Abstract

The estimation of the state of health (SOH) of lithium-ion batteries is a critical technology for enhancing battery lifespan and safety. When estimating SOH, it is essential to select representative features, commonly referred to as health indicators (HIs). Most existing studies primarily focus on HIs related to capacity degradation and internal resistance increase. However, due to the complexity of lithium-ion battery degradation mechanisms, the relationships between these mechanisms and health indicators remain insufficiently explored. This paper provides a comprehensive review of core methodologies for SOH estimation, with a particular emphasis on the classification and extraction of health indicators, direct measurement techniques, model-based and data-driven SOH estimation approaches, and emerging trends in battery management system applications. The findings indicate that capacity, internal resistance, and temperature-related indicators significantly impact SOH estimation accuracy, while machine learning models demonstrate advantages in multi-source data fusion. Future research should further explore composite health indicators and aging mechanisms of novel battery materials, and improve the interpretability of predictive models. This study offers theoretical support for the intelligent management and lifespan optimization of lithium-ion batteries.

1. Introduction

With the growing global demand for sustainable development and clean energy, lithium-ion batteries have become essential energy storage components in various applications, including electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. Their high energy density, long cycle life, low self-discharge rate, and relatively low environmental impact make them a preferred choice for these applications [1,2,3,4,5]. The state of health (SOH) of a battery directly determines its endurance, power performance, and safety. Therefore, accurately estimating SOH is a key technology for ensuring efficient system operation and extending battery lifespan.

In the field of EVs, consumers are placing increasingly stringent demands on battery performance and safety. Accurate SOH estimation not only optimizes charging and discharging strategies while preventing overcharging or over-discharging but also enables real-time battery state monitoring to mitigate potential failure risks [6,7,8,9,10,11]. Similarly, in renewable energy systems, such as solar and wind power generation, lithium-ion batteries play a critical role in energy storage and regulation [12,13,14]. The stability and reliability of battery performance directly impact the overall efficiency and stability of these systems. Precise SOH estimation can optimize charge–discharge strategies in energy storage systems, enhance energy utilization efficiency, and reduce system failures caused by battery degradation, thereby ensuring the continuous and stable supply of renewable energy [15,16]. Additionally, in portable electronic devices (e.g., smartphones and laptops), battery SOH directly affects device runtime and user experience.

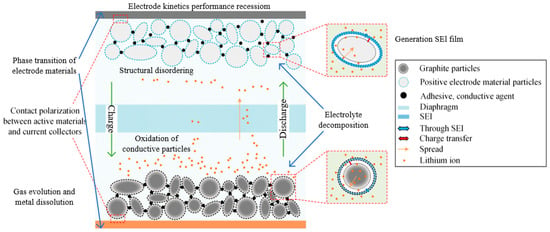

Despite the outstanding performance of lithium-ion batteries in various fields, they inevitably undergo aging over time. Battery aging is a complex, multi-factor process involving the loss of active materials, lithium-ion depletion, increased internal resistance, and changes in the solid electrolyte interphase (SEI) layer [17,18,19,20,21,22,23], as shown in Figure 1. These aging mechanisms interact, leading to gradual performance degradation, manifested as capacity fade, reduced charge–discharge efficiency, and weakened power output. Furthermore, different operating conditions—such as temperature, humidity, charge–discharge rate—and usage patterns, including depth of discharge and cycle count, significantly influence the aging process, making it even more complex and unpredictable [24,25].

Figure 1.

The degradation process of LiB.

In recent years, significant advancements have been made in SOH estimation for lithium-ion batteries. Researchers have continuously innovated methodologies and technologies to address challenges in real-world applications. However, several critical issues remain unresolved. First, while progress has been made in algorithm development, the intrinsic relationships between health indicators and battery aging mechanisms remain inadequately explored. Health indicators serve as fundamental parameters in SOH estimation, and their selection and extraction directly impact estimation accuracy and reliability [26,27,28,29]. However, the sensitivity and effectiveness of different health indicators under varying operating conditions and battery chemistries have not been systematically analyzed and compared. This lack of systematic evaluation hinders the selection of optimal health indicators for specific applications, ultimately limiting the precision and reliability of SOH estimation.

This paper provides a comprehensive review of the latest advancements in lithium-ion battery SOH estimation. It systematically classifies and analyzes existing techniques, including health indicator selection and extraction, direct measurement methods, model-based approaches, and data-driven methodologies such as machine learning and deep learning. Future research directions should focus on exploring composite health indicators, developing aging models for novel battery materials, enhancing the interpretability of machine learning algorithms, and integrating big data with edge-cloud collaborative real-time monitoring systems. These advancements aim to provide more reliable technological support for intelligent battery management and full life-cycle optimization.

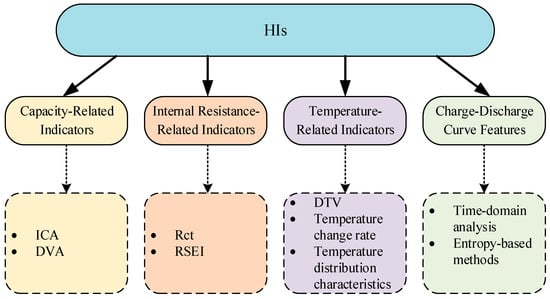

Different types of health indicators play distinct roles in SOH assessment. Capacity-related indicators, such as those derived from incremental capacity analysis (ICA) [30,31,32,33] and differential voltage analysis (DVA) [34,35,36,37], provide critical insights into battery capacity degradation, serving as key references for SOH estimation. However, the evolution of these indicators across different battery chemistries and complex operating conditions remains insufficiently understood and requires further investigation. Internal resistance-related indicators, such as charge transfer resistance (Rct) and SEI film resistance (RSEI) extracted using electrochemical impedance spectroscopy (EIS) combined with equivalent circuit models (ECM), are highly sensitive to electrochemical changes within the battery, but are significantly influenced by measurement conditions and model accuracy [38,39,40,41]. Temperature-related indicators reflect battery aging characteristics under varying thermal conditions, offering valuable information for thermal management and SOH estimation [42,43,44,45]. The charge and discharge curve also contains very rich battery SOH characteristics [46,47,48,49,50]. However, their complex interactions with other degradation factors increase the difficulty of indicator analysis and application.

Direct measurement methods assess the SOH by acquiring fundamental battery physical parameters, primarily including capacity measurement, charge–discharge curve analysis, and internal resistance measurement [51,52,53,54,55]. The capacity method quantifies degradation through the ratio of maximum available capacity to nominal capacity, providing precise evaluation but requiring prolonged testing duration. The charge–discharge curve analysis method employs voltage-capacity curve evolution characteristics combined with signal processing and machine learning to achieve non-invasive estimation, though exhibiting significant susceptibility to environmental factors [46,47,48]. The internal resistance measurement method, utilizing pulse testing among other techniques, detects the markedly increased internal resistance associated with aging, demonstrating high sensitivity [56]. While these approaches are conceptually straightforward and reliable, they commonly suffer from inadequate real-time performance or strong environmental dependence, necessitating integration with intelligent algorithms to enhance their applicability.

Among model-based SOH estimation methods, different models have their own advantages and limitations. ECM is computationally efficient, but it cannot accurately describe the complex electrochemical processes inside the battery [57,58,59,60,61]. In addition, their parameter determination relies heavily on experimental data, limiting adaptability. In contrast, electrochemical models provide a microscopic characterization of the cell reaction mechanism, but their computational complexity is high and therefore not suitable for real-time applications [62,63,64,65,66]. EIS can use information about the battery’s health status to make accurate health assessments, but it is difficult to use in real time. Improving the computational efficiency and adaptability of these models remains a major challenge for model-based SOH estimation.

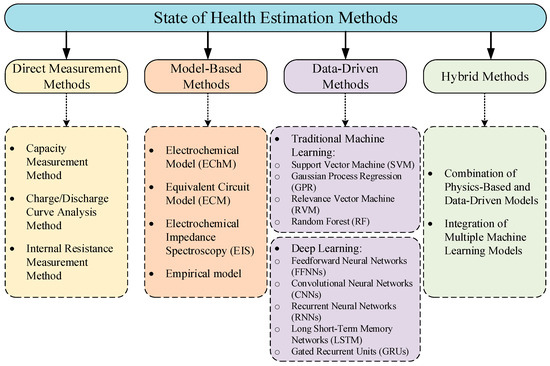

These techniques primarily fall into two categories: traditional machine learning and deep learning. The former, including support vector machines (SVMs) [57,58,59], Gaussian process regression (GPR) [60,61,62,63], Relevance Vector Machine (RVM) [64,65,66] and random forests (RFs) [67,68,69,70], exhibits superior performance in handling small sample sizes and high-dimensional feature spaces. The latter, represented by feedforward neural networks (FFNNs) [71,72,73], convolutional neural networks (CNNs) [74,75,76,77], long short-term memory (LSTM) networks [78,79,80,81,82,83], and gated recursive units (GRUs) [84,85,86,87,88], excels at extracting deep features from large-scale time-series data, making it particularly suitable for long-term SOH prediction tasks. However, single-model architectures often struggle to comprehensively address the coupled multi-factor influences during battery aging. To overcome this limitation, researchers have developed hybrid approaches that combine the interpretability of physical models with the adaptability of data-driven methods, or integrate multiple machine learning algorithms to enhance both accuracy and robustness.

However, data-driven approaches have demonstrated substantial advantages in lithium-ion battery SOH estimation. In contrast to conventional physics-based models, these methods can effectively capture complex nonlinear degradation patterns through analysis of historical operational data, enabling high-accuracy SOH estimation without requiring precise electrochemical mechanism modeling. They still face challenges such as data quality dependence, high computational complexity, and insufficient model generalization.

Battery management systems (BMSs) integrate multiple health indicators and estimation methodologies to enable real-time monitoring and precise control of battery states. However, real-world applications still face challenges related to data quality, computational resource constraints, and the “black-box” nature of machine learning models. In safety-critical applications, ensuring model transparency and reliability remains an urgent issue. Future research should prioritize improving the robustness and interpretability of SOH estimation models while addressing data integration challenges for real-time battery monitoring in intelligent BMS.

To address the respective strengths and limitations of these methods, this review is structured as follows: Section 2 elucidates the classification of health indicators and feature extraction techniques essential for SOH estimation, including capacity fade metrics, impedance characteristics, thermal response features, and charge–discharge curve statistics. Section 3 systematically examines the theoretical foundations, algorithmic implementations, and performance comparisons of direct, model-driven, data-driven, and hybrid SOH estimation techniques. Section 4 discusses emerging application trends such as intelligent BMS integration and cloud-edge collaboration, along with challenges related to data quality, computing resources, and model interpretability. Finally, Section 5 offers perspectives on future research directions, highlighting the potential of multi-source heterogeneous data fusion, reinforcement learning-based online adaptive algorithms, and digital twin platforms in advancing SOH estimation.

The previous reviews mainly focused on classifying the SOH estimation methods (model-based and data-based), and briefly introduced common health indicators (capacity, internal resistance), but lacked systematic analyses on the extraction techniques of health indicators, cross-validation of health indicators under different operating conditions, and integration with emerging trends (such as cloud-edge collaboration). Compared with existing reviews, our work (1) conducted a more detailed classification of health indicators by integrating multiple dimensions of features (capacity, internal resistance, temperature, charge–discharge curves) and their extraction methods (such as ICA, DVA, with detailed experimental steps); (2) emphasized practical applicability, distinguishing between real-time computable health indicators and those requiring offline testing; (3) and discussed emerging directions, such as composite health indicators and interpretable machine learning, which were rarely addressed in earlier reviews.

This review follows a rigorous, three-stage systematic process to ensure reproducibility and comprehensiveness. First, we searched Google Scholar, Web of Science, and IEEE Xplore for keywords such as “SOH review lithium battery health indicators,” “battery SOH estimation,” and “health indicator lithium battery review,” covering publications from 2010 to 2025. Next, we applied predefined inclusion and exclusion criteria:

- (1)

- Inclusion: reviews or original research directly focused on SOH estimation for lithium-ion batteries.

- (2)

- Exclusion: non-lithium-ion technologies, single-case studies without methodological synthesis, or papers lacking SOH-related content.

- (3)

- Screening process: title/abstract screening → full-text review → final selection.

Out of the 1570 initial records, 250 passed the title/abstract screening (after deduplication), and after full-text review, 142 high-quality reviews and key original studies were finally included for detailed analysis and discussion.

2. Classification and Extraction of Health Indicators

During the operation of lithium-ion batteries, their available capacity gradually declines. When the capacity decreases to 80% of the rated initial capacity, the battery is generally considered to have reached the end of its lifespan [89,90]. Consequently, HIs serve as key parameters for assessing the SOH of a battery. The effective extraction of these indicators relies on a multidimensional analysis of battery operation data and holds significant research value. By conducting in-depth mining of battery data, various health indicators can be extracted and analyzed to enable precise SOH assessment and monitoring. These indicators encompass multiple aspects, including capacity, internal resistance, temperature, and charge–discharge curves, and can be employed to develop battery health models for predicting battery lifespan, optimizing battery management strategies, and enhancing safety and reliability. The HIs classification of SOH is shown in Figure 2.

Figure 2.

Classification of health indicators in SOH.

However, in practical applications, batteries are often subjected to complex interactions of multiple factors, leading to fluctuations and noise interference in the extracted HIs. To enhance data reliability and improve the accuracy of battery performance assessments, filtering and smoothing techniques must be applied to cleanse and reconstruct these HIs, thereby mitigating the influence of local disturbances. This approach contributes to more accurate SOH analysis and facilitates effective health management.

2.1. Data Preprocessing and Quality Control

Before extracting and classifying health indicators, it is critical to establish a rigorously cleaned and consistent dataset. Data-driven SOH estimation techniques depend heavily on input quality. This section summarizes the key steps for anomaly removal, imputation, denoising, normalization, and cross-cycle consistency checks:

- (1)

- Outlier Detection and Removal: Employ statistical thresholds or machine-learning methods such as Isolation Forest to identify spikes or sensor faults in voltage, current, and temperature time series. Log the proportion and location of removed points for traceability.

- (2)

- Missing-Value Imputation: Short gaps, fill isolated dropouts using linear or polynomial interpolation to preserve local trends; extended gaps, omit entire cycles or di-charge segments when missing spans risk introducing excessive interpolation error.

- (3)

- Signal filtering and noise reduction: Apply Savitzky–Golay smoothing filters or moving average filters, etc., to retain the slow trends related to battery health while suppressing high-frequency noise.

- (4)

- Feature scaling: By using methods such as min-max scaling and Z-score standardization, the capacity, cumulative charging volume, temperature and other features are standardized. A uniform feature scale ensures that e-sure can achieve stable gradient updates during the model training process.

- (5)

- Cross-Cycle Consistency Checks: Compute the coefficient of variation in key metrics (e.g., discharge capacity, internal resistance) across cycles. Mark batteries with a coefficient of variation greater than 5 % for further review or exclusion to avoid biased learning.

Through the above preprocessing and quality control process, the accuracy of subsequent HI extraction and the stability of model training can be effectively improved, which lays a solid data foundation for SOH estimation based on machine learning.

2.2. Capacity-Related Indicators

Capacity degradation is the most direct and critical indicator for evaluating the SOH of lithium-ion batteries, as it explicitly reflects the decline in their ability to store and release energy over prolonged use [30,31,32,34,35,36]. The SOH is defined using capacity decay, which is expressed as follows:

where Qmax is the maximum available capacity under current conditions, and Qn is the nominal capacity. The calculation of the current maximum capacity Qmax of a battery requires a standardized test: first, charge it at a small current (such as C/20) to the cut-off voltage, then charge it at a constant voltage until the current is ≤C/50 (fully charged), and let it stand for 30 min to eliminate polarization. Then, discharge it at the same small current to the cut-off voltage and record the cumulative discharged charge, which is the current maximum capacity. Repeating the process 1–2 times and taking the average value will be more accurate. The ambient temperature needs to be controlled, a small current reduces polarization interference, and the cut-off voltages of different batteries should match their specifications.

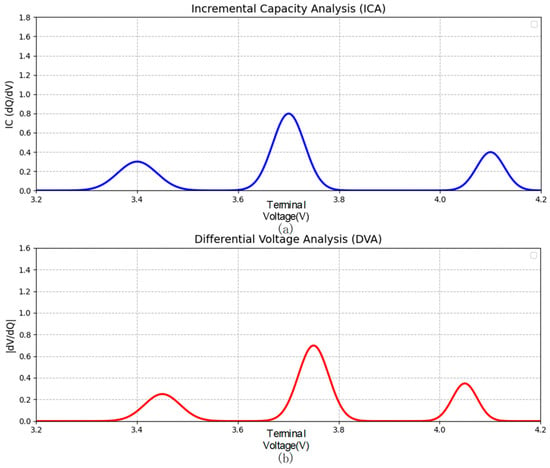

Among the various methods employed to assess battery capacity degradation, ICA and DVA have emerged as particularly effective techniques for extracting features that exhibit strong correlations with capacity fade. ICA and DVA are methods for analyzing battery state through charging and discharging data. The experimental procedure is: select samples and pre-process the battery, then slowly charge and discharge at a small current (C/20~C/10) in a constant-temperature environment, and collect high-precision voltage-capacity data. In data processing, ICA calculates dQ/dV (differential of capacity with respect to voltage), DVA calculates dV/dQ (differential of voltage with respect to capacity), and extracts indicators such as characteristic peaks.

2.2.1. Incremental Capacity Analysis (ICA)

ICA involves differentiating the battery’s charge–discharge capacity with respect to voltage during cycling, generating an incremental capacity curve. As shown in Figure 3a, this curve visually shows capacity variations across different voltage intervals, with peak voltage and area features offering insights into internal battery changes [31,32]. As the battery ages, electrode material structure and performance alterations affect lithium-ion intercalation and deintercalation, modifying ICA curve features. The ICA curve is expressed as follows:

where Q denotes battery capacity, and V represents battery voltage. The peak positions and areas of the ICA curve can provide insights into electrode material changes. Zhou et al. [91] developed a GMR-based SOH estimation method using IC curve peak analysis for LiFePO4 batteries. By leveraging multiple Gaussian distributions to model capacity degradation, the approach achieves <1% estimation error while maintaining low computational complexity. The method demonstrates strong adaptability across different charging regions and battery samples, providing a practical solution for onboard battery management systems. Meanwhile, ICA feature stability is highly sensitive to operational conditions. Elevated temperatures (>40 °C) accelerate peak broadening in IC curves, while high C-rates (>1C) induce voltage hysteresis that obscures phase transition markers. Consequently, ICA-based SOH estimation requires temperature compensation and C-rate normalization.

Figure 3.

(a) ICA curve; (b) DVA curve.

2.2.2. Differential Voltage Analysis (DVA)

DVA differentiates the voltage and capacity of the battery to obtain the differential voltage curve, as shown in Figure 3b. The formula is as follows:

The DVA curve is more sensitive to small changes inside the battery and can reveal a lot of information that is difficult to detect in conventional testing [34,35]. For example, the loss of active substances inside the battery, the loss of lithium ions, and the phase transition of the electrode material will be reflected in the characteristics of the inflection point and the peak and valley values of the DVA curve. Xia et al. [36] developed a BiGRU-AM framework integrating ICA/DVA analysis with CEEMDAN decomposition for battery health prediction. By reconstructing voltage curves through a second-order RC model, the method achieves 0.0006 RMSE in noise suppression while extracting highly correlated aging features. The approach demonstrates strong robustness against capacity regeneration and cell inconsistency, maintaining Remaining Useful Life (RUL) prediction errors within 10 cycles across different battery chemistries.

2.3. Internal Resistance-Related Indicators

An increase in internal resistance is a typical characteristic of lithium-ion battery aging, fundamentally arising from changes in various impedance components within the electrochemical system. As cycling progresses, factors such as electrode structural evolution, SEI growth, and electrolyte decomposition collectively hinder charge transfer processes [38,39]. This is reflected in a significant increase in Rct and RSEI, both of which serve as sensitive indicators of battery aging. The SOH definition based on internal resistance increase is expressed as follows:

where RE is the internal resistance at the end of life, Rreal is the current internal resistance, and RN is the nominal internal resistance. RE is defined by the manufacturer (usually twice the rated resistance of the electric vehicle battery). Rreal is estimated through pulse testing.

Huang et al. [92] developed a hybrid prediction method incorporating future internal resistance and capacity regeneration phenomena to improve LiB RUL estimation. By utilizing only the first 20–40 cycles’ data (5–10% of complete data), the approach achieves accurate long-term aging trajectory predictions while maintaining robustness across different battery types and operating conditions through transfer learning. This method effectively reduces error accumulation in multi-step forecasting, demonstrating strong generalization capability for practical battery management applications.

2.4. Temperature-Related Indicators

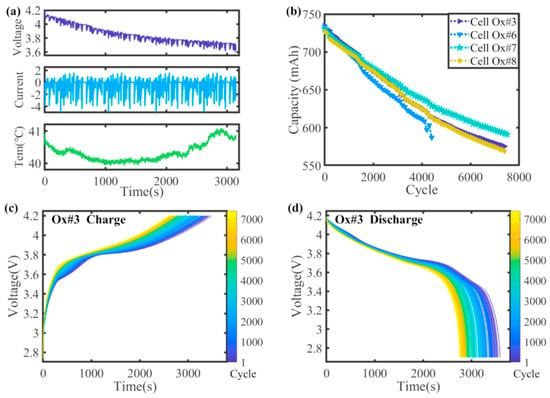

Temperature significantly affects lithium-ion battery performance and lifespan, influencing internal electrochemical reactions, thermodynamic processes, and material properties [42,43]. It has a dual impact on battery aging: high temperatures accelerate electrode material degradation, electrolyte decomposition, and SEI film growth, while low temperatures reduce lithium-ion migration rates and increase polarization [44,45]. Maintaining batteries within the optimal temperature range of 25 °C to 45 °C is crucial for optimal performance, as deviations can hasten capacity decay and lifespan reduction. Effective monitoring and assessment of temperature-related features are vital for accurate SOH evaluation. The battery aging cycle scheme and capacity degradation are shown in Figure 4.

Differential Thermal Voltammetry (DTV) is a vital method for identifying battery aging mechanisms through thermal-voltage coupling analysis [93,94]. By differentiating voltage and temperature data during charge–discharge, DTV curves can reflect internal chemical reaction heat and phase change information, aiding in aging mechanism analysis [95]. Chen et al. [96] proposed a DTV-based ensemble learning method for lithium-ion battery SOH estimation. By extracting key features from filtered DTV curves and combining multiple ELM models, this approach improves prediction accuracy while maintaining computational efficiency. The framework demonstrates strong reliability when validated on Oxford battery aging datasets, offering a robust solution for energy storage system monitoring.

Figure 4.

The battery aging cycle schemes and capacity degradation profiles: (a) a driving cycle test under the discharging process; (b) capacity degradation curves of the four Oxford batteries; (c) the evolution of charging voltage curves for Ox#3 battery; (d) the evolution of discharging voltage curves for Ox#3 battery [94].

Beyond these methods, researchers have explored multiple dimensions of temperature features:

- (1)

- Temperature change rate: Reflects the intensity of internal battery reactions and heat dissipation during charge–discharge. Abnormal changes in the temperature change rate can indicate battery aging, aiding in timely detection of abnormal states.

- (2)

- Performance indicators at specific temperatures: Significant changes in battery internal resistance and capacity occur at high and low temperatures. Establishing a quantitative relationship between these performance indicators and SOH at specific temperatures allows for more accurate assessment of battery health under diverse environmental conditions.

- (3)

- Temperature distribution characteristics: The non-uniformity of surface temperature distribution is closely related to internal aging. Constructing a three-dimensional temperature field model enables comprehensive battery health assessment, offering a basis for optimizing thermal management systems.

2.5. Charge–Discharge Curve Features

Charge–discharge curves provide crucial statistical features for assessing battery SOH. The extraction of statistical features from these curves primarily relies on time-domain analysis and entropy-based methods [46,47,48]. Time-domain indicators include variance and standard deviation, while entropy-based metrics, such as fuzzy entropy and sample entropy, capture nonlinear characteristics.

Variance: A classic measure of data dispersion, directly reflecting the stability of voltage or current. An increase in variance often indicates internal instability, possibly due to uneven electrode material distribution or poor internal contact. Quantitative analysis of these features enables indirect assessment of battery health.

Fuzzy Entropy: A nonlinear dynamic characteristic, effectively reflecting the complexity of internal chemical reactions. As the battery ages, the internal reaction mechanism becomes more complex and chaotic, leading to significant fluctuations in fuzzy entropy values, which can be used for quantitative aging state assessment.

In conclusion, the extraction and optimization of charge–discharge curve features play a crucial role in improving battery health management systems. Future research should focus on advancing feature extraction methods and optimizing feature combinations to achieve more precise SOH assessments.

3. SOH Estimation Methods

Accurately estimating the SOH of lithium-ion batteries is one of the core functions of a BMS. It plays a crucial role in extending battery lifespan, ensuring safe operation, and optimizing energy efficiency. With the widespread application of lithium-ion batteries in electric vehicles and energy storage systems, research on SOH estimation methods has attracted significant attention. This section provides a systematic discussion of SOH estimation methods, focusing on their classification and technical characteristics. The classification of SOH estimation methods is shown in Figure 5, and the comparison is presented in Table 1.

Figure 5.

Classification of SOH estimation methods.

Table 1.

Comparison of SOH estimation methods.

3.1. Classification of SOH Estimation Methods

SOH estimation methods can be broadly classified into two categories: direct measurement and indirect estimation [51,97,98,99]. Direct measurement methods obtain key battery parameters, such as capacity and internal resistance, through experimental techniques, providing a direct representation of battery health. In contrast, indirect estimation methods infer SOH based on battery operation data using models or algorithms. Each approach has distinct advantages and limitations, and the choice of method depends on the specific application scenario and available resources [100].

3.2. Direct Measurement Methods

Direct measurement methods estimate SOH by acquiring the physical parameters of a battery, allowing for an intuitive assessment of battery health. These methods typically rely on laboratory experiments to measure critical physical properties throughout the aging process. Common direct measurement techniques include Coulomb counting, open-circuit voltage (OCV) measurement, and internal resistance measurement [51,52,53].

3.2.1. Capacity Measurement Method

The capacity measurement method estimates SOH by measuring the charge delivered during the discharge process and calculating the ratio of maximum available capacity to the nominal capacity, as shown in Equation (1). This method accurately reflects capacity decay but is unsuitable for high-frequency use due to the long testing time required.

3.2.2. Charge–Discharge Curve Analysis Method

Charge–discharge curve analysis establishes a quantitative relationship between the evolution of voltage-capacity curves and battery aging [46]. This method leverages the phase transition characteristics of electrode materials, as reflected in electrochemical curves, and employs signal processing and machine learning techniques for non-invasive SOH estimation. Beitran et al. [47] proposed a CNN-based method for real-time capacity estimation using partial charge–discharge segments. Their data-driven solution demonstrates superior performance over conventional machine learning algorithms in processing BMS-generated operational data. However, the method exhibits estimation errors exceeding 1.5% for cycles with a depth of discharge (DOD) below 50%, indicating limitations in low-SOC operating regimes. While this approach shows promise for instantaneous capacity diagnostics, its commercial applicability remains constrained by accuracy variations under partial cycling conditions.

3.2.3. Internal Resistance Measurement Method

Internal resistance is a crucial SOH indicator, as it defines the voltage drop when a current is applied to the battery. This parameter is highly sensitive to battery aging and degradation. As SOH declines, internal resistance increases, making it a strong indicator for SOH estimation. Common measurement methods include AC impedance spectroscopy, DC resistance measurement, and pulse testing, with the latter being the most widely used [38,39,40].

In pulse testing, a short current pulse is applied, and the voltage response is recorded. Once the pulse ceases, the voltage returns to its original level. Internal resistance is then calculated as follows:

where Rb is the internal resistance, OCV is the open-circuit voltage, Vbat is the battery voltage, and Ipulse is the applied current. This method is widely used in laboratories to determine battery internal resistance under different operating conditions but has a long measurement time and is highly affected by temperature and state of charge, limiting its standalone accuracy.

3.3. Model-Based Methods

Model-based methods estimate SOH by constructing mathematical models to describe battery behavior. These models adapt to changes in battery state by incorporating operational data, thereby enhancing estimation accuracy [57,58,59,60,61,62,63,64,65,66]. The primary model-based approaches include electrochemical models, equivalent circuit models (ECMs), and empirical models, each with distinct characteristics and application scenarios.

3.3.1. Electrochemical Model (EChM)

Electrochemical models describe lithium-ion transport, reactions, and aging processes using partial differential equations, offering a detailed microscopic simulation of battery behavior [62,63,64,65,66]. Representative electrochemical models include the pseudo-two-dimensional (P2D) model and the single-particle model (SPM).

The P2D model offers a comprehensive multiphase representation of battery systems, explicitly accounting for three critical components: solid-phase active particles, liquid-phase electrolyte, and the separator. This model mathematically characterizes lithium-ion diffusion (governed by Fick’s laws of diffusion), migration phenomena, and electrode reaction kinetics (described by the Nernst equation). While the P2D model delivers exceptional simulation accuracy, its computational intensity stemming from coupled nonlinear equations often precludes real-time applications. To address this limitation, Xiong et al. [101] proposed an innovative electrochemical model-based methodology for battery aging characterization that circumvents the drawbacks of both ECMs and data-driven black-box approaches. Their solution integrates finite analysis with advanced numerical computation techniques to extract five critical aging parameters, achieving SOH estimation errors below 3% while maintaining voltage prediction accuracy within ±50 mV. This physics-based paradigm not only enables transparent interpretation of battery degradation mechanisms but also ensures computational tractability through optimized parameter identification algorithms.

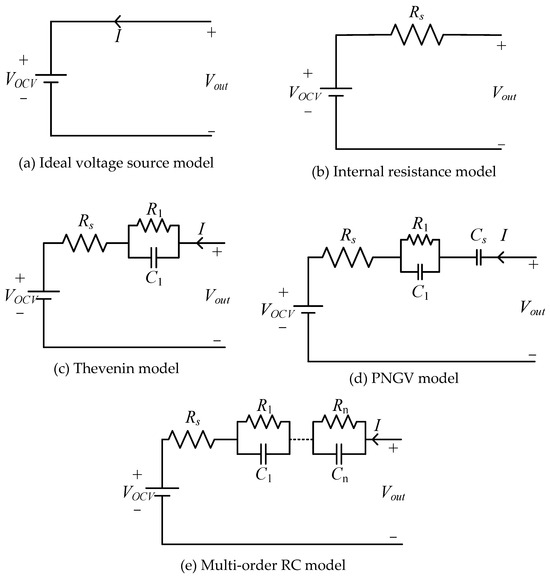

3.3.2. Equivalent Circuit Model (ECM)

ECMs are widely used for lithium-ion battery performance modeling, employing electrical components like resistors and capacitors to create a “black-box” model based on battery input-output relationships [57,58]. This approach simplifies complex internal electrochemical processes, reducing computational burden and enabling real-time applications. ECMs are built using Kirchhoff’s current and voltage laws, combined with measurable quantities to infer SOH-related parameters.

Common ECMs include the ideal voltage source model, internal resistance (Rint) model, Thevenin model, PNGV model, and multi-stage RC model [102,103,104,105], as shown in Figure 6. The Rint model uses a single ohmic resistor to represent battery internal resistance but neglects polarization effects. The Thevenin model adds a polarization resistor and capacitor to form an RC network, capturing battery charge–discharge polarization effects. The PNGV model further includes a capacitor to account for battery hysteresis voltage, improving accuracy. The multi-stage RC model adds more RC networks for higher precision, though increased parameters raise online identification uncertainty and computational complexity.

Figure 6.

Common lithium-ion equivalent circuit models.

Hu et al. [106] compared 12 ECMs and found the first-order RC model best for ternary lithium-ion batteries, while the first-order RC model with single-state hysteresis was optimal for lithium iron phosphate batteries. Others improved the second-order RC ECM using fractional calculus, developing a fractional-order model. Simulation results showed higher accuracy and robustness under different operating conditions, SOC ranges, and temperatures [107].

Despite their computational efficiency and real-time capability, ECMs have limitations. Battery electrochemical processes are influenced by temperature, charge–discharge rate, etc., making it hard for ECMs to accurately capture internal changes across different operating conditions and aging stages. ECMs typically require parameter optimization and adjustment under specific operating conditions to adapt to actual battery usage.

To address this, Liu et al. [108] proposed an autoregressive ECM (AR-ECM) that incorporates historical data for dynamic parameter adjustment. This model significantly enhanced SOH estimation accuracy and robustness in complex operating conditions, such as electric vehicle applications. Experimental results showed reduced SOH and SOC estimation errors and improved real-time battery state tracking, enhancing BMS precision and reliability.

3.3.3. Electrochemical Impedance Spectroscopy (EIS)

EIS is a key tool for studying internal battery electrochemical processes, widely used for SOH evaluation and fault diagnosis. It involves applying AC sinusoidal signals at various frequencies to measure battery/battery pack impedance, comparing impedance values at different states to assess battery degradation and establish frequency–impedance relationships. EIS measurements yield parameters like ohmic resistance, double-layer capacitance, electrolyte impedance, and charge transfer resistance [38].

The Nyquist plot of EIS reveals macroscopic and microscopic electrochemical behaviors of the battery, with distinct electrochemical responses at different frequencies. For example, Wang et al. [10] noted a correlation between the AC impedance phase shift of LIBs and internal temperature, enabling internal temperature prediction at specific frequencies. Illig [11] used deconvolution techniques to analyze impedance spectra datasets, separating charge transfer and solid-state diffusion processes.

However, EIS has challenges in practical applications. Different battery types show significant impedance response variations, making it hard to apply a single model to multiple battery types. Establishing calibration platforms for various battery types is necessary. Additionally, EIS testing is time-consuming and requires high environmental stability, limiting its use in dynamic scenarios like electric vehicles. In summary, EIS provides valuable information on battery health status, particularly for precise health assessments in laboratory settings. However, considering its limitations in real-time monitoring, combining EIS with other estimation methods is often necessary for comprehensive and flexible SOH estimation.

3.3.4. Empirical Model

The empirical model uses a large amount of battery aging data to predict the SOH of the battery by fitting the effects of different aging factors, such as temperature, deep discharge, charge rate, etc. [109,110,111,112]. This kind of model does not need to consider the detailed electrochemical characteristics of the battery, the calculation is simple, the speed is fast, and it is suitable for real-time monitoring. Wang et al. [107] proposed a capacity loss model based on parameters such as temperature, DOD and discharge rate, which could better reflect the aging process of batteries under different working conditions.

However, the disadvantage of empirical models is that they rely too much on experimental data and often fail to account for complex coupling effects. In the process of battery aging at different temperatures, SOC changes may be affected by factors such as self-discharge, and traditional empirical models are difficult to consider the interaction of these factors. Therefore, although the empirical model is relatively simple in practical application, its accuracy and generalization ability are still limited, especially in the variable use environment.

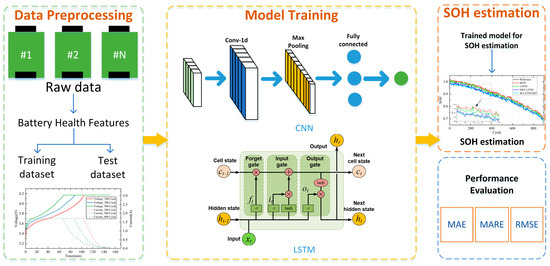

3.4. Data-Driven Methods

In recent years, with the rapid advancements in artificial intelligence (AI) and the Internet of Things (IoT), data-driven approaches have garnered significant attention in the estimation of lithium-ion battery SOH. The proliferation of IoT technology has substantially enhanced the efficiency and accuracy of battery operation data collection, providing a robust foundation for data-driven methodologies. Compared to traditional physics-based models, data-driven methods leverage deep analysis of historical operational data to effectively capture the complex nonlinear degradation patterns of batteries, thereby achieving high-precision SOH estimation without relying on intricate electrochemical modeling [113,114,115,116].

During charge–discharge cycling, cumulative electrochemical side reactions gradually lead to a reduction in the battery’s usable capacity and maximum energy storage capability. This degradation process is irreversible and involves multiple complex physical and chemical mechanisms, making it challenging for physics-based models to comprehensively and accurately characterize a battery’s internal state [117]. In contrast, data-driven methods establish a mapping relationship between degradation features and SOH, offering a more flexible and adaptable solution. Due to their model-free nature, these approaches eliminate the need for precise modeling of internal battery mechanisms, reducing computational complexity and model development challenges while improving generalizability across diverse operating conditions [118].

Based on modeling techniques, data-driven approaches can be broadly categorized into traditional machine learning and deep learning methods. Traditional machine learning techniques, such as Support Vector Machines (SVMs), Random Forests (RFs), and Gaussian Process Regression (GPR), excel in handling small sample sizes and high-dimensional feature spaces, providing stable predictive performance even with limited data. On the other hand, deep learning models, including Convolutional Neural Networks (CNNs) and Long Short-Term Memory (LSTM) networks, demonstrate superior feature extraction capabilities, making them particularly effective for processing large-scale time-series data and capturing complex nonlinear relationships. These methods are especially suited for long-term SOH prediction tasks. Moreover, emerging deep learning frameworks integrating transfer learning, attention mechanisms, and multimodal data fusion are becoming key research directions in SOH estimation.

Future advancements in data-driven SOH estimation are expected to focus on more efficient data preprocessing strategies, robust feature extraction techniques, and hybrid modeling frameworks that integrate physics-based models, further enhancing estimation accuracy and adaptability. An example of battery SOH estimation based on machine learning is shown in Figure 7.

Figure 7.

Example battery SOH estimation based on machine learning.

3.4.1. Traditional Machine Learning

Support Vector Machine (SVM)

SVM is a supervised learning method based on statistical learning theory, specializing in sparse and non-probabilistic binary linear classification [57,58]. Its core objective is to identify an optimal hyperplane that maximizes the margin between distinct data categories in a high-dimensional feature space. Through kernel function mapping, SVM transforms low-dimensional input data into linearly separable representations, enabling effective nonlinear classification [59]. The theoretical framework of SVM integrates Vapnik-Chervonenkis (VC) dimension theory with structural risk minimization principles, which jointly constrain the model’s generalization error bound. This dual mechanism not only suppresses overfitting but also enhances learning efficiency, making SVM particularly suitable for high-dimensional, small-sample scenarios.

In the field of lithium-ion battery SOH estimation, SVM has shown promising results, though further exploration is warranted. Yang et al. [119] developed a PSO-SVM algorithm for online health monitoring of electric vehicle batteries. SOC/SOH estimation was performed by particle swarm optimization of SVM kernel function. This method shows strong adaptability in dynamic stress testing, overcomes the limitation of traditional off-line estimation, and provides an effective solution for real-time BMS applications. To enhance the efficiency of battery SOH estimation, Qian et al. [120] developed an improved SVR algorithm by introducing a smoothing function to transform the original non-differentiable loss function into a convex unconstrained optimization problem. Using four key battery features (voltage at SOC = 100%, voltage, discharge time, and SOC) identified through decision tree analysis of NASA datasets, the method significantly reduced training time while maintaining high estimation accuracy. The conjugate gradient-based optimization approach achieved efficient model training through sequential minimal optimization, demonstrating superior computational performance compared to conventional SVR methods. Furthermore, to improve lithium-ion battery health prediction, Chen et al. [52] developed an ICOA-optimized TWSVM model incorporating VMD decomposition and RF feature selection. By extracting charging time as a health indicator and enhancing global search capabilities through Good Point Set theory, the method achieves exceptional accuracy (RMSE ≤ 0.007, MAPE ≤ 0.0082) on NASA/CALCE datasets. This approach demonstrates superior fitting performance and robustness in both SOH and RUL estimation compared to conventional models.

Despite its strong performance in classification and regression tasks, SVM remains in the exploratory stage for battery SOH estimation. Since SOH estimation inherently involves continuous numerical sequences, it is typically framed as a regression problem. SVM can be extended to regression tasks by introducing the epsilon-insensitive loss function, in which case it is referred to as SVR. SVR offers distinct advantages in handling high-dimensional and small-sample datasets, making it a widely applied approach in lithium-ion battery SOH estimation.

Gaussian Process Regression (GPR)

Gaussian process regression is a non-parametric model based on probability statistics, which has unique advantages in processing nonlinear data, which has made it widely used in lithium-ion battery SOH estimation. The aging process of lithium-ion batteries is affected by a variety of factors, and there is a complex nonlinear relationship between these factors, which leads to the change of the health state of the battery showing a high degree of nonlinear characteristics. By learning the training data, GPR can automatically capture these nonlinear relations and build a probability distribution model of the data [60,61]. When building a model, GPR determines the distribution of data by defining a kernel function that measures the similarity between data points [62,63].

However, the performance of the GPR model largely depends on the choice of kernel function. The data fitting effect and prediction ability of different kernel functions are significantly different. For example, the commonly used radial basis kernel function may perform well when dealing with some data with a specific structure, but for other complex data distributions, it may not accurately capture the data characteristics, resulting in large prediction errors. To enhance lithium-ion battery SOH estimation accuracy, Ye et al. [121] proposed a BO-GPR method integrating gray correlation analysis. By automatically optimizing GPR hyperparameters through Bayesian algorithms and extracting key aging features from charge–discharge data, the method achieves <1% estimation error on NASA/Oxford datasets. This approach demonstrates superior reliability compared to conventional data-driven models while maintaining computational efficiency through intelligent parameter optimization.

Relevance Vector Machine (RVM)

The Bayesian Sparse Kernel Method, also known as the RVM, is a supervised probabilistic model structurally similar to SVM but with distinct advantages. Unlike SVM, RVM eliminates weakly relevant sample points and can construct arbitrary kernel functions without requiring penalty factors, resulting in a sparser solution and significantly enhanced model flexibility [64]. Extracting strongly relevant HIs throughout the battery’s lifecycle is crucial for analyzing performance degradation trends.

In relevant studies, Dong et al. [122] first applied principal component analysis to reduce data dimensionality and extract health indicators. They then utilized a hybrid-kernel RVM (H-RVM) method to perform SOH estimation across multiple time scales. Their approach was validated using two publicly available datasets and six battery SOH estimation tasks, confirming its effectiveness. In kernel function optimization, Wang et al. [123] adopted a multi-kernel (MK) approach to accommodate diverse data categories and lengths, integrating hybrid models with RVM and the whale optimization algorithm (WOA) for battery degradation rate prediction. To further enhance the global search capability of kernel parameter selection and mitigate the inherent randomness of RVM, Chen et al. [124] introduced the Bat Algorithm-Relevance Vector Machine (BA-RVM), dynamically adjusting model parameters to achieve precise tracking of battery capacity degradation trends.

Random Forest (RF)

As an ensemble learning algorithm, RF aggregates predictions from multiple decision trees to generate final outputs. RF’s key advantages in lithium-ion battery SOH estimation include its strong feature-handling capability and interpretability. During decision tree construction, RF randomly selects feature subsets for splitting, enabling it to process large-scale feature data while reducing the risk of overfitting [67]. Additionally, RF quantifies feature importance, providing valuable insights into model decision-making processes [68].

When analyzing factors affecting SOH, RF can quantify the contribution of characteristics such as charge and discharge current, temperature, and cycle number to SOH prediction, which helps to deeply understand the mechanism of battery aging and provides a basis for further optimization of battery management strategies. In practical applications, the researchers try to combine RF with other models (such as neural networks) to give full play to the feature screening capability of RF and the nonlinear fitting capability of neural networks to improve the accuracy and reliability of SOH estimates.

Significant progress has been made in the application of traditional machine learning methods to SOH estimation of lithium-ion batteries. SVM and its variants (such as SVR, GA-LSSVM) perform well in high-dimensional and small-sample situations, and are suitable for scenarios that are heavily affected by noise. GPR provides uncertainty estimation through probabilistic modeling, which is suitable for nonlinear datasets. Because of its sparsity and the advantages of Bayesian framework, RVM has potential in high-dimensional data prediction tasks. As an ensemble learning method, RF is suitable for multivariate analysis tasks due to its interpretability and feature processing capabilities. Although traditional machine learning methods have achieved good results in the field of SOH estimation, they rely on feature engineering and are difficult to make full use of large-scale time series data. In recent years, the rise of deep learning methods has provided new solutions for SOH estimation, and the following chapters will explore the application and development trend of deep learning in this field.

3.4.2. Deep Learning Methods

Neural network algorithms, as an outcome of deep learning advancements, have demonstrated distinct advantages in estimating the SOH of lithium-ion batteries. Compared to traditional machine learning methods, neural networks more effectively capture the complex nonlinear characteristics of batteries, thereby enhancing estimation accuracy [114,115,116]. Currently, SOH estimation methods based on neural networks can be broadly categorized into feedforward neural networks (FFNNs), convolutional neural networks (CNNs), recurrent neural networks (RNNs), long short-term memory networks (LSTMs), and gated recurrent units (GRUs) [125,126].

Feedforward Neural Networks (FFNNs)

A feedforward neural network, also known as a multilayer perceptron, represents the simplest artificial neural network (ANN) structure, where information propagates forward without feedback between layers. Soltani et al. [127] analyzed the cyclic aging behavior of batteries from the perspective of capacity degradation and implemented SOH estimation using FFNN, a data-driven technique. Their findings revealed that capacity degradation is closely related to discharge rate, temperature, and depth of cycle, achieving an estimation accuracy of 95%. This discovery not only facilitated the application of neural networks in battery SOH estimation but also laid a solid foundation for the continuous innovation and advancement of related technologies.

Convolutional Neural Networks (CNNs)

CNNs constitute a multi-layered network structure and a critical category of deep learning algorithms. Its uniqueness lies in applying convolutional operations to generate feature maps. The network architecture consists of an input layer, hidden layers, and an output layer, where hidden layers further include convolutional layers, pooling layers, and fully connected layers. This structure grants CNNs strong capabilities in processing multi-dimensional and long-time-series data, making them particularly advantageous in battery SOH estimation [74,75,76,77].

Numerous studies have demonstrated the effectiveness of CNN in SOH estimation. In [128,129,130], Shen et al. utilized CNN to construct an SOH estimation model, leveraging its powerful feature extraction capabilities to automatically identify key characteristics from raw voltage, current, and temperature trajectory data collected during the charging process. This approach mitigates the subjectivity and limitations associated with traditional feature selection methods, allowing the model to capture battery SOH information more comprehensively and accurately. Xiao et al. [131] proposed a CNN-MMHA model for estimating SOH. The model leverages a masked multi-head attention (MMHA) mechanism to address long-term dependencies in sequential data and encode temporal positional information, while the CNN component captures critical features of battery state. The model successfully achieves accurate SOH estimation and demonstrates strong convergence behavior and generalization capability, validating its effectiveness and practical applicability.

However, in practical applications of LIBs, ambient noises under varying operating conditions interfere with dynamic state diagnosis, leading to degraded prediction accuracy of SoH and RUL. To address this challenge, Chae et al. [132] proposed an allied denoising convolutional neural network (DnCNN) and CNN framework. This model enhances SoH estimation accuracy by employing residual learning techniques to eliminate unknown environmental noises, while simultaneously achieving RUL prediction through multi-dimensional feature analysis. To validate its effectiveness under real-world scenarios, experimental verification was conducted using multi-physics degradation data collected from customized test platforms. Results demonstrate that this integrated denoising-prediction framework significantly improves accuracy and robustness in SoH/RUL estimation compared with conventional methods, providing an innovative solution for handling noise interference in battery health management systems. This advancement expands the application potential of deep learning in battery state diagnosis under complex operating environments.

Recurrent Neural Networks (RNNs)

The physical and chemical degradation processes of batteries exhibit nonlinear characteristics and are closely related to time series [133]. RNNs can optimize internal parameters for SOH estimation by capturing integrated circuit (IC) information and incorporating time-series test data [134]. To overcome the limitations of time-intensive battery characteristic testing and soc related modeling, Schmitt et al. [135] introduced an RNN-based encoder–decoder framework that directly processes raw data. The model only predicts the 2000 order voltage response from the initial voltage and current input, thus bypassing traditional parameter estimation and calculating 120 times faster than traditional methods. The architecture enables real-time monitoring and virtual testing as a digital twin for battery SOH estimates, providing an aging-proof solution that simplifies vehicle electrified battery modeling.

Long Short-Term Memory Networks (LSTM)

As an improved variant of Recurrent Neural Networks (RNNs), Long Short-Term Memory (LSTM) networks are specifically designed to address the gradient vanishing and exploding issues that plague RNNs when processing long time-series data. This structural advancement enables LSTMs to effectively capture long-term dependencies in sequential data, significantly expanding their applicability in dynamic modeling scenarios [78,79,80].

To enhance the robustness of LSTMs in practical applications, especially when handling high-dimensional time-series data, relevant studies have adopted targeted optimization strategies to mitigate overfitting: (1) incorporating dropout layers with a dropout rate of 0.2–0.5 to prevent co-adaptation of neurons; (2) implementing early stopping by setting the patience for validation loss to 10–20 epochs; (3) applying weight regularization. These strategies have been shown to reduce the test root mean square error by 15–30% compared to baseline LSTM algorithms.

In the domain of battery health estimation, LSTMs have demonstrated notable efficacy through various research applications. Yayan et al. [136] develops a stacked LSTM model that estimates SoH using only constant-current phase data. The method achieves accurate SoH prediction at charge completion without requiring full degradation cycles, allowing drivers to optimize battery usage planning. Experimental results validate its effectiveness in quick-charge scenarios, offering a practical solution for EV battery management systems to extend pack lifespan through timely health-aware interventions.

To address low-temperature capacity estimation challenges in aviation batteries, Wang et al. [137] developed an SF-GPR-LSTM model combining singular filtering with multi-task learning. This framework achieves 2.35% RMSE accuracy using only 55% lifecycle data while optimizing ion/electron transport dynamics, demonstrating 92% R2 performance. The computationally efficient solution enables precise cold-environment battery management through spiral feature optimization. Additionally, Huang et al. [138] developed a CNN-LSTM-TPA model incorporating temporal pattern attention and whale optimization. By implementing LOF-based outlier correction and dual correlation analysis for health feature selection, the method achieved 26–73% accuracy improvements over conventional LSTM across NASA/CALCE datasets. This architecture enhances critical degradation pattern recognition while maintaining computational efficiency through optimized hyperparameters, providing a robust framework for energy storage system maintenance. Consequently, in battery degradation studies, LSTM models play a crucial role in full-lifecycle SOH estimation, contributing to safer battery health management technologies.

Gated Recurrent Units (GRUs)

Compared to LSTM, GRU incorporate fewer parameters and have a more streamlined structure, enabling rapid capture of declining SOH trends [84,85,86,87,88]. Thus, GRU offers lower computational complexity than LSTM, making it more suitable for real-time applications. To address the challenge of lithium battery health monitoring in multi-strategy charging scenarios, Guo et al. [139] proposed an SG-GRU fusion model combining Savitzky–Golay filtering with gated recurrent networks. This architecture reduces capacity prediction noise through signal smoothing while maintaining 1% RMSE accuracy across diverse charging protocols. Experimental results demonstrate the model’s rapid response capability and precise tracking of nonlinear capacity degradation trends, providing a computationally efficient solution for cross-application battery safety management.

Considering real-world vehicle data, Hong et al. [140] innovatively employed ohmic resistance as an indirect health factor. Their findings indicated that when using data from different vehicles as GRU input, the SOH estimation error remained below 4%, effectively tracking nonlinear degradation trends throughout a battery’s lifecycle and validating the algorithm’s feasibility. The strong cycle correlation among lithium-ion battery packs, combined with GRU’s superior regression capabilities and reduced risk of overfitting, has led to its widespread application in battery health management.

3.4.3. Hybrid Methods

Hybrid approaches integrate the advantages of multiple models to enhance the accuracy and robustness of lithium-ion battery SOH estimation. Traditional single models often struggle to fully capture the characteristics of battery degradation when handling complex aging data. By leveraging the strengths of different models, hybrid methods can provide a more comprehensive representation of battery health. Currently, hybrid approaches primarily include the combination of physics-based models with data-driven models and the integration of multiple machine learning models.

Combination of Physics-Based and Data-Driven Models

Physics-based models, such as the EChM, theoretically describe the internal electrochemical processes of batteries, providing physical constraints for SOH estimation. However, these models typically require precise parameter measurements and complex computations, making real-time applications challenging. In contrast, data-driven models, such as SVM and ANN, learn aging patterns from historical data and eliminate the need for intricate parameter identification. However, they lack interpretability regarding the internal mechanisms of battery degradation.

To overcome these limitations, researchers have proposed hybrid approaches that combine physics-based and data-driven models. For example, physics-based models can provide electrochemical insights into battery health, while data-driven models can refine these models by correcting prediction errors based on measurement data, thereby improving SOH estimation accuracy. Su et al. [141] proposed a data-efficient SOH estimation framework integrating battery ECM, CNN architecture, and adversarial transfer learning. The method employs ECM to generate virtual cycling data through charge–discharge simulations, utilizes CNN for automatic degradation feature extraction, and implements GAN-based domain adaptation to align virtual and real data distributions. Experimental validation showed the model achieves high prediction consistency with maximum test error below 0.0941 across all operational scenarios, demonstrating effective cost reduction in data acquisition while maintaining estimation reliability.

A key technical strategy in such hybrid models is resolving domain conflicts through residual learning: physical models generate baseline predictions, while data-driven modules learn correction terms to compensate for discrepancies between theoretical simulations and real-world measurements. This dual-module design enables the framework to reconcile the precision of physical principles with the flexibility of data-driven adaptation.

Integration of Multiple Machine Learning Models

Ensemble learning methods improve SOH estimation accuracy and generalization by aggregating predictions from multiple models. Common ensemble techniques include Bagging, Boosting, and Stacking.

Bagging (Bootstrap Aggregating) trains multiple base learners in parallel and combines their predictions via weighted averaging or voting, reducing variance and enhancing stability. For instance, RF, which employs Bagging with multiple decision trees, has been applied to SOH estimation, demonstrating strong robustness against noise.

Boosting sequentially trains weak learners, with each subsequent model focusing on samples that were mispredicted in the previous iteration, progressively improving overall performance. Gradient Boosting Decision Trees (GBDTs) and Extreme Gradient Boosting (XGBoost) have been widely used for battery SOH estimation, achieving outstanding performance on various datasets.

Stacking trains a meta-learner to combine the predictions of multiple base models, further enhancing predictive accuracy. Xue et al. [142] developed a hybrid PF-LSTM prognostic framework integrating two-phase clustering analysis and particle filtering for dynamic SOH classification and RUL prediction under time-varying operational uncertainties. The method employs subtractive-fuzzy clustering to characterize heterogeneous degradation states, combines particle filters for probabilistic uncertainty quantification in capacity/RUL distributions, and leverages LSTM networks for long-term temporal dependency modeling. Experimental comparisons with UPF and RBFN methods demonstrated the framework’s robustness in capturing degradation dynamics, achieving high-precision posterior probability density estimations for maintenance decision-making while addressing challenges posed by measurement errors and non-stationary operating conditions.

Advantages and Challenges of Hybrid Approaches

Hybrid approaches offer significant advantages by effectively leveraging the strengths of different models, improving SOH estimation accuracy and robustness. However, several challenges remain:

- (1)

- Computational Complexity: Hybrid models are computationally demanding, posing challenges for real-time applications. Balancing computational efficiency and estimation accuracy remains a critical issue.

- (2)

- Design and Optimization: The selection of appropriate model combinations and integration strategies depends on specific application scenarios, making the design and optimization process complex.

- (3)

- Interpretability: Hybrid approaches, particularly those incorporating deep learning models, often lack interpretability. Enhancing model explainability is an urgent issue that requires further investigation.

Despite these challenges, hybrid approaches hold great promise for advancing SOH estimation and management technologies, paving the way for more reliable and efficient battery health monitoring systems.

4. Application Trends and Challenges

4.1. Integration into BMS

Despite significant progress in Li-ion battery SOH estimation, practical integration faces challenges. A key gap exists between laboratory models and complex real-world operating conditions, hindering direct translation. Battery pack cycle testing is time-consuming and energy-intensive, while real-time data measurement errors, particularly under dynamic loads, compromise accuracy and consistency. Furthermore, intricate aging mechanisms and cell-to-cell variability, influenced by manufacturing inconsistencies, environmental factors (temperature, humidity), and diverse usage patterns, complicate the development of universally applicable SOH models.

Future research should focus on addressing the following key issues:

- (1)

- Developing efficient online testing methods to minimize the impact of SOH estimation on battery operation, enabling real-time monitoring without disrupting battery performance.

- (2)

- Establishing more accurate battery aging models by integrating electrochemical mechanisms with data-driven approaches to enhance SOH estimation reliability.

- (3)

- Exploring novel data fusion techniques that leverage multi-source information (e.g., voltage, current, temperature, internal resistance) to improve estimation accuracy.

- (4)

- Developing adaptive and robust SOH estimation algorithms to meet the demands of diverse application scenarios. This is particularly critical for electric vehicles and energy storage systems, where operational conditions are highly variable, and model adaptability is essential.

Advancing SOH estimation requires interdisciplinary efforts combining experimentation, modeling, and data analysis. Multi-indicator fusion is vital for real-time BMS capabilities. However, challenges like data quality, computational constraints, and the limited interpretability of “black-box” machine learning models must be resolved for reliable and transparent health assessment.

4.2. Big Data and Cloud-Edge Collaboration

Big data and cloud computing integration is a growing focus for battery health management. Big data platforms facilitate storage, analysis, and mining of operational data to uncover aging patterns and enrich SOH insights. Cloud-edge collaboration enhances real-time capability and efficiency: edge devices handle low-latency monitoring, while the cloud performs complex analysis and model training.

However, the application of big data and cloud-edge collaboration also presents several critical challenges:

- (1)

- Data privacy and security concerns must be addressed, particularly in scenarios involving sensitive user data. Ensuring secure encryption for data transmission and storage remains a key challenge.

- (2)

- Stability of data transmission can be affected by network conditions, especially in remote areas or mobile applications. Maintaining data integrity and real-time availability requires further investigation.

- (3)

- Optimization of cloud-edge collaboration efficiency is crucial, particularly in large-scale battery pack management. Balancing computational resource allocation and task prioritization to achieve efficient health management remains a complex technical challenge.

Among these, network latency is mitigated through the following methods:

- (1)

- Edge cached fallback models that operate during disconnections.

- (2)

- Data prioritization—critical features transmit first.

- (3)

- Compressed telemetry reducing payload by 70%.

4.3. Emerging Research Frontiers

To further advance lithium-ion battery health management technologies, future research should prioritize the following directions.

4.3.1. Composite Health Indicators

Traditional health indicators, such as capacity and internal resistance, provide valuable insights into battery aging but have limitations under complex operating conditions. Future studies should explore composite health indicators that integrate multiple physical parameters (e.g., temperature, pressure, mechanical stress) to provide a more comprehensive assessment of battery health. For example, analyzing the correlation between temperature distribution patterns and mechanical stress variations can improve the accuracy of thermal runaway risk prediction.

4.3.2. Aging Mechanisms of Emerging Battery Materials

With the wide adoption of new battery materials, such as solid electrolytes and high-nickel cathode materials, their aging mechanisms are quite different from those of traditional lithium-ion batteries. Future research should focus on elucidating the aging behaviors of these emerging materials and developing SOH estimation models tailored to next-generation batteries.

4.3.3. Explainable Machine Learning

Although machine learning methods have shown great potential in SOH estimation, their black-box nature limits their applicability in high-security applications. Future research should combine physics-based models with interpretable machine learning techniques to enhance the transparency and interpretability of the models.

4.3.4. Sustainable Recycling and Environmental Monitoring

Recent advances in environmental monitoring, such as paper-based sensors for trace lead ion detection in battery waste streams [143], highlight the growing synergy between battery health management and recycling technologies. These innovations could enhance closed-loop lifecycle control of lithium-ion systems. These innovations facilitate real-time monitoring of heavy metal pollutants during battery recycling, bridging health management with environmental sustainability. Future studies should integrate such low-cost sensors into BMS-edge networks for end-of-life hazard assessment and material recovery optimization.

5. Conclusions

This review analyzed key Li-ion battery SOH estimation techniques, including health indicators, direct measurement, model-based approaches, and advanced data-driven/deep learning methods. Capacity fade and internal resistance rise remain primary indicators, while ML excels in multi-source data fusion and nonlinear feature extraction.

However, unresolved challenges persist due to complex aging interactions:

- (1)

- Limitations of single indicators: Relying solely on capacity or internal resistance fails to comprehensively capture battery degradation characteristics under diverse operating conditions. There is a pressing need to develop composite health indicators that integrate multiple physical quantities.

- (2)

- Model generalization capability: Model parameters and algorithms derived under laboratory conditions often struggle to generalize to real-world applications, resulting in reduced estimation accuracy and real-time performance under complex and dynamic working conditions.

- (3)

- Data quality and acquisition issues: Noise, uneven sampling, and inconsistencies in multi-source information during battery operation pose challenges to accurate SOH evaluation.

- (4)

- Lack of interpretability: Although machine learning techniques enhance predictive accuracy, their “black-box” nature limits quantitative insights into intrinsic battery degradation mechanisms, hindering their deployment in high-safety applications.

To address these challenges, future research should focus on the following directions:

- (1)

- Development of Composite Health Indicators: Integrating capacity, internal resistance, temperature, and other physical parameters into a new health indicator system will enable a more comprehensive and dynamic representation of battery degradation, providing a richer foundation for SOH estimation.

- (2)

- Model Optimization and Cross-Modal Fusion: Enhancing estimation models to balance high accuracy and real-time performance, incorporating both physical models and data-driven approaches, and leveraging interpretable machine learning techniques will improve model transparency and generalization across diverse operating environments.

- (3)

- Data Standardization and Cloud-Edge Collaboration: Standardizing experimental data management, establishing large-scale data platforms for information sharing and multi-dimensional data fusion, and utilizing cloud-edge collaboration to support low-latency real-time monitoring while enabling complex online computations will provide a robust data infrastructure for battery management systems.

- (4)

- Interdisciplinary Collaboration and New Material Research: Promoting interdisciplinary cooperation among electrochemistry, materials science, and artificial intelligence will enable in-depth exploration of aging mechanisms in emerging battery materials, such as solid-state electrolytes and high-nickel cathodes. Developing SOH estimation models tailored to these novel materials will expand the research frontiers of battery health management.

In conclusion, while significant progress exists, practical demands for safety, real-time capability, and adaptability necessitate further advances in indicators, models, and data fusion. Integrating theoretical modeling, data-driven insights, and cross-domain collaboration is key to achieving intelligent, highly reliable battery health management for next-generation energy systems.

Author Contributions

K.T.: Writing—original draft, methodology, conceptualization. B.L. and D.C.: writing—review and revision of the original draft. C.W. (Chengshuo Wang): data curation, formal analysis. L.C.: methodology, investigation. F.L.: software, editing. Y.C.: validation, supervision. C.W. (Chunsheng Wang): funding acquisition, resources. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (NNSF) (Grant No. 62103443), Hunan Natural Science Foundation (Grant No. 2022JJ40630).

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhou, Z.; Liu, Y.; Zhao, Z.; Xia, H.; Chen, Z.; Zhang, Y. Automatic Feature Extraction-Enabled Lithium-Ion Battery Capacity Estimation Using Random Fragmented Charging Data. IEEE Trans. Transp. Electrif. 2024, 10, 8845–8856. [Google Scholar] [CrossRef]

- Zhou, Z.; Duan, B.; Li, C.; Kang, Y.; Shang, Y.; Zhang, C. Life-Cycle State of Charge Estimation for Lithium-ion Battery Considering Coulomb Efficiency and Capacity Decay. IEEE Trans. Transp. Electrif. 2024, 11, 6335–6343. [Google Scholar] [CrossRef]

- Yao, L.; Wen, J.; Xiao, Y.; Zhang, C.; Shen, Y.; Cui, G.; Xiao, D. State of health estimation approach for Li-ion batteries based on mechanism feature empowerment. J. Energy Storage 2024, 84, 110965. [Google Scholar] [CrossRef]

- Zhang, C.; Du, J.; Li, S.; Zhang, L.; Zhang, W. Cross-domain machine transfer learning for capacity aging trajectory prediction of lithium-ion batteries. J. Power Sources 2024, 624, 235534. [Google Scholar] [CrossRef]