Potential for Methane Generation by Lignocellulosic Household Waste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Description of the Study Area

2.2. Study of the Composition and the Generation of Domestic Solid Waste

2.3. Chemical Characterisation of the Domestic Lignocellulosic Waste

2.4. CH4 Generation Potential of Domestic Lignocellulosic Waste

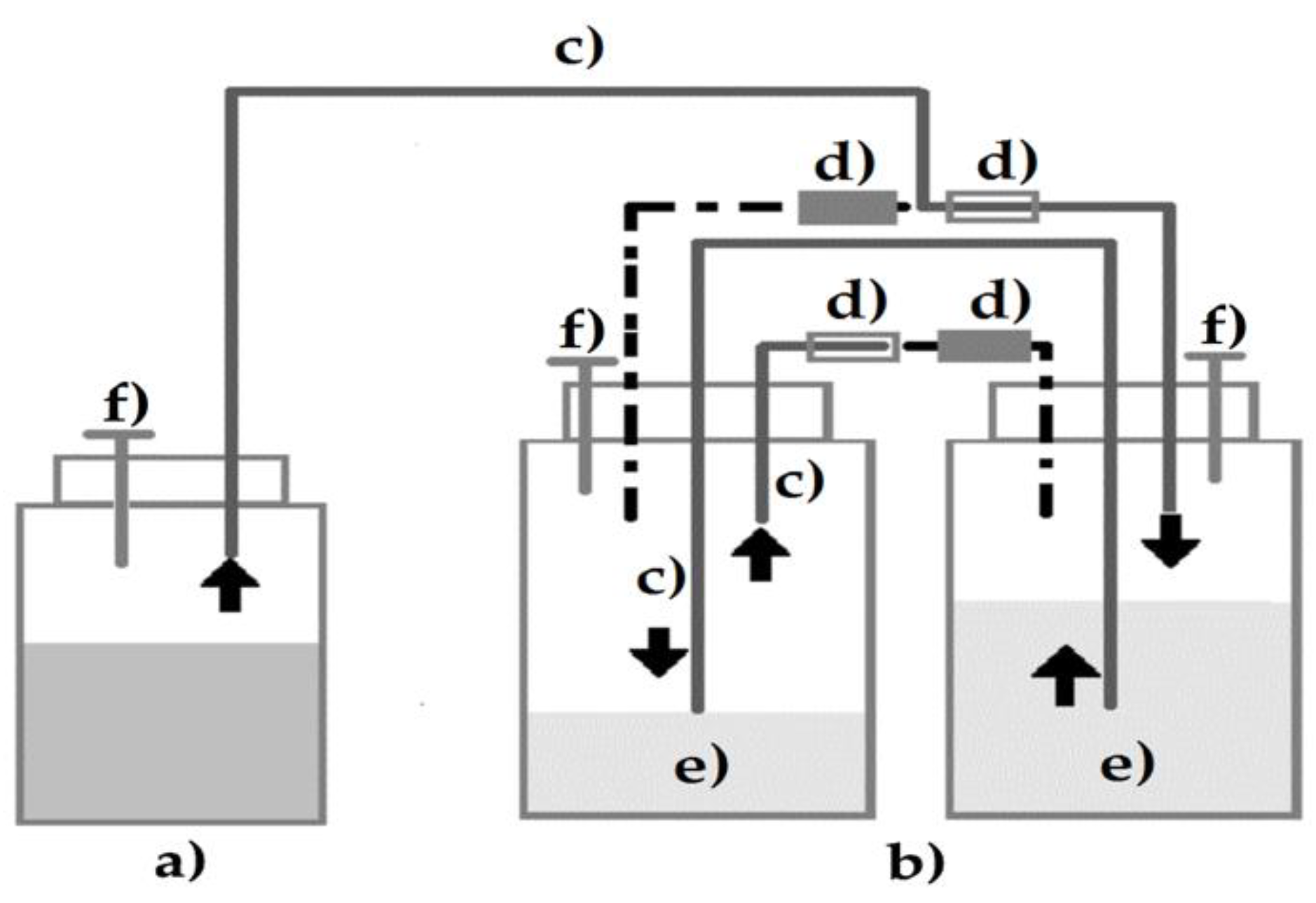

2.4.1. Obtainment of Biogas Producer Inoculum

2.4.2. Mesophilic Anaerobic Biodegradation Assays

2.5. Calculation of CO2eq Emissions by the Anaerobic Degradation of Waste

2.5.1. Emissions Relative to the Amount of Domestic Lignocellulosic Waste Produced in the Dwelling

2.5.2. Emissions Calculated by Emission Factors

3. Results

3.1. Composition and Generation of Domestic Solid Waste

3.2. Chemical Characterization of Waste Paper, Cardboard, and Derivatives

3.3. The Potential for CH4 Generation by Domestic Lignocellulosic Waste during the Biodegradability Test

4. Discussion

4.1. Composition and Generation of Lignocellulosic Household Waste

4.2. Chemical Characterisation of Paper and Cardboard Waste

4.3. The Potential for the Generation of CH4 by Domestic Lignocellulosic Waste

4.4. YCH4 and Its Equivalence in CO2eq Emissions

5. Conclusions

Author Contributions

Conflicts of Interest

References

- INECC (National Institute of Ecology and Climate Change). Diagnóstico Básico Para la Gestión Integral de los Residuos. Versión Extensa del Instituto Nacional de Ecología y Cambio Climático y del Centro Nacional de Investigación y Capacitación Ambiental de la Secretaría de Medio Ambiente y Recursos Naturales; INECC: México City, Mexico, 2012. (In Spanish) [Google Scholar]

- Castillo-González, E.; Medina-Salas, L.D. Generación y composición de residuos sólidos domésticos en localidades urbanas pequeñas en el estado de Veracruz, México. Rev. Int. Contam. Ambient. 2014, 30, 81–90. [Google Scholar]

- STID (Former Secretariat of Trade and Industrial Development). NMX-AA-22-1985. Selección y Cuantificación de Subproductos; STID: México City, Mexico, 1985. (In Spanish) [Google Scholar]

- Sáez, A.; Urdaneta, G. Manejo de residuos sólidos en América Latina y el Caribe. Omnia 2014, 20, 121–135. [Google Scholar]

- Gavrilescu, D. Energy from biomass in pulp and paper mills. Environ. Eng. Manag. J. 2008, 7, 537–546. [Google Scholar] [CrossRef]

- Cámara del Papel (Chamber of Paper). Plan de Manejo Para Residuos de Papel y Cartón en México. Cámara Nacional de las Industrias de la Celulosa y el Papel. Plan de Manejo; Cámara del Papel: México City, Mexico, 2012. (In Spanish) [Google Scholar]

- Ben Hassen Trabelsi, A.; Zaafouri, K.; Baghdadi, W.; Naoui, S.; Ouerghi, A. Second generation biofuels production from waste cooking oil via pyrolysis process. Renew. Energy 2018, 126, 888–896. [Google Scholar] [CrossRef]

- Molino, A.; Larocca, V.; Chianese, S.; Musmarra, D.; Molino, A.; Larocca, V.; Chianese, S.; Musmarra, D. Biofuels Production by Biomass Gasification: A Review. Energies 2018, 11, 811. [Google Scholar] [CrossRef]

- Fonoll, X.; Astals, S.; Dosta, J.; Mata-Alvarez, J. Impact of paper and cardboard suppression on OFMSW anaerobic digestion. Waste Manag. 2016, 56, 100–105. [Google Scholar] [CrossRef] [PubMed]

- Lesteur, M.; Latrille, E.; Maurel, V.B.; Roger, J.M.; Gonzalez, C.; Junqua, G.; Steyer, J.P. First step towards a fast analytical method for the determination of Biochemical Methane Potential of solid wastes by near infrared spectroscopy. Bioresour. Technol. 2011, 102, 2280–2288. [Google Scholar] [CrossRef] [PubMed]

- Mou, Z.; Scheutz, C.; Kjeldsen, P. Evaluating the biochemical methane potential (BMP) of low-organic waste at Danish landfills. Waste Manag. 2014, 34, 2251–2259. [Google Scholar] [CrossRef] [PubMed]

- EC (European Commission). Methodology for the Analysis of Solid Waste (SWA-Tool) User Version. Available online: https://www.wien.gv.at/meu/fdb/pdf/swa-tool-759-ma48.pdf (accessed on 10 April 2016).

- Al-Khatib, I.A.; Arafat, H.A.; Basheer, T.; Shawahneh, H.; Salahat, A.; Eid, J.; Ali, W. Trends and problems of solid waste management in developing countries: A case study in seven Palestinian districts. Waste Manag. 2007, 27, 1910–1919. [Google Scholar] [CrossRef] [PubMed]

- Karousakis, K.; Birol, E. Investigating household preferences for kerbside recycling services in London: A choice experiment approach. J. Environ. Manag. 2008, 88, 1099–1108. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Ni, W.; Li, Z.; Ma, L. Strategic thinking on IGCC development in China. Energy Policy 2008, 36, 1–11. [Google Scholar] [CrossRef]

- Alqader, A.A.; Hamad, J. Municipal Solid Waste Composition Determination Supporting the Integrated Solid Waste Management in Gaza Strip. Int. J. Environ. Sci. Dev. 2012, 3, 172–176. [Google Scholar] [CrossRef]

- Monavari, S.M.; Omrani, G.A.; Karbassi, A.; Raof, F.F. The effects of socioeconomic parameters on household solid-waste generation and composition in developing countries (a case study: Ahvaz, Iran). Environ. Monit. Assess. 2012, 184, 1841–1846. [Google Scholar] [CrossRef] [PubMed]

- Edjabou, M.E.; Jensen, M.B.; Götze, R.; Pivnenko, K.; Petersen, C.; Scheutz, C.; Astrup, T.F. Municipal solid waste composition: Sampling methodology, statistical analyses, and case study evaluation. Waste Manag. 2015, 36, 12–23. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pop, I.N.; Baciu, C.; Bican-Brisan, N. Survey on household waste composition generated in cluj-napoca, romania during the summer season. Environ. Eng. Manag. J. 2015, 14, 2643–2651. [Google Scholar] [CrossRef]

- Edjabou, M.E.; Petersen, C.; Scheutz, C.; Astrup, T.F. Food waste from Danish households: Generation and composition. Waste Manag. 2016, 52, 256–268. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Edjabou, M.E.; Martín-Fernández, J.A.; Scheutz, C.; Astrup, T.F. Statistical analysis of solid waste composition data: Arithmetic mean, standard deviation and correlation coefficients. Waste Manag. 2017, 69, 13–23. [Google Scholar] [CrossRef] [PubMed]

- Weichgrebe, D.; Speier, C.; Mondal, M.M. Scientific approach for municipal solid waste characterzation. In Advances in Solid and Hazardous Waste Management; Goel, S., Ed.; Springer: New Delhi, India, 2017; pp. 65–100. ISBN 978-3-319-57076-1. [Google Scholar]

- Edjabou, M.E.; Boldrin, A.; Astrup, T.F. Compositional analysis of seasonal variation in Danish residual household waste. Resour. Conserv. Recycl. 2018, 130, 70–79. [Google Scholar] [CrossRef]

- Yang, N.; Damgaard, A.; Scheutz, C.; Shao, L.-M.; He, P.-J. A comparison of chemical MSW compositional data between China and Denmark. J. Environ. Sci. 2018. [Google Scholar] [CrossRef]

- Wagland, S.T.; Veltre, F.; Longhurst, P.J. Development of an image-based analysis method to determine the physical composition of a mixed waste material. Waste Manag. 2012, 32, 245–248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater. Scope and Application of Methods, 21st ed.; Centennial Edition; APHA: Washington, DC, USA, 2005. [Google Scholar]

- Sun, R.C.; Tomkinson, J.; Zhu, W.; Wang, S.Q. Delignification of maize stems by peroxymonosulfuric acid, peroxyformic acid, peracetic acid, and hydrogen peroxide. 1. Physicochemical and structural characterization of the solubilized lignins. J. Agric. Food Chem. 2000, 48, 1253–1262. [Google Scholar] [CrossRef] [PubMed]

- Wise, L.E. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and studies on the hemicelluloses. Pap. Trade J. 1946, 122, 35–43. [Google Scholar]

- Runkel, R.O.H. Zur Kenntnis des thermoplastischen Verhaltens von Holz. Holz Roh Werkst. 1951, 9, 41–53. [Google Scholar] [CrossRef]

- Espinosa Lloréns, M.D.C.; López Torres, M.; Pellón Arrechea, A.; Mayarí Navarro, R.; Fernández Colomina, A. La fracción orgánica de los residuos sólidos urbanos como fuente potencial de producción de biogás. Rev. CENIC. Cienc. Biol. 2007, 38, 33–37. [Google Scholar]

- Loehr, R.C. Pollution Control for Agriculture: Problems, Processes, and Applications, 2nd ed.; Academic Press: Cambridge, MA, USA, 1984; ISBN 978-0-323-13884-0. [Google Scholar]

- Vigil, S.A.; Tchobanoglous, G. Comparison of the environmental effects of aerobic and anaerobic composting technologies. In Proceedings of the Civil and Environmental Engineering; Air and Waste Management Association: Pittsburgh, PA, USA, 1994; p. 11. [Google Scholar]

- Kayhanian, M.; Tchobanoglous, G.; Brown, R.C. Biomass conversion processes for energy recovery. In Handbook of Energy Efficiency and Renewable Energy; Goswami, D.Y., Kreith, F., Eds.; CRC Press: Boca Raton, FL, USA, 2007; pp. 1–65. ISBN 978-1-4200-0348-2. [Google Scholar]

- Law, J.; Peterson, E.; Hudgins, M. Water requirement estimates for an aerobic bioreactor landfill in China. In Proceedings Sardinia; CISA (Environmental Sanitary Engineering Centre): Cagliari, Italy, 2011; pp. 1–9. [Google Scholar]

- Castells, X.E. Reciclaje de Residuos Industriales: Residuos Sólidos Urbanos y Fangos de Depuradora, 2nd ed.; Ediciones Díaz de Santos: Madrid, España, 2012; ISBN 978-84-9969-366-8. [Google Scholar]

- Alexis, P.-O.B.; Patricia, T.-L.; Fernando, M.-R.L.; Marcela, C.-C.L.; Carlos, V.-F.; Alexander, T.-L.W.; Abdón, O.-A.J. Efecto de la relación sustrato-inóculo sobre el potencial bioquímico de metano de biorresiduos de origen municipal. Ing. Investig. Technol. 2015, 16, 515–526. [Google Scholar] [CrossRef]

- Soto, J.; Torres, P.; Barba, L.E.; Marmolejo, L.F.; Torres, W.A.; Guzmán, M.A.; Perea, L.M. Dissolved oxygen effect on the biodegradability of biowaste. Rev. UDCA Actual. Divulg. Cient. 2015, 18, 485–495. [Google Scholar]

- Trzcinski, A.P.; Stuckey, D.C. Microbial biomethane from solid wastes: Principles and biotechnogical processes. In Microbial Fuels: Technologies and Applications; Harzevili, F.D., Hiligsmann, I.S., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 77–152. ISBN 978-1-4987-6380-6. [Google Scholar]

- Baltierra-Trejo, E.; Márquez-Benavides, L.; Sánchez-Yáñez, J.M. Modelo experimental de difusión de biogás en raíces vegetales. Rev. Int. Contam. Ambient. 2012, 28, 133–139. [Google Scholar]

- Yuan, X.; Cao, Y.; Li, J.; Wen, B.; Zhu, W.; Wang, X.; Cui, Z. Effect of pretreatment by a microbial consortium on methane production of waste paper and cardboard. Bioresour. Technol. 2012, 118, 281–288. [Google Scholar] [CrossRef] [PubMed]

- Myhre, G.; Shindell, D.; Breon, F.-M.; Collins, W.; Fuglesttvedt, J.; Huang, J.; Koch, D.; Lamarque, J.-F.; Lee, D.; Mendoza, B.; et al. Anthropogenic and Natural Radiative Forcing. In Climate Change 2013: The Physical Science Basis: Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F., Qin, G.-K., Plattner, M., Tignor, S.K., Allen, J., Boschung, A., Nauels, Y., Xia, B., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; pp. 659–740. ISBN 978-1-107-05799-9. [Google Scholar]

- Daviet, F. Designing a Customized Greenhouse Gas Calculation Tool; World Resources Institute: Washington, DC, USA, 2007; ISBN 978-1-56973-659-3. [Google Scholar]

- DEFRA (Department for Environment, Food and Rural Affairs). 2016 Government GHG Conversion Factors for Company Reporting: Methodology Paper for Emission Factors; DEFRA: London, UK, 2016.

- Turner, D.A.; Williams, I.D.; Kemp, S. Greenhouse gas emission factors for recycling of source-segregated waste materials. Resour. Conserv. Recycl. 2015, 105, 186–197. [Google Scholar] [CrossRef]

- Leschine, S.B. Cellulose degradation in anaerobic environments. Annu. Rev. Microbiol. 1995, 49, 399–426. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W.; Phoungthong, K.; Lü, F.; Shao, L.-M.; He, P.-J. Evaluation of a classification method for biodegradable solid wastes using anaerobic degradation parameters. Waste Manag. 2013, 33, 2632–2640. [Google Scholar] [CrossRef] [PubMed]

- Venelampi, O.; Weber, A.; Rönkkö, T.; Itävaara, M. The Biodegradation and Disintegration of Paper Products in the Composting Environment. Compost Sci. Util. 2003, 11, 200–209. [Google Scholar] [CrossRef]

- Bengtström, L.; Trier, X.; Granby, K.; Rosenmai, A.K.; Petersen, J.H. Fractionation of extracts from paper and board food contact materials for in vitro screening of toxicity. Food Addit. Contam. 2014, 31, 1291–1300. [Google Scholar] [CrossRef]

- Rosenmai, A.K.; Bengtström, L.; Taxvig, C.; Trier, X.; Petersen, J.H.; Svingen, T.; Binderup, M.-L.; Barbara Medea Alice, V.-L.; Dybdahl, M.; Granby, K.; et al. An effect-directed strategy for characterizing emerging chemicals in food contact materials made from paper and board. Food Chem. Toxicol. 2017, 106, 250–259. [Google Scholar] [CrossRef] [PubMed]

- Baawain, M.; Al-Mamun, A.; Omidvarborna, H.; Al-Amri, W. Ultimate composition analysis of municipal solid waste in Muscat. J. Clean. Prod. 2017, 148, 355–362. [Google Scholar] [CrossRef]

- Jara-Samaniego, J.; Pérez-Murcia, M.D.; Bustamante, M.A.; Pérez-Espinosa, A.; Paredes, C.; López, M.; López-Lluch, D.B.; Gavilanes-Terán, I.; Moral, R. Composting as sustainable strategy for municipal solid waste management in the Chimborazo Region, Ecuador: Suitability of the obtained composts for seedling production. J. Clean. Prod. 2017, 141, 1349–1358. [Google Scholar] [CrossRef]

- Eleazer, W.E.; Odle, W.S.; Wang, Y.-S.; Barlaz, M.A. Biodegradability of municipal solid waste components in laboratory-scale landfills. Environ. Sci. Technol. 1997, 31, 911–917. [Google Scholar] [CrossRef]

- Abbassi-Guendouz, A.; Brockmann, D.; Trably, E.; Dumas, C.; Delgenès, J.-P.; Steyer, J.-P.; Escudié, R. Total solids content drives high solid anaerobic digestion via mass transfer limitation. Bioresour. Technol. 2012, 111, 55–61. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, T.; Xu, K.-Q.; Li, Y.-Y.; Inamori, Y. Evaluation of hydrogen and methane production from municipal solid wastes with different compositions of fat, protein, cellulosic materials and the other carbohydrates. Int. J. Hydrogen Energy 2012, 37, 15711–15718. [Google Scholar] [CrossRef]

- Díaz Domínguez, Y.; Férnandez Santana, E.; Sárvári Horváth, I.; Rodríguez Muñoz, S. Hidrólisis química y digestión anaerobia termofílica de la fracción orgánica de los residuos sólidos urbanos. Rev. Cuba. Ing. 2014, 5, 59–66. [Google Scholar] [CrossRef]

- Ghasimi, D.S.M.; Zandvoort, M.H.; Adriaanse, M.; van Lier, J.B.; de Kreuk, M. Comparative analysis of the digestibility of sewage fine sieved fraction and hygiene paper produced from virgin fibers and recycled fibers. Waste Manag. 2016, 53, 156–164. [Google Scholar] [CrossRef] [PubMed]

- Naroznova, I.; Møller, J.; Scheutz, C. Characterisation of the biochemical methane potential (BMP) of individual material fractions in Danish source-separated organic household waste. Waste Manag. 2016, 50, 39–48. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bardales, J.; Cruz, E.; Cabrera, C. Manejo integral de residuos sólidos domiciliarios por medio de la segregación en la fuente en el distrito de San Luis, Lima, Perú. Rev. Inst. Investig. Fac. Ing. Geol. Miner. Met. Geogr. 2015, 18, 23–29. [Google Scholar]

- Sánchez Bernal, E.I.; Rodríguez León, A.; Sandoval Orozco, G.; Camacho Escobar, M.A.; Estrada Vázquez, C. Generación de residuos sólidos municipales en San Pedro Mixtepec, Juquila, Oaxaca: Impactos ambientales y alternativas de mitigación. Rev. Int. Cienc. Soc. 2015, 2, 21–36. [Google Scholar]

- Castañeda Delgado, G.A.; Pérez Escatel, A.A. La problemática del manejo de los residuos sólidos en seis municipios del sur de Zacatecas. Reg. Soc. 2015, 27, 97–115. [Google Scholar] [CrossRef]

- Gu, B.; Wang, H.; Chen, Z.; Jiang, S.; Zhu, W.; Liu, M.; Chen, Y.; Wu, Y.; He, S.; Cheng, R.; et al. Characterization, quantification and management of household solid waste: A case study in China. Resour. Conserv. Recycl. 2015, 98, 67–75. [Google Scholar] [CrossRef]

- Taboada-González, P.; Aguilar-Virgen, Q.; Cruz-Sotelo, S.E.; Ramirez-Barreto, M.E. Manejo y potencial de recuperación de residuos sólidos en una comunidad rural de México. Rev. Int. Contam. Ambient. 2013, 29, 43–48. [Google Scholar]

- Taboada-González, P.; Aguilar-Virgen, Q.; Ojeda-Benitez, S. Análisis estadístico de residuos sólidos domésticos en un municipio fronterizo de México. Avances en Ciencias e Ingeniería 2011, 2, 9–20. [Google Scholar]

- Francisco, A.A.; Rodríguez, Y. Caracterización residuos sólidos domiciliarios en Santo Domingo Oeste, Provincia Santo Domingo, (i). Cienc. Soc. 2010, 35, 566–587. [Google Scholar] [CrossRef]

- Thanh, N.P.; Matsui, Y.; Fujiwara, T. Household solid waste generation and characteristic in a Mekong Delta city, Vietnam. J. Environ. Manag. 2010, 91, 2307–2321. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; De la Cruz, F.B.; Ximenes, F.; Barlaz, M.A. Decomposition and carbon storage of selected paper products in laboratory-scale landfills. Sci. Total Environ. 2015, 532, 70–79. [Google Scholar] [CrossRef] [PubMed]

- Yuan, X.; Wen, B.; Ma, X.; Zhu, W.; Wang, X.; Chen, S.; Cui, Z. Enhancing the anaerobic digestion of lignocellulose of municipal solid waste using a microbial pretreatment method. Bioresour. Technol. 2014, 154, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Wan, S.; Sun, L.; Douieb, Y.; Sun, J.; Luo, W. Anaerobic digestion of municipal solid waste composed of food waste, wastepaper, and plastic in a single-stage system: Performance and microbial community structure characterization. Bioresour. Technol. 2013, 146, 619–627. [Google Scholar] [CrossRef] [PubMed]

- Pommier, S.; Llamas, A.M.; Lefebvre, X. Analysis of the outcome of shredding pretreatment on the anaerobic biodegradability of paper and cardboard materials. Bioresour. Technol. 2010, 101, 463–468. [Google Scholar] [CrossRef] [PubMed]

- Mañon-Salas, M.; Hernández-Berriel, M.; Márquez-Benavides, L. Uso del análisis multivariado para modelar el asentamiento de RSU en biorreactores con recirculación de lixiviados. Rev. Int. Contam. Ambient. 2012, 28, 51–58. [Google Scholar]

| Domestic Solid Waste | Fractions | Specifications |

|---|---|---|

| Domestic lignocellulosic residues | Food waste | Residues of vegetable, animal and artificial origin. |

| Sanitary waste (diaper and sanitary napkin) | Includes adult and child diapers. | |

| Wood | Wood and similar. | |

| Yard trimming | Residues of flowers, leaves, grass, branches or the like. | |

| Bond paper | Includes white and colored paper (printed or not), of notebooks and books. With a grammage of 50, 60, 68, 75, 90, 105, 120, 150 g/m2. | |

| Glossy paper | It includes magazines, brochures, triptychs (grammage of 70, 90 y 120 g/m2), linings of magazines and books (grammage of 200 to 300 g/m2) and pictures (grammage of 175 to 250 g/m2). | |

| Newspaper | Newspaper recovered (recycled) or mechanical pulp paper, grammage 40 to 65 g/m2. | |

| Toilet paper | Includes disposable tissues and napkins, weight of 12 to 30 g/m2. | |

| Cardboard | Includes brown, white and mixed cardboard boxes, grammage 160 to 600 g/m2. | |

| Others | Non-biodegradable | Includes high and low density polyethylene, polyethylene, transparent and colored glass, cans, aluminum, polypropylene, polystyrene, tetrapak, and ferrous material. |

| Miscellaneous | Mixed materials difficult to separate. |

| Domestic Solid Waste | Mean ± Standard Deviation (%, p/p) | Percentage DLW a (%) | |

|---|---|---|---|

| DLW | Food waste | 47.4 ± 5.4 | - |

| Sanitary waste (diaper and sanitary napkin) | 7.8 ± 3.0 | 30.7 | |

| Cardboard (CB) | 4.8 ± 1.6 | 18.9 | |

| Toilet paper (TP) | 4.3 ± 2.3 | 16.9 | |

| Yard trimming | 3.2 ± 3.1 | 12.6 | |

| Bond paper (BP) | 2.2 ± 1.2 | 8.7 | |

| Glossy paper (GP) | 1.6 ± 1.4 | 6.3 | |

| Wood | 1.1 ± 1.6 | 4.3 | |

| Newspaper (NP) | 0.4 ± 0.4 | 1.6 | |

| Total | 25.4 b | 100 | |

| Others | Non-biodegradable | 23.5 ± 9.0 | |

| Miscellaneous | 3.8 ± 1.9 | ||

| Chemical Composition | Domestic Lignocellulosic Residues | |||||

|---|---|---|---|---|---|---|

| TP | BP | GP | CB | NP | ||

| Total Solid (TS) | (%, p/p) | 98.8 | 98.8 | 99.6 | 97.9 | 97.6 |

| σ | 0.1 | 0.3 | 0.2 | 0.1 | 0.1 | |

| (p ≤ 0.05) * | b | b | a | c | d | |

| Total Volatile Solid (TVS) | (% TS) | 98.7 | 79.6 | 67.9 | 91.7 | 87.0 |

| σ | 0.2 | 0.2 | 1.6 | 0.6 | 0.8 | |

| (p ≤ 0.05) * | a | d | e | b | c | |

| Lignin | (% TS) | 1.0 | 2.2 | 12.9 | 15.4 | 24.5 |

| σ | 0.1 | 0.0 | 0.5 | 1.5 | 1.2 | |

| (p ≤ 0.05) * | d | d | c | b | a | |

| Holocellulose | (% TS) | 84.9 | 86.3 | 74.5 | 68.4 | 62.7 |

| σ | 1.0 | 0.4 | 0.8 | 0.8 | 0.7 | |

| (p ≤ 0.05) * | a | a | b | c | d | |

| Biodegradability factor (BF) | 0.8 | 0.8 | 0.5 | 0.4 | 0.2 | |

| Paper (%) | Cardboard (%) | Season | Socioeconomic Stratum | City/Country | Reference |

|---|---|---|---|---|---|

| 8.5 | 4.8 | Summer | Medium-Low | Morelia, Michoacán/Mexico | This study |

| 6.8 | 1.6 | NS | Low-Medium | San Luis, Lima/Peru | [58] |

| 13 | Summer | Medium | San Pedro Mixtepec Juquila, Oaxaca/Mexico | [59] | |

| 4.3 to 8.7 | Summer | Low-Medium | Zacatecas Mexico | [60] | |

| 14.3 | Four seasons | Medium-High | Suzhou/China | [61] | |

| 8.6 | Summer/Winter | Rural | Ensenada, B.C.N./Mexico | [62] | |

| 5.1 | 5.3 | Winter | Popular-Medium-Residencial | Xico, Veracruz/Mexico | [2] |

| 6.2 | 6.5 | NS | High-Medium-Low | Mexico | [1] a |

| 21.6 | Summer | ProMedium High, Medium y Low | Ensenada, B.C.N./Mexico | [63] | |

| 16.5 | Summer | Medium-Low | San Quintín, B.C.N./Mexico | [63] | |

| 15.9 | Summer | Medium-Low | Vicente Guerrero, B.C.N./Mexico | [63] | |

| 11.4 | Summer | Low | Santo Domingo/Dominican Republic | [64] | |

| 4.7 | Dry/Rainy | High-Medium-Low | Can Tho/Vietnam | [65] b | |

| DLW | Lignin (% TS) | Pretreatment a | Experimental Phase b | Temperature Regime | Test Time (Days) | YCH4 Accum. (mL/g TVS) | Ref |

|---|---|---|---|---|---|---|---|

| BP | 2 | - | Semi-Solid | Mesophilic | 200 | 902 | This study |

| NC | Biological | Liquid | Thermophilic | 40 | 380 | [54] | |

| 2 | - | Liquid | Mesophilic | 45 | 372 | [57] | |

| 1 | - | Liquid | Mesophilic | 55 | 287 | [40] | |

| 2 | - | Solid | Mesophilic | 700 | 214 | [52] | |

| 2 | Biological | Liquid | Mesophilic | 60 | 184 | [66] | |

| GP | 13 | - | Semi-Solid | Mesophilic | 200 | 504 | This study |

| 12 | Biological | Liquid | Mesophilic | 60 | 92 | [66] | |

| 15 | - | Solid | Mesophilic | 230 | 63 | [52] | |

| CB | 15 | - | Semi-Solid | Mesophilic | 200 | 66 | This study |

| NC | Biological | Liquid | Thermophilic | 40 | 280 | [54] | |

| 3 | - | Liquid | Mesophilic | 45 | 271 | [57] | |

| 18 | - | Liquid | Mesophilic | 55 | 231 | [40] | |

| 9 | - | Liquid | Mesophilic | 45 | 202 | [57] | |

| 16 | Addition of nutrients | Semi-Solid | Mesophilic | 298 | 197 | [53] | |

| 21 | - | Solid | Mesophilic | 450 | 113 | [52] | |

| NP | 25 | - | Semi-Solid | Mesophilic | 200 | 2 | This study |

| 23 | - | Liquid | Mesophilic | 55 | 287 | [40] | |

| NC | Biological | Liquid | Thermophilic | 40 | 280 | [54] | |

| 24 | - | Solid | Mesophilic | 450 | 73 | [52] | |

| 25 | Biological | Liquid | Mesophilic | 60 | 59 | [66] | |

| TP | 1 | - | Semi-Solid | Mesophilic | 200 | −28 | This study |

| 1 | - | Liquid | Mesophilic | 45 | 419 | [57] | |

| NC | - | Liquid | Mesophilic | 15 | 230 | [56] | |

| Mixture containing domestic lignocellulosic residues (similar to paper and cardboard) | |||||||

| BP, NP, and CB (1:1:1) | 1 | Biological | Liquid | Mesophilic | 10 | 569 | [67] |

| Food and paper (9:1) | NC | Chemical | Liquid | Thermophilic | 32 | 499 | [55] |

| Diverse paper | NC | Biological | Liquid | Thermophilic | 40 | 380 | [54] |

| Food paper and plastic (2:1:1) | NC | Thermal | Solid | Mesophilic | 37 | 370 | [68] |

| BP, NP, CB and GP (1:2:3:3) | 2 | - | Liquid | Mesophilic | 50 | 117 | [69] |

| Domestic Lignocellulosic Residues | Domestic Solid Waste a (kg) | Experimental Performance of CH4 b (m3/kg of Material, Dry Base) | CH4 (m3) | Emissions of CH4 (kg CO2eq/kg of Waste) | ||

|---|---|---|---|---|---|---|

| This Study c | DEFRA [18] c | Turner et al. [19] d | ||||

| Bond paper | 22 | 0.72 | 16 | 259 | 13 | 35 |

| Glossy paper | 16 | 0.36 | 6 | 94 | 9 | 25 |

| Toilet paper | 43 | -- | --- | 0.1 | 25 | 68 |

| Cardboard | 48 | 0.06 | 3 | 47 | 28 | 27 |

| Newspaper | 4 | <0 | <0 | 0.1 | 2 | 6 |

| Total | 23 | 400 | 77 | 161 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peña Contreras, K.; Sánchez Yáñez, J.M.; Aguilar-Virgen, Q.; Taboada-González, P.; Marquez-Benavides, L. Potential for Methane Generation by Lignocellulosic Household Waste. Sustainability 2018, 10, 3461. https://doi.org/10.3390/su10103461

Peña Contreras K, Sánchez Yáñez JM, Aguilar-Virgen Q, Taboada-González P, Marquez-Benavides L. Potential for Methane Generation by Lignocellulosic Household Waste. Sustainability. 2018; 10(10):3461. https://doi.org/10.3390/su10103461

Chicago/Turabian StylePeña Contreras, Karla, Juan Manuel Sánchez Yáñez, Quetzalli Aguilar-Virgen, Paul Taboada-González, and Liliana Marquez-Benavides. 2018. "Potential for Methane Generation by Lignocellulosic Household Waste" Sustainability 10, no. 10: 3461. https://doi.org/10.3390/su10103461