Effect of Pre-Determined Maintenance Repair Rates on the Health Index State Distribution and Performance Condition Curve Based on the Markov Prediction Model for Sustainable Transformers Asset Management Strategies

Abstract

:1. Introduction

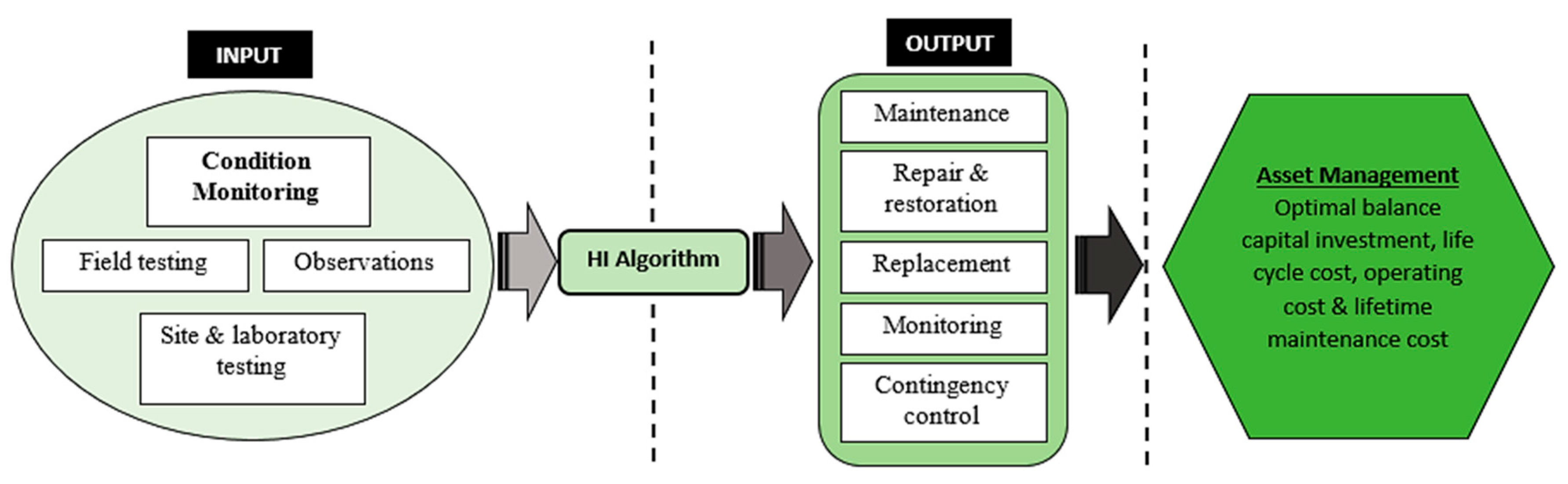

2. Health Index (HI) and Asset Management Strategy

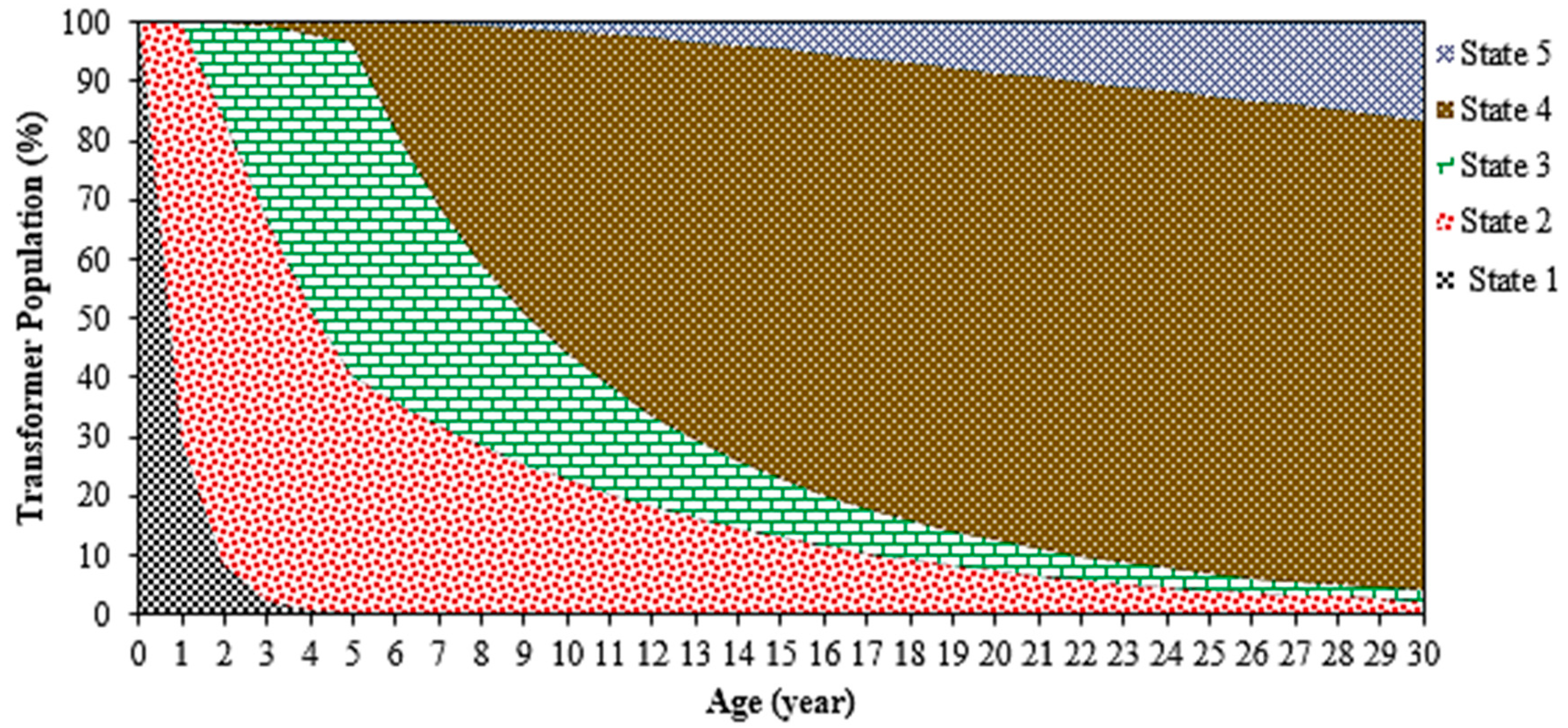

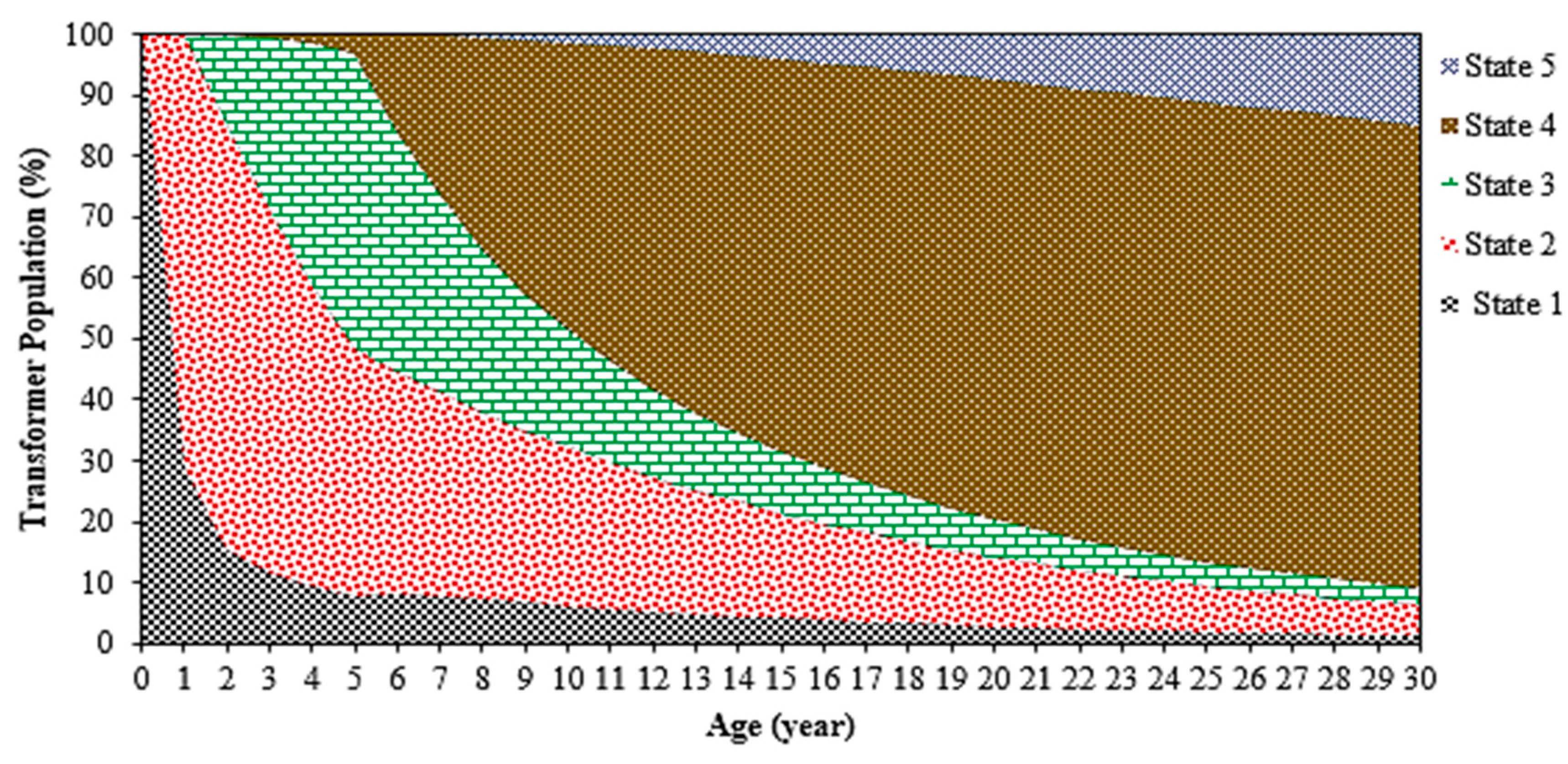

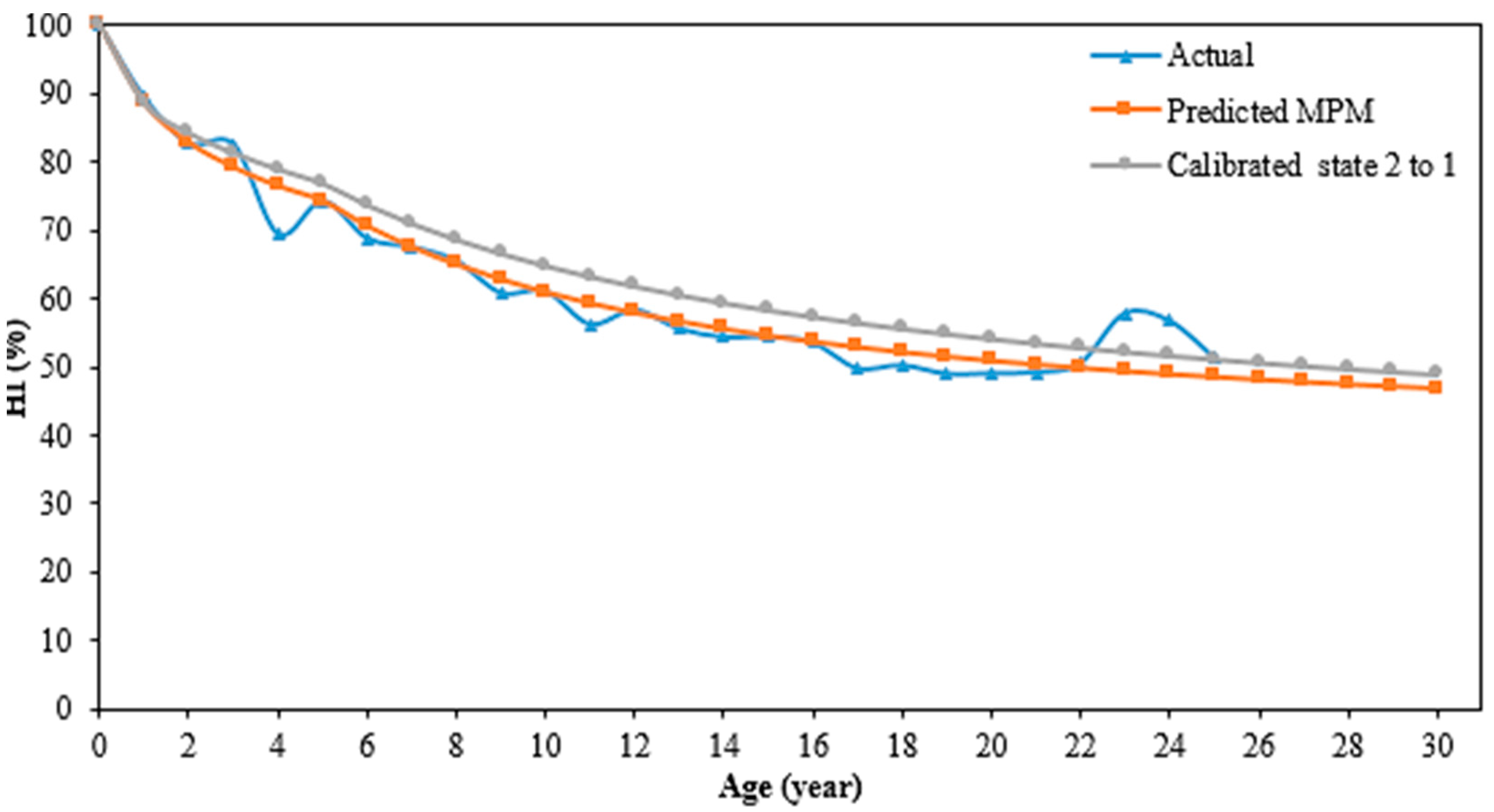

3. Updating Markov Prediction Model (MPM)

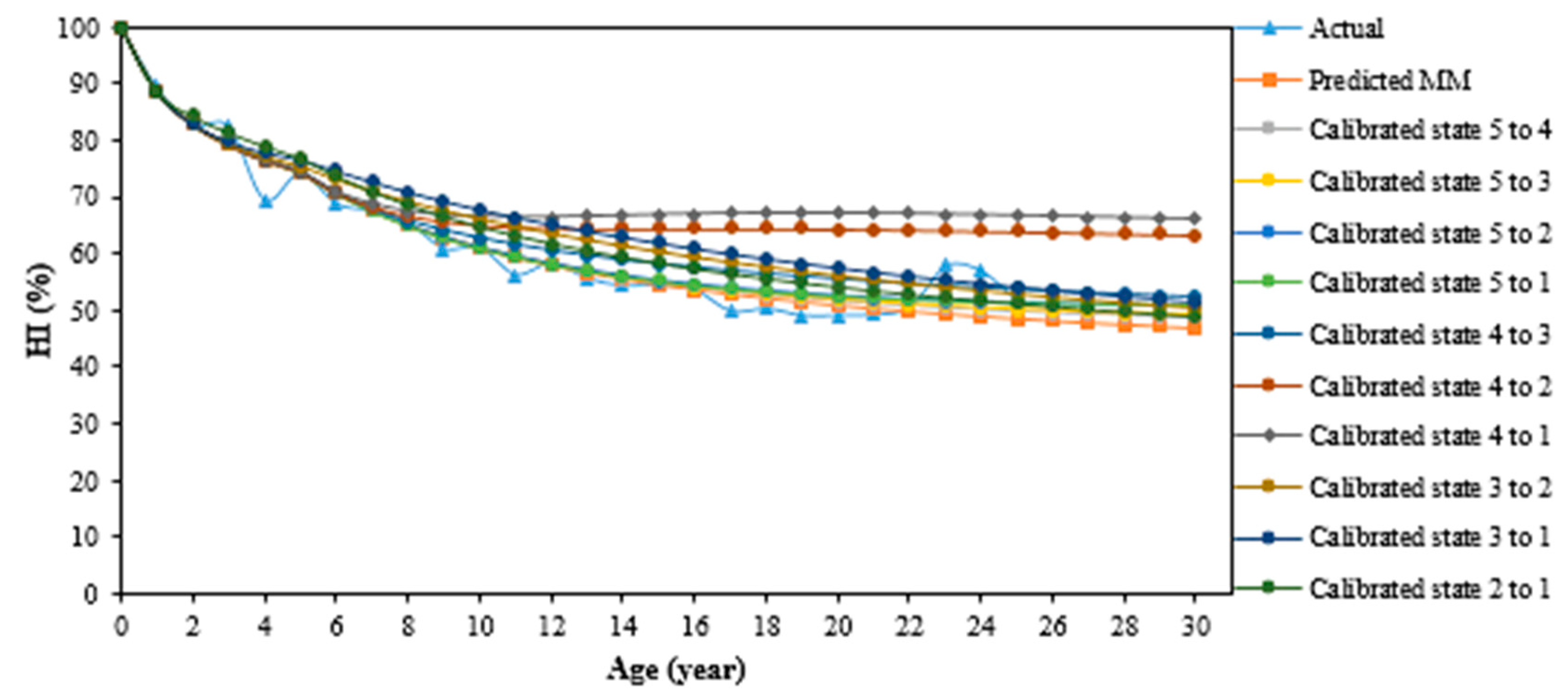

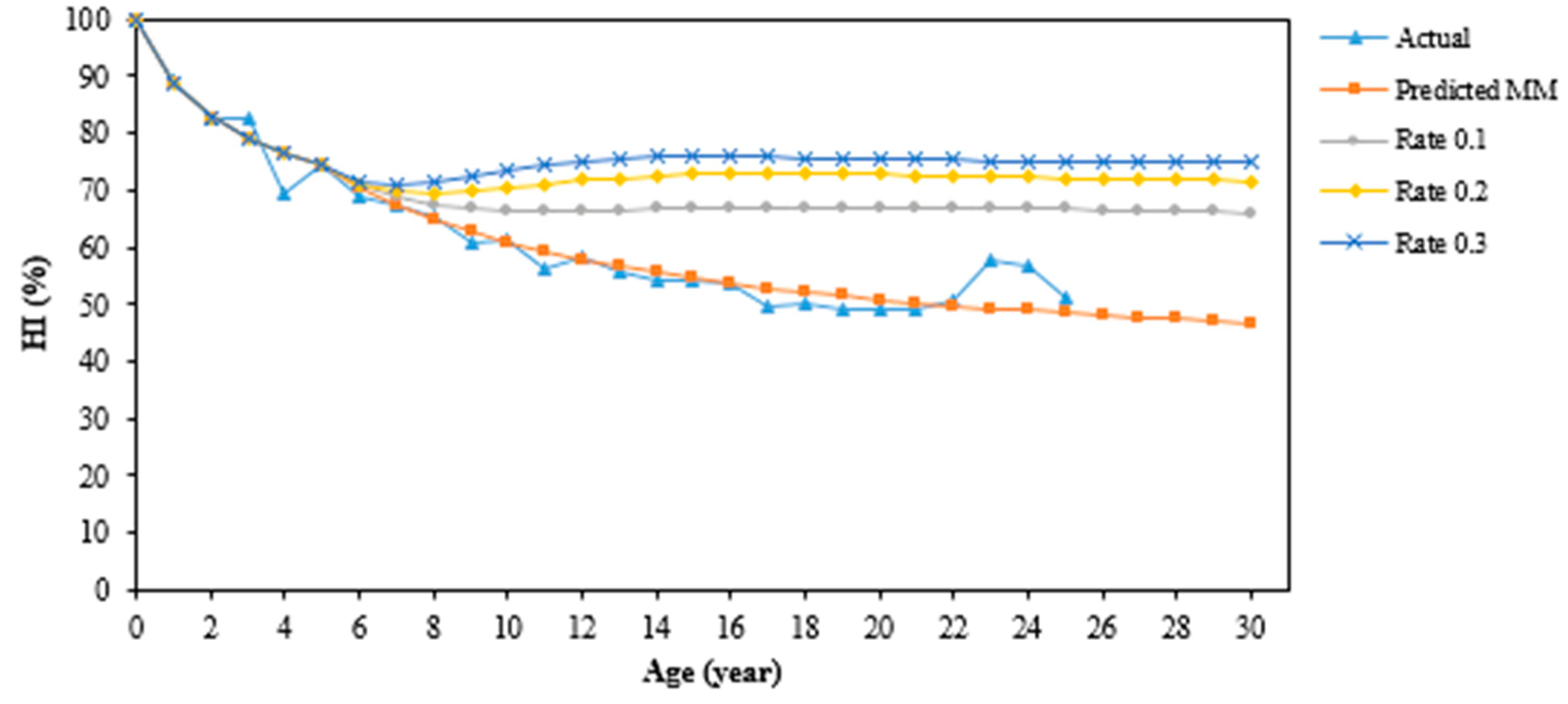

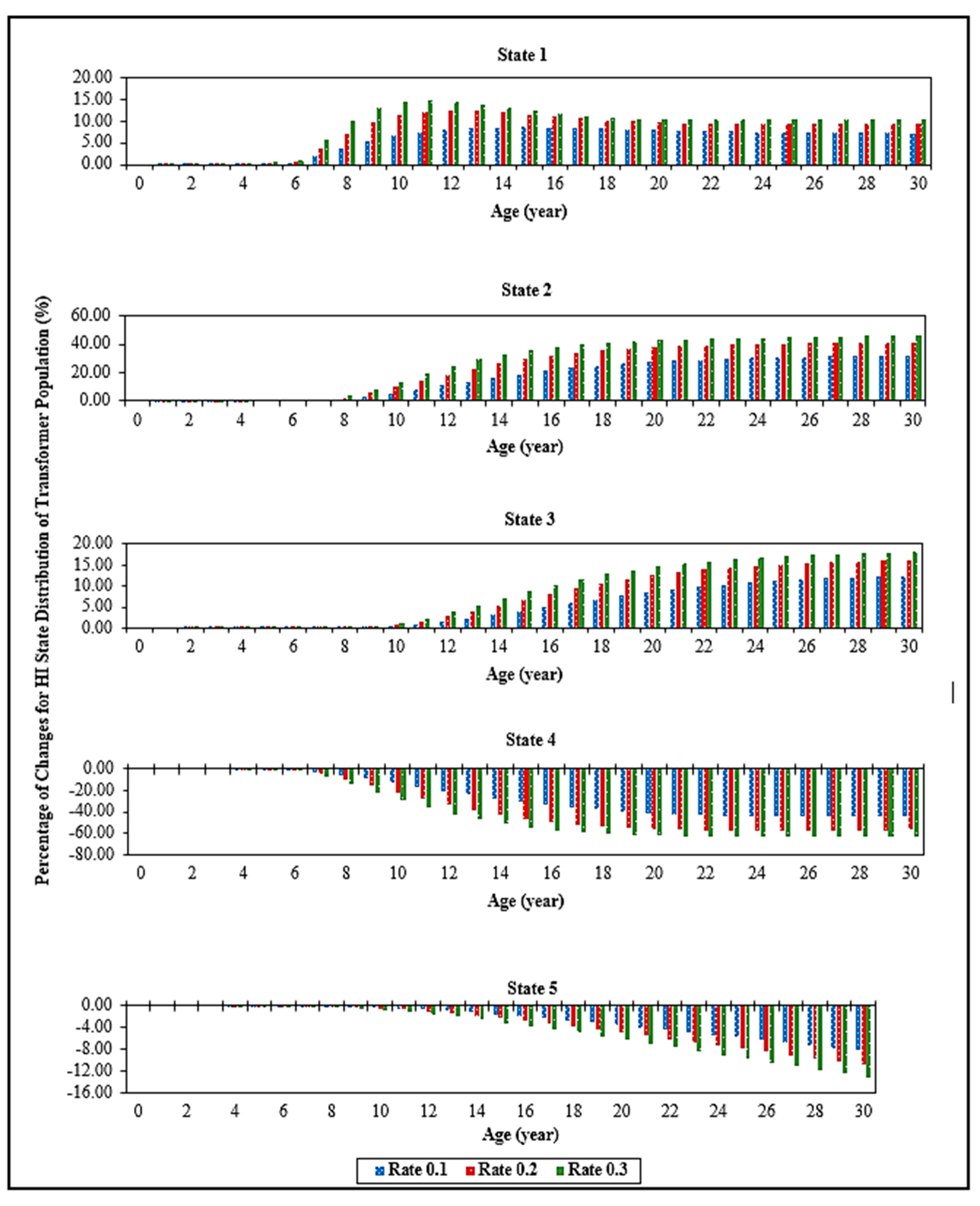

4. Application of Updated Markov Prediction Model (MPM)

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abu-Elanien, A.E.B.; Salama, M.M.A. Asset management techniques for transformers. Elect. Power Syst. Res. 2010, 80, 456–464. [Google Scholar] [CrossRef]

- Juan, L.; Valasquez, C.; Miguel, A.S.; Samuel, G.A. General asset management model in the context of an electric utility: Application to power transformers. Elect. Power Syst. Res. 2011, 81, 2015–2037. [Google Scholar]

- A2.18 W.G. Life Management Techniques for Power Transformer; CIGRE: Paris, France, 2003. [Google Scholar]

- Hamoud, G.A. Use of Markov models in assessing spare transformer requirements for distribution stations. IEEE Trans. Power Syst. 2012, 27, 1098–1105. [Google Scholar] [CrossRef]

- Jahromi, A.; Piercy, R.; Cress, S.; Service, J.; Fan, W. An approach to power transformer asset management using health index. IEEE Electr. Insul. Mag. 2009, 25, 20–34. [Google Scholar] [CrossRef]

- Yang Ghazali, Y.Z.; Talib, M.A.; Ahmad Rosli, H. TNB experience in condition assessment and life management of distribution power transformers. In Proceedings of the Electricity Distribution-Part 1 (CIRED 2009), Prague, Czech Republic, 8–11 June 2009; pp. 1–4. [Google Scholar]

- Scatiggio, F.; Pompili, M. Health index: The TERNA’s practical approach for transformers fleet management. In Proceedings of the Electrical Insulation Conference (EIC), Ottawa, ON, Canada, 2–5 June 2013; pp. 178–182. [Google Scholar]

- Tanasescu, G.; Notingher, P.V.; Dragomir, O.; Gorgan, B.; Voinescu, L. Health index calculation of electrical equipments using DiagConsole software. In Proceedings of the Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 23–25 May 2013; pp. 1–6. [Google Scholar]

- Haema, J.; Phadungthin, R. Condition assessment of the health index for power transformer. In Proceedings of the IEEE Power Engineering and Automation Conference (PEAM), Wuhan, China, 18–20 September 2012; pp. 1–4. [Google Scholar]

- Brandtzæg, G. Health Indexing of Norwegian Power Transformers. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2015. [Google Scholar]

- Wang, M.; Vandermaar, A.J.; Srivastava, K.D. Review of condition asessment of power transformers in service. Electr. Insul. Mag. IEEE 2002, 18, 12–25. [Google Scholar] [CrossRef]

- A2.27 W.G. Rcommendations for Condition Monitoring and Condition Assessment Facilities for Transformer; CIGRE: Paris, France, 2008. [Google Scholar]

- Emsley, A.; Steven, G. Review of chemical indicators of degradation of cellulosic electrical paper insulation in oil-filled transformers. IEE Proc. Sci. Meas. Technol. 1994, 141, 324–334. [Google Scholar] [CrossRef]

- Daniel, M.; Tapan, S.; Richard, D.; Gary, B.; Srinivasan, C.; Greg, C.; Jian, B.Z.; Russell, G. Determining water in transformer paper insulation: Analyzing aging transformers. Electr. Insul. Mag. IEEE 2015, 31, 23–32. [Google Scholar]

- Lars, R.L.; Walter, H.; Dag, L.; Terence, J.P. Aging of Oil-Impregnated Paper in Power Transformers. IEEE Trans. Power Deliv. 2004, 19, 230–239. [Google Scholar]

- D1.01 W.G. Furanic Compounds for Diagnosis; CIGRE: Paris, France, 2011. [Google Scholar]

- Zhou, D.; Wang, Z.; Li, C. Data requisites for transformer statistical lifetime modelling-part I: Aging related failures. IEEE Trans. Power Deliv. 2013, 28, 1750–1757. [Google Scholar] [CrossRef]

- Zhou, D.; Wang, Z.; Jarman, P. Data requisites for transformer statistical lifetime modelling-part II: Aging related failures. IEEE Trans. Power Deliv. 2014, 29, 154–160. [Google Scholar] [CrossRef]

- Ridwan, M.I.; Talib, M.A.; Ghazali, Y.Z.Y. Application of weibull-bayesian for the reliability analysis of distribution transformers. In Proceedings of the IEEE 8th International Power Engineering and Optimization Conference (PEOCO2014), Langkawi, The Jewel of Kedah, Malaysia, 24–25 March 2014. [Google Scholar]

- Yahaya, M.S.; Azis, N.; Ab Kadir, M.Z.; Jasni, J.; Hairi, M.H.; Talib, M.A. Estimation of transformers Health Index based on the Markov chain. Energies 2017, 10, 1824. [Google Scholar] [CrossRef]

- Butt, A.A.; Shahin, M.Y.; Feighan, K.J.; Carpenter, S.H. Pavement performance predíction model using the Markov process. Transp. Res. Rec. 1987, 1123, 12–99. [Google Scholar]

- Jiang, Y.; Saito, M.; Sinha, K. Bridge performance prediction model using the Markov chain. Transp. Res. Rec. 1988, 1180, 25–32. [Google Scholar]

- Jiang, Y.; Sinha, K. Bridge service life prediction model using the Markov chain. Transp. Res. Rec. 1989, 1223, 24–30. [Google Scholar]

- Riveros, G.A.; Arredondo, E. Guide to the Development of a Deterioration Rate Curve Using Condition State Inspection Data; Report, No.: ERDC/CHL CHETN-IX-25; US Army Corps of Engineers: Davis, CA, USA, 2010; pp. 1–12. [Google Scholar]

- Micevski, T.; Kuczera, G.; Coombes, P. Markov model for storm water pipe deterioration. J. Infrastruct. Syst. 2002, 8, 49–56. [Google Scholar] [CrossRef]

- Li, L.; Feng, L.; Zhang, C.; Lijun, S. Use of Markov chain model Bbsed on actual repair status to predict bridge deterioration in Shanghai, China. Transp. Res. Rec. J. Transp. Res. Board 2016, 2550, 106–114. [Google Scholar] [CrossRef]

- Hoskins, R.P.; Strbac, G.; Brint, A.T. Modelling the degradation of condition indices. IEE Proc. Gener. Transm. Distrib. 1999, 146, 386–392. [Google Scholar] [CrossRef]

- Zhang, Y.; Augenbroe, G.; Vidakovic, B. Uncertainty analysis in using Markov Chain to predict roof life cycle performance. In Proceedings of the Durability of Building Material and Components (10DBMC), Lyon, France, 17–20 April 2005. [Google Scholar]

- Camahan, J.V.; Davis, W.J.; Shahin, M.Y.; Keane, P.L.; Wu, M.I. Optimal maintenance decisions for pavement management. J. Transp. Eng. 1987, 113, 554–572. [Google Scholar] [CrossRef]

- Agrawal, A.K.; Kawaguchi, A.; Chen, Z. Deterioration rates of typical bridge elements in New York. J. Bridg. Eng. 2010, 15, 419–429. [Google Scholar] [CrossRef]

- Cesare, M.A.; Santamarina, C.; Turkstra, C.; Vanmarcke, E.H. Modeling bridge deterioration with Markov chains. J. Transp. Eng. 1993, 118, 820–833. [Google Scholar] [CrossRef]

- Jiang, Y. Application and comparison of regression and Markov chain methods in bridge condition prediction and system benefit optimization. J. Transp. Res. Forum 2010, 49, 91–110. [Google Scholar]

- Si, X.S.; Wang, W.; Hu, C.H.; Zhou, D.H. Remaining useful life estimation—A review on the statistical data driven approaches. Eur. J. Oper. Res. 2011, 213, 1–14. [Google Scholar] [CrossRef]

- Martins, M.A. Condition and risk assessment of power transformers: A general approach to calculate a health index. Ciência Tecnol. Mater. 2014, 26, 9–16. [Google Scholar] [CrossRef]

- A2.34 W.G. Guide for Transformer Maintenance; CIGRE: Paris, France, 2011. [Google Scholar]

- Richard, E.B.; Bruce, G.H. Asset Management for Transmission and Distribution. IEEE Power Energy Mag. 2005, 3, 39–45. [Google Scholar]

- Dhillon, B.S. Engineering Maintenance: A Modern Approach, 1st ed.; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Deloitte Asset Management; Canadian Electricity Associate (CEA). Asset Health Indices: A Utility Industry Necessity; Whitepaper; Deloitte: London, UK, 2014. [Google Scholar]

- Naderian, A.; Cress, S.; Piercy, R.; Wang, F.; Service, J. An approach to determine the health index of power transformers. In Proceedings of the IEEE International Symposium on Electrical Insulation (ISEI), Vancouver, BC, Canada, 9–12 June 2008; pp. 192–196. [Google Scholar]

- Azmi, A.; Jasni, J.; Azis, N.; Kadir, M.Z.A. Evolution of transformer health index in the form of mathematical equation. Renew. Sustain. Energy Rev. 2017, 76, 687–700. [Google Scholar] [CrossRef]

- Jasni, J.; Azmi, A.; Yahaya, M.S.; Talib, M.A. Assessment of transformer Health Index using different model. Pertanika J. Sci. Technol. 2017, 25, 143–150. [Google Scholar]

- Yates, R.D.; Goodman, D.J. Probability and Stochastic Processes, 2nd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2005; pp. 445–451. [Google Scholar]

| Health Index | Condition | State | Required Maintenance Action |

|---|---|---|---|

| 85–100% | Very Good | 1 | Normal maintenance. |

| 70–84% | Good | 2 | Normal maintenance. |

| 50–69% | Fair | 3 | Increase diagnostic testing, possible remedial work or replacement needed depending on criticality. |

| 30–49% | Poor | 4 | Start planning process to replace or rebuild considering risk and consequences of failure. |

| 0–29% | Very Poor | 5 | Immediately assess risk, replace or rebuild based on assessment. |

| No | Updated State | TP Zone 1 | TP Zone 2 | |

|---|---|---|---|---|

| From | To | |||

| 1 | Good | Very good | ||

| 2 | Fair | Good | ||

| 3 | Fair | Very good | ||

| 4 | Poor | Fair | ||

| 5 | Poor | Good | ||

| 6 | Poor | Very good | ||

| 7 | Very poor | Poor | ||

| 8 | Very poor | Fair | ||

| 9 | Very poor | Good | ||

| 10 | Very poor | Very good | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yahaya, M.S.; Azis, N.; Mohd Selva, A.; Ab Kadir, M.Z.A.; Jasni, J.; Hairi, M.H.; Yang Ghazali, Y.Z.; Talib, M.A. Effect of Pre-Determined Maintenance Repair Rates on the Health Index State Distribution and Performance Condition Curve Based on the Markov Prediction Model for Sustainable Transformers Asset Management Strategies. Sustainability 2018, 10, 3399. https://doi.org/10.3390/su10103399

Yahaya MS, Azis N, Mohd Selva A, Ab Kadir MZA, Jasni J, Hairi MH, Yang Ghazali YZ, Talib MA. Effect of Pre-Determined Maintenance Repair Rates on the Health Index State Distribution and Performance Condition Curve Based on the Markov Prediction Model for Sustainable Transformers Asset Management Strategies. Sustainability. 2018; 10(10):3399. https://doi.org/10.3390/su10103399

Chicago/Turabian StyleYahaya, Muhammad Sharil, Norhafiz Azis, Amran Mohd Selva, Mohd Zainal Abidin Ab Kadir, Jasronita Jasni, Mohd Hendra Hairi, Young Zaidey Yang Ghazali, and Mohd Aizam Talib. 2018. "Effect of Pre-Determined Maintenance Repair Rates on the Health Index State Distribution and Performance Condition Curve Based on the Markov Prediction Model for Sustainable Transformers Asset Management Strategies" Sustainability 10, no. 10: 3399. https://doi.org/10.3390/su10103399