Comparative Life Cycle Analysis of Conventional and Hybrid Heavy-Duty Trucks

Abstract

1. Introduction

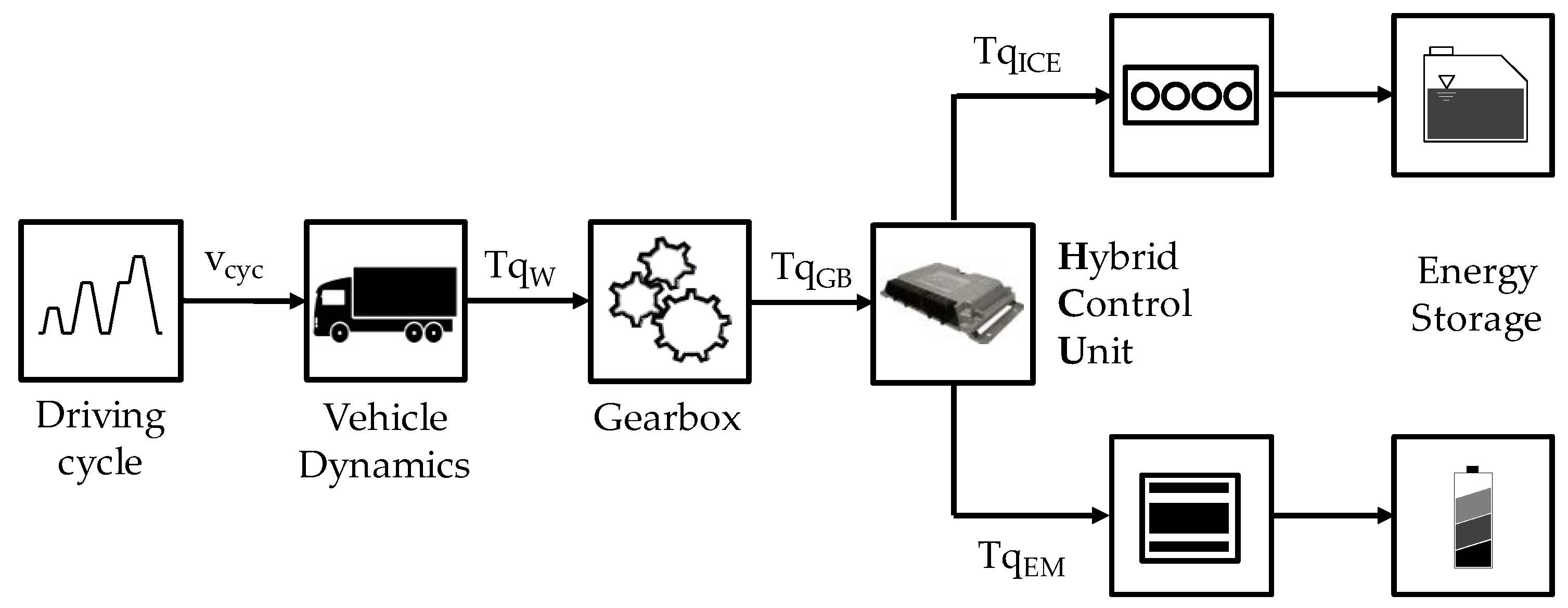

2. Methodology

2.1. Goal and Scope

- How large is the difference in environmental impact for the hybrid truck during its life cycle, using the conventional vehicle as a baseline?

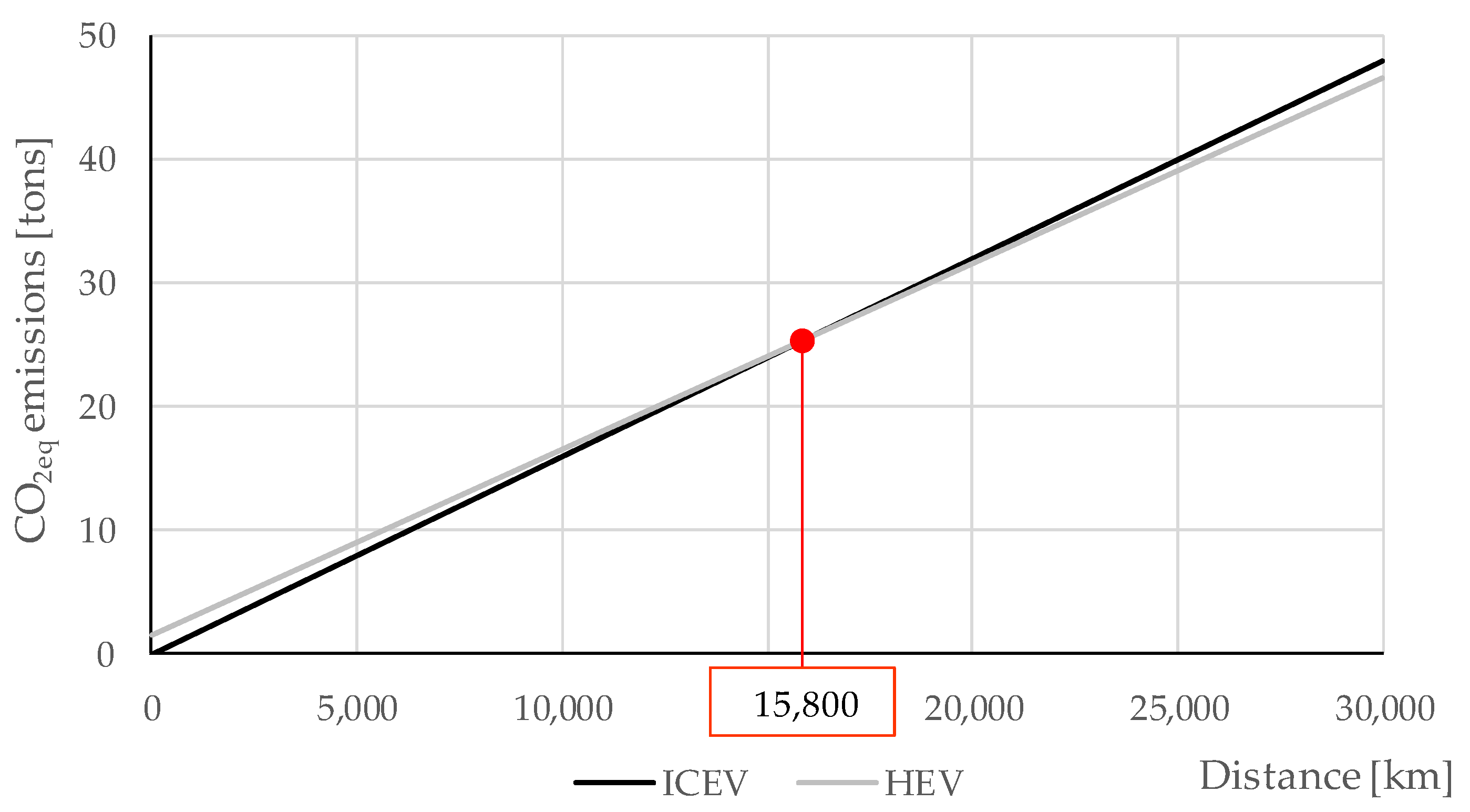

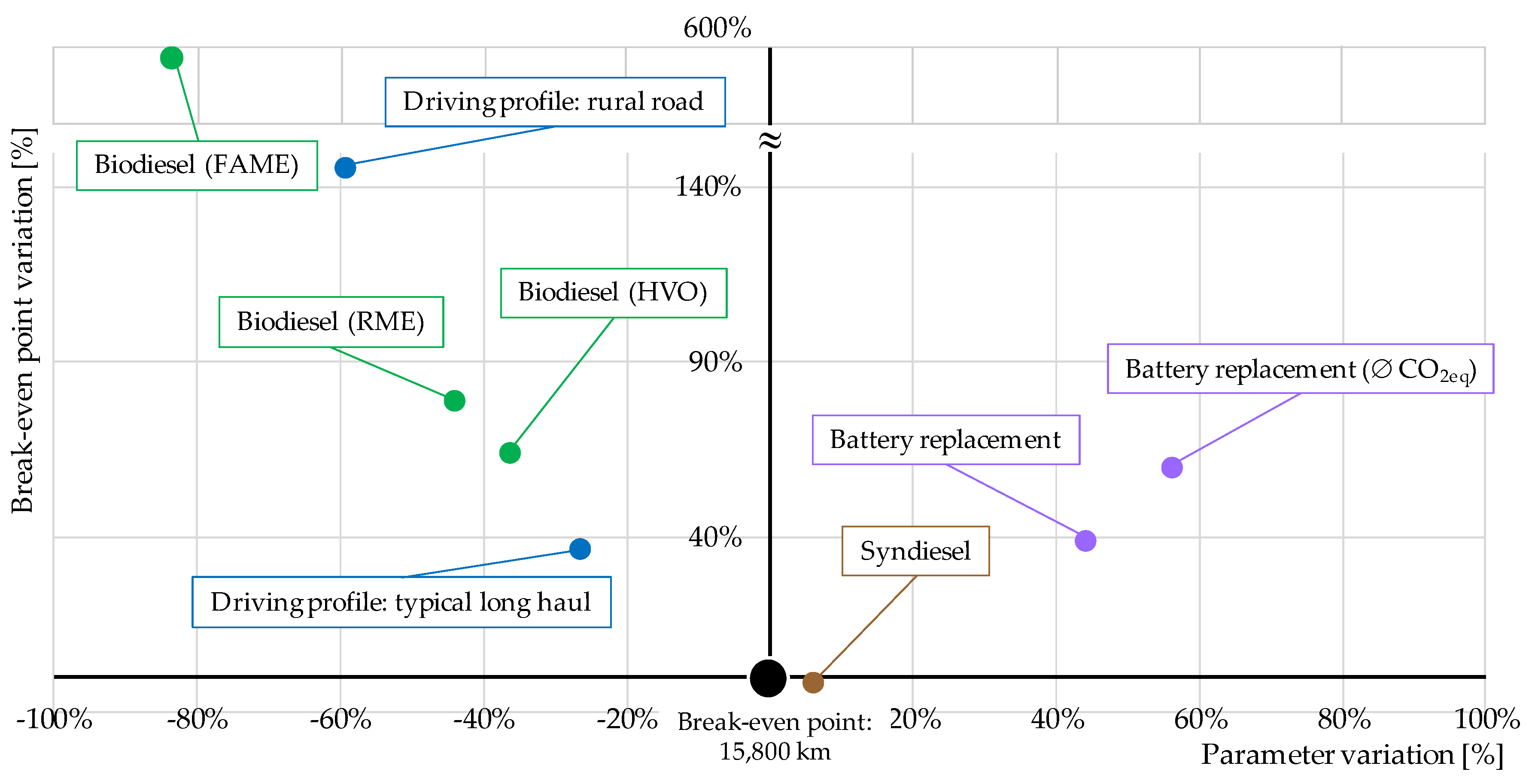

- At what mileage are the larger environmental burdens due to the production of the hybrid drivetrain compensated compared to the conventional one and which parameters affect the break-even point?

2.2. Life Cycle Inventory

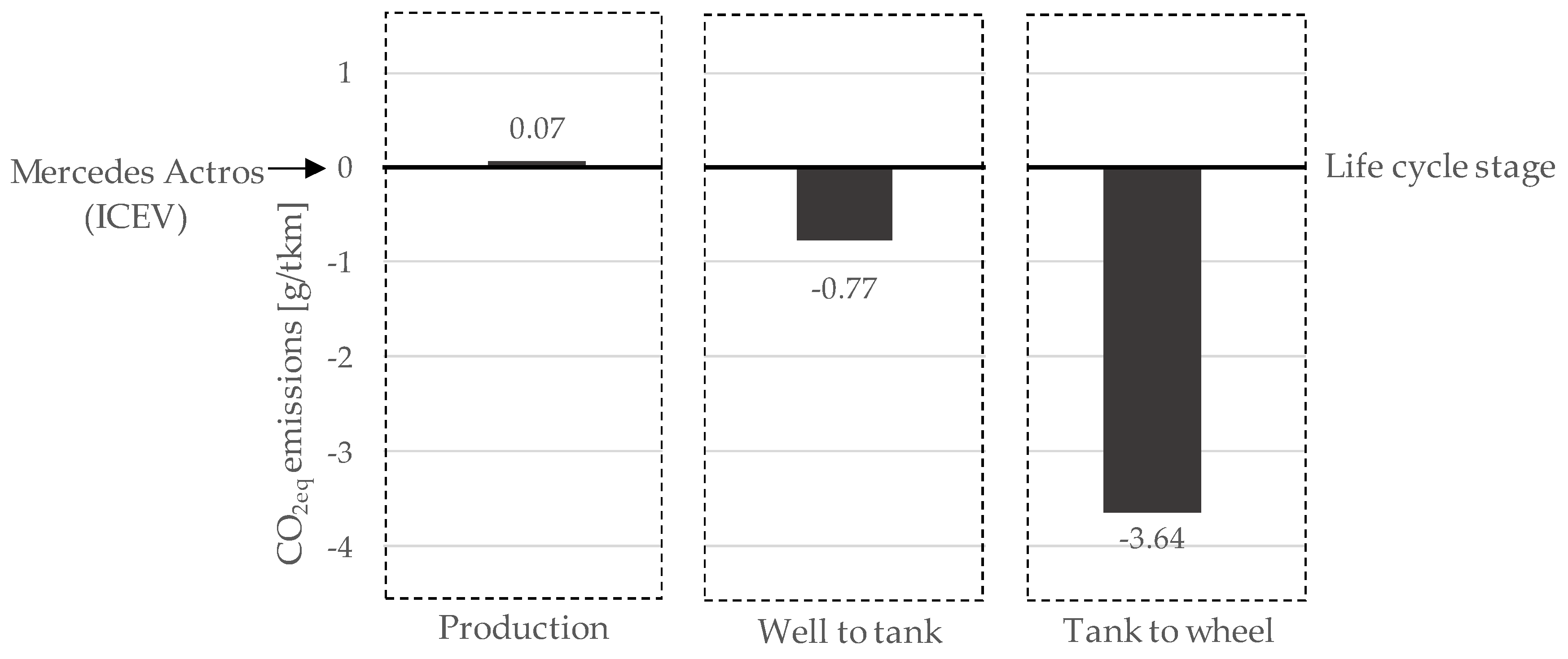

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Federal Ministry for the Environment, Nature Conservation, Building and Nuclear Safety (BMUB). The German Government’s Climate Action Programme 2020: Cabinet Decision of 3 December 2014. Available online: http://www.bmub.bund.de/fileadmin/Daten_BMU/Pools/Broschueren/aktionsprogramm_klimaschutz_2020_broschuere_en_bf.pdf (accessed on 29 August 2016).

- Federal Ministry for Economic Affairs and Energy. Energiekonzept für eine Umweltschonende, Zuverlässige und Bezahlbare Energieversorgung. Available online: http://www.bmwi.de/BMWi/Redaktion/PDF/E/energiekonzept-2010,property=pdf,bereich=bmwi2012,sprache=de,rwb=true.pdf (accessed on 29 August 2016).

- Nationale Plattform Elektromobilität (NPE). Zweiter Bericht der Nationalen Plattform Elektromobilität. Gemeinsame Geschäftsstelle Elektromobilität der Bundesregierung (GGEMO). Berlin, Germany, 2011. Available online: https://www.erneuerbar-mobil.de/sites/default/files/2016-08/nep%20bericht_emob_2.pdf (accessed on 12 August 2018).

- Umweltbundesamt. Entwicklung der Treibhausgasemissionen in Deutschland. Available online: https://www.umweltbundesamt.de/bild/entwicklung-der-treibhausgasemissionen-in (accessed on 29 August 2016).

- Kraftfahrt-Bundesamt (KBA). Der Fahrzeugbestand im Überblick am 1. Januar 2013 gegenüber 1. Januar 2012. Available online: http://www.kba.de/DE/Statistik/Fahrzeuge/Bestand/Ueberblick/2013/2013_b_ueberblick_pdf.pdf?__blob=publicationFile&v=4 (accessed on 29 August 2016).

- Kraftfahrt-Bundesamt (KBA). 14.259 Kilometer: Die Jährliche Fahrleistung Deutscher Pkw: Erstmals Ergebnisse aus Echtdaten. Available online: https://www.kba.de/SharedDocs/Pressemitteilungen/DE/2015/pm_15_15_jaehrliche_fahrleistung_deutscher_pkw_pdf.pdf?__blob=publicationFile&v=5 (accessed on 27 April 2016).

- Kraftfahrt-Bundesamt (KBA). Fahrzeugzulassungen (FZ): Neuzulassungen von Kraftfahrzeugen Nach Umwelt-Merkmalen Jahr 2012. Available online: http://www.kba.de/SharedDocs/Publikationen/DE/Statistik/Fahrzeuge/FZ/2015/fz14_2015_pdf.pdf?__blob=publicationFile&v=3 (accessed on 31 August 2016).

- Frank Dünnebeil, Carsten Reinhard, Udo Lambrecht, Antonius Kies, Stefan Hausberger, Martin Rexeis. Zukünftige Maßnahmen zur Kraftstoffeinsparung und Treibhausgasminderung bei schweren Nutzfahrzeugen. Umweltbundesamt: Dessau-Roßlau, Germany, 2015. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/378/publikationen/texte_32_2015_kraftstoffeinsparung_bei_nutzfahrzeugen.pdf (accessed on 31 August 2016).

- Kraftfahrt-Bundesamt (KBA). Fahrzeugzulassungen (FZ): Bestand an Kraftfahrzeugen nach Umwelt-Merkmalen 1. Januar 2015. Available online: https://www.kba.de/SharedDocs/Publikationen/DE/Statistik/Fahrzeuge/FZ/2015/fz13_2015_pdf.pdf?__blob=publicationFile&v=4 (accessed on 31 August 2016).

- Marques, G.G.; Alves, M.F.; Krinke, S.; Koffler, C. Life Cycle Thinking in the Brazilian Automotive Industry; SAE International: Troy, MI, USA, 2008. [Google Scholar]

- Gaines, L.; Stodolsky, F.; Cuenca, R. Lifecycle-Analysis for Heavy Vehicles; Air and Waste Management Association: Pittsburgh, PA, USA, 1998. [Google Scholar]

- Rose, L.; Hussain, M.; Ahmed, S.; Malek, K.; Costanzo, R.; Kjeang, E. A comparative life cycle assessment of diesel and compressed natural gas powered refuse collection vehicles in a Canadian city. Energy Policy 2013, 52, 453–461. [Google Scholar] [CrossRef]

- Nam, S.K.; Bert, V.W. Assessment of CO2 emissions for truck-only and rail-based intermodal freight systems in Europe. Transport. Plan. Technol. 2009, 32, 313–333. [Google Scholar]

- Baumann, H.; Tillmann, A.-M. The Hitch Hiker’s Guide to LCA: An. Orientation in Life Cycle Assessment Methodology and Application; Studentlitteratur: Lund, Sweden, 2004. [Google Scholar]

- International Organization for Standardization. Environmental Managemen—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Notter, D.A; Gauch, M.; Widmer, R.; Wager, P.; Stamp, A.; Zah, R.; Althaus, H.-J. Contribution of Li-ion batteries to the environmental impact of electric vehicles. Environ. Sci. Technol. 2010, 44, 6550–6556. [Google Scholar] [CrossRef] [PubMed]

- Law, K.; Jackson, M.D.; Chan, M. European Union Greenhouse Gas Reduction Potential for Heavy-Duty Vehicles; The International Council on Clean Transportation: San Francisco, CA, USA, 2011. [Google Scholar]

- GreenDelta GmbH. OpenLCA; GreenDelta GmbH: Berlin, Germany, 2016. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Edwards, R.; Larivé, J.-F.; Rickeard, D.; Weindorf, W. Well-to-Wheels Version 4.0: Tank-to-Wheels (TTW); Well-to-Wheels Analysis of Future Automotive Fuels and Powertrains in the European Context; Publication Office of the European Union: Luxembourg, 2013. [Google Scholar]

- Guzzella, L.; Sciarretta, A. Vehicle Propulsion Systems: Introduction to Modeling and Optimization; Springer: Berlin, Germany, 2013. [Google Scholar]

- Wallner, S.; Lamke, M.; Mohr, M.; Sedlacek, M.; Speck, F.D. Hybrid Plattform: Wirtschaftlicher Hybridantrieb für Nutzfahrzeuge. In Proceedings of the 32nd International Vienna Motor Symposium, Vienna, Austria, 5–6 May 2011; pp. 244–262. [Google Scholar]

- Frank, Z. Hybridlösung für Schwere LKW. Available online: https://www.eurotransport.de/news/zf-friedrichshafen-hybridloesung-fuer-schwere-lkw-629341.html (accessed on 11 June 2018).

- Sonntag, M.; Sawodny, O.; Kauffmann, F.; Gehring, O. Vorausschauendes HV-Batteriemanagement für E-Hybrid LKW im Fernverkehr. In Proceedings of the 6. VDI/VDE-Fachtagung Steuerung und Regelung von Fahrzeugen und Motoren, Baden-Baden, Germany, 5–6 June 2013; pp. 69–80. [Google Scholar]

- The European Parliament and the Council of the European Union. Directive (eu) 2015/719 of the European Parliament and of the Council of 29 April 2015 Amending Council Directive 96/53/EC Laying down for Certain Road Vehicles Circulating within the Community the Maximum Authorised Dimensions in National and International Traffic and the Maximum Authorised Weights in International traffic; The European Parliament and the Council of the European Union: Brussels, Belgium, 2015. [Google Scholar]

- De Jong, A.J.; Bram, I. Technology for a Heavy-Duty Hybrid Business-Case. In Proceedings of the 23rd Aachen Colloquium Automobile and Engine Technology 2014, Aachen, Germany, 6–8 October 2014; pp. 629–636. [Google Scholar]

- Thomas, W.; Frank, D. TraXon Hybrid Macht Fernverkehr Noch Wirtschaftlicher. Available online: http://www.zf.com/media/media/de/document/corporate_2/press_3/press_kits_1/2012_iaa_1/txIAA12_3_TraXon-Hybrid_d.pdf (accessed on 13 June 2014).

- Andreas, L. Fernverkehr der Zukunft: IAA-Premiere des Concept MAN TGX Hybrid. Im Fernverkehr liegt weiterhin großes CO2-Einsparpotenzial Im Fernverkehr liegt weiterhin großes CO2-Einsparpotenzial. Available online: https://www.truck.man.eu/man/media/de/content_medien/doc/entry_page_germany_1/presse_und_medien_4/140926_MAN_SE_IAA_TGX_Hybrid.pdf (accessed on 14 May 2017).

- Hongrui, M.; Felix, B.; Nigel, T.; Xavier, R.-P.; Andrew, H. A new comparison between the life cycle greenhouse gas emissions of battery electric vehicles and internal combustion vehicles. Energy Policy 2012, 44, 160–173. [Google Scholar]

- Samaras, C.; Meisterling, K. Life Cycle Assessment of Greenhouse Gas Emissions from Plug-in Hybrid Vehicles: Implications for Policy. Environ. Sci. Technol. 2008, 42, 3170–3176. [Google Scholar] [CrossRef] [PubMed]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Michael, H. Current LCA Results and Need for Further Research. Fraunhofer System Research for E-Mobility (FSEM). Echterdingen, Germany, 2011. Available online: http://www.lcaforum.ch/portals/0/df43/DF43-01%20Michael%20Held.pdf (accessed on 24 February 2017).

- Rolf, F. Umweltaspekte von Elektroautos Ein Argumentarium; Bundesamt für Umwelt BAFU: Uster, Swiss, 2012; Available online: http://esu-services.ch/fileadmin/download/frischknecht-2012-Umweltaskpekte-Elektroautos.pdf (accessed on 16 June 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rupp, M.; Schulze, S.; Kuperjans, I. Comparative Life Cycle Analysis of Conventional and Hybrid Heavy-Duty Trucks. World Electr. Veh. J. 2018, 9, 33. https://doi.org/10.3390/wevj9020033

Rupp M, Schulze S, Kuperjans I. Comparative Life Cycle Analysis of Conventional and Hybrid Heavy-Duty Trucks. World Electric Vehicle Journal. 2018; 9(2):33. https://doi.org/10.3390/wevj9020033

Chicago/Turabian StyleRupp, Matthias, Sven Schulze, and Isabel Kuperjans. 2018. "Comparative Life Cycle Analysis of Conventional and Hybrid Heavy-Duty Trucks" World Electric Vehicle Journal 9, no. 2: 33. https://doi.org/10.3390/wevj9020033

APA StyleRupp, M., Schulze, S., & Kuperjans, I. (2018). Comparative Life Cycle Analysis of Conventional and Hybrid Heavy-Duty Trucks. World Electric Vehicle Journal, 9(2), 33. https://doi.org/10.3390/wevj9020033