Study on Multiple-Inverter-Drive Method for IPMSM to Improve the Motor Efficiency

Abstract

1. Introduction

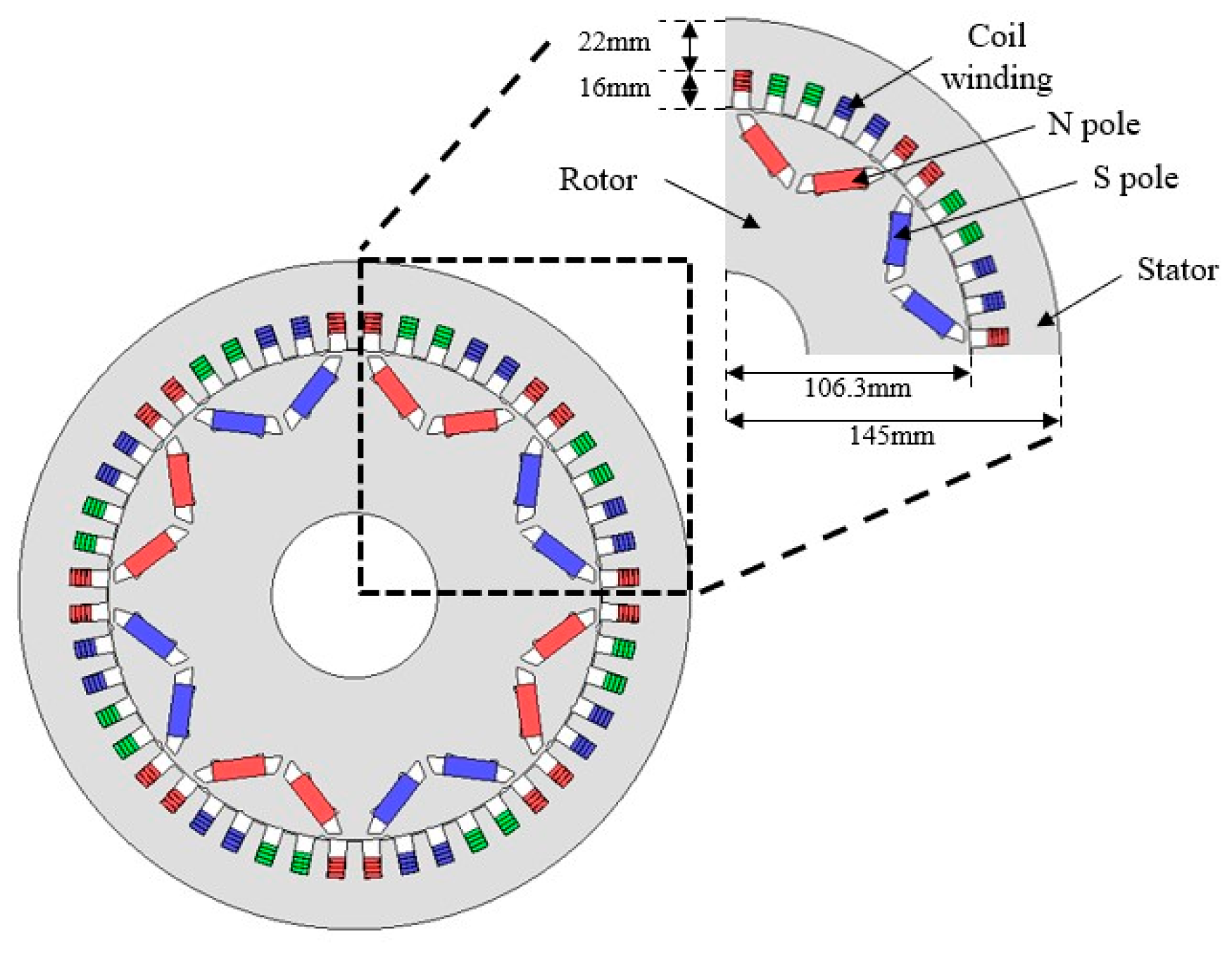

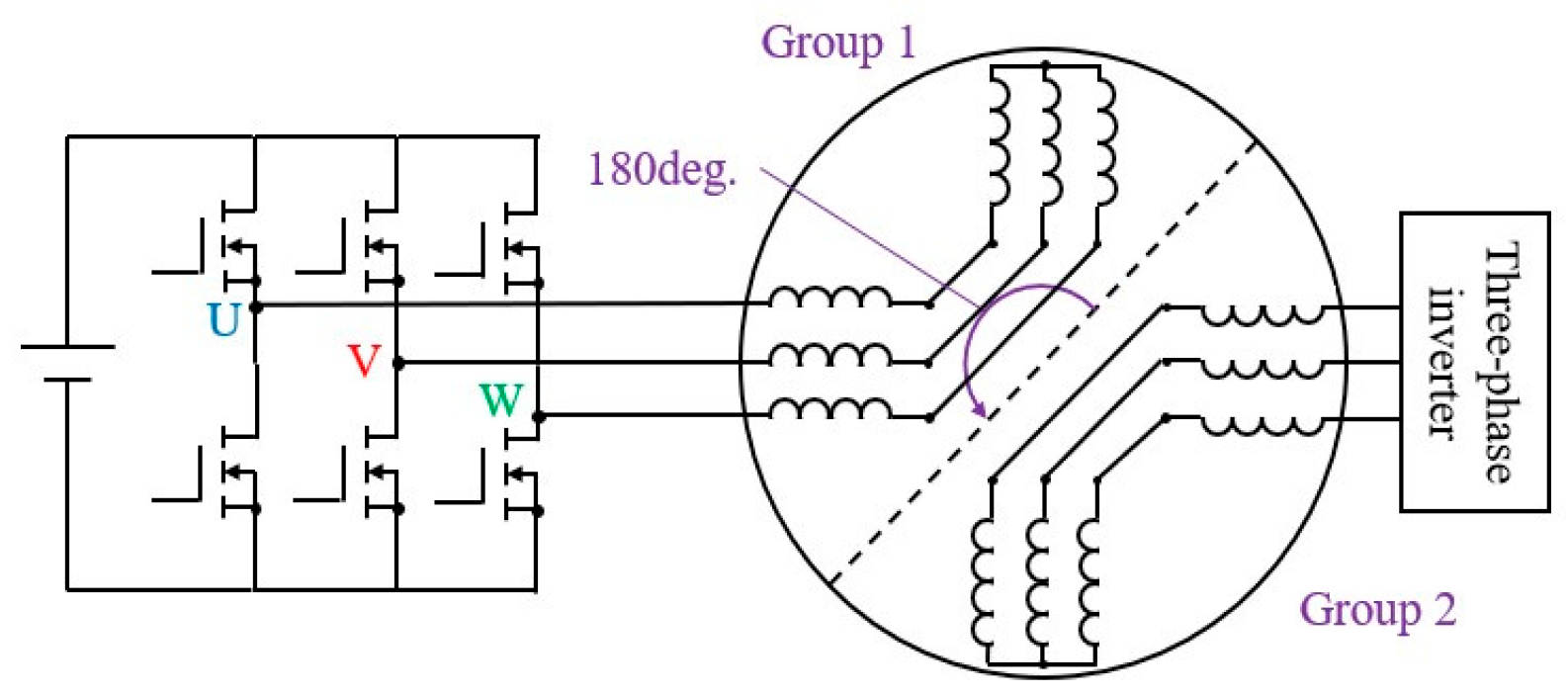

2. Proposed Method and System Overview

2.1. Proposed System

2.2. Advantages and Disadvantages of the Proposed Motor

- Improved control freedom;

- Improved fault tolerance;

- Lower voltage system.

- Increased number of parts;

- Increased cost;

- Increase in harmonic current.

3. Achieving High-Efficiency Drive Using Intermittent Operation

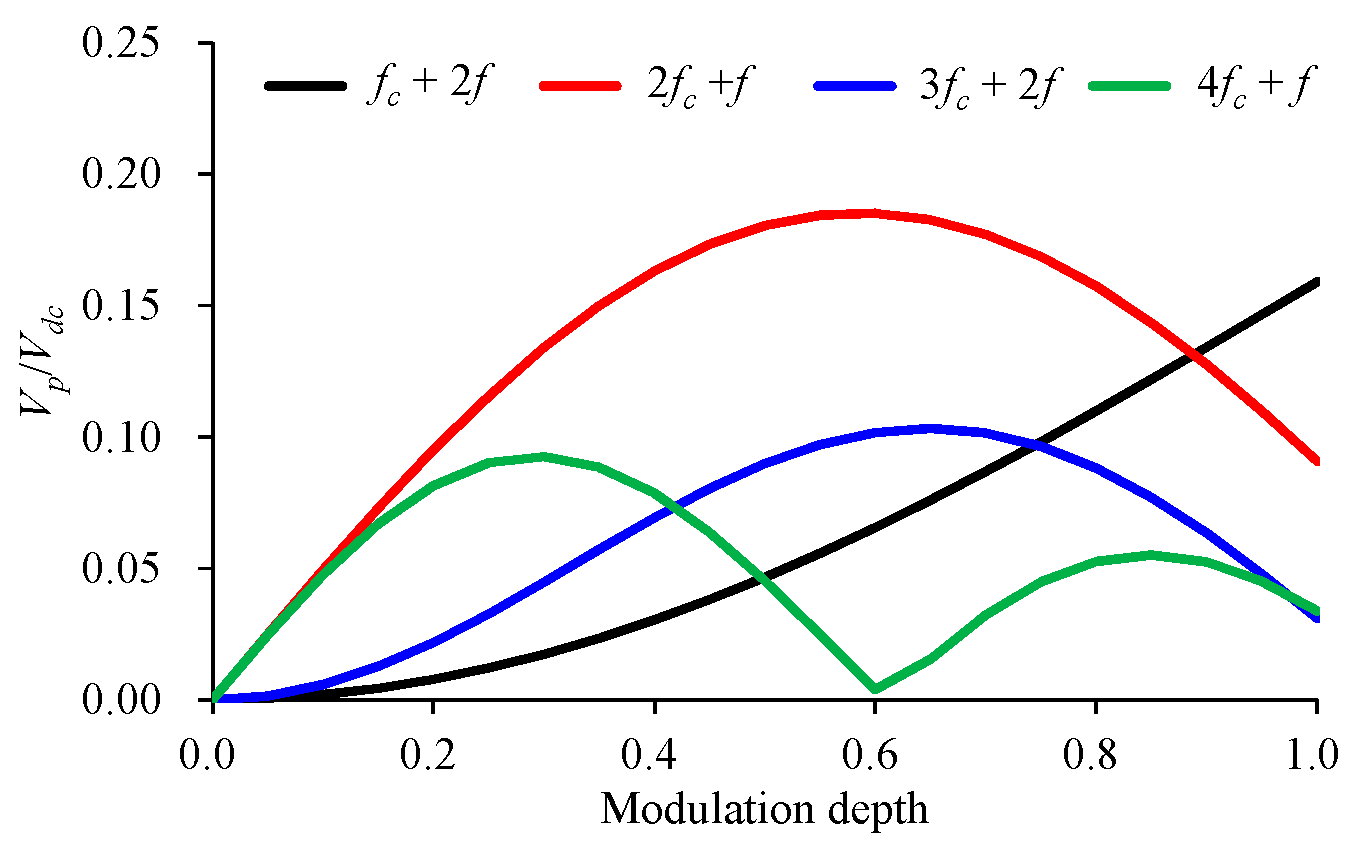

3.1. Intermittent Operation Method

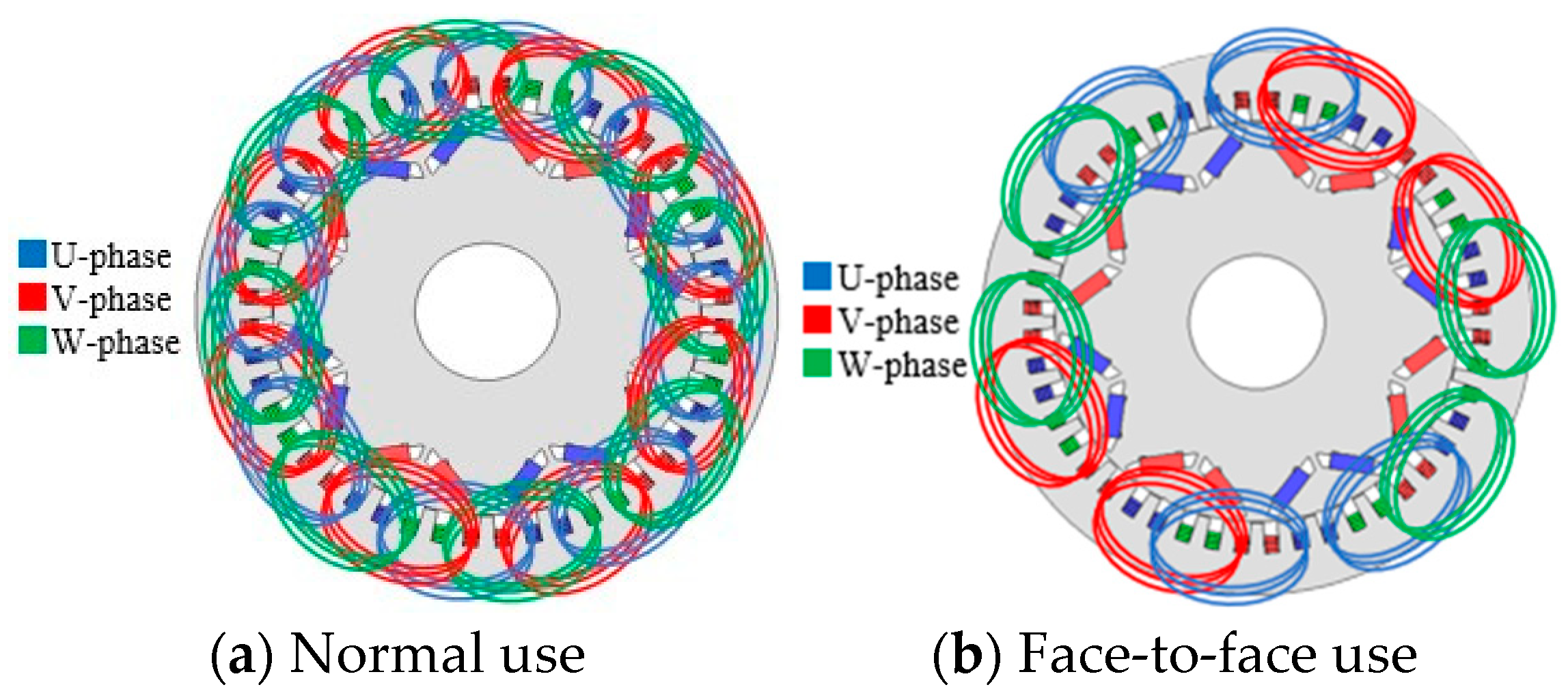

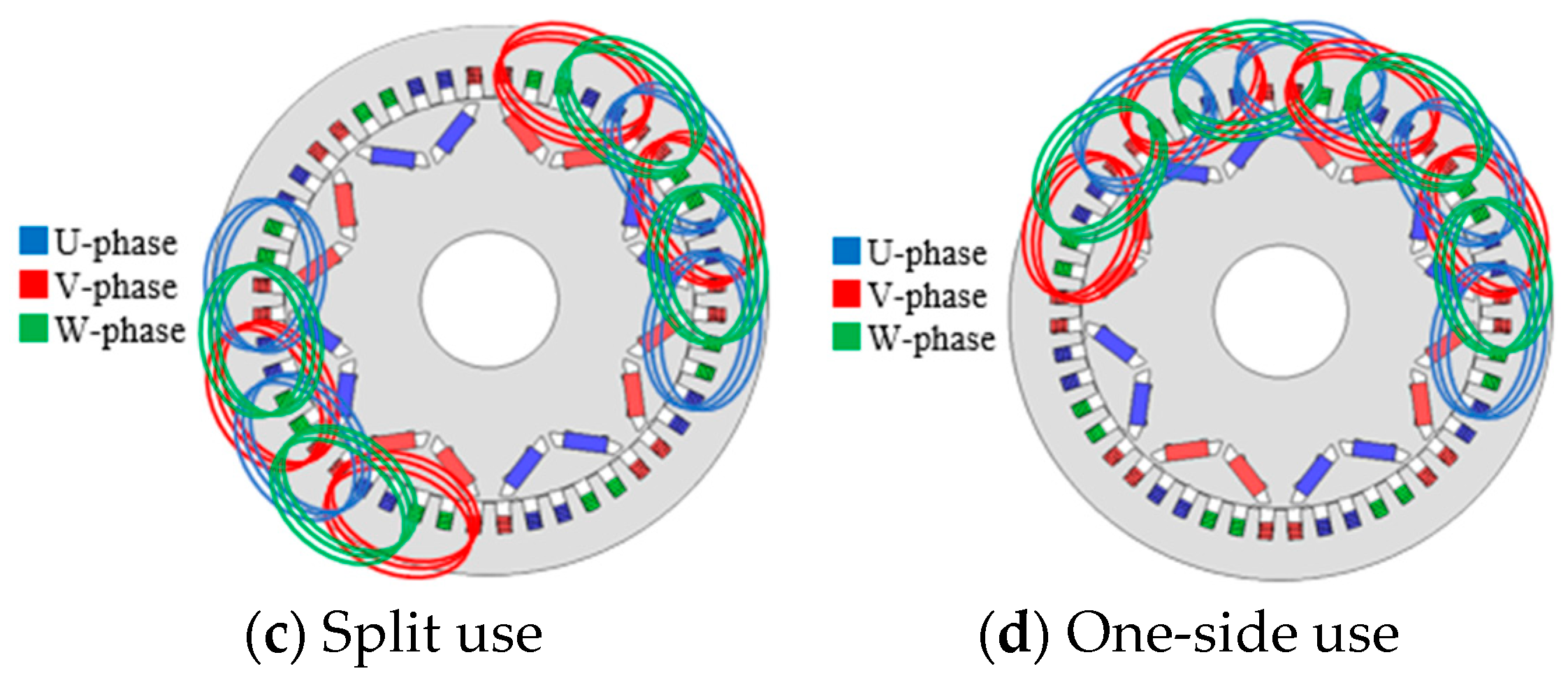

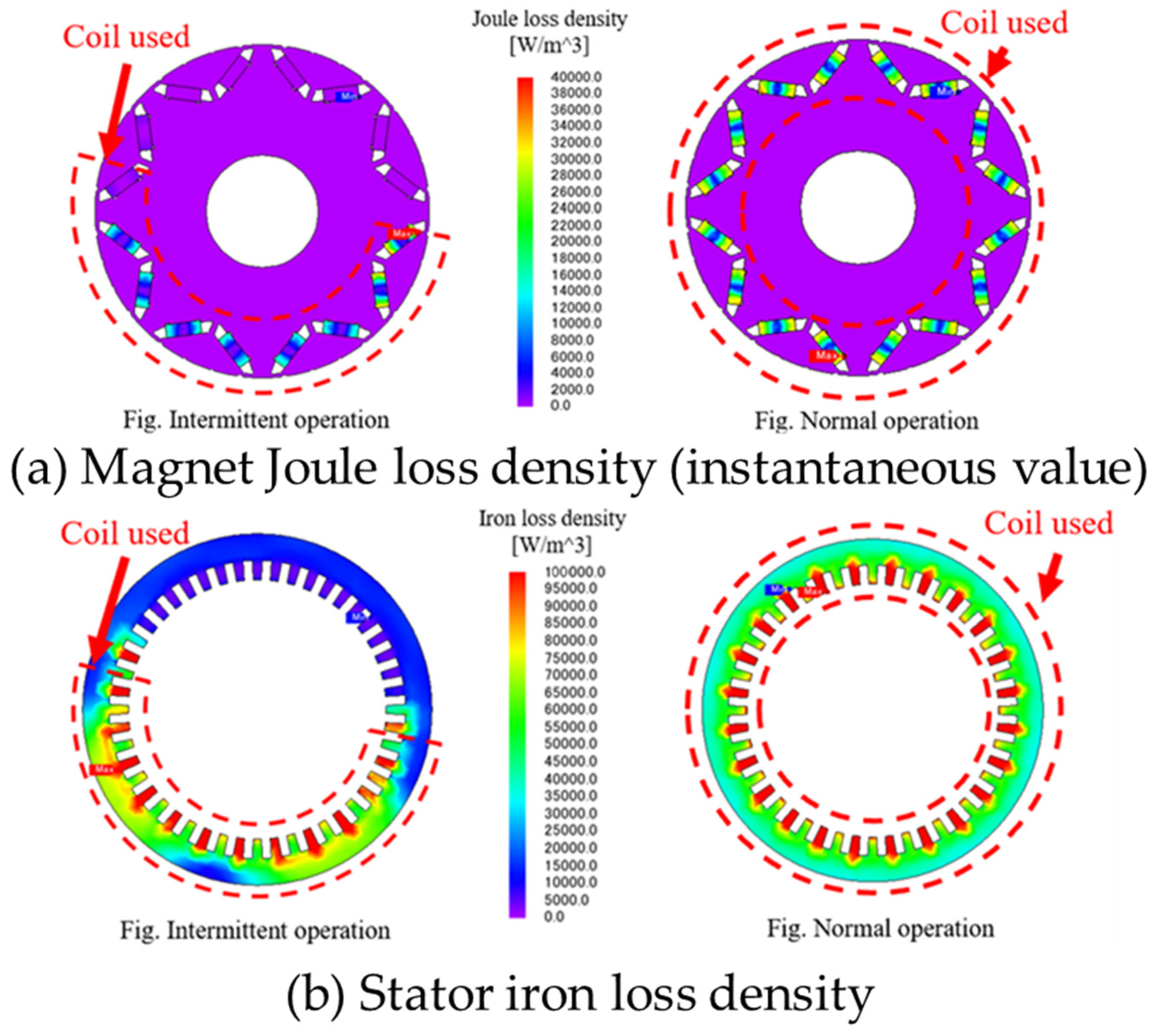

3.2. Winding Arrangement During Intermittent Operation

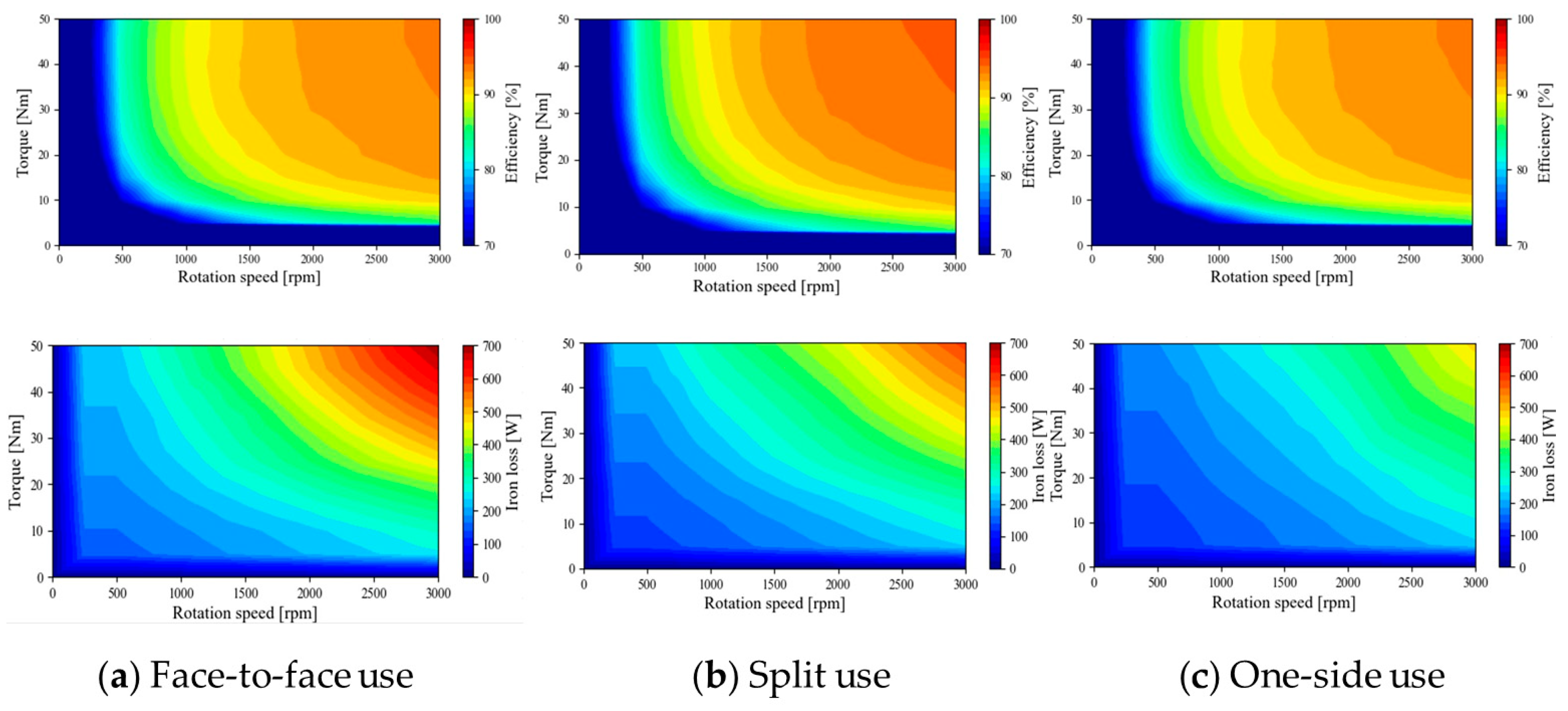

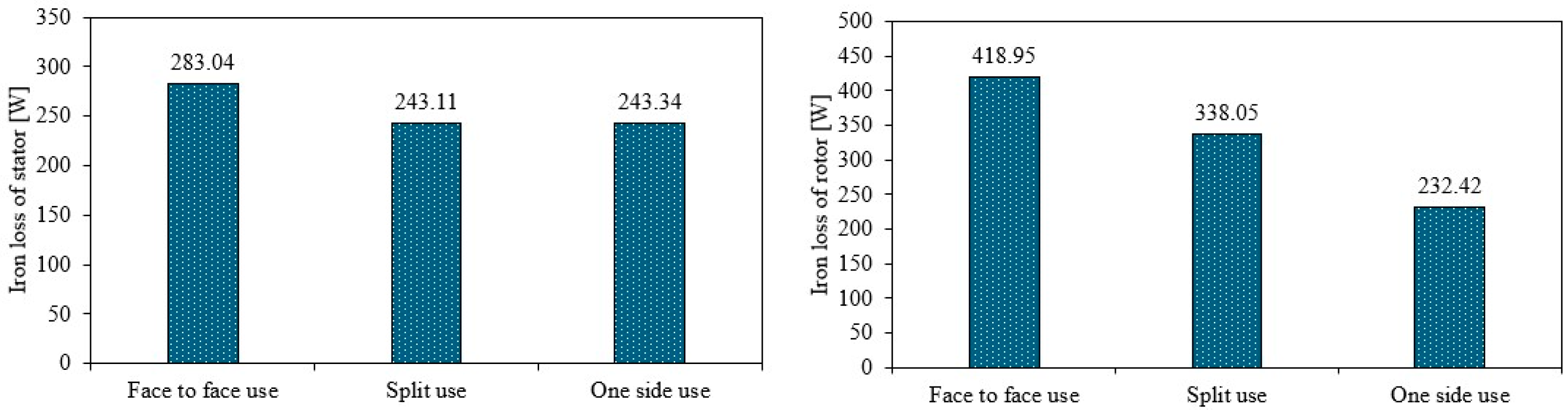

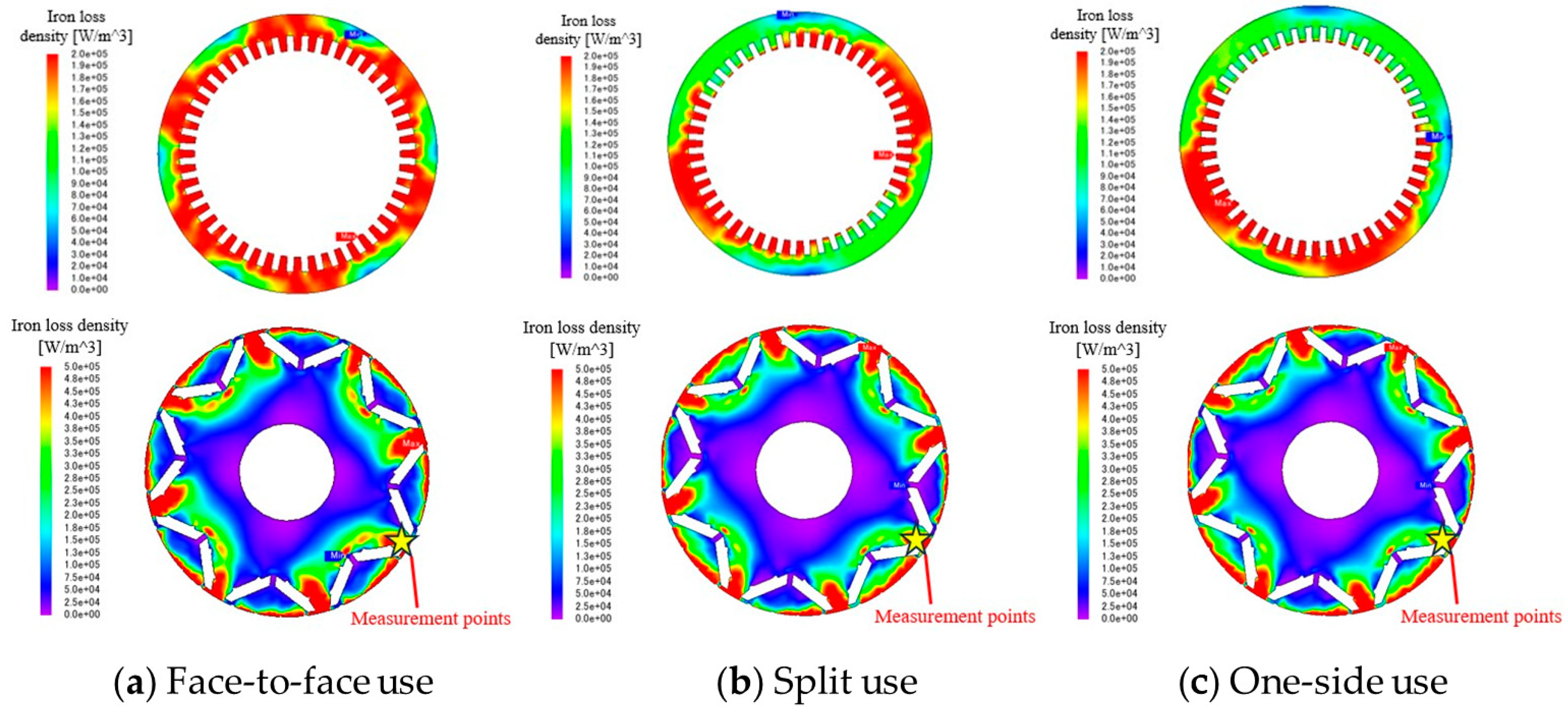

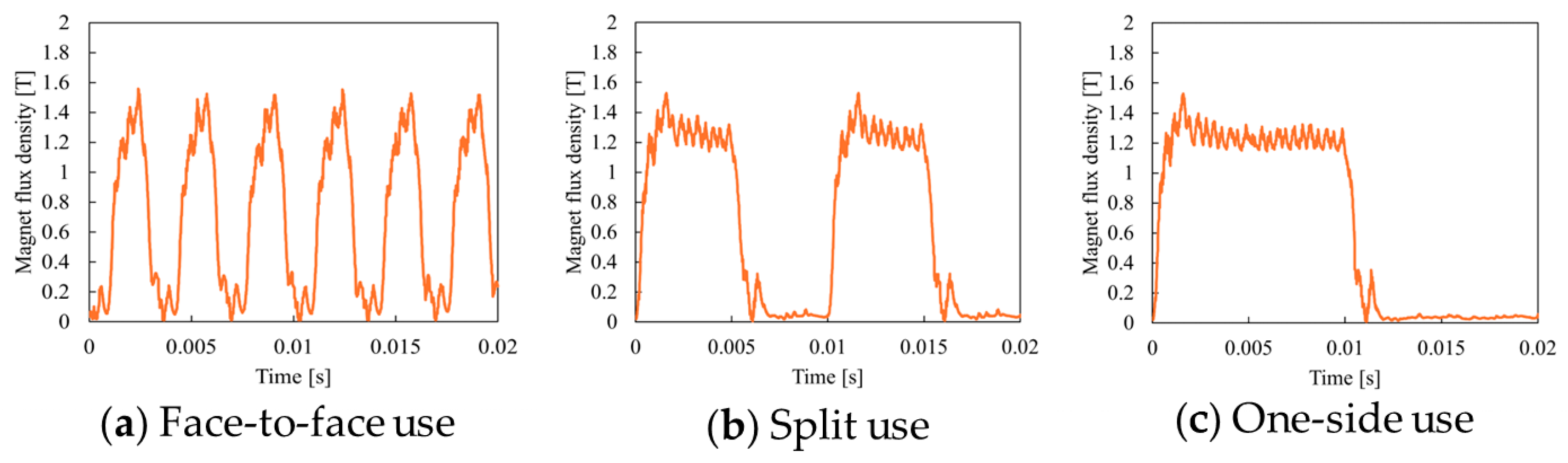

3.3. Comparison of Characteristic of Each Winding Layout Pattern

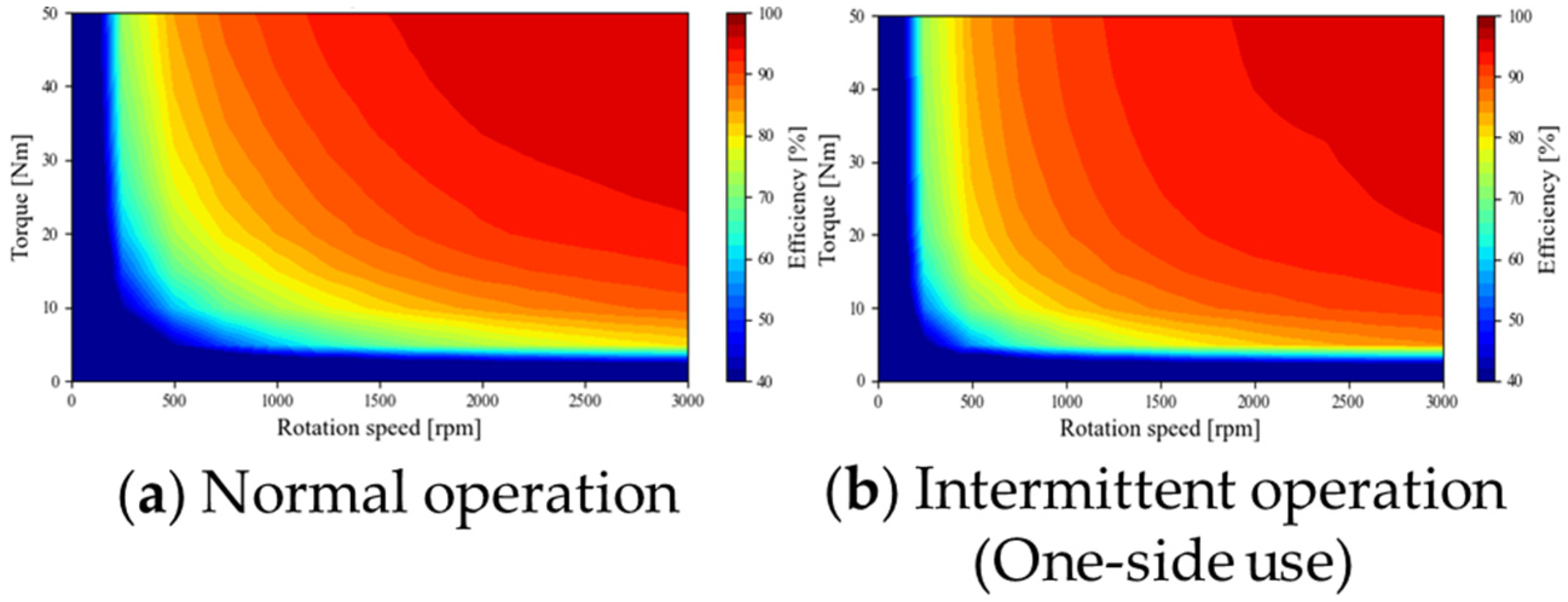

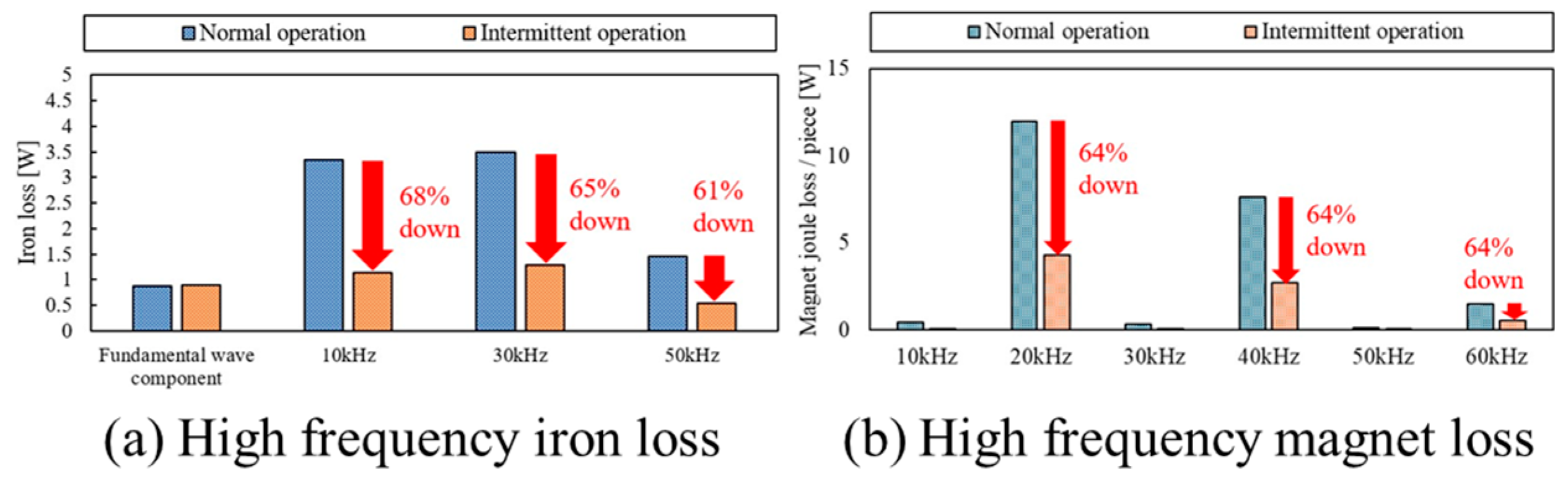

3.4. Efficiency Comparison Between Normal Operation and Intermittent Operation

4. Comparison of Electricity Consumption Through Driving Simulation

4.1. System Efficiency Comparison

4.1.1. Method for Calculating Power Unit Efficiency

4.1.2. Power Unit Efficiency Comparison Results

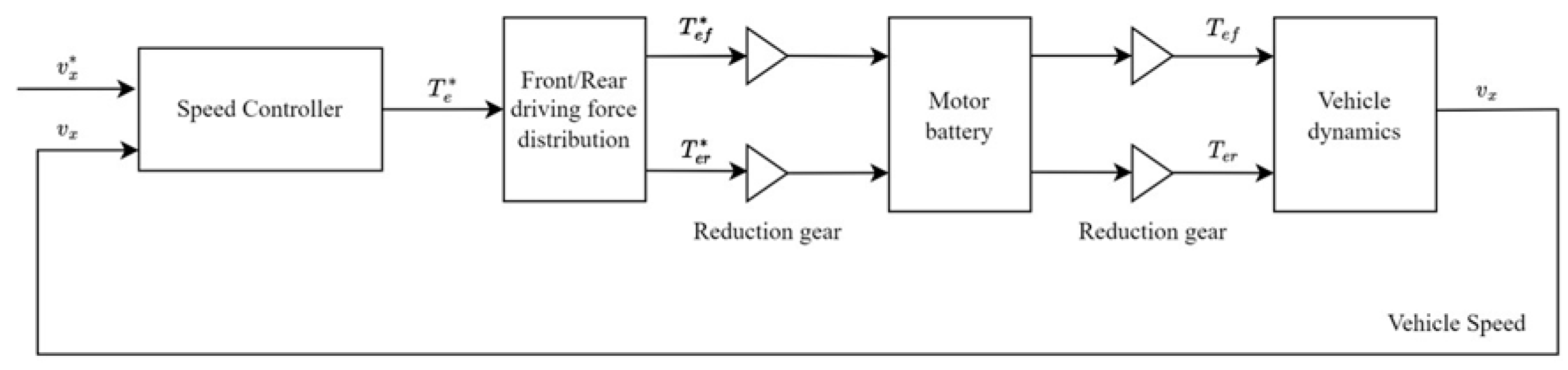

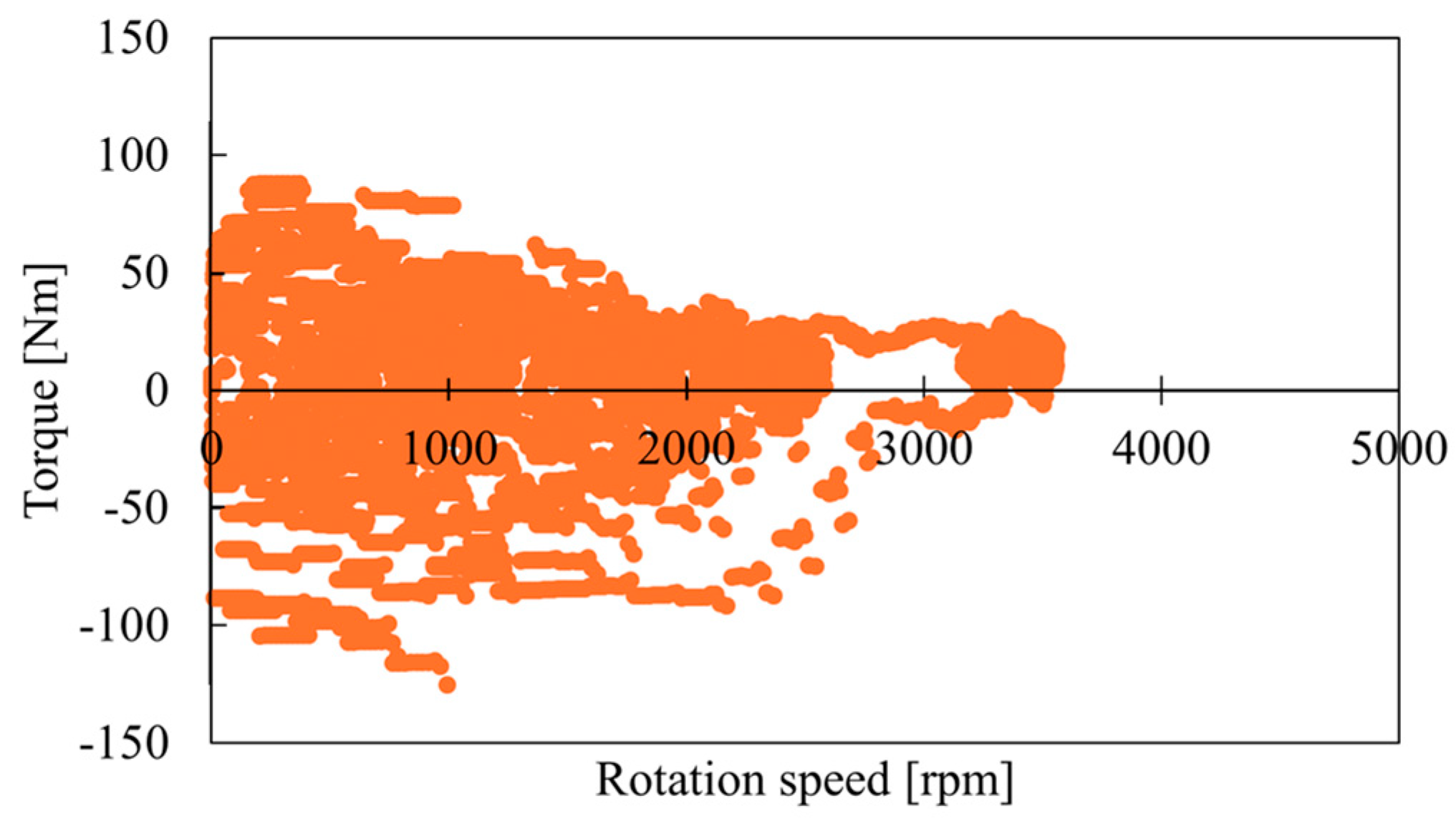

4.2. Verification of Power Consumption Through Vehicle Running Simulation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hijikata, H.; Sakai, Y.; Akatsu, K.; Miyama, Y.; Arita, H.; Daikoku, A. Wide speed range operation by low-voltage inverter-fed 218 MATRIX motor for automobile traction motor. IEEE Trans. Power Electron. 2018, 33, 6887–6896. [Google Scholar] [CrossRef]

- Levi, E.; Bojoi, R.; Profumo, F.; Toliyat, H.A.; Williamson, S. Multiphase induction motor drives—A technology status review. IET Electr. Power Appl. 2007, 4, 489–516. [Google Scholar] [CrossRef]

- Zhao, Y.; Lipo, T.A. Space vector PWM control of dual three phase induction machine using vector space decomposition. IEEE Trans. Ind. Appl. 1995, 31, 1100–1109. [Google Scholar] [CrossRef]

- Barcaro, M.; Bianchi, N.; Magnussen, F. Faulty Operations of a PM Fractional-Slot Machine with a Dual Three-Phase Winding. IEEE Trans. Ind. Electron. 2011, 58, 3825–3832. [Google Scholar] [CrossRef]

- Yang, R.; Schofield, N.; Zhao, N.; Emadi, A. Dual three-phase permanent magnet synchronous machine investigation for battery electric vehicle power-trains. J. Eng. 2019, 2019, 3981–3985. [Google Scholar] [CrossRef]

- Karttunen, J.; Kallio, S.; Peltoniemi, P.; Silventoinen, P.; Pyrhönen, O. Decoupled Vector Control Scheme for Dual Three-Phase Permanent Magnet Synchronous Machines. IEEE Trans. Ind. Electron. 2014, 61, 2185–2196. [Google Scholar] [CrossRef]

- Demarcos, A.; Robles, E.; Ugalde, U.; Elosegui, I.; Andreu, J. Output Current Ripple in Electric Vehicles With Asymmetrical Dual Three-Phase Arrangement Applying Interleaved Carrier-Based PWM Techniques. IEEE Access 2025, 13, 41743–41767. [Google Scholar] [CrossRef]

- Yoshida, A.; Akatsu, K. Study of Winding Structure to Reduce Harmonic Currents in Dual 3-phase Motor. World Electr. Veh. J. 2023, 14, 100. [Google Scholar] [CrossRef]

- Demir, Y.; Aydin, M. A Novel Dual Three-Phase Permanent Magnet Synchronous Motor With Asymmetric Stator Winding. IEEE Trans. Magn. 2016, 52, 8105005. [Google Scholar] [CrossRef]

- Demir, Y.; Aydin, M. A Novel Asymmetric and Unconventional Stator Winding Configuration and Placement for a Dual Three-Phase Surface PM Motor. IEEE Trans. Magn. 2017, 53, 8111805. [Google Scholar] [CrossRef]

- Welchko, B.A. A Double-ended Inverter System for the Combined Propulsion and Energy Management Functions in Hybrid Vehicles with Energy Storage. In Proceedings of the 31st Annual Conference of IEEE Industrial Electronics Society, 2005. IECON 2005, Raleigh, NC, USA, 6–10 November 2005. [Google Scholar]

- Matsumori, H.; Maeda, Y.; Kosaka, T.; Matsui, N.; Saha, S. Dual Inverter-Fed Open Winding IPMSM Drive System for High-Power Premium Class EV. IEEE Trans. Ind. Appl. 2023, 59, 2069–2080. [Google Scholar] [CrossRef]

- Matsumori, H.; Kosaka, T.; Matsui, N.; Saha, S. Alternative PWM Switching Strategy Implementation for a Dual Inverter Fed Open Winding Motor Drive System for an Electric Vehicle Application. IEEE Trans. Ind. Appl. 2023, 59, 5957–5970. [Google Scholar] [CrossRef]

- Li, X.; Zhang, S.; Zhang, C.; Zhou, Y.; Zhang, C. An Improved Deadbeat Predictive Current Control Scheme for Open-Winding Permanent Magnet Synchronous Motors Drives With Disturbance Observer. IEEE Trans. Power Electron. 2021, 36, 4622–4632. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, C.; Zhang, S. Torque Ripple Suppression for Open-End Winding Permanent-Magnet Synchronous Machine Drives With Predictive Current Control. IEEE Trans. Ind. Electron. 2020, 67, 1771–1781. [Google Scholar] [CrossRef]

- Matsumori, H.; Kosaka, T.; Matsui, N.; Saha, S. Inverter Power Device Fault Detection and Fail Safe Action Strategy for Electric Vehicle With a Dual Inverter Fed Open Winding Motor. IEEE Trans. Ind. Appl. 2023, 59, 3875–3888. [Google Scholar] [CrossRef]

- An, Q.; Liu, J.; Peng, Z.; Sun, L.; Sun, L. Dual-Space Vector Control of Open-End Winding Permanent Magnet Synchronous Motor Drive Fed by Dual Inverter. IEEE Trans. Power Electron. 2016, 31, 8329–8342. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, S.; Zhang, C.; Li, X.; Zhao, M. A Robust Dual-Vector Model Predictive Current Control Scheme for Open-Winding Permanent Magnet Synchronous Motor Drives with Sliding Mode Observer. In Proceedings of the 2023 IEEE Energy Conversion Congress and Exposition (ECCE), Nashville, TN, USA, 29 October–2 November 2023; pp. 5235–5242. [Google Scholar] [CrossRef]

- Levi, E. Multiphase electrical machines for variable-speed applications. IEEE Trans. Ind. Electron. 2008, 55, 1893–1909. [Google Scholar] [CrossRef]

- Mori, M.; Mizuno, T.; Ashikaga, T.; Matsuda, I. A control method of an inverter-fed six-phase pole change induction motor for electric vehicles. In Proceedings of the Power Conversion Conference—PCC ‘97, Nagaoka, Japan, 6 August 1997; Volume 1, pp. 25–32. [Google Scholar] [CrossRef]

- Mallampalli, S.; Zhu, Z.Q.; Mipo, J.C.; Personnaz, S. Six-Phase Pole-Changing Winding Induction Machines with Improved Performance. IEEE Trans. Energy Convers. 2021, 36, 534–546. [Google Scholar] [CrossRef]

- Latif, T.; Agoro, S.; Jaffar, M.Z.M.; Husain, I. Control of a 4-Pole/2-Pole Electronic Pole-Changing Induction Motor for Traction Applications. IEEE Trans. Ind. Appl. 2023, 59, 6704–6714. [Google Scholar] [CrossRef]

- Yang, K.; Akatsu, K.; Okazaki, K.; Miyama, Y. Imbalanced Force Suppression Due to Static Eccentricity by Using Triple Three-phase Winding Motor. IEEJ J. Ind. Appl. 2023, 12, 763–772. [Google Scholar] [CrossRef]

- Yan, H.; Buticchi, G.; Yang, J.; Zhao, W.; Zhang, H.; Gerada, C. Active Thermal Control for Power Converters in Modular Winding Permanent Magnet Synchronous Motor. In Proceedings of the 2019 IEEE 13th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG), Sonderborg, Denmark, 23–25 April 2019; pp. 1–6. [Google Scholar]

- Miyama, Y.; Akatsu, K. Optimal Carrier Phase-shift Angle on Dual Three-Phase Windings Permanent Magnet Synchronous Motor. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 1362–1367. [Google Scholar] [CrossRef]

- Wolfspeed; C3M0015065K. Available online: https://www.wolfspeed.com/products/power/sic-mosfets/650v-silicon-carbide-mosfets/c3m0015065k/ (accessed on 9 July 2025).

- Japanese Test Cycle. Available online: https://dieselnet.com/standards/cycles/jp_je05.php (accessed on 9 July 2025).

| Parameter | Value |

|---|---|

| Number of poles | 8 |

| Number of slots | 48 |

| Number of turns [turn/slot] | 4 |

| Motor output [kW] | 150 |

| Maximum voltage [V] | 150 |

| Maximum current [Arms] | 400 |

| Maximum torque [Nm] | 300 |

| Maximum speed [rpm] | 17,000 |

| Parameter | Value |

|---|---|

| Inverter DC voltage [V] | 300 |

| PWM carrier frequency [kHz] | 10 |

| Rotation speed [rpm] | 50~3000 |

| Phase current [A] | 0~200 |

| Output torque [Nm] | 5~50 |

| Parameter | Value |

|---|---|

| Model | C3M0015065K [26] |

| Maximum voltage [V] | 300 |

| Maximum drain current [A] | 96 |

| Rise/fall time [ns] | 32/15 |

| On-resistance [mΩ] | 21 |

| Parameter | Value |

|---|---|

| Vehicle type | Hatchback |

| Drive system | AWD |

| Vehicle weight [kg] | 1000 |

| Reduction ratio | 5 |

| Coefficient drag | 0.601 |

| Driving mode | JE05 [27] |

| Parameter | Mode1 | Mode2 |

|---|---|---|

| Total electrical energy consumption [Wh] | 1387.6 | 1240.0 |

| Electricity cost [km/kWh] | 10.01 | 11.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takeuchi, K.; Akatsu, K. Study on Multiple-Inverter-Drive Method for IPMSM to Improve the Motor Efficiency. World Electr. Veh. J. 2025, 16, 398. https://doi.org/10.3390/wevj16070398

Takeuchi K, Akatsu K. Study on Multiple-Inverter-Drive Method for IPMSM to Improve the Motor Efficiency. World Electric Vehicle Journal. 2025; 16(7):398. https://doi.org/10.3390/wevj16070398

Chicago/Turabian StyleTakeuchi, Koki, and Kan Akatsu. 2025. "Study on Multiple-Inverter-Drive Method for IPMSM to Improve the Motor Efficiency" World Electric Vehicle Journal 16, no. 7: 398. https://doi.org/10.3390/wevj16070398

APA StyleTakeuchi, K., & Akatsu, K. (2025). Study on Multiple-Inverter-Drive Method for IPMSM to Improve the Motor Efficiency. World Electric Vehicle Journal, 16(7), 398. https://doi.org/10.3390/wevj16070398