the Relationship between Construction Supply Chain Integration and Sustainable Use of Material: Evidence from China. Sustainability, 10(10), 3581. https://doi.org/10.3390/su10103581