Abstract

Tractors are widely used self-propelled power machinery. Electrification is one of the main directions for the green and low-carbon development of tractors. Currently, electric tractors have become one of the main research hotspots in countries around the world. This study provides a comprehensive review of the research progress on electric tractors in China. Firstly, a brief analysis is conducted on the development history of electric tractors, the current research status in other countries around the world, and the situation regarding China’s tractor industry. Secondly, the classifications and characteristics of electric tractors are summarized. We focused on the research progress of electric tractor motors and their drive transmission systems, batteries, and energy management technology, as well as other key technologies. Finally, some opportunities and challenges faced by the development of electric tractors in China are pointed out from the aspects of market demand, national policies, and standard setting.

1. Introduction

As is well known, tractors are one of the main power machinery technologies widely used in agriculture, forestry, and industrial production, especially playing an important role in agricultural production practice. However, the issue of carbon emissions during tractor operation is not easily overlooked. It has become one of the main sources of carbon emissions in the agricultural sector [1,2,3].

The tractors currently in use are generally powered by internal combustion engines that consume diesel or gasoline. Diesel or gasoline engines typically have higher levels of pollutants in their combustion emissions [4,5]. Electric tractors have the advantages of lower emissions and higher energy savings compared to traditional tractors driven by internal combustion engines [6,7,8,9]. Pascuzzi et al. [10] found that the fuel consumption and carbon dioxide emissions of hybrid electric tractors are ten times and five times lower than those of internal combustion engine driven tractors, respectively. Mousazadeh et al. [11] found that a solar-assisted plug-in hybrid electric tractor can reduce carbon dioxide emissions by 14 tons per year compared to traditional internal combustion engine-driven tractors. Ueka et al. [12] found that electric tractors reduce the energy consumption and carbon dioxide emissions required for field operations by about 70% compared to traditional internal combustion engine-driven tractors.

In recent years, with the increasingly severe global energy and environmental pollution problems, many countries such as China [6], the United States [13], India [8,14,15], Italy [10,16,17], Brazil [18,19], Japan [12,20], Belarus [21], South Korea [22,23,24], Russia [25], Australia [26], the United Kingdom [27], Romania [28], Iran [11], Sweden [29,30], and Canada [31,32] have begun to vigorously develop electric tractors. These research results will make important contributions to global energy conservation and emissions reduction.

To further understand the current status of research and application of electric tractors in China, this study conducted a comprehensive review. The research results can provide a reference for the development of the electric tractor industry in China and other countries.

2. Development of Electric Tractors in Other Countries Around the World

To be precise, the electrification of tractors is not a new phenomenon. Electric tractors have been around for over 130 years, since the late 1880s [33]. Throughout the development history of electric tractors, they can be divided into two stages: power-grid-powered and battery-powered.

2.1. Electric Tractors Powered by Power Grids

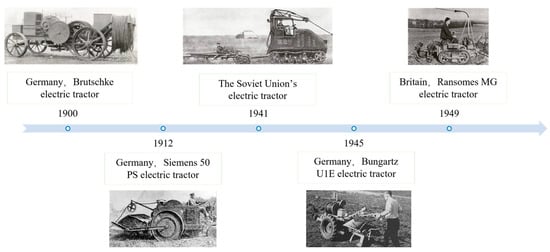

Electric tractors powered by the power grid were mainly developed before the 1950s and require power supply through overhead power lines and long cables. They first appeared in Germany in the early 20th century and in Russia and the United Kingdom in the 1930s and 1940s [34]. Figure 1 shows some representative agricultural electric tractors produced by Germany, the United Kingdom, and the Soviet Union.

Figure 1.

Historical timeline of electric tractors powered by power grids being used in agriculture [34,35].

However, practice has shown that the biggest problem faced by tractors powered by the power grid is how to handle the power cables. Moreover, there is a risk of wear and tear when dragging cables on the soil’s surface, and they are prone to entanglement with tractor wheels when turning at headlands. At the same time, oil prices were cheap at that time, and environmental pollution issues were not taken seriously, so this electric tractor did not achieve large-scale replacement applications for traditional tractors.

In recent years, the American manufacturer John Deere has proposed a plan to develop cable-driven electric tractors, and successfully developed a prototype by the end of 2018 [36]. Although the electric tractor developed by John Deere uses a robotic arm to release and retract the power cable, it to some extent avoids the problem of cable entanglement with tractor wheels. But it is still unknown whether electric tractors powered by cables can be widely used in the future.

2.2. Electric Tractors Powered by Batteries

In fact, the development of battery-powered electric tractors comes with energy and environmental issues, alongside the rapid development of electric vehicles. In particular, the energy crisis that emerged in the 1970s greatly propelled the development of electric tractors in countries around the world. And, at this stage, electric tractors are no longer constrained by power cables, and are powered by batteries.

In 1954, the International Harvester Company launched the Farmall 400 tractor. The world’s first fuel-cell electric tractor was manufactured by Allis Chalmers Manufacturing Company in 1959. This tractor is equipped with 1008 independent fuel cells, which generate electricity to drive a 20 horsepower DC motor. In the 1960s and 1970s, General Electric in the United States launched the Elec Trak electric tractor driven by lead-acid batteries and permanent magnet DC brushless motors, which further promoted the development of battery-powered tractors. Subsequently, many countries around the world conducted research and development on electric tractors powered by batteries. Figure 2 shows some representative battery-powered electric tractors.

Figure 2.

Historical timeline of some battery-powered electric tractors in other countries [37,38].

3. Current Situation of China’s Tractor Industry

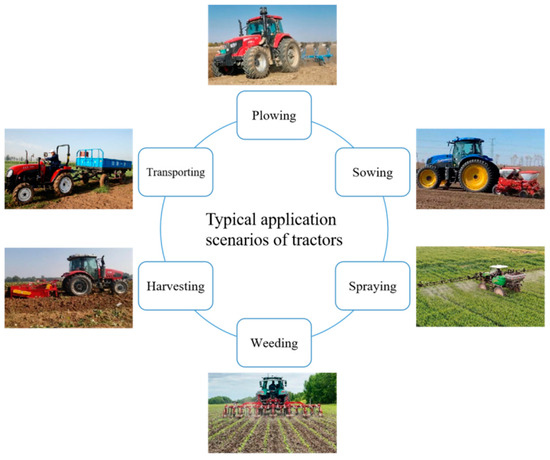

Tractors are the most important power machinery for agricultural production. As shown in Figure 3, tractors play an important role in agricultural production processes such as plowing, planting, managing, harvesting, and transportation.

Figure 3.

Schematic diagram of typical application scenarios for tractors.

The ownership of tractors is one of the important indicators of a country’s level of agricultural mechanization development. Figure 4 shows tractor ownership in China over the past 48 years. According to Figure 4, by the end of 2022, the ownership of tractors in China exceeded 21 million. The ownership of tractors in 2022 is 278 times that of 1965. Among them, the ownership of large- and medium-sized tractors exceeds 5 million. The ownership of large- and medium-sized tractors remained relatively stable from 1978 to 2005. It surpassed 1 million in 2004 and 2 million in 2007. After 2007, it showed a rapid growing trend and reached a peak of 6.7 million in 2017. The ownership of small tractors had been on the rise until 2011. In 1997, it exceeded 10 million, and reached 18 million in 2011. After that, it gradually decreased year by year.

Figure 4.

Ownership of tractors in China over the past 48 years. Note: The data are obtained from China Rural Statistical Yearbook, Beijing, 1980–2023, China Statistics Press. The classification standard for large- and medium-sized tractors and small tractors after 2018 has been changed from an engine power of 14.7 kW to 22.1 kW.

We need to point out that the classification criteria for tractors changed in 2018. Specifically, the upper limit of power for small tractors was changed from 14.7 kW to 22.1 kW. This means that, according to this standard, the ownership of small tractors will inevitably increase, while the ownership of large- and medium-sized tractors will inevitably decrease because, according to previous standards, tractors ranging from 14.7 to 22.1 kW would be classified as large- and medium-sized tractors. However, in 2018 and beyond, they will be classified as small tractors. Therefore, this can also explain why the ownership of small tractors in 2018 suddenly increased compared to the previous year. The ownership of large- and medium-sized tractors will suddenly decrease this year. However, with the development of agriculture in China, the demand for small tractors has weakened, and farmers generally purchase large- and medium-sized tractors. So even though the classification rules for tractors changed in 2018, the ownership of small tractors in the following years has been on a downward trend. On the contrary, the ownership of large- and medium-sized tractors is increasing. This phenomenon is consistent with the trend of the large-scale and high-efficiency development of agricultural machinery in China.

In addition, the export quantity of tractors from China in 2023 is about 150,000 units. This will play an important role in promoting the development of agricultural mechanization in other countries around the world, especially in developing countries along the Belt and Road.

4. Classification and Characteristics of Electric Tractors in China

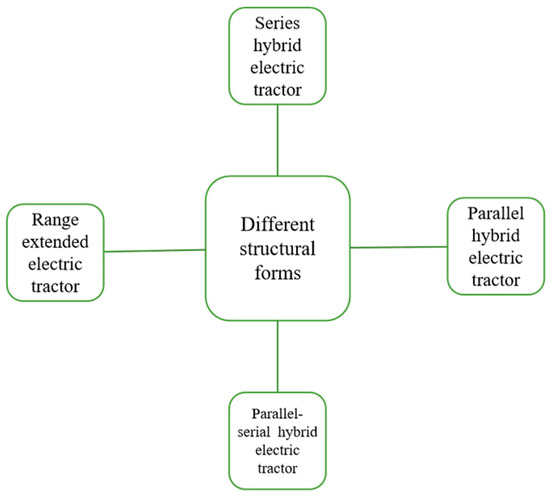

As is well known, the main characteristic of electric tractors is that the walking system is driven by an electric motor. At present, electric tractors mainly include three types: pure electric tractors, hybrid electric tractors, and fuel cell electric tractors. We refer to the relevant standards [39,40] and provide a brief analysis of the concepts and characteristics of three types of electric tractors below.

A pure electric tractor refers to a tractor whose operating power comes entirely from the onboard electrical energy storage device or the power grid. It has a simple structure and does not require an engine or gearbox. A fuel cell electric tractor refers to a tractor that uses a fuel cell system as a single power source or a hybrid power source of a fuel cell system and a rechargeable energy storage system. It can be further divided into two categories: pure fuel cell electric tractors and fuel cell hybrid electric tractors. A hybrid electric tractor refers to a tractor that can obtain power from at least two types of onboard energy storage devices. As shown in Figure 5, hybrid electric tractors can be divided into multiple types.

Figure 5.

Classification of hybrid electric tractors.

The driving force of a series hybrid electric tractor only comes from the motor, and different types of energy are mixed using electrical coupling. The driving force of a parallel hybrid electric tractor is supplied simultaneously or separately by the motor and engine, and different types of energy are mixed using mechanical coupling. The parallel-serial hybrid electric tractor has both series and parallel drive modes, and different types of energy mixing modes can be switched between electrical coupling and mechanical coupling. The structural principles of extended-range electric tractors and series hybrid electric tractors are similar. The difference is that extended-range electric tractors generally operate in pure electric mode, and only turn on the auxiliary power supply device to provide electrical energy to the drive motor when the on-board rechargeable energy storage system cannot meet the operating mileage.

As shown in Table 1, after the previous analysis, we can summarize the advantages and disadvantages of these types of electric tractors.

Table 1.

Advantages and disadvantages of different types of electric tractors.

5. Development History and Recent Progress Regarding Electric Tractors in China

5.1. Development History of Electric Tractors

The development history of electric tractors in China is consistent with that of other countries in the world. Electric tractors have also gone through two main stages: power grid supply and battery-powered supply.

In the 1950s, Chinese researchers developed the first grid-powered wheeled electric tractor based on the imitation of Soviet electric tractors. Due to its power of 28 kW, it was named Electric Bull 28. Later, after improvement, the second wheeled electric tractor Electric Bull 33 and the first tracked electric tractor Electric Bull 55 were produced. These three electric tractors were powered by the power grid and long cables. Due to various factors, these electric tractors have not been widely used.

Entering the 21st century, with the development of China’s electric vehicle industry, electrification improvement of tractors has also been on the agenda. Many companies and academic institutions in China have conducted research on battery-powered electric tractors and their key technologies. In particular, in 2007, Chinese scholar Gao Huisong wrote and published a review article titled ‘Development of electric tractor and key technologies’ [33]. This paper presents, in detail, the current research status of electric tractors in the world at that time, which also accelerated the process of electric tractor research in China.

5.2. Research Progress Regarding Electric Tractors

5.2.1. Production Status of Electric Tractors

In the production and manufacturing of electric tractors, Hiboridd (Beijing, China) Automotive Technology Co., Ltd., developed a battery powered electric tractor in 2011. In 2012, China Yituo Group Co., Ltd. (Luoyang, China), developed the ET1400 and ET1400-1 electric tractors. In the same year, Northwest Agriculture and Forestry University developed a small electric crawler tractor. In 2018, the National Agricultural Machinery Equipment Innovation Center successively developed China’s first unmanned electric tractor. In 2020, Shandong Shifeng (Group) Co., Ltd. (Liaocheng, China), developed 25 horsepower and 35 horsepower electric tractors. In 2021, Jiangsu Yueda Intelligent Agricultural Equipment Co., Ltd. (Yancheng, China), developed the YL series electric tractor. In 2022, China Yituo Group Co., Ltd., developed a high-power diesel electric hybrid tractor. In 2024, Lingong Agricultural Equipment Co., Ltd. (Linyi, China), developed the world’s largest horsepower hybrid electric tractor. Since 2020, the Engineering Laboratory of Intelligent Agricultural Machinery Equipment, Chinese Academy of Sciences, has successively developed the Honghu T series unmanned electric tractors. The representative electric tractors currently developed and produced in China are shown in Table 2.

Table 2.

Typical electric tractors in China.

5.2.2. Analysis of the Relevant Literature on Electric Tractors

We conducted a search for graduate theses using the keyword “electric tractor” on two data knowledge service platforms, China National Knowledge Infrastructure (CNKI) and Wanfang Data. After comprehensive analysis, there were 108 graduate theses directly related to electric tractors as of 2023. Among them, there are 6 doctoral theses and 102 master’s theses. As shown in Figure 6, the classification is based on the academic institution, completion time, and research content of the graduate thesis.

Figure 6.

Classification of hybrid electric tractors. Note: NJAU is the abbreviation of Nanjing Agricultural University. NWSUAF is Northwest Agriculture and Forestry University. UJS is Jiangsu University. HAUST is Henan University of Science & Technology. TUST is Tianjin University of Science & Technology. SDUST is Shandong University of Science & Technology. SXAU is Shanxi Agricultural University. ZAFU is Zhejiang Agriculture and Forestry University. QLU is Qilu University of Technology. SDUT is Shandong University of Technology. Others mainly refer to China Agricultural University, Tianjin University of Technology and Education, Chinese Academy of Agricultural Sciences, Shihezi University, Chongqing Three Gorges University, Hubei University of Technology, Xi’an University of Technology, Hunan University, Liaoning University of Technology, and Zhongkai University of Agriculture and Engineering. (a) The number of graduate theses from different academic institutions. (b) The number of graduate theses at different times. (c) Analysis of the top three institutions in terms of the number of graduate theses. (d) The number of graduate theses divided by research content.

According to Figure 6a, the top three academic institutions with the highest number of graduate theses are NJAU, UJS, and HAUST. The sum of graduate theses from these three institutions accounts for 62% of the total. According to Figure 6b,c, the earliest graduate thesis was published in 2008 at NJAU. In both 2019 and 2020, there were 15 graduate students engaged in research on electric tractors. As shown in Figure 6d, the research content of these graduate theses mainly involves the drive transmission system and power energy management of electric tractors. Their proportion has reached over 50%. This indirectly indicates that the drive transmission system and power energy management are hot and difficult topics in the research of electric tractors. Overall, there are many graduate students in China engaged in research on electric tractors.

Similarly, these academic institutions have conducted extensive research on different types of electric tractors and their key technologies since 2007, and have achieved fruitful results.

5.2.3. Research Progress on the Key Technologies of Electric Tractors

Motor and Drive Transmission Systems

The use of electric motors for driving is one of the main differences between electric tractors and traditional tractors [41,42,43]. Research on electric motors and their drive transmission systems is also one of the hot topics for electric tractors [44,45,46]. Figure 7 shows the type of motors used in electric tractors.

Figure 7.

Types of motors used in electric tractors.

At present, the drive transmission systems used for electric tractors mainly include single-motor drives, dual-motor independent or coupled drives, and four-motor independent drives [47,48,49,50]. Table 3 matches drive systems with different numbers of motors and agricultural scenarios.

Table 3.

Matching different driving systems and agricultural scenarios.

Meanwhile, Chinese scholars have conducted extensive research on these motor drive systems and their parameter matching.

- (1)

- Single-motor drive

A single-motor drive refers to the use of one motor to drive the two rear wheels or both tracks of a tractor. Figure 8 shows a typical structural schematic diagram of pure electric tractors driven by a single motor.

Figure 8.

Schematic diagram of an electric tractor driven by a single motor: (a) wheeled electric tractor; (b) crawler-type electric tractor. Note: Mechanical transmission device mainly refers to the combination of gearbox, clutch, reducer, differential, etc.

The single-motor driven electric tractors is the earliest and simplest type of drive transmission system, widely used in various types of electric tractors.

- ①

- Single-motor-driven wheeled pure electric tractor

Nanjing Agricultural University was one of the earliest institutions to conduct research on wheeled pure electric tractors driven by a single motor. They systematically studied the design theory, driving force, and transmission efficiency of single-motor drive transmission [51,52]. They conducted simulation experiments on motor drive systems using ADVISOR software [53,54], and developed a test bench for performance testing [55]. Shi et al. proposed a drive system scheme for a hand-held pure electric tractor [56]. Chen et al. studied a single-motor drive system for pure electric tractors suitable for hilly and mountainous areas [57]. Xie et al. designed a motor controller for wheeled pure electric tractors [58]. Ning et al. developed a pure electric tractor with an adjustable battery position driven by a single motor [59].

- ②

- Single-motor-driven crawler-type electric tractor

Northwest Agriculture and Forestry University conducted research on pure electric tractors driven by a single motor. They developed a crawler-type pure electric tractor for use in greenhouses [60,61]. The results of the plowing experiment conducted show a reduction of over 80% in energy consumption costs [62]. Jiangsu University has also conducted a series of studies on crawler-type pure electric tractors used in facility greenhouses [63,64,65]. They matched the parameters of the electric tractor transmission system and constructed corresponding control strategies based on the motor power requirements under different operating modes.

- ③

- Hybrid electric tractor driven by a single motor

In recent years, many scholars in China have conducted research on series, parallel, and extended-range hybrid electric tractors and their drive transmission systems driven by a single motor. Shi [66] and Xu [67] et al. designed a transmission system for a series hybrid tractor driven by a single motor. Deng [68] and Xie [69] et al. analyzed a transmission system of a parallel hybrid tractor driven by a single motor. Zhao [70] and Wang [71,72] et al. conducted experimental tests on the drive systems of extended-range electric tractors driven by a single motor.

- (2)

- Dual-motor drive

A dual-motor drive refers to the use of two motors to independently drive the two rear wheels or both tracks of a tractor. Alternatively, two motors can be coupled together to drive the two rear wheels or both tracks of the tractor. Figure 9 shows a schematic diagram of the structure of a typical electric tractor driven independently by dual motors.

Figure 9.

Schematic diagram of an electric tractor driven independently by dual motors: (a) wheeled electric tractor; (b) crawler-type electric tractor.

Lu et al. [73] studied a rear-wheel dual-motor independent drive system for a series of hybrid tractors and conducted plowing experiments. Mao et al. [74] constructed a dual-motor drive system for electric tractors and conducted simulation experiments. Zhao et al. [75] developed a mode-switching method for the dual-motor drive system of an electric tractor. Xie et al. [76,77,78] studied the transmission performance of dual motor drive in electric tractors. Li et al. [79,80] conducted a systematic study on the transmission characteristics of a dual-motor coupled drive system for electric tractors. Chen et al. [81] designed and analyzed a torque-distribution strategy for a dual-motor coupled drive electric tractor. Zhang et al. [82] studied a fuzzy PI control strategy for dual-motor coupled drive electric tractors.

- (3)

- Four-motor drive

A four-motor drive refers to the use of four motors to independently drive the four wheels of a tractor [23,83]. Figure 10 shows a wheeled electric tractor driven independently by four motors. An et al. [84] studied the differential steering characteristics of a four-wheel independent-drive electric tractor. Deng et al. [85] analyzed the dynamic characteristics of a four-motor independent-drive electric tractor. Zhou et al. [86] studied the torque-distribution problem of a four-motor independently driven electric tractor.

Figure 10.

Schematic diagram of an electric tractor driven independently by four motors.

Battery and Energy Management Technology

The battery is the power source of electric tractors, and its selection and energy management technology are of great significance for improving the performance and service life of electric tractors [87,88,89,90]. Early electric tractors used lead-acid batteries as their power source. Currently, electric tractors commonly use lithium-ion batteries, supercapacitors, and fuel cells as power sources.

Currently, Chinese scholars have conducted extensive research on the battery and energy management technologies used in electric tractors. Li et al. [91] analyzed the issues of adaptive energy management and capacity configuration in the power supply systems of pure electric tractors. Wang et al. [92] constructed an energy management model for extended-range electric tractors. Xu and Wu et al. [93,94] studied energy management control algorithms for extended-range electric tractors. Zhao et al. [95] studied the energy management strategies of hybrid electric tractors. Li et al. [96] studied a real-time adaptive energy management strategy for dual-motor-driven electric tractors. Li et al. [97] analyzed the energy control strategies of electric tractors based on dynamic programming. Sheng et al. [98] studied energy management strategies for electric tractors based on demand power prediction. Xia et al. [99] studied an energy management strategy for electric tractors based on lithium-ion electronics and supercapacitors. Researchers from HAUST [100,101,102,103] and UJS [104,105] conducted a systematic study on the energy management strategies of fuel cell electric tractors, which has made important contributions to promoting the energy utilization of fuel-cell electric tractors.

Test Bench Development and Other Key Technologies

The development of a test bench for the performance testing of electric tractors and their key components is of great significance. Wang et al. [106] built a series hybrid electric tractor test platform and conducted rotary tillage tests under pure electric and hybrid power modes. Xu et al. [107] designed a comprehensive test bench for electric tractors using a modular approach. The performance test results conducted on the test bench showed that the error compared to the previous simulation analysis was within 10%.

In addition, there have been many studies on the design of key components for electric tractors [108,109], overall performance testing [110,111,112], operation path planning [113,114], and unmanned driving [115,116]. These research results further promote the technological progress and intelligence level of electric tractors in China.

6. Development Prospects Regarding Electric Tractors in China

A large amount of practice has proven that electric tractors have many advantages, such as environmental protection, energy savings, simple operation, and easy implementation of intelligence [117,118,119,120,121]. Table 4 shows performance comparison results between electric tractors and traditional tractors.

Table 4.

Comparison of performance between electric tractors and traditional tractors.

Therefore, research and applications of electric tractors are of great significance, especially for agricultural production and tractor-using countries like China. However, there are also many opportunities and challenges around the development of electric tractors.

The main opportunities are listed as follows:

- (1)

- Currently, China is the world’s largest producer and user of tractors. At the end of 2022, the ownership of tractors in use exceeded 21 million. The development and application of electric tractors have broad market prospects. Meanwhile, China has developed various electric tractors in recent years. Table 5 shows a comparison between electric tractors developed in China and those developed in other countries around the world. From Table 5, we can see that the electric tractors developed in China are synchronized with the international advanced level and outperform other countries in terms of working horsepower.

Table 5. Comparison between typical electric tractors in China and other countries around the world.

Table 5. Comparison between typical electric tractors in China and other countries around the world. - (2)

- China’s new energy vehicles have been widely promoted and used. In 2024, the production and sales of new energy vehicles in China were 12.888 million and 12.866 million, respectively, an increase of 34.4% and 35.5% year-on-year. Figure 11 shows the market penetration rate of new energy electric vehicles in China. We can see that it has been continuously growing in recent years. Especially in 2021, there was an increase of 8 percentage points compared to the previous year. The motors, batteries, and electronic control technologies used in new energy vehicles can be directly applied to electric tractors. The rapid development of electric vehicles in China will undoubtedly greatly promote the electrification process of tractors.

Figure 11. The market penetration rate of new energy vehicles in China.

Figure 11. The market penetration rate of new energy vehicles in China. - (3)

- In recent years, the Chinese government has continued to support the research and application of electric tractors. This includes launching national key research and development projects related to electric tractors, developing a promotion and evaluation outline for wheeled electric tractors, and providing subsidies for the purchase of high-power hybrid tractors. As shown in Table 6, the Chinese government has supported the development of electric tractors through policies, projects, and funding subsidies.

Table 6. National policies and project support for electric tractors.

Table 6. National policies and project support for electric tractors.

The main challenges are listed as follows:

- (1)

- The application scenarios of tractors are significantly different from those of vehicles. In addition to road-driving functions, it is generally necessary to carry agricultural machinery for field operations. Tractors often require a large amount of power to operate in complex field environments, especially in the application scenarios of using electric tractors for plowing and excavating and harvesting underground crops. This is one of the challenges faced in the research and design of electric tractors.

- (2)

- There is a lack of charging and swapping facilities around farmland. At present, China’s charging infrastructure is mainly concentrated in large- and medium-sized cities, and these charging facilities are mainly used for electric vehicles. There are few charging facilities for electric vehicles or electric agricultural machinery in rural areas. In recent years, the government has also introduced policies to support the construction of charging infrastructure in rural areas, for example, the Guiding Opinions of the General Office of the State Council on Further Building a High-quality Charging Infrastructure System in 2023. This opinion clearly states the need to build effective coverage of rural charging networks. Overall, the construction of charging infrastructure in rural areas of China is still in its early stages, mainly constrained by the following reasons:

- ①

- Land in rural areas is protected, and private enterprises find it difficult to solve the problem of land attributes to build a large number of charging stations.

- ②

- The rural landmass is very large, the population is scattered, and the power grid density is low, making it difficult to meet the large-scale charging demand.

- ③

- Due to the large area of rural areas, there is a shortage of offline maintenance personnel for charging infrastructure.

To solve the above problems, the government should conduct pilot projects in rural areas with good power grid infrastructure, and explore experience models for building charging and swapping infrastructure in rural areas. On the other hand, we should accelerate the improvement of rural power grid conditions and enhance power security. At the same time, we will strengthen the training of personnel for the operation and maintenance of charging and swapping infrastructure. It is also possible to consider the issue of rural charging infrastructure in the construction of high-standard farmland. We also need to fully utilize the current situation of wind and photovoltaic power generation in rural areas in China, and build an integrated charging and swapping infrastructure, as shown in Figure 12.

Figure 12.

Schematic diagram of integrated charging and swapping infrastructure.

- (3)

- At present, although there are some standards for electric tractors, these standards have not been systematized. Therefore, it is unable to effectively support the entire process of research and development, manufacturing, promotion, and application of electric tractors. According to the query on the National Public Service Platform for Standards Information, as shown in Table 7, there are currently only eight standards related to electric tractors in China (one industry standard and seven group standards). Compared to the 542 standards for electric vehicles (117 national standards, 76 industry standards, and 349 group standards), there is a significant gap in the number of standards. Although some standards related to electric vehicles can be used for electric tractors, there are still many aspects that need to be improved and supplemented, especially those standards that involve agricultural scenarios and have significant differences from electric vehicles.

Table 7. The current standards for electric tractors in China.

Table 7. The current standards for electric tractors in China.

- (4)

- A systematic solution should be developed for the recycling and utilization of waste batteries. The issue of recycling used batteries has become one of the challenges facing the healthy development of the electric vehicle industry. This problem will inevitably be faced and solved by electric tractors in the near future. Only by addressing this issue can we ensure the healthy development of electric tractors in the future. Therefore, it is necessary to establish a multi-party collaboration mechanism. Not only should the producer responsibility system be implemented, but also a multi-party responsibility community of “battery producers + users + recyclers” should be built to thoroughly solve the problem of recycling waste batteries for electric tractors.

7. Conclusions

This study elucidates the classifications and characteristics of electric tractors in China. We summarized the research status of electric tractor motors and their transmission systems, batteries, and energy management technologies. We also analyzed some of the main opportunities and challenges facing the research and development around electric tractors in China. This research found that electric tractors in China are still in their early stages of development, with many still in the prototype stage. There is still a significant gap from development to industrial application. Meanwhile, the application scenarios of pure electric tractors are mostly in facilities such as greenhouses. Electric tractors with high power generally use hybrid modes.

Overall, China’s active research around and applications of electric tractors are timely and of great significance in reducing labor intensity, fossil energy consumption, and carbon emissions in agricultural production.

Author Contributions

Conceptualization, H.Y., X.Z. and Z.H.; methodology, F.W. and H.X.; software, F.G.; validation, X.Z., J.W. and Z.H.; data curation, L.S. and H.X.; writing—original draft preparation, H.Y.; writing—review and editing, H.Y., X.Z. and Z.H.; visualization, F.W.; supervision, J.W.; funding acquisition, F.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key R&D Program of Henan Province, China, grant number 251111113100.

Data Availability Statement

The data presented in this study are available on demand from the first author.

Conflicts of Interest

Author Jiangtao Wang was employed by the companies Henan Province Planting and Harvesting Agricultural Equipment Co., Ltd., and Henan Nongyouwang Agricultural Equipment Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Gao, D.; Zhi, Y.; Yang, X. Assessing carbon emission reduction benefits of the electrification transition of agricultural machinery for sustainable development: A case study in China. Sustain. Energy Technol. Assess. 2024, 63, 103634. [Google Scholar] [CrossRef]

- Guru, P.; Shrivastava, A.; Tiwari, P. Estimation of carbon emissions of agricultural machinery use in India. Oryza 2022, 59, 260–268. [Google Scholar] [CrossRef]

- Zhuang, M.; Wang, X.; Yang, Y.; Wu, Y.; Wang, L.; Lu, X. Agricultural machinery could contribute 20% of total carbon and air pollutant emissions by 2050 and compromise carbon neutrality targets in China. Nature Food 2025, 6, 513–522. [Google Scholar] [CrossRef]

- Lanças, K.; Filho, A.M.; Santana, L.; Ferraz, G.; Faria, R.; Martins, M. Agricultural tractor test: A bibliometric review. AgriEngineering 2024, 6, 2229–2248. [Google Scholar] [CrossRef]

- Lajunen, A.; Kivekäs, K.; Freyermuth, V.; Vijayagopal, R.; Kim, N. Simulation-based assessment of energy consumption of alternative powertrains in agricultural tractors. World Electr. Veh. J. 2024, 15, 86. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A.; Martelli, S.; Martini, V. Trends and future perspective of electrification in agricultural tractor-Implement applications. Energies 2023, 16, 6601. [Google Scholar] [CrossRef]

- Ali, D.; de Castro, R.; Ehsani, R.; Vougioukas, S.; Wei, P. Unlocking the potential of electric and hybrid tractors via sensitivity and techno-economic analysis. Appl. Energy 2025, 377, 124545. [Google Scholar] [CrossRef]

- Malik, A.; Kohli, S. Electric tractors: Survey of challenges and opportunities in India. Mater. Today Proc. 2020, 28, 2318–2324. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, X.; Zhang, J.; Liu, M.; Wang, L.; Du, X.; Yan, X. Temperature-influenced SOC estimation of LiFePO4 batteries in hybrid electric tractors based on SAO-LSTM model. World Electr. Veh. J. 2025, 16, 283. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Łyp-Wrońska, K.; Gdowska, K.; Paciolla, F. Sustainability evaluation of hybrid agriculture-tractor powertrains. Sustainability 2024, 16, 1184. [Google Scholar] [CrossRef]

- Mousazadeh, H.; Keyhani, A.; Javadi, A.; Mobli, H.; Abrinia, K.; Sharifi, A. Life-cycle assessment of a solar assist plug-in hybrid electric tractor (SAPHT) in comparison with a conventional tractor. Energy Convers. Manag. 2011, 52, 1700–1710. [Google Scholar] [CrossRef]

- Ueka, Y.; Yamashita, J.; Sato, K.; Doi, Y. Study on the development of the electric tractor: Specifications and traveling and tilling performance of a prototype electric tractor. Eng. Agric. Environ. Food 2013, 6, 160–164. [Google Scholar]

- Bessette, D.; Brainard, D.; Srivastava, A.; Lee, W.; Geurkink, S. Battery electric tractors: Small-scale organic growers’ preferences, perceptions, and concerns. Energies 2022, 15, 8648. [Google Scholar] [CrossRef]

- Gade, C.; W, R. Control of permanent magnet synchronous motor using MPC–MTPA control for deployment in electric tractor. Sustainability 2022, 14, 12428. [Google Scholar] [CrossRef]

- Shinde, M.; Agrewale, M.; Bhateshvar, Y. Development of sensor data fusion for obstacle detection for electric mini tractor. Mater. Today Proc. 2022, 72, 1206–1211. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V.; Somà, A. Comparative analysis of hybrid electric architectures for specialized agricultural tractors. Energies 2022, 15, 1944. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. Analysis of a parallel hybrid electric tractor for agricultural applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Vogt, H.; De Melo, R.; Daher, S.; Schmuelling, B.; Antunes, F.; dos Santos, P.; Albiero, D. Electric tractor system for family farming: Increased autonomy and economic feasibility for an energy transition. J. Energy Storage 2021, 40, 102744. [Google Scholar] [CrossRef]

- de Melo, R.; Tofoli, F.; Daher, S.; Antunes, F. Wheel slip control applied to an electric tractor for improving tractive efficiency and reducing energy consumption. Sensors 2022, 22, 4527. [Google Scholar] [CrossRef]

- Inuzuka, S.; Shen, T. Optimal energy consuming planning for a home-based microgrid with mobility constraint of electric vehicles and tractors. Control Theory Technol. 2021, 19, 465–483. [Google Scholar] [CrossRef]

- Amelchenko, P.; Zhukovskiy, I.; Stasilevich, A.; Klyuchnikov, A.; Zhukovskiy, A. Electric traction and electric power take-off of agricultural tractor. Tract. Agric. Mach. 2014, 81, 3–10. [Google Scholar] [CrossRef]

- Hwang, I.; Kim, J.; Im, W.; Jeung, H.; Nam, J.; Shin, C. Analyzing safety factors and predicting fatigue life of weak points in an electrically driven, multi-purpose cultivation tractor. Agriculture 2024, 14, 416. [Google Scholar] [CrossRef]

- Baek, S.; Baek, S.; Jeon, H.; Kim, W.; Kim, Y.; Sim, T.; Choi, K.; Hong, S.; Kim, H.; Kim, Y. Traction performance evaluation of the electric all-wheel-drive tractor. Sensors 2022, 22, 785. [Google Scholar] [CrossRef]

- Baek, S.; Kim, Y.; Kim, W.; Baek, S.; Kim, Y. Development and verification of a simulation model for 120 kW class electric AWD (All-Wheel-Drive) tractor during driving operation. Energies 2020, 13, 2422. [Google Scholar] [CrossRef]

- Shishkov, A.; Sychev, D.; Bychkov, A.; Sidorenko, N. The DET-400 tractor traction electric drive. Russ. Electr. Eng. 2014, 85, 610–612. [Google Scholar] [CrossRef]

- Varlese, C.; Ferrara, A.; Hametner, C.; Hofmann, P. Experimental validation of a predictive energy management strategy for agricultural fuel cell electric tractors. Int. J. Hydrogen Energy 2024, 77, 1–14. [Google Scholar] [CrossRef]

- Williams, T.; Wilson, J.; Partington, L.; Andrews, C.; Chavula, I.; Gondwe, F.; Betts, T.; Strickland, D. Micro-electric tractors for deep bed farming and sustainable micro-grid electricity. Front. Energy Res. 2024, 12, 1384568. [Google Scholar] [CrossRef]

- Cristea, M.; Matache, M.G.; Sorica, C.; Biris, S.; Cristea, R. Study on the behavior of a battery on an electric tractor prototype. INMATEH-Agric. Eng. 2020, 62, 19–28. [Google Scholar] [CrossRef]

- Lagnelv, O.; Larsson, G.; Nilsson, D.; Larsolle, A.; Hansson, P. Performance comparison of charging systems for autonomous electric field tractors using dynamic simulation. Biosyst. Eng. 2020, 194, 121–137. [Google Scholar] [CrossRef]

- Lagnelv, O.; Dhillon, S.; Larsson, G.; Nilsson, D.; Hansson, P. Cost analysis of autonomous battery electric field tractors in agriculture. Biosyst. Eng. 2021, 204, 358–376. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Mousazadeh, H.; Malvajerdi, A.; Rafiee, S. Design, development, and evaluation of a pv_bio-gen range extender for an off- road electric tractor. Int. J. Renew. Energy Res. 2020, 10, 389–399. [Google Scholar]

- Ghobadpour, A.; Mousazadeh, H.; Kelouwani, S.; Zioui, N.; Kandidayeni, M.; Boulon, L. An intelligent energy management strategy for an off-road plug-in hybrid electric tractor based on farm operation recognition. IET Electr. Syst. Transp. 2021, 11, 333–347. [Google Scholar] [CrossRef]

- Gao, H.; Zhu, S.; Lv, B. Development of electric tractor and key technologies. Tract. Farm. Transp. 2007, 34, 4–7. [Google Scholar]

- Williams, M. Machinery Milestones: Electric Tractor Power. Farmers Weekly. 21 June 2019. Available online: https://www.fwi.co.uk/machinery/technology/machinery-milestones-electric-tractor-power (accessed on 29 August 2024).

- Caslin, B. Are diesel’s farm days numbered? Today’s Farm 2021, 3, 34–35. Available online: https://www.teagasc.ie/media/website/publications/2021/Rural-development---Are-diesels-farm-days-numbered.pdf (accessed on 29 August 2024).

- Karthik, S. John Deere GridCON Autonomous Electric Tractor. 26 February 2021. Available online: https://electricvehicles.in/john-deere-gridcon-autonomous-electric-tractor/ (accessed on 29 August 2024).

- Lovarelli, D.; Bacenetti, J. Exhaust gases emissions from agricultural tractors: State of the art and future perspectives for machinery operators. Biosyst. Eng. 2019, 186, 204–213. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Monsalve, G.; Cardenas, A.; Mousazadeh, H. Off-road electric vehicles and autonomous robots in agricultural sector: Trends, challenges, and opportunities. Vehicles 2022, 4, 843–864. [Google Scholar] [CrossRef]

- T/NJ 1318; 2024 Electric Tractors—Terminology. Chinese Society of Agricultural Machinery: Beijing, China, 2024.

- T/CAAMM 210; 2023 Range-Extended Electric Tractor-Part1: Terminology. China Association of Agricultural Machinery Manufacturers: Beijing, China, 2023.

- Liu, M.; Li, Y.; Zhao, S.; Han, B.; Lei, S.; Xu, L. Multi-objective optimization and test of a tractor drive motor. World Electr. Veh. J. 2022, 13, 43. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor torque distribution strategy for different tillage modes of agricultural electric tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, M.; Liu, M.; Wang, D.; Yan, X.; Xu, L.; Wu, Y. Design method of dual-motor electric tractor drive system based on mass constraint algorithm under uncertainty using mass. Energy 2025, 322, 135140. [Google Scholar] [CrossRef]

- Zhang, S.; Xie, B.; Wen, C.; Zhao, Y.; Du, Y.; Zhu, Z.; Song, Z.; Li, L. Intelligent ballast control system with active load-transfer for electric tractors. Biosyst. Eng. 2022, 215, 143–155. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, J.; Wu, J.; Zhang, S.; Chen, Z.; Xie, B. Research on a hydraulic cylinder pressure control method for efficient traction operation in electro-hydraulic hitch system of electric tractors. Agriculture 2023, 13, 1555. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Song, Z.; Wu, X. Design and experiment of distributed hybrid electric tractor powertrain system based on TRIZ theory. J. Jilin Univ. Eng. Technol. Ed. 2025, 55, 366–381. [Google Scholar]

- Yang, J.; Chen, F.; Zheng, E.; Deng, X.; Wang, X.; Wang, L.; Lu, Z.; Liu, M. Electromagnetic performance analysis and structural optimization of the wheel-side motors for electric tractors based on magneto-thermal bidirectional coupling. Trans. Chin. Soc. Agric. Eng. 2023, 39, 73–82. [Google Scholar]

- Yang, H.; Zhou, J.; Qi, Z.; Sun, C.; Lai, G. Rotary tillage stability of greenhouse electric tractor based on time series analysis and feedforward PID. Trans. Chin. Soc. Agric. Mach. 2024, 55, 412–420. [Google Scholar]

- Li, X.; Xu, L.; Liu, M.; Yan, X.; Zhang, M. Research on torque cooperative control of distributed drive system for fuel cell electric tractor. Comput. Electron. Agric. 2024, 219, 108811. [Google Scholar] [CrossRef]

- Li, X.; Liu, M.; Hu, C.; Yan, X.; Zhao, S.; Zhang, M.; Xu, L. Parameters collaborative optimization design and innovation verification approach for fuel cell distributed drive electric tractor. Energy 2024, 292, 130485. [Google Scholar] [CrossRef]

- Gao, H.; Wang, S.; Zhu, S. Experiment on characteristics of driving force and transmission efficiency of electric tractor. Trans. Chin. Soc. Agric. Mach. 2008, 39, 40–43, 58. [Google Scholar]

- Gao, H.; Zhu, S. Study on design theory and method for driving line of electric tractor. J. Nanjing Agric. Univ. 2009, 32, 140–145. [Google Scholar]

- Gao, H.; Zhang, Y.; Zhu, S. Development and application of electric tractor simulation system based on ADVISOR. Comput. Simul. 2009, 26, 282–285. [Google Scholar]

- Gao, H.; Zhu, S. Simulation on driving system of electric tractor based on ADVISOR. J. Mach. Des. 2008, 10, 28–33. [Google Scholar]

- Gao, H.; Zhu, S. Development of electric tractor test bench. J. Nanjing Agric. Univ. 2014, 37, 160–164. [Google Scholar]

- Shi, J.; Zhu, S.; Gao, H.; Chang, Y. Design of driving system of miniature electric tractor. Tract. Farm. Transp. 2012, 39, 47–49, 52. [Google Scholar]

- Chen, L.; Zhan, Q.; Wang, W.; Huang, X.; Zheng, Q. Design and experiment of electric drive system for pure electric tractor. Trans. Chin. Soc. Agric. Mach. 2018, 49, 388–394. [Google Scholar]

- Xie, B.; Zhang, C.; Mao, E.; Chen, Y. Motor controller design and indoor experiment for electric tractor based on myRIO. Trans. Chin. Soc. Agric. Eng. 2015, 31, 55–62. [Google Scholar]

- Ning, P.; Su, K.; Wang, M.; Cui, G.; Li, K.; Cui, Y.; Wang, W. Design and test of electric tractor with battery position longitudinally adjustable mechanism. J. Agric. Mech. Res. 2022, 44, 212–218. [Google Scholar]

- Lu, Y.; Yang, F.; Liu, Y.; Lan, Y.; Chen, Z.; Liu, S.; Liu, H. Research and design of miniature electric tractor. J. Mach. Des. 2013, 30, 82–85. [Google Scholar]

- Yang, F.; Lu, Y.; Liu, Y.; Lan, Y.; Liu, D.; Wang, Z. Design and preliminary test of tiny remote controlled electric tractor used in greenhouse. Appl. Mech. Mater. 2012, 184, 1533–1541. [Google Scholar]

- Wang, Y.; Liu, Y.; Yang, F.; Lu, Y.; Lan, Y.; Chen, Z. Development and test of tiny remotely controlled electric tractor for greenhouses. Trans. Chin. Soc. Agric. Eng. 2012, 28, 23–29. [Google Scholar]

- Shang, G.; Xia, Y. Power-train matching and optimization of crawler electric tractor. J. Agric. Mech. Res. 2015, 3, 250–253. [Google Scholar]

- Shang, G.; Zhang, J.; Zhang, J. Research on control strategy of tracked electric tractor drive system. J. Chongqing Univ. Technol. Nat. Sci. 2017, 31, 32–38. [Google Scholar]

- Liu, J.; Xia, C.; Jiang, D.; Shang, G.; Han, J.; Sun, Y. Determination and application of maximum efficiency curve of crawler electric tractor motors. Math. Probl. Eng. Theory Methods Appl. 2021, 52, 1310926. [Google Scholar] [CrossRef]

- Shi, L.; Zhu, S.; Niu, X. Design of tractor transmission parameters based on series hybrid power system. Aeta Agricuhurae Jiangxi 2010, 22, 115–117. [Google Scholar]

- Xu, L.; Liu, M.; Zhou, Z. Design of drive system for series hybrid electric tractor. Trans. Chin. Soc. Agric. Eng. 2014, 30, 11–18. [Google Scholar]

- Deng, X.; Zhu, S.; Gao, H.; Zhang, Y. Design theory and method for drive train of hybrid electric tractor. Trans. Chin. Soc. Agric. Mach. 2012, 43, 24–31, 36. [Google Scholar]

- Xie, B.; Hao, L.; Song, Z.; Mao, E. Powertrain system design of medium-sized hybrid electric tractor. Inf. Technol. J. 2013, 12, 7228–7233. [Google Scholar] [CrossRef]

- Zhao, J.; Xu, L.; Liu, E.; Liu, M.; Meng, T. Design for drive system of extended-range electric tractor. J. Agric. Mech. Res. 2018, 40, 236–240. [Google Scholar]

- Wang, B.; Qiao, M.; Chu, X.; Shang, S.; Wang, D. Design and experiment on extended-range electric caterpillar tractor. Trans. Chin. Soc. Agric. Mach. 2023, 54, 431–439. [Google Scholar]

- Wang, B.; Lv, Y.; Chu, X.; Wang, D.; Shang, S. Design and experimental testing of extended-range power supply system for 15 horsepower electric tractor. Agriculture 2024, 14, 1551. [Google Scholar] [CrossRef]

- Lu, Z.; Hou, X.; Deng, X. Matching design and traction tests for driving system of series hybrid electric tractor. J. Nanjing Agric. Univ. 2017, 40, 928–935. [Google Scholar]

- Mao, Y.; Wu, Y.; Yan, X.; Liu, M.; Xu, L. Simulation and experimental research of electric tractor drive system based on Modelica. PLoS ONE 2022, 17, 0276231. [Google Scholar] [CrossRef]

- Zhao, Z.; Xie, B.; Wen, C.; Xing, S.; Luo, Z.; Feng, R. Transient characteristics and control methods of mode switching in electric tractor dual motor drive system. Trans. Chin. Soc. Agric. Mach. 2025, 56, 532–542. [Google Scholar]

- Xie, B.; Zhang, C.; Chen, S.; Mao, E.; Du, Y. Transmission performance of two-wheel drive electric tractor. Trans. Chin. Soc. Agric. Mach. 2015, 46, 8–13. [Google Scholar]

- Wu, Z.; Xie, B.; Li, Z.; Chi, R.; Ren, Z.; Du, Y.; Inoue, E.; Mitsuoka, M.; Okayasu, T.; Hirai, Y. Modelling and verification of driving torque management for electric tractor: Dual-mode driving intention interpretation with torque demand restriction. Biosyst. Eng. 2019, 182, 65–83. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, B.; Du, Y.; Mao, E. Powertrain parameter matching and optimal design of dual-motor driven electric tractor. Int. J. Agric. Biol. Eng. 2019, 12, 33–41. [Google Scholar] [CrossRef]

- Li, T.; Xie, B.; Song, Z.; Li, J. Transmission characteristics of dual-motor coupling system for electric tractors. Trans. Chin. Soc. Agric. Mach. 2019, 50, 379–388. [Google Scholar]

- Li, T.; Xie, B.; Li, Z.; Li, J. Design and optimization of a dual-input coupling powertrain system: A case study for electric tractors. Appl. Sci. 2020, 10, 1608. [Google Scholar] [CrossRef]

- Chen, A.; Chen, S.; Shi, A.; Xu, L.; Zhang, H. Design of torque distribution strategy for dual-motor variable-speed drive electric tractor. J. Agric. Mech. Res. 2021, 43, 1–6. [Google Scholar]

- Zhang, Q.; Hu, C.; Li, R. Research on distributed dual-wheel electric-drive fuzzy PI control for agricultural tractors. Agriculture 2024, 14, 1442. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Liu, M.; Xu, L.; Yan, X.; Lei, S. Optimized design and validation of distributed drive system for electric tractor based on multi-island genetic algorithm. Trans. Chin. Soc. Agric. Mach. 2024, 55, 401–411. [Google Scholar]

- An, Y.; Wang, L.; Deng, X.; Chen, H.; Lu, Z.; Wang, T. Research on differential steering dynamics control of four-wheel independent drive electric tractor. Agriculture 2023, 13, 1758. [Google Scholar] [CrossRef]

- Deng, X.; Sun, H.; Lu, Z.; Cheng, Z.; An, Y.; Chen, H. Research on dynamic analysis and experimental study of the distributed drive electric tractor. Agriculture 2023, 13, 40. [Google Scholar] [CrossRef]

- Zhou, H.; Lu, Z.; Deng, X.; Zhang, C.; Luo, G.; Zhou, R. Study on torque distribution of traction operation of four wheel independent driven electric tractor. J. Nanjing Agric. Univ. 2018, 41, 962–970. [Google Scholar]

- Zhang, K.; Deng, X.; Lu, Z.; Wang, T. Research on the energy management strategy of a hybrid tractor OS-ECVT based on a dynamic programming algorithm. Agriculture 2024, 14, 1658. [Google Scholar] [CrossRef]

- Kwon, D.; Ahn, D.V.; Kim, J.G.; Park, Y.J. Effect analysis of motor power characteristics on the energy consumption of dual motor driven powertrain for electric tractor. J. Biosyst. Eng. 2024, 49, 465–475. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Wang, W.; Cui, Y.; Song, Y. Performance investigation of piezoelectric-mechanical electromagnetic compound vibration energy harvester for electric tractor. Energy 2023, 15, 128285. [Google Scholar] [CrossRef]

- Zhu, Z.; Sheng, J.; Zhang, H.; Wang, D.; Chen, L. Optimization of mode-switching quality of hybrid tractor equipped with HMCVT. Appl. Sci. 2024, 14, 6288. [Google Scholar] [CrossRef]

- Li, L.; Ran, G.; Gao, Z.; Liu, Y.; Nie, J. Adaptive energy management and capacity configuration for electric tractor power supply system. Trans. Chin. Soc. Agric. Eng. 2024, 40, 82–91. [Google Scholar]

- Wang, Z.; Zhou, J.; Wang, X. Research on energy management model for extended-range electric rotary-tilling tractor. Trans. Chin. Soc. Agric. Mach. 2024, 55, 428–438. [Google Scholar]

- Xu, L.; Zhang, J.; Liu, M.; Zhou, Z.; Liu, C. Control algorithm and energy management strategy for extended range electric tractors. Int. J. Agric. Biol. Eng. 2017, 5, 35–44. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, J.; Xing, Y.; Li, S.; Yi, J.; Zhao, C. Energy management of sowing unit for extended-Range electric tractor based on improved CD-CS fuzzy rules. Agriculture 2023, 13, 1303. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, L.; Zhao, C.; Xu, H.; Yan, X. Research on energy management strategy for hybrid tractors based on DP-MPC. Energies 2024, 17, 3924. [Google Scholar] [CrossRef]

- Li, T.; Xie, B.; Wang, D.; Zhang, S.; Wu, L. Real-time adaptive energy management strategy for dual-motor-driven electric tractors. Trans. Chin. Soc. Agric. Mach. 2020, 51, 530–543. [Google Scholar]

- Li, Y.; Liu, L.; Jin, T.; Yuan, K.; Chen, Y. Energy control strategy of electric tractor power supply based on dynamic programming. Trans. Chin. Soc. Agric. Mach. 2020, 51, 403–410. [Google Scholar]

- Sheng, Z.; Xia, C.; Sun, Y.; Han, J. Energy management strategy of electric tractor based on power demand prediction. J. Agric. Mech. Res. 2024, 46, 216–221. [Google Scholar]

- Xia, C.; Sun, Y.; Zhou, W. Study on energy management of double power electric tractor. J. Agric. Mech. Res. 2019, 41, 234–240. [Google Scholar]

- Li, X.; Zhang, M.; Yan, X.; Liu, M.; Xu, L. Power allocation strategy for fuel cell distributed drive electric tractor based on adaptive multi-resolution analysis theory. Energy 2023, 284, 129350. [Google Scholar] [CrossRef]

- Liu, M.; Li, Y.; Xu, L.; Wang, Y.; Zhao, J. General modeling and energy management optimization for the fuel cell electric tractor with mechanical shunt type. Comput. Electron. Agric. 2023, 213, 108178. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, B.; Zhang, J.; Xu, L.; Zhang, K. Research on power optimization for energy system of hydrogen fuel cell wheel-driven electric tractor. World Electr. Veh. J. 2024, 15, 188. [Google Scholar] [CrossRef]

- Li, X.; Zhang, M.; Liu, M.; Yan, X.; Xu, L. Drive power allocation strategy for electric tractor based on adaptive multiresolution analysis. Trans. Chin. Soc. Agric. Eng. 2023, 39, 55–66. [Google Scholar]

- Yang, H.; Sun, Y.; Xia, C.; Zhang, H. Research on energy management strategy of fuel cell electric tractor based on multi-algorithm fusion and optimization. Energies 2022, 15, 6389. [Google Scholar] [CrossRef]

- Wu, J.; Xia, C.; Sun, Y.; Han, J.; Sheng, Z. Energy management strategy of fuel cell electric tractors. J. Agric. Mech. Res. 2024, 46, 248–253. [Google Scholar]

- Wang, Z.; Zhou, J.; Yang, H.; Wang, X. Design and test of measurement and control system for rapid prototype platform used in electric tractors. Trans. Chin. Soc. Agric. Mach. 2022, 53, 412–420. [Google Scholar]

- Xu, L.; Zhao, Y.; Zhao, X.; Liu, M.; Ni, Q. Design and test of multifunctional test system for electric tractor. Trans. Chin. Soc. Agric. Mach. 2020, 51, 355–363. [Google Scholar]

- Zhang, K.; Quan, L.; Jin, S. Sensorless control of permanent magnet motor for electric tractor based on fuzzy sliding mode observer. Trans. Chin. Soc. Agric. Mach. 2023, 54, 431–438. [Google Scholar]

- Du, Y.; Sun, X.; Sun, Y.; Xiao, F.; Zhu, X.; Mao, Y.; Yan, X. Electronic pole-changing strategy and analysis for PC-DSPM motor in electric tractors. Trans. Chin. Soc. Agric. Eng. 2023, 39, 44–53. [Google Scholar]

- Wang, Q.; Wang, X.; Wang, W.; Song, Y.; Cui, Y. Joint control method based on speed and slip rate switching in plowing operation of wheeled electric tractor equipped with sliding battery pack. Comput. Electron. Agric. 2023, 215, 108426. [Google Scholar] [CrossRef]

- Xi, Z.; Feng, T.; Liu, Z.; Xu, H.; Zheng, J.; Xu, L. Estimation of soil characteristic parameters for electric mountain tractor based on gauss–newton iteration method. World Electr. Veh. J. 2024, 15, 217. [Google Scholar] [CrossRef]

- Zeng, H.; Yang, Z.; Lei, L.; Yao, L.; Ni, Y.; Zhang, Q.; Zhang, P. Based on hub motor drive electric tractor general design and experiment. J. Agric. Mech. Res. 2021, 43, 246–253. [Google Scholar]

- Guo, H.; Li, Y.; Wang, H.; Wang, C.; Zhang, J.; Wang, T.; Rong, L.; Wang, H.; Wang, Z.; Huo, Y.; et al. Path planning of greenhouse electric crawler tractor based on the improved A* and DWA algorithms. Comput. Electron. Agric. 2024, 227, 109596. [Google Scholar] [CrossRef]

- Guo, H.; Li, Y.; Wang, H.; Wang, T.; Rong, L.; Wang, H.; Wang, Z.; Wang, C.; Zhang, J.; Huo, Y.; et al. Research on autonomous navigation system of greenhouse electric crawler tractor based on LiDAR. Front. Plant Sci. 2024, 15, 1377269. [Google Scholar] [CrossRef]

- Chen, Z.; Xie, B.; Luo, Z.; Liu, K.; Zhang, S.; Wen, C. Fuzzy control strategy for path tracking-tillage depth of unmanned electric tractor ploughing unit. Trans. Chin. Soc. Agric. Mach. 2024, 55, 491–504. [Google Scholar]

- Chen, Y.; Chen, L.; Chang, M. A design of an unmanned electric tractor platform. Agriculture 2022, 12, 112. [Google Scholar] [CrossRef]

- Wen, C.; Ren, W.; Zhu, Q.; Zhao, C.; Luo, Z.; Zhang, S.; Xie, B.; Meng, Z. Reducing operation emissions and improving work efficiency using a pure electric wheel drive tractor. Engineering 2024, 37, 230–245. [Google Scholar] [CrossRef]

- Scolaro, E.; Beligoj, M.; Estevez, M.P.; Alberti, L.; Mattetti, M. Electrification of agricultural machinery a review. IEEE Access 2021, 9, 164520–164541. [Google Scholar] [CrossRef]

- Wu, H.; Quan, L.; Hao, Y.; Pan, Z.; Xie, S. Research on the characteristics of a range-extended hydraulic–electric hybrid drive system for tractor traveling systems. Energies 2025, 18, 2075. [Google Scholar] [CrossRef]

- Oncescu, T.; Persu, I.; Bostina, S.; Biris, S.; Vilceleanu, M.; Nenciu, F.; Matache, M.; Tarnita, D. Comparative analysis of vibration impact on operator safety for diesel and electric agricultural tractors. AgriEngineering 2025, 7, 40. [Google Scholar] [CrossRef]

- Link, S.; Plötz, P. Technical feasibility of heavy-duty battery-electric trucks for urban and regional delivery in Germany—A real-world case study. World Electr. Veh. J. 2022, 13, 161. [Google Scholar] [CrossRef]

- Liu, M.; Xu, L.; Zhou, Z.; Liu, W. Establishment of extended range electric tractor and Its rotary tillage cultivator’s simulation platform. China Mech. Eng. 2016, 27, 413–419. [Google Scholar]

- JB/T 15126; 2025 Electric tractor. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2025.

- T/CAAMM 345; 2023 Electric Tractor—Walking System—Accelerated Durability Test Method. China Association of Agricultural Machinery Manufacturers: Beijing, China, 2024.

- T/NJ 1309; 2024 Pure Electric Tractors—Performance Index Calculation Method. Chinese Society of Agricultural Machinery: Beijing, China, 2024.

- T/NJ 1308; 2024 Electric Tractors—Performance Test Method. Chinese Society of Agricultural Machinery: Beijing, China, 2024.

- T/NJ 1256; 2021 Electric Tractor—Electric Power Train—Efficiency Determination Method. Chinese Society of Agricultural Machinery: Beijing, China, 2024.

- T/NJ 1177; 2020 Electric Tractor—Interface for Electric Power Take-Off. Chinese Society of Agricultural Machinery: Beijing, China, 2024.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).